Energy-saving mixed ration capable of increasing daily gain of sheep and preparation method of energy-saving mixed ration

A technology of sheep and parts by weight, which is applied in the forming or processing of animal feed, animal feed, additional food elements, etc., can solve the problems of high labor cost for feeding, shortage of roughage resources, and low daily weight gain, and achieve improvement of intestinal tract High performance, solving procurement problems, and low fattening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

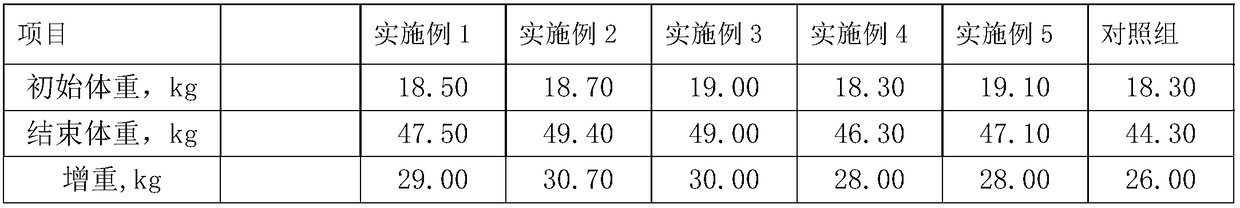

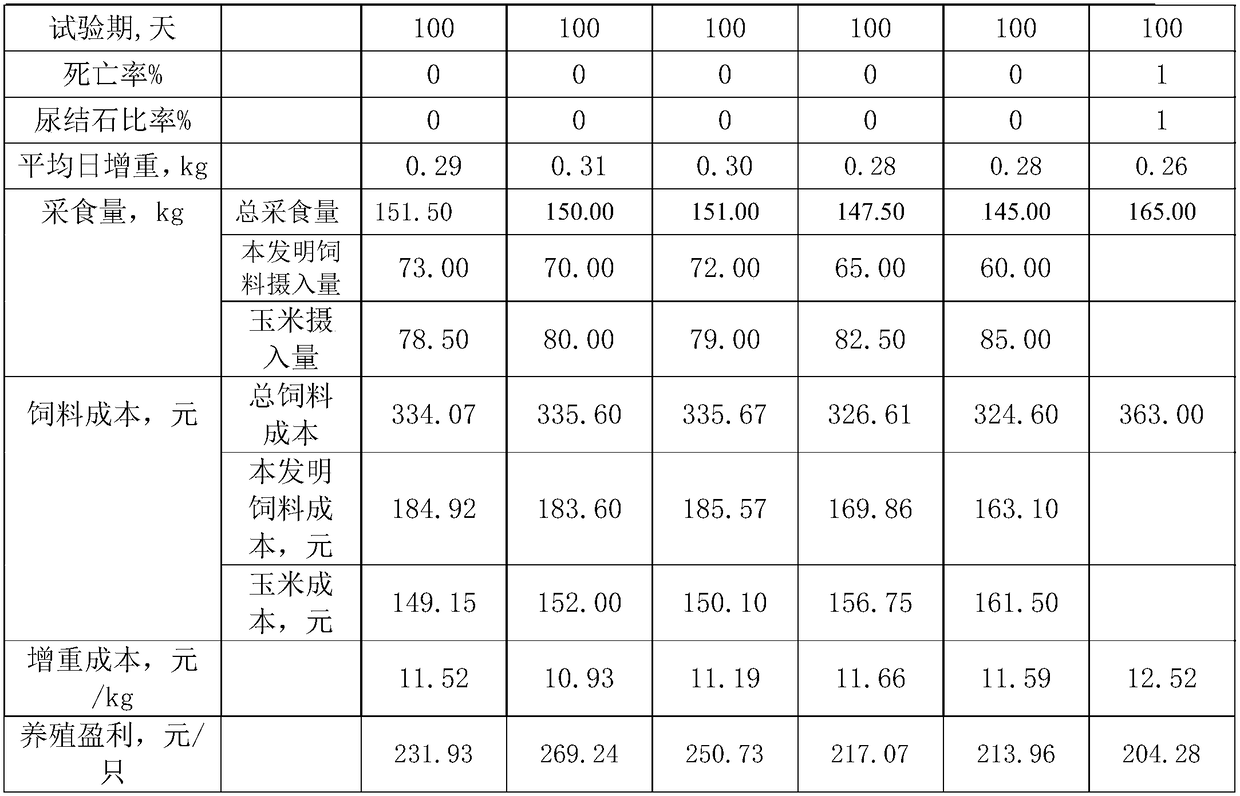

Examples

Embodiment 1

[0054] An energy-saving mixed ration for improving daily weight gain of sheep is made of the following raw materials in parts by weight:

[0055] 20 parts of alfalfa, 10 parts of peanut vines, 15 parts of sunflower skin, 4 parts of soybean meal, 6 parts of sesame meal, 2 parts of cotton meal, 12.7 parts of corn fiber feed, 20 parts of corn germ meal, 1 part of grape seed meal, 5 parts of stone powder 0.5 parts of salt, 1 part of rumen-passed fat powder, 0.1 part of rumen-passed methionine, 1 part of compound premixed feed for sheep fattening period, 1 part of slow-release urea, 1 part of ammonium chloride, 0.1 part of compound enzyme preparation, yeast culture 0.1 copies;

[0056] Described yeast culture is the product of American Xinke Company;

[0057] The mass ratio composition of the compound enzyme preparation is: protease: pectinase: cellulase: lipase: xylanase=12:6:25:2:4.

[0058] The compound premixed feed for sheep fattening period is produced by Beijing Sanyuan He...

Embodiment 2

[0067] An energy-saving mixed ration for improving daily weight gain of sheep is made of the following raw materials in parts by weight:

[0068] 25 parts of alfalfa, 15 parts of peanut seedlings, 5 parts of sunflower skin, 4 parts of soybean meal, 5 parts of sesame meal, 2 parts of cotton meal, 5 parts of grape seed meal, 10 parts of corn fiber feed, 17.7 parts of corn germ meal, 5 parts of stone powder 0.5 parts of salt, 1 part of rumen-passed fat powder, 0.1 part of rumen-passed methionine, 1 part of compound premixed feed for sheep fattening period, 1 part of ammonium chloride, 0.1 part of compound enzyme preparation, and 0.1 part of yeast culture;

[0069] Described yeast culture is the product of American Xinke Company;

[0070] The mass ratio composition of the compound enzyme preparation is: protease: pectinase: cellulase: lipase: xylanase=12:6:25:2:4.

[0071] The compound premixed feed for the sheep fattening period is produced by Liaoning Hefeng Animal Husbandry Co...

Embodiment 3

[0080] An energy-saving mixed ration for improving daily weight gain of sheep is made of the following raw materials in parts by weight:

[0081] 15 parts of alfalfa grass, 20 parts of peanut seedlings, 10 parts of sunflower skin, 4 parts of soybean meal, 5 parts of sesame meal, 2 parts of cotton meal, 18.7 parts of corn fiber feed, 15 parts of corn germ meal, 3 parts of grape seed meal, 5 parts of stone powder 0.5 parts of salt, 1 part of rumen-passed fat powder, 0.1 part of rumen-passed methionine, 1 part of compound premixed feed for sheep fattening period, 1 part of slow-release urea, 1 part of ammonium chloride, 0.1 part of compound enzyme preparation, yeast culture 0.1 copies;

[0082] Described yeast culture is the product of American Xinke Company;

[0083] The mass ratio composition of the compound enzyme preparation is: protease: pectinase: cellulase: lipase: xylanase=12:6:25:2:4.

[0084] The compound premixed feed for sheep fattening period is produced by Beijing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com