Lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and preparation method thereof

A lignosulfonate and high-performance technology, which is applied in the field of lignosulfonate-polycarboxylic acid copolymerized high-performance water reducer and its preparation, can solve the problem of dosage sensitivity, poor compatibility, and expensive raw materials Problems, to achieve the effect of tenderness and stability, improve safety performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

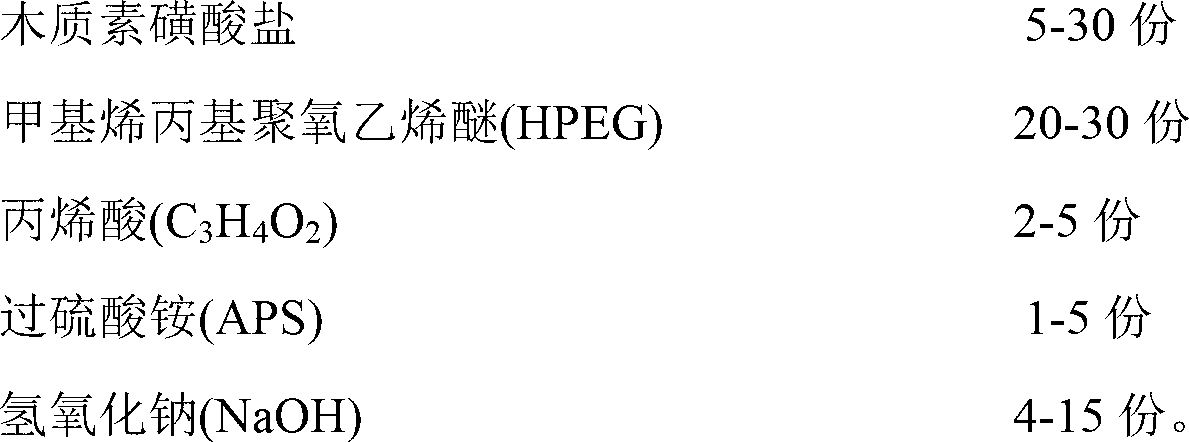

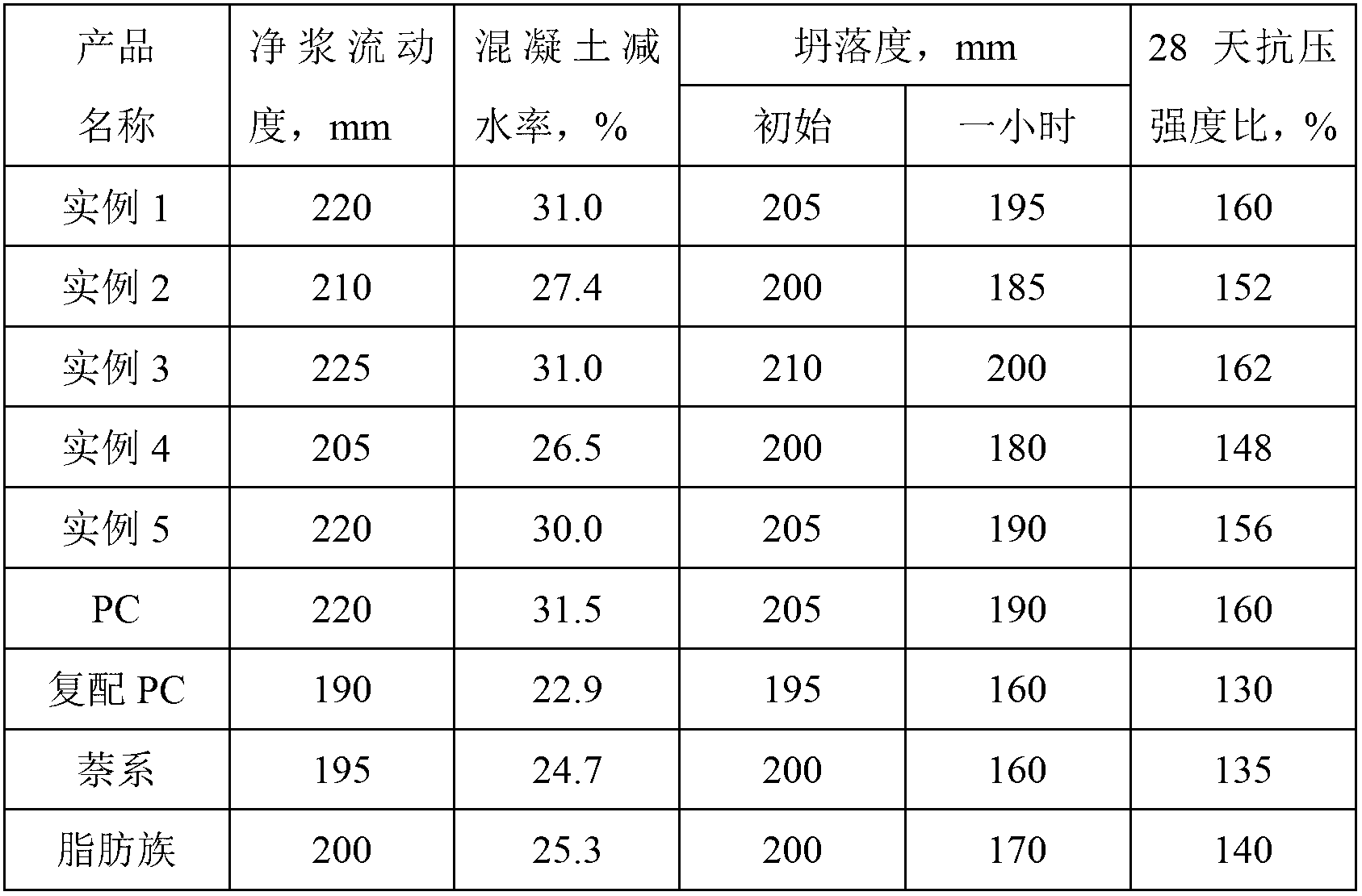

[0024] A lignosulfonate-polycarboxylic acid copolymer composite high-performance water reducer, the raw material composition and parts by weight are as follows: 5 parts of lignosulfonate, 20 parts of methallyl polyoxyethylene ether, 2 parts of acrylic acid , 1 part of ammonium persulfate, 4 parts of sodium hydroxide, and the rest are water; the lignosulfonate is the modified sodium lignosulfonate produced by Shandong Gaotang Duoyuan Lignin Co., Ltd., the raw material is brown liquid, the density 1.250±0.200g / ml, the solid content is 40.00±2.00%, and the relative molecular weight of the methallyl polyoxyethylene ether is 2650~2950. The synthesis process is as follows: (1) Accurately weigh each raw material, dissolve methallyl polyoxyethylene ether in water, add to a reaction kettle, heat to 40°C, and stir and mix for 30 minutes. (2) Add ammonium persulfate and stir for 5 minutes. (3) Add acrylic acid solution and lignin sulfonate dropwise to the reactor for 3.5 hours; graduall...

Embodiment 2

[0026] A lignosulfonate-polycarboxylic acid copolymer composite high-performance water reducer, the raw material composition and parts by weight are as follows: 30 parts of lignosulfonate, 30 parts of methallyl polyoxyethylene ether, 5 parts of acrylic acid , 5 parts of ammonium persulfate, 15 parts of sodium hydroxide, and the rest is water. The synthesis process is as follows: (1) Accurately weigh each raw material, dissolve methallyl polyoxyethylene ether in water, add to a reaction kettle, heat to 30°C, and stir and mix for 40 minutes. (2) Add ammonium persulfate and stir for 20 minutes. (3) Add acrylic acid solution and lignosulfonate dropwise to the reactor for 6 hours; gradually heat up, the early reaction time is 1.5 hours, and the temperature is at 40°C; the middle stage of the reaction is 2.5 hours, and the temperature is 45°C; The post time was 2 hours and the temperature was 55°C. (4) The temperature is controlled at 55°C, and the reaction is continued for 4 hour...

Embodiment 3

[0028] A lignosulfonate-polycarboxylic acid copolymer composite high-performance water reducer, the raw material composition and parts by weight are as follows: 5 parts of lignosulfonate, 30 parts of methallyl polyoxyethylene ether, and 5 parts of acrylic acid , 5 parts of ammonium persulfate, 4 parts of sodium hydroxide, and the rest is water. The lignosulfonate is modified sodium lignosulfonate produced by Shandong Gaotang Duoyuan Lignin Co., Ltd., the raw material is brown liquid, and the density 1.250±0.200g / ml, the solid content is 40.00±2.00%, and the relative molecular weight of the methallyl polyoxyethylene ether is 2650~2950. The synthesis process is as follows: (1) Accurately weigh each raw material, dissolve methallyl polyoxyethylene ether in water, add to a reaction kettle, heat to 40°C, and stir and mix for 30 minutes. (2) Add ammonium persulfate and stir for 5 minutes. (3) Add acrylic acid solution and lignosulfonate dropwise to the reactor for 4.5 hours; gradua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com