Concrete spraying additive

A technology of sprayed concrete and admixtures, which is applied in the field of admixtures added to shotcrete, and can solve problems that plague the development of shotcrete, unstable shot quality, and affect project quality and construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

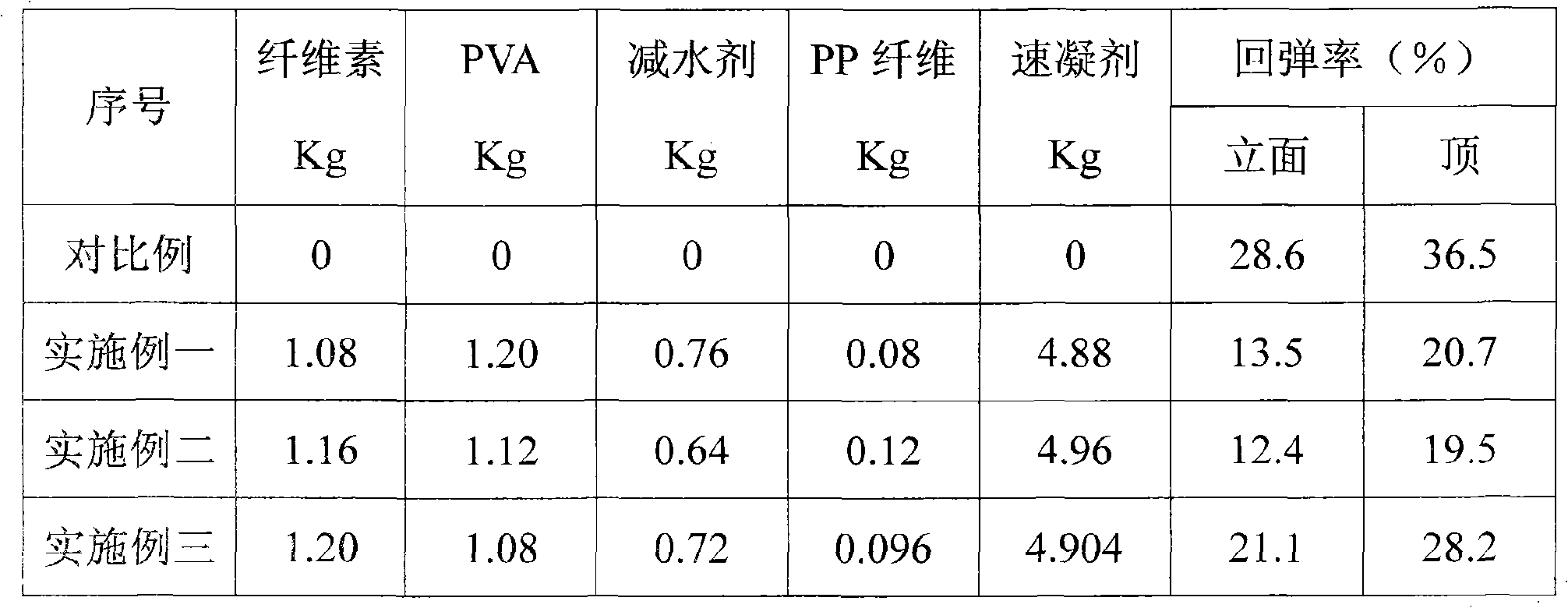

Embodiment 1

[0016] Embodiment one: choose powdery carboxymethyl cellulose 13.5%, powdery polyvinyl alcohol 15%, naphthalene series water reducer 9.5%, reticular polypropylene fiber 1.0% and quick-setting agent 61%, promptly according to concrete 100Kg cement According to the amount calculation, the dosage of each component is 1.08Kg of powdery carboxymethyl cellulose, 1.2Kg of powdery polyvinyl alcohol, 0.76Kg of naphthalene-based water reducer, 0.08Kg of reticular polypropylene fiber and 4.88Kg of quick-setting agent.

Embodiment 2

[0017] Embodiment two: choose powdery carboxymethyl cellulose 14.5%, powdery polyvinyl alcohol 14.0%, naphthalene series water reducer 8.0%, reticular polypropylene fiber 1.50% and quick-setting agent 62%, promptly according to concrete 100Kg cement According to the amount calculation, the dosage of each component is 1.16Kg of powdered carboxymethyl cellulose, 1.12Kg of powdered polyvinyl alcohol, 0.64Kg of naphthalene-based water reducer, 0.12Kg of reticular polypropylene fiber and 4.96Kg of quick-setting agent.

Embodiment 3

[0018] Embodiment three: choose powdery carboxymethyl cellulose 15%, powdery polyvinyl alcohol 13.5%, naphthalene series water reducer 9%, reticular polypropylene fiber 1.20% and quick-setting agent 61.3%, namely according to concrete 100Kg cement According to the amount calculation, the dosage of each component is 1.2Kg of powdered carboxymethyl cellulose, 1.08Kg of powdered polyvinyl alcohol, 0.72Kg of naphthalene-based water reducer, 0.096Kg of reticular polypropylene fiber and 4.904Kg of accelerator.

[0019] In the embodiment, the cold water instant powdery methyl cellulose ether is selected from the MKX45000PF20L type methyl cellulose ether produced by Bayer Company of Germany. The cold water instant powdered polyvinyl alcohol is selected from the polyvinyl alcohol produced by Beijing Luojian Technology Co., Ltd. or Shanghai Tiance Trading Co., Ltd. The naphthalene-based powdery water reducer is FDN naphthalene-based water reducer produced by Beijing Muhu Admixture Co., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com