Patents

Literature

50 results about "Hydrogen ion binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water soluble package and liquid contents thereof

InactiveUS6451750B2AvoidanceDissolve fastInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHydrogen ion bindingHydrogen

A water soluble package formed from a copolymeric polyvinyl alcohol film, wherein the comonomer comprises a carboxylate function, the package containing a substantially non-aqueous liquid composition which comprises: at least one ionic ingredient with an exchangeable hydrogen ion; and a molar excess (with respect to the amount of exchangeable hydrogen ions in the at least one ionic ingredient) of a stabilizing compound effective for combining with the exchangeable hydrogen ions to hinder the formation of lactones within the film, but can be as low as 95 mole % if the stabilizing compound comprises an inorganic base and / or ammonium hydroxide.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Water soluble package and liquid contents therof

InactiveUS20020013243A1AvoidanceDissolve fastNon-ionic surface-active compoundsOrganic detergent compounding agentsHydrogen ion bindingHydrogen

A water soluble package formed from a copolymeric polyvinyl alcohol film, wherein the comonomer comprises a carboxylate function, the package containing a substantially non-aqueous liquid composition which comprises: at least one ionic ingredient with an exchangeable hydrogen ion; and a molar excess (with respect to the amount of exchangeable hydrogen ions in the at least one ionic ingredient) of a stabilizing compound effective for combining with the exchangeable hydrogen ions to hinder the formation of lactones within the film, but can be as low as 95 mole % if the stabilizing compound comprises an inorganic base and / or ammonium hydroxide.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

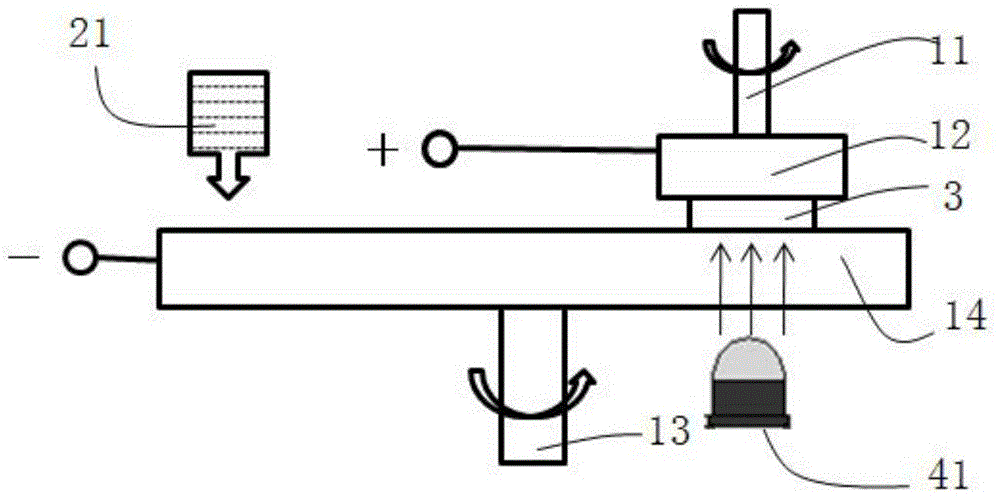

Method for efficiently grinding and polishing GaN chips

InactiveCN106141900AHigh surface flatnessImprove polishing rateSemiconductor/solid-state device manufacturingLapping machinesHydrogen ion bindingHydrogen

The invention provides a method for efficiently grinding and polishing GaN chips, namely the photoelectrochemistry mechanical polishing method for efficiently grinding the GaN chips. The method includes the steps that under the effects of illumination and an external electric field, the to-be-polished surfaces of the GaN chips are oxidized to form gallium oxide, the gallium oxide and hydroxyl ions in a polishing solution are combined to form gallium hydroxide passivation layers, and the gallium oxide and hydrogen ions in the polishing solution are combined to form gallium ions; and under the protection of the gallium hydroxide passivation layers and the polishing solution rich in gallium ion, illumination and oxidation on concave parts of the to-be-polished surfaces are effectively restrained, high convex parts of the to-be-polished surfaces are mechanically removed, and new GaN surfaces are exposed and continue to be selectively removed through illumination and oxidation. The illumination intensity, voltage values and pressure applied to an upper tray are regulated and controlled, the oxidation speed of the to-be-polished surfaces of the chips is matched with the mechanical removing speed, and therefore the surface flatness and polishing efficiency of the GaN chips are improved, and high-quality polished GaN chips are obtained.

Owner:SINO NITRIDE SEMICON

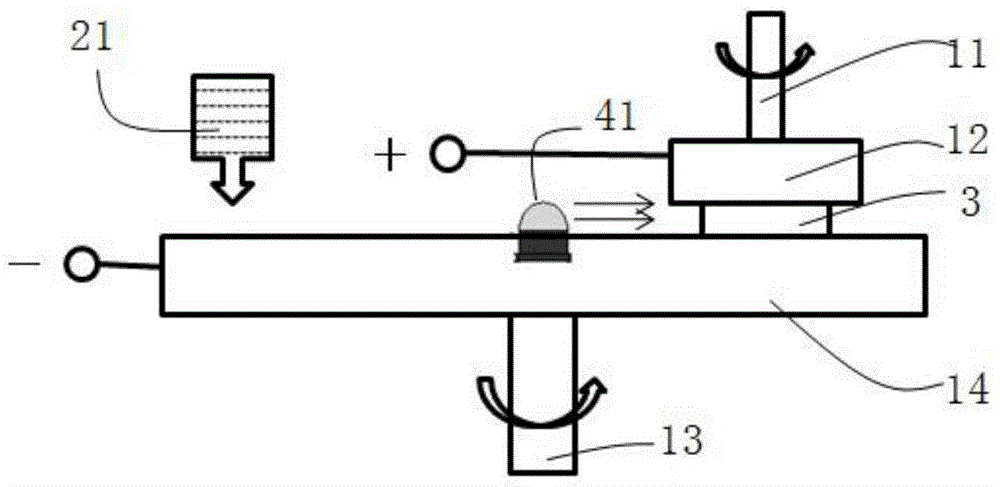

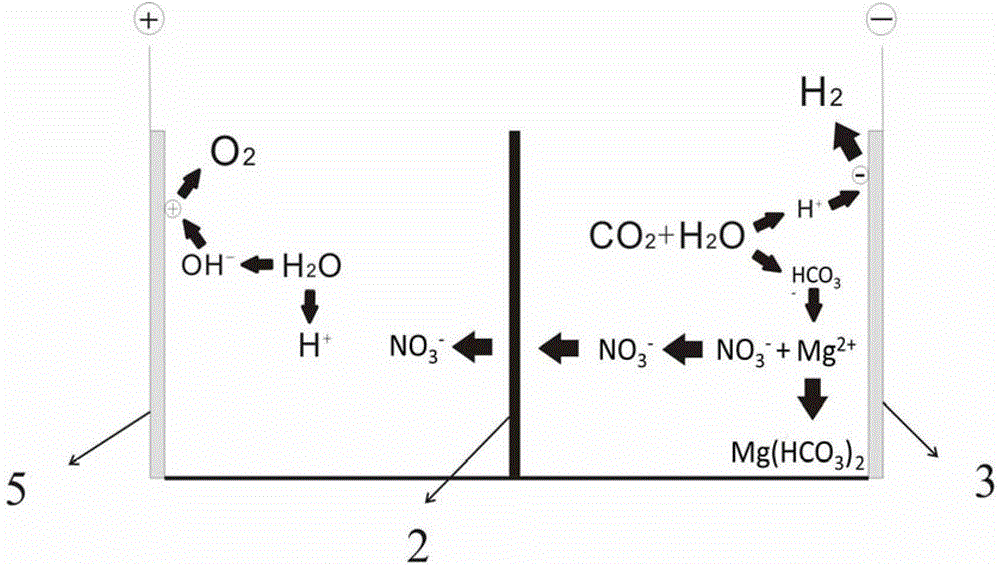

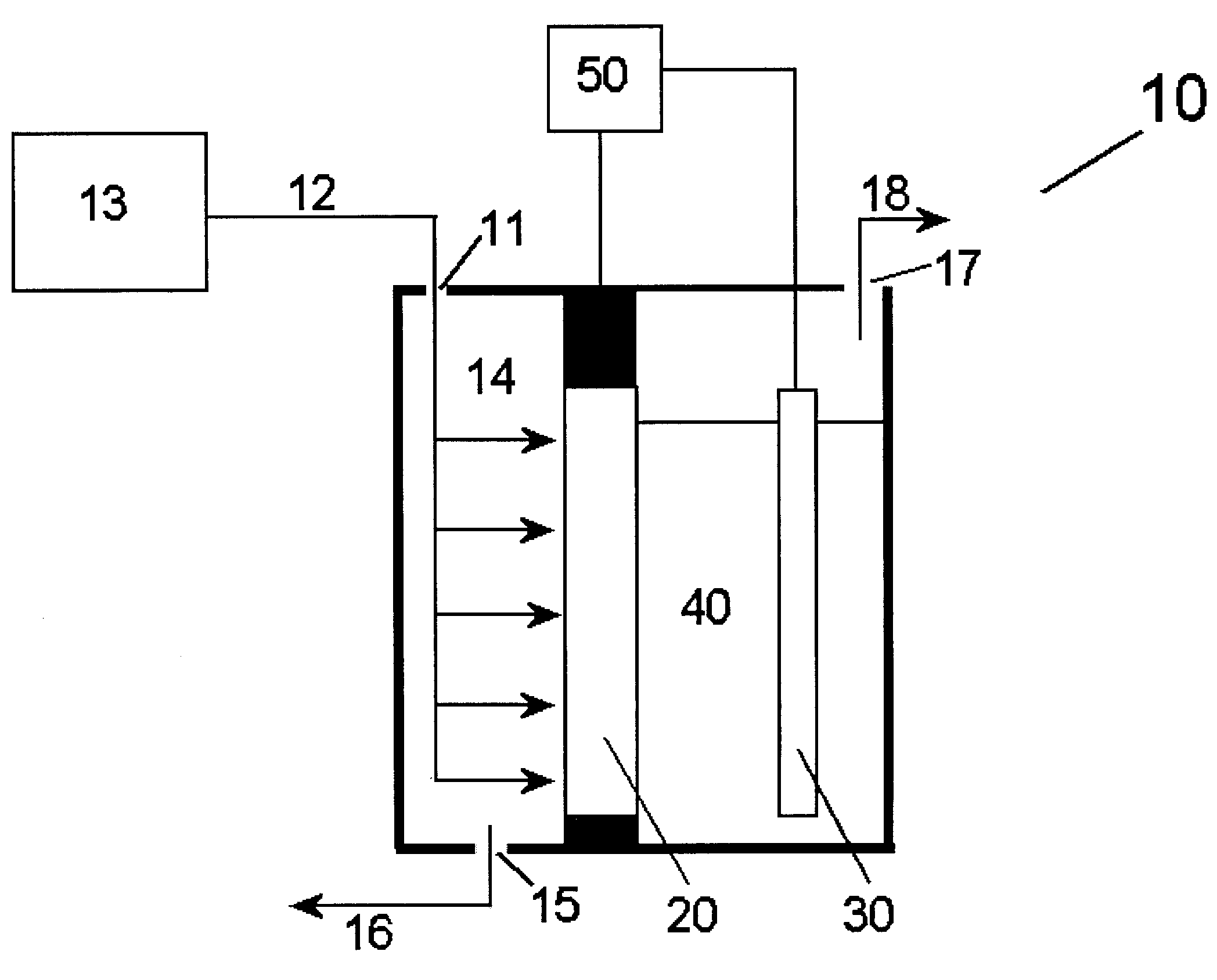

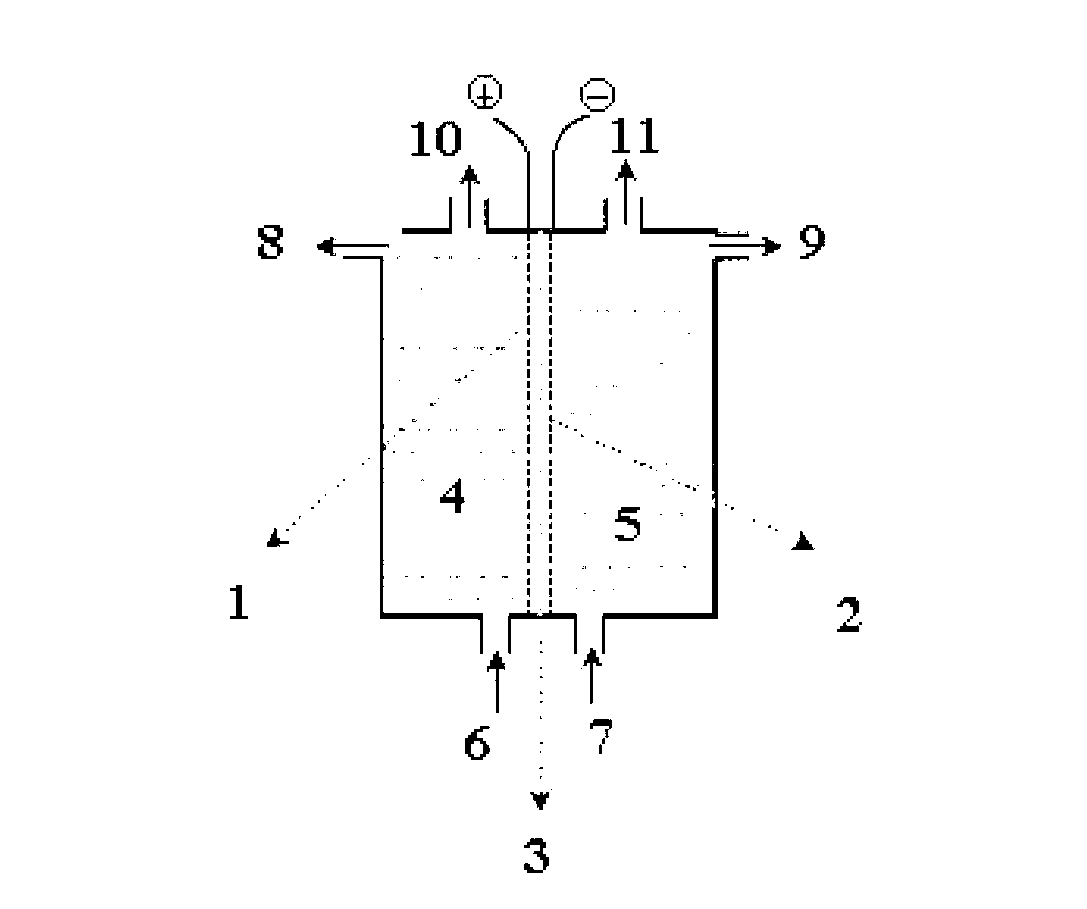

Method for membrane electrolysis of mineralized CO2 co-produced strong acid

The invention discloses a method for membrane electrolysis of mineralized CO2 co-produced strong acid. The method comprises the following steps of: placing an anion-exchange membrane in an electrolytic bath to ensure that the electrolytic bath is separated into a positive area and a negative area; adding a mineralized raw material and a negative electrode solution into the negative area, charging carbon dioxide gas into the negative area at the same time; adding a positive electrode solution into the positive area; and applying a direct current supply between a positive electrode and a negative electrode, wherein the negative electrode reduces hydrogen ions in the negative electrode solution into hydrogen gas to ensure that the carbon dioxide in the solution is transformed into carbonate radicals or bicarbonate radicals which react with positive ions in the mineralized raw material to realize the mineralization of the CO2 and obtain a mineralized product, and negative ions in the mineralized raw material permeate through the anion-exchange membrane and enter the positive area under the action of current to combine with the hydrogen ions generated by the positive electrode so as to generate the strong acid. The method has the characteristics operation at normal temperature and pressure, simple process, low energy consumption and suitability for industrial production.

Owner:SICHUAN UNIV

Solid wood furniture plate anti-cracking processing technology

InactiveCN104526800AImprove plasticityAvoid crackingWood treatment detailsWood impregnation detailsAir humidityHydrogen ion

The invention provides a solid wood furniture plate anti-cracking processing technology, and is characterized in that the processing technology includes the following steps: splitting logs into halves; putting the split wood into a water pool, and soaking for 20-30 days with salty water; cutting the wood material into plates with corresponding thickness; air-drying the plates for 5-10 days naturally; putting the plates into a drying oven, and drying until the water content is 4%-5%; injecting a preservative into cells of the plates with a device. The logs are split and then are soaked with the salty water, the logs can be really dead, and moreover, the soaking time can be shortened and the efficiency can be improved by soaking with the salty water; with combination of sodium ions with hydrogen ions in the logs, the plasticity of the wood can be increased, and cracking and deformation caused by changes of wood internal moisture absorbing air humidity are prevented; the mode of firstly naturally drying and then drying can avoid the cracking and the deformation during the wood drying process; the plates are dried by steam, so that the wood can be plasticized, and the plates can be more flexible.

Owner:TIANJIN NAITE FURNITURE

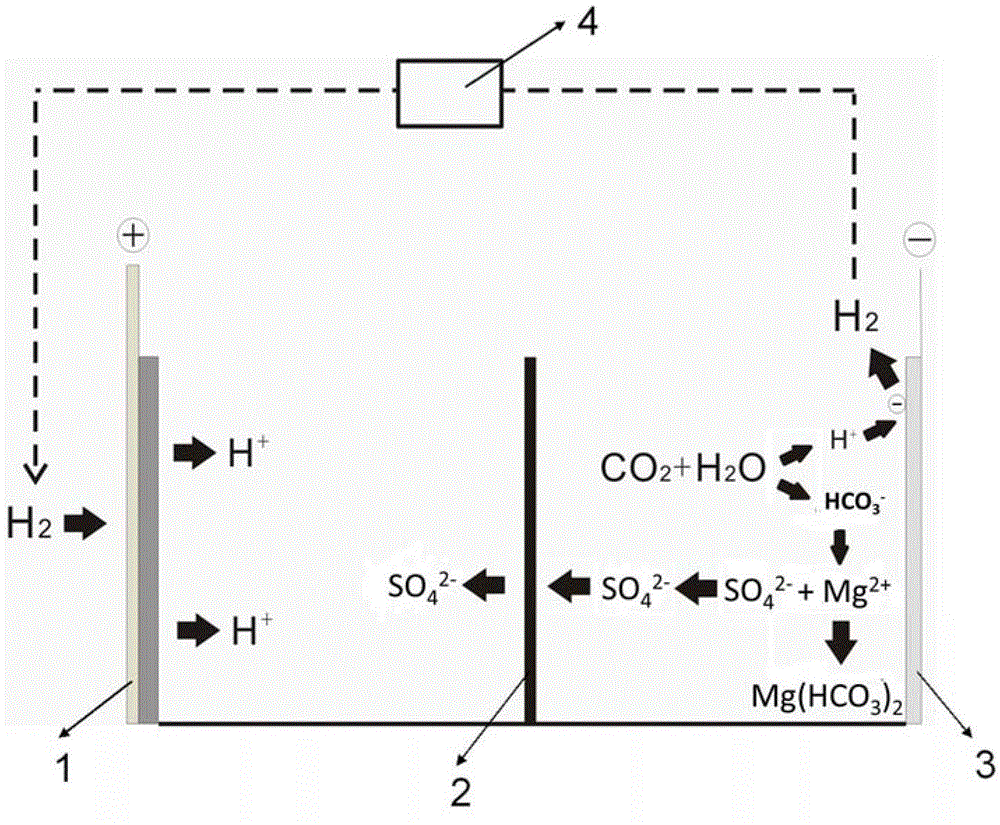

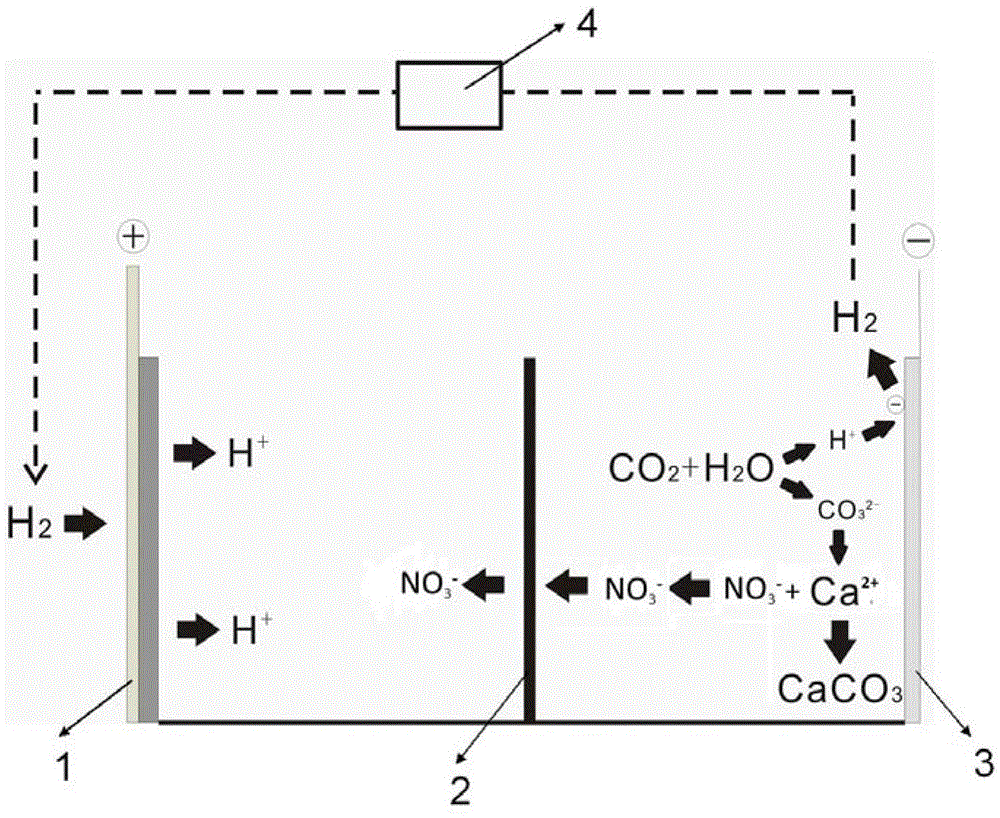

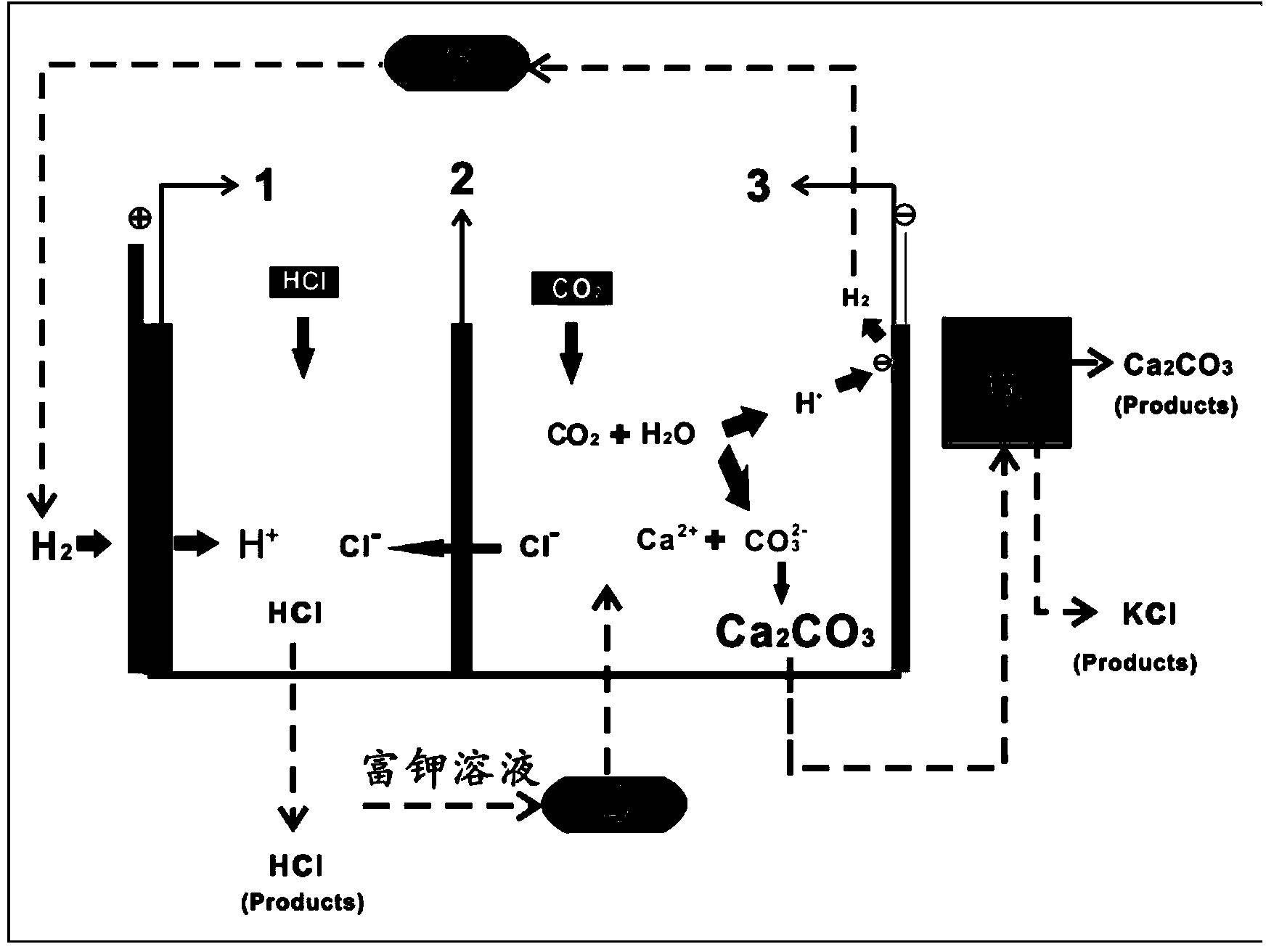

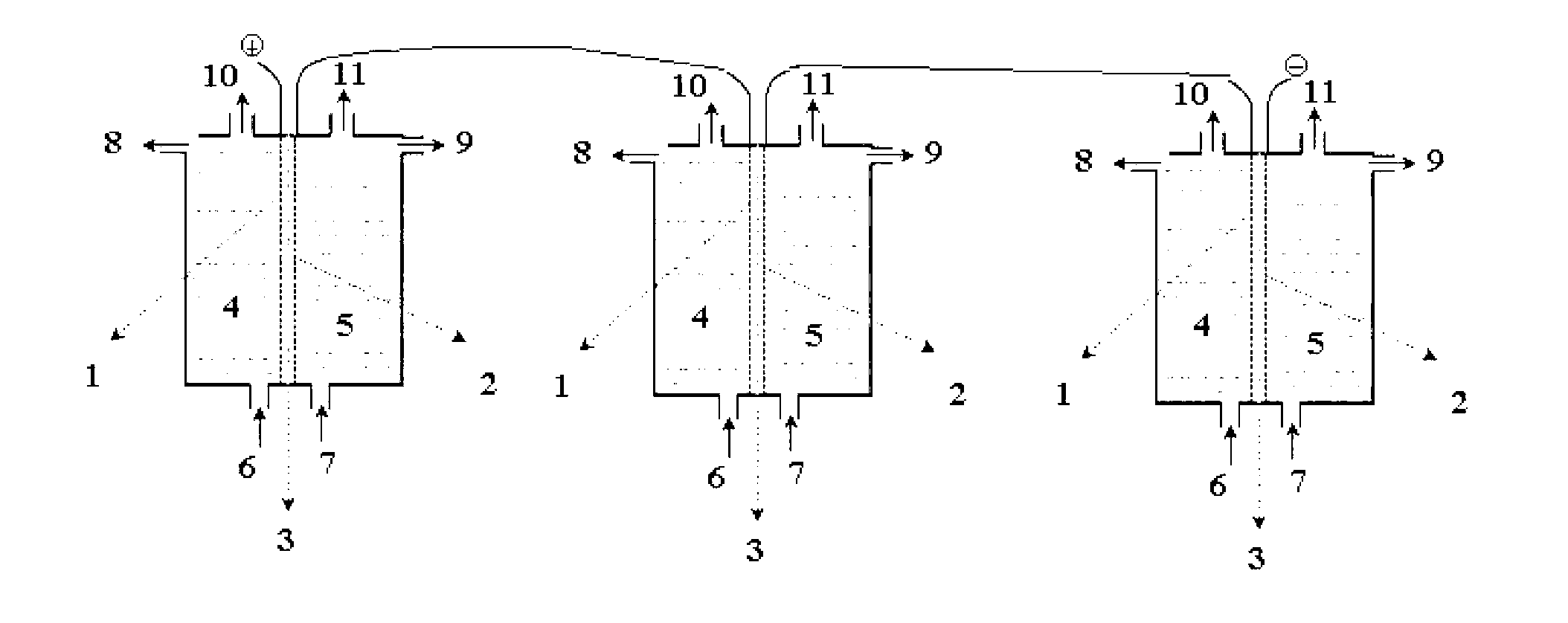

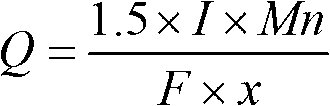

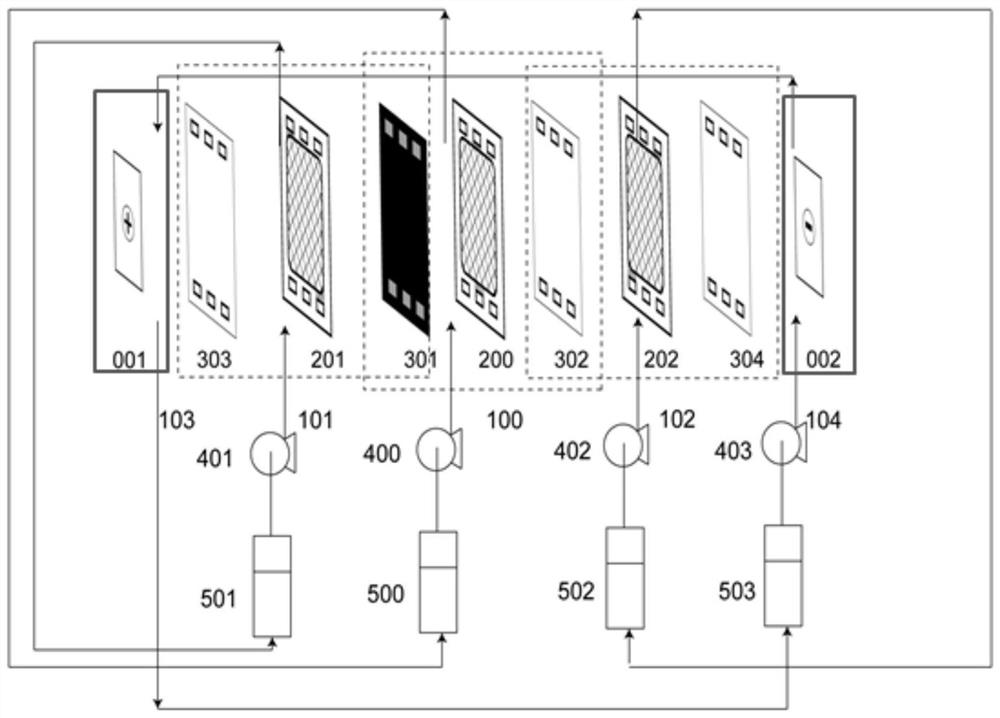

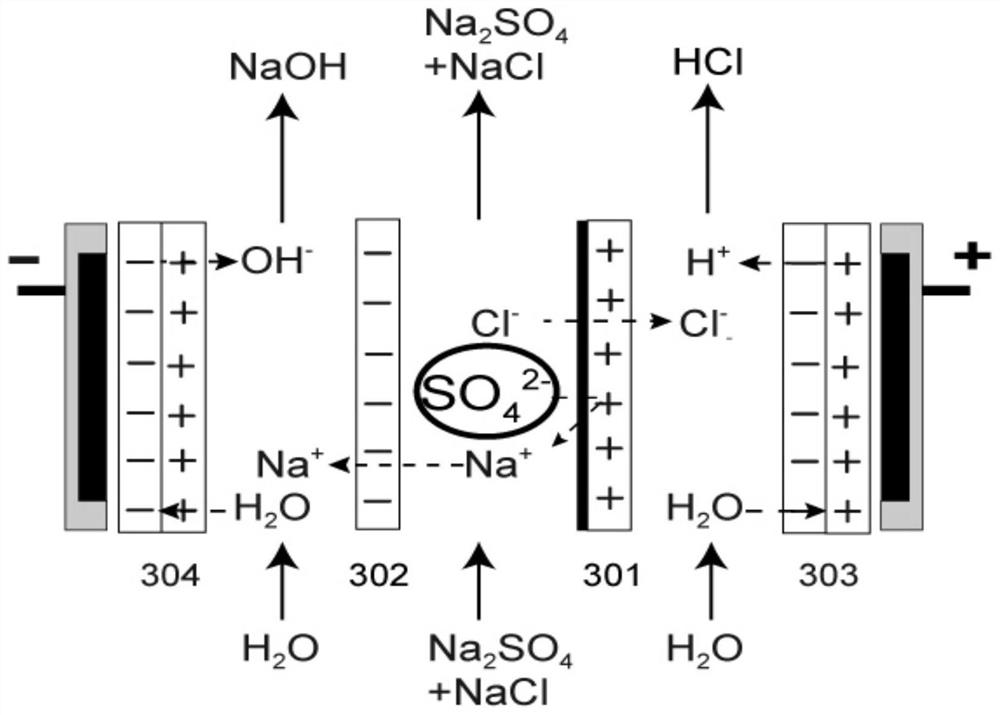

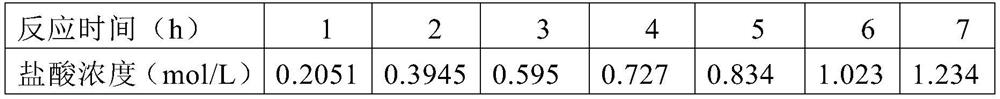

Method for realizing separation of potassium-rich solution through hydrochloric acid coproduced by utilizing membrane electrolysis technology to mineralize CO2

InactiveCN103966622AImprove efficiencySolve the costElectrolysis componentsElectrolysisCalcium carbonate precipitation

The invention discloses a method for realizing separation of a potassium-rich solution through hydrochloric acid coproduced by utilizing membrane electrolysis technology to mineralize CO2. According to the method, diluted hydrochloric acid is added into an anodic area formed by using an anion exchange membrane to separate, the potassium-rich solution containing calcium chloride is added into the cathodic area, direct current is applied between an anode electrode and a cathode electrode, and chloride ions in a catholyte permeate the anion exchange membrane to reach the anodic area under the action of current, so as to combine with hydrogen ions, generated on the anode electrode through hydrogen oxidation, to generate hydrochloric acid; carbon dioxide is pumped into the catholyte to enable the carbon dioxide to be converted into carbonate, so as to enable the carbonate and calcium ions to generate a calcium carbonate precipitation, the hydrogen ions in the catholyte is reduced to be hydrogen on the cathode electrode, the calcium carbonate precipitation is removed out after the electrolysis reaction is completed, the precipitation is filtered and dried to obtain a high-purity calcium carbonate, and the filtrate is potassium chloride solution subjected to purification. According to the method, the mineralization of the carbon CO2 is realized under the conditions of low consumption and high raw material utilization, the production of the high-purity calcium carbonate is realized, and the separation of potassium ions and calcium ions in the potassium-rich solution is realized at the same time.

Owner:SICHUAN UNIV

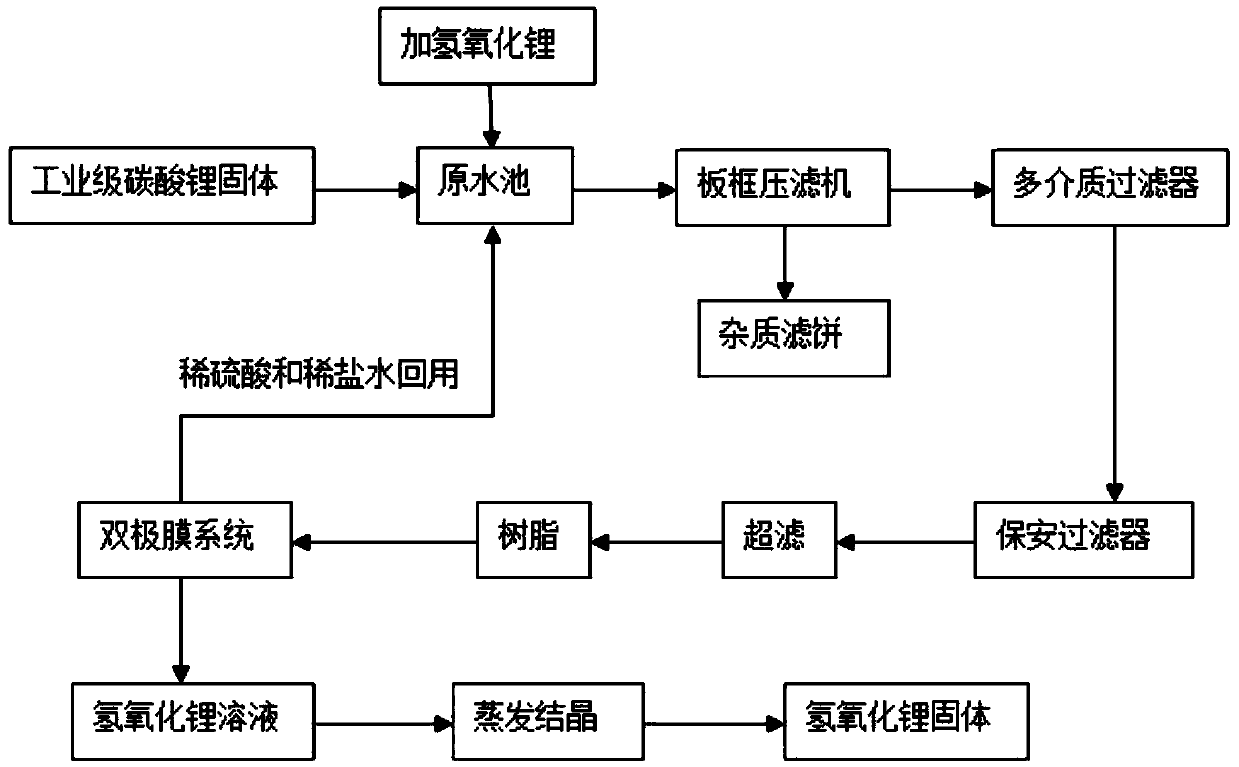

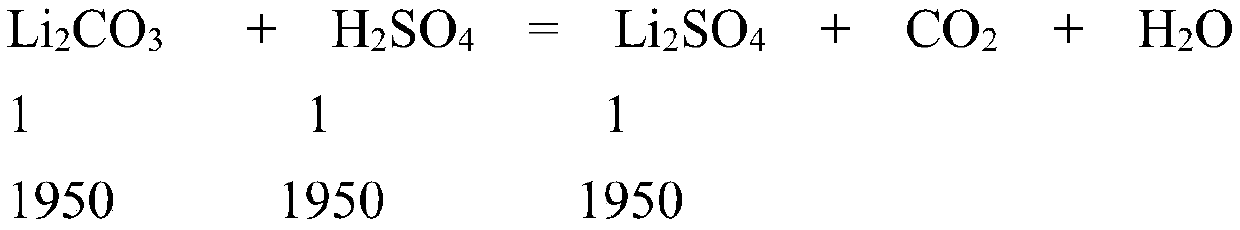

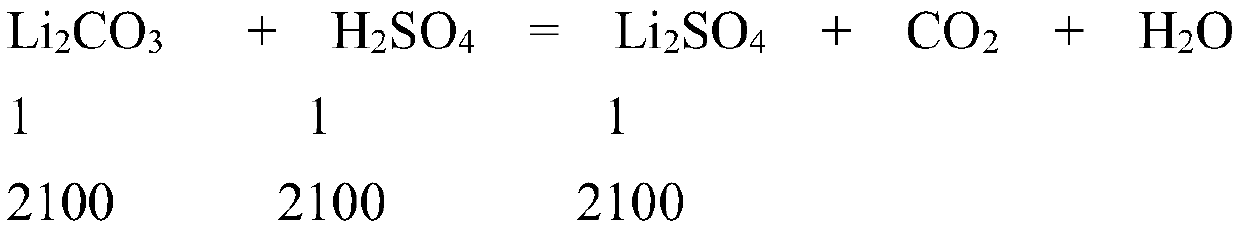

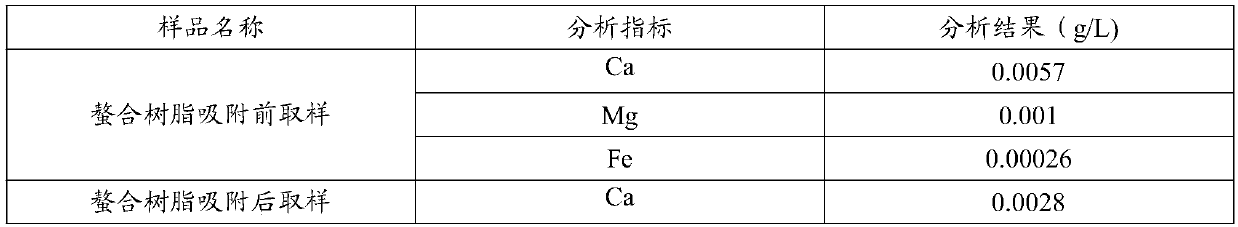

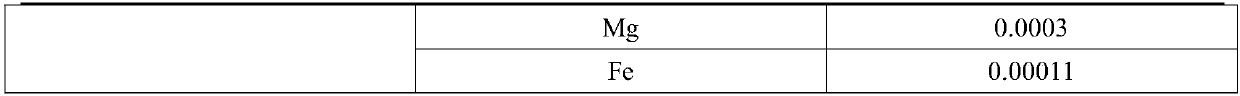

Method for preparing lithium hydroxide by industrial-grade lithium carbonate solid

ActiveCN109680295AAchieve purification effectAchieve separationElectrolysis componentsSulfate radicalsUltrafiltration

The invention provides a method for preparing lithium hydroxide by an industrial-grade lithium carbonate solid and belongs to the field of preparation of lithium hydroxide. The lithium hydroxide is prepared by taking the industrial-grade lithium carbonate solid as a raw material; solid impurities, sodium, calcium, magnesium, aluminum, iron and other ions in the industrial-grade lithium carbonate solid are removed through pH value regulation, plate and frame filtration, multi-medium filtration, ultra-filtration and chelate resin adsorption treatment; the plate and frame filtration can separatesolid from liquid; the multi-medium filtration is used for removing suspended matters, colloids, organic matters and the like; the ultra-filtration can further reduce the contents of residual COD, thesuspended matters and macromolecular dissolved matters to realize the purification and the separation of the liquid; chelate resin enables the content of high-valent ions in the liquid to meet the bipolar membrane water ingress requirements; sulfate radicals in a pre-electrolyte migrate to an acid chamber and are combined with hydrogen ions decomposed by the surface of a bipolar membrane to formsulfuric acids; lithium ions in the pre-electrolyte migrate to an alkaline chamber and are combined with hydroxyl ions decomposed by the surface of the bipolar membrane to generate the lithium hydroxide.

Owner:BEIJING TINGRUN MEMBRANE TECH DEV +1

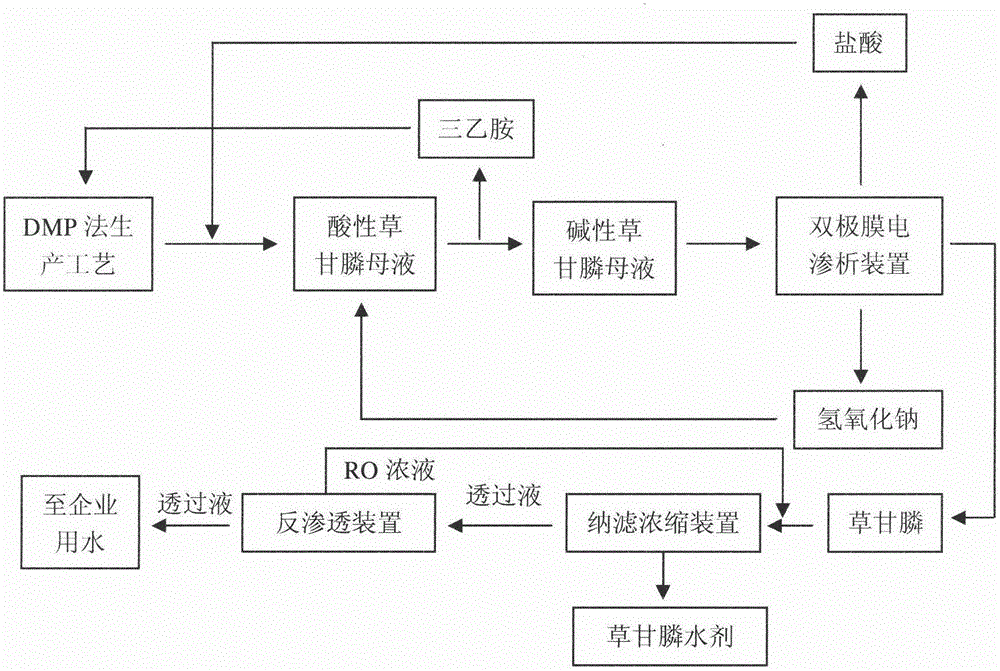

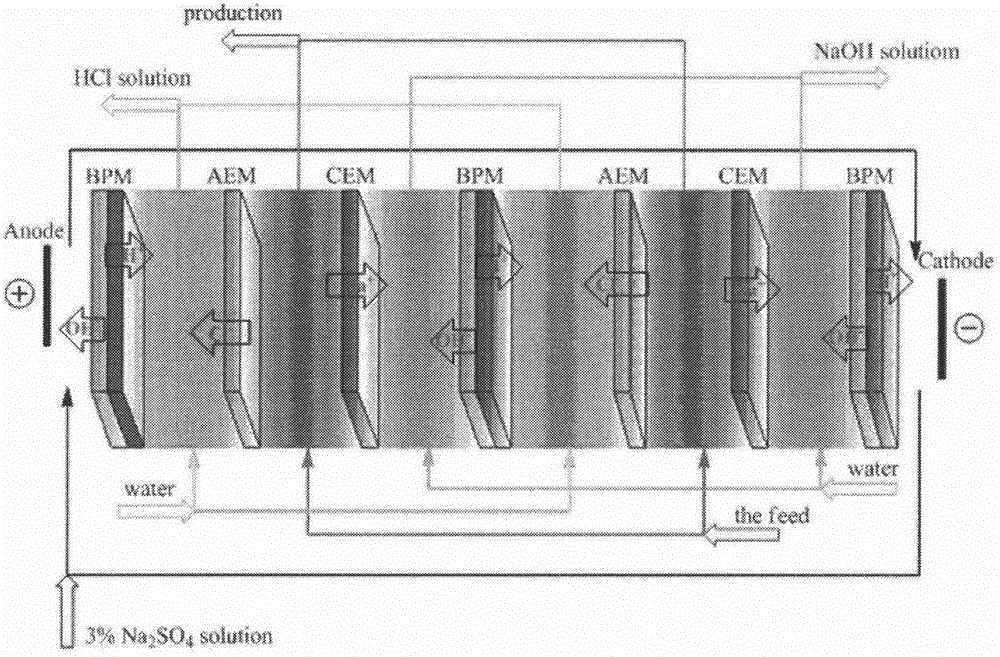

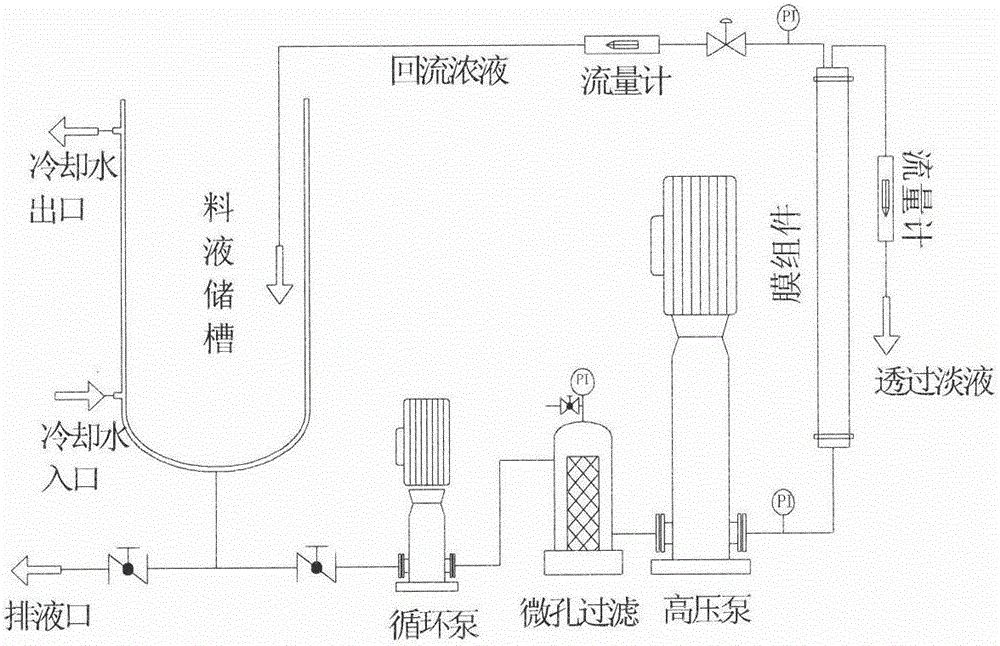

Method and apparatus for resourceful treatment of glyphosate mother liquor by bipolar membrane electrodialysis integrated nanofiltration and reverse osmosis technology

InactiveCN103949160AImprove pollutionAchieve resource recyclingChlorine/hydrogen-chlorideBiocideReverse osmosisHydrolysis

The invention discloses a method and apparatus for resourceful treatment of glyphosate and neutralization of mother liquor by integrated membrane electrodialysis integrated nanofiltration and reverse osmosis technology. The bipolar membrane electrodialysis technology is used for treating glyphosate and neutralizing mother liquor; sodium ions in the mother liquor enter into an alkali chamber through a cation exchange membrane, and combine with hydroxyl ions produce by the bipolar membrane to produce sodium hydroxide; and chloride ions enter into an acid chamber through an anion exchange membrane, and combine with the hydrogen ions generated by the bipolar membrane to form hydrochloric acid. When the conductance in the mother liquor is less than 10000, the desalinated mother liquor is subjected to desalination concentration and reverse osmosis concentration by the nanofiltration membrane, so as to recover glyphosate. The concentration of acid and alkali obtained by the invention is above 2 mol / L, the obtained hydrochloric acid can be used for hydrolysis of esterification reaction in a production process, sodium hydroxide can be used for recycling tri ethylamine, and the concentrated glyphosate has concentration more than 10%. The invention achieves glyphosate mother liquor cleaning technology with zero discharge and can be widely applied to treatment of the glyphosate mother liquor with high salt content.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

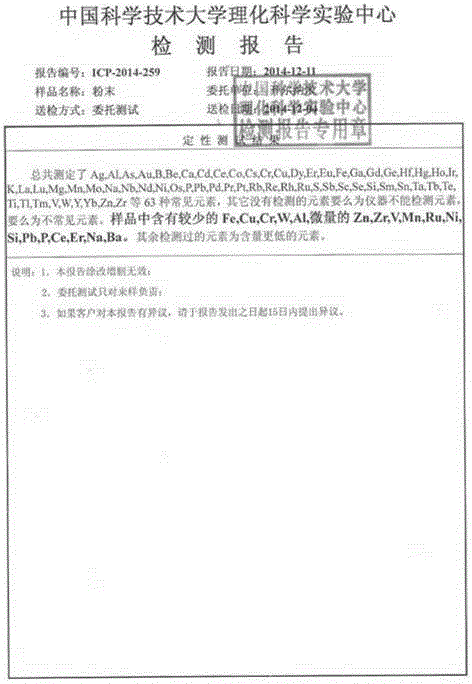

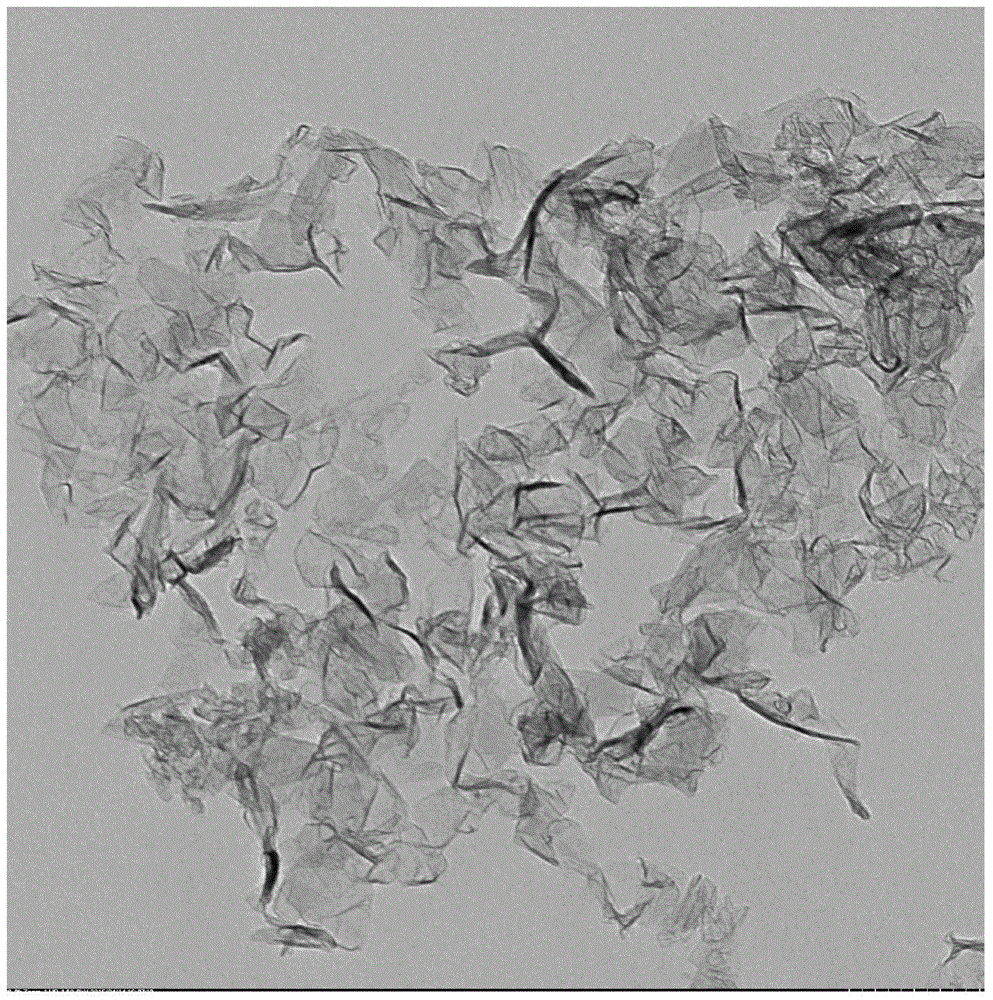

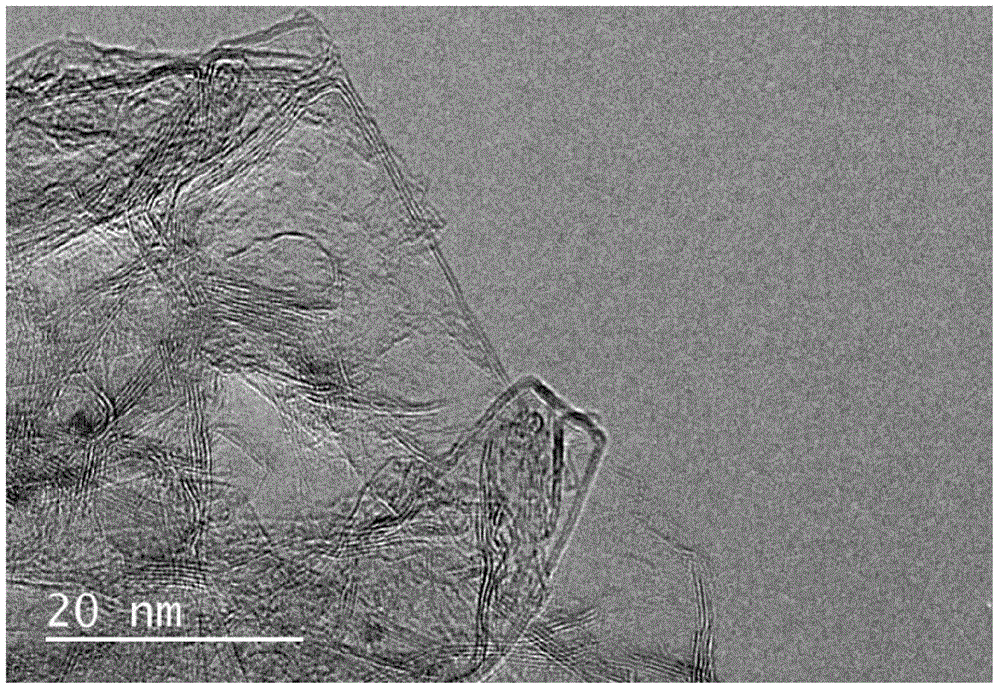

Method for preparing nano graphene powder by plasma chemical vapor synthesis

InactiveCN104961127AHigh purityLow impurity contentMaterial nanotechnologyCarbon ionMetal impurities

The invention discloses a method for preparing nano graphene powder by plasma chemical vapor synthesis, which comprises the following steps: by using nitrogen as a working medium, the raw material methane is ionized into carbon ions and hydrogen ions under the ionization action of plasma arc, wherein the carbon ions are rearranged into a network in the reactor to generate complete-structure graphene powder, the hydrogen ions are combined into hydrogen gas to be discharged, and the graphene powder is led by the air flow to enter a powder collector. The graphene prepared by the method has the advantages of lower layer number (2-10), complete structure, large single-layer diameter, low oxygen content, no sulfur and low metal impurity content, and can implement continuous industrialized production.

Owner:HEFEI KAIER NANOMETER ENERGY & TECH

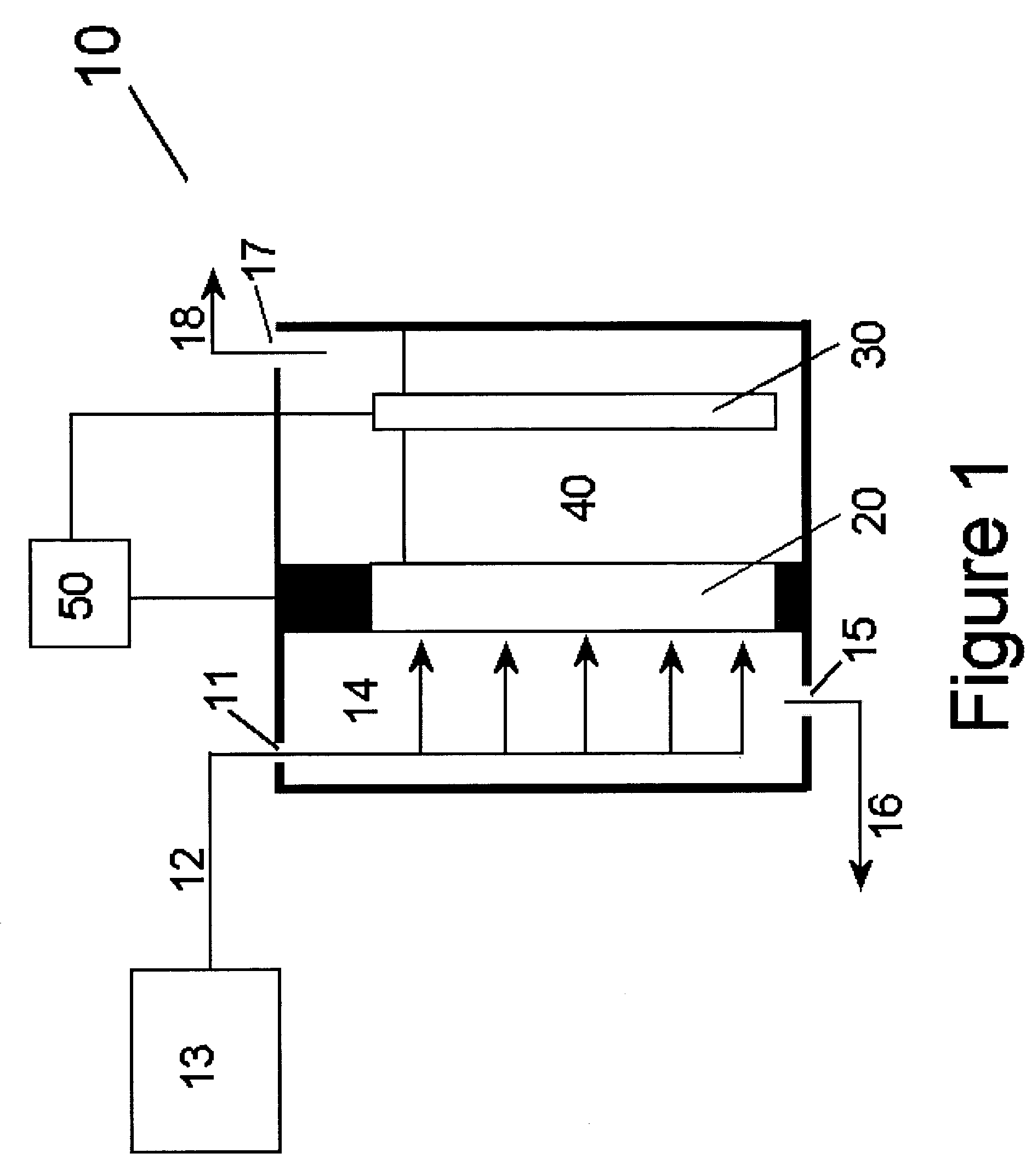

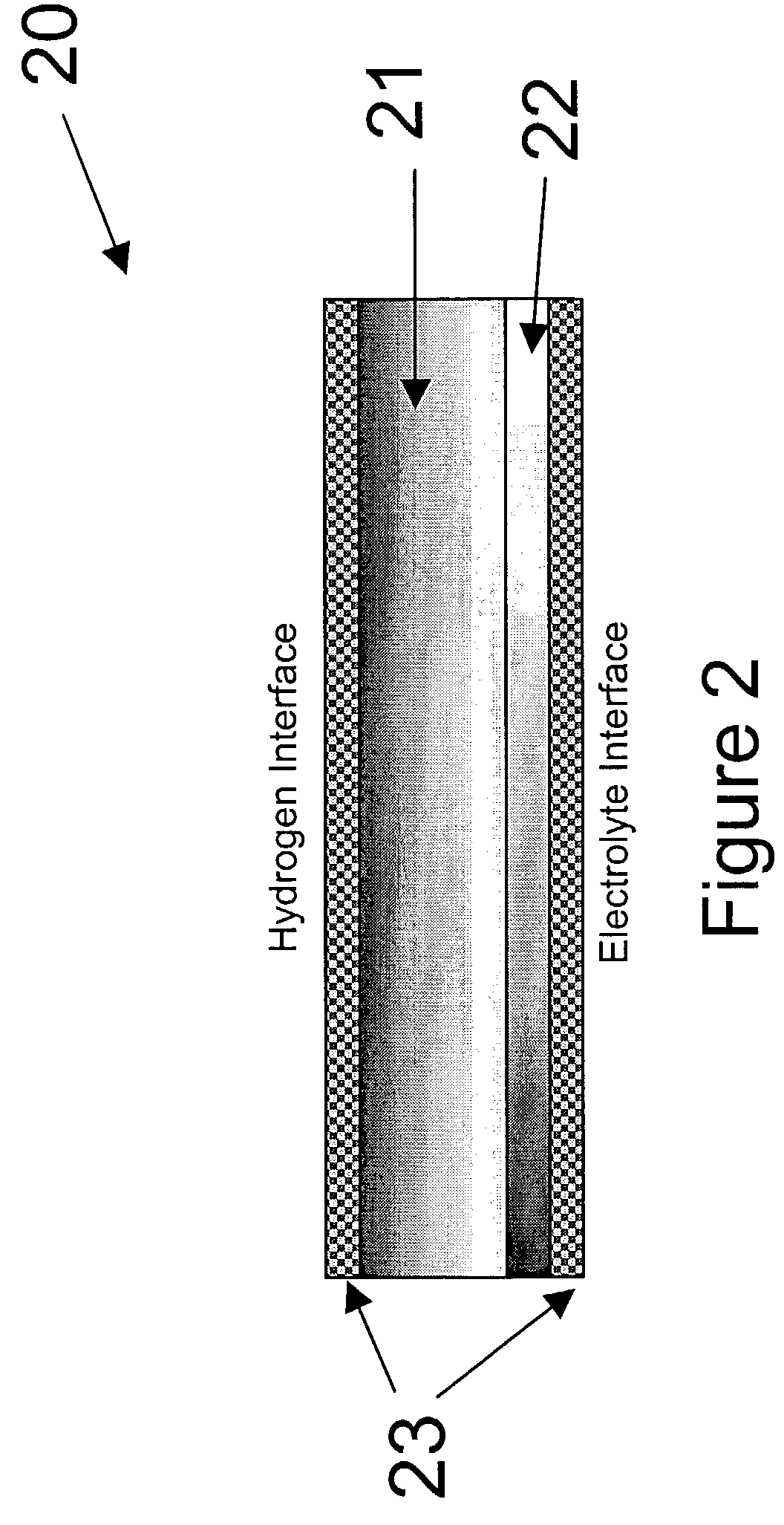

Method and apparatus for electrorefining impure hydrogen

A method and system for electrochemically purifying an impure stream of hydrogen. Hydrogen is absorbed into a gas diffusion anode from the impure hydrogen stream and oxidized to form hydrogen ions and electrons which are released into an alkaline solution. An electrolytic cathode also positioned in the alkaline solution decomposes water to form hydrogen and hydroxyl ions which combine with the hydrogen ions to maintain equilibrium of the system.

Owner:TACTICAL FUEL CELLS

Novel process of treatment of waste mother solution for itaconic acid fermentation through seawater desalination and membrane separation

ActiveCN102816055AHigh yieldReduce manufacturing costOrganic compound preparationCarboxylic compound separation/purificationFermentationPollution

The invention discloses a novel process of treatment of waste mother solution for itaconic acid fermentation through seawater desalination and membrane separation. According to the process, at first, inorganic anions in waste mother solution for itaconic acid fermentation are separated by an electrodialysis device, the itaconic acid mother solution is subjected to ionization with sodium hydroxide solution, the ionized itaconic acid mother solution is delivered by a centrifugal pump into a salt chamber of a bipolar membrane electrodialysis device, itaconic acid is produced through combination with hydrogen ions produced by a bipolar membrane, itaconic acid solution is repeatedly concentrated and crystallized, and itaconic acid is extracted. By adopting the process, the waste mother solution for itaconic acid fermentation can be made into resources, the total yield of the itaconic acid produced in a fermentation method can be increased, and the production cost can be reduced. Meanwhile, the sodium hydroxide solution used in the process can be repeatedly used, and no additional sodium hydroxide solution needs to be added continuously. Moreover, the process has the advantages of short flow, easiness in operation, no secondary pollution, low energy consumption and the like.

Owner:QINGDAO LANGYATAI GRP

Method for preventing crystal defect on fluorine-doped oxide film surface

InactiveCN101246823AReduce in quantityCrystalline defects do notSemiconductor/solid-state device manufacturingHydrogen ion bindingHydrofluoric acid

The invention provides a method for preventing crystal-like flaw on the surface of a fluorine-doping oxide film, relating to a process for manufacturing a semiconductor device. In current process, when a wafer having a surface deposited with a fluorine-doping oxide film is exposed to a vapor-containing environment, crystal-like flaw can be formed on the wafer surface in a short time (usually a few hours), resulting in the decrease of wafer yield. According to the method for preventing crystal-like flaw on the surface of a fluorine-doping oxide film, after the fuorine-doping oxide film is deposited on the wafer surface, the wafer is cleaned by weak acid with a pH value between 5 and 7. In this method, fluorine ion and hydrogen ion produced by weak acid electrolysis are integrated to form hydrofluoric acid, so that the hydrofluoric acid can be directly volatilized or washed by water, the fluorine ion amount on the wafer surface is effectively reduced, and crystal-like flaw can not be formed even the cleaned wafer is exposed to the vapor-containing environment.

Owner:SEMICON MFG INT (SHANGHAI) CORP

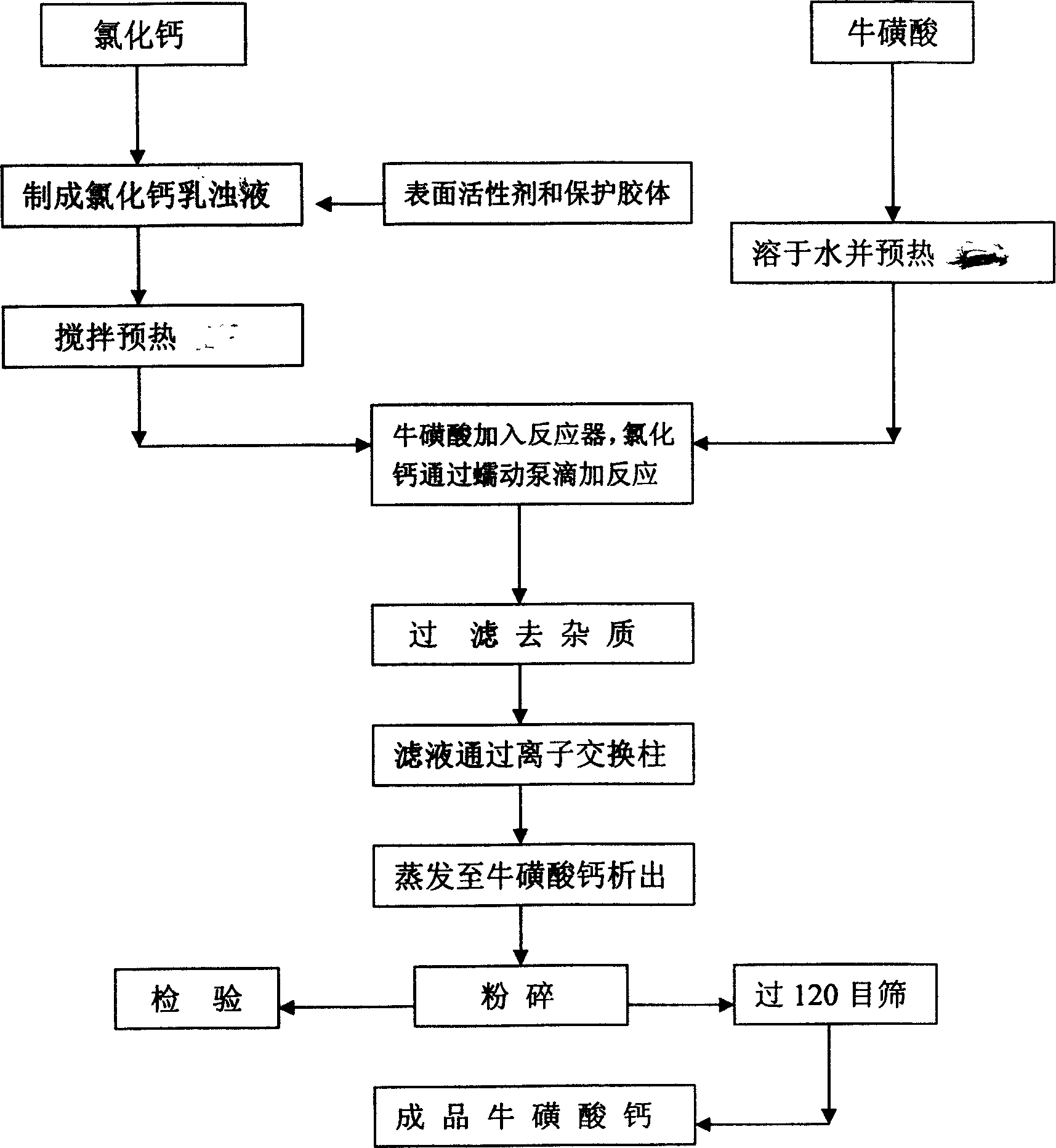

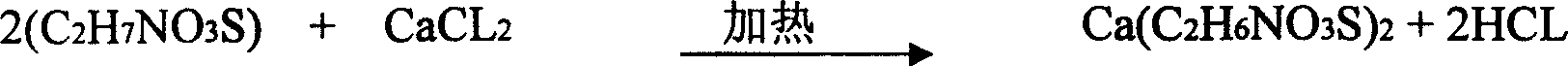

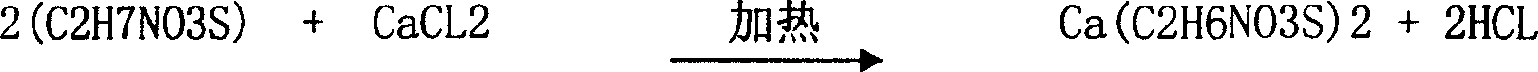

Ion exchange resin purifying process for synthesizing calcium taurine

InactiveCN1546466AMeet the requirementsSulfonic acids salts preparationFood additiveHydrogen ion binding

The invention relates to a process for synthesizing calcium taurate, in particular the process for synthesizing calcium taurate through ion exchange resin purification method which comprises, synthesizing calcium taurate from taurine and calcium chloride, removing chloride ions by using ion exchange method, thus achieving the objective of high purity synthesis and meeting the requirement of food additives. The chlorine ions in the outcome yield are exchanged and adsorbed through highly basic anion exchange resin. The beneficial effects of the invention are environmental pollution proof, purified calcium taurate, and meeting the national requirement for food additives.

Owner:NANKAI UNIV +1

Method for preparing organic acid by electrolyzing organic acid salt on basis of chlor-alkali perfluor ion exchange membrane

ActiveCN102839383ANo pollution in the processNon-toxicElectrolytic organic productionDiaphragmsElectrolysisHydrogen ion

The invention relates to a method for preparing an organic acid by electrolyzing an organic acid salt on the basis of a chlor-alkali perfluor ion exchange membrane. According to the method, an electrolytic bath which is equipped with a perfluor ion exchange membrane between electrodes and is mainly composed of an anode chamber, an anode, the perfluor ion exchange membrane, a cathode and a cathode chamber is adopted. The method comprises the following steps: respectively supplying an anode solution and a cathode solution to the anode chamber and the cathode chamber of the electrolytic bath and performing electrochemical ion exchange, wherein the anode solution is an aqueous solution of the organic acid salt and the cathode solution is an alkali solution corresponding to cations in the organic acid salt; applying a direct current to the electrolytic bath so as to perform constant current electrolysis, and combining the anions in the organic acid salt solution enriched in the anode chamber with hydrogen ions generated by the anode chamber, thereby generating the organic acid; and collecting discharged solution containing the organic acid enriched in the anode chamber, concentrating and crystallizing, thereby obtaining the high-purity organic acid. The method has the advantages of simple process, easiness in industrial amplification, high current efficiency, and the like, and can realize the industrial preparation for the high-purity organic acid.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

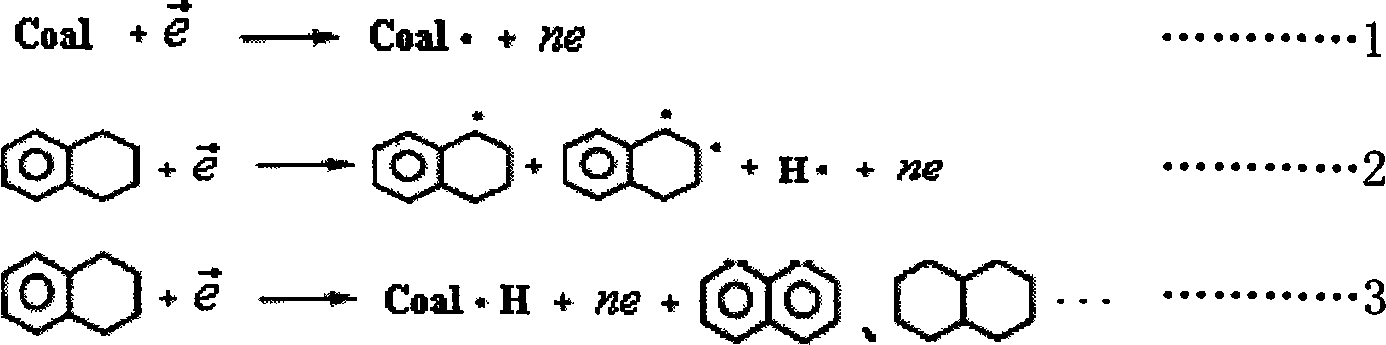

Method for liquefying liquid-solid medium barrier plasma coal under atmospheric normal pressure

InactiveCN101074386AMild conditionsReduce energy consumptionLiquid hydrocarbon mixture productionAtmospheric airReactive system

A coal hydrogenation liquefying method is liquid-solid medium baffling plasma liquefying at atmosphere normal pressure. The process is carried out by adopting medium baffling discharge, adding liquid-solid mixture of coal grain and hydrogen-supplying solvent into quartz medium baffling plasma reactor, combining into liquid-solid reactive phase medium baffling discharge reactive system, inputting into high-voltage and frequency electric field with peak voltage 3000-20000 volt and impulse power-supply frequency 500-30000 HZ, forming into plasma thin layer on surface of coal grain solid, dehydrogenating for hydrogen-supplying solvent in liquid-solid reactive system to generate active hydrogen ion, colliding electron in plasma thin-layer coal grain solid surface to form into free-base fragments and combining with hydrogen ion to form into coal liquefied products. The coal-liquefied products consist of petroleum, asphalt olefin and pro-asphalt olefin.

Owner:SOUTHEAST UNIV

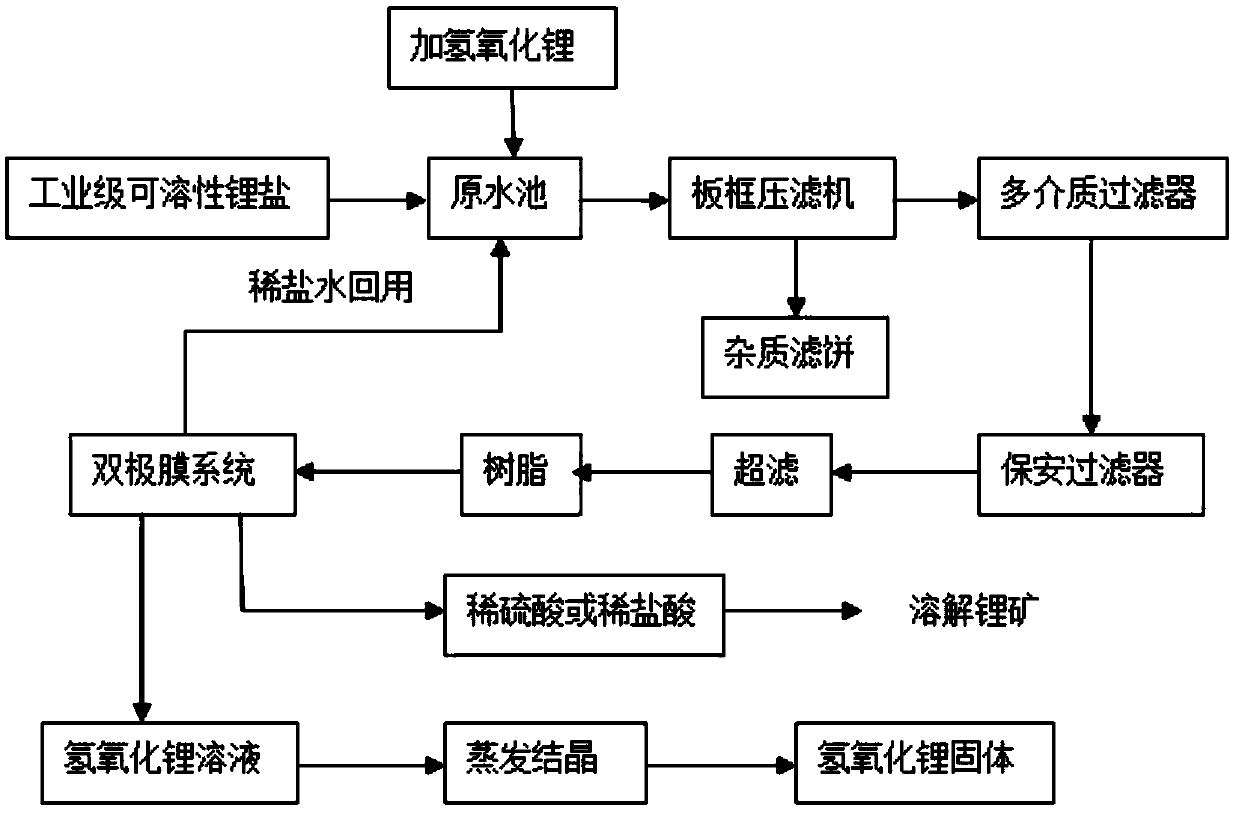

Method for preparing lithium hydroxide by industrial-grade soluble lithium salt

The invention provides a method for preparing lithium hydroxide by industrial-grade soluble lithium salt and belongs to the field of preparation of lithium hydroxide. The lithium hydroxide is preparedby taking the industrial-grade soluble lithium salt as a raw material; impurities, calcium, magnesium, aluminum, iron and other ions in the industrial-grade soluble lithium salt are removed through pH value regulation, plate and frame filtration, multi-medium filtration, ultra-filtration and chelate resin adsorption treatment; the plate and frame filtration can separate solid from liquid; the multi-medium filtration is used for removing suspended matters, colloids, organic matters and the like; the ultra-filtration can further reduce the contents of residual COD, the suspended matters and macromolecular dissolved matters to realize the purification and the separation of the liquid; chelate resin enables the content of high-valent ions in the liquid to meet the bipolar membrane water ingress requirements; anions in a pre-electrolyte migrates to an acid chamber and are combined with hydrogen ions decomposed by the surface of a bipolar membrane to form dilute acids; lithium ions in the pre-electrolyte migrate to an alkaline chamber and are combined with hydroxyl ions decomposed by the surface of the bipolar membrane to generate the lithium hydroxide.

Owner:BEIJING TINGRUN MEMBRANE TECH DEV

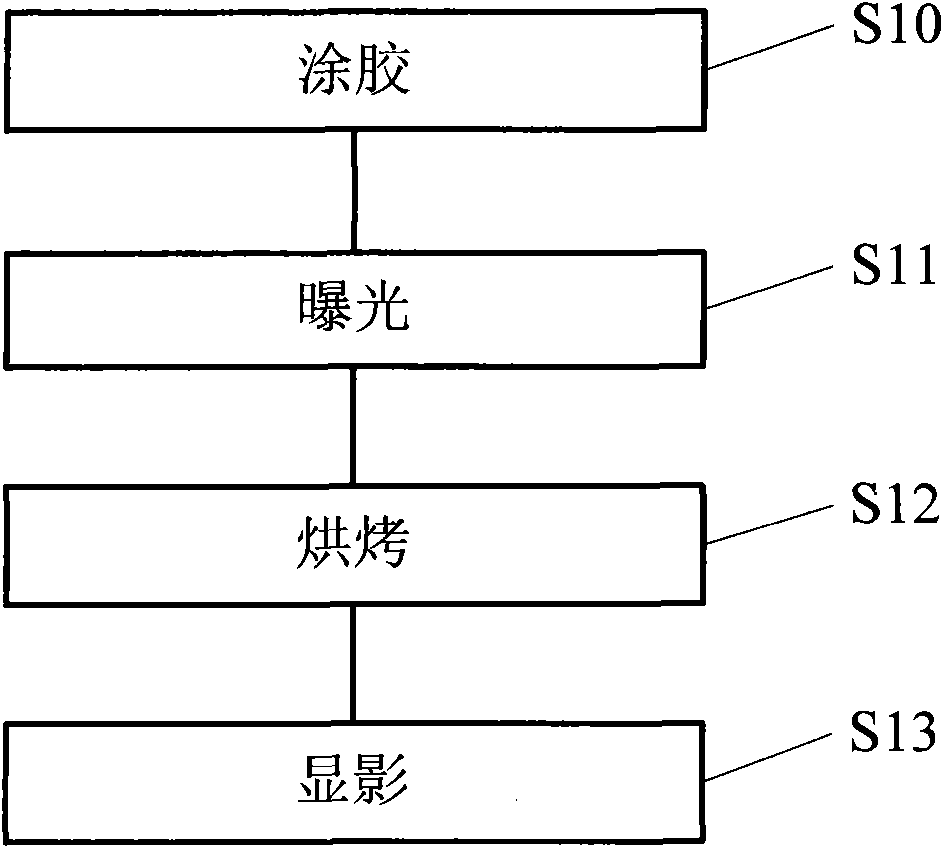

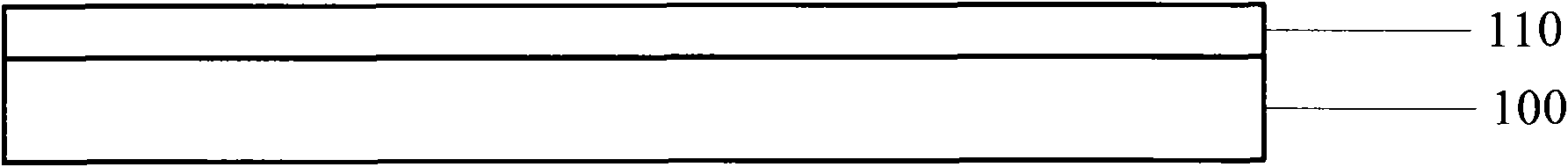

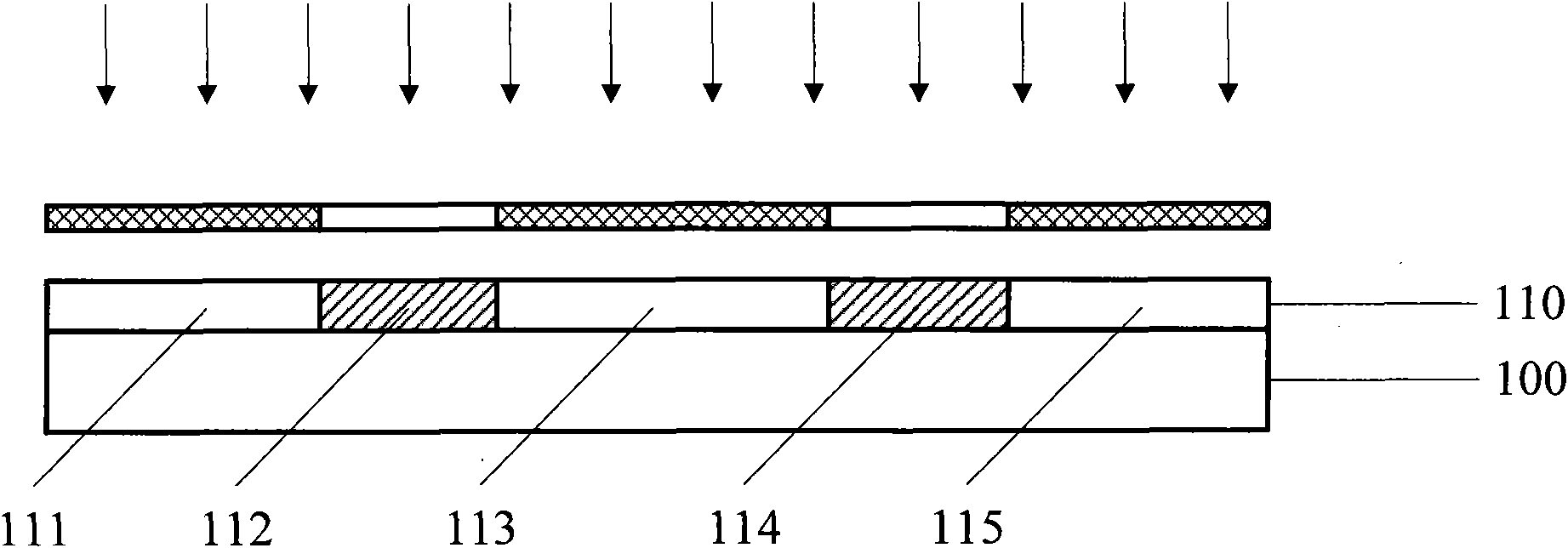

Photoetching method capable of reducing width of exposure pattern

InactiveCN101640170AReduce widthReduce graphic widthSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusHydrogen ion bindingHydrogen

The invention provides a photoetching method capable of reducing the width of an exposure pattern. The method comprises the following steps of: providing a semiconductor substrate of which the surfaceis provided with a photoresist layer; exposing the photoresist layer, and defining a pattern in the photoresist layer; carrying out a passivation reaction of a passivating agent containing trivalentnitrogen atoms and the exposed photoresist layer to form a coating layer on the exposed surface and side surfaces of the photoresist layer for the trivalent nitrogen atoms in the passivating agent cancombine with the hydrogen ions on the exposed surface of the photoresist layer; and developing the passivated photoresist layer to remove the unexposed part of the photoresist layer and keep the coating layer and the exposed part of the photoresist layer coated by the coating layer. The method has the advantages that: because the passivating agent containing trivalent nitrogen atoms is used to becombined with the hydrogen ions on the exposed surface and side surfaces of the photoresist layer to form the coating layer, the pattern width of the unexposed part is reduced, the limitation of thewavelength on the minimum width is broken through, and the pattern with smaller width can be obtained.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Machining process of anti-cracking furniture

InactiveCN107803910AAvoid crackingAvoid deformationWood treatment detailsWood impregnation detailsHydrogen ion bindingHydrogen

The invention discloses a machining process of anti-cracking furniture. The method comprises following steps: a, a raw material is split into two halves; b, the split wood is put into a pond to be soaked with saline for 20 to 30 days; c, the soaked wood is dried; d, the dried wood is cut; e, the cut wood is cleaned; f, the cleaned wood is subject to natural air drying for 5 to 8 days; g, the woodis put into an oven to be dried until the water containing amount ranges from 4% to 5%; h, equipment is used for injecting an anti-corrosion agent into cells of the wood. Saline soaking is carried out, the soaking time can be shortened, efficiency is improved, sodium ions and hydrogen ions in raw wood are combined to increase plasticity of the wood, wood cracking and deforming caused by air humidity change influences on the water can be prevented, natural drying is carried out, then drying is carried out, cracking and deforming in the wood drying process can be avoided, the wood is dried through stream, wood can be plastified, and the wood can be more tough.

Owner:CHENGDU JINCHUANTIAN AGRI MACHINE MFG

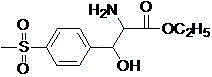

Preparation method of p-methyl sulfone phenyl ethyl serinate

InactiveCN104860853ASolve pollutionAvoid generatingOrganic chemistryOrganic compound preparationSerineSodium hydroxide

The invention discloses a preparation method of p-methyl sulfone phenyl ethyl serinate and belongs to the technical field of a synthetic technology of veterinary drugs and pharmaceutical intermediates. According to the technical scheme, the preparation method is characterized in that p-methyl sulfone phenyl serine copper is dissolved in a sodium hydroxide solution, an Na2S solution is added to precipitate Cu<2+>, activated carbon is added to adsorb excess S<2->, the mixture is mechanically agitated and subjected to suction filtration, hydrochloric acid is added to a filtrate to regulate pH to be 3-7, and the mixture is subjected to condensation crystallization and suction filtration to obtain p-methyl sulfone phenyl serine; the p-methyl sulfone phenyl serine is dissolved in absolute ethyl alcohol, concentrated sulfuric acid is added, the mixture is subjected to reflux for 4 h, cooling crystallization and suction filtration, a filter cake is dissolved in water, a saturated Na2CO3 solution is added to regulate pH to be neutral, and the p-methyl sulfone phenyl ethyl serinate is obtained after suction filtration. The preparation method has the advantages as follows: the Na2S solution is added in an alkaline environment to remove Cu ions, the excess S<2-> is removed through activated carbon adsorption, and production of toxic and irritant gas H2S through combination of S ions and H ions is avoided, so that the problem of environmental pollution is solved effectively.

Owner:HENAN NORMAL UNIV

Anti-cracking processing process of wood board

InactiveCN109454737AImprove plasticityAvoid crackingWood treatment detailsWood impregnation detailsSaline waterHydrogen ion binding

The invention discloses an anti-cracking processing process of a wood board. The anti-cracking processing process comprises the following steps that a, a log is split into two halves; b, the split wood is placed into a water tank and is soaked by using saline water for 20-30 days; c, the soaked wood is dried; d, the dried wood is cut; e, the cut board is cleaned; f, natural air drying is carried out on the cleaned board for 5-8 days; g, the board is placed into a drying oven to be dried until the water content is 4%-5%; and h, a preservative is injected into cells of the board by utilizing equipment. According to the anti-cracking processing process, the soaking time can be shortened by using the saline water to perform soaking, and the efficiency is improved; sodium ions are combined withhydrogen ions in the log so that the plasticity of the wood can be increased, and cracking and deformation caused by the influence of changes of air humidity on moisture in the wood are prevented; cracking and deformation of the wood in the drying process can be avoided through the mode of performing natural air drying first and then drying; and the board is dried by using steam so that wood canbe plasticized, and then the board is tougher.

Owner:成都千佳世纪家具有限责任公司

Technology for adopting bipolar membrane electrodialysis for preparing beta-aminopropionic acid

InactiveCN109851515AProduced noGood atom economySemi-permeable membranesOrganic compound preparationPotassium hydroxideSolvent

The invention discloses a method for using bipolar membrane electrodialysis for preparing beta-aminopropionic acid. The method comprises the steps of using 3-aminopropanenitrile and a sodium hydroxideaqueous solution or a potassium hydroxide aqueous solution as raw materials for reaction to obtain a sodium beta-aminopropionate solution, then making sodium beta-aminopropionate directly subjected to action of bipolar membrane electrodialysis equipment, forming sodium hydroxide by combining ionized sodium ions and hydroxyl, forming the beta-aminopropionic acid by combining aminopropionic acid radicals and hydrogen ions, and obtaining a high-purity product by conducting concentration and crystallization on the beta-aminopropionic acid. According to the production method, no hydrochloric acidor sulfuric acid is used for acidifying the sodium beta-aminopropionate, no wastewater is generated, no solvents need to be used in the crystallization process, solvent residues in the product are avoided, the purify can be over 99%, moreover, a generated sodium hydroxide solution can be recycled, thus an economic effect is good, moreover, the theoretical yield of the technology is 100%, and the actual yield can be over 90%.

Owner:江西兄弟医药有限公司

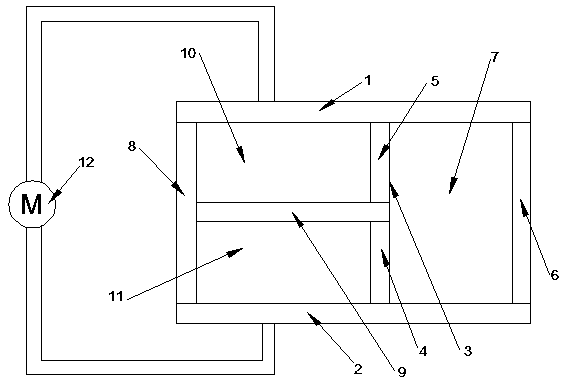

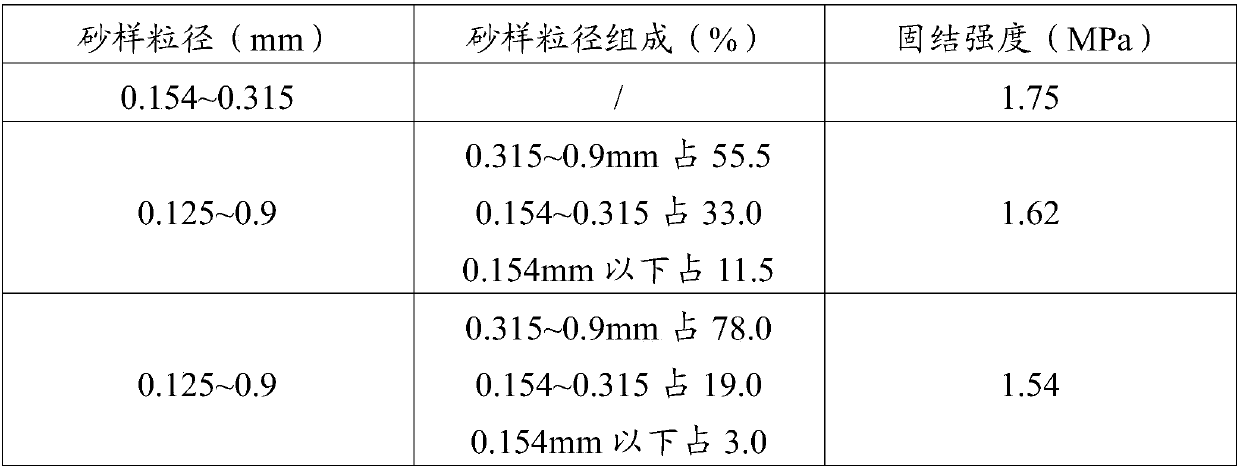

Oil-water well sand consolidation agent as well as preparation method and application thereof

InactiveCN107779185AControl or reduce sand productionReduce sand productionDrilling compositionSilicon oxygenPetroleum

The invention discloses an oil-water well sand consolidation agent as well as a preparation method and application thereof, and belongs to the field of oil-water well sand consolidation. The oil-waterwell sand consolidation agent is prepared from the following components in percentage by weight 41 to 45 percent of aqueous solution of silicate, 8 to 20 percent of carbamide or ammonium carbonate, 0.06 to 0.1 percent of coupling agent and the balance of water, wherein the mass fraction of silicate in the silicate aqueous solution is 35 to 40 percent. The oil-water well sand consolidation agent covers the surfaces of sand after entering a petroleum reservoir stratum, and is combined with the carbamide or hydrogen ion generated by hydrolyzing ammonium carbonate through silicate ion generated by hydrolyzing silicate to form a polymer poly-silicate; silicon-oxygen bonds in the poly-silicate are cross-bonded to from a three-dimensional structure, so that curing layers on the surface of the sand in the petroleum reservoir stratum are cemented together for a sand production rate of the reservoir stratum; meanwhile, influence of the oil-water well sand consolidation agent on large cracks andgaps in the reservoir stratum is lowered, so that the permeation rate of the reservoir stratum and oil well yield are ensured.

Owner:PETROCHINA CO LTD

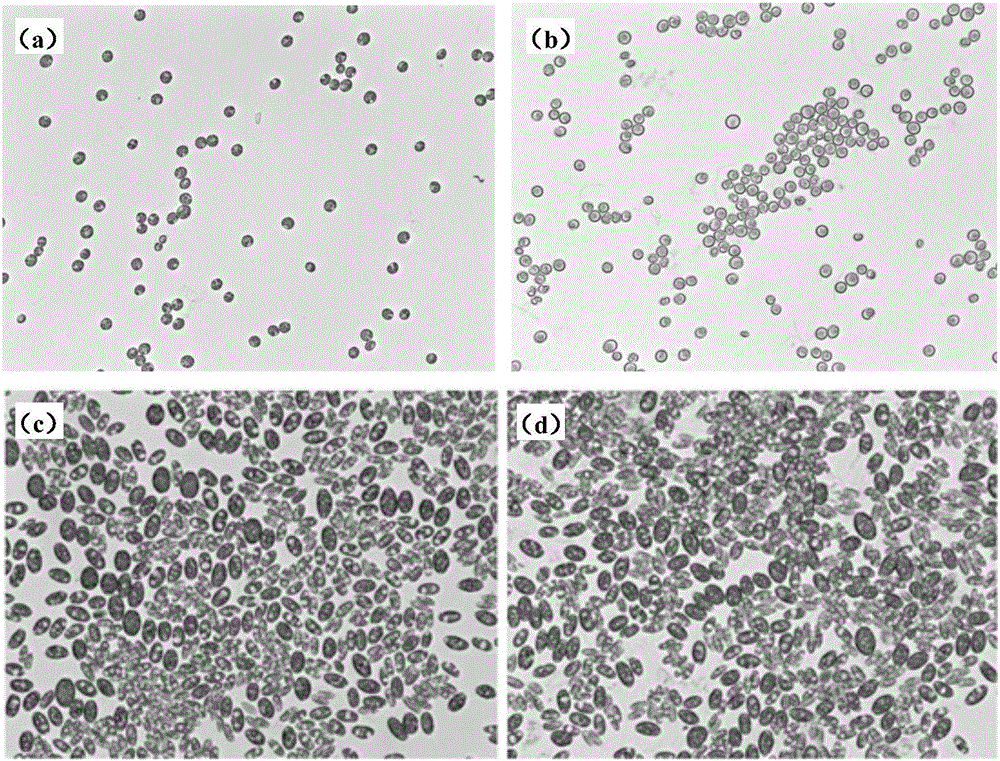

Method for flocculating microalgae by using flue gas and application thereof

InactiveCN106047712ACost-freeEliminate mutual repulsionUnicellular algaeMicroorganism based processesNutrient solutionHydrogen ion

The invention discloses a method for flocculating microalgae by using flue gas and application thereof, belonging to the technical field of biomass energy. The method comprises the following concrete steps: introducing flue gas containing sulfur dioxide into a nutrient solution where microalgae are cultured until microalga agglomeration algae is generated; carrying out standing; and removing supernatant so as to obtain flocculated microalgae; wherein the microalgae refer to fresh-water microalgae. According to the invention, flue gas from a coal-fired plant is continuously introduced into the microalga nutrient solution and sulfur dioxide hydrate in the flue gas interacts with extracellular polysaccharide organic matters secreted by the surfaces of microalgae, so the negatively-charged extracellular polysaccharide organic matters bond with the sulfur dioxide hydrate and free hydrogen ions produced thereof, surface expulsive force among cells is eliminated, and the balance state of microalgae in the nutrient solution is broken; thus, agglomeration and settlement of microalga cells are realized, and harvesting efficiency reaches 90% or above. The method is simple to operate and high in separation efficiency, has almost no cost and can be applied to separation of microalgae.

Owner:JINAN UNIVERSITY

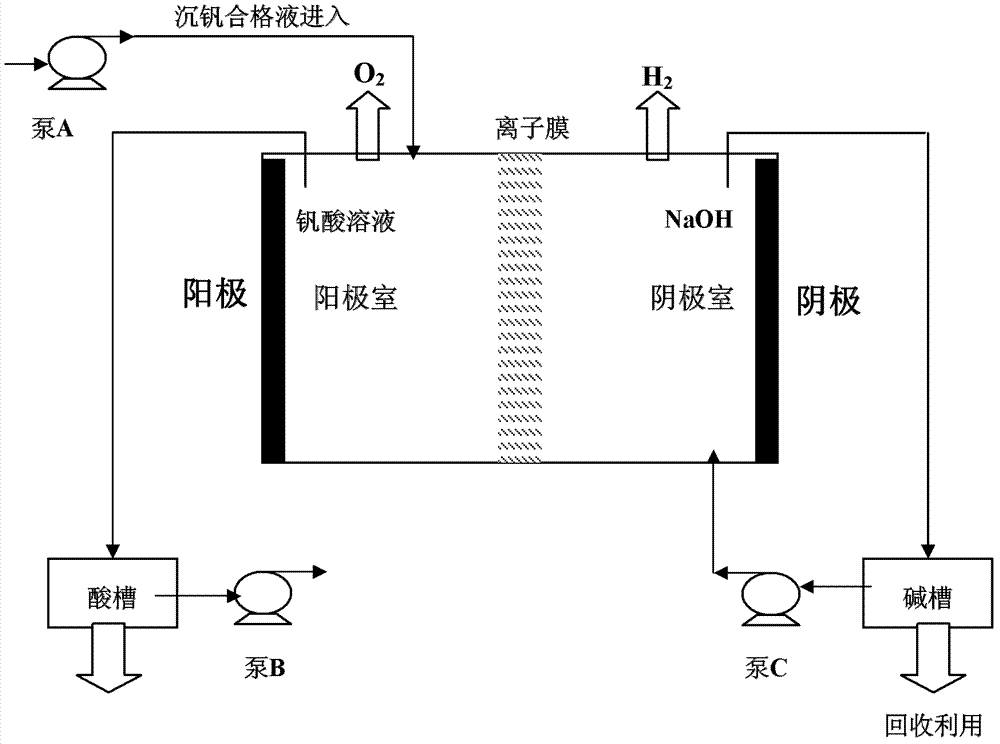

Method for decreasing pH (potential of hydrogen) value of vanadium precipitation qualified liquid

The invention provides a method for decreasing a pH (potential of hydrogen) value of vanadium precipitation qualified liquid. The method is characterized by including: under the condition of ion-exchange membrane electrolysis, introducing the vanadium precipitation qualified liquid into an anode chamber of an ion-exchange membrane electrolyzer, and introducing electrolyte water solution into a cathode chamber of the ion-exchange membrane electrolyzer so that ion-exchange membrane electrolysis is performed. By the method, the pH value of the vanadium precipitation qualified liquid is decreased while acid radical negative ions cannot be introduced. During electrolysis, the vanadium precipitation qualified liquid is disposed in the anode chamber, water of the anode chamber is electrolyzed to oxygen and hydrogen ions, water of the cathode chamber is electrolyzed to hydrogen and hydroxyl ions, sodions in vanadate in the anode chamber enter the cathode chamber by penetrating through a positive ion membrane, the sodions and the hydroxyl ions produced in the cathode chamber produce sodium hydroxide, vanadate ions are retained in the anode chamber, and the vanadate ions and the hydroxyl ions produced in the anode chamber are combined into vanadic acid (or acidic vanadate). Therefore, the purpose of decreasing the pH value of the vanadium precipitation qualified liquid in a non-acid manner is achieved by means of ion-exchange membrane electrolysis.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

Cultivation of selenium-germanium-rich ganoderma lucidum

The invention discloses cultivation of selenium-germanium-rich ganoderma lucidum, and belongs to the technical field of farmer-benefiting science functional edible mushroom ganoderma lucidum cultivatino. The selenium-germanium-rich ganoderma lucidum is prepared from a ganoderma lucidum strain potato glucose GeO2 germanium inorganic selenium agar medium, a selenium-germanium-rich zinc, magnesium and potassium potato vitamin B1 synthetic medium, a nano selenium organic germanium peptone glucose agar medium and an inoculation medium prepared from ganoderma lucidum mother strains through inoculation and cultivation. It is proved through modern pharmacological research that the selenium-germanium-rich ganoderma lucidum can prevent, resist and treat more than 80 diseases such as cancers, immunodeficiency diseases, aids and cerebral-cardio vascular diseases, achieves prevention and auxiliary treatment effects, is an immunopotentiator and an anti-aging agent, induces generation of interferons,and obviously restrains growth of cancer cells, germanium and hydrogen ions in the human body can be bound, toxins are removed in the forms of urea and sweat, blood circulation is promoted, the celloxygen carrying capacity is enhanced, body circulation and metabolism are promoted, and the life is prolonged.

Owner:NANTONG SNAKEBITE THERAPY INST

A new process for treating waste mother liquor of itaconic acid fermentation using seawater desalination membrane separation technology

ActiveCN102816055BHigh yieldReduce manufacturing costOrganic compound preparationCarboxylic compound separation/purificationSeparation technologyFermentation

The invention discloses a novel process of treatment of waste mother solution for itaconic acid fermentation through seawater desalination and membrane separation. According to the process, at first, inorganic anions in waste mother solution for itaconic acid fermentation are separated by an electrodialysis device, the itaconic acid mother solution is subjected to ionization with sodium hydroxide solution, the ionized itaconic acid mother solution is delivered by a centrifugal pump into a salt chamber of a bipolar membrane electrodialysis device, itaconic acid is produced through combination with hydrogen ions produced by a bipolar membrane, itaconic acid solution is repeatedly concentrated and crystallized, and itaconic acid is extracted. By adopting the process, the waste mother solution for itaconic acid fermentation can be made into resources, the total yield of the itaconic acid produced in a fermentation method can be increased, and the production cost can be reduced. Meanwhile, the sodium hydroxide solution used in the process can be repeatedly used, and no additional sodium hydroxide solution needs to be added continuously. Moreover, the process has the advantages of short flow, easiness in operation, no secondary pollution, low energy consumption and the like.

Owner:QINGDAO LANGYATAI GRP

Electrodialysis miscellaneous salt resource recycling device

PendingCN112158922ARealize resource reuseReduce energy consumptionChlorine/hydrogen-chlorideSulfur compoundsHydrogen ion bindingPolypyrrole

The invention discloses an electrodialysis miscellaneous salt resource recycling device. Under the effect of electric field force, negatively charged salt ions are driven to penetrate a PS-g-PE anionic membrane, and positively charged salt ions penetrate through a cation exchange membrane; when anions contained in the miscellaneous salt permeate through a polypyrrole modification layer on the anionic membrane, negatively charged anions are repelled by negatively charged polypyrrole, and the electric repulsive force of polyvalent anions is far higher than that of monovalent anions, so that themonovalent anions selectively permeate and polyvalent salt ions are intercepted, namely, selective separation of monovalent from multivalent salt ion is achieved. Monovalent salt ions penetrating through the anion exchange membrane are combined with hydrogen ions generated by the bipolar membrane to form pure acid; and salt ions penetrating through the cation exchange membrane are combined with hydroxide radicals generated by the bipolar membrane to form sodium carbonate. Therefore, monovalent salt is separated from multivalent hydrochloric acid in the carnallite, pure acid and sodium carbonate are synchronously produced, and the prepared pure acid and alkali can be recycled.

Owner:SHANGHAI JIAO TONG UNIV

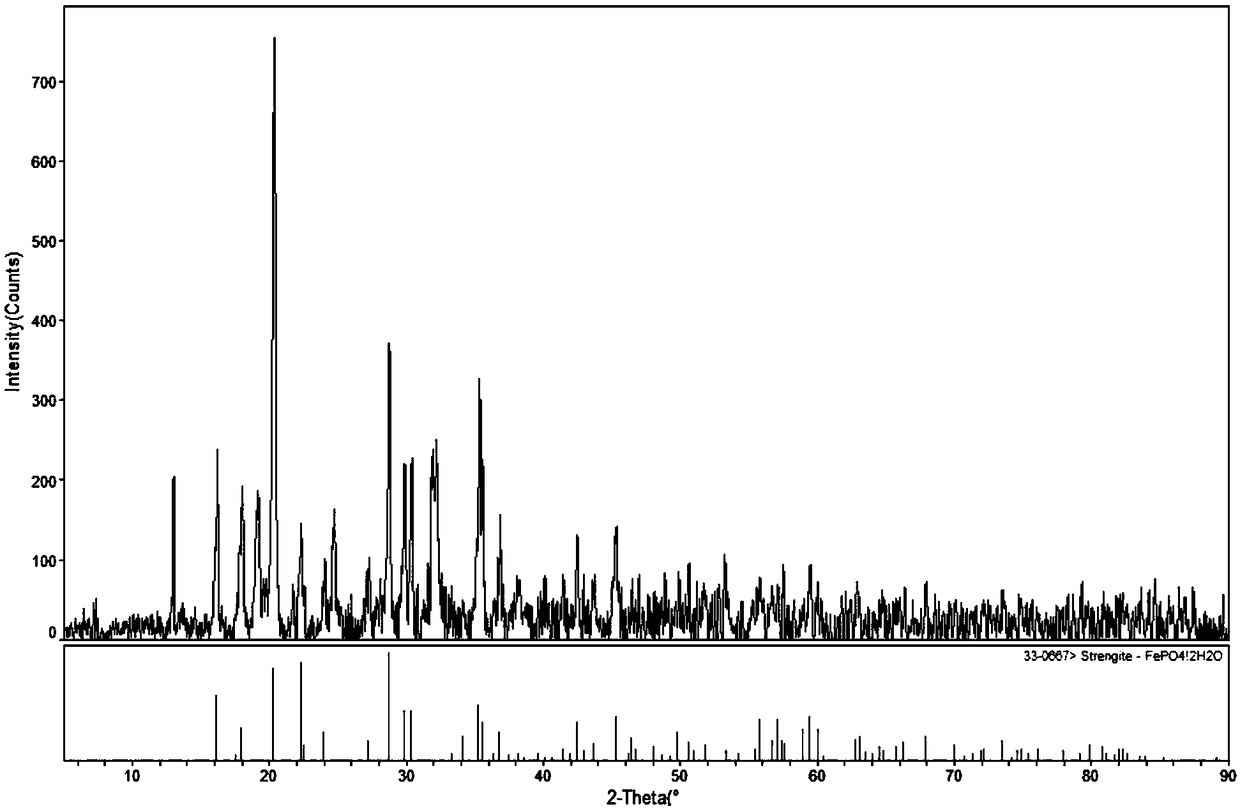

Method for recycling residual lithium in reaction mother liquid of electrode material by hydrothermal method

ActiveCN109504861ALow costNo wasteCell electrodesProcess efficiency improvementElectrolysisLithium hydroxide

The invention discloses a method for recycling residual lithium in reaction mother liquid of an electrode material by a hydrothermal method. Lithium hydroxide is added into the reaction mother liquid, solid and liquid are separated after a heating reaction, after a reaction of precipitate and phosphoric acid, the solid and liquid are separated again, and a clarified solution is obtained and usedas a raw material of the electrode material by the hydrothermal method; lithium sulphate is separated from the first separated clarified solution through an ion exchange membrane, a remaining solventis concentrated and recycled to obtain a lithium sulfate aqueous solution to pass through a bipolar membrane, a lithium ion and a sulfate ion are separated and combined with a hydroxide ion and a hydrogen ion obtained by water electrolysis correspondingly, and a lithium hydroxide solution and a sulfuric acid solution are finally obtained correspondingly; and the concentrated lithium hydroxide solution is used as the raw material of the electrode material by the hydrothermal method. According to the method for recycling the residual lithium in the reaction mother liquid of the electrode material by the hydrothermal method, the application range is wide, the raw material cost of hydrothermal method process production is greatly lowered, no new raw materials are added, the recycling effect isgood, the process is simple, cost performance is high, and application and promotion in industrial production are facilitated.

Owner:德阳威旭锂电科技有限责任公司

A method for recycling residual lithium in the reaction mother liquor of electrode material prepared by hydrothermal method

ActiveCN109504861BLow costNo wasteCell electrodesProcess efficiency improvementLithium oxideElectrolysis

The invention discloses a method for recycling residual lithium in reaction mother liquor in preparation of electrode materials by a hydrothermal method. Lithium hydroxide is added in the reaction mother liquor; the solid-liquid separation is performed after the heating reaction; the solid-liquid separation is performed again after the reaction between precipitates and phosphoric acid; obtained clarified solution is used as raw materials for preparing the electrode materials by the hydrothermal method; lithium sulfate is separated from the first-separated clarified solution through an ion exchange membrane; remained solvent is concentrated and recycled; lithium ions and sulfate ions in obtained lithium sulfate water solution are separated through a bipolar membrane, and are combined with hydroxide ions and hydrogen ions obtained through water electrolysis to obtain lithium hydroxide solution and sulfuric acid solution; and the lithium hydroxide solution is concentrated as the raw materials for preparing the electrode materials by the hydrothermal method. The method is wide in application range, greatly reduces the cost of the raw materials for production by the hydrothermal method,adds no new raw materials, achieves good recycling effect, simple procedures and high cost performance, and facilitates application and popularization in industrial production.

Owner:DEYANG WEI XU LITHIUM ELECTRICITY TECH CO LTD

Method for recycling residual lithium in reaction mother liquor in preparation of electrode materials by hydrothermal method

InactiveCN109295312ALow costNo wasteCell electrodesProcess efficiency improvementElectrolysisLithium hydroxide

The invention discloses a method for recycling residual lithium in reaction mother liquor in preparation of electrode materials by a hydrothermal method. Lithium hydroxide is added in the reaction mother liquor; the solid-liquid separation is performed after the heating reaction; the solid-liquid separation is performed again after the reaction between precipitates and phosphoric acid; obtained clarified solution is used as raw materials for preparing the electrode materials by the hydrothermal method; lithium sulfate is separated from the first-separated clarified solution through an ion exchange membrane; remained solvent is concentrated and recycled; lithium ions and sulfate ions in obtained lithium sulfate water solution are separated through a bipolar membrane, and are combined with hydroxide ions and hydrogen ions obtained through water electrolysis to obtain lithium hydroxide solution and sulfuric acid solution; and the lithium hydroxide solution is concentrated as the raw materials for preparing the electrode materials by the hydrothermal method. The method is wide in application range, greatly reduces the cost of the raw materials for production by the hydrothermal method,adds no new raw materials, achieves good recycling effect, simple procedures and high cost performance, and facilitates application and popularization in industrial production.

Owner:德阳威旭锂电科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com