Electrodialysis miscellaneous salt resource recycling device

An electrodialysis and recycling technology, applied in the field of electrodialysis, can solve the problems of lengthy acid-base process, uneconomical process, inability to directly process multi-component salts, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

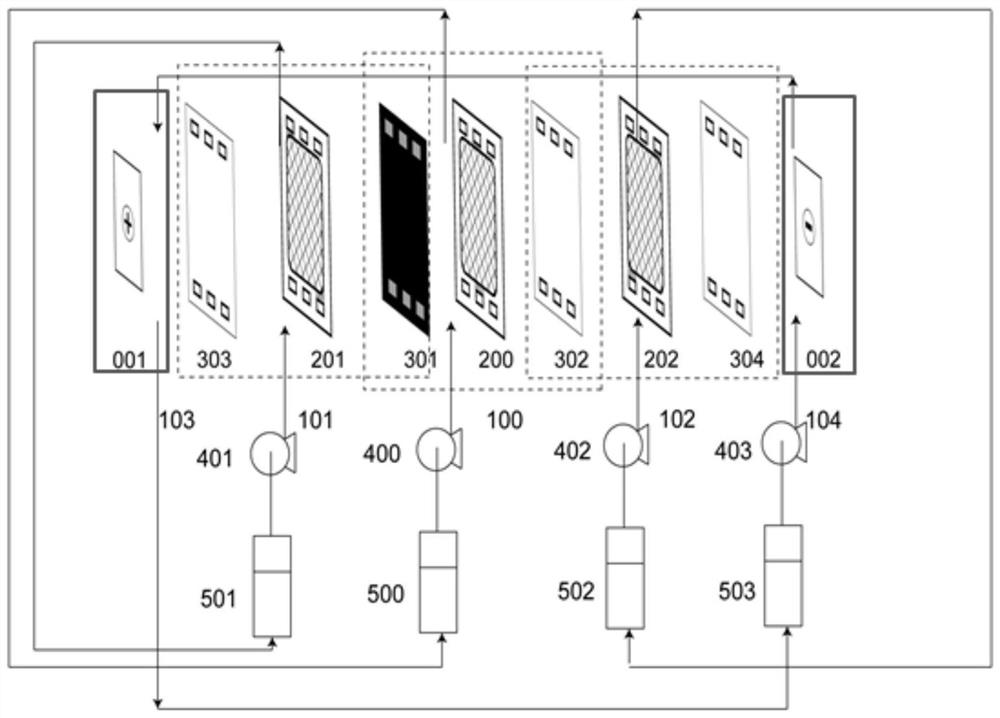

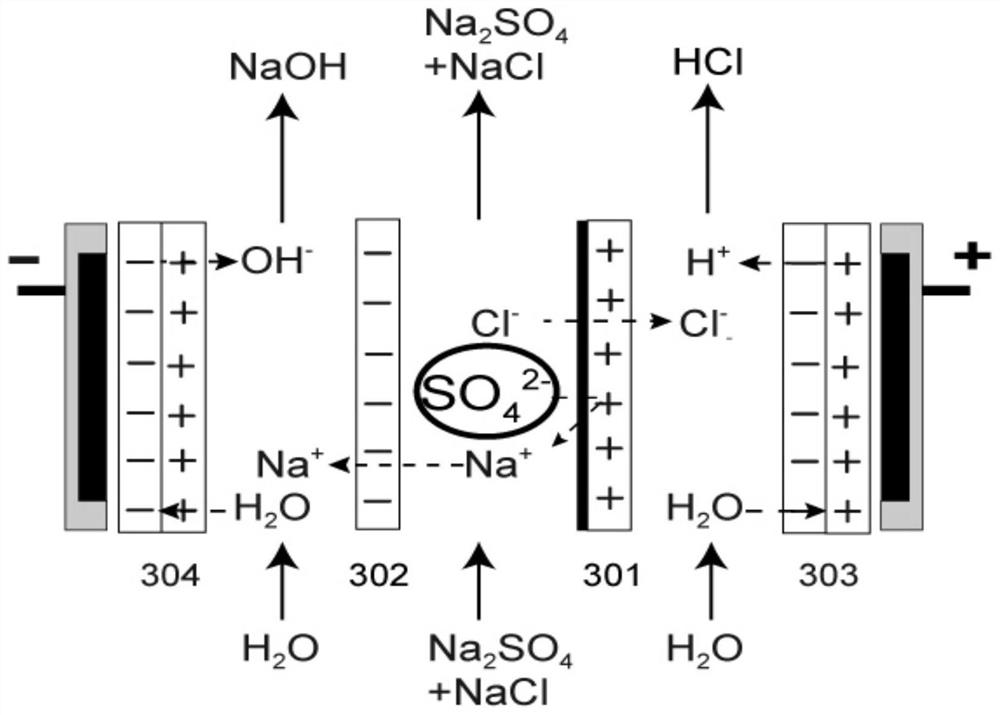

[0047] Embodiment 1 adopts electrodialysis miscellaneous salt recycling device, such as figure 1 As shown, connect the acid tank to the acid pump, the alkali tank to the alkali pump, the salt pump to the salt tank, and the electrolyte pump to the electrolyte tank to control the acid tank, alkali tank, salt tank, and electrolyte tank. Before starting the experiment, first Circulate for 30 minutes to ensure that the air bubbles in each reaction tank are discharged.

[0048] The treatment object is the simulated miscellaneous salt of industrial crystalline salt effluent, and simulates the treatment effect of different proportions of sodium chloride and sodium sulfate. The ratio of sodium chloride and sodium sulfate is selected as 1:1, 3:1.19:1, and the molar concentration of sodium sulfate is constant at 0.02 mol / L (pH7.0, electrode solution is 3% Na 2 SO 4 ) simulated waste water with a volume of 500mL, of which the acid and alkali tanks contain 0.01mol / L HCl and NaOH with a v...

Embodiment 2

[0059] Embodiment 2 adopts electrodialysis miscellaneous salt recycling device, such as figure 1 As shown, the acid tank is connected to the acid pump, the alkali tank is connected to the alkali pump, the salt pump is connected to the salt tank, and the electrolyte pump is connected to the electrolyte tank to control the acid tank, alkali tank, salt tank, and electrolyte tank. For 30 minutes, ensure that the air bubbles in each chamber of the reaction tank are expelled.

[0060] The object of treatment is the crystalline miscellaneous salt produced in the coal chemical industry process. Dissolve the crystalline miscellaneous salt in a 500mL beaker at a room temperature of 25 degrees Celsius, and stir it at a speed of 400rpm by magnetic force to dissolve it completely.

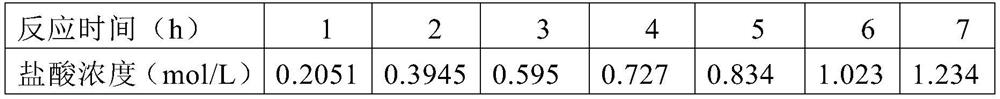

[0061] After the online conductivity value of the system is stable and no air bubbles are discharged, an external DC power supply box can be connected and adjusted to the constant current mode, and the current ...

Embodiment 3

[0068] Embodiment 3 adopts electrodialysis miscellaneous salt recycling device, such as figure 1 As shown, the acid tank is connected to the acid pump, the alkali tank is connected to the alkali pump, the salt pump is connected to the salt tank, and the electrolyte pump is connected to the electrolyte tank. Before the experiment, first circulate for 30 minutes to ensure that the air bubbles in each reaction tank are discharged.

[0069] The treatment object is RO reverse osmosis concentrated water, and the mixed salt concentration of the concentrated water produced by reverse osmosis is about 70-100g / L. First dilute the concentrated water, the dilution factor is about 2 to 3 times, and then obtain 25 to 30g / L diluted mixed brine.

[0070] After the online conductivity value of the system is stable and no air bubbles are discharged, an external DC power supply box can be connected and adjusted to the constant current mode, and the current density is 5.0mA / cm 2 , to start the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com