Biodegradable resin composition

A biodegradable, resin composition technology, applied in the field of biodegradable resin compositions, can solve the problem of underutilization of biodegradability, and achieve the effects of excellent biodegradability, excellent transparency, and avoiding the increase of garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070]

[0071] The biodegradable resin composition of the present invention containing the above-mentioned various components can be prepared as follows: the above-mentioned (A) and (B), and various additives such as an appropriate ester decomposition promoting agent (C) are mixed, and the It is prepared by melt-kneading at a temperature (for example, about 150° C. to 240° C.) at which each component does not decompose during discharge. In this case, the ester decomposition accelerator (B) (copolymerized polyester) may be directly mixed with the biodegradable resin (A), or a masterbatch of the ester decomposition accelerator (B) and other components may be prepared and mixed with Biodegradable resin (A) mixed.

[0072] The resin composition is used as a molded body of various shapes by a molding method known per se, such as extrusion molding, injection molding, compression molding, and the like.

[0073] In particular, the resin composition of the present invention is exce...

Embodiment

[0087] In the following examples and comparative examples, measurements of haze, TOC (measurement of eluted total organic carbon), and enzymatic decomposability were performed by the following methods.

[0088] Haze measurement:

[0089] The haze of each film was measured based on JIS K6714 using a color discriminator (color computer) [SM-4: Suga Test Instruments Co., Ltd.].

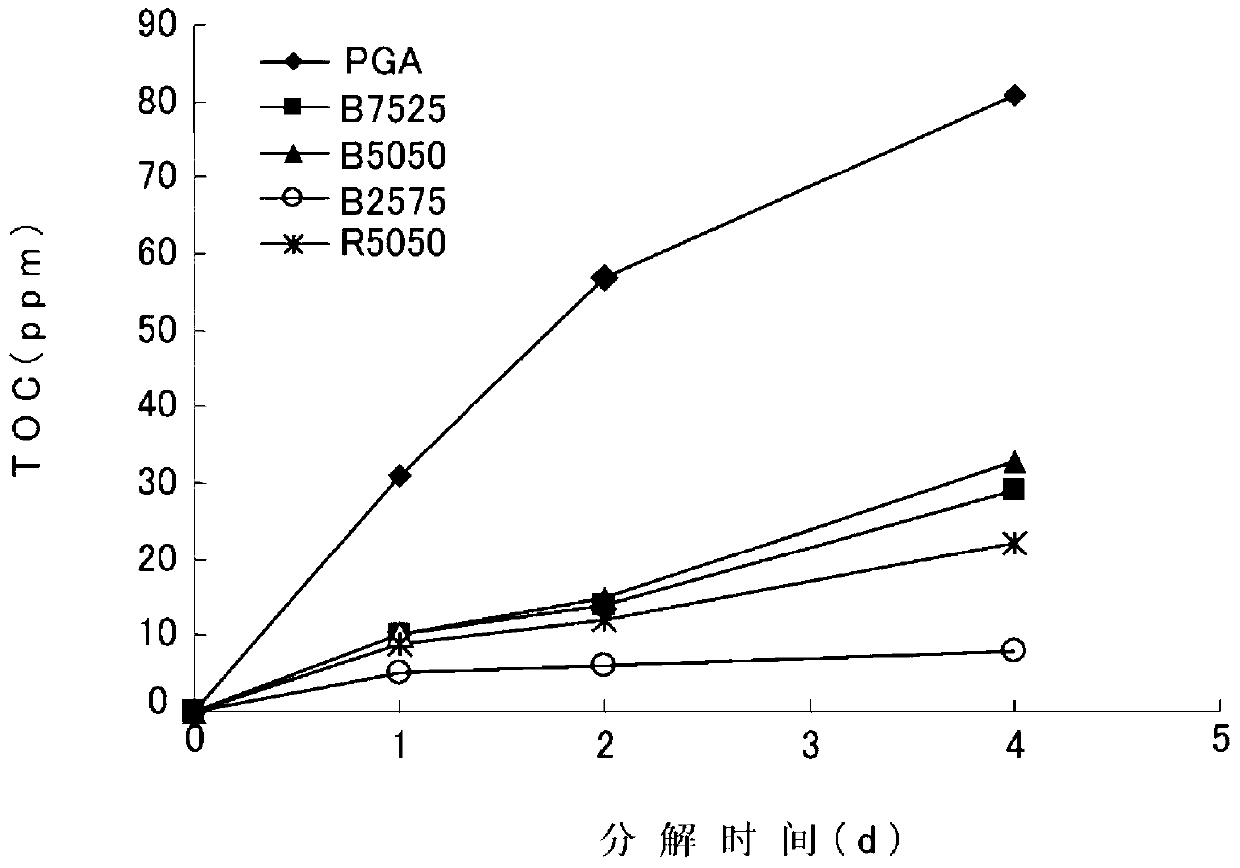

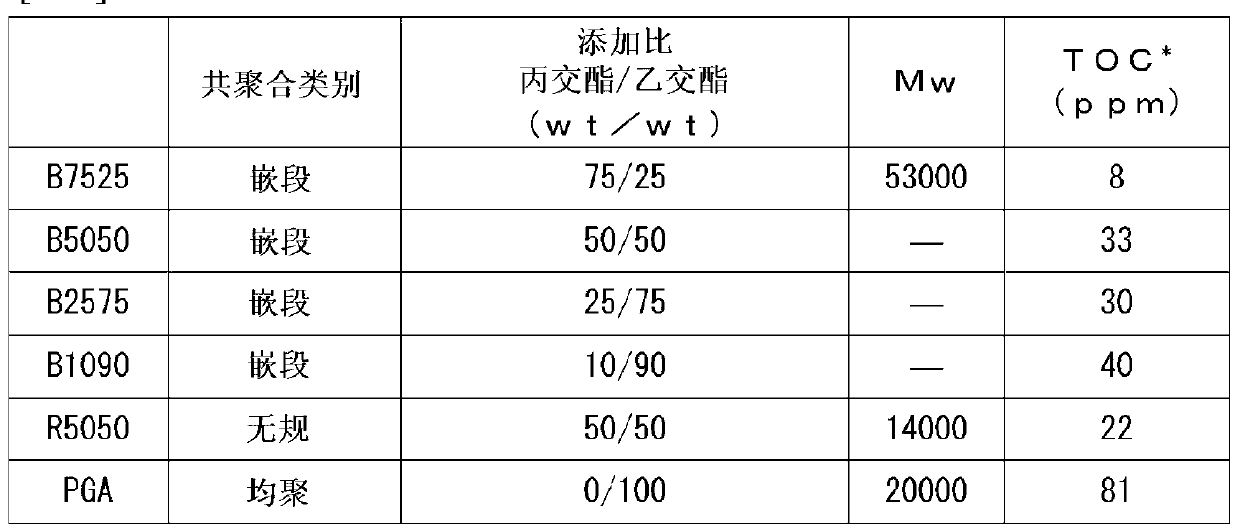

[0090] Determination of TOC (total organic carbon dissolved) (evaluation of hydrolyzability):

[0091] The sample polymer was frozen and pulverized using a freeze pulverizer (JFC-300 manufactured by Japan Analytical Industry Co., Ltd.). 100 mg of a powdered sample polymer and 10 ml of distilled water were put together into a 25 ml vial, and shaken at 45° C. and 100 rpm for hydrolysis. Take out 1ml of the supernatant of the sample liquid every certain time (every day) from the beginning of the test, pass through a 0.45 μm filter, dilute 10 times, and measure the amount of dissolved total organic carbon ...

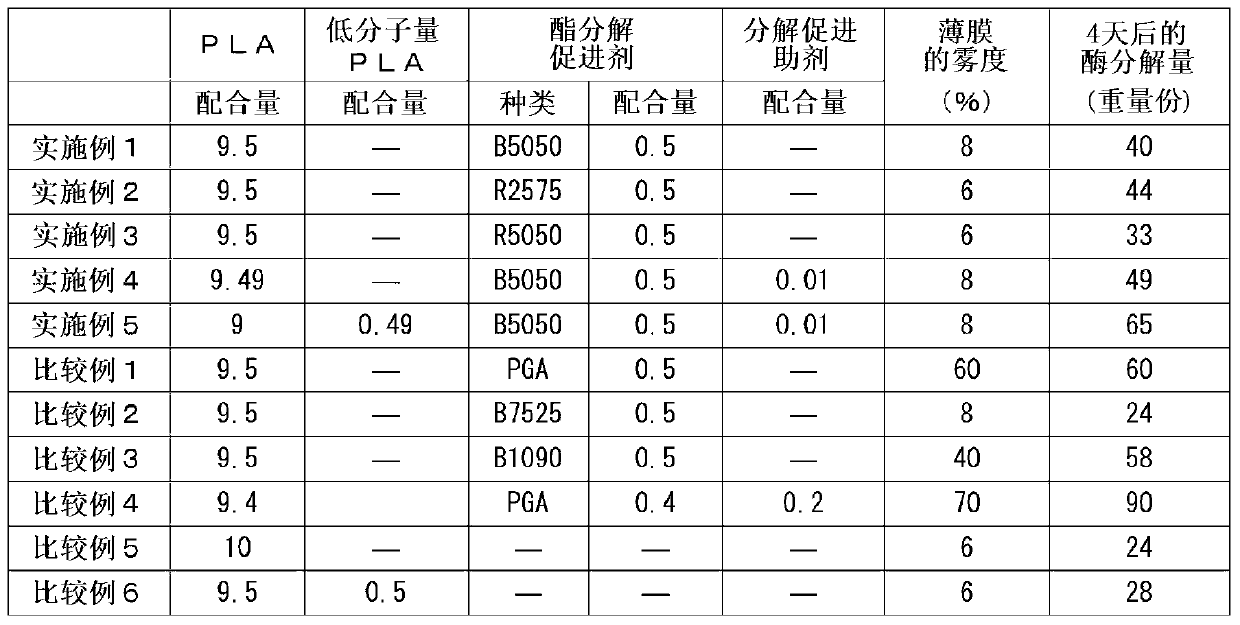

Embodiment 2、3

[0126] Except having used the copolymerization polyester R2575, R5050 as an ester decomposition accelerator, it carried out similarly to Example 1, the biodegradable resin composition was prepared, and it molded into a film. R2575 is a random copolymerized polyester obtained by adding lactide / glycolide in a weight ratio of 25 / 75. It carried out similarly to Example 1, and measured the haze and the enzymatic decomposition amount. Table 2 shows the compounding amount of each component used in the preparation of the composition, and the measurement results of haze and enzymatic decomposition amount.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com