Formula for producing compound microbial fertilizer by use of algae and preparation method

A technology of compound microorganisms and seaweeds, applied in the direction of fertilizer mixture, application, fertilization equipment, etc., can solve the problems of high temperature, uneconomical, long process time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

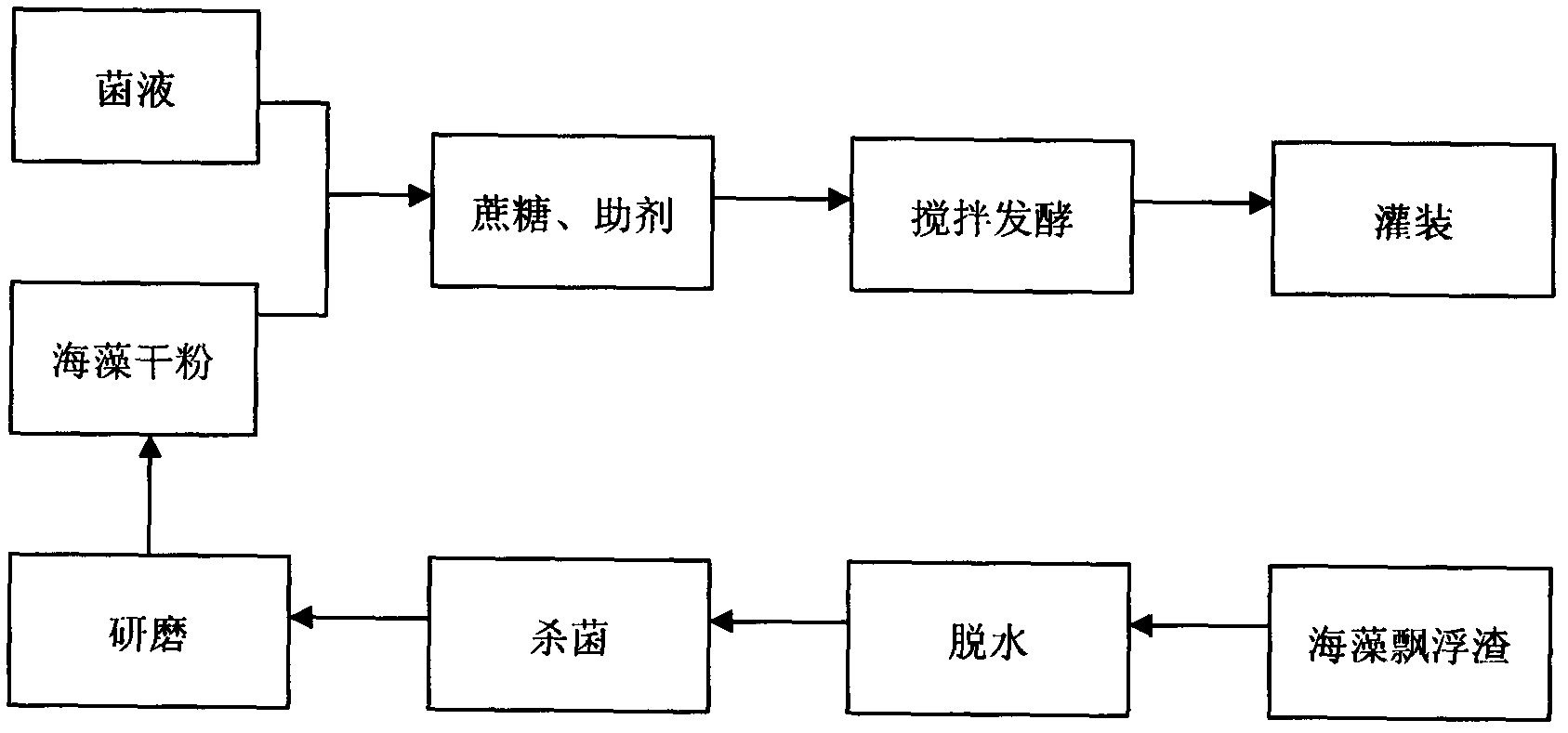

[0005] Below in conjunction with accompanying drawing, the present invention will be further described:

[0006] Its formula (calculated by percentage): 20% of seaweed dry powder, 5% of fermented bacteria liquid, 2% of additives, 3% of sucrose, 70% of clean water, all of which are commercially available except seaweed powder.

[0007] The preparation process of the seaweed dry powder: washing the seaweed floating residue, dehydrating the seaweed floating residue to make the water content of the seaweed floating residue within 15%, performing ultraviolet sterilization, and grinding into a 1200-mesh seaweed dry powder through a grinder.

[0008] Its foliage fertilizer is prepared according to formula (calculated by percentage): 5% of fermented liquid prepared by dry seaweed powder, 50% of Lactobacillus casei and 50% of Pichia membranosa, 2% of potassium dihydrogen phosphate, and 3% of sucrose , clean water 70%, sent to a ventilated fermenter for fermentation, the time is 6 days,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com