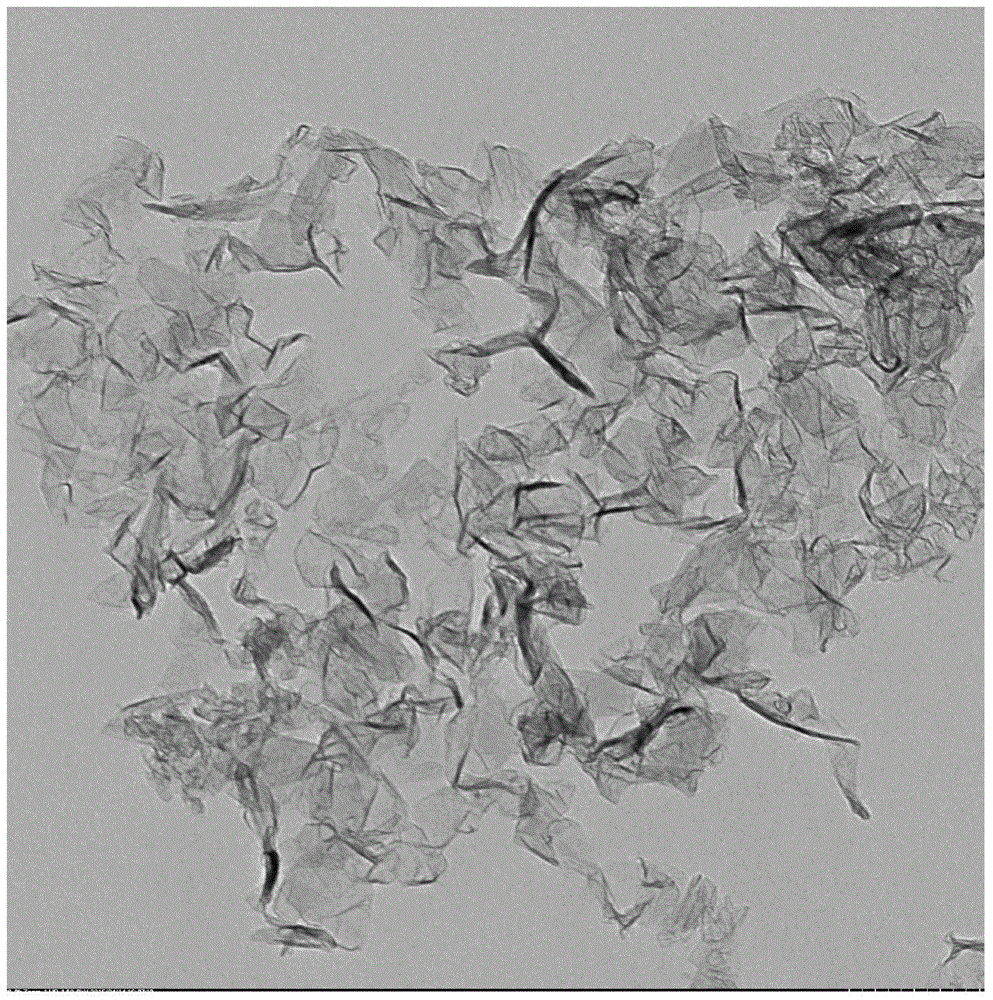

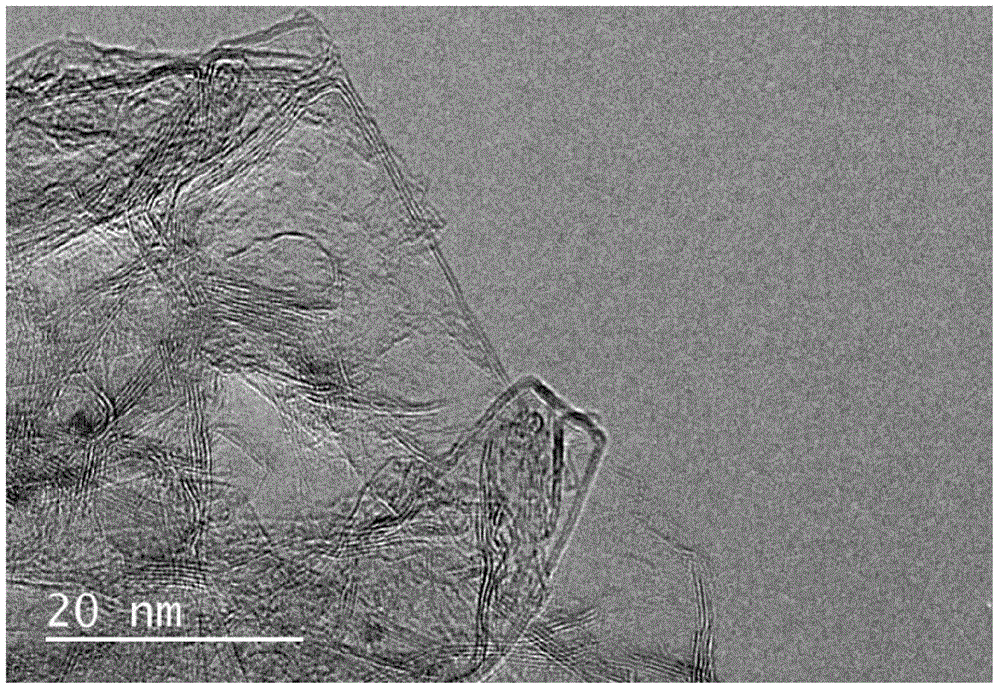

Method for preparing nano graphene powder by plasma chemical vapor synthesis

A nano-graphene, chemical vapor-phase technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of graphene with large structural defects, inability to produce large areas, and low production efficiency. Achieve the effect of low cost, less layers and less impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Remove impurities from methane to make it more than 98% pure to ensure the purity of graphene;

[0036] 2. Turn on the power supply of the plasma generator, the operating voltage of the plasma generator is 280V, the load current is 190A, and the plasma arc is generated in the reaction chamber under the ionization action of the positive electrode 4 of the plasma generator and the negative electrode 5 of the plasma generator.

[0037] 3. Open the top blowing nitrogen delivery pipe 2, and set the nitrogen partial pressure to 0.5MPa.

[0038] 4. Raise the temperature of the plasma arc to 3000°C, and at this time, the temperature in the reaction furnace reaches 900°C.

[0039] 5. Open the methane feeding pipe 1, set the methane partial pressure to 0.8MPa, let the methane gas enter the reaction furnace 3, and the methane begins to ionize into carbon atoms and hydrogen atoms and rearrange them.

[0040] 6. After 10 minutes, turn off the power of the plasma generator, and c...

Embodiment 2

[0044] 1. Remove impurities from methane to make it more than 98% pure to ensure the purity of graphene;

[0045] 2. Turn on the power supply of the plasma generator, the operating voltage of the plasma generator is 300V, the load current is 200A, and the plasma arc starts to be generated in the reaction chamber under the ionization action of the positive pole 4 of the plasma generator and the negative pole 5 of the plasma generator.

[0046] 3. Open the top blowing nitrogen delivery pipe 2, and set the nitrogen partial pressure to 0.6MPa.

[0047] 4. Raise the temperature of the plasma arc to 3000°C, and at this time, the temperature in the reaction furnace reaches 900°C.

[0048] 5. Open the methane feeding pipe 1, set the methane partial pressure to 0.9MPa, let the methane gas enter the reaction furnace 3, and the methane begins to ionize into carbon atoms and hydrogen atoms and rearrange them.

[0049] 6. After 10 minutes, turn off the power of the plasma generator, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com