Technology for adopting bipolar membrane electrodialysis for preparing beta-aminopropionic acid

A bipolar membrane electrodialysis and aminopropionic acid technology, applied in the field of electrochemistry, can solve the problems of low reaction yield, low yield, high raw material cost, etc., and achieve obvious economic effect, simple process operation, and good atom economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

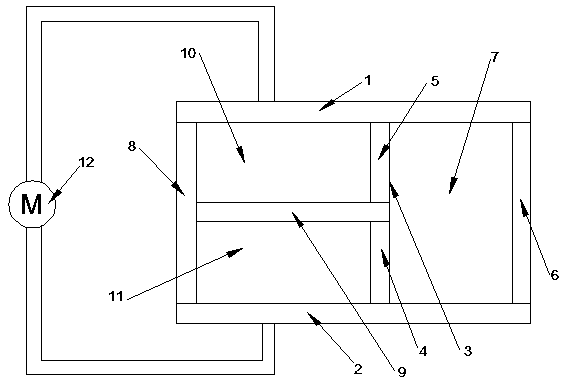

[0025] Add 6kg of liquid caustic soda with a mass fraction of 32% to the hydrolysis kettle, heat it to 95°C, add 1kg of refined aminopropionitrile with a chromatographic purity greater than 99%, dropwise at 100°C, dropwise for 2 hours, and control the vacuum degree - 0.02Mpa; After the dropwise addition, under the vacuum degree, 100°C for 1 hour to obtain the hydrolyzate, the hydrolyzate is passed through the bipolar membrane electrodialysis device, constant voltage electroosmosis, the current density is 40mA / cm 2 , control the pH of the acid chamber to 7.0, and stop until the conductivity of the hydrolyzed solution drops below 600 μS / cm. The acid chamber solution is collected as the GALA solution. The GABA solution is concentrated to 70% at -0.095Mpa at 60°C, and then Cool to 10°C to crystallize and centrifuge to obtain 1.22kg of β-alanine product with a yield of 96.06% and a purity of 99.97%. Among them, the bipolar membrane electrodialysis device includes a dialysis tank, an...

Embodiment 2

[0027] Add 1 kg of liquid caustic soda with a mass fraction of 32% to the hydrolysis kettle, heat it to 100°C, add 1 kg of refined aminopropionitrile with a chromatographic purity greater than 99%, dropwise at 100°C, dropwise for 3 hours, and control the vacuum degree to - 0.02Mpa; After the dropwise addition, under the vacuum degree, 100 ℃ for 1 hour to obtain the hydrolyzate, the hydrolyzate is passed through the bipolar membrane electrodialysis device, constant voltage electroosmosis, the current density is 20mA / cm 2 , control the pH of the acid chamber to 7.0, and stop until the conductivity of the hydrolyzed solution drops below 600 μS / cm. Collect the solution in the acid chamber, which is the aminopropionic acid solution. The aminopropionic acid solution is concentrated to 30% at -0.095Mpa, 60°C, and then Cool to 20°C to crystallize and centrifuge to obtain 1.207 kg of β-alanine product with a yield of 95.04% and a purity of 99.94%. Others are the same as in Example 1.

Embodiment 3

[0029] Add 10kg of liquid caustic soda with a mass fraction of 32% to the hydrolysis kettle, heat to 90°C, add 1kg of refined aminopropionitrile with a chromatographic purity greater than 99%, dropwise at 95°C, dropwise for 2 hours, and control the vacuum degree to - 0.02Mpa; After the dropwise addition, under the vacuum degree, the hydrolyzate was obtained after 90°C for 1 hour, and the hydrolyzate was passed through the bipolar membrane electrodialysis device, and the constant voltage electroosmosis, the current density was 80mA / cm 2 , control the pH of the acid chamber to 7.0, and stop until the conductivity of the hydrolyzed solution drops below 600 μS / cm. The acid chamber solution is collected to be the GALA solution. The GABA solution is concentrated to 80% at -0.095Mpa, 60°C, and then Cool to -10°C to crystallize and centrifuge to obtain 1.213kg of β-alanine product with a yield of 95.51% and a purity of 99.96%. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com