Patents

Literature

39results about How to "Control crystal form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing nano-flame-proof magnesium hydroxide

InactiveCN101219801AWide variety of sourcesControl granularityMagnesium hydroxideSalt lakeGranularity

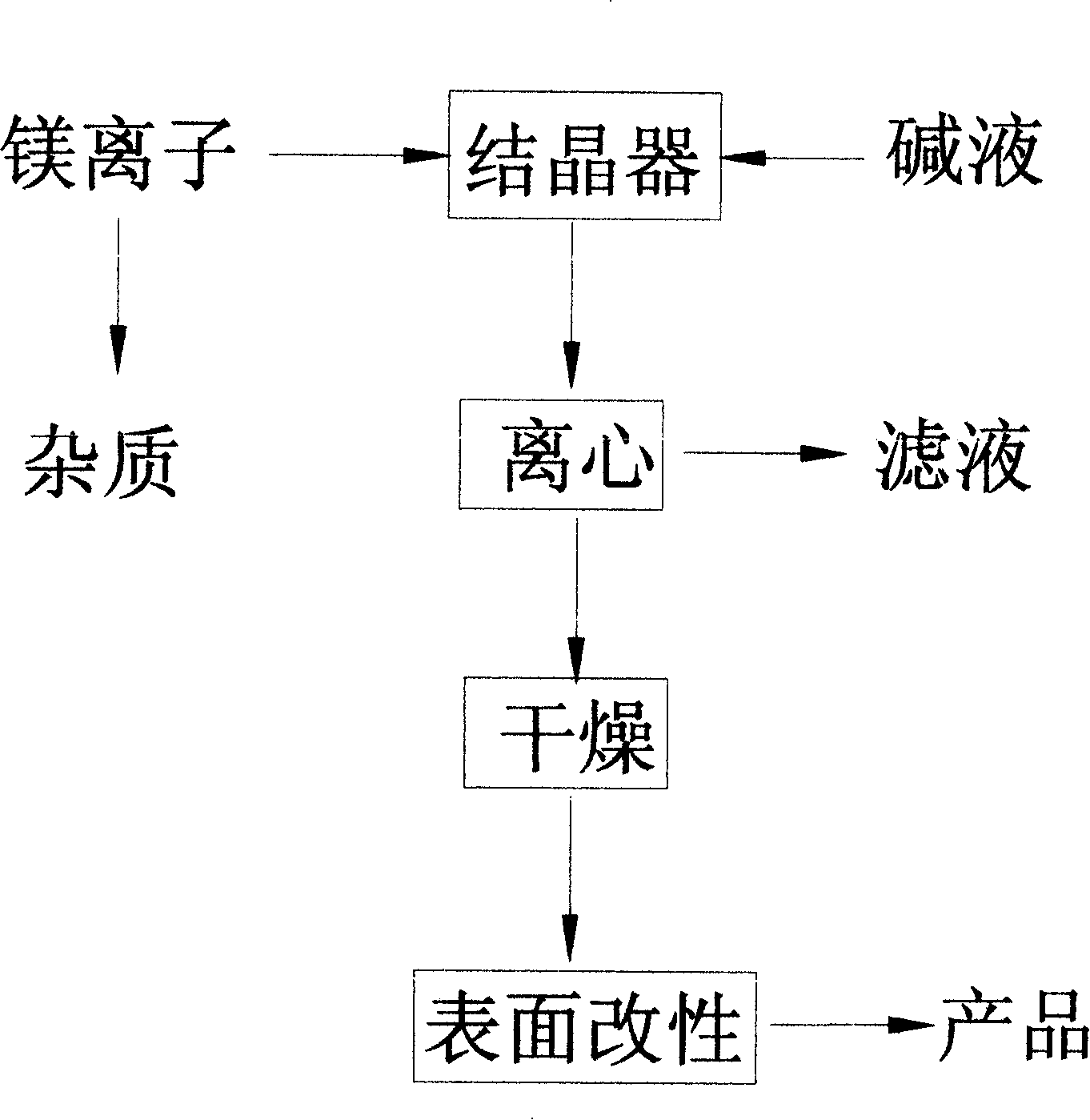

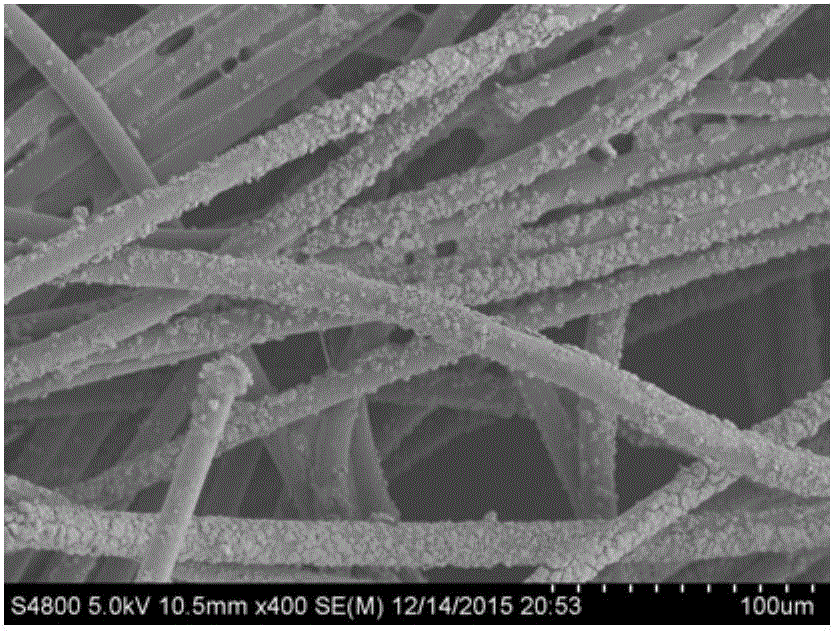

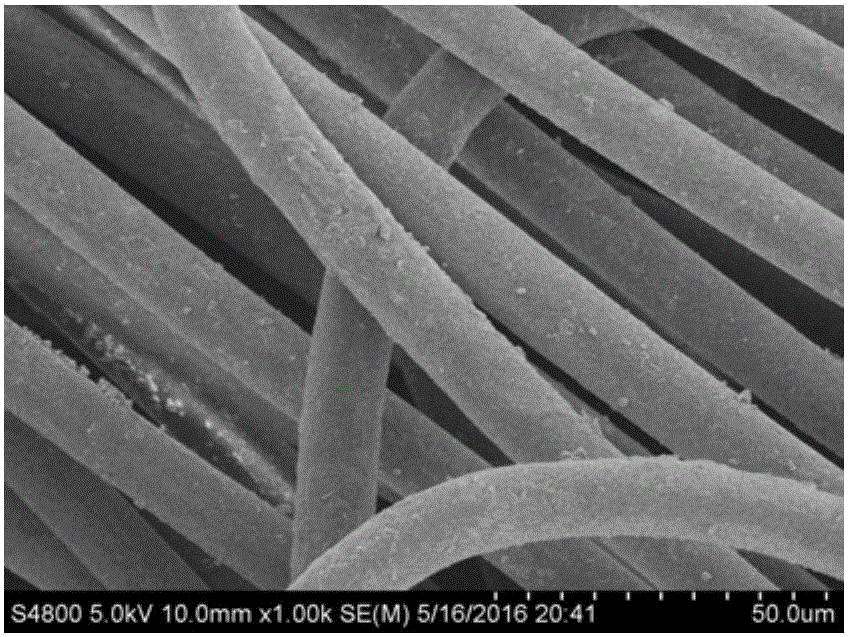

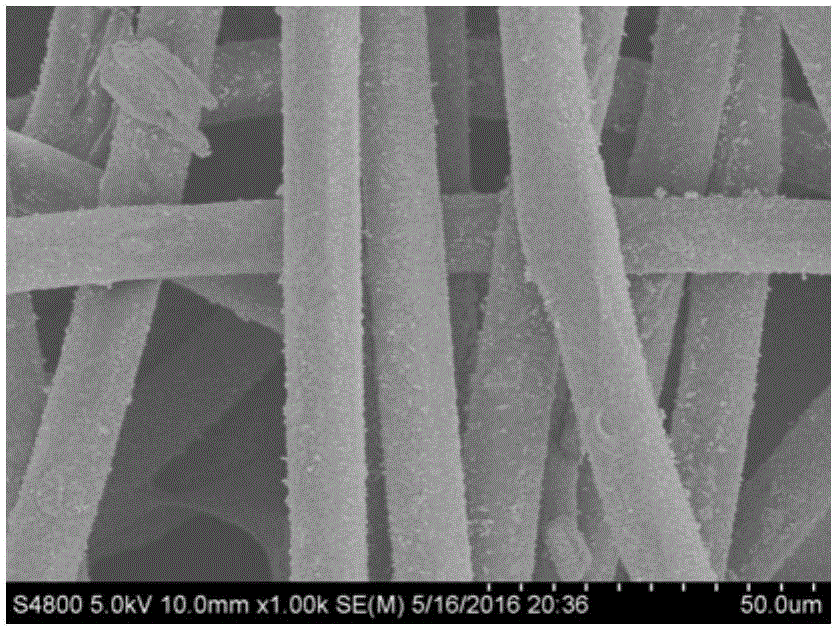

The invention relates to a method for preparing nanometer flame-retardant-grade magnesium hydrate by using an impinging stream and through the surface modification. The main processes are: the magnesia ion solution obtained by means of the salt lake water chloromagnesite or impurity removal of concentrated brine after sea water desalinization is reacted with a sodium hydroxide to crystallize and couple to prepare nanometer magnesium hydrate; proper surface activator is selected to modify the nanometer magnesium hydrate, which can obtain acicular or flake magnesium hydrate of 10-20nm. The technological characteristics are: 1) the purity of the magnesium hydrate of which the material source is widely obtained can be above 98 percent; 2) by adopting a jet impinging stream reaction crystallizer, the reacting conditions such as impinging stream rate can be regulated to control granularity and the shape of the crystal; 3) the reacting condition is moderate and the selected surface modifier has no harm to environment.

Owner:TIANJIN URBAN CONSTR COLLEGE

Method for growing titanium dioxide particles on base material

InactiveCN106311204AReduce high temperature requirementsWide selectionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrofluoric acidTithonia longiradiata

The invention discloses a method for growing titanium dioxide particles on a base material. The method includes the steps that 1, acid liquor and a titanium containing compound are mixed and stirred uniformly to obtain hydrothermal reaction liquid; 2, the base material is put in the hydrothermal reaction liquid, hydrothermal reaction is carried out at the temperature of 70-120 DEG C, and the titanium dioxide particles grow on the base material. The acid liquor is at least one of hydrochloric acid solution, nitric acid solution, sulfuric acid solution and hydrofluoric acid solution. The titanium containing compound is tetra-n-butyl titanate and / or isopropyl titanate. The size of the titanium containing compound accounts for 3-14% of the hydrothermal reaction liquid. The preparing method for growing the titanium dioxide particles on the base material is simple, the raw materials are easy to obtain, titanium dioxide firmly grows on the base material, and the crystal form and size of the titanium dioxide particles can be controlled to obtain high photocatalytic efficiency.

Owner:ZHEJIANG UNIV

Preparation method of hydro-thermal coupling spray pyrolysis MnO2/graphene electrode material

InactiveCN103915613AStable structureWide variety of sourcesMaterial nanotechnologyHybrid capacitor electrodesActive agentGraphene electrode

The invention discloses a preparation method of a hydro-thermal coupling spray pyrolysis MnO2 / graphene electrode material, belonging to the technical field of electrode materials for energy storage systems. The preparation method comprises the following steps: uniformly mixing graphene oxide (GO) prepared by using a Hummer method with an aqueous solution of bivalent manganese salt and a doped metal ion compound, adding a dispersing agent, an oxidant and a surfactant, and ultrasonically dispersing for a certain period of time; putting the mixed solution into a hydrothermal kettle, adjusting the temperature, and keeping for a certain period of time; filtering and washing a reaction product to obtain a precursor; adding the dispersing agent and the surfactant into the precursor, uniformly stirring for mixing, and adjusting the solid-liquid ratio, inlet temperature and outlet temperature to perform spray pyrolysis in order to obtain a metal ion-doped MnO2 / graphene nanometer composite electrode material. According to the nanometer composite electrode material prepared by using the method, components are uniform and the batch stability is high.

Owner:SHANDONG RUNSHENG POWER TECH +1

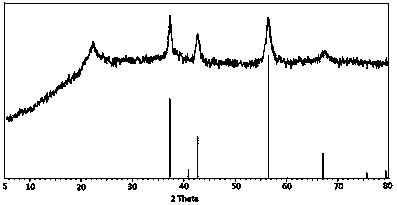

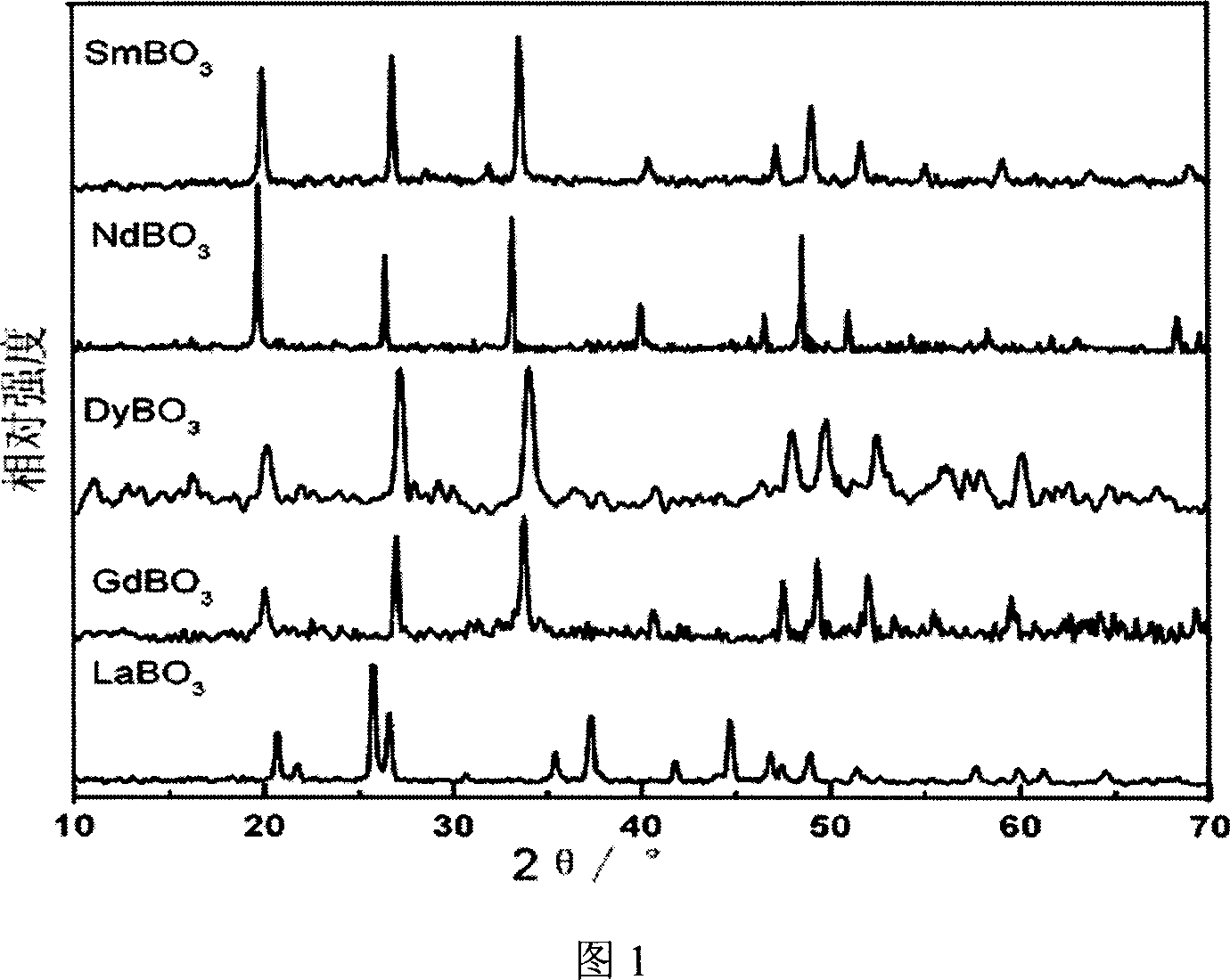

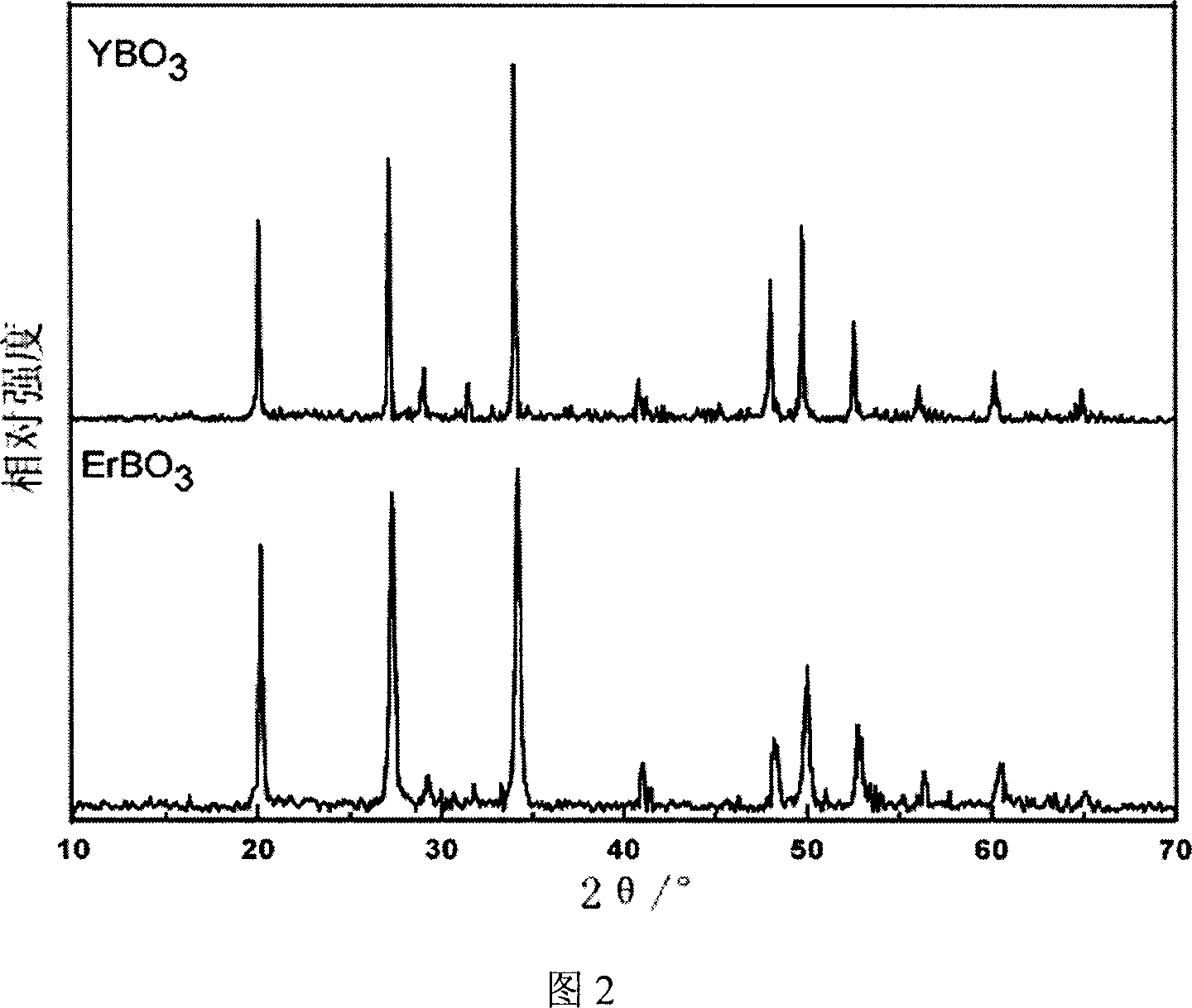

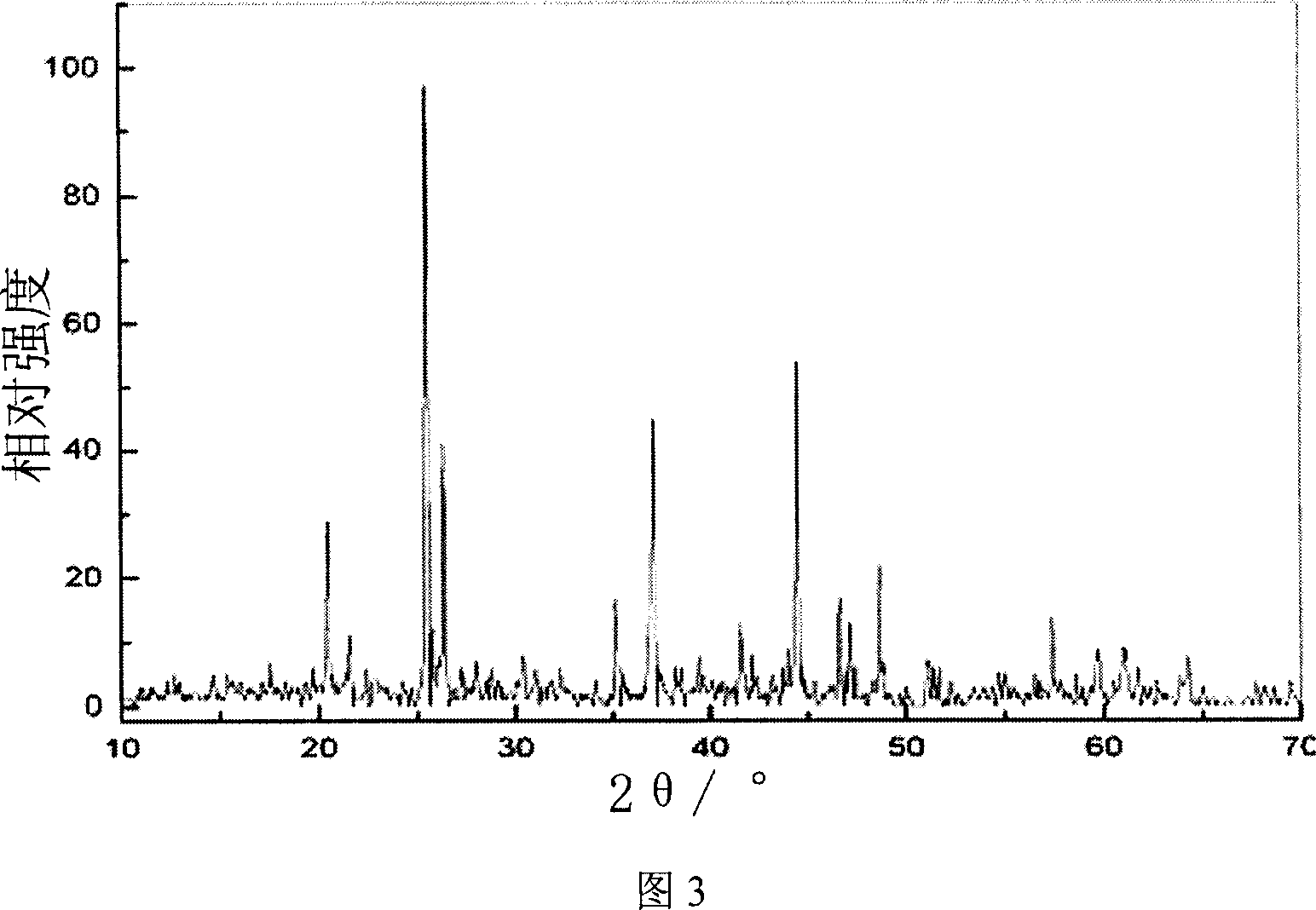

Low temperature process of preparing RE borate crystal with oxide as precursor

InactiveCN1974885AMeet the requirements of sustainable developmentEasy to operatePolycrystalline material growthFrom normal temperature solutionsRare earthHydrothermal synthesis

The present invention belongs to the field of micron / nanometer material preparing technology and hydrothermal synthesis technology, and is especially low temperature process of preparing RE borate crystal with oxide as precursor. In the hydrothermal system, insoluble RE oxide and hydrated boron trioxide or boron trioxide as the boron source and precursor are reacted at 190-280 deg.c for 12-48 hr, and through further washing, the required RE borate crystal is obtained. The present invention provides one inorganic synthesis way, and the production process has no any pollution. The present invention has simple technological process, easy-to-constitute reaction system, high product purity and other advantages, and is suitable for industrial production.

Owner:TONGJI UNIV

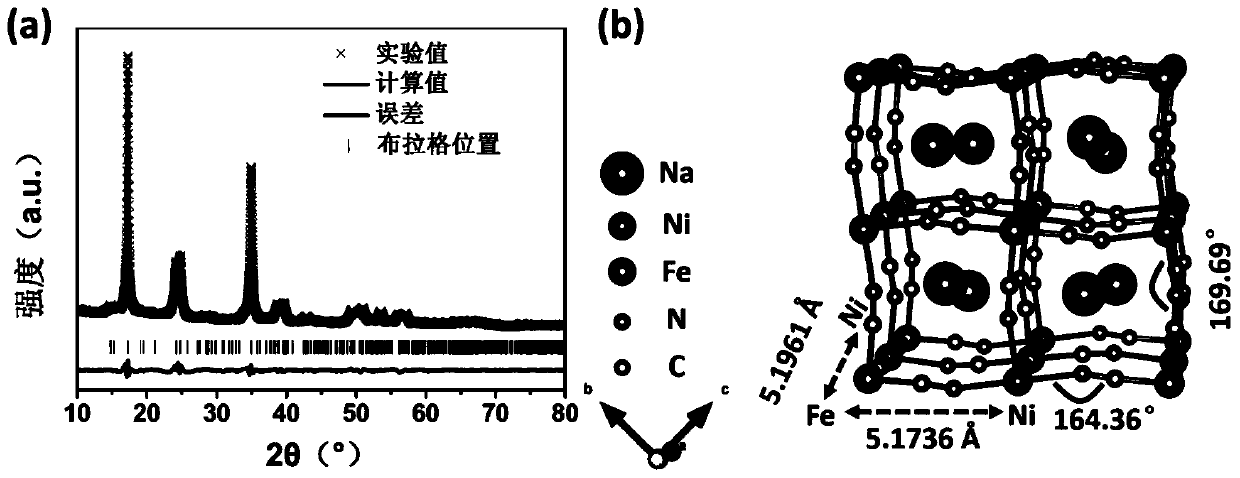

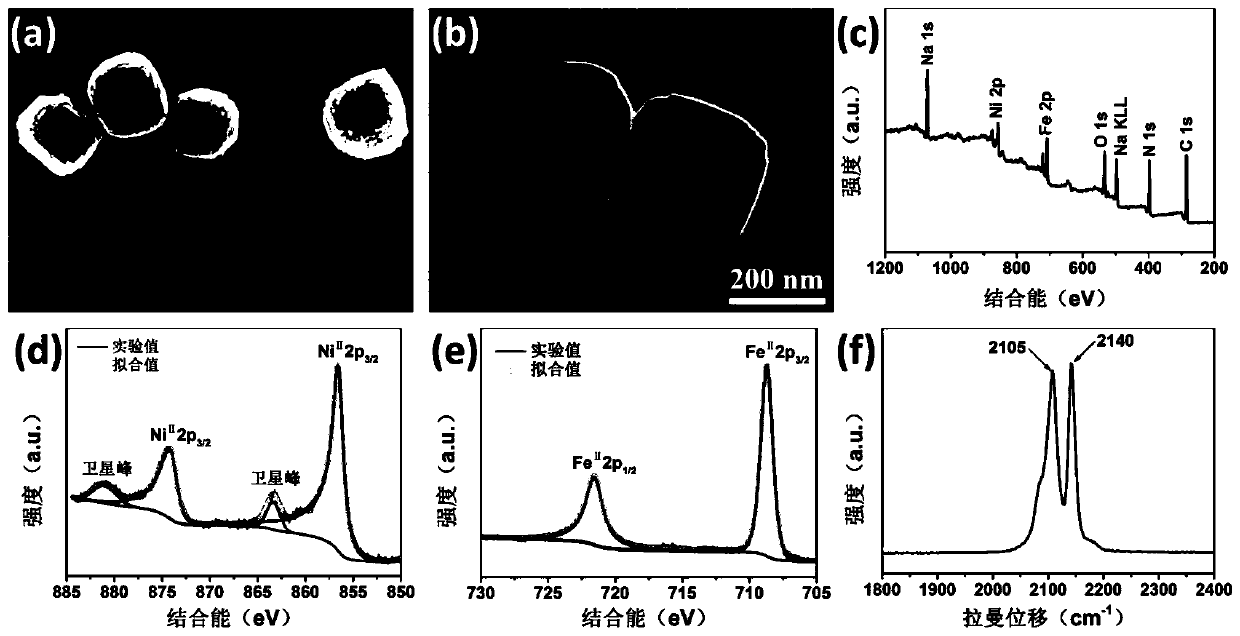

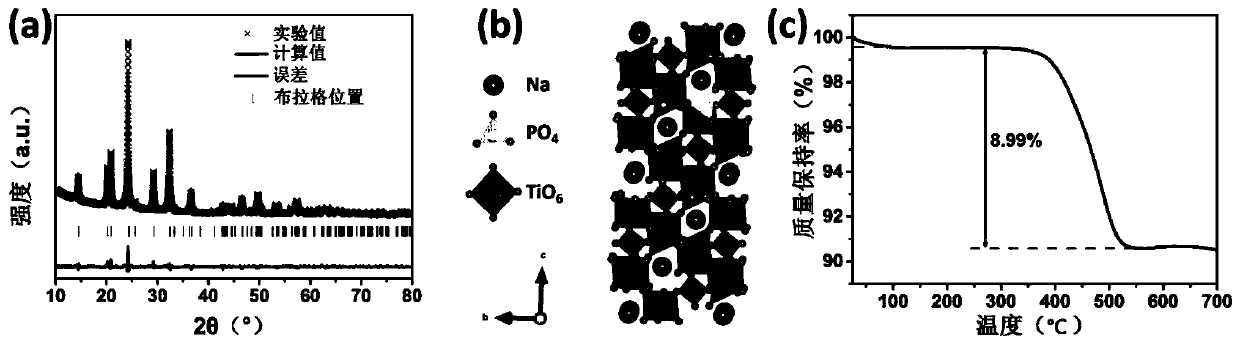

Water-based sodium ion total battery based on nickel prussian blue positive electrode material and preparation method and application thereof

InactiveCN111525129AControl crystal formControl shapeEnergy inputSecondary cellsElectrolytic agentNew energy

The invention discloses a water-based sodium ion total battery based on a nickel prussian blue positive electrode material and a preparation method and application thereof, and belongs to the field oflarge-scale energy storage. According to the invention, sodium citrate is added as a chelating agent and polyvinylpyrrolidone is added as a surfactant to control the growth process of the Prussian blue material in the process of preparing the Prussian blue positive electrode material by a coprecipitation method, and finally, the monoclinic phase nickel Prussian blue nanocube is synthesized. The carbon-coated sodium titanium phosphate negative electrode material, a carbon-coated sodium titanium phosphate negative electrode material and a water-soluble sodium salt electrolyte are assembled intoa low-cost and high-performance water-based sodium ion battery by taking the carbon-coated sodium titanium phosphate negative electrode material as a positive electrode material. The method is expected to be applied to a large-scale energy storage system to promote the development of new energy and renewable energy industries.

Owner:DALIAN UNIV OF TECH

Preparation method of fine aspirin crystals

ActiveCN103613500AControl crystal formControl UniformityOrganic compound preparationCarboxylic acid esters preparationAspirinAcetic anhydride

The invention relates to a preparation method of fine aspirin crystals, belonging to the field of medical and chemical engineering. The preparation method comprises the following steps: (1) putting salicylic acid, acetic anhydride and fine aspirin crystal mother liquor into a dissolving tank to be stirred, and after rising the antipyretic temperature to 80-90 DEG C to dissolve, preserving the temperature for 1-2 hours to obtain hot liquor; (2) adding acetic anhydride, fine aspirin crystal mother liquor or the mixture of acetic anhydride and fine aspirin crystal mother liquor into a crystallizing tank to stir to obtain cold liquor; (3) filtering the hot liquor after preserving temperature to the crystallizing tank, controlling the temperature of the crystallizing tank in the filtering process to gradually rise, after preserving temperature after filtering, and then cooling and carrying out centrifugal separation to obtain solid state fine aspirin crystals. The obtained fine aspirin crystals mother liquor is recycled to the steps (1) and (2). According to the method provided by the invention, the crystal form, the uniformity and the granularity which are fine aspirin crystals are effectively controlled, so that the preparation method is environment-friendly, and the product yield is improved and the production cost is lowered.

Owner:SHANDONG XINHUA PHARMA CO LTD

Preparation method of rare-earth polishing powder containing fluorine and phosphorus

InactiveCN102816554AEffective control of crystal formControl crystal formOther chemical processesRare earthHigh surface

The invention relates to a preparation method of rare-earth polishing powder containing fluorine and phosphorus, which is characterized by comprising the following steps: precipitating, treating with a fluorine-phosphorus composite additive, roasting, crushing and grading. The elements fluorine and phosphorus are simultaneously added in the synthesis process of the polishing powder precursor to effectively control the crystal form of the polishing powder, so that the polishing powder has certain crystal defects, thereby obtaining better polishing property, higher grinding capacity and higher surface accuracy.

Owner:GANSU UNITED NEW RARE EARTH MATERIAL

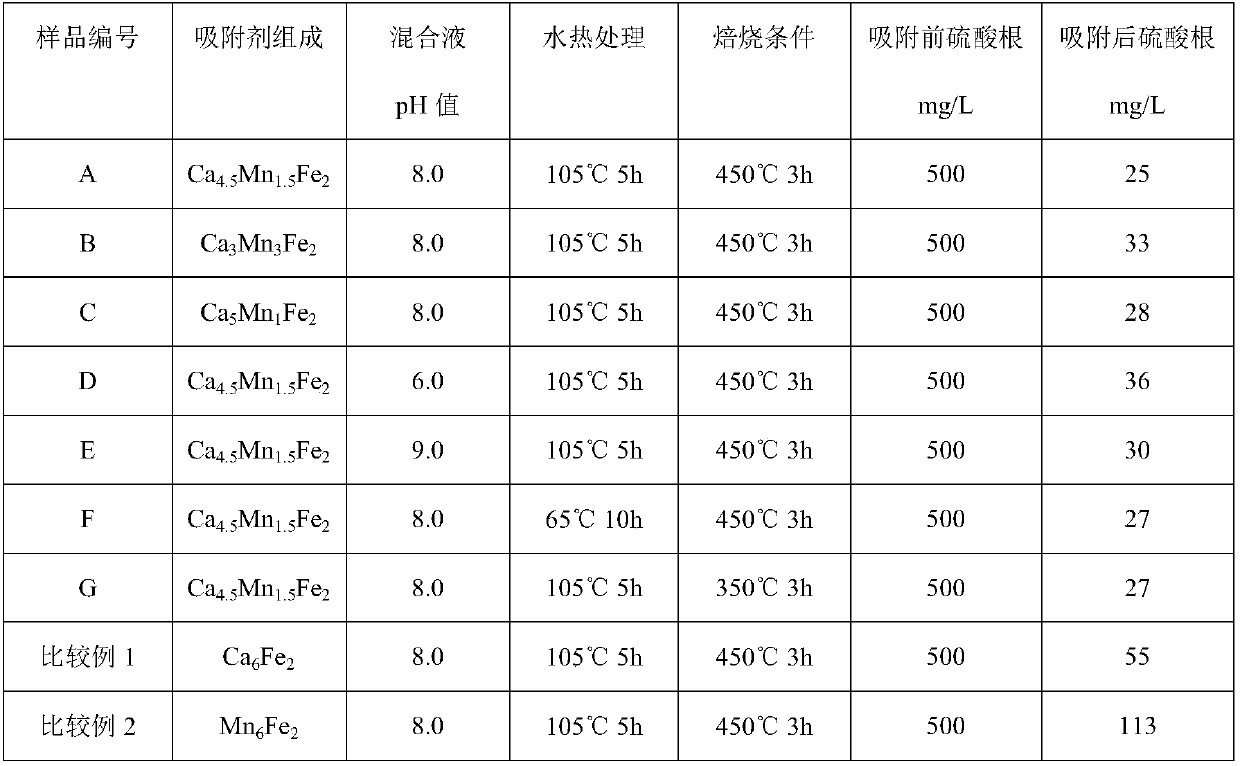

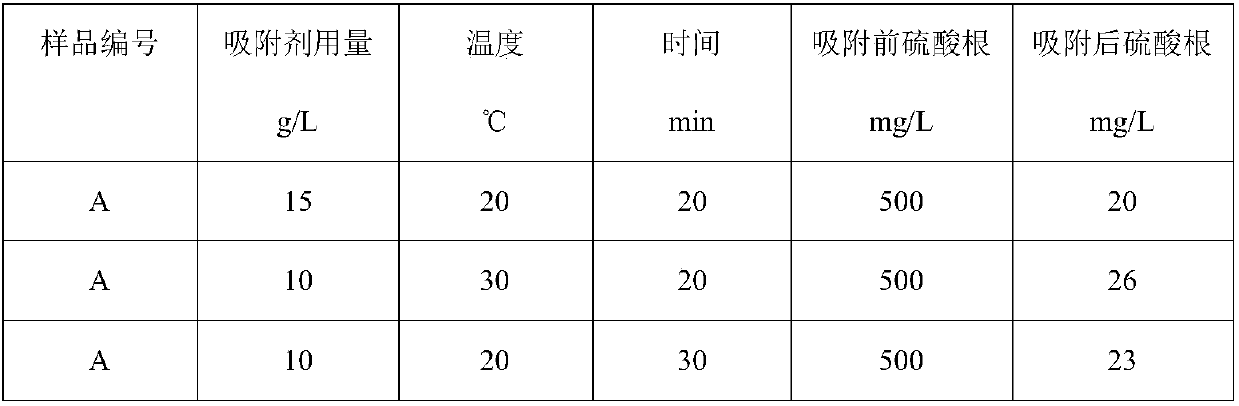

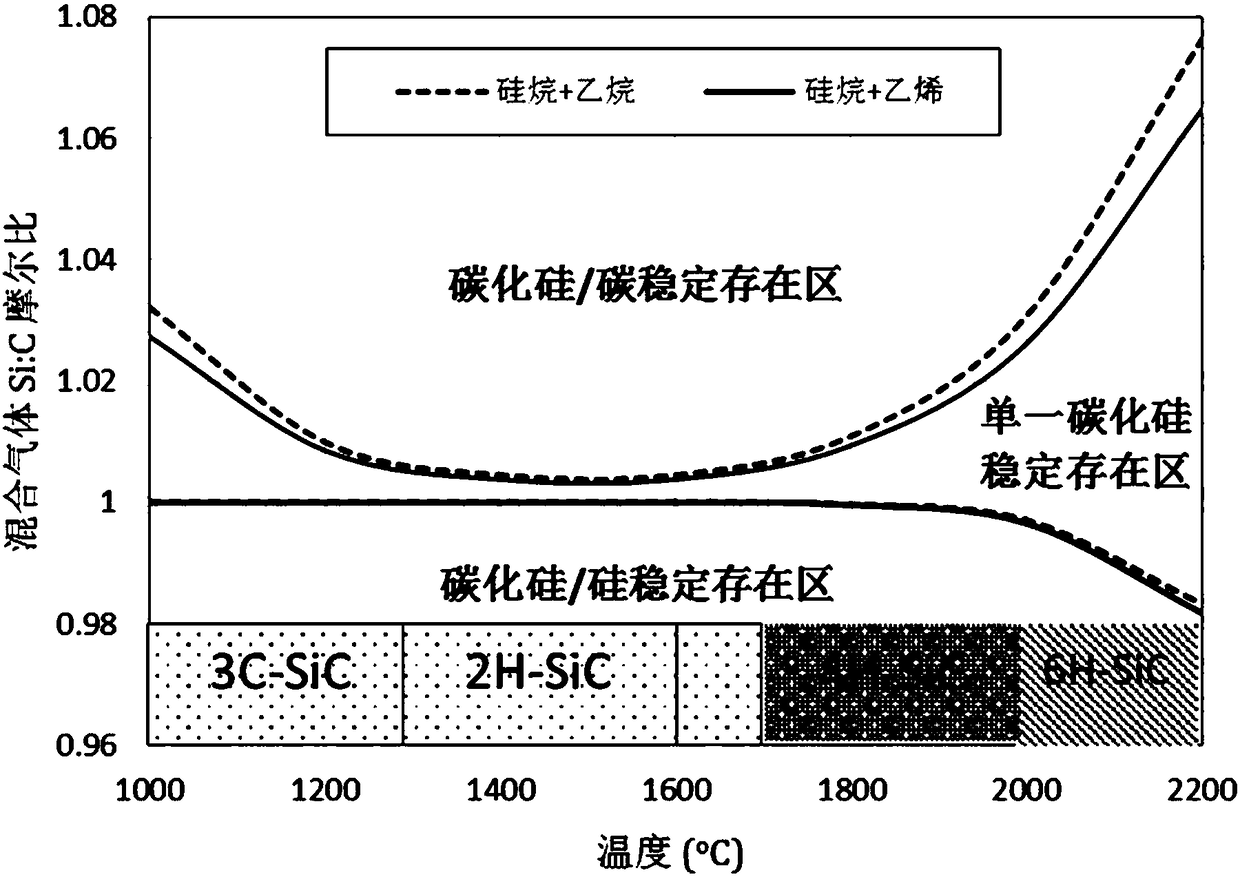

Adsorbent for efficiently adsorbing sulfate ions in water, and preparation method thereof

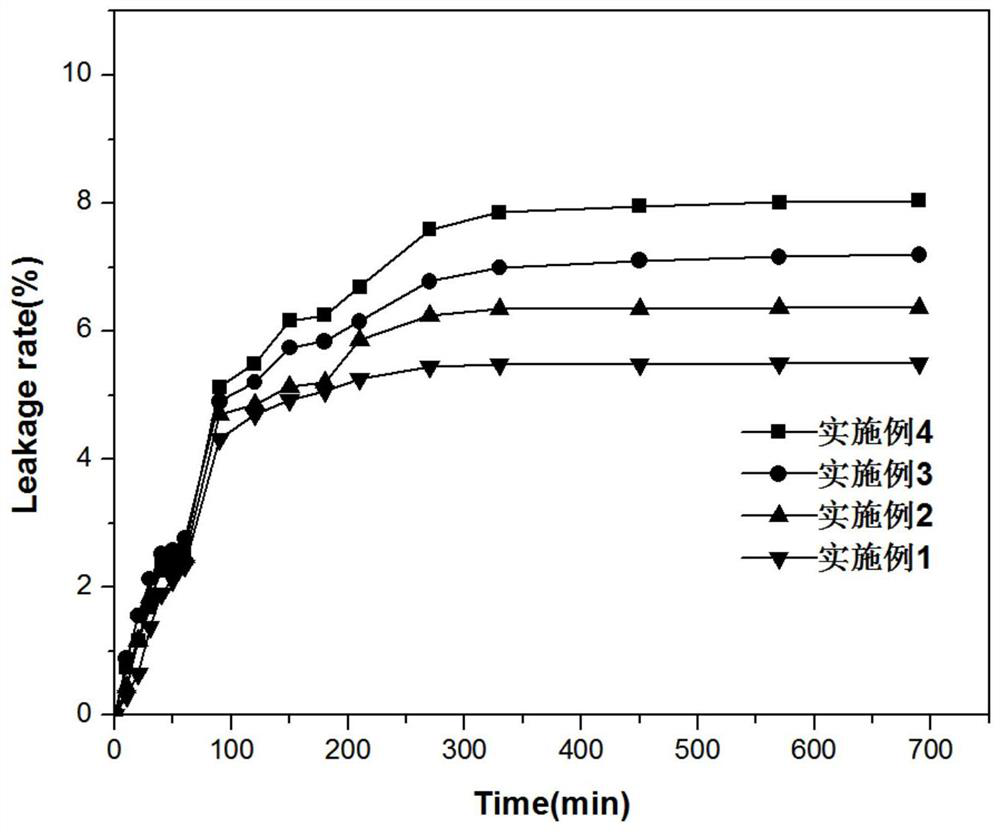

ActiveCN109692648AImprove adsorption capacityReduce dosageOther chemical processesWater contaminantsSorbentWastewater

The invention relates to an adsorbent for efficiently adsorbing sulfate ions in water, and a preparation method thereof. In the prior art, the removal efficiency of the sulfate ions in the industrialwastewater is not high. A purpose of the present invention is mainly to solve the problem in the prior art. According to the technical scheme, a hydrotalcite-like structure CaxMn6-xFe2(OH)18.4H2O as an adsorbent is prepared by combining co-precipitation and hydrothermal treatment, and x is 3-5.5. With the technical scheme, the problem in the prior art is well solved. According to the present invention, the adsorbent prepared by the method can efficiently remove sulfate ions from water, and can be used in the field of environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

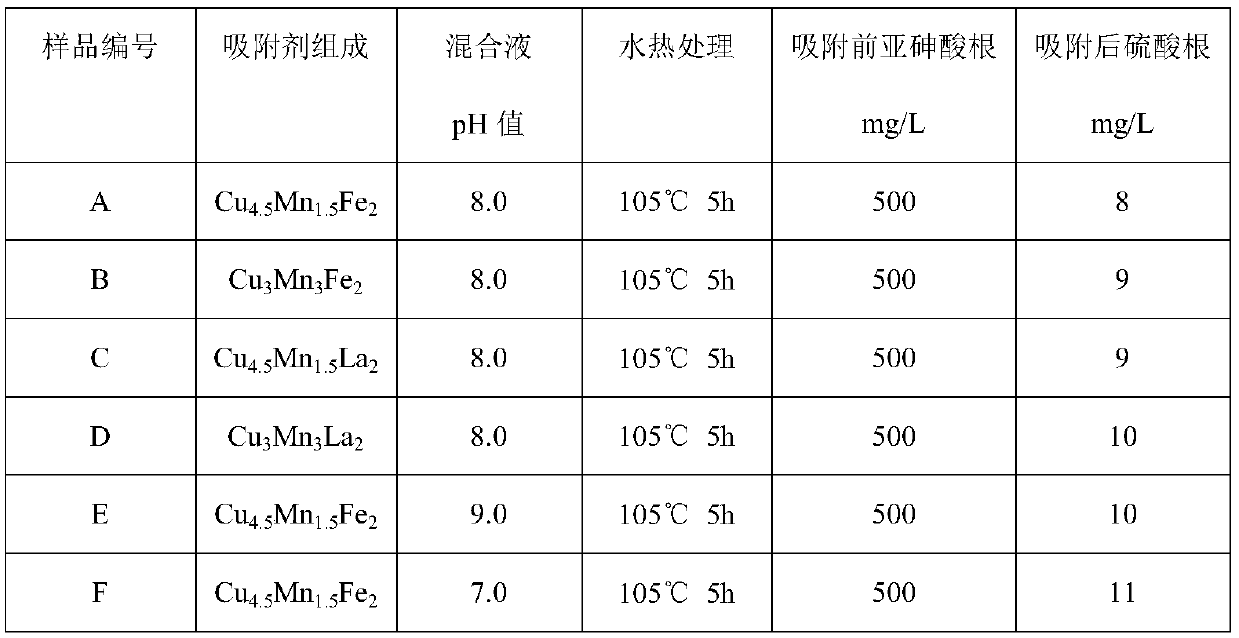

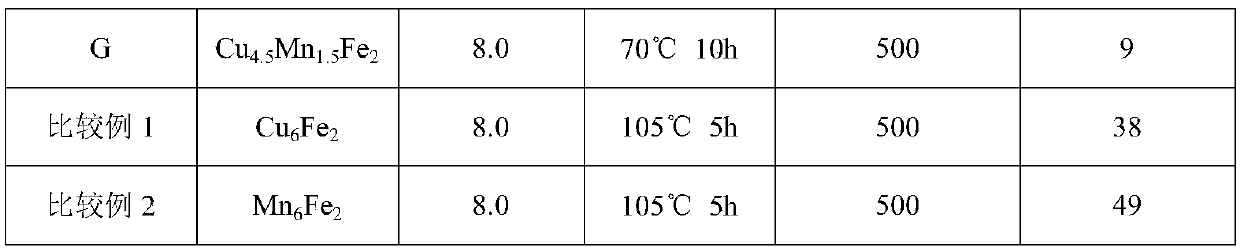

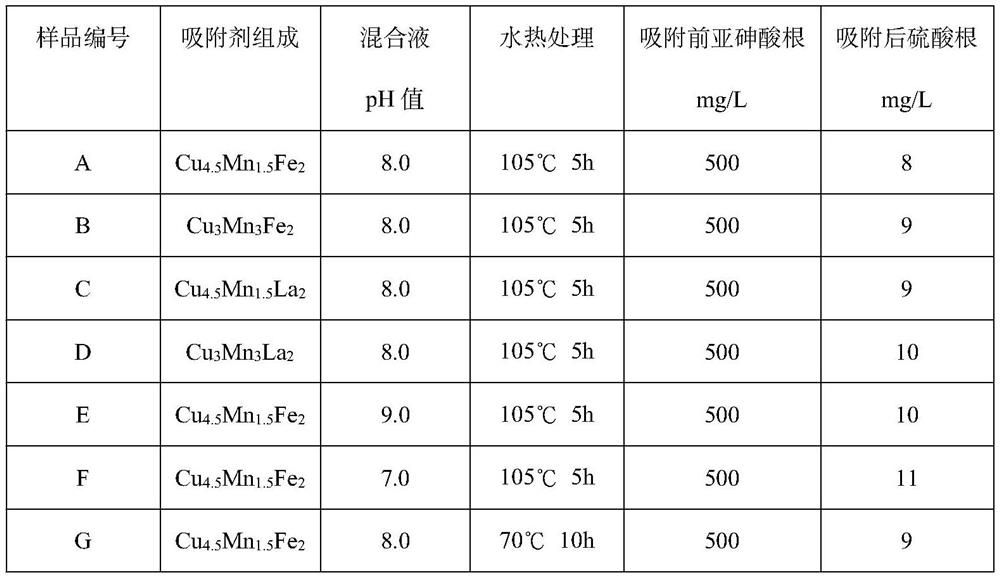

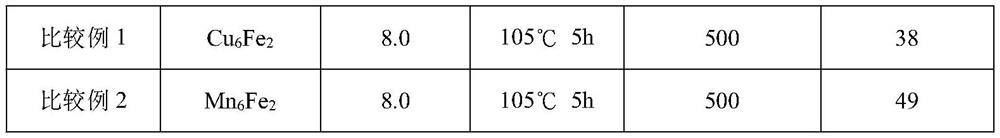

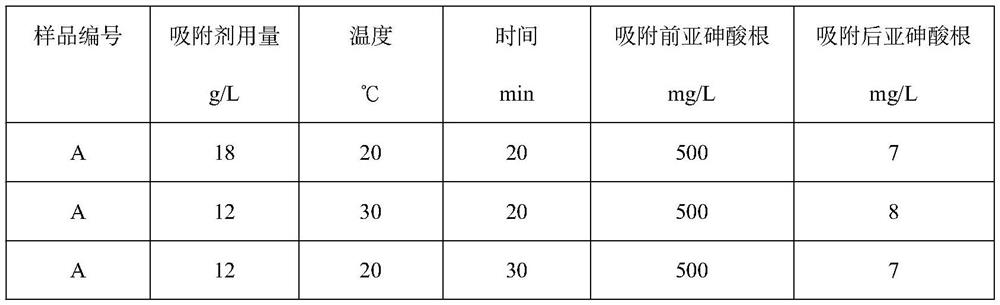

Adsorbent for efficiently removing arsenite ions from water, and preparation method thereof

ActiveCN109692650AImprove adsorption capacityReduce dosageOther chemical processesWater contaminantsSorbentWastewater

The invention provides an adsorbent for efficiently removing arsenite ions from water, and a preparation method thereof, and relates to an adsorbent for efficiently adsorbing arsenite ions in water, and a preparation method thereof. In the prior art, the removal efficiency of the arsenite ions in the wastewater solution is not high. A purpose of the present invention is mainly to solve the problemin the prior art. According to the technical scheme, a metal complex CuxMn6-xLa2(OH)18.4H2O or CuxMn6-xFe2(OH)18.4H2O as an adsorbent is prepared by combining co-precipitation and hydrothermal treatment, and x is 2-5. With the technical scheme, the problem in the prior art is well solved. According to the present invention, the adsorbent prepared by the method can efficiently remove arsenite ionsfrom water, and can be used in the field of environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

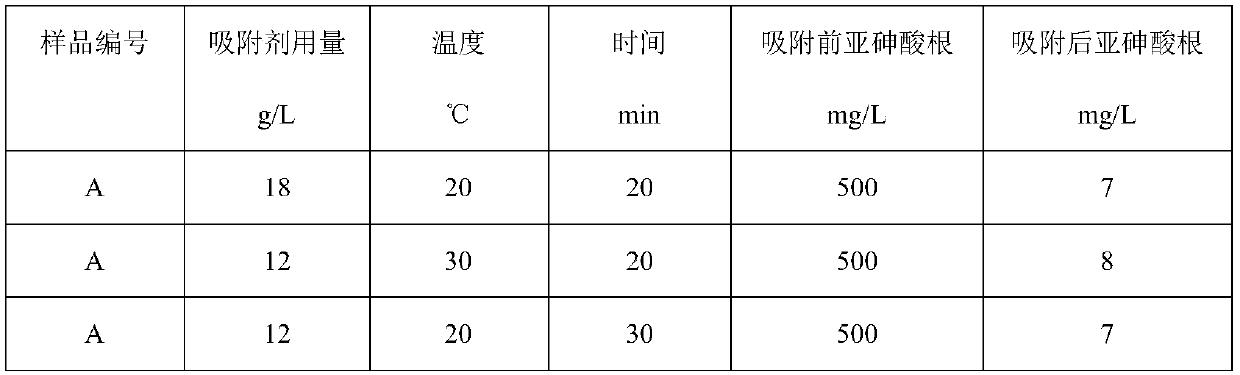

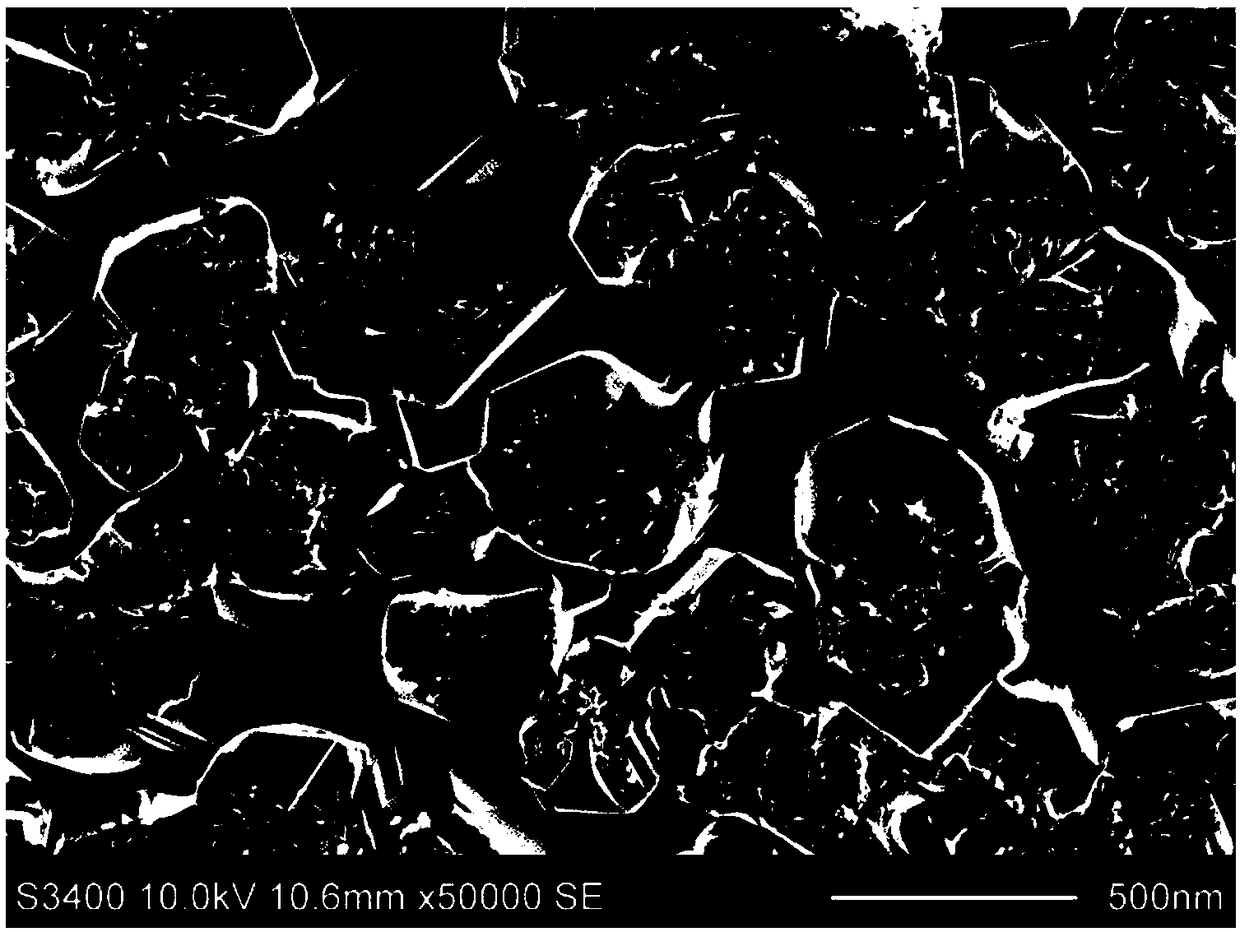

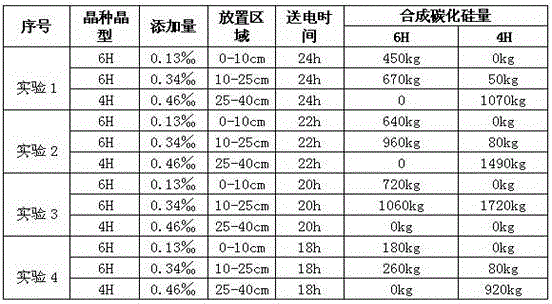

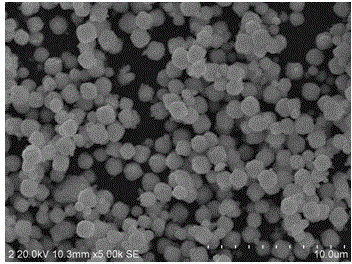

Ultra-pure nanometer silicon carbide and preparation method thereof

InactiveCN108557823AControl crystal formControl impurity contentCarbon compoundsNanotechnologySingle crystalAtmospheric pressure

The invention provides ultra-pure nanometer silicon carbide and a preparation method thereof. the preparation method comprises the following steps: preparation of a gas reaction precursor: mixing a carbonaceous gas and a silicon-containing gas at the Si:C molar ratio of 1: 1.0-1:1.06 to obtain the gas reaction precursor; preparation of ultra-pure nanometer silicon carbide: introducing the gas reaction precursor into a preheated ceramic reactor such that the gas reaction precursor is directly synthesized in a high-temperature zone of the ceramic reactor into nanometer silicon carbide with granularity of 50-500 nm. Temperature in the preheated ceramic reactor is 1100-2200 DEG C. pressure of the ceramic reactor is 1-5 atmospheric pressures. A single crystal form of nanometer silicon carbide can be synthesized in the invention.

Owner:JIANGSU UNIV

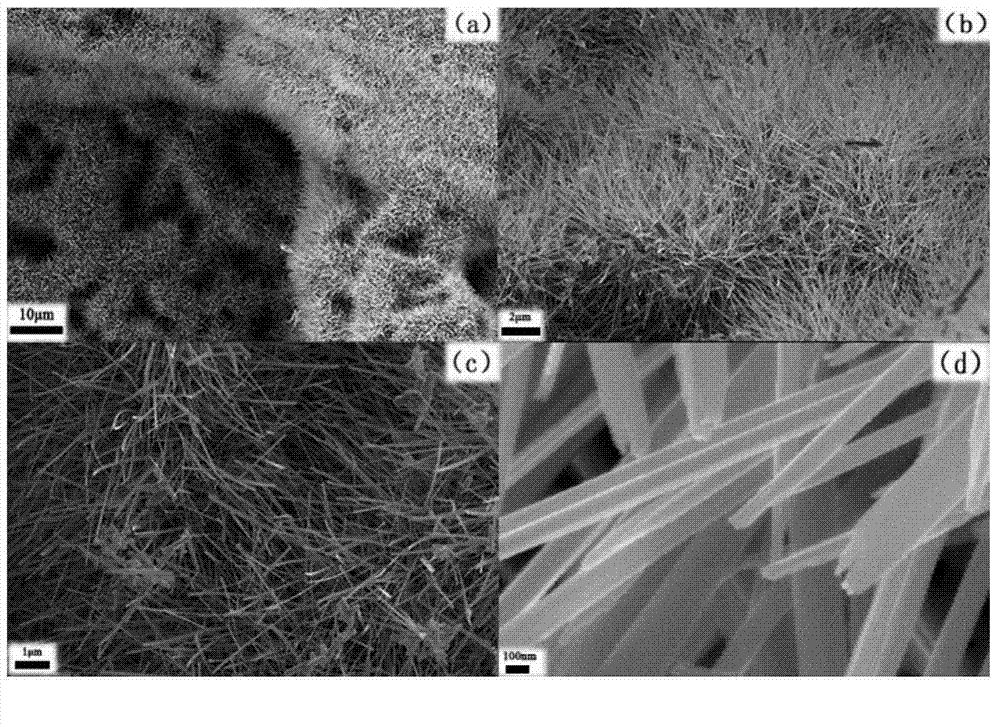

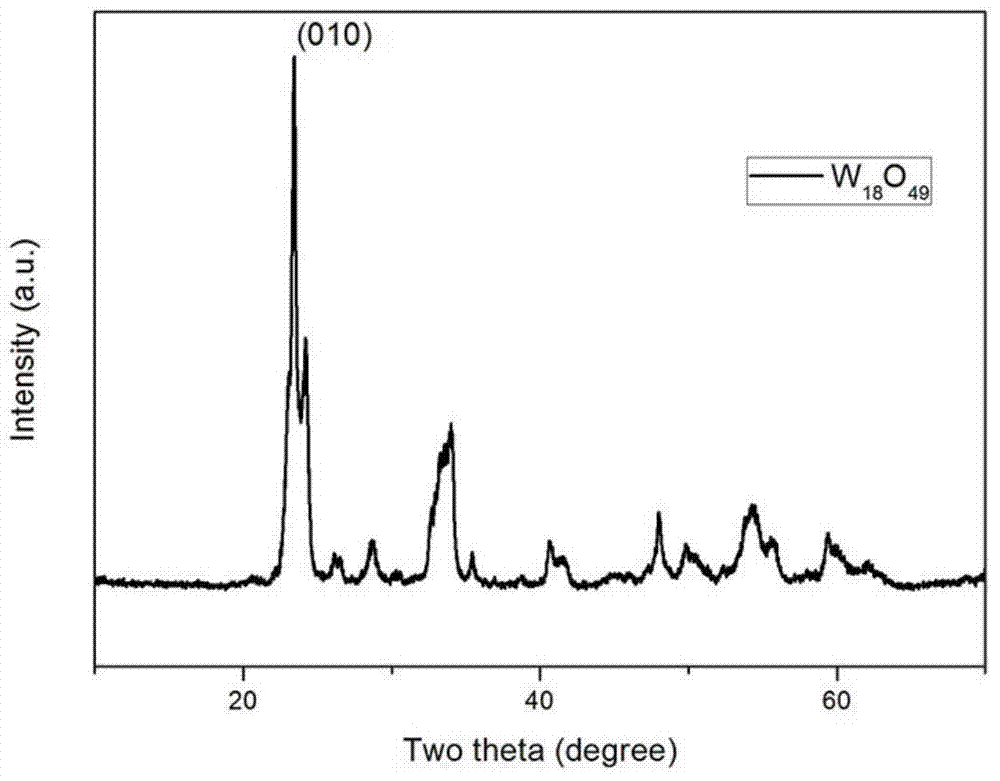

Method for preparing nano needle-shaped purple tungsten powder

ActiveCN104843792AHigh purityLarge specific surface areaMaterial nanotechnologyTungsten oxides/hydroxidesDiameter ratioRotary furnace

The present invention, belonging to the technical field of advanced power metallurgy preparation, relates to a method for preparing a nano needle-shaped purple tungsten powder. The nano needle-shaped purple tungsten powder disclosed by the present invention has a diameter of 20-200 nm, a length of 0.5-10 micro m, and a length-diameter ratio of 5-300. In addition, the present invention discloses a method for preparing nan purple tungsten. According to the method, the purple tungsten is synthesized in one step by a solution process. Therefore, the reaction time is short, and the reaction initiation temperature is low. A large quantity of gases are produced in the reaction course, and sufficient contact with air is impeded, so that the generated product, namely, the purple tungsten, is relatively single, favorable to the subsequent utilization of the powder. The method according to the present invention solves the problem that the particle size of the purple tungsten powder prepared through the calcination of a traditional rotary furnace is coarse and large. In addition, the method according to the present has higher efficiency for preparing the nanometer purple tungsten compared with other methods; and has the advantages of high efficiency, low cost, high utilization rate of raw material powder and the like.

Owner:UNIV OF SCI & TECH BEIJING

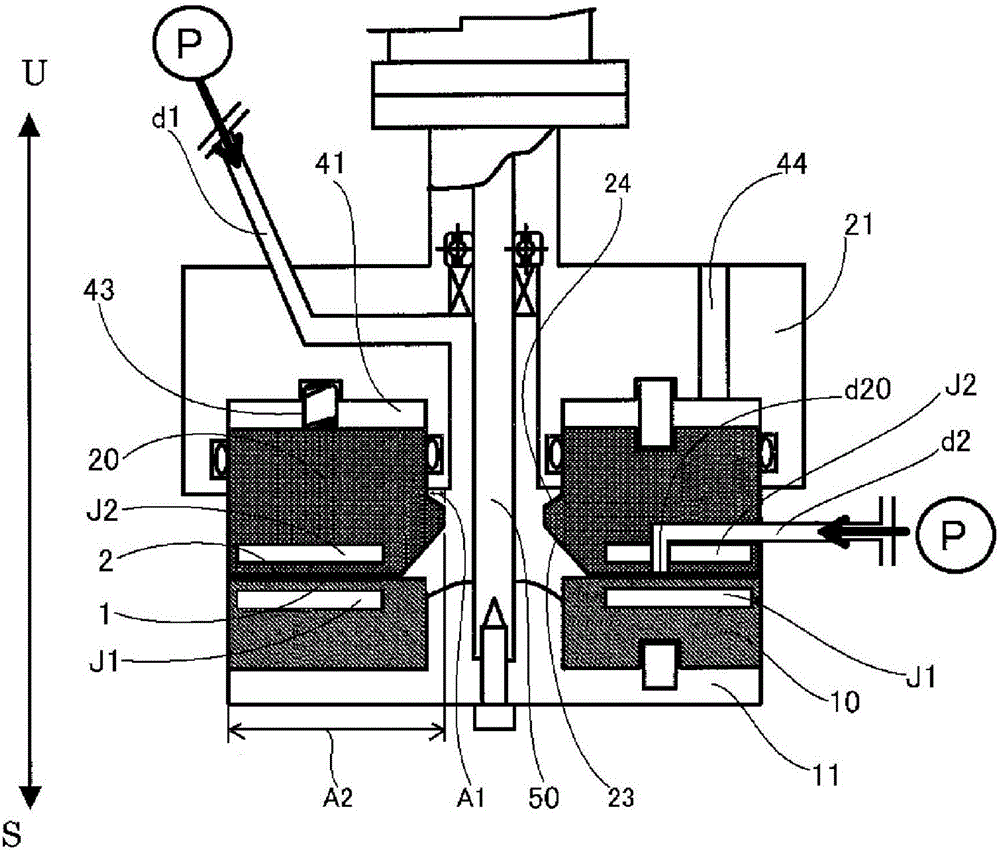

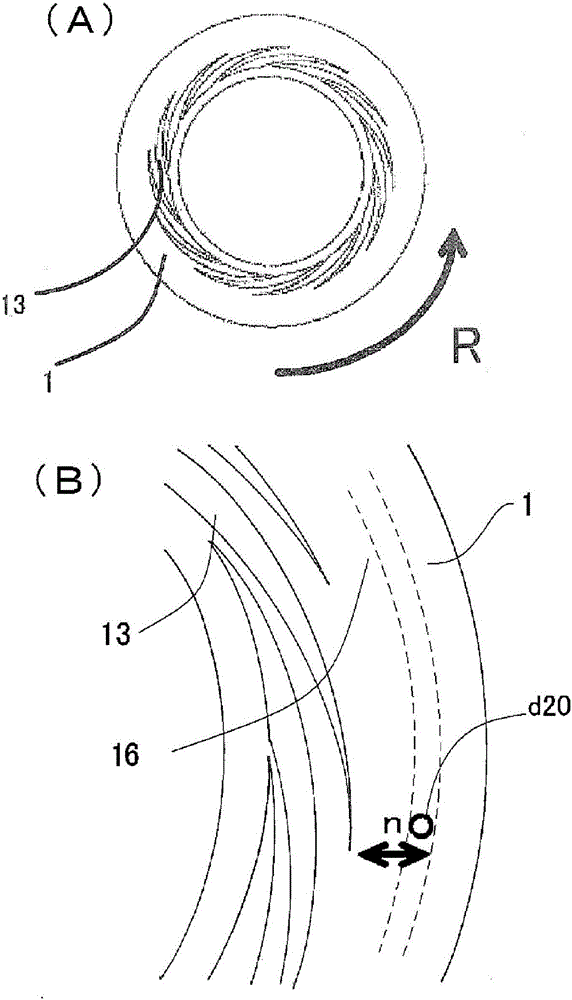

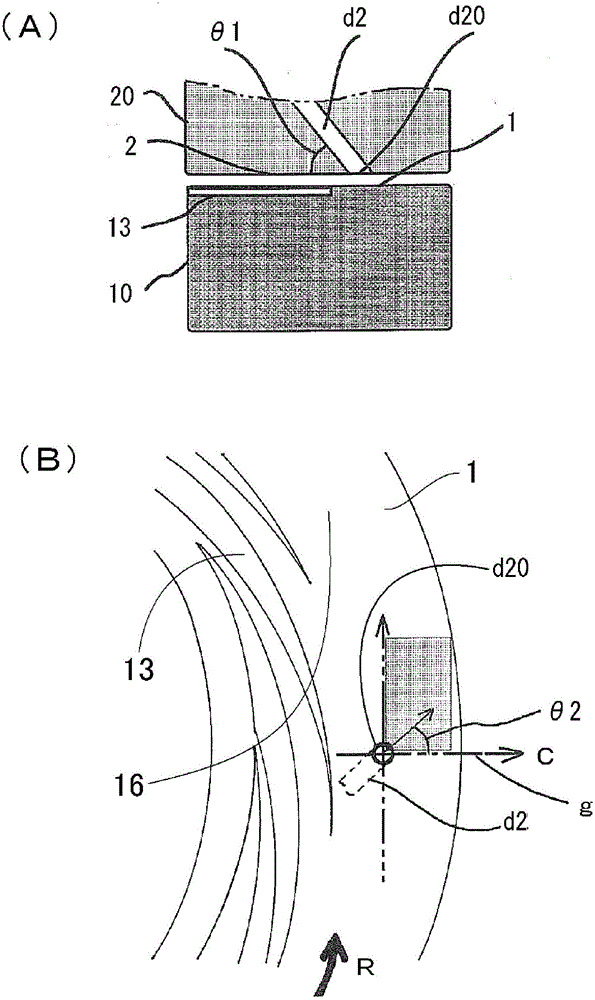

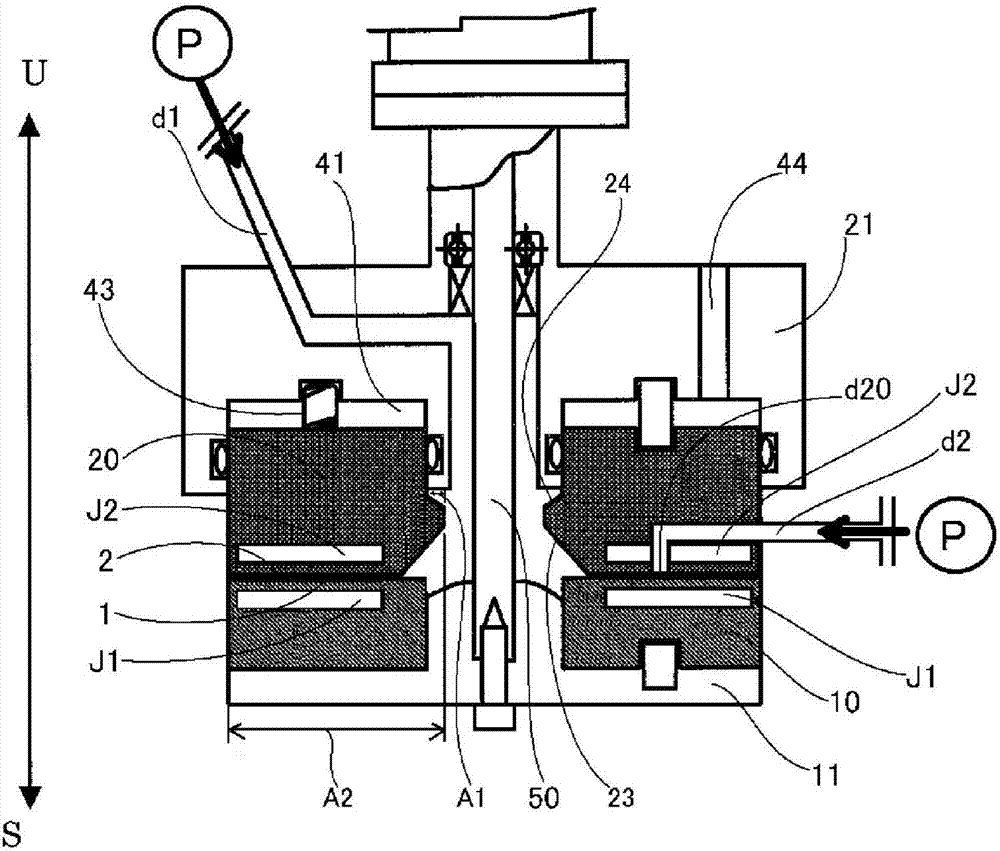

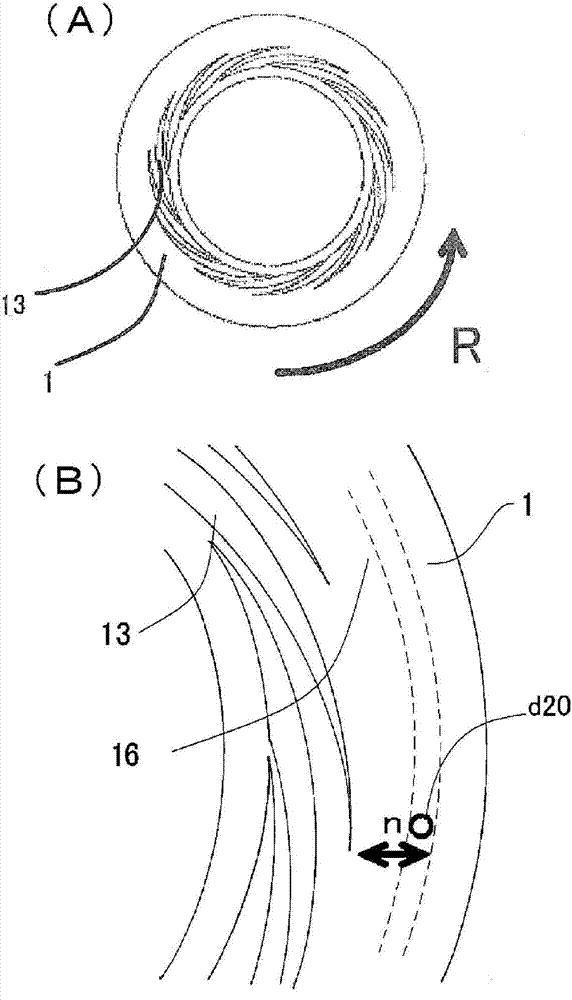

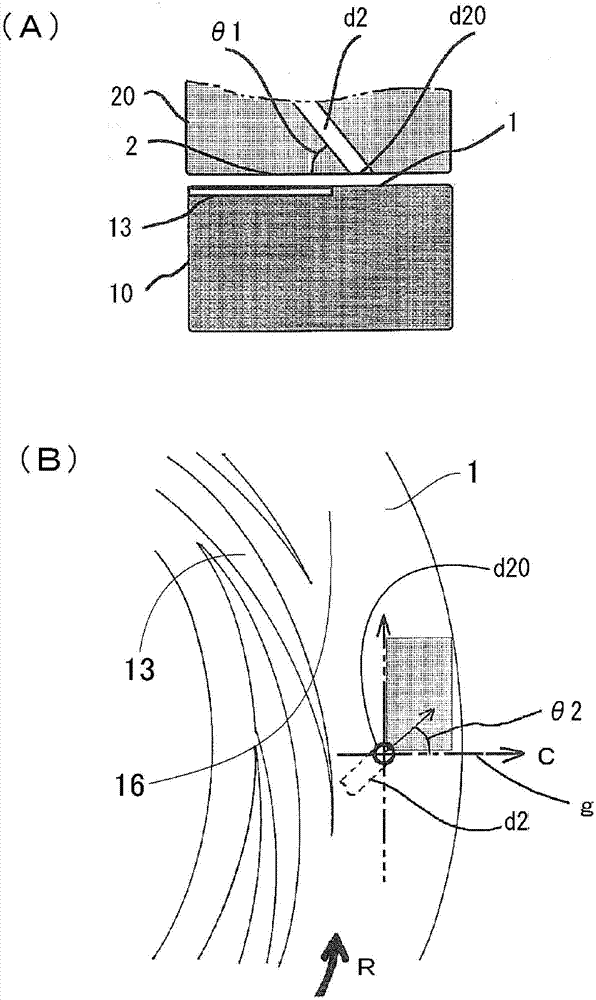

Fine particle production method

InactiveCN106029216AReduce crystallinityControl crystal formCosmetic preparationsOrganic active ingredientsTime conditionSolvent

This fine particle production method involves a dissolving step in which a stirrer having a rotating stirring blade is used to dissolve at least one type of fine particle raw material in a solvent to obtain a fine particle raw material solution, and a precipitation step in which the fine particle raw material solution and at least one type of precipitation solvent for precipitating the fine particle raw material from the fine particle raw material solution are introduced between at least two treatment surfaces which are arranged oppositely one another, can move closer to and farther apart from one another, and at least one of which can rotate relative to the other, and the fine particle raw material solution and the at least one type of precipitation solvent are mixed in a thin film fluid formed between the at least two treatment surfaces, and the fine particles are precipitated. The stirring energy is determined by the stirring time conditions of the stirrer, the circumferential velocity conditions of the stirring blade, and the temperature conditions of the fine particle raw material solution, and in the dissolving step, the stirring energy is varied by changing at least one of the aforementioned conditions, and by changing the stirring energy, the degree of crystallization and the crystal form of the fine particles obtained in the precipitation step are controlled.

Owner:M TECH CO LTD

Method for preparing nano iron oxide yellow

A process for preparing nano-class iron oxide yellow from refined FeSO4 includes such steps as adding sodium hexametaphosphate and alkylphenol polyoxyvinylether to the solution of refined FeSo4 while stirring, dropping 10% Na2CO3 solution to make pH=3.5-6.5, introducing O2 gas, reaction at 20-40 deg.C to obtain crystal seeds, introducing O2 gas at 50-60 deg, dropping Na2CO3 solution to make pH=3.0-5.5, reaction for 8 hr to grow crystal, filter, drying and pulverizing.

Owner:上海工大科技园区环境工程有限公司

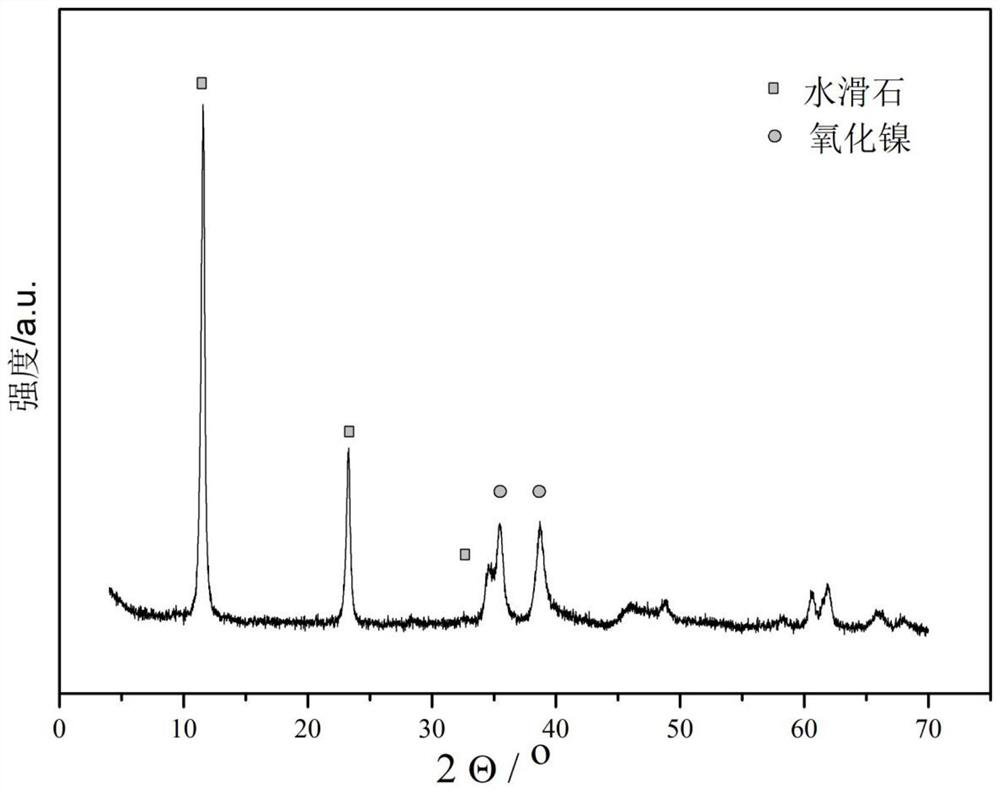

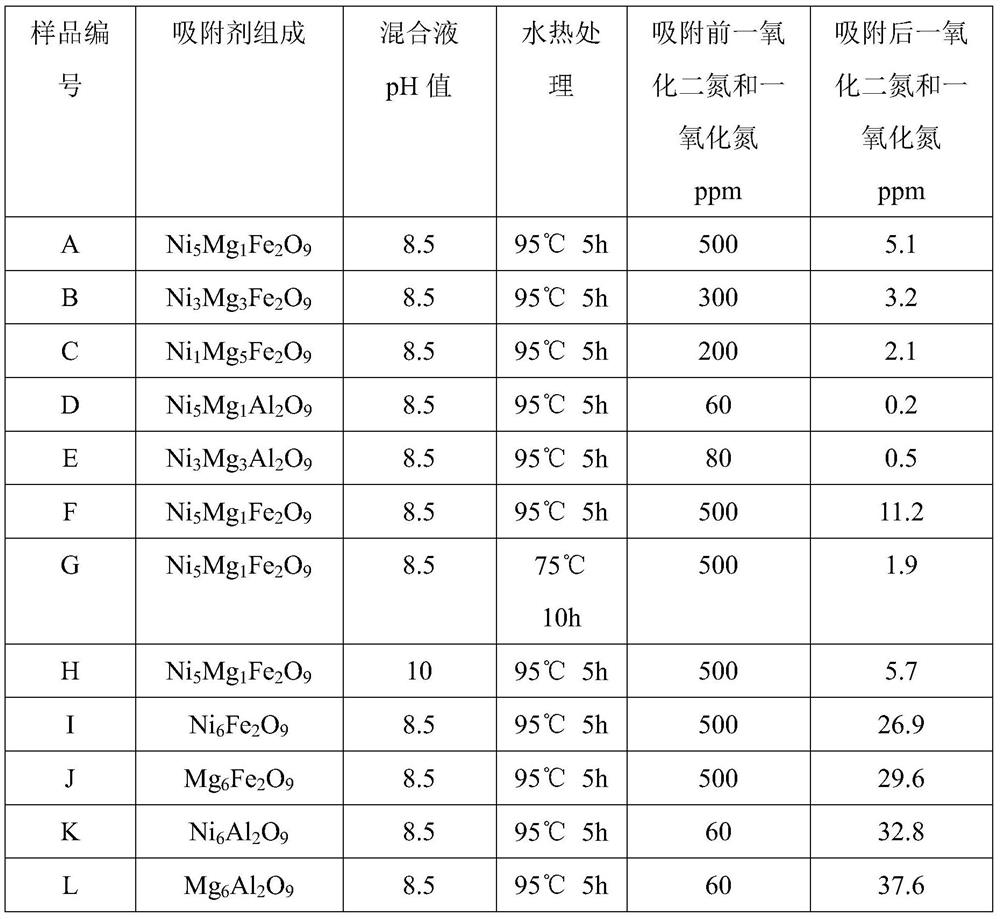

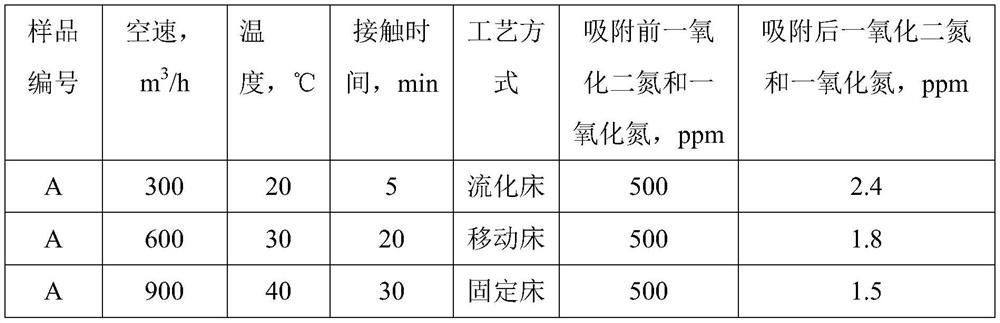

Adsorbent for removing nitric oxide in fluid as well as preparation method and application of adsorbent

ActiveCN112755953AReduce dosageFast adsorptionIon-exchange process apparatusNitrous oxide captureNitrogen oxidesSorbent

The invention discloses an adsorbent for removing nitric oxide in fluid as well as a preparation method and application of the adsorbent. The composition of the adsorbent is Ni<x> Mg<6-x>Fe<2>O<9> or Ni<x>Mg<6-x> Al<2>O<9>, wherein x is equal to 1-6. The preparation method of the adsorbent comprises the following steps of: dropwise adding an alkaline solution into a solution containing nickel, magnesium and iron or aluminum to carry out precipitation reaction, and then carrying out hydrothermal crystallization, drying, roasting and the like to obtain the adsorbent. The adsorbent has the characteristics of high efficiency of removing nitrogen oxide in fluid, simple preparation method, environment-friendly and pollution-free production process, simple operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

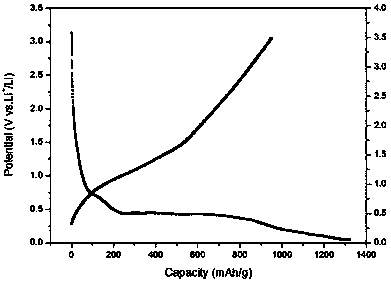

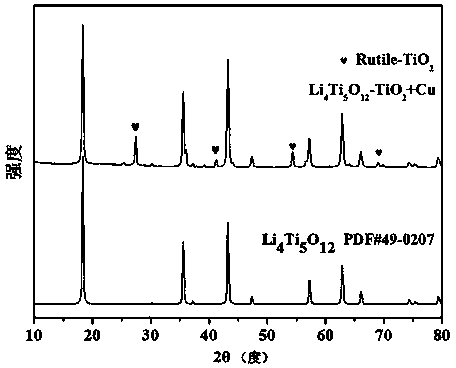

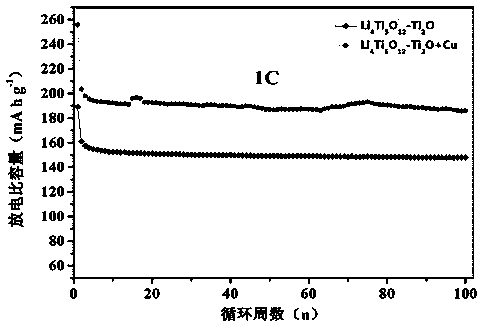

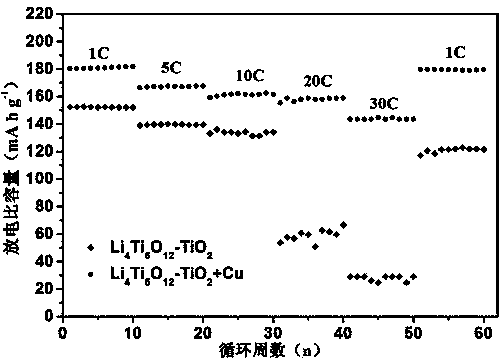

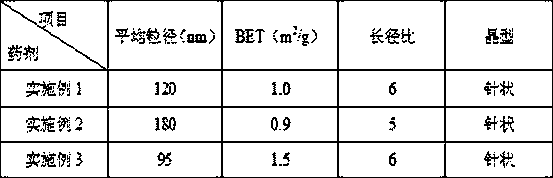

Preparation method of copper-doped Li4Ti5O12-TiO2 regulation and control composite material

InactiveCN104201344AImprove cycle lifeImprove securityCell electrodesSecondary cellsLithium hydroxideEthylic acid

The invention relates to a preparation method of copper-doped Li4Ti5O12-TiO2 regulation and control composite material. The method comprises the steps of feeding tetrabutyl titanate into ethyl alcohol to prepare a solution A; feeding lithium hydroxide into distilled water to prepare a solution B; slowly feeding the solution B into the solution A, stirring for half an hour, and then feeding copper acetate into the mixed solution; continuing to stir for an hour to obtain a mixed solution; putting the mixed solution into a high-pressure reaction kettle, and carrying out a reaction for 12-24 hours at the temperature of 160-180 DEG C to obtain a precursor; calcining the precursor for 2-6 hours at the temperature of 600 DEG C to obtain a target product. The preparation method has the advantages that the copper element with different contents is fed into the material, so that the crystal form and the content of TiO2 in a Li4Ti5O12-TiO2 system are effectively regulated and controlled; the prepared composite material is an anode material which is long in cycle life, and high in safety, energy and power density; the preparation method is simple in technology, easy in operation and high in practicality.

Owner:NANKAI UNIV

Preparation method of high-purity calcium oxide

PendingCN111573705AHigh purityHigh yieldMaterial nanotechnologyCalcium/strontium/barium oxides/hydroxidesCalcium hydroxidePolyvinyl alcohol

The invention provides a preparation method of high-purity calcium oxide. Calcium hydroxide is produced by using raw materials with extremely high calcium oxide content, the dispersity of calcium ionsis improved by using stearic acid and polyvinyl alcohol 124, and the crystal form and the particle size of the calcium ions are controlled so that calcium hydroxide solids are high in fineness and good in dispersity, and finally, calcium oxide with high purity and good dispersity is prepared through high-temperature calcination. Calcium hydroxide with good dispersity can be better and more uniformly calcined at high temperature so that the production efficiency is improved, the yield of waste gas CO2 is reduced, and the cost of subsequent treatment is reduced. The method is simple in process,safe, environmentally friendly and high in production efficiency, and the prepared calcium oxide product is high in purity and good in dispersity.

Owner:NANNING XIAYANG CHEM TECH CO LTD

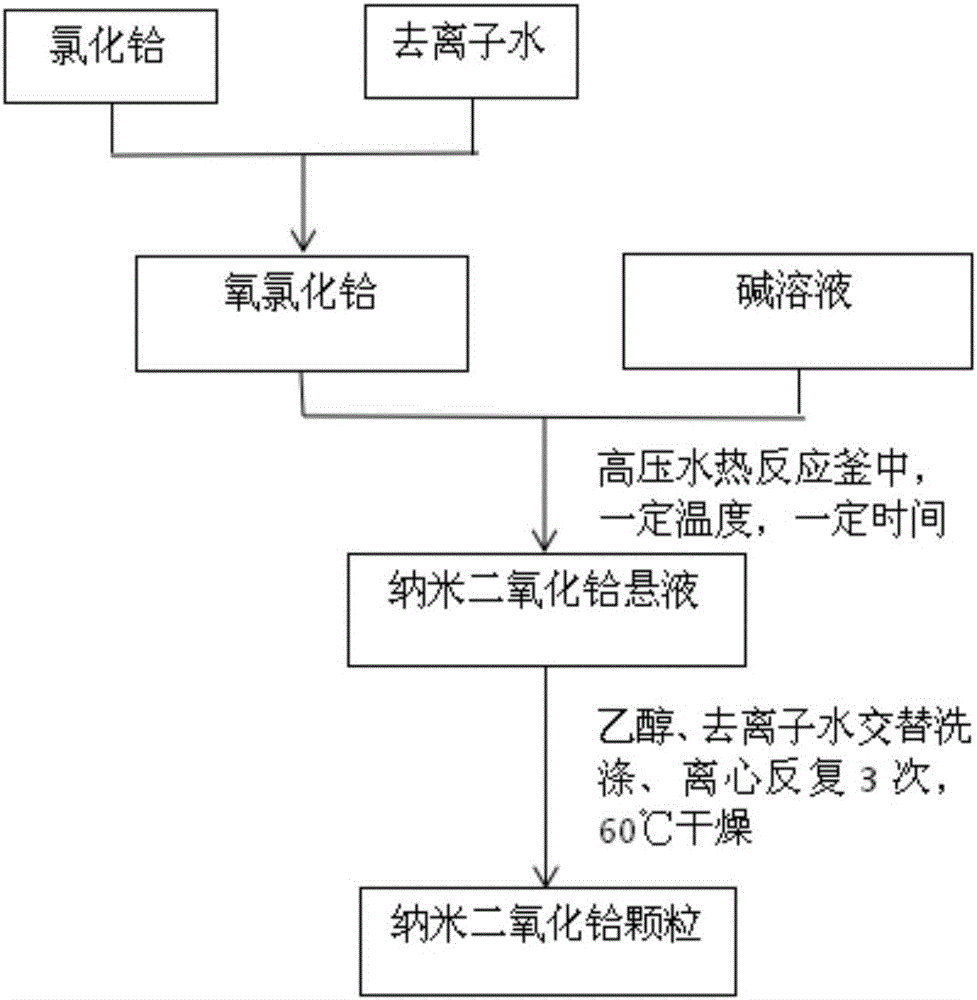

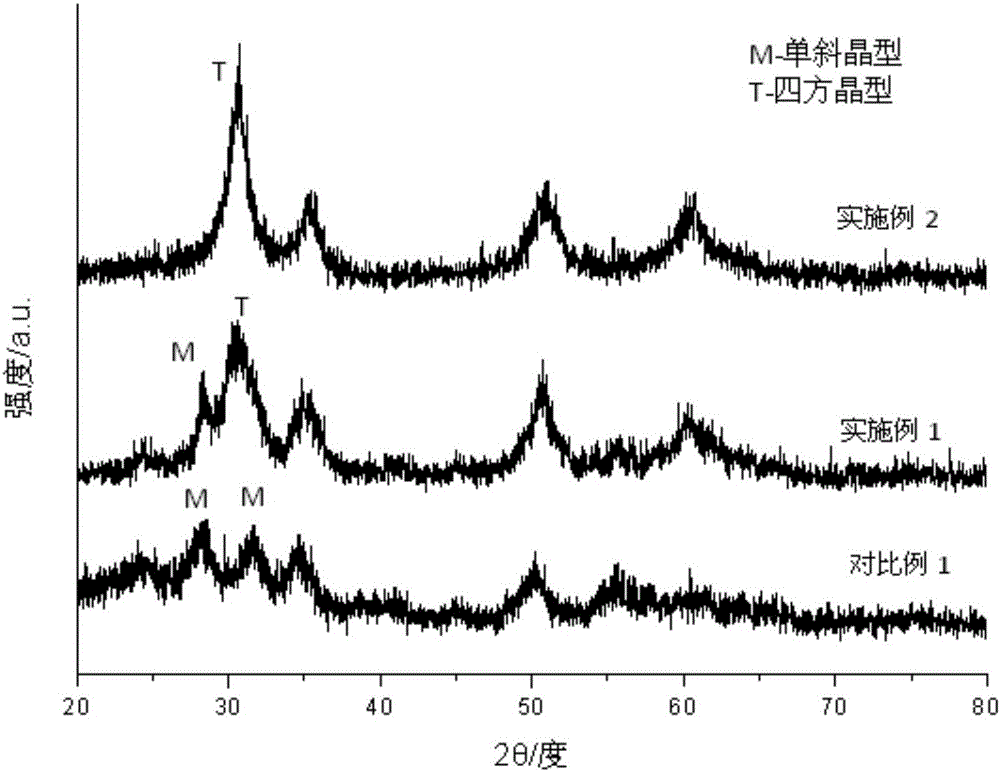

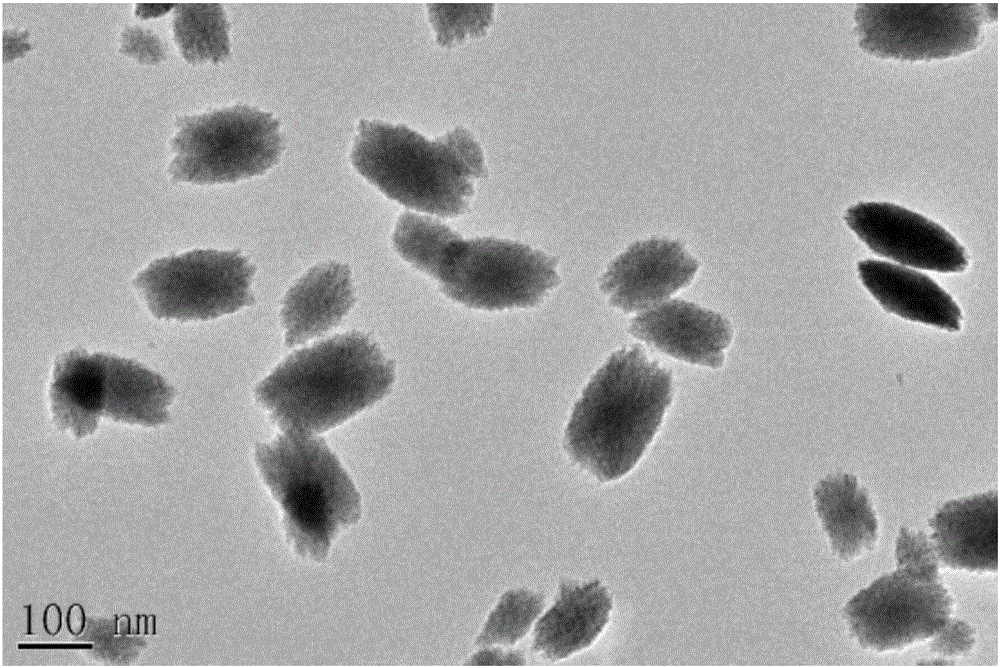

Method of preparing nanometer hafnium oxide particles of different crystal forms by adjusting alkali concentration

InactiveCN106082325AControl crystal formUniform particle size distributionDispersityRoom temperature

The invention relates to a method of preparing nanometer hafnium oxide particles of different crystal forms by adjusting alkali concentration. The method includes the steps that at the room temperature, an alkaline solution is added into a hafnium oxide solution dropwises to obtain a mixed solution; the mixed solution is subjected to reaction at the constant temperature of 100-130 DEG C, and the nanometer hafnium oxide particles are obtained through washing, centrifuging and drying. The method has the advantages of being simple in operation method, high in repeatability, low in temperature requirement and free of calcinations, and reaction conditions are easy to control; the crystal form of the product can be controlled by controlling the alkali concentration in the solution; the prepared good nanometer hafnium oxide particles are uniform in particle size distribution and high in dispersity and have good application prospects.

Owner:DONGHUA UNIV +1

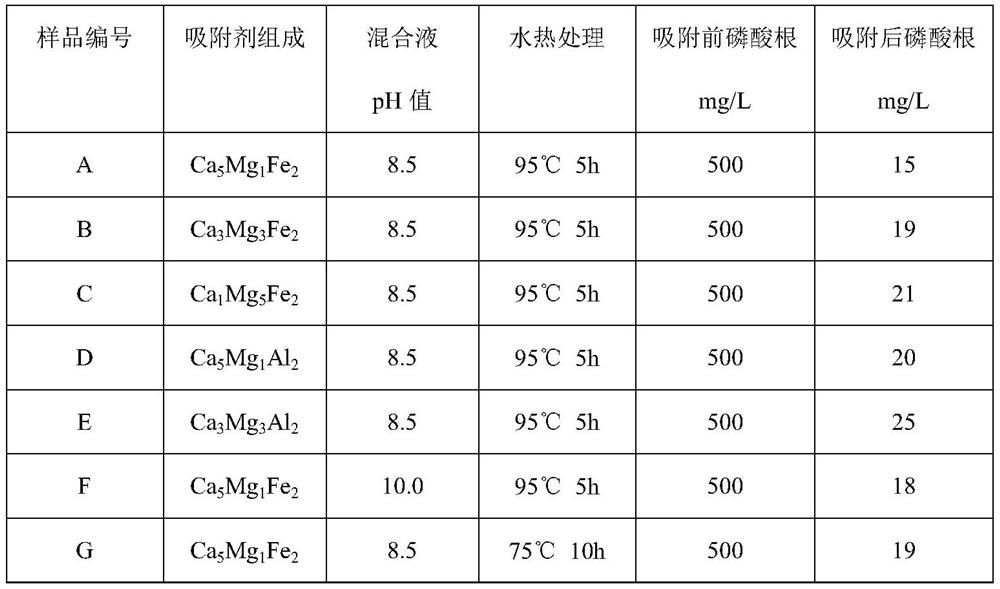

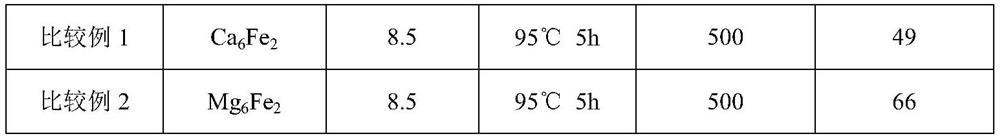

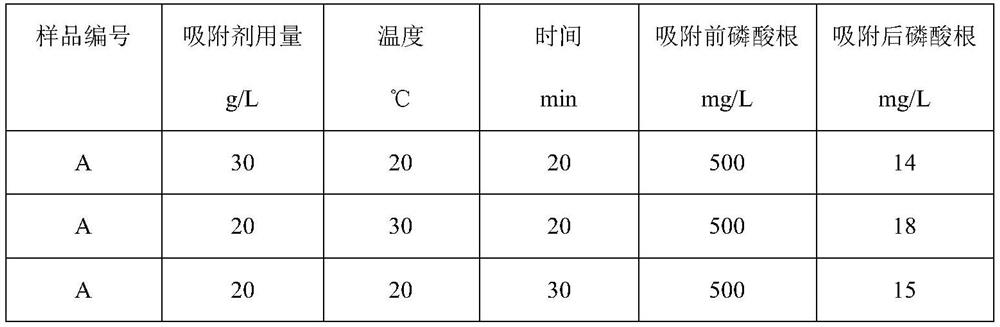

Adsorbent for efficiently adsorbing phosphate ions in water and preparation method thereof

ActiveCN109692653BImprove adsorption capacityReduce dosageOther chemical processesWater contaminantsIndustrial waste waterPhosphate ion

The invention relates to an adsorbent for efficiently adsorbing phosphate ions in water and a preparation method thereof. The invention mainly solves the problem of low removal efficiency of phosphate ions in industrial wastewater existing in the prior art. The present invention adopts the method of co-precipitation and hydrothermal treatment to prepare the metal composite Ca x Mg 6‑x Fe 2 (OH) 18 ·4H 2 O or Ca x Mg 6‑x Al 2 (OH) 18 ·4H 2 O, where x=1-5 is the technical solution of the adsorbent, which better solves this problem. The adsorbent prepared by the method of the invention has the characteristics of high efficiency in removing phosphate ions from water, and can be used in the field of environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Adsorbent for efficiently removing arsenite ion in water and preparation method thereof

ActiveCN109692650BImprove adsorption capacityReduce dosageOther chemical processesWater contaminantsSorbentWastewater

The invention relates to an adsorbent for efficiently removing arsenite ions in water and a preparation method thereof, and relates to an adsorbent for efficiently adsorbing arsenite ions in water and a preparation method thereof. It mainly solves the problem of low removal efficiency of arsenite ions in wastewater solution existing in the prior art. The present invention adopts the method of co-precipitation and hydrothermal treatment to prepare the metal composite Cu x Mn 6‑x La 2 (OH) 18 .4H 2 O or Cu x Mn 6‑x Fe 2 (OH) 18 .4H 2 O, where x=2-5 is the technical solution of the adsorbent, which better solves this problem. The adsorbent prepared by the method of the invention has the characteristics of high removal efficiency of arsenite ions in water, and can be used in the field of environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silicon carbide smelting method

Owner:JIANGSU LEYUAN MATERIAL

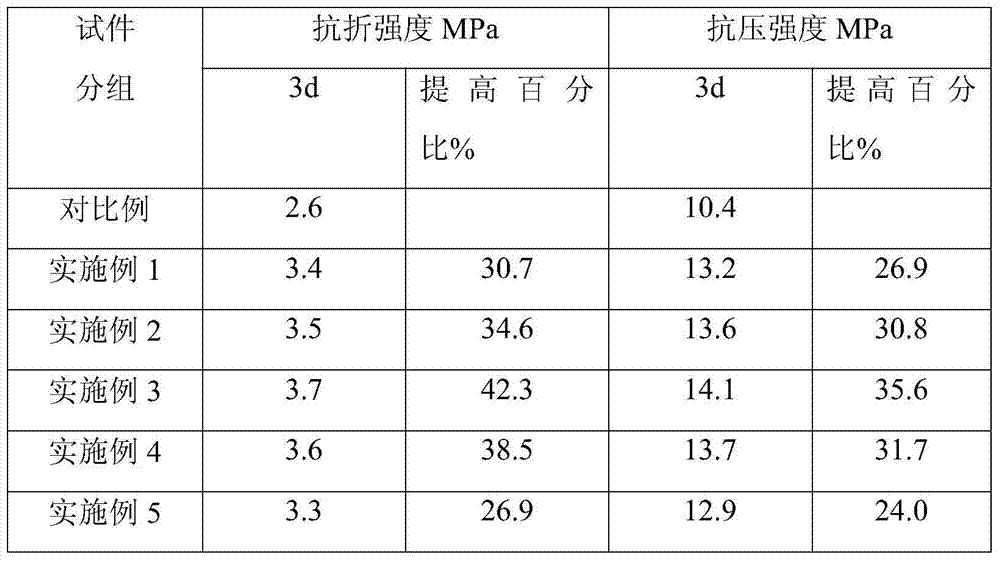

Modified high belite cement and method for improving early strength of high belite cement

The invention relates to a modified high belite cement and a method for improving the early strength of the high belite cement, aiming at solving the technical problem of low early strength of the existing high belite cement. The present invention is to add nano indium oxide to high belite cement according to the mass ratio of high belite cement:nano indium oxide=9~4999:1 and mix evenly, the added nano indium oxide can excite C 2 The activity of S in the early stage can accelerate the hydration rate, generate more gels, regulate the crystal form of hydration products, and improve the early strength of high belite cement. The invention not only effectively solves the problem of high energy consumption in the cement industry, but also provides a simple and easy method for improving the early strength of high belite cement, which has low production cost and is easy to popularize.

Owner:宁夏青铜峡水泥股份有限公司

Process for preparing Co3O4

InactiveCN1151971CSimple processThe process is simple and easy to controlCobalt oxides/hydroxidesNitrateCobalt(II,III) oxide

A process for preparing Co3O4 includes such steps as dissolving Co in nitric acid, hydrochloric acid or sulfuric acid to generate cobolt nitrate (or sulfate, or chloride), dissolving precipitant and complexing agent in deionized water to prepare saturated solution, adding the prepared to solution to reactor, regulating pH=4-5.5, adding complexing precipitant at 35-100 deg.c while stirring, reacting, filtering, washing with deionized water at temp higher than 90 deg.C, calcining at 300-1000 deg.C for 5-25 hr, pulverizing and classifying.

Owner:戴振华

Method for preparing SrHfO3:Ce super-microsphere luminescent powder by adopting monohydric alcohol thermal method

InactiveCN103333688BWide range of raw materialsSimple and fast operationLuminescent compositionsAlcoholMicrosphere

The invention discloses a method for preparing SrHfO3:Ce super-microsphere luminescent powder by adopting a monohydric alcohol thermal method and relates to a method for preparing luminescent powder. The method is characterized in that high-purity Sr(NO3)2, HfOCl2.8H2O, Ce(NO3)3.6H2O are used as raw materials, KOH is used as a mineralizing agent, and alcohol / water mixed solution is used as a reaction solvent; the correlated conditions of the preparation process comprise: preparation of materials, adding and mixing of the mineralizing agent, hydrothermal reaction, filtering, washing and drying, wherein the content of Ce in the SrHfO3:Ce uminescent powder is between 0.1mol% and 1.5mol%. The method for preparing the SrHfO3:Ce uminescent powder is simple in process, and good in appearance and particle diameter controllability of the super-microsphere particles. Besides, the super-microsphere powder prepared by the method is an important raw material of a ceramic scintillator substrate material and can be burnt into sparkling transparent ceramic with excellent optical performances.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

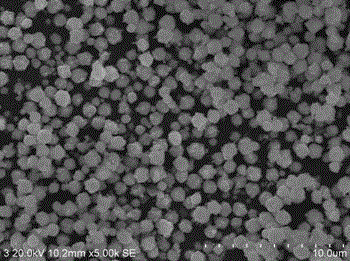

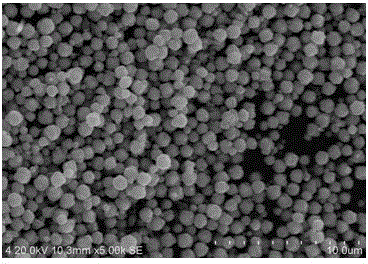

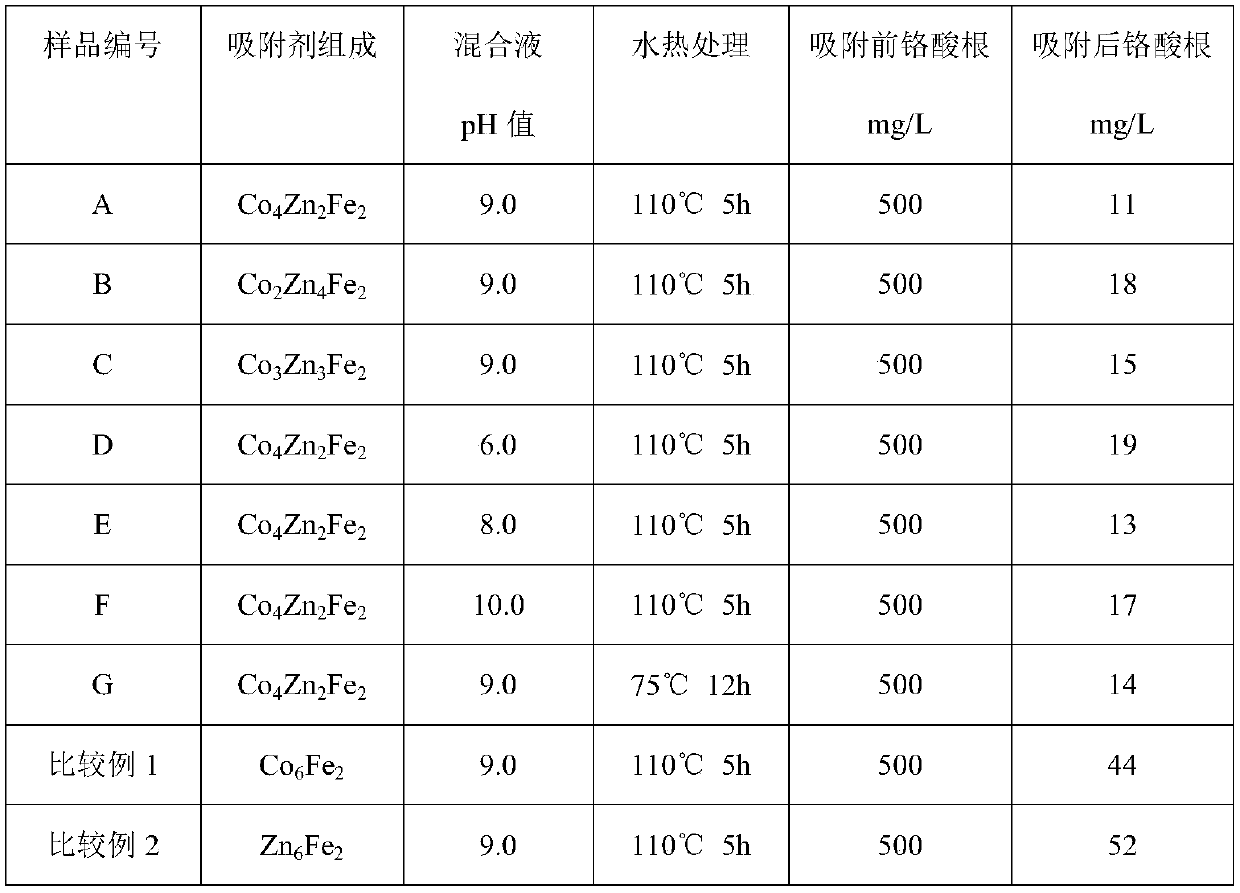

Adsorbent for removing chromate ions from water, and preparation method thereof

InactiveCN109692649AGood adsorption performanceStrong adsorption capacityOther chemical processesWater contaminantsCompound sEnvironmental chemistry

The invention relates to an adsorbent for removing chromate ions from water, and a preparation method thereof. In the prior art, the removal efficiency of the chromate ions in the industrial wastewater solution is not high. A purpose of the present invention is mainly to solve the problem in the prior art. According to the technical scheme, a metal complex CoxZn6-xFe2(OH)18.4H2O as an adsorbent isprepared by combining co-precipitation and hydrothermal treatment, and x is 2-5. With the technical scheme, the problem in the prior art is well solved. According to the present invention, the adsorbent prepared by the method can efficiently remove chromate ions from water, and can be used in the field of environmental protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of modified nickel hydroxide positive electrode material

PendingCN114132973AReduces electrochemical polarizationStable structurePositive electrodesNickel oxides/hydroxidesPhysical chemistryConductive materials

The invention discloses a preparation method of a modified nickel hydroxide positive electrode material. The preparation method comprises the following steps: 1, obtaining a positive electrode through an electrochemical method or a chemical coprecipitation method; and 2, coating the positive electrode with the conductive material through an electrochemical method or a solid-phase polymerization method. The positive electrode material prepared by the method has the characteristics of high conductivity, excellent cycle performance, high capacity, high magnification and the like.

Owner:南京安捷驰新能源科技有限公司

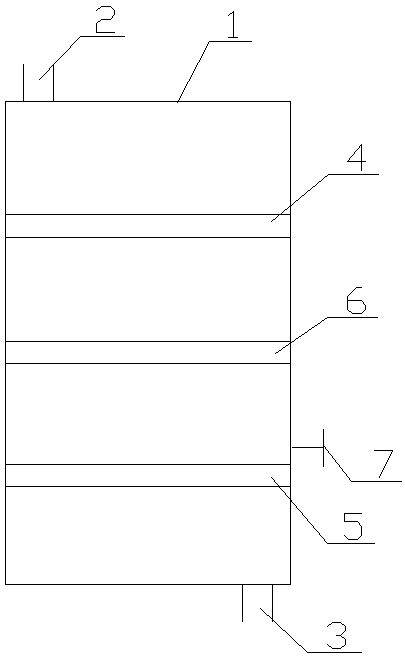

A kind of ultrafiltration membrane water purifier

ActiveCN105923867BControl crystal formControl particle morphologySemi-permeable membranesWater/sewage treatment by irradiationActivated carbon filtrationUltrafiltration

The invention discloses a water purifier with an ultrafiltration membrane. The water purifier comprises a filtration tank, wherein the top of the filtration tank is provided with a water inlet, and the bottom of the filtration tank is provided with a water outlet; the filtration tank is internally provided with an activated carbon filtration layer and an ultrafiltration membrane filtration layer. A preparation method of an Al2O3-PVA ultrafiltration membrane comprises the following steps: firstly preparing Al2O3 sol, then preparing an Al2O3-PVA casting membrane solution, and finally solidifying to obtain the ultrafiltration membrane. According to the preparation, PVA is modified by use of Al2O3, and cerium ions are doped, so that the crystal form, particle morphology, pore size and distribution, membrane thickness and the like of the membrane can be effectively controlled, and thus the ultrafiltration membrane has an excellent retention rate on impurities in water and excellent acid and alkali resistance property, and has certain bactericidal performance. The water purifier with the ultrafiltration membrane, provided by the invention, is simple and reliable in structure, good in purification effect and beneficial to large-scale popularization.

Owner:巴马万家福长寿家族康复连锁股份有限公司

A method for preparing phase-change microcapsules by hydrothermal method

ActiveCN112126414BControl crystal formControl shapeHeat-exchange elementsBulk chemical productionEngineeringRadiation protection

Owner:SOUTHWEAT UNIV OF SCI & TECH

Microparticle Manufacturing Method

InactiveCN106029216BReduce crystallinityControl crystal formOrganic active ingredientsCosmetic preparationsParticulatesTime condition

Provided is a method for producing fine particles, comprising: a dissolving step of dissolving at least one kind of fine particle raw materials in a solvent using a stirrer having a rotating stirring blade to obtain a fine particle raw material solution; At least one of the precipitated solvents and the fine particle raw material solution are introduced between at least two processing surfaces that are oppositely arranged, accessible and / or separate, and at least one of them rotates relative to the other. This is a precipitation step in which fine particles are precipitated by mixing in the thin film fluid formed between the treatment surfaces. In the above-mentioned dissolving step, the stirring energy specified by the stirring time conditions using the stirrer, the peripheral speed conditions of the stirring blades, and the temperature conditions of the fine particle raw material solution is increased or decreased by changing at least one of the above conditions. , by increasing or decreasing the stirring energy, the crystallinity and crystal form of the particles obtained in the precipitation step are controlled.

Owner:M TECH CO LTD

Preparation method of rare-earth polishing powder containing fluorine and phosphorus

InactiveCN102816554BEffective control of crystal formControl crystal formOther chemical processesPhysical chemistryCrystallographic defect

The invention relates to a preparation method of rare earth polishing powder containing fluorine and phosphorus, which is characterized in that it comprises the following steps: precipitation, fluorine-phosphorus compound additive treatment, roasting, crushing and classification. In the present invention, fluorine and phosphorus elements are added at the same time when the polishing powder precursor is synthesized, which can effectively control the crystal form of the polishing powder and make it have certain crystal defects, thereby obtaining better polishing performance, higher grinding ability, and surface accuracy. better.

Owner:GANSU UNITED NEW RARE EARTH MATERIAL

Preparation method of aspirin fine crystals

ActiveCN103613500BControl crystal formControl UniformityOrganic compound preparationCarboxylic acid esters preparationAspirinAcetic anhydride

Owner:SHANDONG XINHUA PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com