Modified high belite cement and method for improving early strength of high belite cement

An early strength, belite technology, applied in the field of building materials, can solve the problems of high production cost, complex process steps, difficult to popularize, etc., to accelerate the hydration rate, broaden the scope of application, and be easy to promote.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A modified high belite cement, the preparation method is as follows:

[0024] Take In 2 o 3 (nano-indium oxide) 0.2 gram (the particle diameter of described nano-indium oxide is 30~70nm), 99.8 grams of high belite cement (produced by Anyang Zhonglian Cement Co., Ltd.), dry mix uniformly in the mixer, get final product A modified high belite cement with high early strength is obtained.

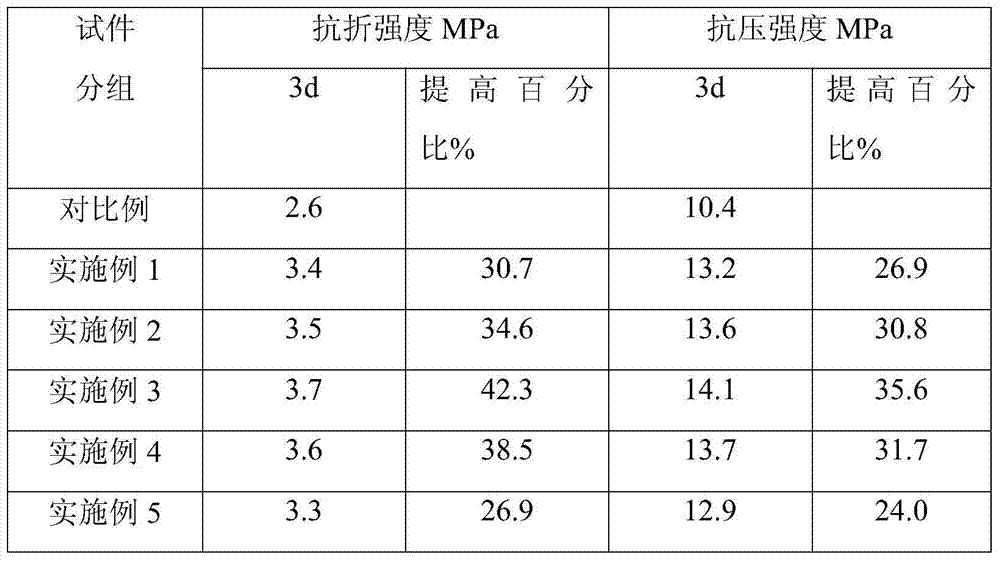

[0025] The 3-day compressive and flexural strengths were tested according to the method and standard of the comparative example, and the specific experimental data are shown in Table 1.

Embodiment 2

[0027] Take In 2 o 3 (nano-indium oxide) 0.5 gram (the particle diameter of described nano-indium oxide is 30~70nm), 99.5 grams of high belite cement (produced by Anyang Zhonglian Cement Co., Ltd.), dry mix uniformly in the mixer, get final product A modified high belite cement with high early strength is obtained.

[0028] The 3-day compressive and flexural strengths were tested according to the method and standard of the comparative example, and the specific experimental data are shown in Table 1.

Embodiment 3

[0030] Take In 2 o 3 (nano-indium oxide) 1.0 gram (the particle diameter of described nano-indium oxide is 30~70nm), 99.0 grams of high belite cement (produced by Anyang Zhonglian Cement Co., Ltd.), dry mix uniformly in the mixer, get final product A modified high belite cement with high early strength is obtained.

[0031] The 3-day compressive and flexural strengths were tested according to the method and standard of the comparative example, and the specific experimental data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com