Preparation method of high-purity calcium oxide

A calcium oxide, high-purity technology, applied in calcium/strontium/barium oxide/hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve production costs, high energy consumption, and product purity Low, poor dispersion and other problems, to achieve the effect of improving production efficiency, high purity, small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

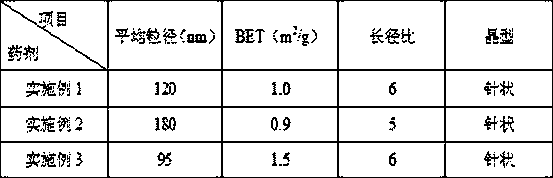

Examples

Embodiment 1

[0023] A preparation method of high-purity calcium oxide, comprising the following steps:

[0024] (1) Crush the limestone into 1cm particles, then put it into the calcination furnace and calcine at 600°C for 40~60min to obtain quicklime, and cool it down to room temperature naturally;

[0025] (2) According to the gray-water ratio of 1g:6mL, mix quicklime with hot water at 80°C, stir and age for 24 hours, and then sieve through a 200-mesh sieve to prepare a calcium hydroxide suspension with a concentration of 1.3mol / L ;

[0026] (3) Put the calcium hydroxide solution in the reaction kettle, add 0.8% of its mass modifier, stir and react at 35°C and 140r / min for 60min, and then vacuum dry at 50°C to obtain calcium hydroxide solid ;

[0027] The mixed modifier is obtained by mixing sodium stearate and polyvinyl alcohol 124 according to a mass ratio of 1:0.3;

[0028] (4) Calcinate the obtained calcium hydroxide solid at 600°C for 1 hour, then cool it to room temperature, put ...

Embodiment 2

[0031] A preparation method of high-purity calcium oxide, comprising the following steps:

[0032] (1) Crush the limestone into 2cm particles, then put it into the calciner and calcinate at 800°C for 60 minutes to obtain quicklime, and cool it down to room temperature naturally;

[0033] (2) According to the gray-water ratio of 1g:8mL, mix quicklime with hot water at 80°C, stir and age for 24 hours, and then sieve through a 200-mesh sieve to prepare a calcium hydroxide suspension with a concentration of 1.3mol / L ;

[0034] (3) Put the calcium hydroxide solution in the reaction kettle, add 1.2% of its mass modifier, stir and react at 55°C and 210r / min for 120min, and then vacuum dry at 60°C to obtain calcium hydroxide solid ;

[0035] The mixed modifier is obtained by mixing sodium stearate and polyvinyl alcohol 124 according to a mass ratio of 1:0.5;

[0036] (4) Calcinate the obtained calcium hydroxide solid at 800°C for 3 hours, then cool it to room temperature, put it in...

Embodiment 3

[0039] A preparation method of high-purity calcium oxide, comprising the following steps:

[0040] (1) Crush the limestone into 2cm particles, then put it into the calciner and calcinate at 700°C for 50 minutes to obtain quicklime, and cool it down to room temperature naturally;

[0041] (2) According to the gray-water ratio of 1g:7mL, mix quicklime with hot water at 80°C, stir and age for 24 hours, and then sieve through a 200-mesh sieve to prepare a calcium hydroxide suspension with a concentration of 1.3mol / L ;

[0042] (3) Take the calcium hydroxide solution and place it in a reaction kettle, add a mixed modifier of 1% of its mass, stir and react at 45°C, 140~210r / min for 80min, and then dry it in vacuum at 55°C to obtain hydroxide calcium solids;

[0043] The mixed modifying agent is obtained by mixing sodium stearate and polyvinyl alcohol 124 according to a mass ratio of 1:0.4;

[0044] (4) Calcinate the obtained calcium hydroxide solid at 700°C for 2 hours, then cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com