Patents

Literature

46results about How to "Uniform crystal form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

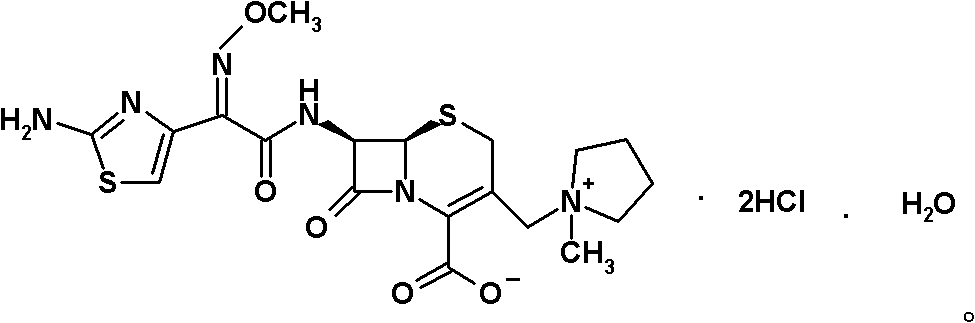

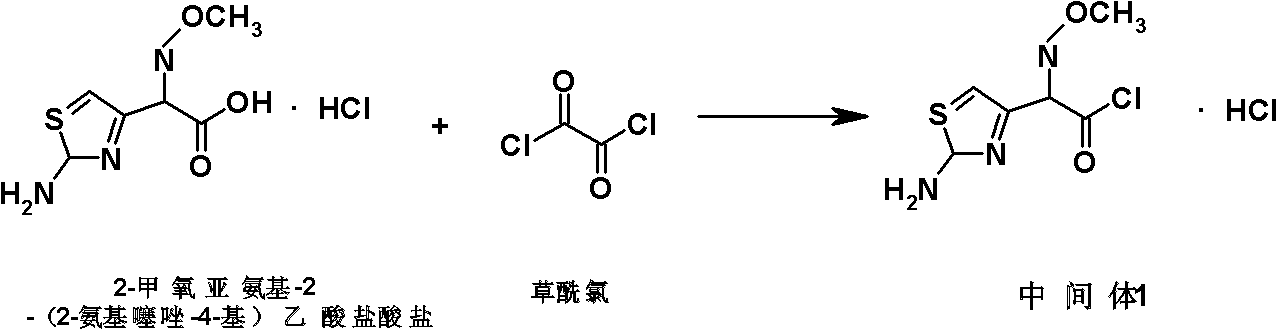

Preparation method of cefepime hydrochloride

ActiveCN101935325ASimple processAvoid the phenomenon of inhomogeneous crystal form and poor fluidityOrganic chemistryCefepime hydrochlorideBetaine

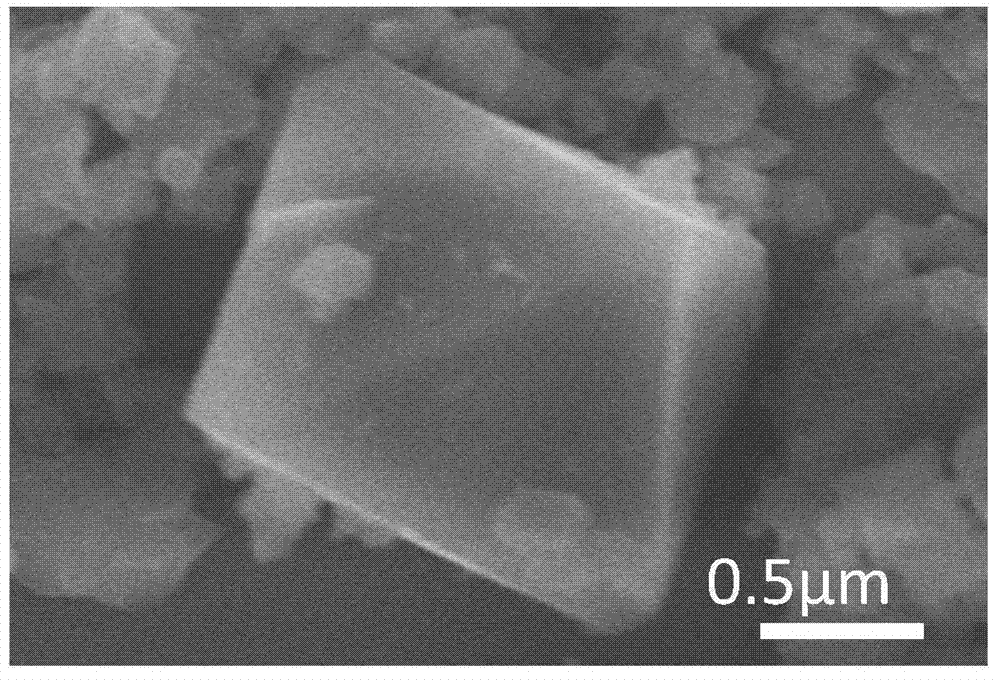

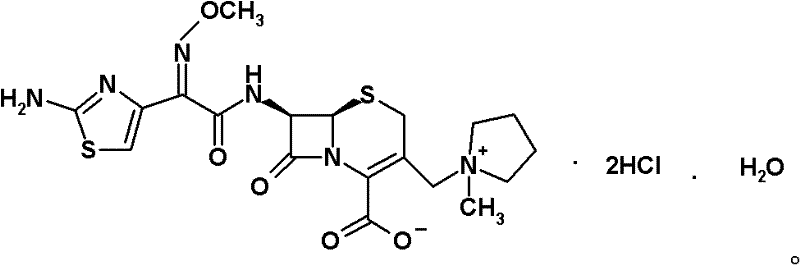

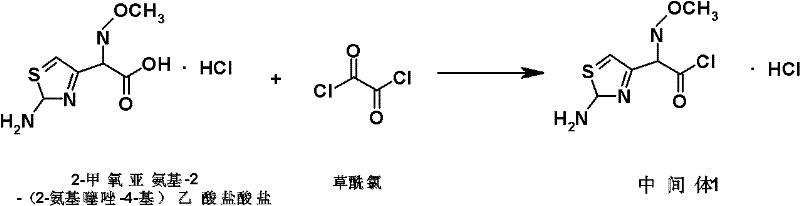

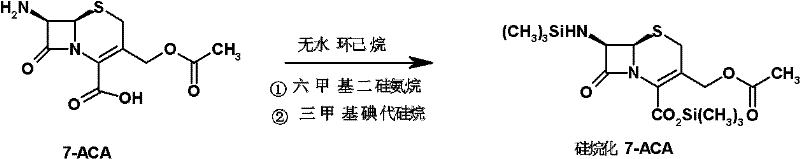

The invention discloses a preparation method of cefepime hydrochloride, comprising the following steps of: reacting oxalyl chloride with 2-methoxyimino-2-(2-aminothiazole-4-yl) acetic acid hydrochloride to obtain a midbody I, i.e. 2-methoxyimino-2-(2-aminothiazole-4-yl) acetyl chloride hydrochloride; mixing silanized 7-aminoce-phalosporanic acid and silanized N-methylpyrrolidine, and reacting to obtain a midbody II, i.e. hydriodic acidification (6R, 7R)-7-amino-3-[(1-methyl-1-tetrahydro pyrrolidine) methyl]-3-cephem-4-formic betaine, in the presence of trimethyl idodine silicon hydride, isopropanol and an aqueous solution of hydrogen iodide; dissolving the midbody II into dichloromethane, sequentially adding trimethylchlorosilane and hexamethyldisilazane for reaction, and then adding the midbody I and triethylamine to react to prepare the cefepime hydrochloride. The cefepime hydrochloride prepared by the method has the advantages of uniform crystal form, good flowability and simple process and is suitable for industrialized production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

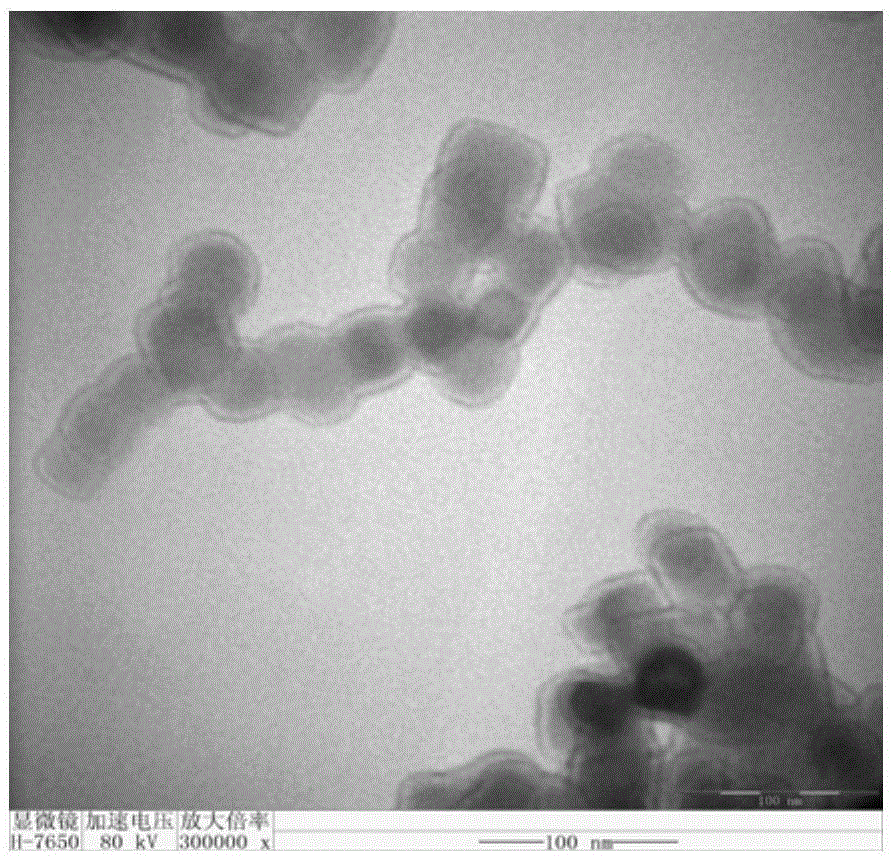

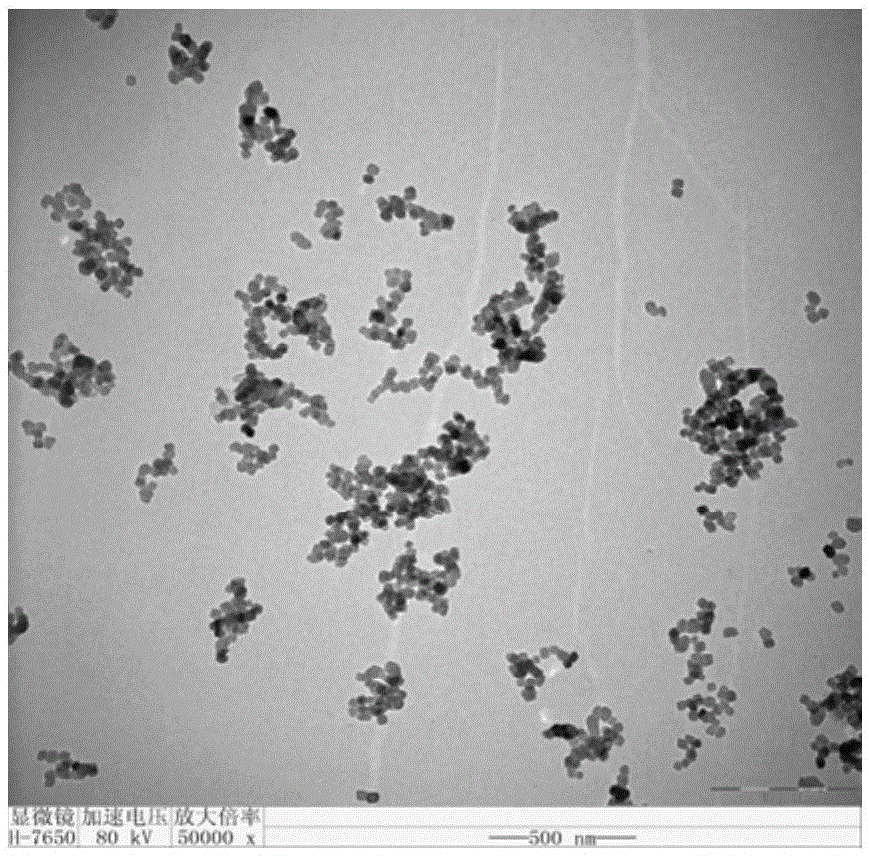

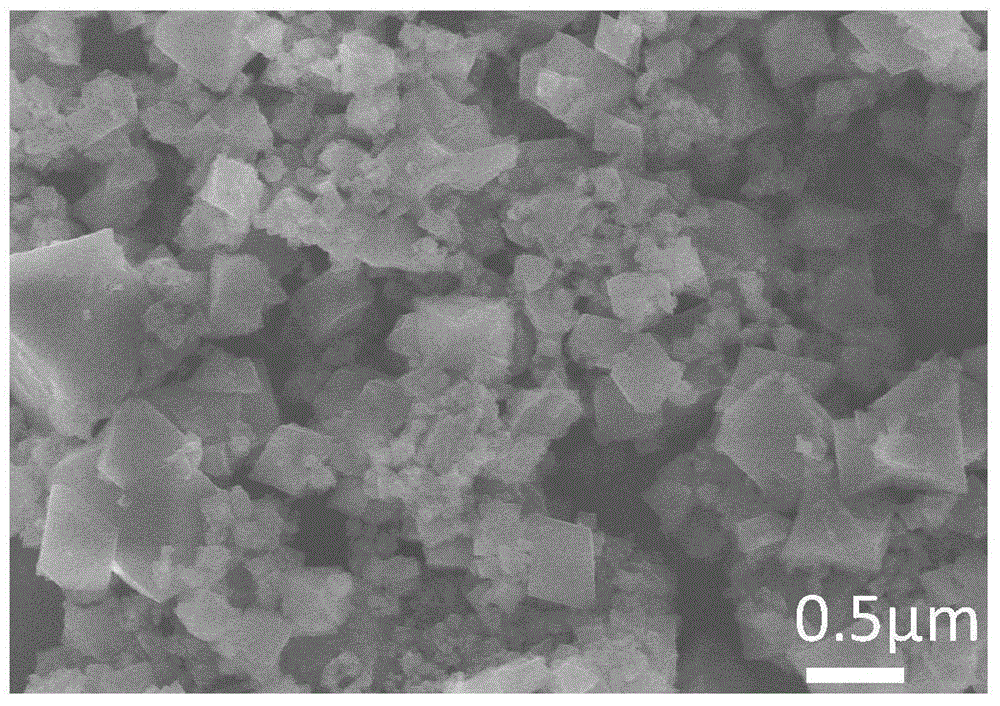

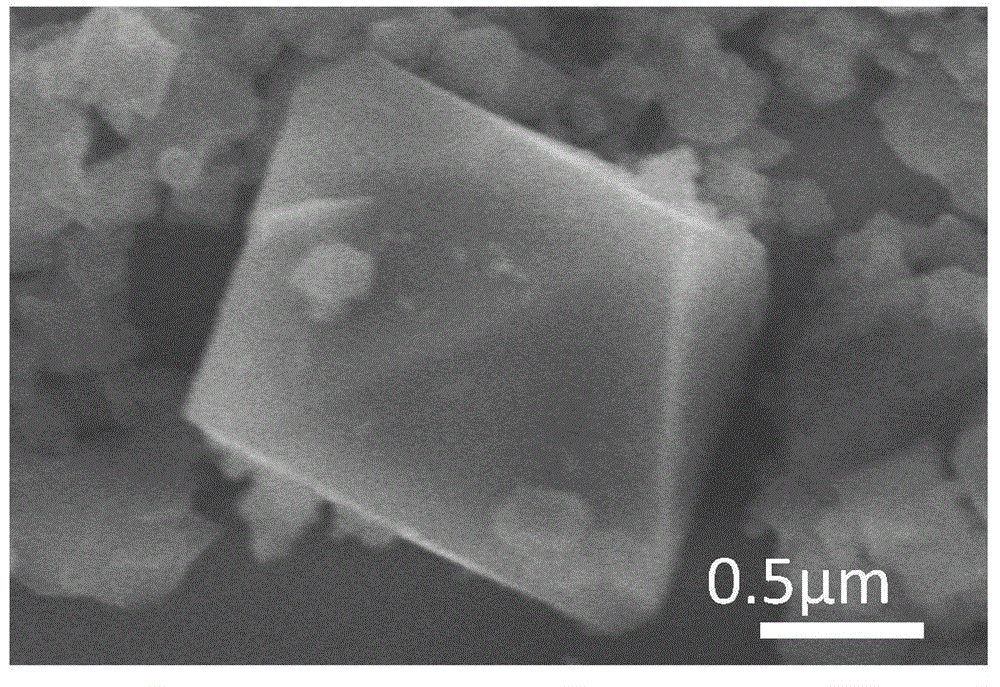

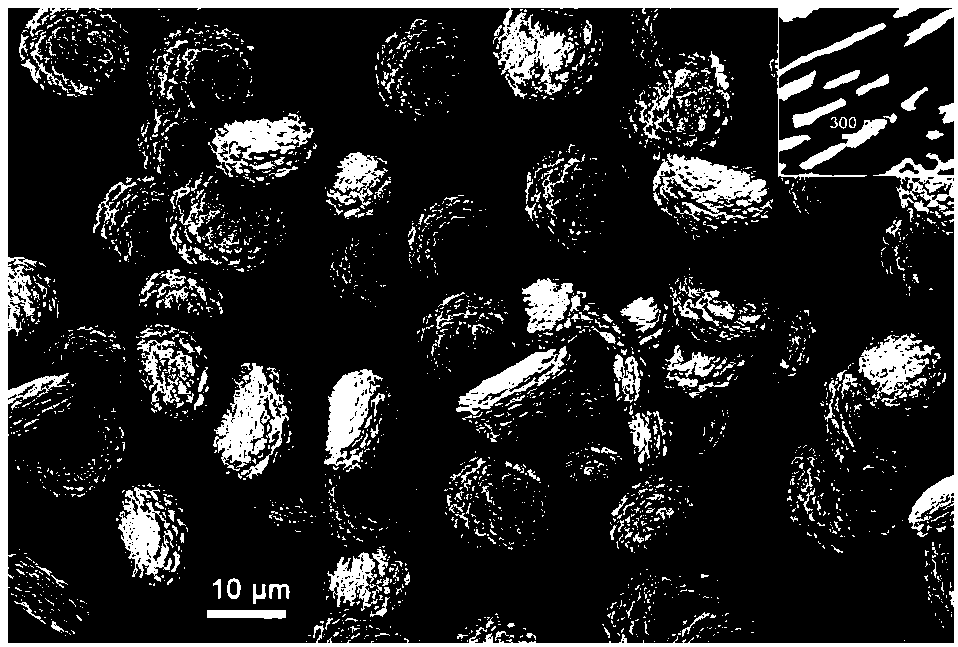

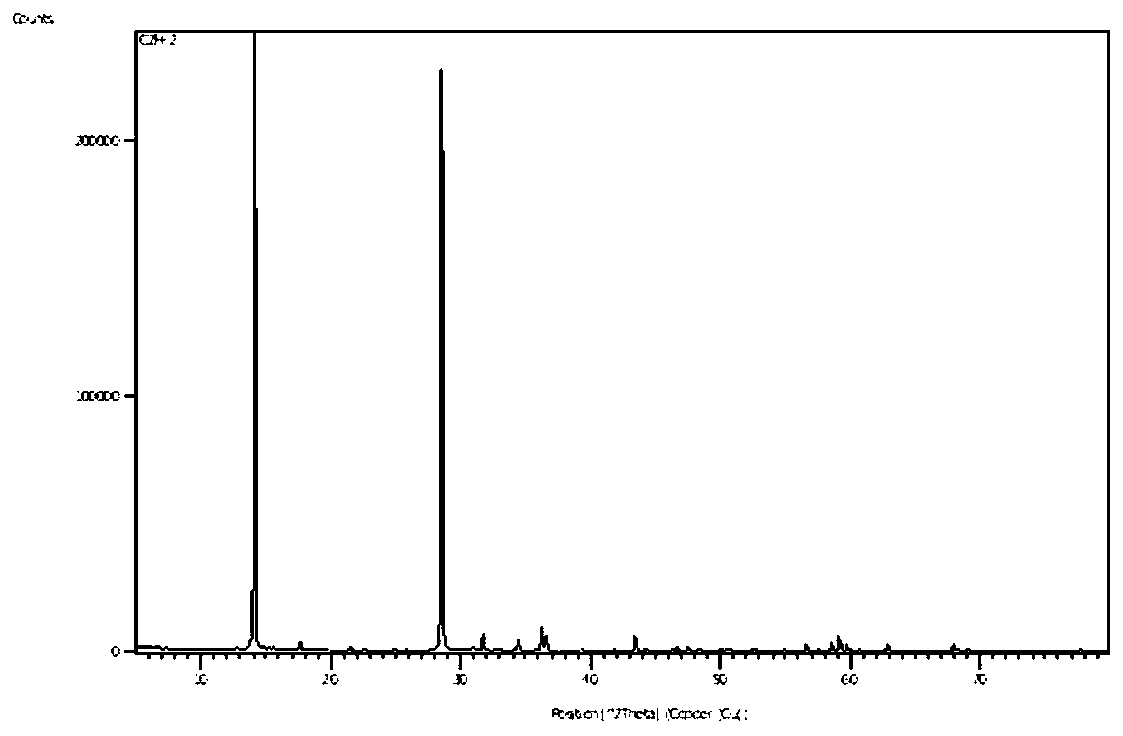

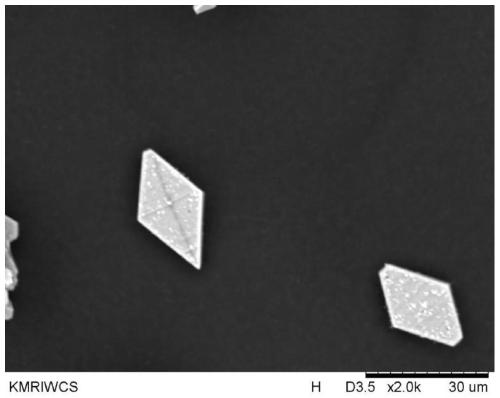

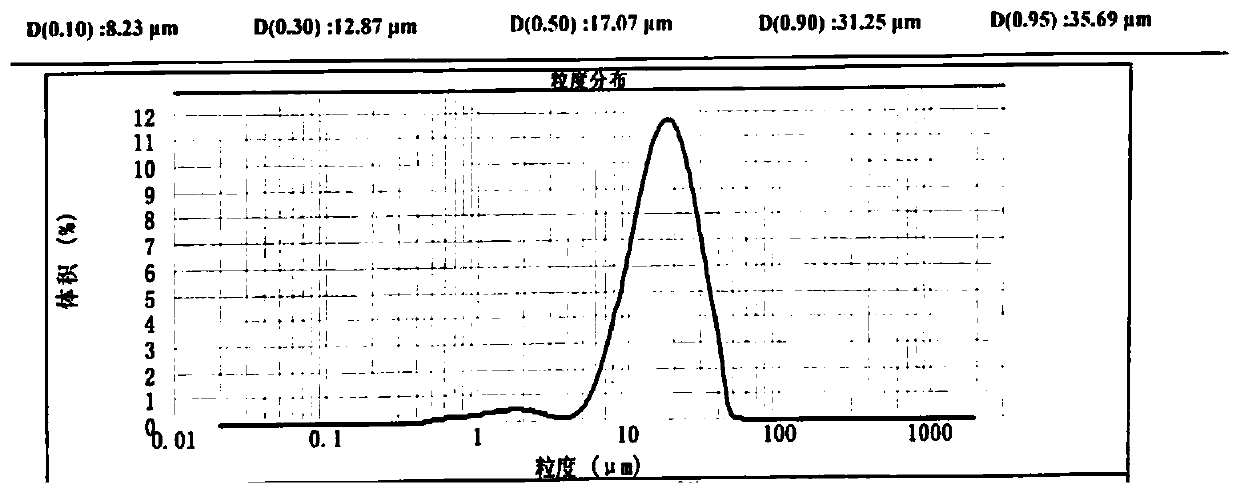

Cubic CaCO3 and SiO2 composite particles and preparing method thereof

InactiveCN105417565AIncrease profitGood dispersionCalcium/strontium/barium carbonatesMaterial nanotechnologyCalcium hydroxideCarbonization

The invention discloses a preparing method for cubic CaCO3 and SiO2 composite particles. The preparing method includes the steps that nano calcium carbonate prepared through a carbonization method is used as a raw material, while calcium hydroxide is carbonized into calcium carbonate, surface modification is carried out by using sulfuric acid as a crystal form control agent, polyethylene glycol as a dispersing agent and silica sol as a surface modifier, the surface of calcium carbonate is coated with nano silica sol, and the cubic CaCO3 and SiO2 composite particles are prepared through one step. Compared with a traditional method, the preparing method adopts the one-step method and has the advantages of being short in time, high in efficiency, easy to operate, low in cost and the like. The obtained cubic CaCO3 and SiO2 composite particle product is uniform in size and crystal form, pure and free of impurities and is coated completely.

Owner:GUANGXI UNIV +1

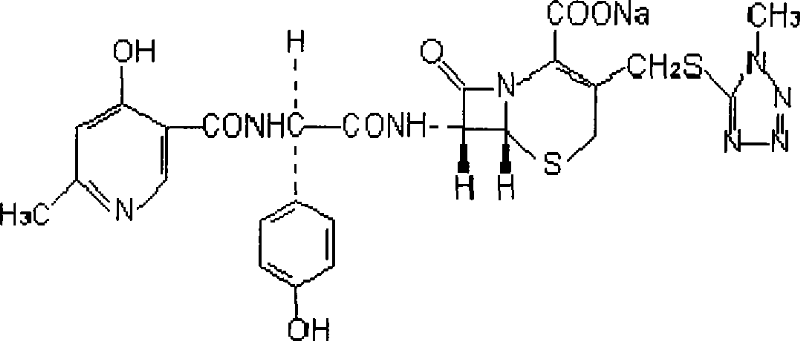

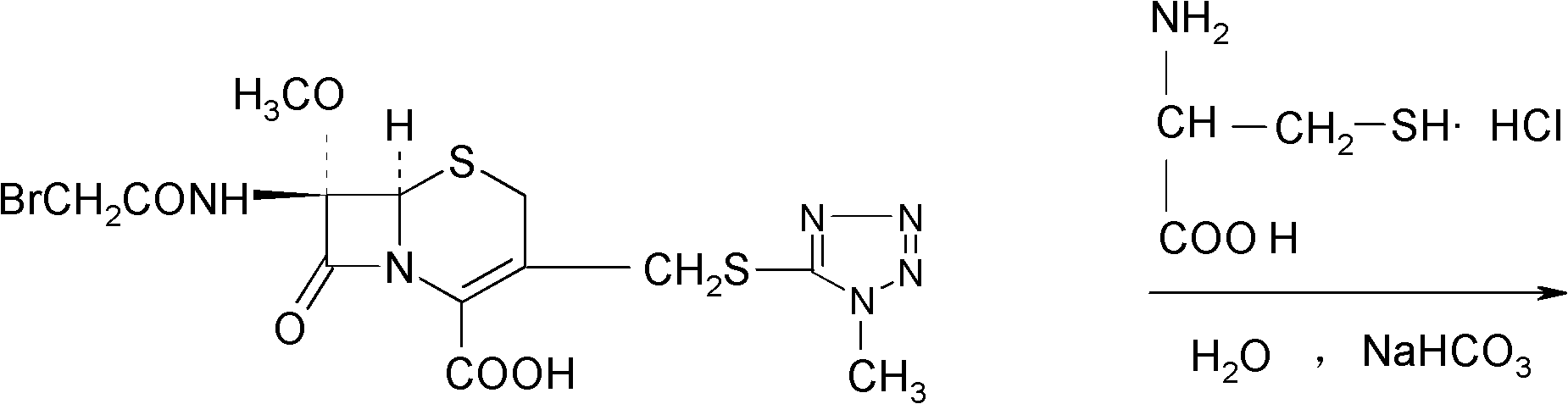

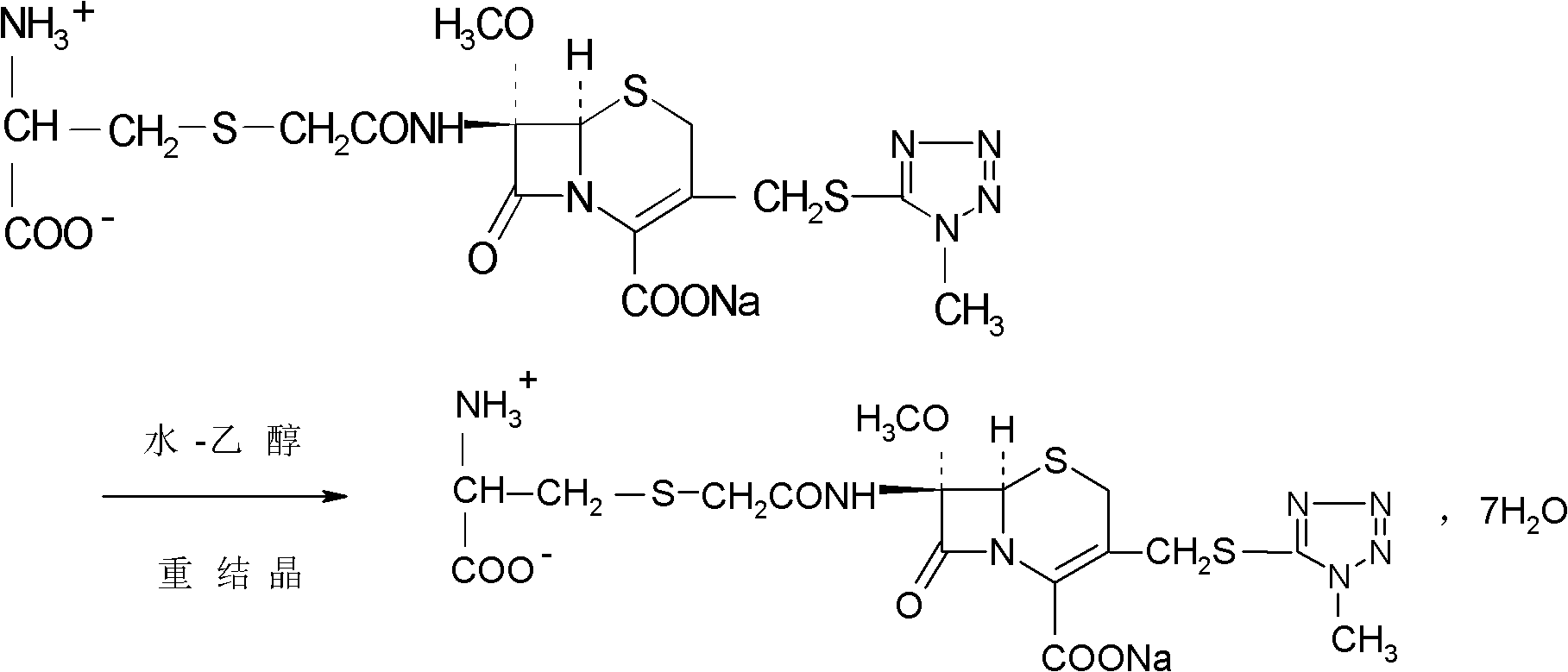

Method for synthesizing compound of cefpiramide sodium

The invention relates to a synthesis method of cefpiramide sodium, including reacting of cefpriamide free acid with triethylamine, diethylamine or diethylamine in the organic solvent in -10-40 deg c, then getting mixture after reaction, dripping 10-15wt% sodium sulfocyanate acetone solution, adjusting pH to 6-8, filtering, drying to obtain cefpiramide sodium. The synthesis cefpiramide sodium has an even polytype, a good color, a high purity, and a good product stability and a safe conservation.

Owner:武汉同源药业有限公司

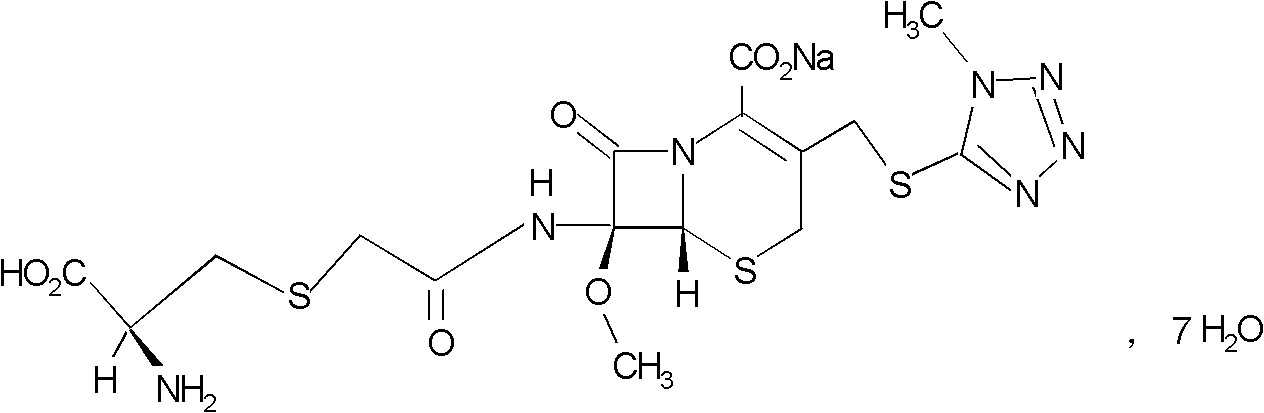

Preparation method of cefminox sodium

The invention discloses a preparation method of cefminox sodium, which comprises the following steps: 7 beta-bromoacetamide-7 alpha-methoxy-3-(1-methyl-1H-5-tetrazyl)sulfur methyl-3- cephem-4-carboxylic acid and D-cysteine hydrochloride are dissolved in water, the pH value is regulated to 6.0-7.0 by sodium bicarbonate, condensation reaction is carried out, and reaction products are post-treated to obtain the cefminox sodium. In the method, cefminox sodium raw material can be prepared through low-temperature reaction, a nonpolar macroporous resin X5 chromatography column is used for purification, ethanol-aqueous solution or anhydrous alcohol recrystallization and other simple operations are adopted to obtain target products, the yield and the purity of the target products are high, the products have uniform crystal forms and good fluidity, no special equipment is needed for the production, and the method is suitable for industrial production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

Method for preparing recombinant human insulin crystal

InactiveCN105753966AUniform crystal formLarge particlesPeptide preparation methodsInsulinsOrganic solventHazardous substance

The invention provides a method for preparing recombinant human insulin crystal, and belongs to the technical field of protein crystallization. According to the method, zinc ions are subjected to three times of crystallization, the obtained insulin crystal is large in particle size and good in homogeneity, phenols or organic solvents used in normal methods are not used in the method, so that residues of harmful substances in the product are avoided and the quality of the insulin crystal is improved; moreover, the method is stable in preparation process and beneficial to industrial production.

Owner:TONGHUA DONGBAO PHARMA

Method for producing natural bornite products

The invention relates to a production method of natural mottled copper products, belonging to the technical field of metallic material processing. The inventive method comprises the steps of sculpturing and molding, mould fabrication, molten mould duplication, pattern die fabrication, demoulding, smelting, casting, secondary crystallization, forging molding, polishing, sintering, mottle formation, dyeing, inspection and packaging, wherein the smelting step comprises: (a) directly adding metal elements (including Si, Al, Pb, Sb, S, Na, Ba, Ag, Mg, Zn, P and B) into the molten liquid of natural mottled copper when the smelting temperature reaches 1100-1280 DEG C, the usage amount of Zn being 1-10 percent and the rest 0.5-5 permillage; (b) the secondary crystallization and forging molding steps are added following the casting step. The other steps and operational conditions of the inventive method are the same as the prior art. Compared with the prior art, the invention has the advantages of delicate appearance, multi-crystalline property and uniform size of crystal type, good three-dimensional effect, and improved quality of natural mottled copper products.

Owner:张建中

High-purity silicon carbide, silicon carbide wafer and preparation method of high-purity silicon carbide

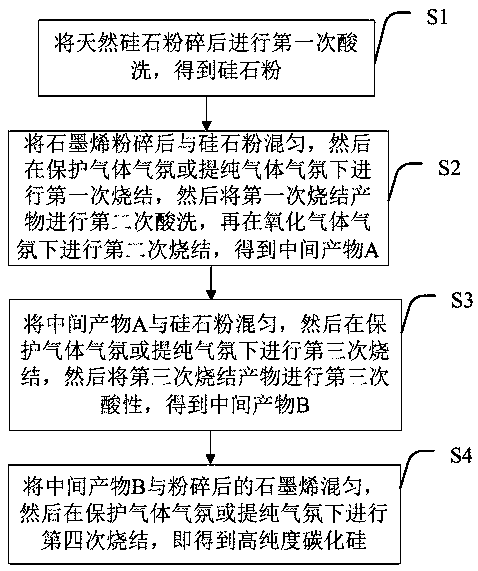

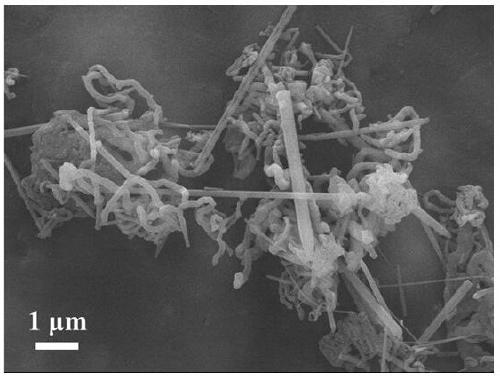

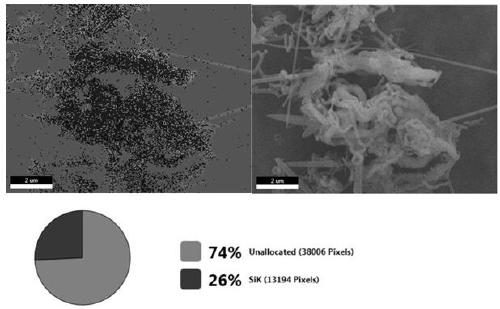

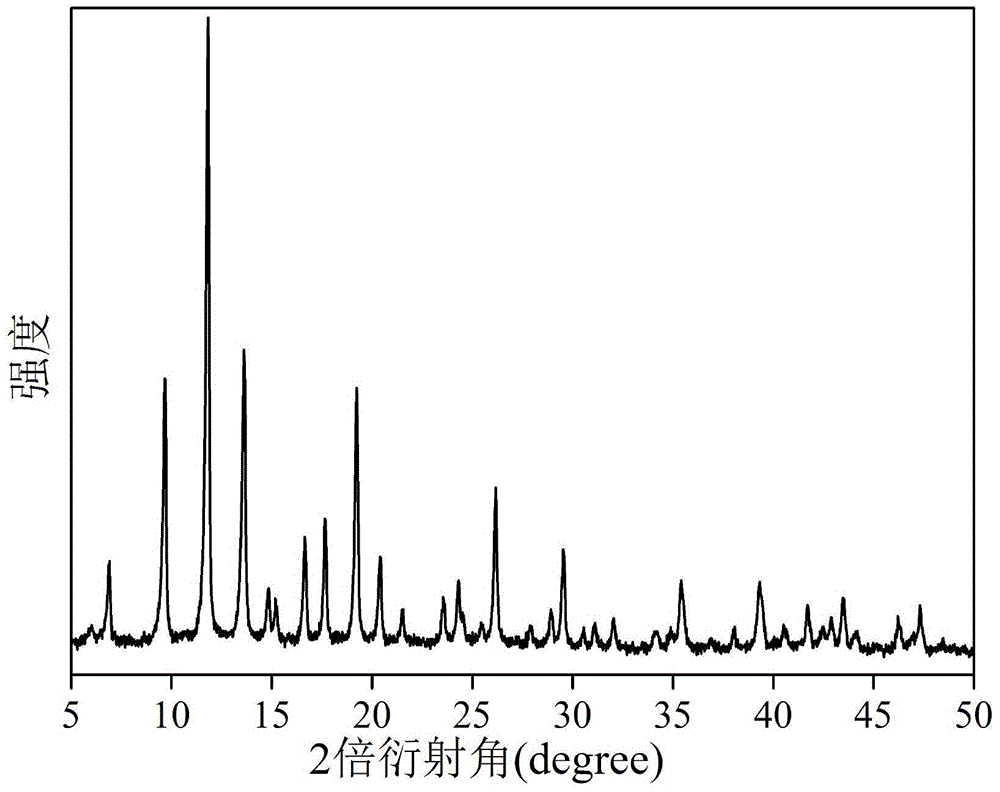

ActiveCN110104651AImprove integrityUniform sizePolycrystalline material growthNanotechnologyShielding gasCvd graphene

The invention discloses high-purity silicon carbide, a silicon carbide wafer and a preparation method of high-purity silicon carbide. The preparation method of high-purity silicon carbide comprises the steps that natural silica is pulverized and subjected to first pickling to obtain silica powder; graphene is pulverized and uniformly mixed with the silica powder, the mixture is subjected to firstsintering under a protective gas atmosphere or a purified gas atmosphere, and a first sintering product is subjected to second pickling and then subjected to second sintering under an oxidizing gas atmosphere to obtain an intermediate product A; the intermediate product A is uniformly mixed with the silica powder and then subjected to third sintering under a protective gas atmosphere or a purification atmosphere, and a third sintering product is subjected to third pickling to obtain an intermediate product B; the intermediate product B is uniformly mixed with the pulverized graphene and then subjected to fourth sintering under a protective gas atmosphere or a purification atmosphere to obtain high-purity silicon carbide. The problems are solved that preparation processes of high-purity silicon carbide in the prior art are complicated and the cost is too high.

Owner:SHENZHEN EIGEN EQUATION GRAPHENE TECH CO LTD

Method for electrochemical synthesis of Cu3 (BTC) 2 as catalyst and NH3-SCR application of Cu3 (BTC) 2

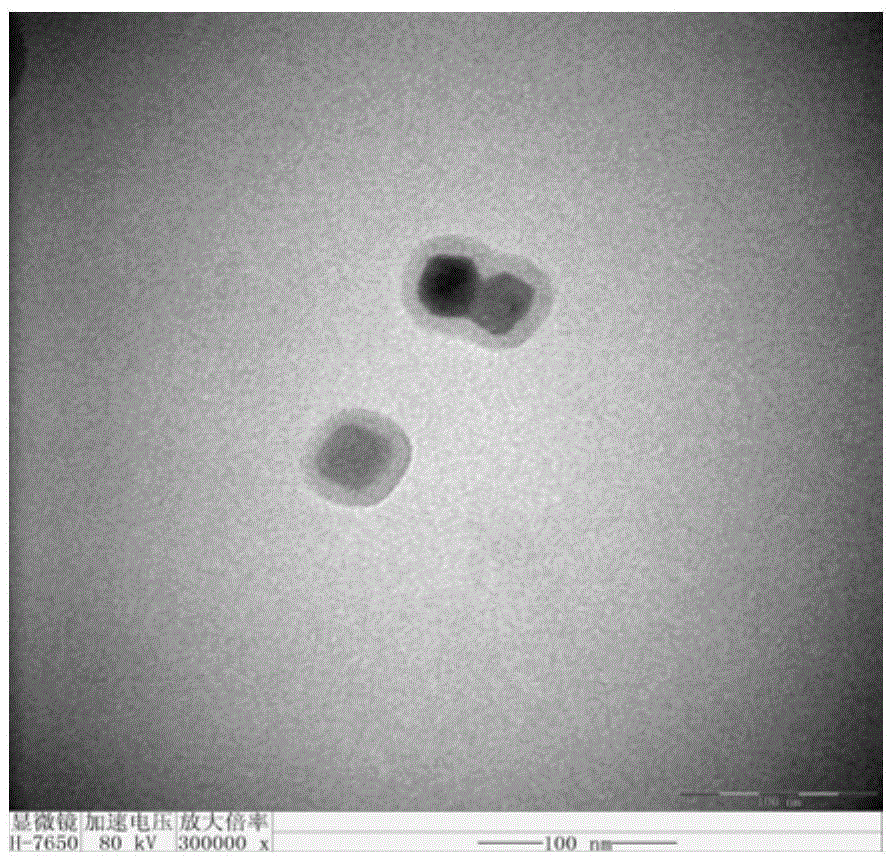

InactiveCN104801341AUniform crystal formFlexible approachOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationEthylenediamineOctahedron

The invention relates to a method for electrochemical synthesis of Cu3 (BTC) 2 and belongs to the field of preparation technologies of catalytic material and nanometer material. The method comprises the following steps: preparing a mixed solution of 1-butyl-3 methylimidazole bromide, trimesic acid, methyl alcohol and ethyl alcohol, adopting a copper electrode as an anode and a platinum electrode as a cathode, and adjusting the impressed voltage through a mixed solution of EDTA and DETA for electrolysis to obtain the Cu3 (BTC) 2 material. According to the invention, the adopted raw materials are cheap and easy to obtain, the operation is simple and easy, the preparation method is simple and easy to control, the equipment requirements are low, the environmental friendliness is achieved, and the Cu3 (BTC) 2 material is of a regular octahedron structure and has a diameter of 10-20 nm and a specific area of 950 m<2>g<-1>; the test conditions of the reaction are as follows: 500 ppm of NO, 500 ppm of NH3, 5% of O2, N2 as balance gas, the total flow of exhaust gas being 100ml / min, and the denitration catalytic efficiency reaching 100% at 230-280 DEG C.

Owner:DALIAN UNIV OF TECH

Medicine composition without any excipients and preparation process thereof

ActiveCN101524345AImprove molding qualityGood lookingNervous disorderPharmaceutical delivery mechanismVacuum pressurePharmaceutical preservatives

The invention relates to a medicine composition without any excipients and a preparation process thereof; the invention carries out deep and careful research to the composition of sodium vedproate for injection and the preparation process, finally, the medical prescription, only containing effective ingredients: sodium vedproate and water, is determined. By adopting a plurality of critical processes in the adjusting and freeze-dry process, namely, in the pre-freezing step, the medicine composition is kept for a long time at the eutectic point of -2 degrees, so as to ensure a crystal nucleus to be big enough; vacuum pressure is adjusted in the steps of a first drying and a second drying, the action is repeated in a large-range vacuum degree with mass transferring and heat transmission principles. Under the condition that any excipients are not used, the appearance of the freeze-dry products and the compound dissolubility are remarkably improved, the freeze-dry time is obviously shortened, and the energy source is saved.

Owner:SHENYANG XINMA PHARMA

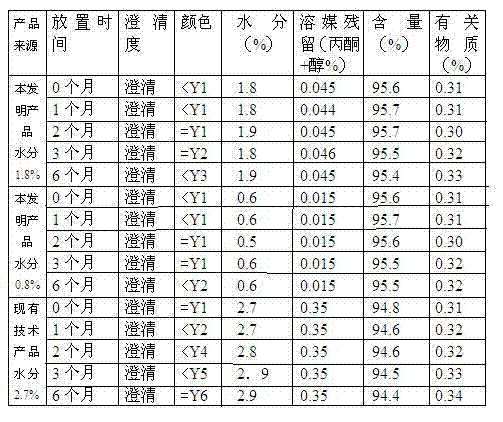

Preparation method of low-moisture and high-stability sterile cefuroxime sodium

The invention discloses a preparation method of low-moisture and high-stability sterile cefuroxime sodium, which comprises the steps of (a) dissolving cefuroxime acid in an anhydrous mixed solvent, decolorizing, conducting sterile filtration, collecting filter liquor to a crystallizing tank, (b) dissolving soda in an organic solvent, decolorizing, conducting the sterile filtration, collecting filter liquor to a sodium solution metering tank, (c) controlling temperature for 10-50min, adding a soda solution into the crystallizing tank dropwise, controlling a stirring rate at 20-60r / min, crystallizing, adding acetone after the sterile filtration to ensure full crystallizing; (d) pressing crystallized liquid in a three-in-one multifunctional tank for filtration, washing with the mixed solvent, drying at 30-60 DEG C, obtaining the sterile cefuroxime sodium, and (e) transferring materials in a sterile bicone at 30-70 DEG C, continuing to dry under reduced pressure for 2-5h, and obtaining the sterile cefuroxime sodium with better stability and the moisture less than 1%. The preparation method is short in drying time and simple and practicable, the sterile cefuroxime sodium is easy to smash, low in moisture, less in solvent residual and stable in quality, the color, clarity and color points of the sterile cefuroxime sodium are not affected, and the production cost is lowered.

Owner:潘行远

Production technology and application of calcium hydrophosphate

InactiveCN102992292AComplete crystal formRegular crystal formPhosphorus compoundsLuminescent compositionsSlurryDigestion

The invention relates to a production technology and application of calcium hydrophosphate. The production technology comprises the following steps of: by using an ammonium dibasic phosphate and a calcium chloride solution as raw materials, carrying out double liquid phases to obtain hydryoxyapetite by stirring at a certain temperature and flow rate, then dewatering through a belt filter to separate and washing a mother liquid till chloride ions reach 500PPM, thus obtaining hydryoxyapetite; adding a certain amount of deionized water to hydryoxyapetite, adjusting a slurry ratio to be in line with technological requirements, adding a certain amount of acid, carrying out high-temperature digestion after adjusting a pH value, observing the state of the slurry after raising the temperature to 90 DEG C, stopping heating when the slurry is expanded and solidified, and removing two crystal water after settling for 30 minutes, thereby obtaining calcium phosphate dibasic anhydrous; carrying out washing chlorine, dewatering, drying and sieving, thus obtaining the calcium hydrophosphate finished product. The production technology has the advantages that the synthetic technology is simple, raw materials are easily obtained, by-products can be recycled, and the environmental pollution is little.

Owner:LIAONING GOLDEN ANCHOR IND

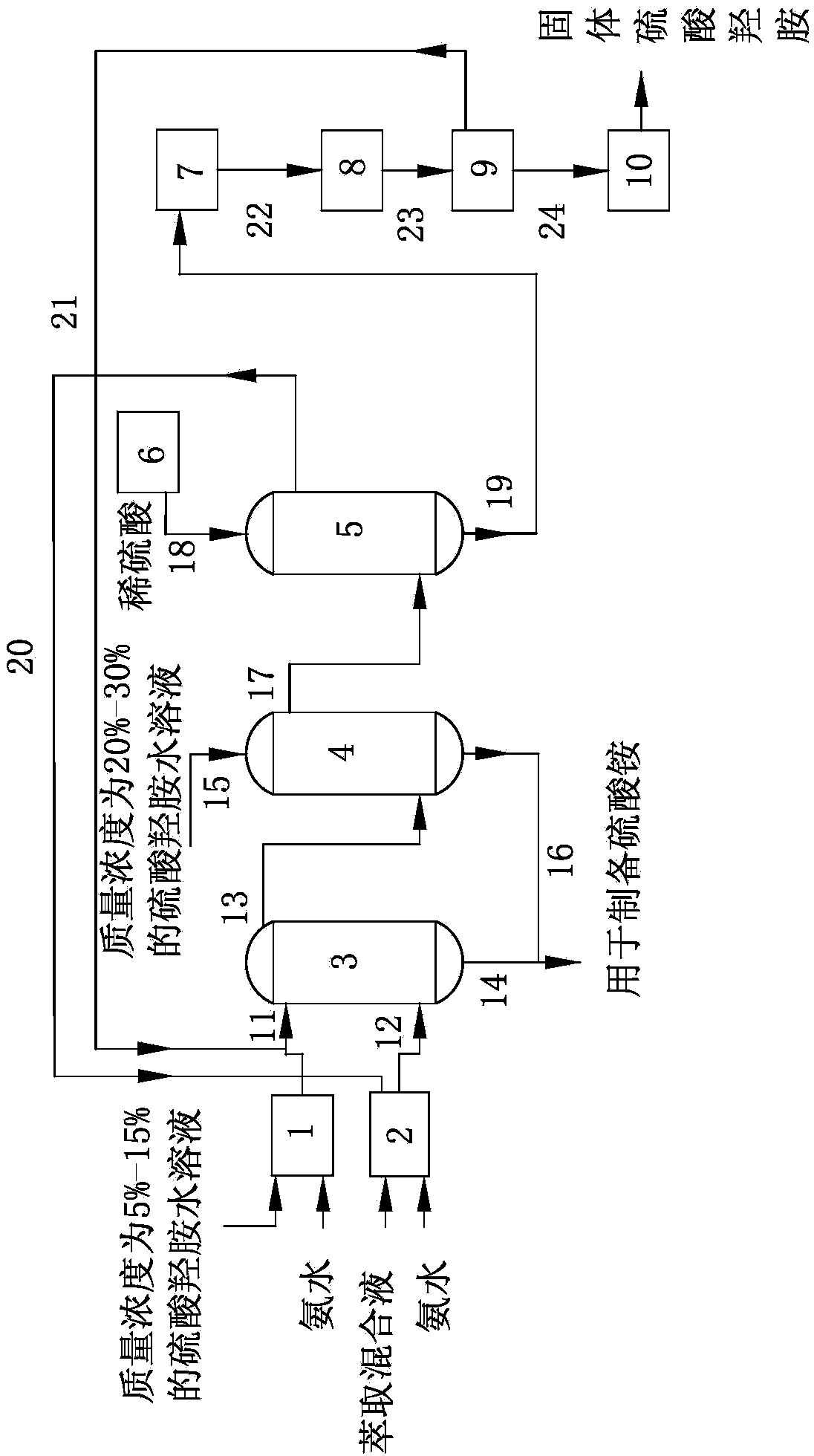

Preparation method of high-purity solid hydroxylamine sulphate

The invention discloses a preparation method of high-purity solid hydroxylamine sulphate. The preparation method of the high-purity solid hydroxylamine sulphate comprises the following steps: adding a 5-15% hydroxylamine sulphate aqueous solution into a first reactor, mixing the hydroxylamine sulphate aqueous solution with 18-23% ammonia water, controlling the temperature of the first reactor to 20-30 DEG C, and regulating the pH value of the solution to 5.8-6.5, so that a first reaction product is obtained; fully mixing an extracting agent, a diluter and a stabilizer in a volume ratio of 1:(3-3.5):(0.001-0.002), putting the obtained mixture into a second reactor, regulating the pH value to 7.0-7.8 by adopting 18-23% ammonia water, and controlling the temperature of the second reactor to 20-30 DEG C, so that a second reaction product is obtained; carrying out extraction, concentration, cold crystallization, centrifugation and vacuum drying on the first reaction product and the second reaction product, so that the target product high-purity solid hydroxylamine sulphate is obtained. The preparation method of the high-purity solid hydroxylamine sulphate has the advantages of simple temperature, mild reaction conditions, high yield and low cost.

Owner:QUZHOU JUHUA POLYAMIDE FIBER

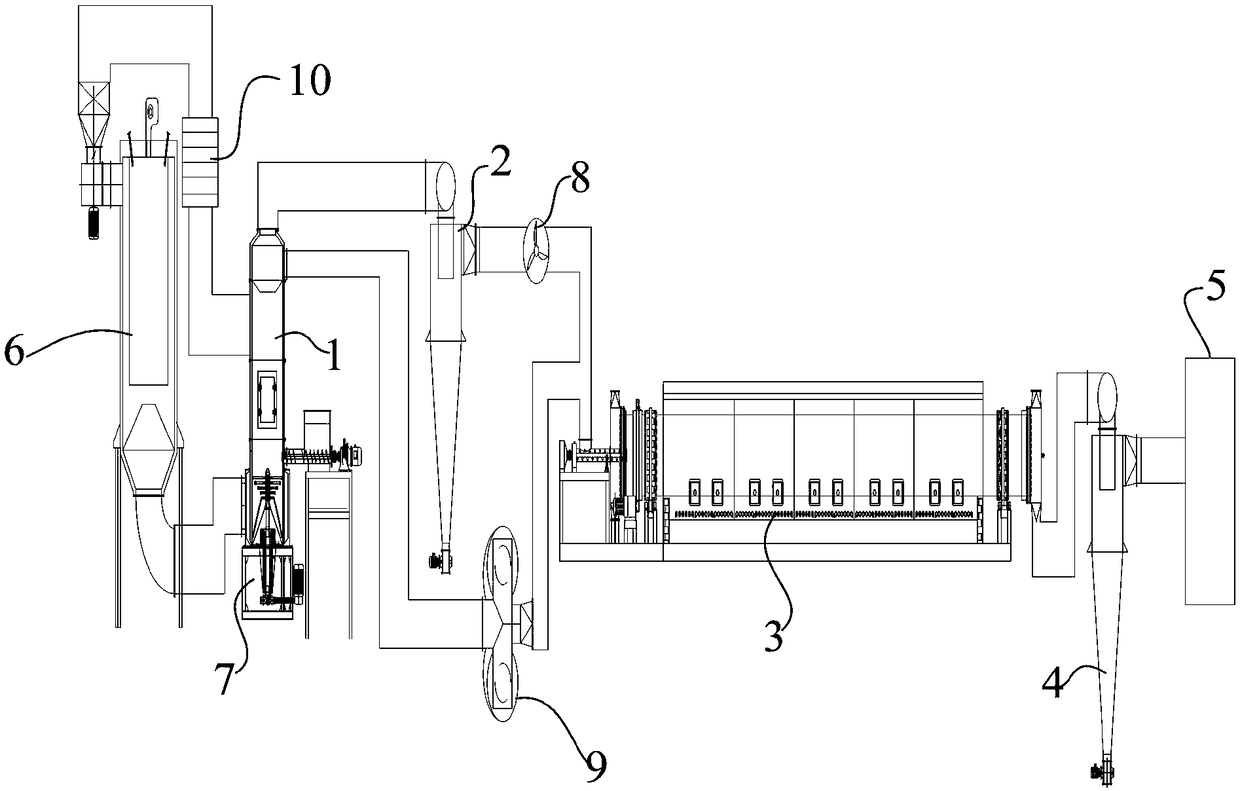

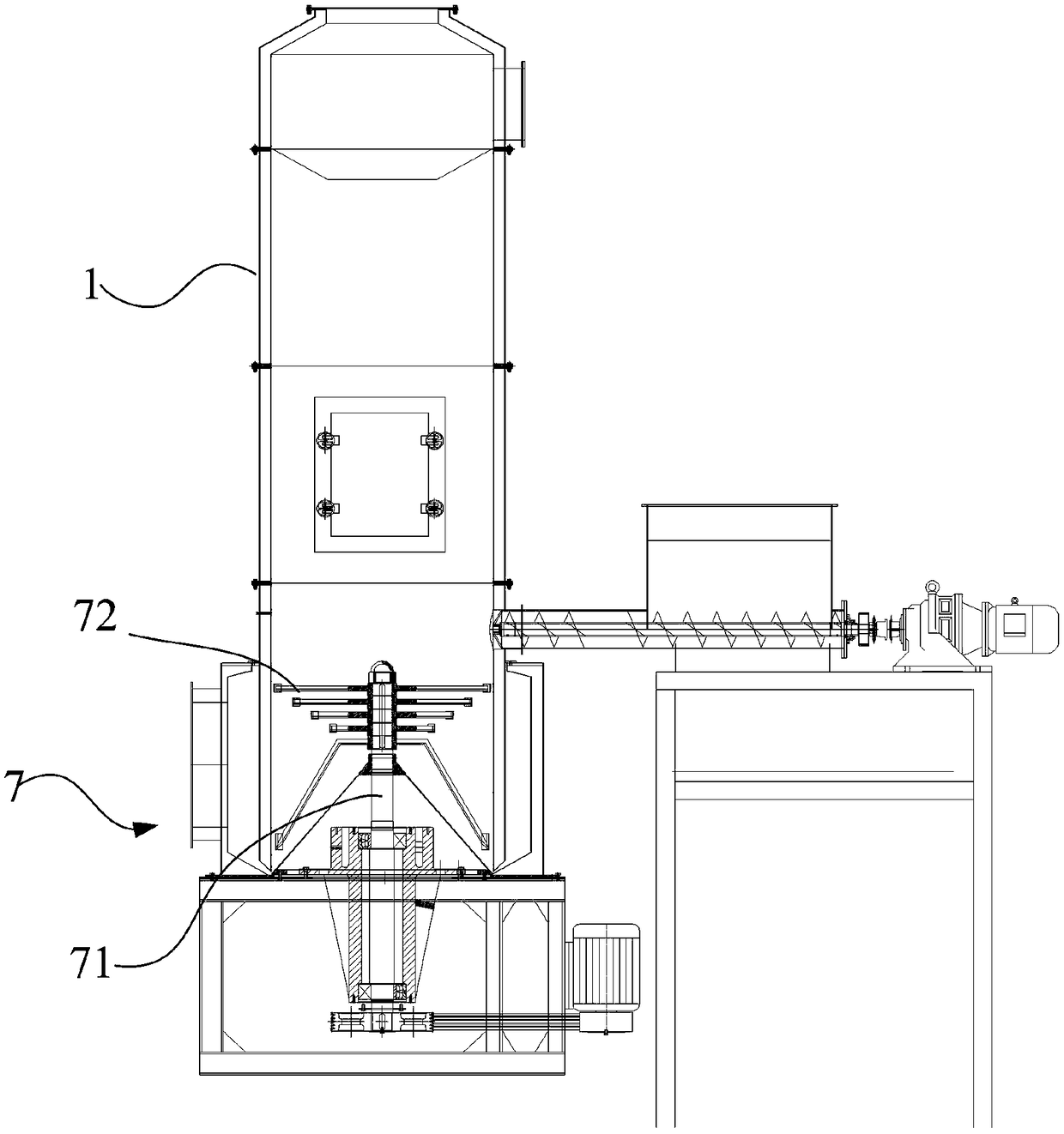

Iron phosphate continuous dehydration and crystal form controllable system and control method thereof

InactiveCN108731429AImprove sintering efficiencyCrystal form controllableRotary drum furnacesDrying gas arrangementsElectric heatingIron phosphate

The invention belongs to the field of iron phosphate preparation, and particularly relates to an iron phosphate continuous dehydration and crystal form controllable system and a control method thereof. The system comprises a flash steaming dryer, a cyclone dust collector, a rotary kiln, a second cyclone dust collector and a packaging machine, which are arranged in sequence along a logistical direction; a hot air blower which is used for supplying air to the flash steaming dryer is arranged at one side of the flash steaming dryer; the hot air blower is communicated with the bottom of the flashsteaming dryer; a beater which is used for beating the hot air and forming cyclone in the flash steaming dryer is arranged at the bottom of the flash steaming dryer; a second beater is arranged between the cyclone dust collector and the rotary kiln; the rotary kiln is an external electric heating type rotary calcining kiln; and a flash dry bag filter which is used for collecting free water tail gas not dehydrated by the cyclone dust collector is arranged between the flash steaming dryer and the rotary kiln. The iron phosphate continuous dehydration and crystal form controllable system and thecontrol method thereof are small in investment, low in energy consumption and suitable for large-scale popularization and application.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

Water-soluble nano-titania with adjustable particle size

InactiveCN107043460AParticle size controllableUniform crystal formMaterial nanotechnologyTitanium dioxideHigh pressureDyeing wastewater

The invention provides water-soluble nano-titania with an adjustable particle size. A crystal structure of water-soluble nano-titania is an anatase type, the particle size range is 1nm-100m. Water-soluble nano-titania is prepared by the steps of adding a titanium precursor into a heated and fused polymer, stirring to obtain a sticky mixture, adding concentrated hydrochloric acid, continuing to stir for 20-60 minutes, adding titanium tetrachloride, continuing to stir for 20-40 minutes, finally, transferring the product into a high-pressure reaction kettle, and reacting at 140-180 DEG C for 4-8 hours, washing the product with absolute ethanol, carrying out centrifuging, and drying, so as to obtain water-soluble nano-titania with a surface grafted with the polymer. By adjusting the addition amount of water-soluble nano-titania, the particle size of water-soluble nano-titania can be adjusted and controlled, a preparation method of water-soluble nano-titania is simple and feasible, the preparation process is easy to control, and the problem that nano-titania is very easy to be polymerized and coagulated in a water environment in the prior art can be effectively solved; water-soluble nano-titania has potential market application prospects in the field of printing and dyeing wastewater treatment.

Owner:SICHUAN UNIV

Method for crystallizing psicose from ethanol solution

InactiveCN109748940AImprove primary crystallization rateUniform crystal formSugar derivativesSugar derivatives preparationAnhydrous ethanolAlcohol

The invention provides a method for crystallizing psicose from an ethanol solution. The method comprises the steps that a purified psicose solution is taken, and decompression concentration is carriedout to obtain a solution I; the concentrated solution I is heated, absolute ethyl alcohol is added, decompression concentration is carried out again, so that ethyl alcohol takes away the moisture inthe psicose solution to become an ethanol solution II of the psicose; the absolute ethyl alcohol is added into the concentrated solution II, heating is carried out until the psicose is completely dissolved, slow cooling is carried out, after crystals are separated out, slow cooling is carried out until crystals are no longer added, and a mixed liquor III is obtained; solid-liquid separation is carried out to on the mixed liquor III to obtain a solid IV and a clear liquid V; decompression drying is carried out on the solid IV to obtain psicose crystals; the clear liquid V continues to be concentrated, the above steps are repeated, and crystallization is carried out to obtain remaining psicose crystals. The method for crystallizing psicose from the ethanol solution has the advantages that through the cooling crystallization of the psicose in the ethanol solution, one-time crystallization ratio is high, the crystal forms of crystallization are uniform, the drying preservation and transportation are easy, the preparation process is safe and reliable, the process is simplified, the conventional operability of equipment is strong, and the material consumption is low.

Owner:JILIN COFCO BIOCHEM +2

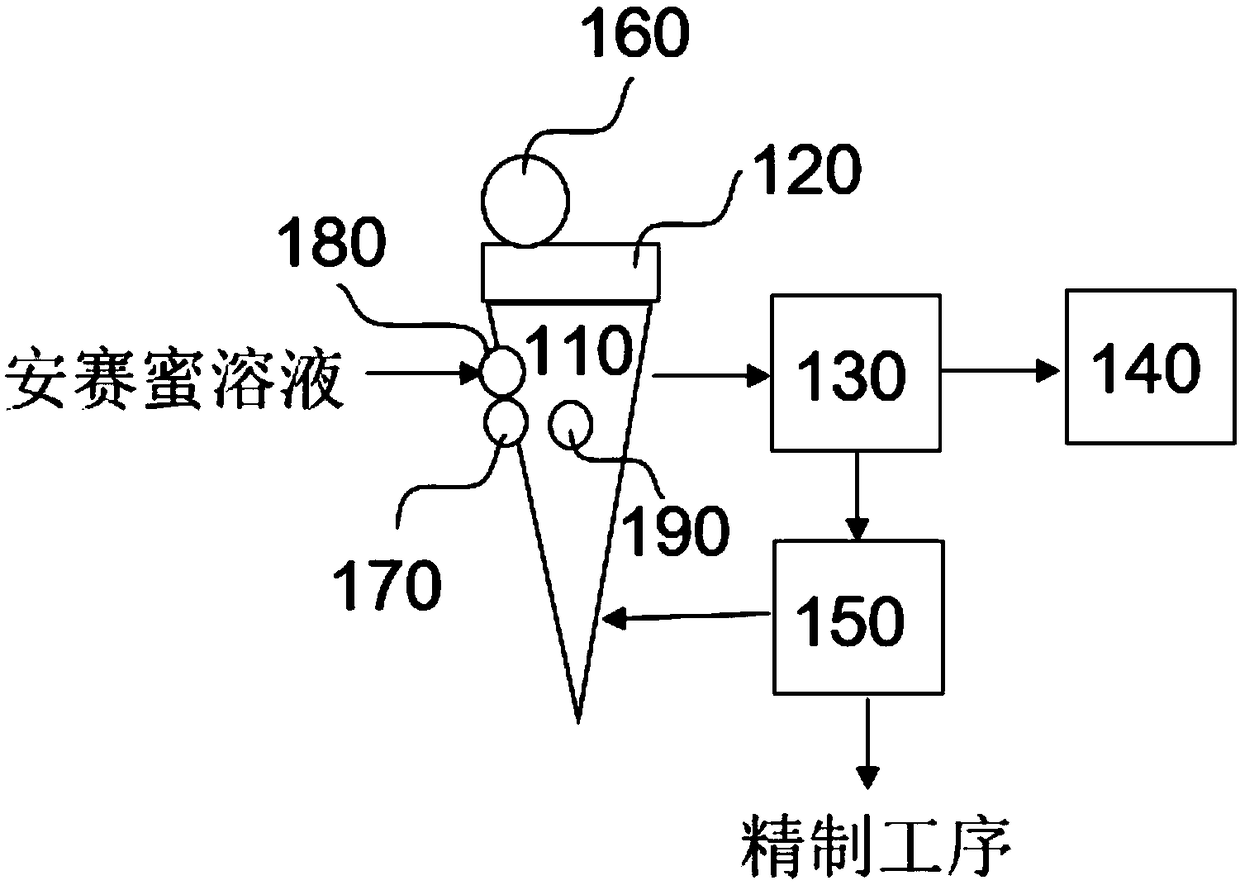

Method and device for continuously and stably preparing acesulfame potassium crystal

ActiveCN109045744AUniform crystal formHigh degree of industrializationOrganic chemistrySolution crystallizationMultiple deviceMother liquor

The invention relates to a method and a device for continuously and stably preparing an acesulfame potassium crystal. The device comprises a decompressing evaporator, a heat exchanger, a crystal kettle, a scraper-type centrifugal machine and a mother liquor tank, wherein the decompressing evaporator is provided with the heat exchanger. The decompressing evaporator is communicated with the crystalkettle. The crystal kettle is communicated with the scraper-type centrifugal machine. The scraper-type centrifugal machine is communicated with the mother liquor tank. The mother liquor tank is communicated with the decompressing evaporator. The device for continuously and stably preparing the acesulfame potassium crystal is capable of solving a series of technical problems existing in an acesulfame potassium crystallization process that the process is tedious, multiple device crossings are existed, crystallization time is long, the crystal is non-uniform, quality is unstable and the like, andproviding a crystallizing device which is continuous in crystallization, uniform in crystal form, stable in technology quality, efficient in production, and high in industrialization degree, and capable of realizing remote control.

Owner:山东亚邦化工科技有限公司

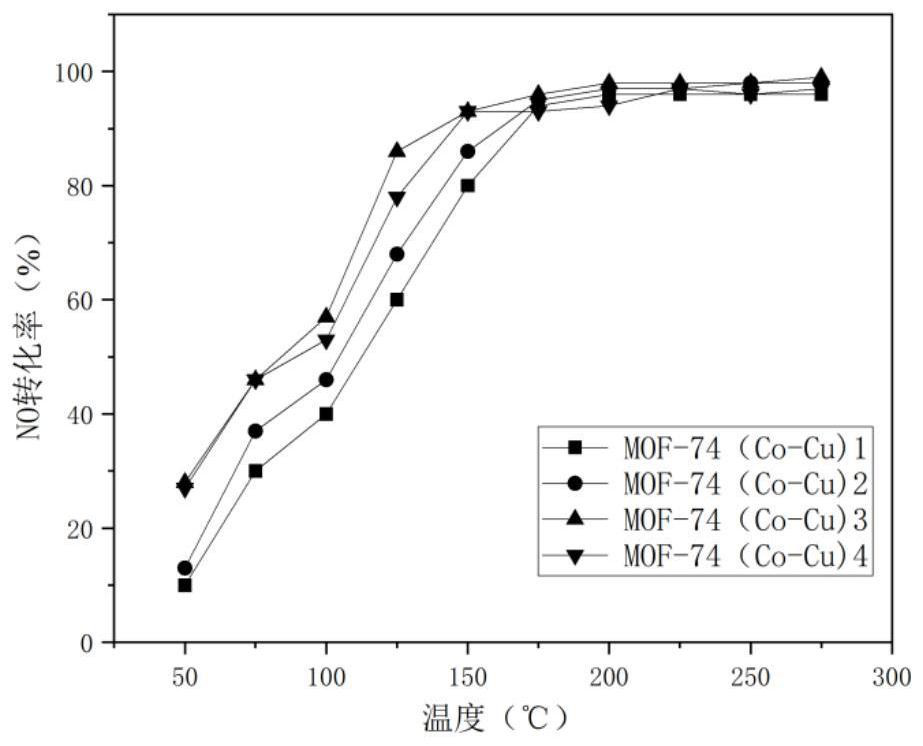

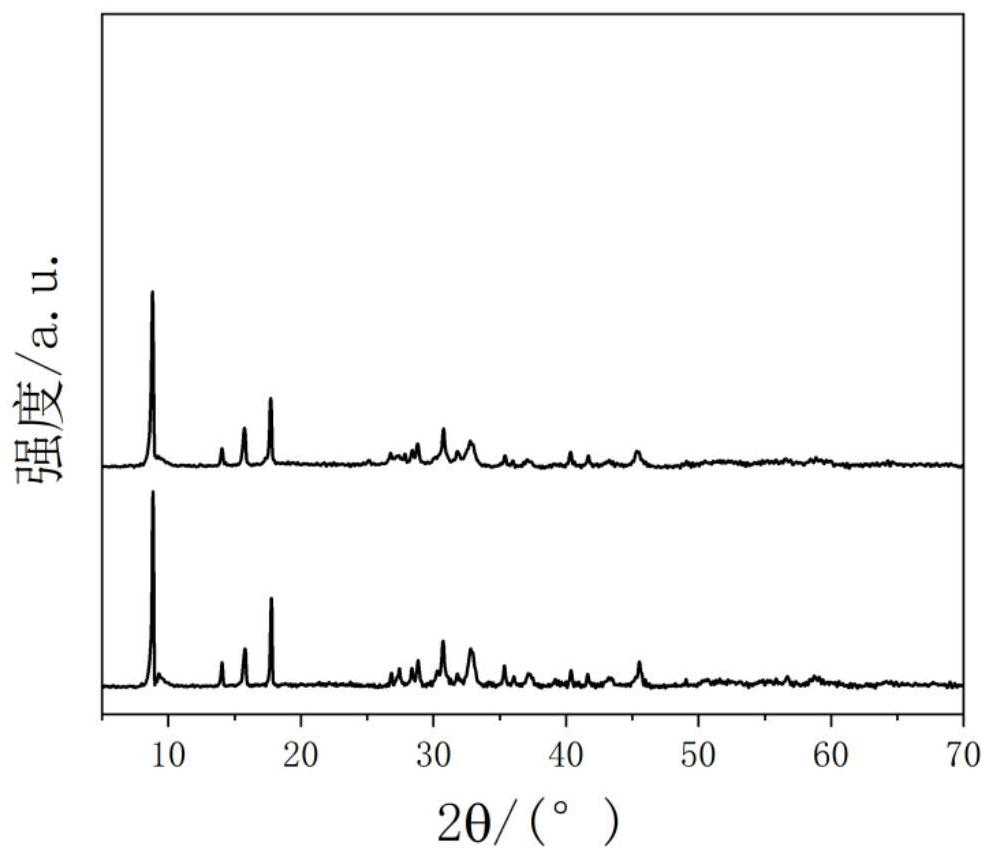

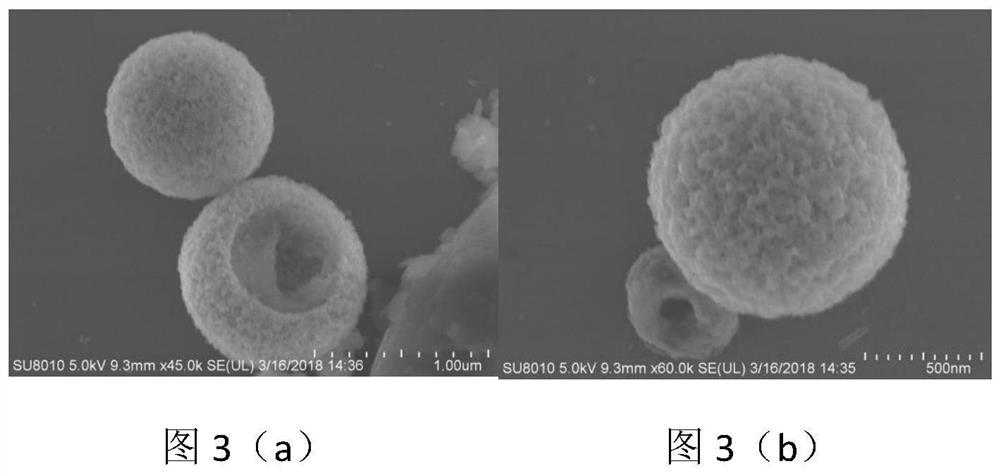

Preparation method and denitration application of bimetal MOF-74(Co-Cu) with meso-scale regulation and control multi-level core-shell structure

ActiveCN112625256ASmall sizeUniform crystal formOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPtru catalystNitrogen oxides

The invention provides a preparation method and denitration application of bimetal MOF-74(Co-Cu) with a meso-scale regulation and control multi-level core-shell structure. According to the catalyst, cobalt-containing long-chain organic molecular salt is selected to be efficiently coordinated with an organic ligand, special surface treatment is conducted on the cobalt-containing long-chain organic molecular salt and the organic ligand, then synthesis modification is conducted in a low-temperature steam environment through crystals, and Cu metal nanometer modified by a surface active agent grows on the surface of a Co precursor to form a multi-level core-shell structure composite material with different thicknesses. The prepared catalyst has the advantages of large specific surface area, good dispersibility and high selectivity. The prepared catalyst has excellent low-temperature catalytic denitration activity, and the conversion rate of nitric oxide reaches 96% or above within an operation window of 200-275 DEG C.

Owner:DALIAN UNIV OF TECH

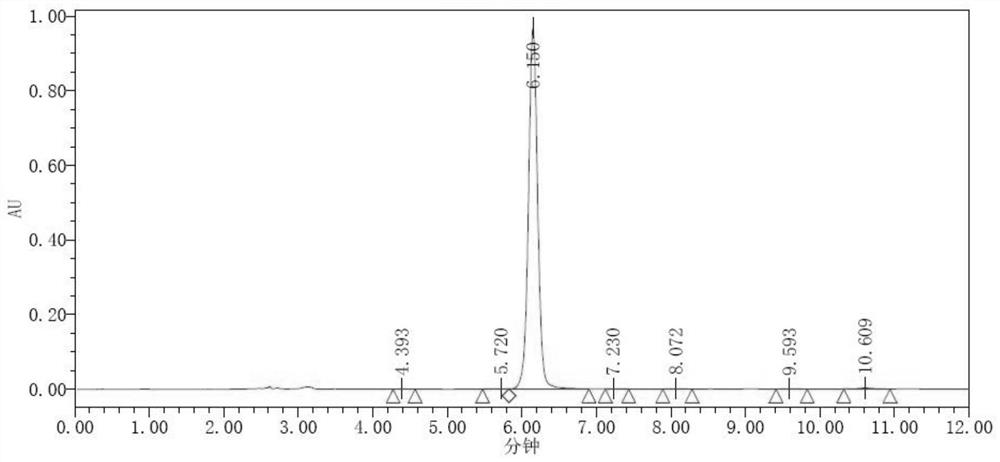

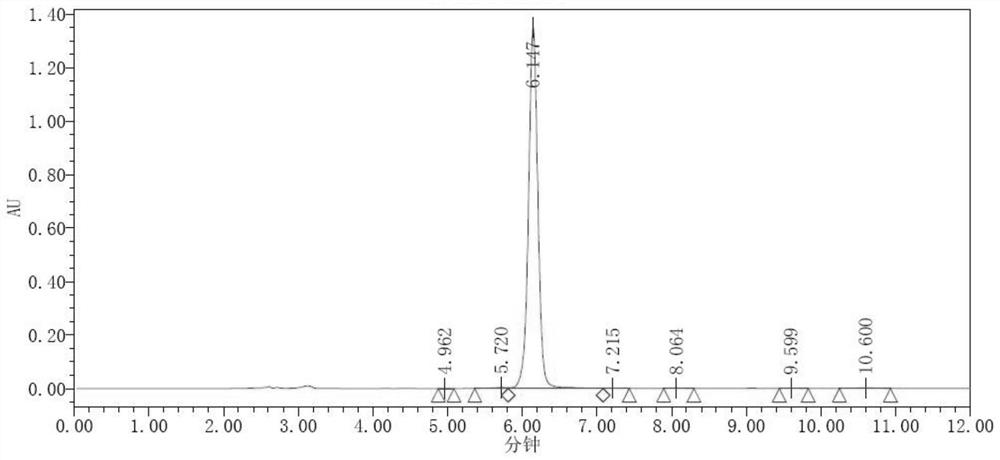

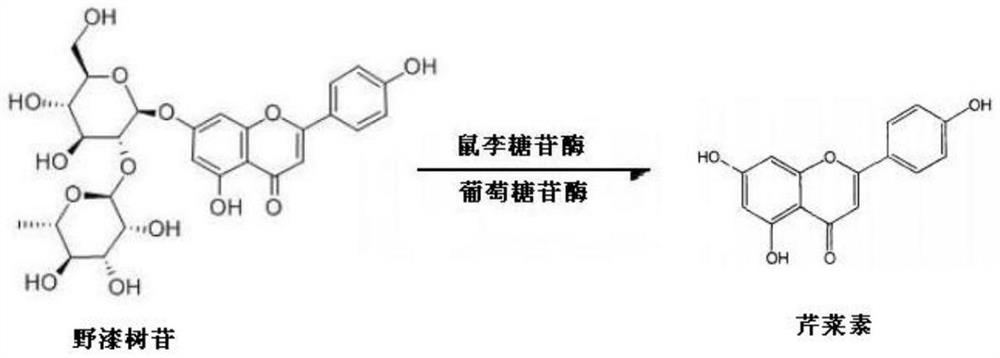

Method for preparing apigenin by utilizing biological enzymolysis

ActiveCN112813116AHigh purityUniform crystal formOrganic chemistryFermentationAlglucerasePhysical chemistry

The invention discloses a method for preparing apigenin by utilizing biological enzymolysis. The method comprises the following steps of: S1, enzymolysis: adding rhoifolin and water or a lower alcohol solution into a reaction container, uniformly mixing, heating to 70 DEG C or above, preserving heat, cooling to 60 DEG C or below, adding acid to adjust the pH value, adding a compound enzyme for an enzymolysis reaction, detecting whether the rhoifolin is completely reacted or not, and heating to extinguish the compound enzyme after the enzymolysis reaction is completed to obtain a reaction solution, wherein the compound enzyme comprises rhamnosidase and glucosidase; S2, separation: filtering the reaction solution to obtain apigenin coarse crystals, mixing the apigenin coarse crystals with an alcohol solution, and stirring until the apigenin coarse crystals are completely dissolved to obtain a complex solution; and S3, purification: cooling and crystallizing the complex solution, and filtering to obtain the apigenin. According to the method for preparing the apigenin by utilizing the biological enzymolysis, the rhoifolin is hydrolyzed into the apigenin by adopting biological enzyme catalysis, so that the method is easy and convenient to operate, green, pollution-free and suitable for large-scale production.

Owner:LIANYUAN KANGLU BIOLOGICAL TECH CO LTD +2

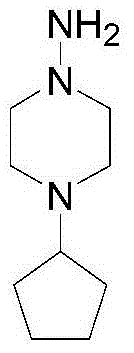

Preparation method of rifapentine

The invention discloses a preparation method of rifapentine, and the steps are as follows: rifamycin S is used as a starting material for reacting with dihydroxy methyl tert-butyl amine in a first organic solvent to convert into intermediate rifaoxazine; a catalyst and a reductant are added into a second organic solvent for hydrolysis ring opening of the intermediate rifaoxazine; a rifapentine solution is obtained by condensation of a rifaoxazine hydrolysis product and 1-amino-4-cyclopentyl piperazine; and a rifapentine finished product is obtained by filtration, segmented crystallization at multistage crystallization temperature, first separation, washing, second separation, drying, soaking, third separation, drip washing, spin drying, sieving, drying, and powder mixing refining processes of the rifapentine solution. The preparation method adopts the reductant which can play a role in anti oxidation; different crystallization temperature is adopted in the segmented crystallization process; and by combination with the adding of a crystallization solvent, the crystalline polymorph is uniform, the particles are uniform, the stability is good, and the defects of high impurity content and nonuniform particles of rifapentine processes in the prior art can be solved.

Owner:SICHUAN LONG MARCH PHARMA CO LTD

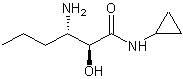

Chiral intermediate (S, S)-3-amino-N-cyclopropyl-2-hydroxyalkanamide or its salt and preparation method thereof

InactiveCN102659618AMild conditions for crystallizationReduce energy consumptionCarboxylic acid amide separation/purificationAminalHydroxyhexamide

The invention relates to a chiral intermediate (S, S)-3-amino-N-cyclopropyl-2-hydroxyalkanamide or its salt and a preparation method thereof. The chiral intermediate (S, S)-3-amino-N-cyclopropyl-2-hydroxyalkanamide is an important intermediate for preparing a hepatitis C-resistant drug Telaprevir. The preparation method utilizes D-tartaric acid as a resolving agent to resolve 3-amino-N-cyclopropyl-2-hydroxyalkanamide so that the chiral intermediate (S, S)-3-amino-N-cyclopropyl-2-hydroxyalkanamide or its salt is obtained.

Owner:PORTON FINE CHEM

Preparation method of calcium carbonate with layered structure

InactiveCN108439447AEasy to prepareShorten the timeCalcium/strontium/barium carbonatesSolventCopolymer

The invention belongs to the technical field of nano materials, and particularly relates to a preparation method of calcium carbonate with a layered structure. The preparation method comprises the following steps: firstly, self-assembling amphiphilic block copolymers in a selective solvent to form flexible polymer nano-wires with core-shell structures; secondly, carrying out hydrophobic core crosslinking on the nano-wires to obtain nano-wires which can stably exist in a solution; and thirdly, crystalizing calcium carbonate in a mixed solution of the flexible polymer nano-wires and calcium chloride at the atmosphere of carbon dioxide to form a layer-by-layer stacked structure. The layered calcium carbonate structure prepared by the method is quite close to a natural shell structure, the crystal form is single and orderly, a preparation process is simple, and an efficient method is provided for artificial preparation of the calcium carbonate.

Owner:FUDAN UNIV

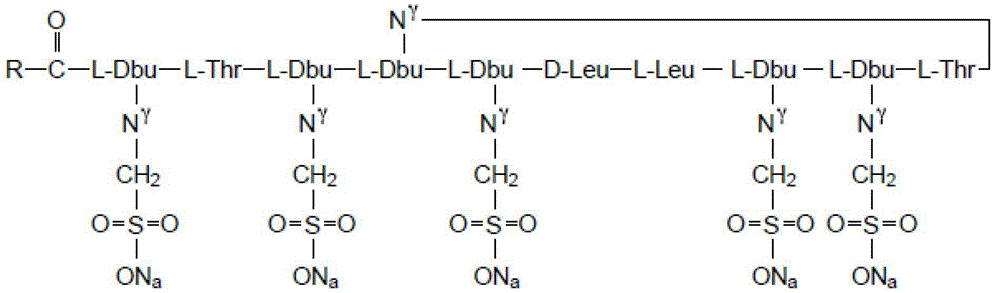

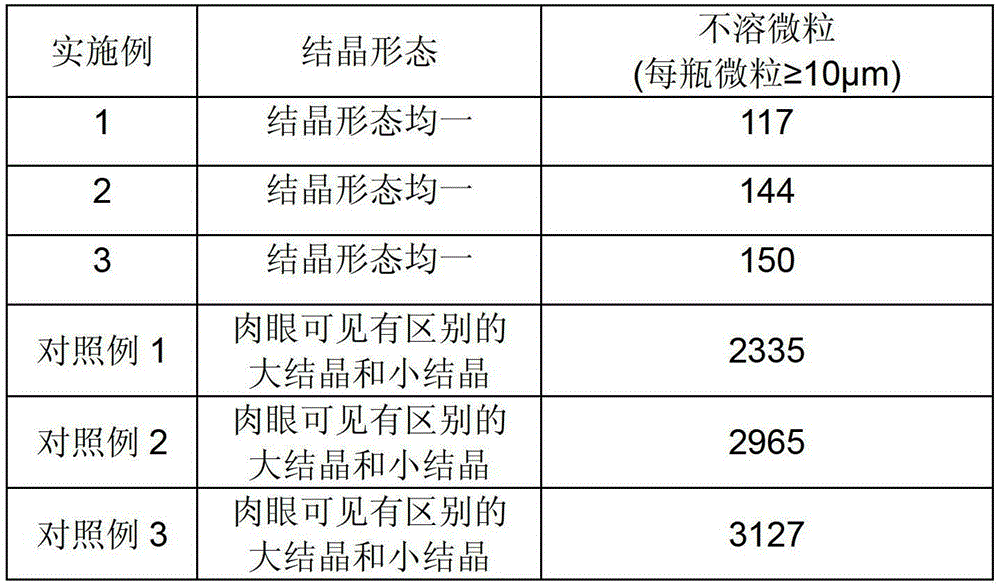

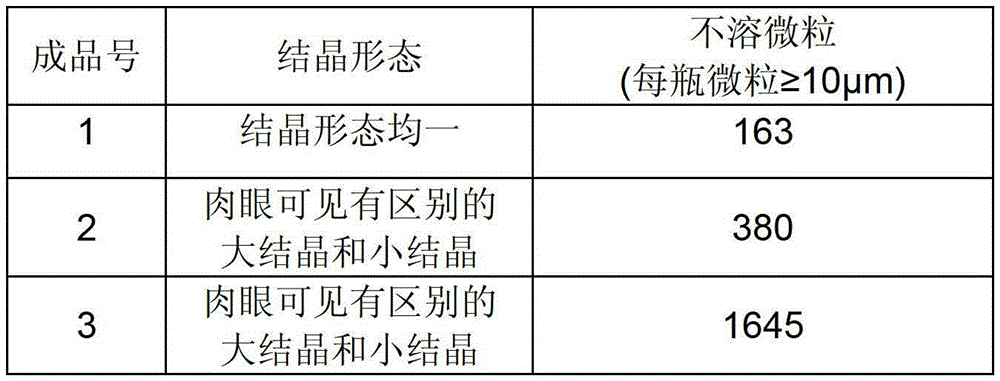

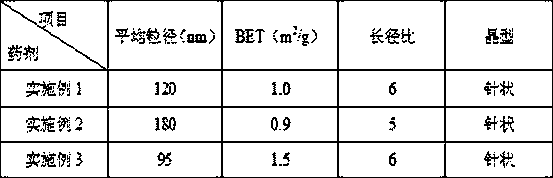

A kind of polymyxin e sodium methanesulfonate freeze-dried preparation and preparation method thereof

ActiveCN104043103BEasy to rehydrateFull appearanceAntibacterial agentsPowder deliveryFiltration membraneFreeze-drying

The invention provides a freeze-dried preparation employing polymyxin E methanesulfinic acid sodium salt as an active component and a preparation method thereof. The preparation method of the polymyxin E methanesulfinic acid sodium salt includes following steps: adding polymyxin E methanesulfinic acid sodium salt to water, carrying out a stirring and dissolving process to obtain a polymyxin E methanesulfinic acid sodium salt solution, filtering the solution through a microporous filtration membrane to obtain a filtrate, and carrying out a freeze-drying process to obtain the freeze-dried preparation. The polymyxin E methanesulfinic acid sodium salt preparation is plump in appearance, is uniform in crystallization form and is easy to rehydrate. When a bottle of the preparation is rehydrated, the number of insoluble particles, which are not less than 10 [mu]m in particle sizes, is not more than 200.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

High-strength electronic copper foil preparation method

PendingCN112680751AHigh tensile strengthHigh elongationElectroforming processesElectrolytic agentCopper wire

The invention discloses a high-strength electronic copper foil preparation method. The method comprises the following steps that S1, a copper rod, a copper wire and chlorides are dissolved into an aqueous solution by using sulfuric acid to be adopted as a main electrolyte, contents of copper and the sulfuric acid in the main electrolyte being 60 g / L to 100 g / L, 70 g / L to 160 g / L and 0 mg / L to 25 mg / L respectively, S2, additives are put into the main electrolyte, the additives including an agent A, an agent B and an agent C with concentrations of 3 mg / L to 50 mg / L, 5 mg / L to 80 mg / L and 1 mg / L to 20 mg / L respectively; S3, the main electrolyte with the additives is electrolyzed under the conditions that a temperature is 35 DEG C to 65 DEG C, a flow is 45 m-50<3> / h and a current density is 2000 A / m<2> to 8200 A / m<2>; and S4, the main electrolyte is electrolyzed to form electro-deposition with a thickness of 9 microns to 105 microns on a cathode. According to the high-strength electronic copper foil preparation method, an electronic copper foil produced through the preparation method has the advantages of high tensile strength, high elongation and uniform thickness, and can meet the development requirement of an ultrahigh-density printed circuit board.

Owner:JIUJIANG TELFORD ELECTRONICS MATERIAL CO LTD +1

Preparation method of high-purity calcium oxide

PendingCN111573705AHigh purityHigh yieldMaterial nanotechnologyCalcium/strontium/barium oxides/hydroxidesCalcium hydroxidePolyvinyl alcohol

The invention provides a preparation method of high-purity calcium oxide. Calcium hydroxide is produced by using raw materials with extremely high calcium oxide content, the dispersity of calcium ionsis improved by using stearic acid and polyvinyl alcohol 124, and the crystal form and the particle size of the calcium ions are controlled so that calcium hydroxide solids are high in fineness and good in dispersity, and finally, calcium oxide with high purity and good dispersity is prepared through high-temperature calcination. Calcium hydroxide with good dispersity can be better and more uniformly calcined at high temperature so that the production efficiency is improved, the yield of waste gas CO2 is reduced, and the cost of subsequent treatment is reduced. The method is simple in process,safe, environmentally friendly and high in production efficiency, and the prepared calcium oxide product is high in purity and good in dispersity.

Owner:NANNING XIAYANG CHEM TECH CO LTD

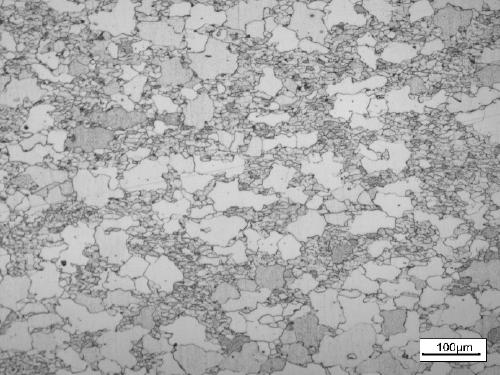

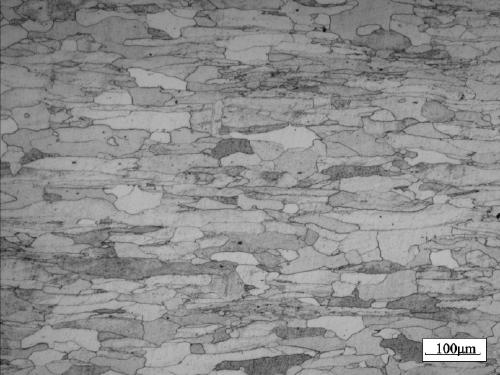

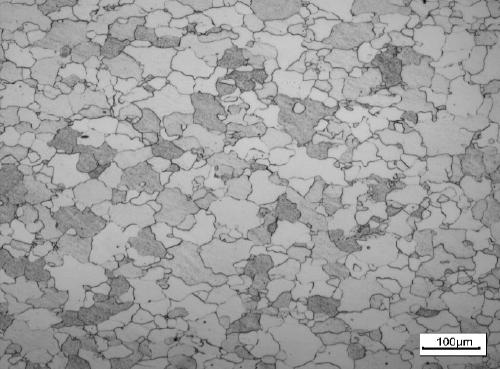

Production process for controlling metallographic structure formation in ferrite hot-rolling process

The invention relates to a ferrite hot-rolling process, and in particular to a production process for controlling metallographic structure formation in the ferrite hot-rolling process. The raw materials comprises according to percentage by mass: less than or equal to 0.06 percent of C,less than or equal to 0.10 percent of Si, less than or equal to 0.30 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.020 percent of S, less than or equal to 0.03 percent of Al, less than or equal to 0.05 percent of Cu, less than or equal to 0.05 percent of Cr, less than or equal to 0.05 percent of Ni and the balance of iron. The materials are sequentially smelted by a converter, a RH furnace and an LF furnace; and the material hot-rolling process can be carried out by a CSP orESP production line. By optimizing the proportion of the materials, a suitable process window is set according to the proportion of the materials in order to eliminate mixed crystal and caky structures in ferrite rolling and optimize the mechanical performance index of rolling.

Owner:RIZHAO STEEL HLDG GROUP

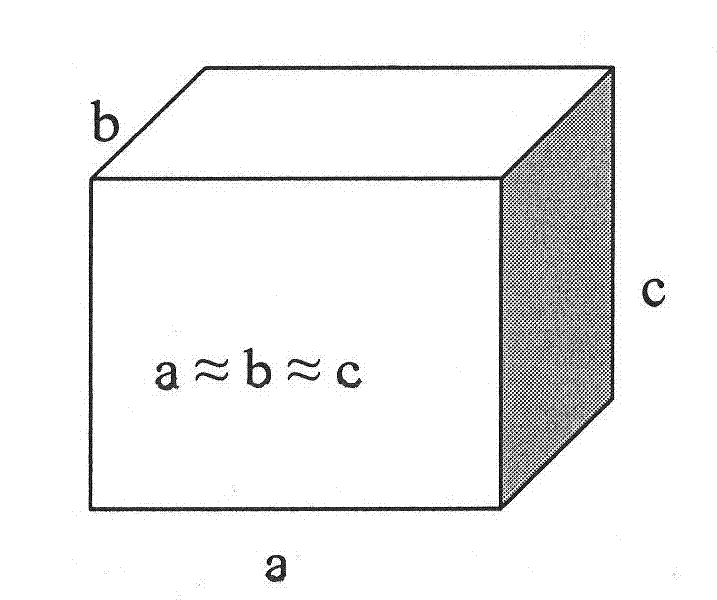

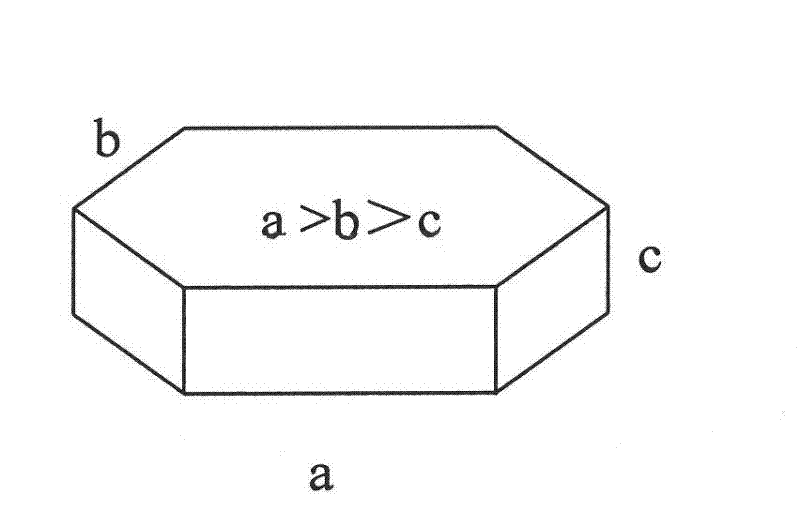

Process for preparing high dispersivity square blocky superfine magnesium hydroxide by one-step method

InactiveCN101723417BFull crystal formUniform crystal formMagnesium hydroxideFiltrationReaction temperature

The invention provides a process for preparing high dispersivity square blocky superfine magnesium hydroxide by a one-step method, which relates to a process for preparing a chemical material. The process comprises the following steps of: taking magnesium chloride as a raw material; preparing solution of the magnesium chloride; reacting the solution of the magnesium chloride with ammonia gas passed in at a certain speed rate in a bubbling reactor with stirring; controlling the stirring speed and the reaction temperature; and after the reaction, performing constant temperature aging, filtration washing and drying on reaction solution to obtain incompact square blocky (hexahedral structure) superfine magnesium hydroxide powder. An ammonium salt in filtrate can be used for preparing the ammonia gas used in the process of magnesium deposition through ammonia evaporation reactions so as to realize ammonia circulation. The process realizes a technique for synthesizing a magnesium hydroxide fire retarding agent through the one-step method at the normal temperature under a condition that no auxiliary agent is used. Besides, the process has good product quality, needs no hydro-thermal treatment, has simple operating steps, less equipment occupied area, low production cost and small pollutant discharge amount, and is suitable for large-scale production.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

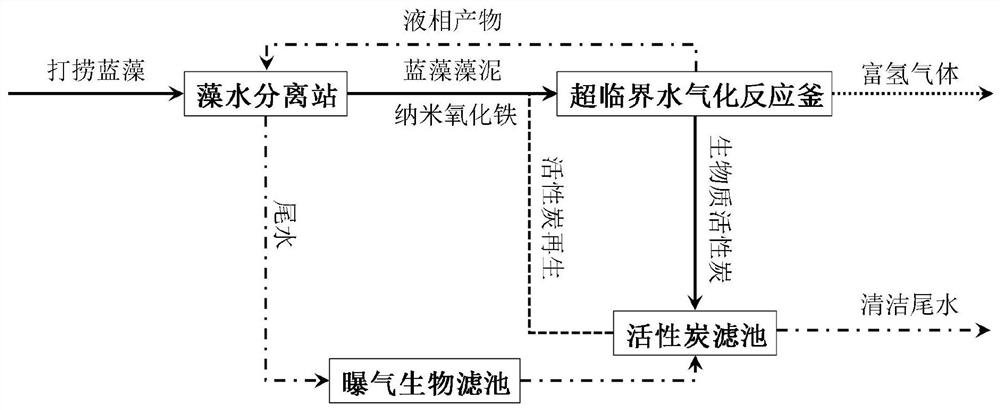

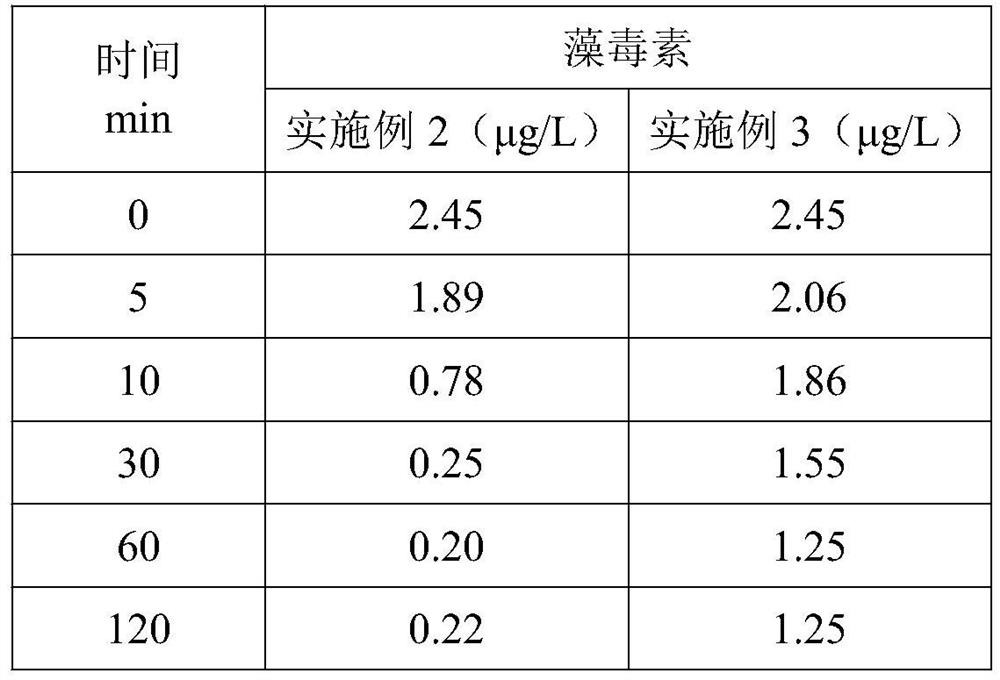

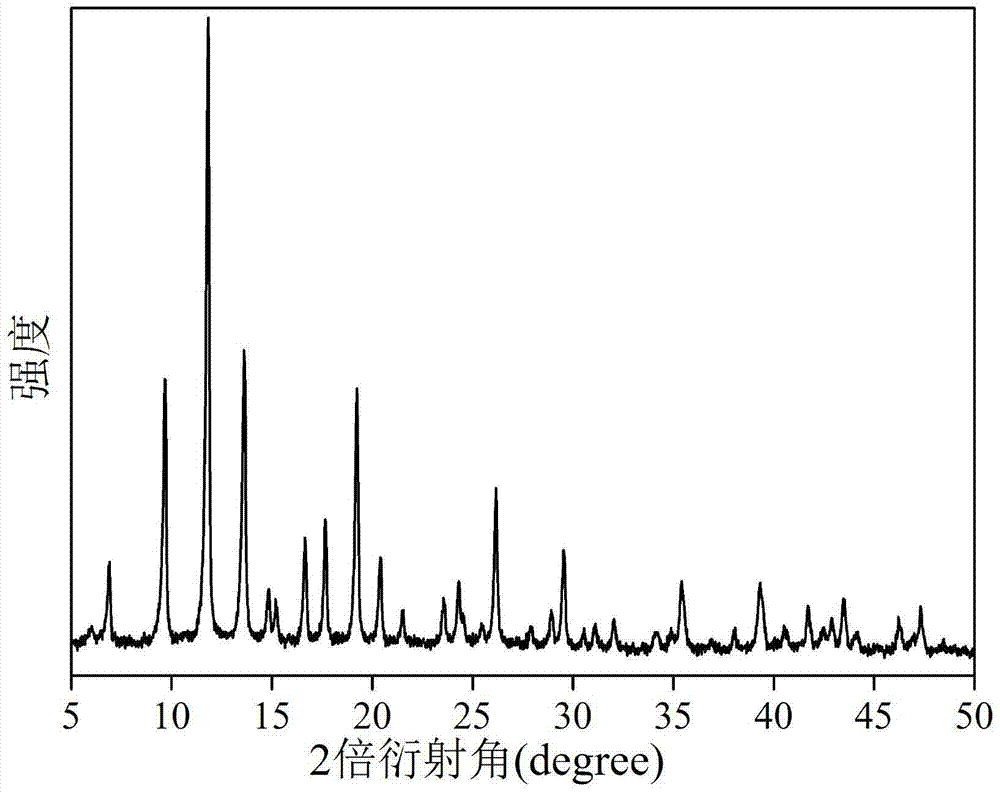

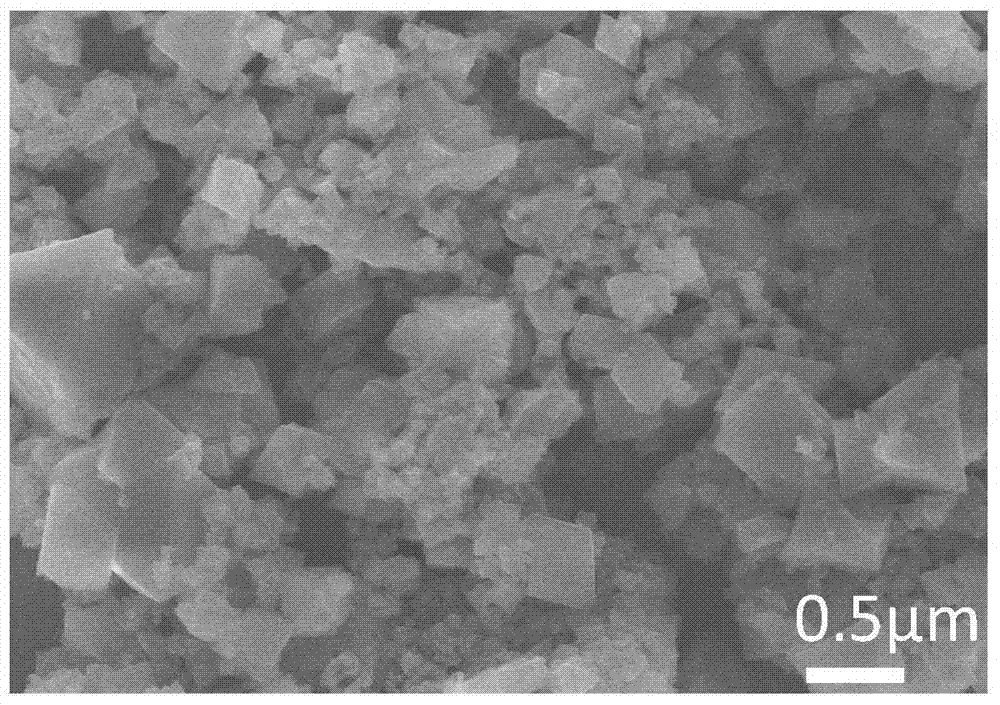

A kind of use of cyanobacteria and algae mud of algae water separation station to prepare biomass activated carbon and use it for the adsorption of algal toxins in tail water

ActiveCN110523378BUniform particle sizeUniform shapeCarbon compoundsOther chemical processesActivated carbonEnvironmental engineering

The invention discloses a use of cyanobacteria and algae mud in an algae-water separation station to prepare biomass activated carbon and use it for the adsorption of algal toxins in tail water. The biomass activated carbon is prepared by the following method: step S1, uniformly dispersing nano-iron oxide in the algae-water separation station to produce The cyanobacteria algae mud to obtain the algae mud to be treated, the water content of the algae mud is controlled at 80-95%, and the addition ratio of nano-iron oxide in the algae mud is 1-3wt%; step S2, the algae mud to be treated is passed through a high-pressure plunger pump Transport to the continuous supercritical water gasification reactor, heat up to 450-600°C at a rate of 10-15°C / min for supercritical water gasification reaction, the reaction product is cooled, gas-liquid-solid separation, solvent cleaning, and drying Biomass activated carbon with network polymorphic pore structure is obtained. The biomass activated carbon of the invention can effectively absorb algae toxins in tail water, and the cyanobacteria algae mud can be used as a raw material to realize high-efficiency reduction, harmless treatment and reuse of the cyanobacteria algae mud.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of electrochemical synthesis catalyst cu 3 (btc) 2 method and its nh 3 ‑scr application

InactiveCN104801341BUniform crystal formFlexible approachOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationEthylenediamineElectrolysis

Owner:DALIAN UNIV OF TECH

Preparation method of cefepime hydrochloride

ActiveCN101935325BUniform crystal formImprove liquidityOrganic chemistryCefepime hydrochlorideBetaine

The invention discloses a preparation method of cefepime hydrochloride, comprising the following steps of: reacting oxalyl chloride with 2-methoxyimino-2-(2-aminothiazole-4-yl) acetic acid hydrochloride to obtain a midbody I, i.e. 2-methoxyimino-2-(2-aminothiazole-4-yl) acetyl chloride hydrochloride; mixing silanized 7-aminoce-phalosporanic acid and silanized N-methylpyrrolidine, and reacting to obtain a midbody II, i.e. hydriodic acidification (6R, 7R)-7-amino-3-[(1-methyl-1-tetrahydro pyrrolidine) methyl]-3-cephem-4-formic betaine, in the presence of trimethyl idodine silicon hydride, isopropanol and an aqueous solution of hydrogen iodide; dissolving the midbody II into dichloromethane, sequentially adding trimethylchlorosilane and hexamethyldisilazane for reaction, and then adding the midbody I and triethylamine to react to prepare the cefepime hydrochloride. The cefepime hydrochloride prepared by the method has the advantages of uniform crystal form, good flowability and simple process and is suitable for industrialized production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

Preparation method for ultrafine calcium zincate crystal applied to zinc battery

InactiveCN110386619AImprove electrical performanceSmall particle sizeFinal product manufactureAlkaline accumulator electrodesCalcium silicateFiltration

Embodiments of the invention disclose a preparation method for an ultrafine calcium zincate crystal applied to a zinc battery. The preparation method comprises the following steps: (a) dissolving zincoxide in an alkaline solution to prepare an alkaline saturated zinc oxide solution; (b) adding a calcium silicate seed crystal having a particle size of 2000-8000 meshes into the alkaline saturated zinc oxide solution under stirring to obtain a mixed solution; (c) separately adding calcium hydroxide and zinc oxide in a molar ratio of 1: 2 into the mixed solution for a reaction under the conditionof continuous stirring; and (d) after the reaction is completed, performing suction filtration, washing and drying to obtain the ultrafine calcium zincate crystal. The calcium zincate crystal prepared by using the preparation method of the invention has a small and uniform particle size, a complete crystal form and a high purity, and can effectively inhibit battery deformation and zinc dendrite formation when added to a zinc-nickel battery as a negative electrode material of the battery. The preparation method is short in reaction time, does not require long-time aging, saves energy consumption, and has high labor productivity.

Owner:KUNMING METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com