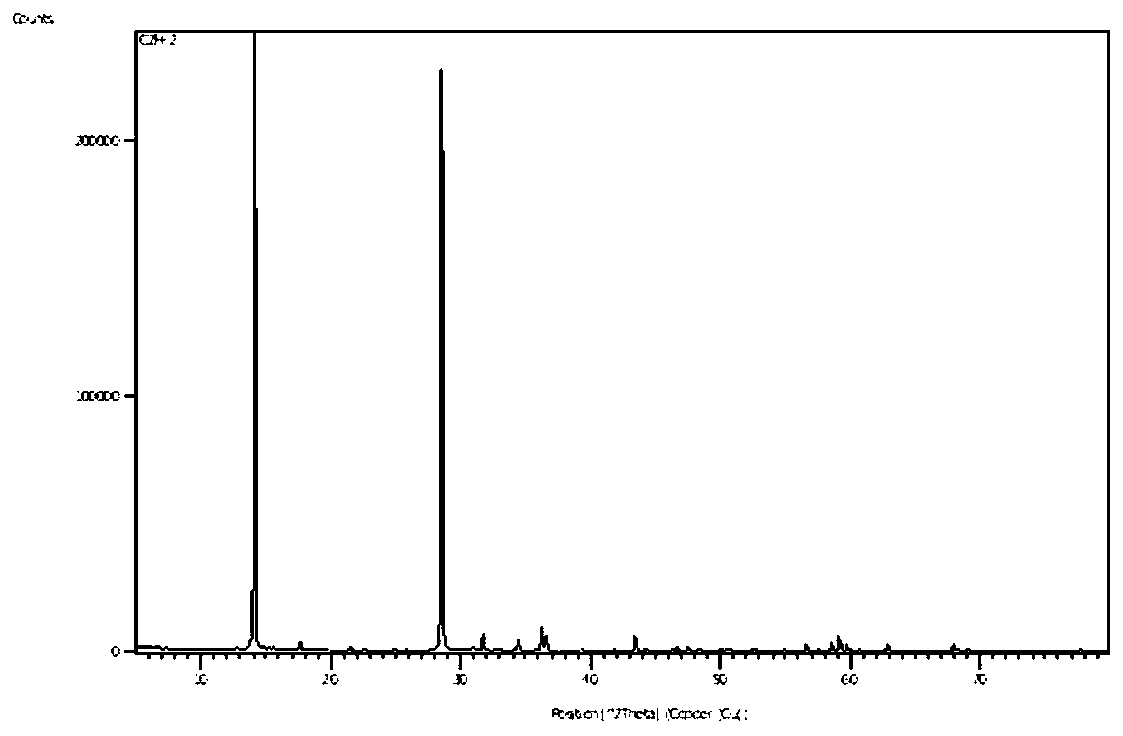

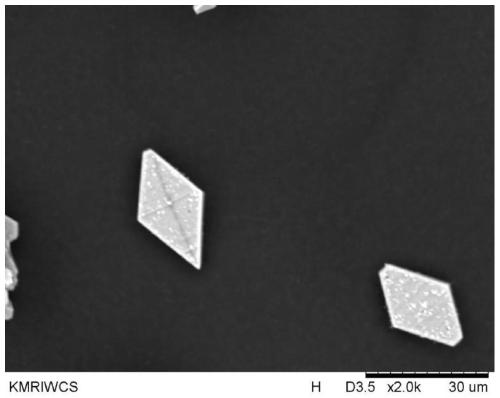

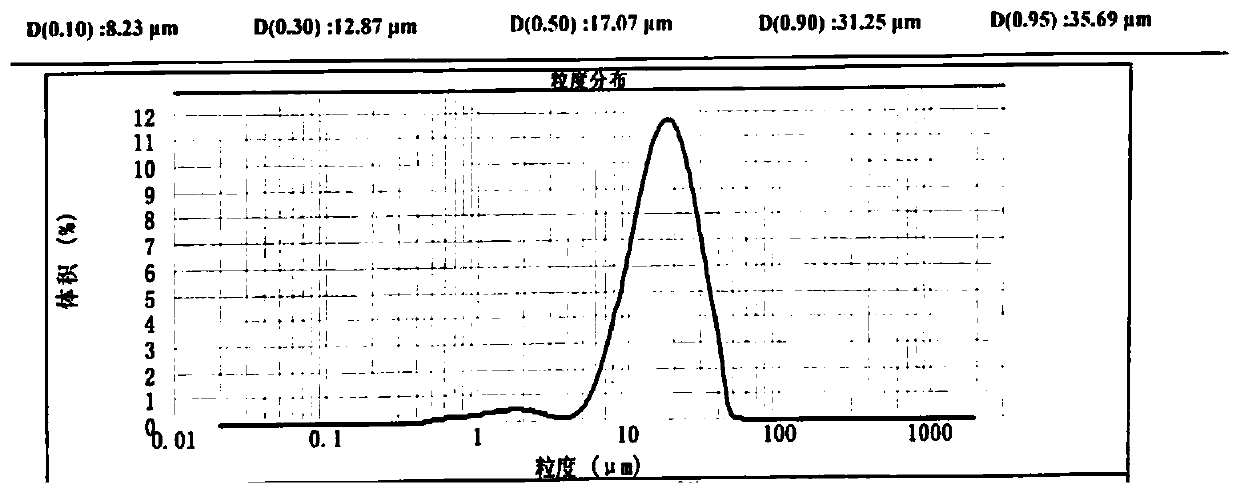

Preparation method for ultrafine calcium zincate crystal applied to zinc battery

A calcium zincate and zinc battery technology, which is applied in the manufacture of alkaline storage batteries, secondary batteries, battery electrodes, etc., can solve the problems of industrial production efficiency, limited equipment, large particle size, etc., and achieve the goal of inhibiting zinc dendrites Generation, improvement of electrical properties, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is a preparation method of ultrafine calcium zincate crystals for zinc batteries, the preparation method comprising the following steps:

[0033] (a) zinc oxide is dissolved in the potassium hydroxide solution of 200ml 5wt%, makes alkaline saturated zinc oxide solution;

[0034] (b) under agitation, add 1.43g of calcium zincate crystal seeds with a particle size of 2000 mesh to the alkaline saturated zinc oxide solution to obtain a mixed solution;

[0035] (c) Under the condition of continuing to stir, calcium hydroxide and zinc oxide were respectively added to the mixed solution at a molar ratio of 1:2 and reacted at 25° C. for 1.5 h, wherein the amount of calcium hydroxide added was 0.2 mol;

[0036] (d) After the reaction is finished, perform suction filtration, washing, and then dry below 50° C. to obtain ultrafine calcium zincate crystals.

Embodiment 2

[0038] This embodiment is a preparation method of ultrafine calcium zincate crystals for zinc batteries, the preparation method comprising the following steps:

[0039] (a) zinc oxide is dissolved in the potassium hydroxide solution of 200ml 25wt%, makes alkaline saturated zinc oxide solution;

[0040] (b) under agitation, add 0.29 g of calcium octanoate crystal seeds with a particle size of 8000 mesh to the alkaline saturated zinc oxide solution to obtain a mixed solution;

[0041] (c) Under the condition of continuous stirring, calcium hydroxide and zinc oxide were added to the mixed solution at a molar ratio of 1:2 and reacted at 45° C. for 6 hours, wherein the amount of calcium hydroxide added was 0.3 mol;

[0042] (d) After the reaction is finished, perform suction filtration, washing, and then dry below 80°C to obtain ultrafine calcium zincate crystals.

Embodiment 3

[0044] This embodiment is a preparation method of ultrafine calcium zincate crystals for zinc batteries, the preparation method comprising the following steps:

[0045] (a) zinc oxide is dissolved in the potassium hydroxide solution of 200ml 15wt%, makes alkaline saturated zinc oxide solution;

[0046] (b) under stirring conditions, adding 0.4 g of calcium octanoate crystal seeds with a particle size of 4000 mesh to the alkaline saturated zinc oxide solution to obtain a mixed solution;

[0047] (c) Under the condition of continuing stirring, calcium hydroxide and zinc oxide were added to the mixed solution at a molar ratio of 1:2 and reacted at 35° C. for 2 hours, wherein the amount of calcium hydroxide added was 0.2 mol;

[0048] (d) After the reaction is finished, perform suction filtration, washing, and then dry below 50° C. to obtain ultrafine calcium zincate crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com