Iron phosphate continuous dehydration and crystal form controllable system and control method thereof

A technology of iron phosphate and crystal form, applied in chemical instruments and methods, sustainable manufacturing/processing, furnace type, etc., can solve the problem that there are not many researches on reaction kinetics, and achieve excellent dehydration effect and consistent crystal form. Controlled and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

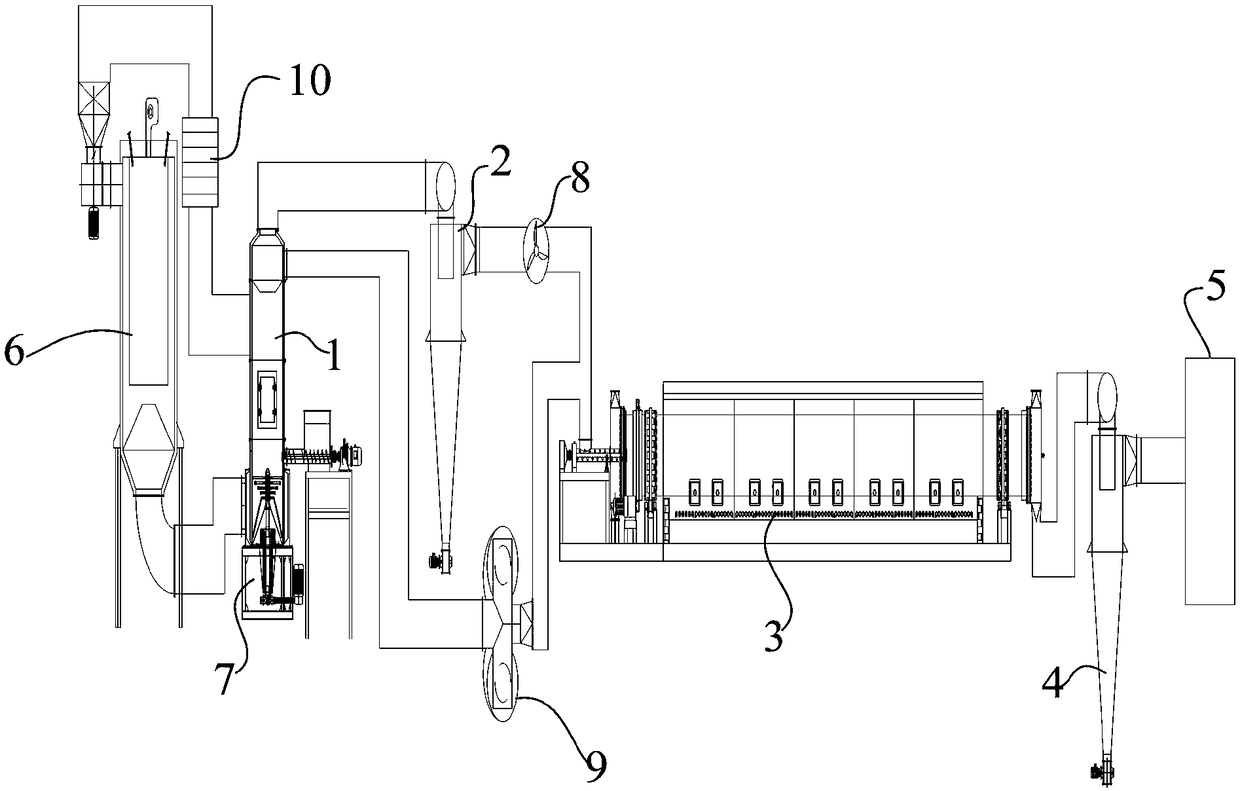

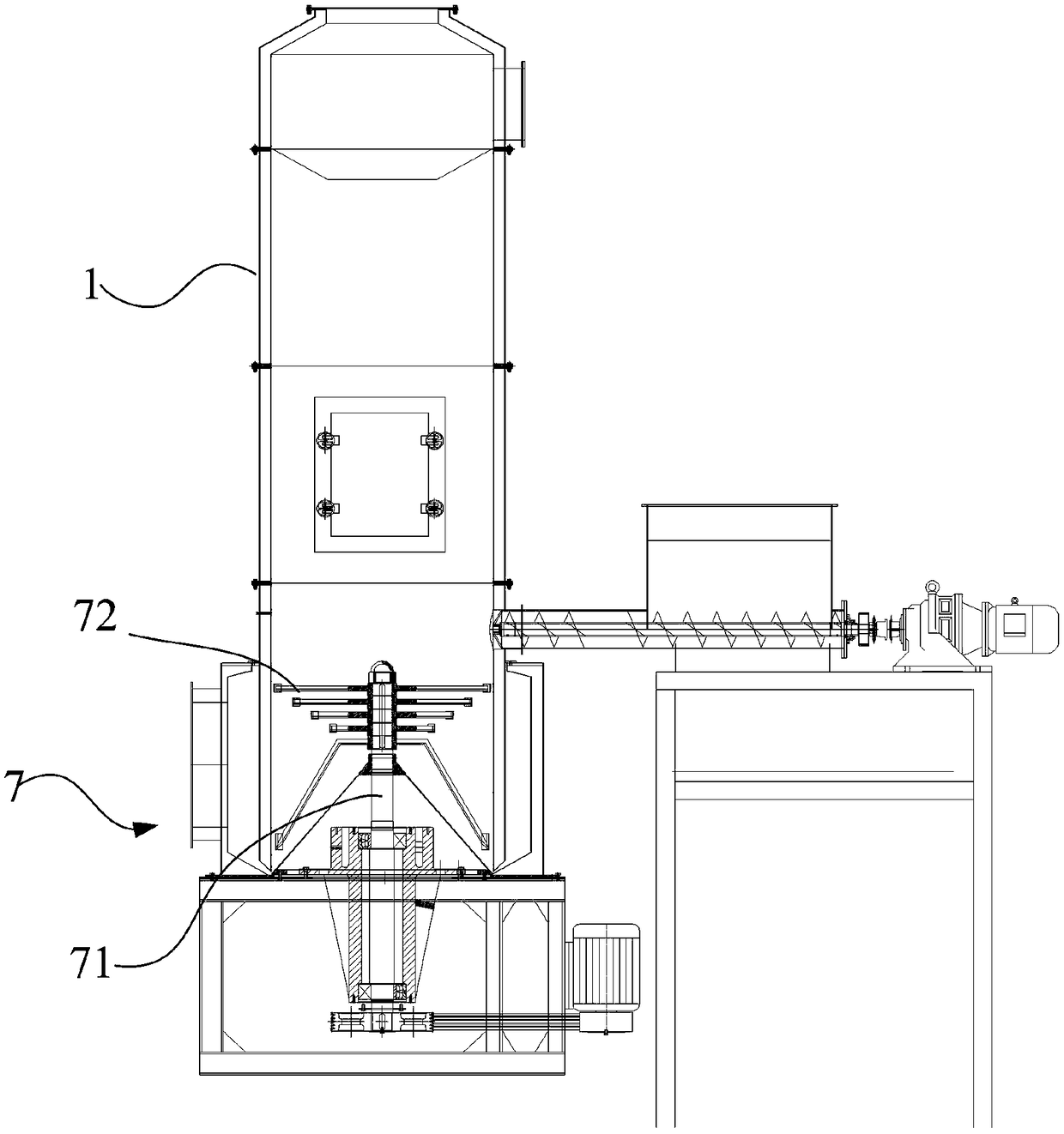

[0026] Example 1, such as figure 1 , figure 2 As shown, this embodiment provides a continuous dehydration and crystal form controllable system for ferric phosphate, aiming to solve the existing technical problems of complete ferric phosphate crystal form development, high crystallinity, and consistent and controllable crystal form. It is explained here that the current method of crystal form also relies on heating. In this embodiment, the problems of crystal form development and crystallinity are mainly solved. For this reason, the continuous dehydration and crystallization of iron phosphate provided by this embodiment The type controllable system includes a flash dryer, a cyclone dust collector, a rotary kiln, a second cyclone dust collector and a packaging machine arranged in sequence along the logistics direction. The flash dryer mainly removes the free iron phosphate dihydrate wet product Water, the main function of the cyclone dust collector is to collect the ferric pho...

Embodiment 2

[0034] Embodiment 2, this embodiment provides a control method using the iron phosphate continuous dehydration and crystal form control system provided in the above embodiment 1

[0035] Firstly, the iron phosphate filter cake is transported to the hopper of the flash dryer, and is continuously fed into the flash dryer by the screw feeder.

[0036] Then the blower sends the cold air into the hot blast stove for heating to form 250℃~300℃ hot air tangentially enters the bottom of the flash drying, and forms a strong rotating wind field driven by the dispersing motor. The setting of the dispersing machine is to filter the iron phosphate The cake is broken, and at the same time, its rotation can also rotate the wind delivered from the hot blast stove, so that the wet product of ferric phosphate dihydrate can be dispersed, crushed and dried under the action of high temperature and high speed rotating wind field, and free water can be removed.

[0037] After the free water is remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com