Nickel ore sintering machine

A sintering machine and nickel ore technology, applied in the field of nickel ore processing equipment, can solve the problems of heat energy loss, increased heat loss, large discharge particle size, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

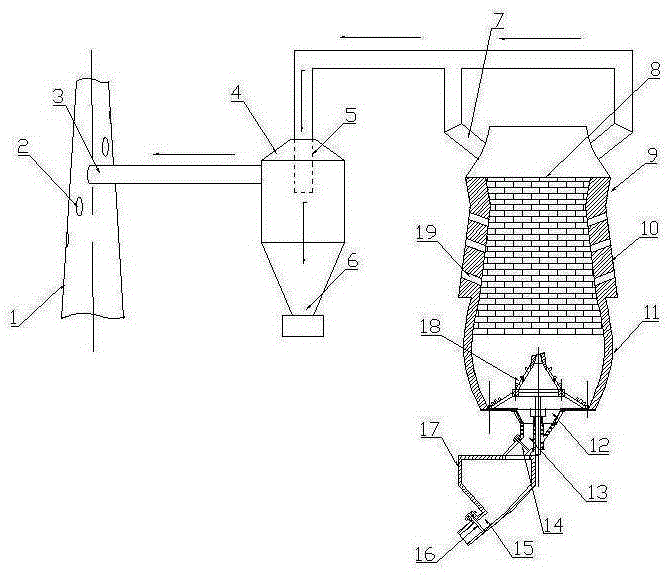

[0022] refer to Figure 1-3 , a nickel ore sintering machine, including several vertical kilns and a chimney 1 for concentrated discharge of exhaust gas, and a dust removal cylinder 4 is arranged between each vertical kiln and the chimney 1;

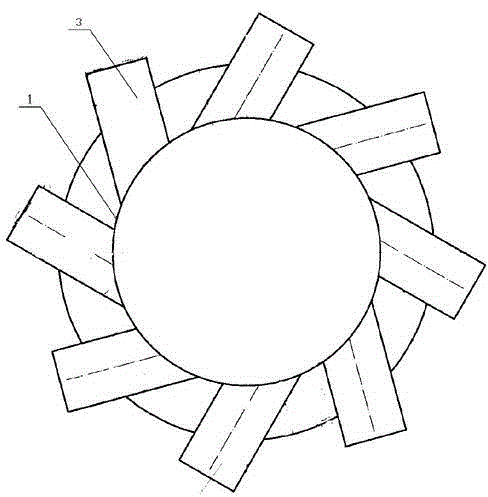

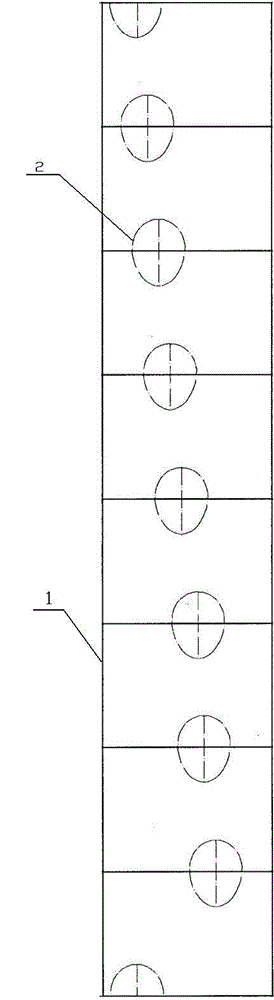

[0023] The vertical kiln comprises a kiln body consisting of an upper kiln body 9, a middle kiln body 10 and a lower kiln body 11. The top of the upper kiln body 9 is provided with a feeding port 8 and an exhaust gas discharge port 7, and the bottom of the lower kiln body 11 is provided with There is a discharge port 12, and a central tower grate 18 is installed at the discharge port 12. The lower section of the kiln body 11 opposite to the central tower grate 18 is set to expand outward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com