Production process for controlling metallographic structure formation in ferrite hot-rolling process

A technology of metallographic structure and production process, which is applied in the field of production process to control the formation of metallographic structure in ferrite hot rolling process, which can solve the problem of mixed crystal and grain deformation into cake structure, poor control of metallographic structure, etc. problem, to achieve the effect of reducing the amount of secondary oxide scale, excellent mechanical properties, and good metallographic structure and crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

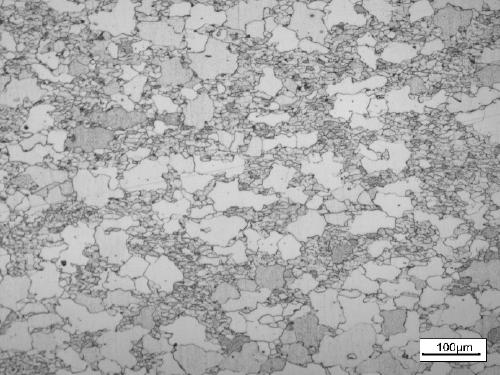

[0031] A production process for controlling the formation of metallographic structure in a ferrite hot rolling process is characterized in that the raw materials include by mass percentage: C is 0.045%; Si is 0.04%; Mn is 0.12%; P is 0.016%; S is 0.0012%; Alt is 0.012%; Cu is 0.02%; Cr is 0.02%; Ni≤0.01%, the rest is iron element; raw materials are smelted in converter, RH furnace and LF furnace in turn; raw materials are hot-rolled through ESP without end The thin slab continuous casting and rolling production line was completed. Molten steel passes through continuous casting machine, rough rolling mill, pendulum shear, scrap pushing, induction heating furnace, finishing mill, laminar flow cooling, high-speed flying shear and coiler in sequence. Among them, the continuous casting is produced at a constant speed of 5.0m / min, the rough rolling entrance temperature is 960°C, the induction heating furnace exit temperature is 1100°C, the finish rolling exit temperature is 770°C, t...

Embodiment 2

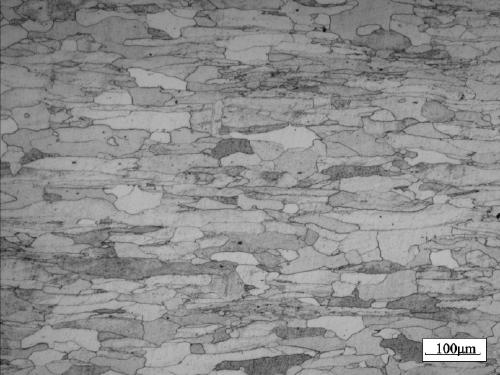

[0034] A production process for controlling the formation of a metallographic structure in a ferrite hot rolling process, characterized in that the raw materials include: 0.017% for C; 0.03% for Si; 0.09% for Mn; 0.015% for P; 0.0008%; Alt is 0.025%; Cu is 0.01%; Cr is 0.02%; Ni≤0.01%, the rest is iron element; raw materials are smelted in converter, RH furnace and LF furnace in turn; raw materials are hot-rolled through ESP without end The thin slab continuous casting and rolling production line was completed. Molten steel passes through continuous casting machine, rough rolling mill, pendulum shear, scrap pushing, induction heating furnace, finishing mill, laminar flow cooling, high-speed flying shear and coiler in sequence. Among them, the continuous casting is produced at a constant speed of 5.5m / min, of which the rough rolling inlet temperature is 950°C, the induction heating furnace outlet temperature is 1110°C, the finish rolling outlet temperature is 813°C, the coiling...

Embodiment 3

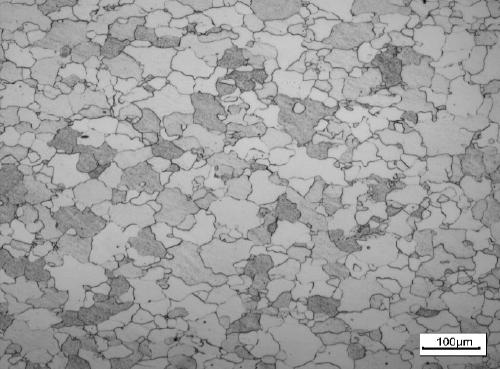

[0037] A production process for controlling the formation of metallographic structure in a ferrite hot rolling process is characterized in that the raw materials include by mass percentage: C is 0.008%; Si is 0.03%; Mn is 0.15%; P is 0.012%; S is 0.0010%; Alt is 0.025%; Cu is 0.02%; Cr is 0.02%; Ni≤0.01%, the rest is iron element; raw materials are smelted in converter, RH furnace and LF furnace in turn; raw materials are hot-rolled through ESP without end The thin slab continuous casting and rolling production line was completed. Molten steel passes through continuous casting machine, rough rolling mill, pendulum shear, scrap pushing, induction heating furnace, finishing mill, laminar flow cooling, high-speed flying shear and coiler in sequence. Among them, the continuous casting is produced at a constant speed of 5.2m / min, of which the rough rolling inlet temperature is 965°C, the induction heating furnace outlet temperature is 1160°C, the finishing rolling outlet temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com