690MPa-stage anti-seismic fire-proof weather-proof building structure steel and preparing method thereof

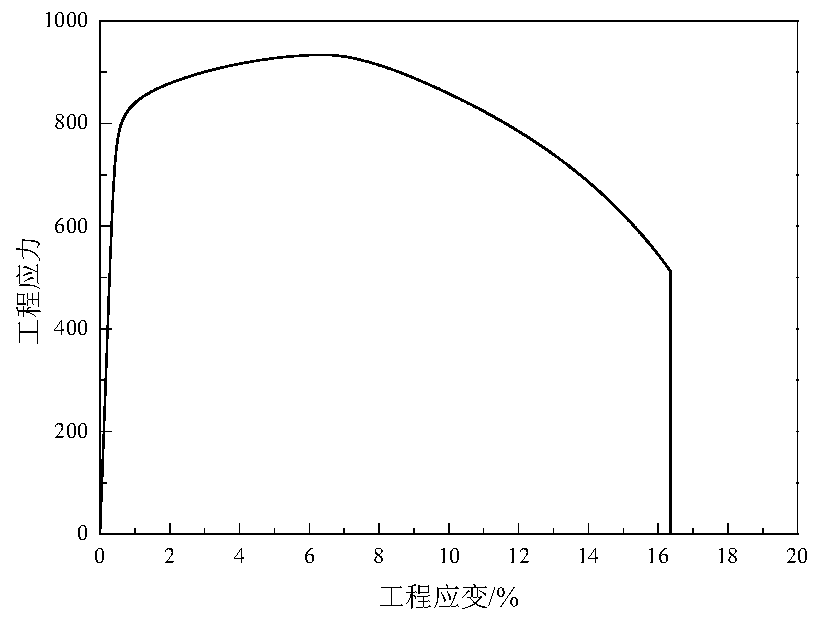

A fire-resistant and weather-resistant technology for steel for building structures, which is applied in the field of steel for building structures, can solve the problems of dependence on imports, and achieve the effect of low yield ratio and excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] A method for preparing 690MPa grade earthquake-resistant, fire-resistant and weather-resistant building structure steel, including the following steps:

[0069] Step 1, smelting process:

[0070] (1) Carry out the pretreatment process of molten iron, and then use the converter for smelting, and complete the refining treatment by top blowing or top-bottom composite blowing, so that the chemical composition of the steel is C: 0.05-0.10%, Si: 0.01-0.30% , Mn: 1.0-1.4%, P: 0-0.01%, S: 0-0.002%, Mo: 0.01-0.5%, Nb: 0.01-0.05%, Ti: 0.01-0.03%, V: 0-0.06%, Cr: 0.4~1.0%, Cu: 0.3~0.4%, Ni: 0.3~0.4%, B: 0~0.003%, N: 0.001~0.08%, the rest is Fe and unavoidable impurities;

[0071] (2) Enter the continuous casting process after refining, and finally obtain the continuous casting slab with a thickness of 130-140mm;

[0072] Step 2, rolling process:

[0073] (1) After the continuous casting slab is opened, put it into the heating furnace for heating, the heating temperature is 1100...

Embodiment

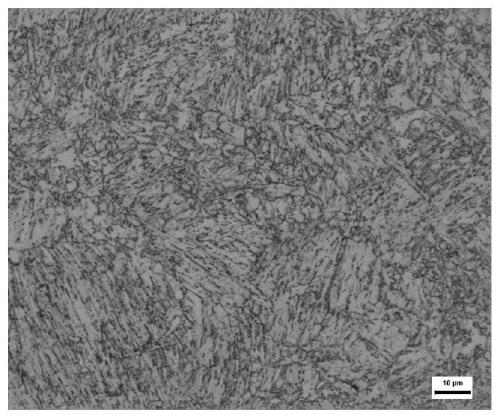

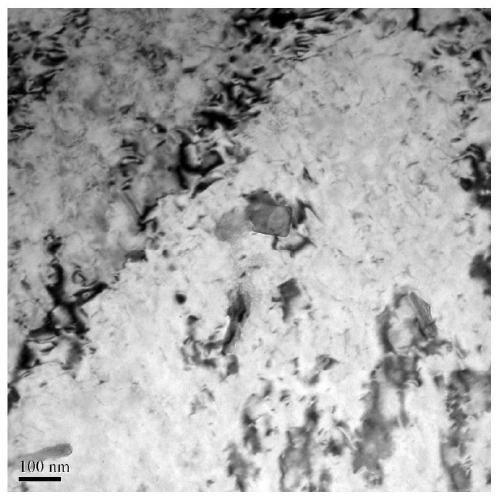

[0084] A total of 17 examples are included, and the steel plates are all smelted in vacuum smelting furnaces, a total of 5 furnaces, and the chemical composition is shown in Table 1. The continuous casting slab obtained after casting is forged and opened, wherein the thickness of the continuous casting slab is 140mm, put it into a heating furnace at 1100-1200°C, and heat it for 3-6h. Among them, Examples 1-5 and 9-11 The heating temperature is 1100°C, and the time is 6h; the heating temperature of Examples 6-8 and 12-17 is 1200°C, and the time is 3h;

[0085] After heating, two-stage rolling is carried out on a four-high reversible rolling mill. The starting and finishing temperatures of rough rolling and the starting and finishing temperatures of finish rolling are shown in Table 2. It is made to 80-90mm, and the thickness is waited for at this thickness. The second-stage finish rolling is rolled from 80-90mm to a finish-rolled plate of 12-40mm through 5-9 passes. Wherein, em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com