Patents

Literature

125 results about "Supercritical water gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

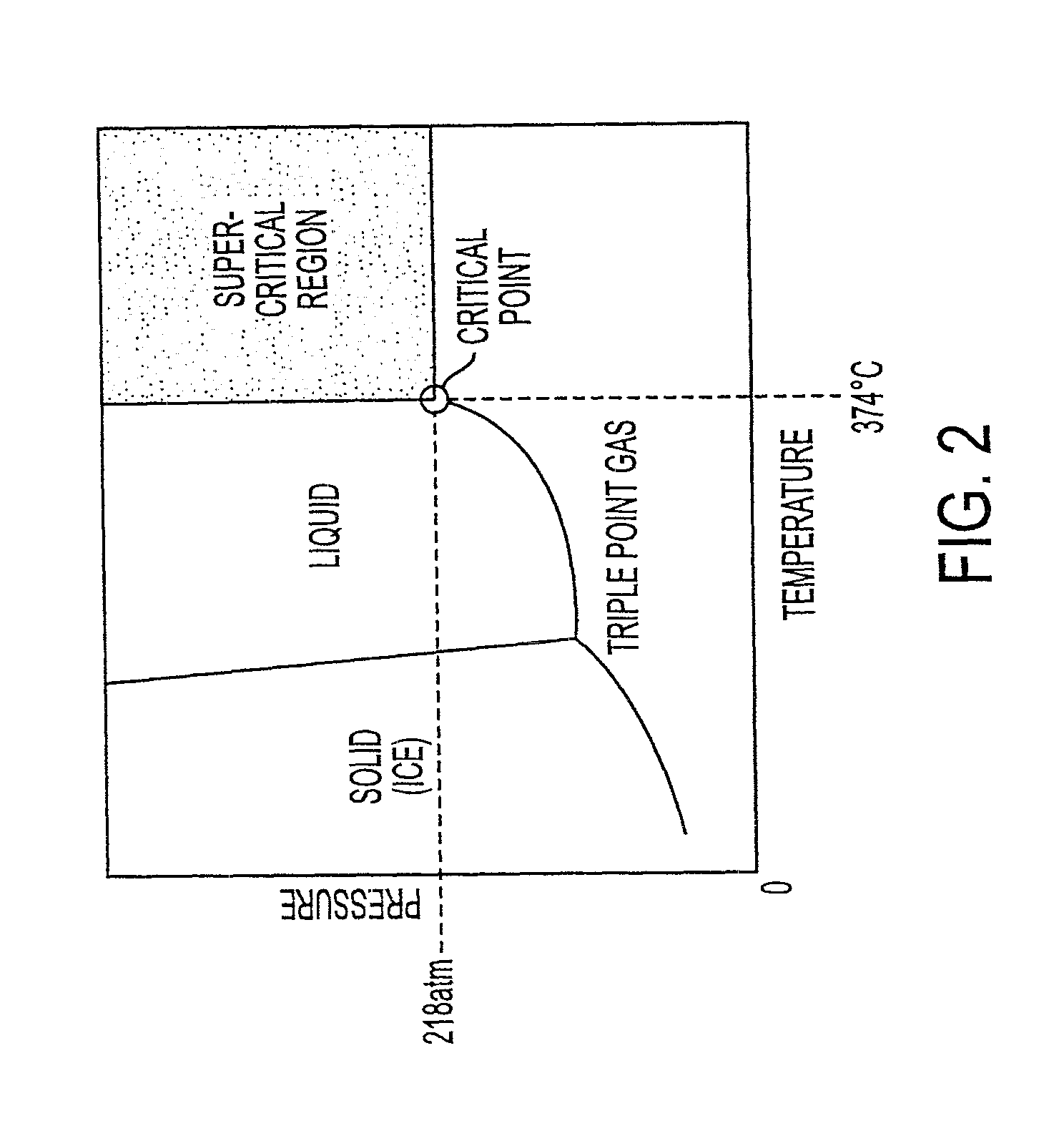

Supercritical water gasification. Supercritical water gasification is a process of exploiting the beneficial effect of supercritical water to convert aqueous biomass streams into clean water and gases like H 2, CH 4, CO 2, CO etc. Supercritical fluid in power generation

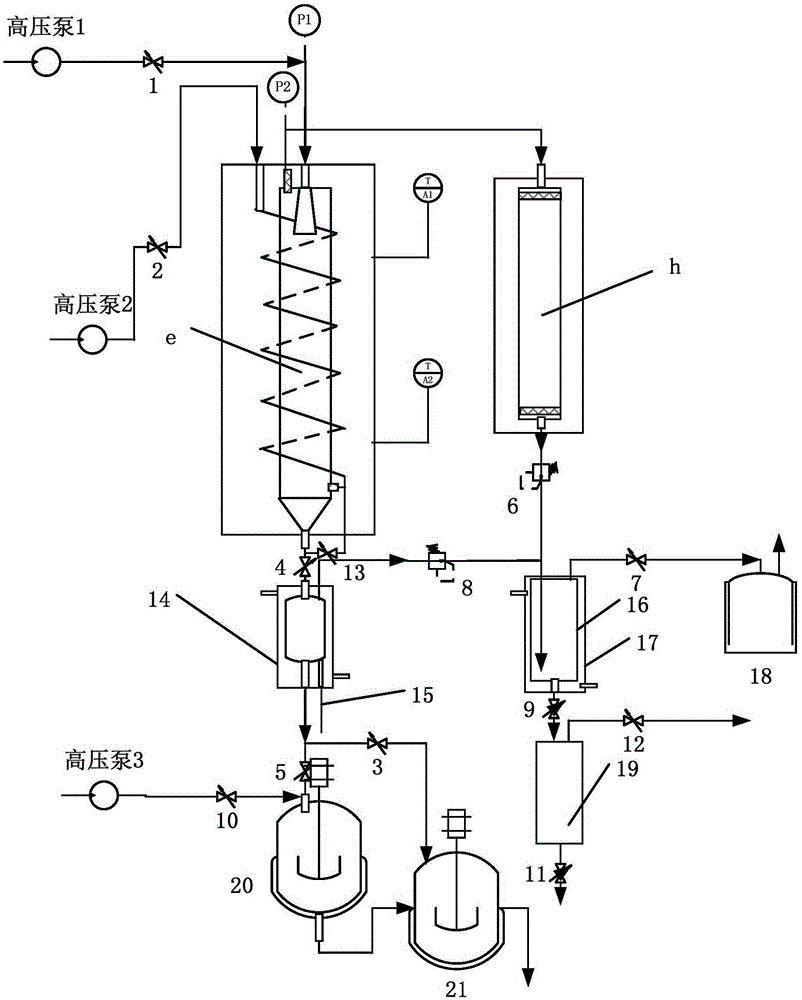

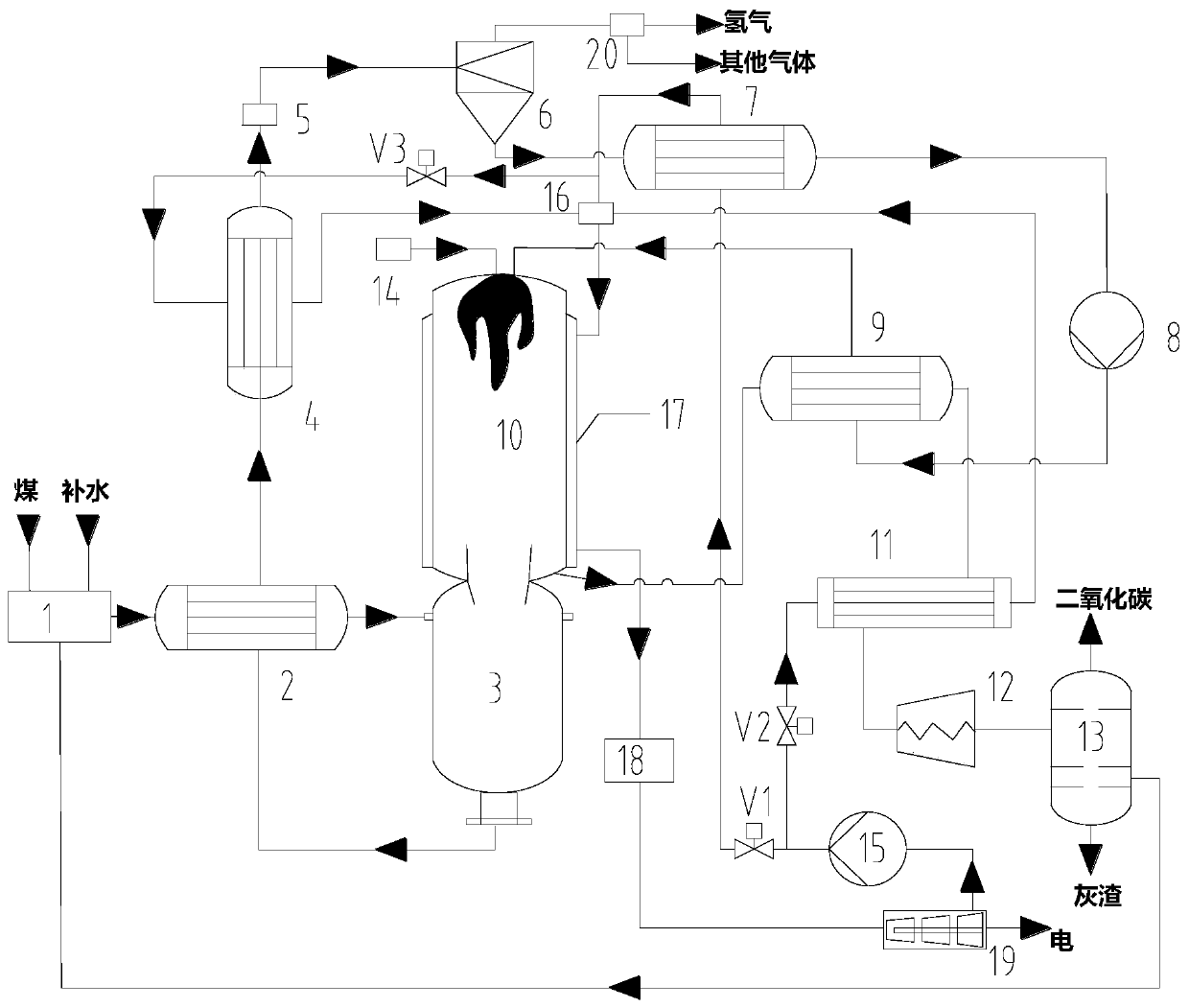

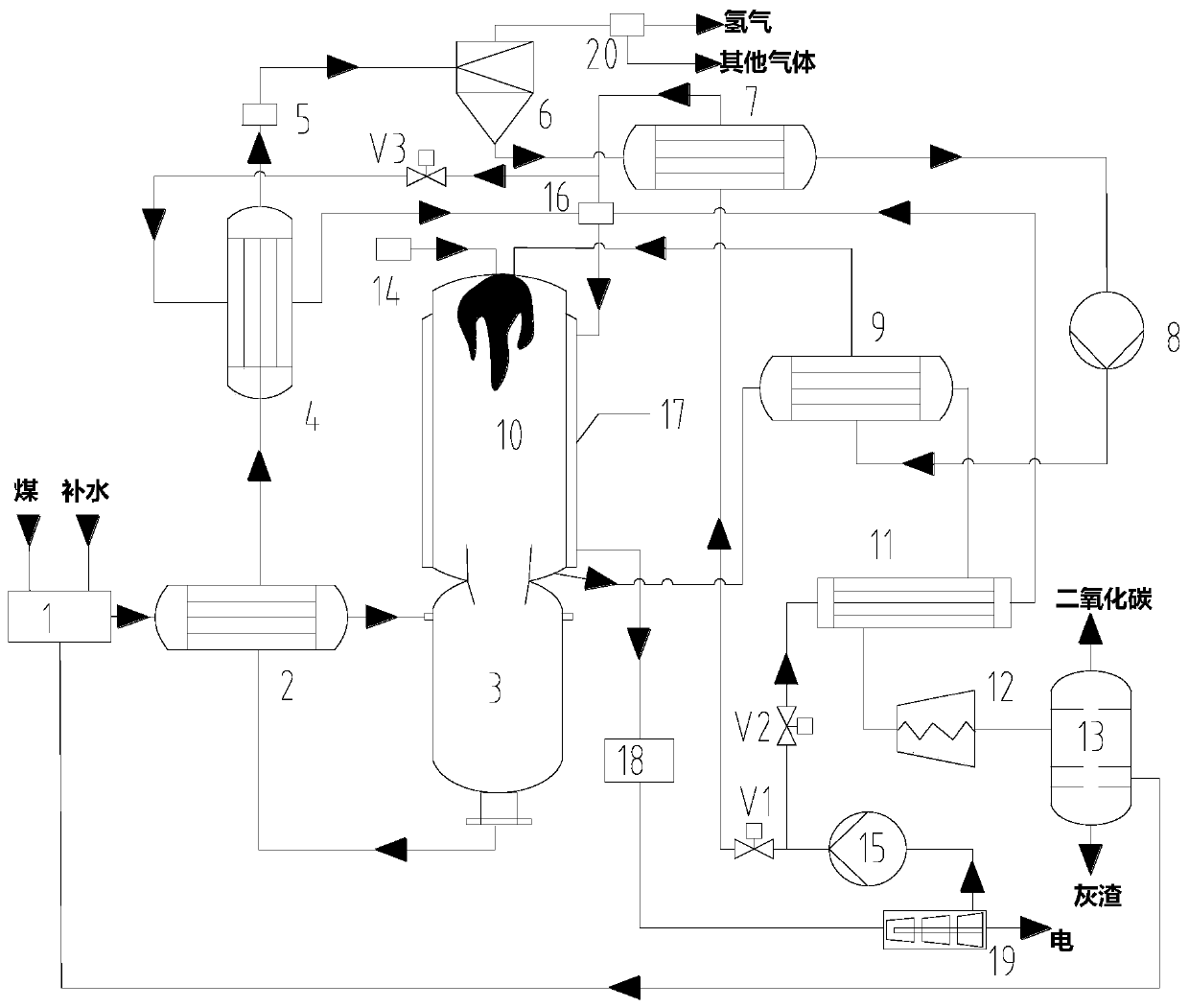

Comprehensive method and system for utilizing carbon-contained organic matter

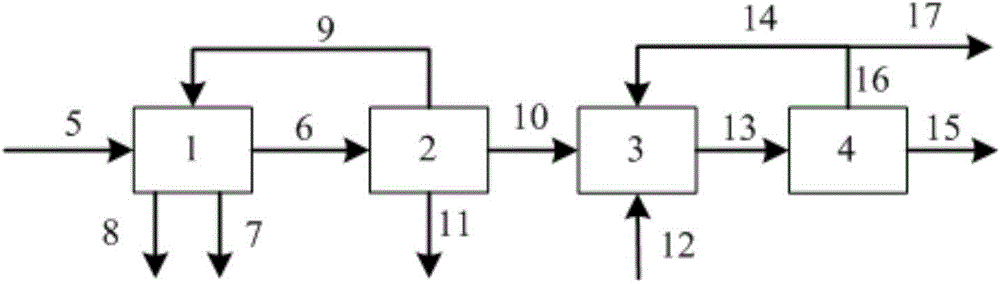

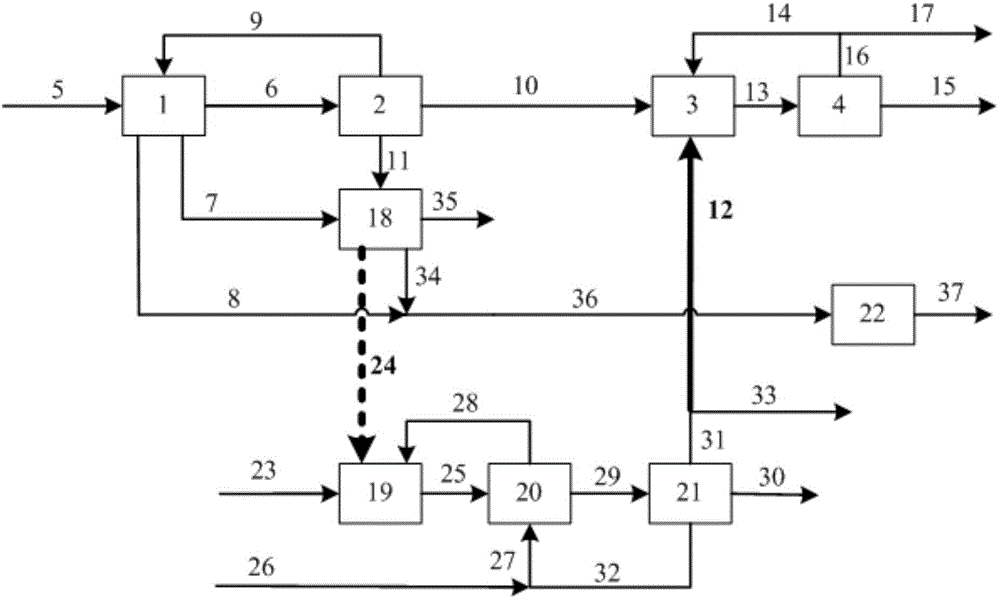

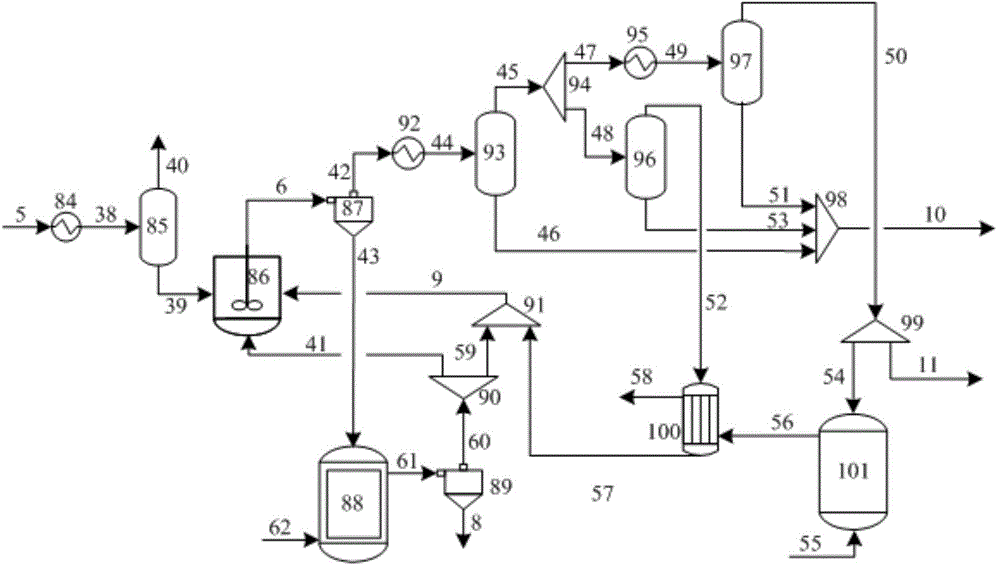

The invention relates to a comprehensive method for utilizing a carbon-contained organic matter, comprising a high-pressure hot water / supercritical water gasifying sub-method and a poly-generation sub-method, wherein the high-pressure hot water / supercritical water gasifying sub-method is continuously carried out by the decompression continuous discharge of a reaction product. The decompression continuous discharge is realized by adopting at least two buffer tanks which are operated in parallel connection or at least one decompressing valve. The invention converts the carbon-contained organic matter into a clean energy chemical product, such as methane, and the like and / or clean electricity by coupling the high-pressure hot water / supercritical water gasifying sub-method, the poly-generation sub-method, an alga carbon absorbing sub-method and / or a composite energy source hydrogen preparation sub-method to form an ecological cycle mode for the development and utilization of carbon-contained organic matter resources. The invention also provides a comprehensive system for implementing the comprehensive method.

Owner:ENN SCI & TECH DEV

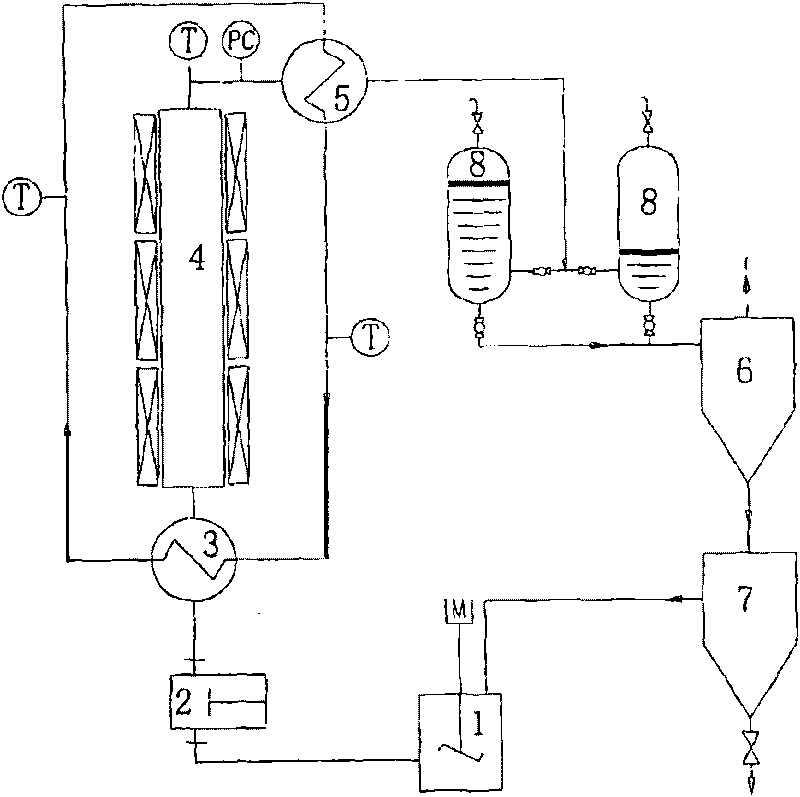

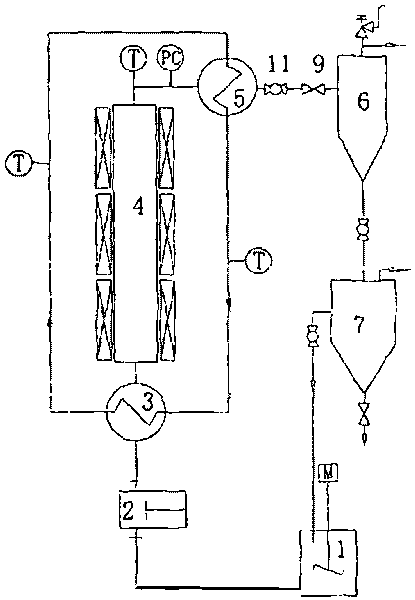

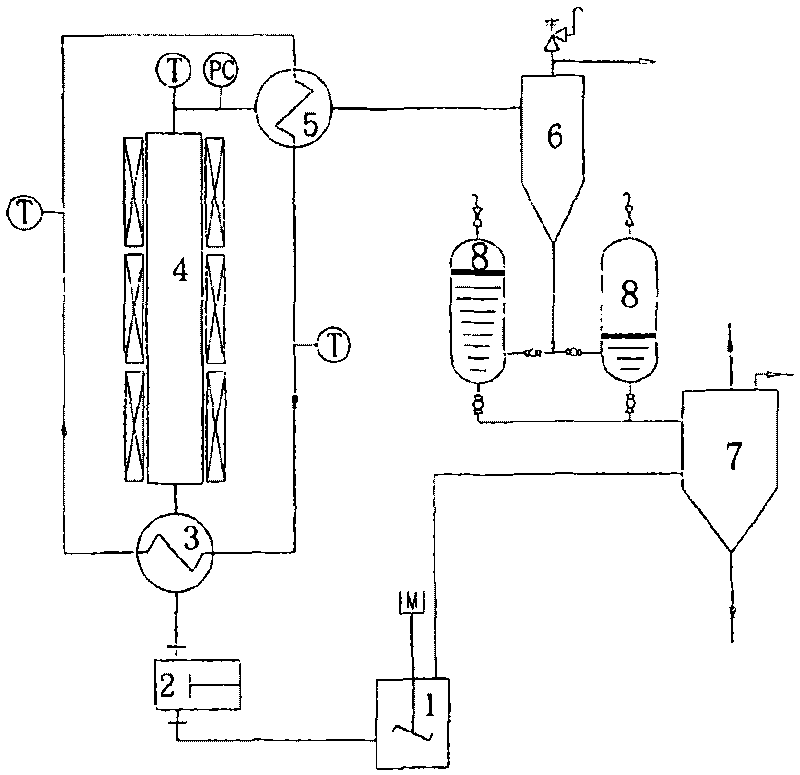

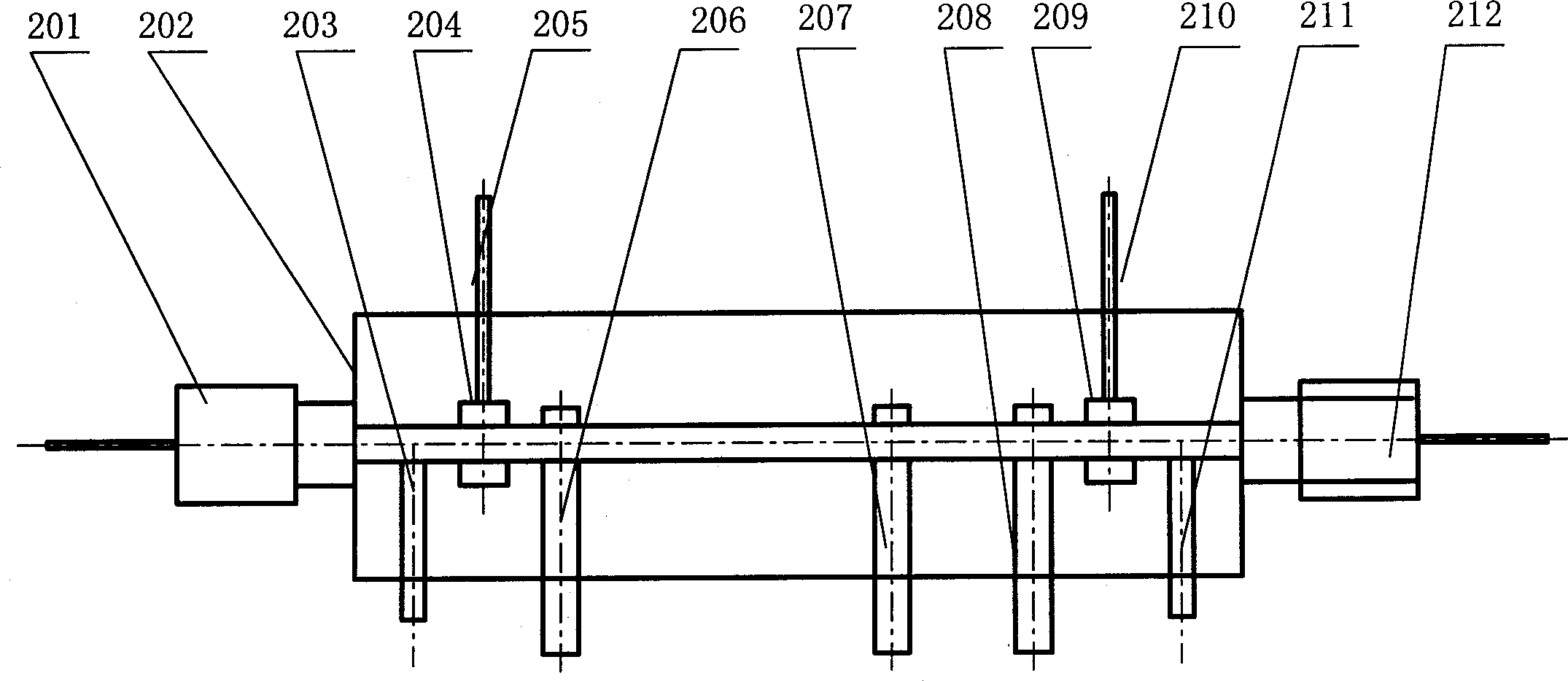

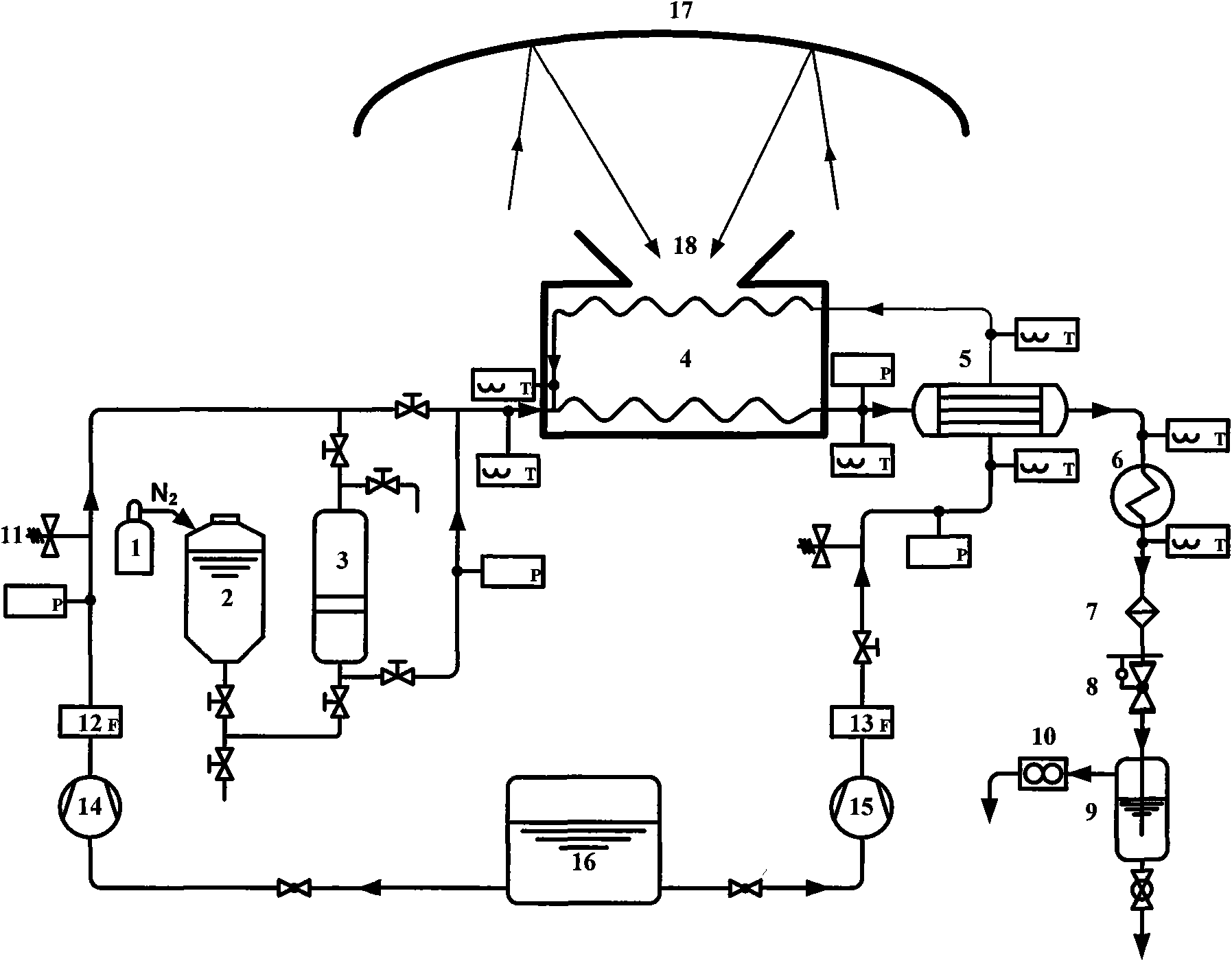

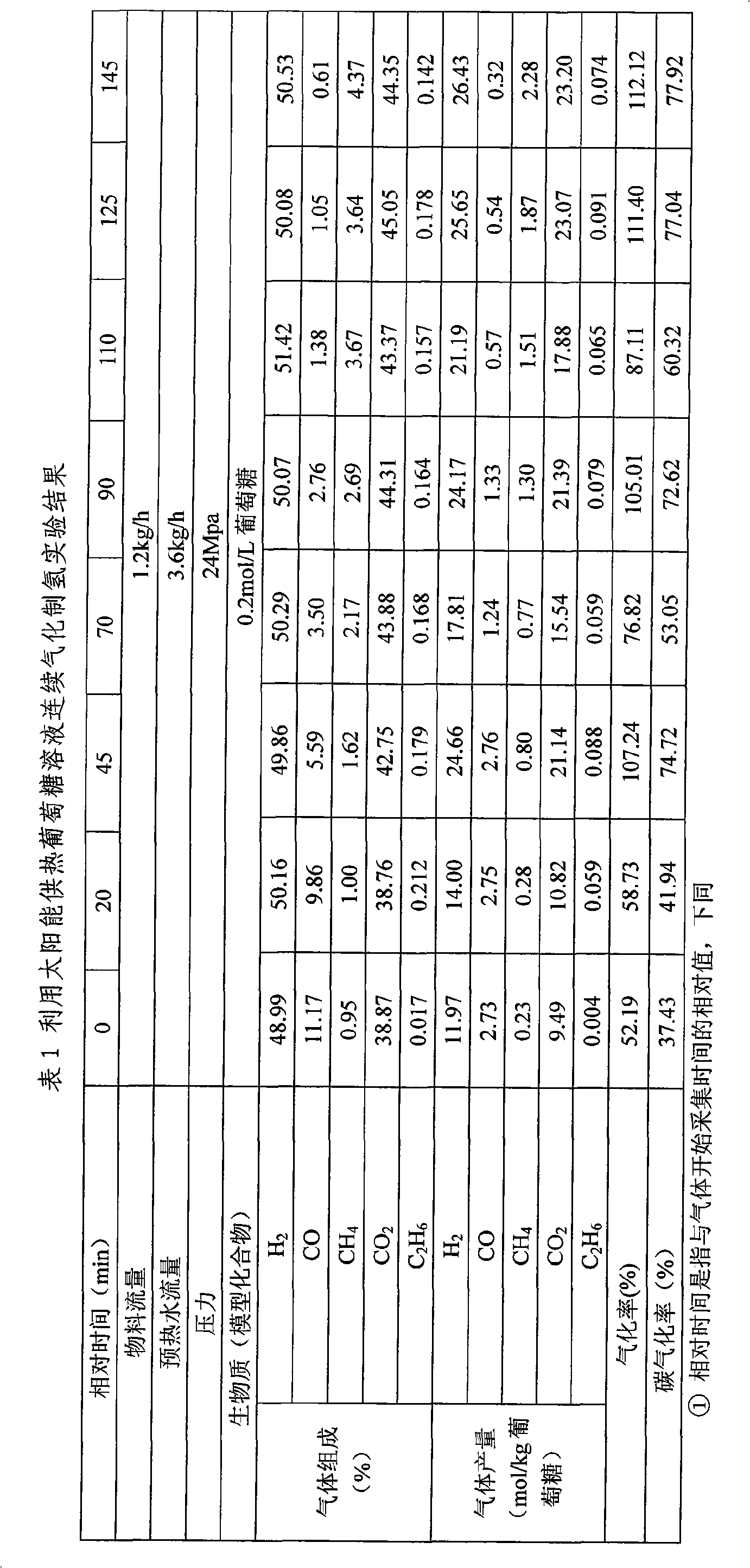

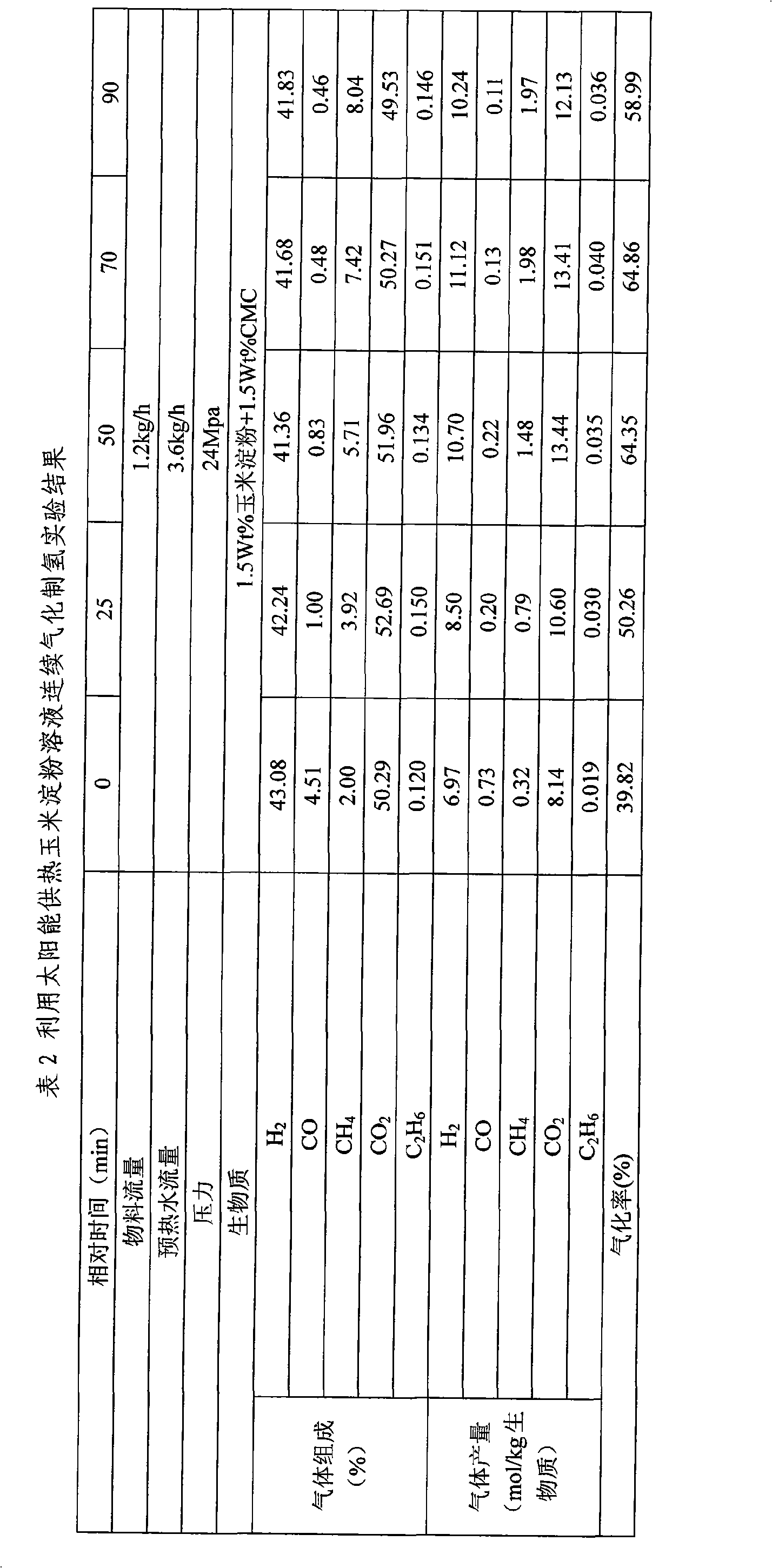

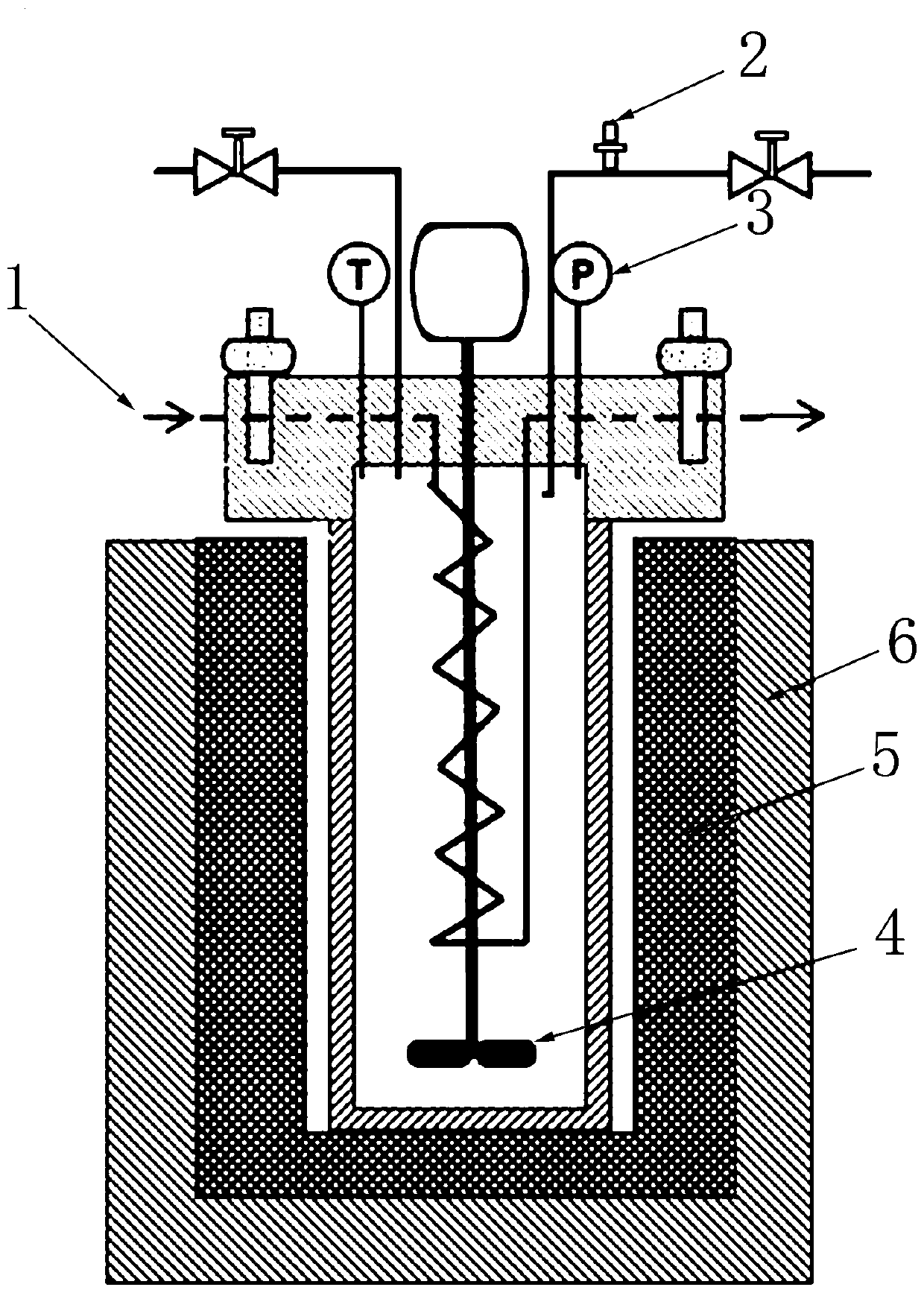

Continuous supercritical water gasifying hydrogen producing method and apparatus with organic solid matter

InactiveCN1375447AHeating up fastFast and efficient gasification reactionPlastic recyclingHydrogen productionHigh pressureSolid matter

The solid raw material has no need of drying treatment, can be pulverized and directly added into reaction system; said invention uses carboxymethyl-cellulose sodium as additive and implement high-pressure multiphase mixed continuous transmission of solid raw material; its reaction equipment is formed from double-pump, double feeding system, reactor, back pressure valve, gas-liquid separator, sampling device and wet gas flowmeter; it adopts the reactor with current heating mode and radiation heating mode, can implement quick heating and high-effective gasification reaction. The hydrogen-making and sampling device provided by said invention can product hydrogen gas and CO2 gas as main product, its CO volume content is less than 1%, and its gasification rate can be up to 100%.

Owner:陕西中核交大超洁能源技术有限公司

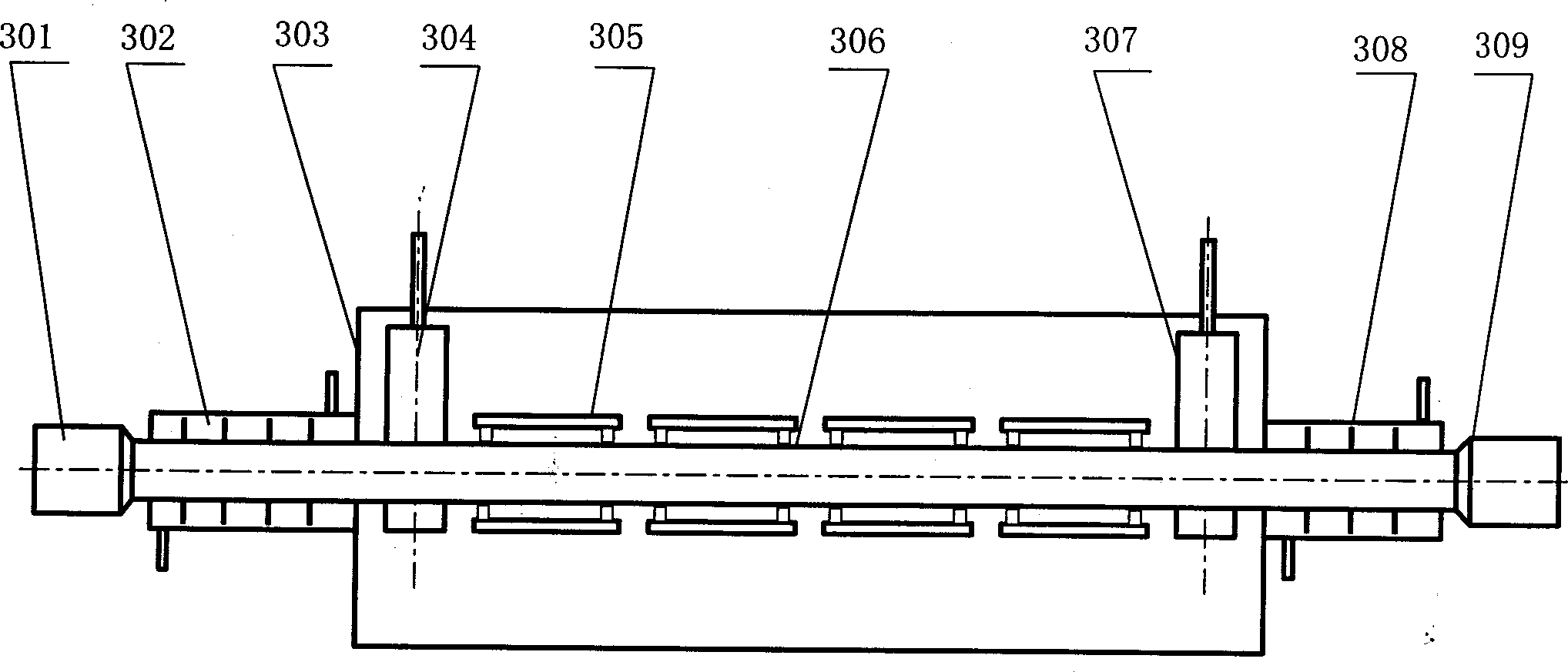

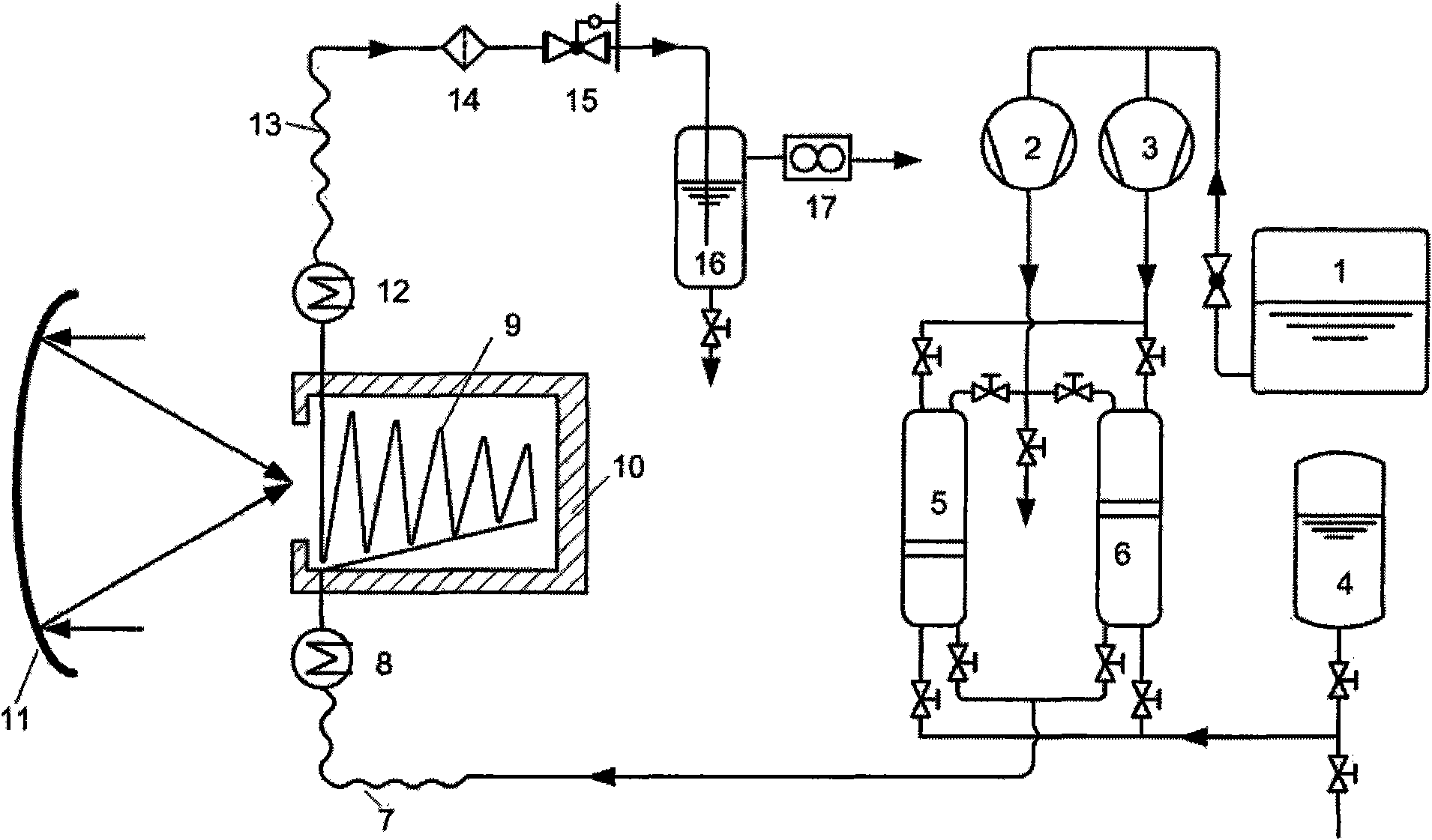

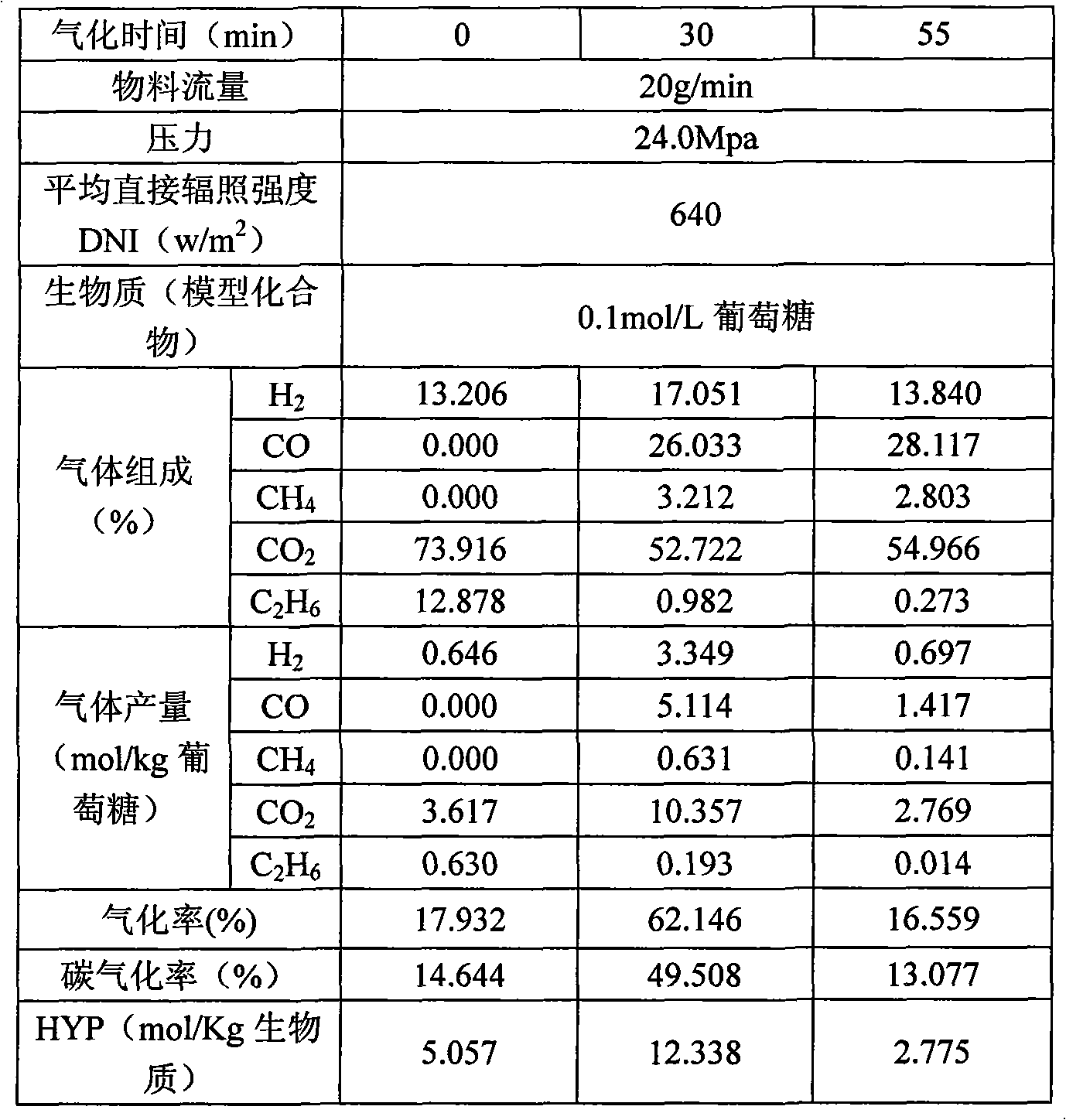

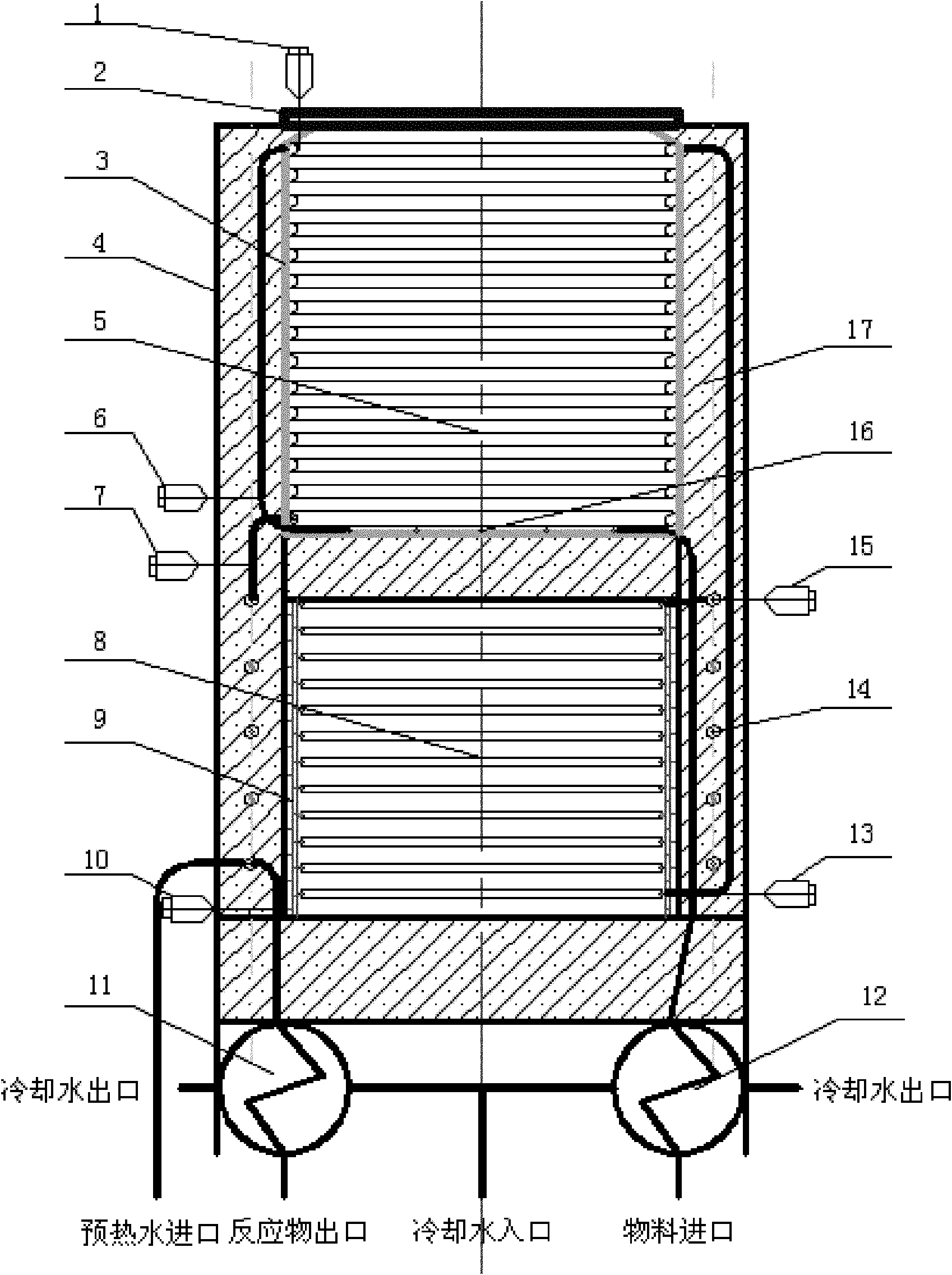

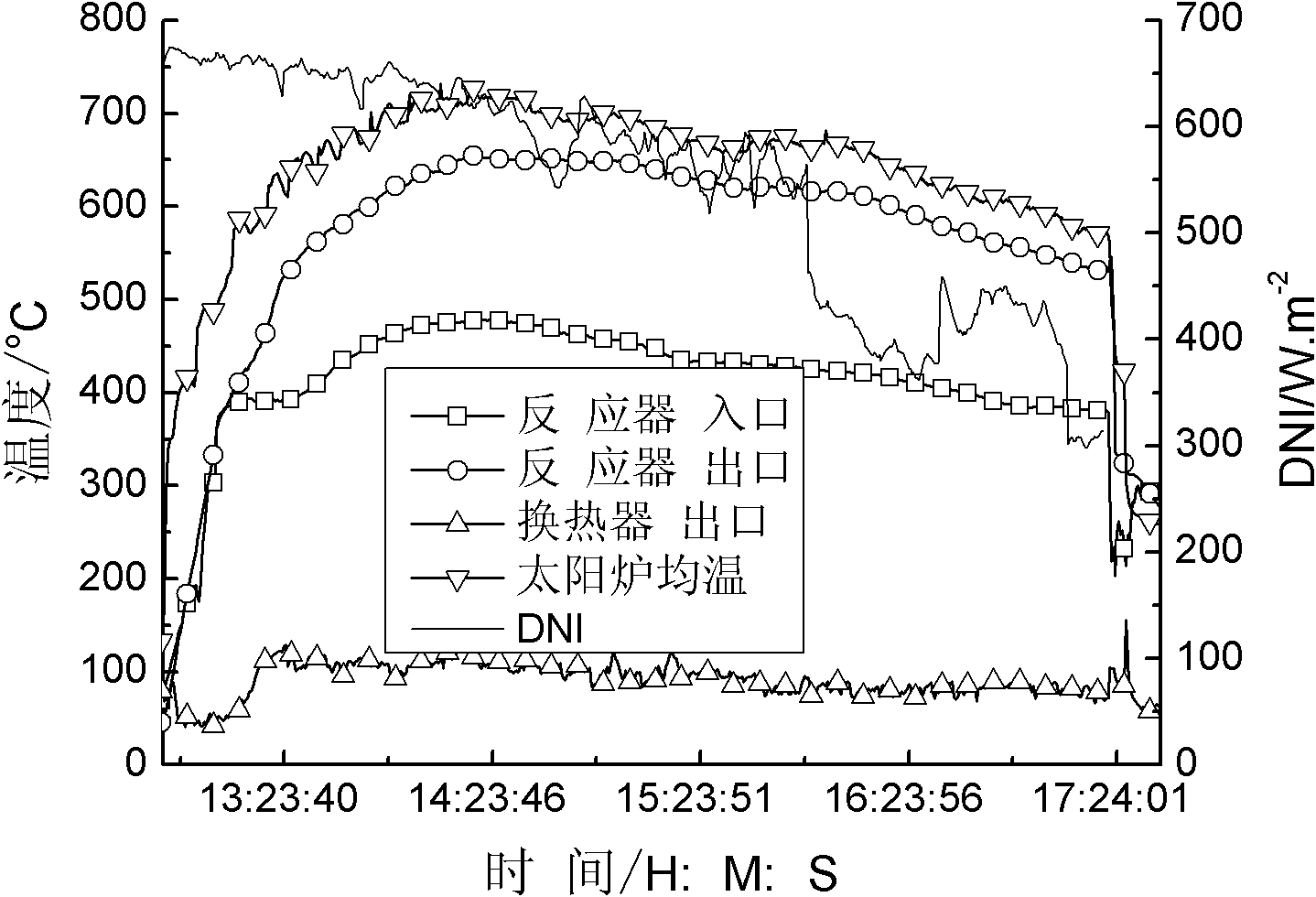

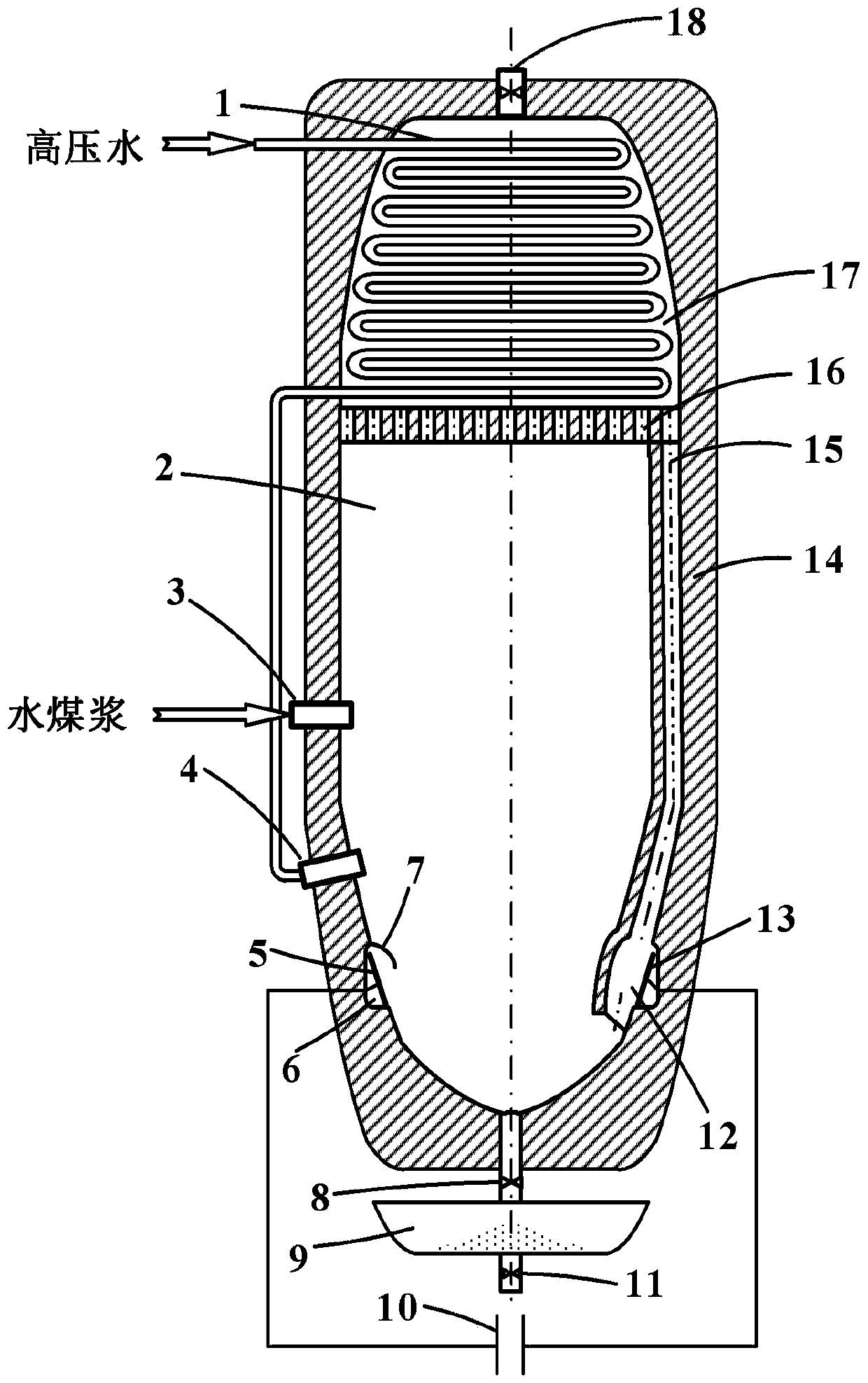

Biomass supercritical water gasification hydrogen production absorption reactor thermally driven by solar energy

ActiveCN101597025AReduce heat lossIncrease the concentration ratioEnergy inputHydrogen productionHeat fluxHeat flow

The invention discloses a biomass supercritical water gasification hydrogen production absorption reactor thermally driven by solar energy. An absorption reactor cavity is connected with a conical surface solar energy secondary condenser, thus effectively improving heat flux density at the daylight opening of the absorption reactor; the absorption reactor cavity is internally provided with a coiler flow biomass supercritical water reactor, biomass and supercritical water continuously flow in a reaction tube to absorb and focus solar energy direct radiation and cavity inner wall secondary radiation for gasification hydrogen production reaction; the coil flow reactor is divided into a preheating section and a reaction section, thus realizing fast warming of biomass material; the inner wall of the absorption reactor is built by laying firebricks and coated with silicate heat insulation cotton; and the inclined angle of the absorption reactor can be adjusted by a pedestal adjusting screw rod. The absorption reactor, being one core part of the biomass supercritical water gasification hydrogen production devices thermally driven by solar energy, can realize continuous gasification hydrogen production of various biomasses in supercritical water and has the characteristics of low cost, safety and high efficiency.

Owner:陕西中核交大超洁能源技术有限公司

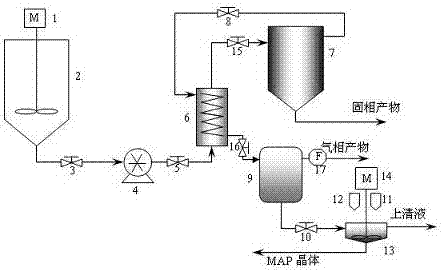

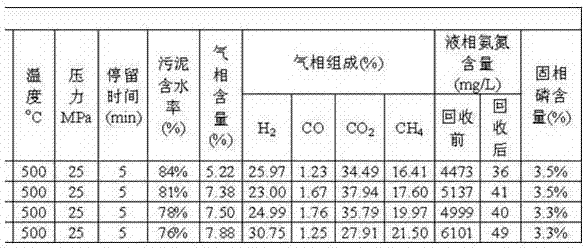

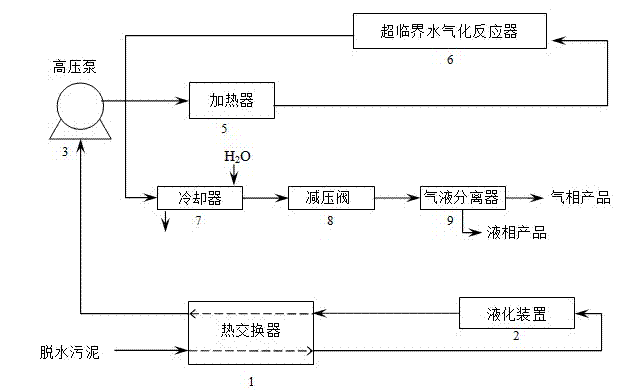

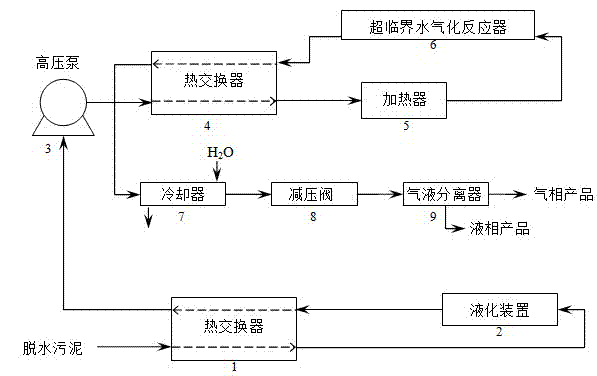

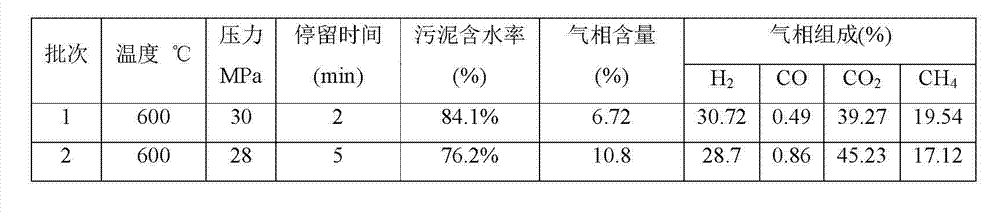

Method and equipment for resource utilization of dewatered sludge in sewage plant by supercritical treatment

InactiveCN102267789AImprove liquidityImprove processing efficiencyOther chemical processesSolid waste disposalSorbentResource utilization

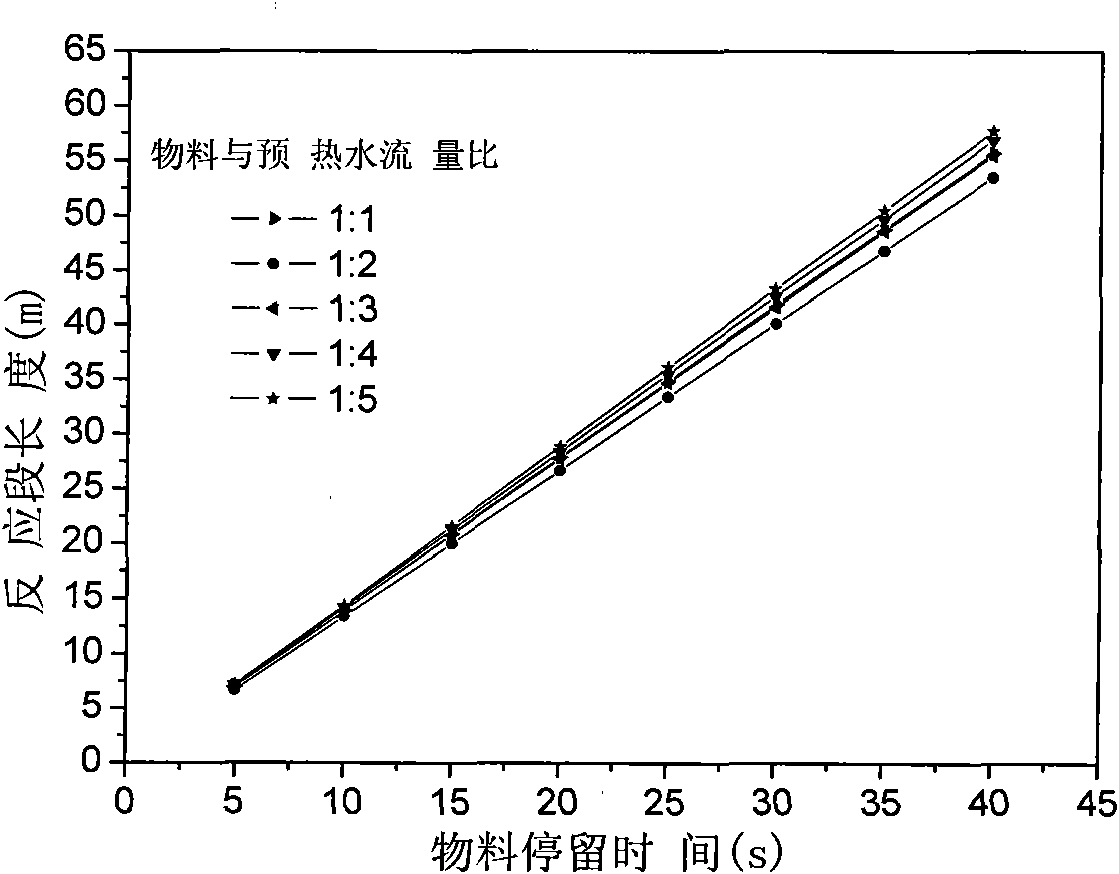

The invention discloses a method and equipment for supercritical treatment and resource utilization of dewatered sludge of a sewage plant. The method is characterized in that: the dewatered sludge (the water content is 77 to 85 percent) is directly treated in a supercritical water vaporization mode, the flowability of the sludge is improved through a high-speed stirring device, blockage of a tubular reactor is prevented by adopting a high-pressure fluidized bed device, high heat of a gas-liquid separation process is fully utilized, and the low-temperature sludge is heated by using a heat exchanger; and the liquid phase product with high ammonia nitrogen content is directly recycled by a magnesium ammonium phosphate (MAP) method. The method has the advantages that: any moisture is not added in the vaporization process, and the sludge treatment efficiency is high; the heat can be utilized in the process; ammonia nitrogen in the liquid phase product is timely reclaimed so as to reduce secondary pollution; the reclaimed supernate can be recycled, the periodically discharged solid phase product with low heavy metal content can be directly used as a phosphate fertilizer, and the solid phase product with high heavy metal content can be used as an adsorbent; and the treatment expense of the whole system is reduced by resource utilization of the liquid phase product and the solid phaseproduct.

Owner:HOHAI UNIV

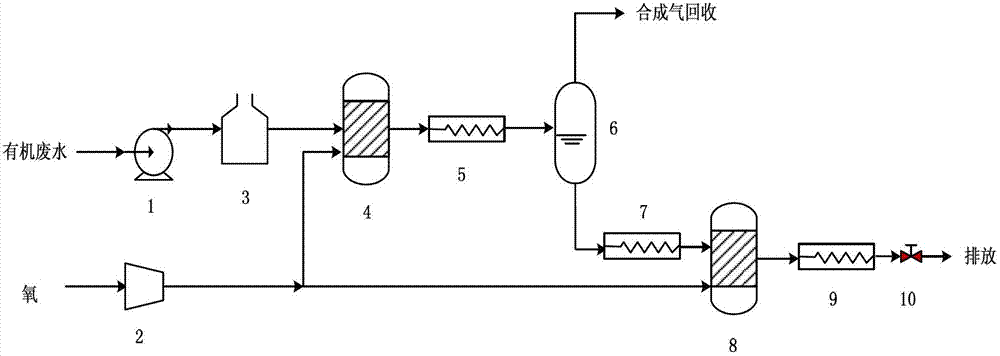

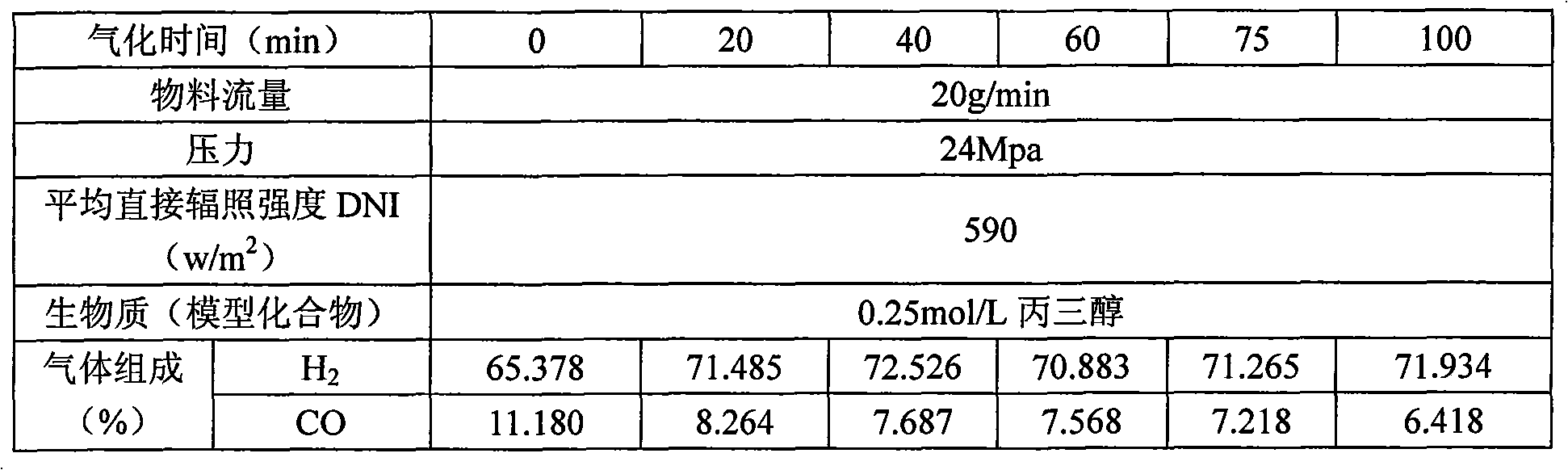

Supercritical water gasification-oxidation method for treating organic wastewater and recycling synthesis gas

ActiveCN102874916AImplement resourcesAchieving processing powerHydrogenBulk chemical productionHigh concentrationHigh pressure

The invention discloses a supercritical water gasification-oxidation method for treating organic wastewater and recycling synthesis gas. The supercritical water gasification-oxidation method comprises the following steps that: (1) the organic wastewater enters a preheater and a supercritical water gasification device sequentially by a high-pressure pump, and oxygen is divided by a compressor, so that one part of oxygen enters the supercritical water gasification device; (2) fluid from an outlet of the supercritical water gasification device enters a high-pressure gas-liquid separator by a heat exchanger, the synthesis gas of H2, CO and CH4 on the upper part is recycled, the fluid at the bottom enters a heater and a supercritical water oxidation reactor sequentially, and the part of oxygen which is divided by the compressor enters the supercritical water oxidation reactor; and (3) the fluid passing through the supercritical water oxidation reactor passes through a cooler and a back pressure valve sequentially and is discharged under the condition of reaching the standard. The supercritical water gasification-oxidation method can be widely applied to the treatment of the high-concentration organic wastewater.

Owner:XI AN JIAOTONG UNIV +1

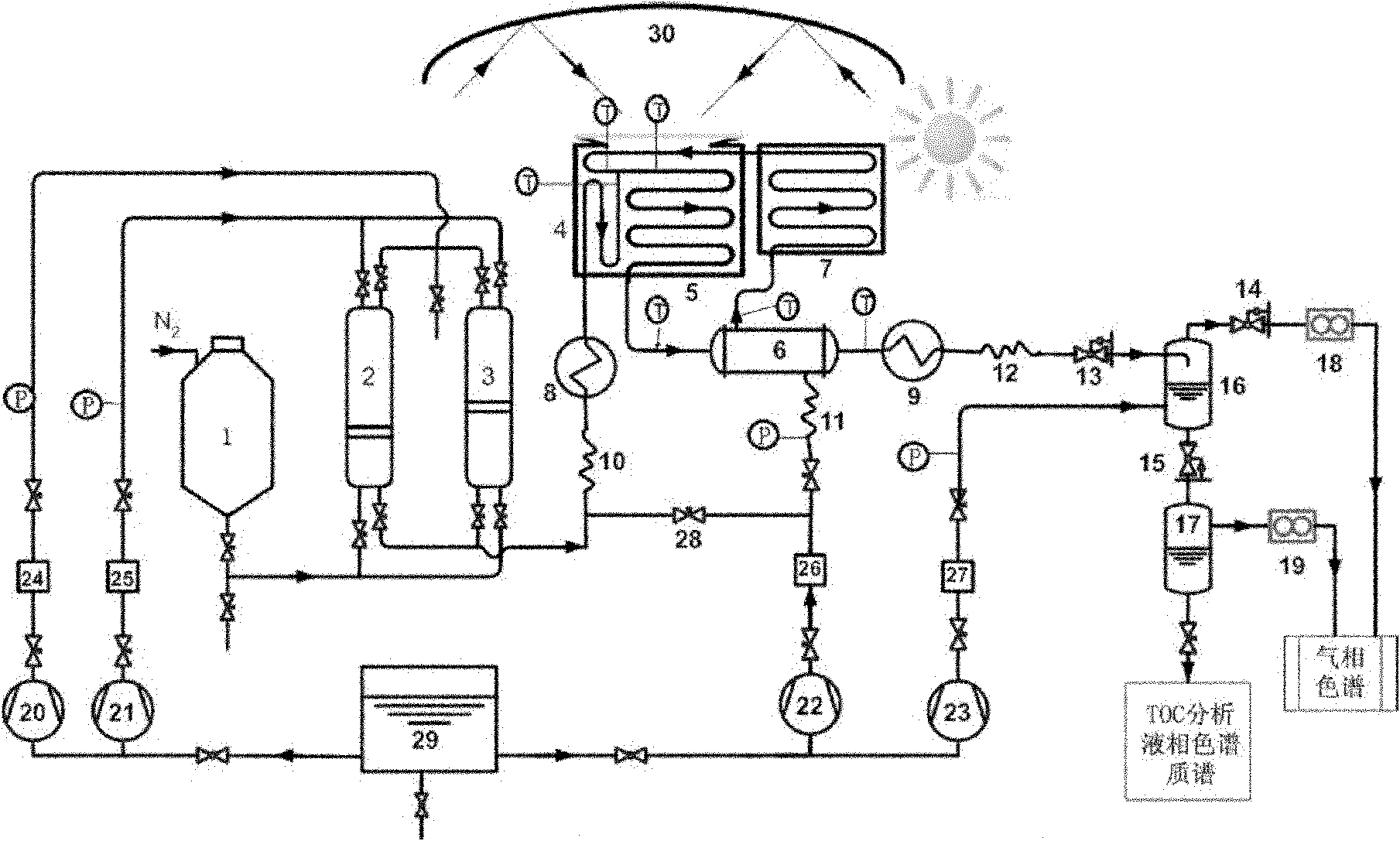

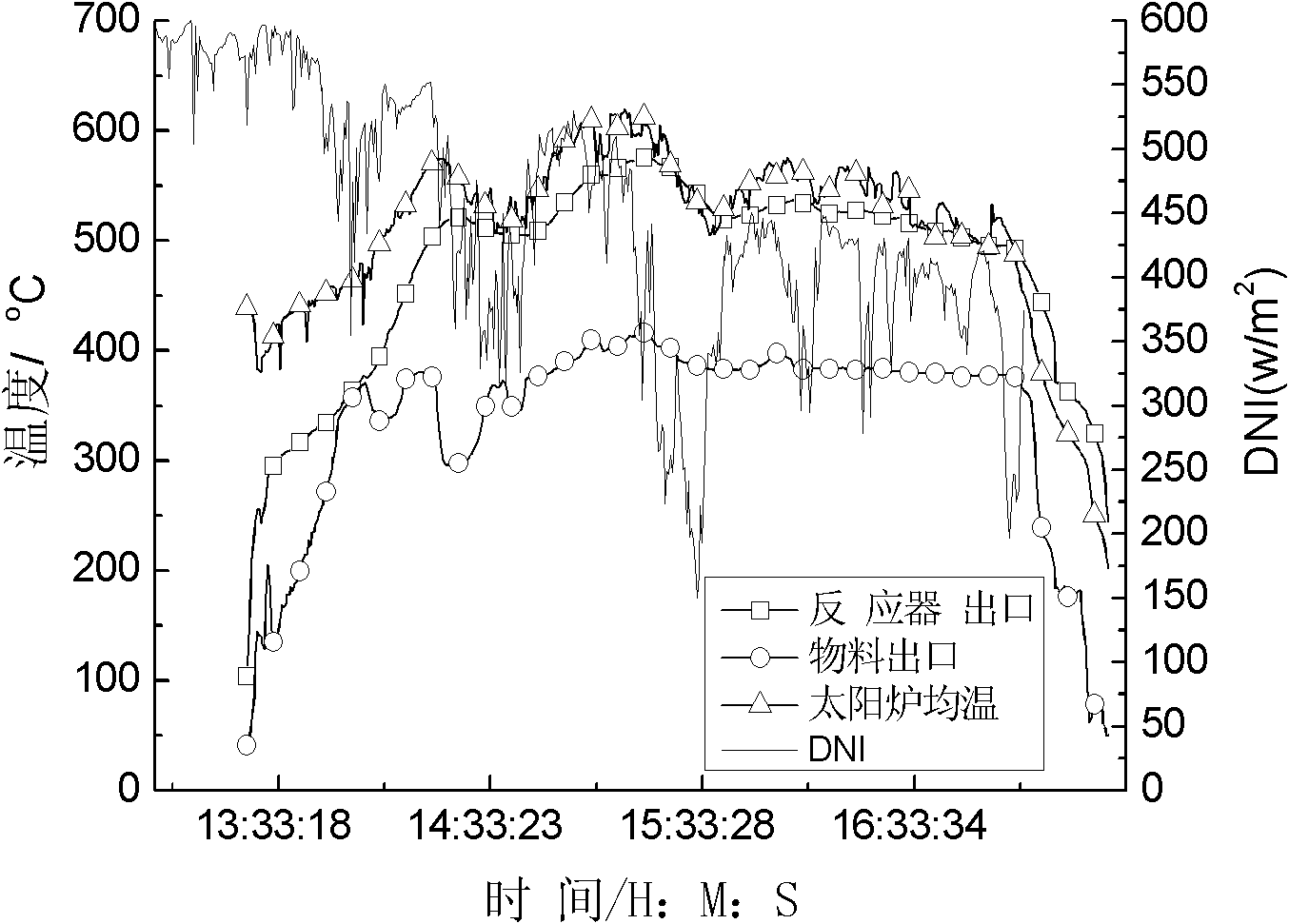

Biomass supercritical water gasification hydrogen production system and method thermally driven by focusing solar energy

ActiveCN101597026AEfficient use ofReach storageEnergy inputHydrogen productionSystem parametersPollution

The invention discloses a biomass supercritical water gasification hydrogen production system and method thermally driven by focusing solar energy; wherein the system mainly comprises a concentrating system composed of a spinning-pitching tread heliostat and a conical surface solar secondary condenser, a solar cavity absorption reactor internally provided with a coiler flow reactor, a biomass and water transmission system, a product collection and analysis system and a systemic parameter acquisition system. Biomass and supercritical water absorb and focus solar radiation and carry out gasification hydrogen production reaction in the coil flow reactor. Compared with the plate type coupling hydrogen production system, the invention has the characteristics of simplified system, low cost, strong stability and favoured industrial amplification. The solar hydrogen production method provided by the invention utilizes solar heat supply to transform low-class biomass into high quality hydrogen energy through supercritical water gasification hydrogen production, the whole process is environmental-friendly without pollution, and renewable energy source is fully utilized, thus being beneficial to large-scale promotion and application of solar hydrogen production.

Owner:陕西中核交大超洁能源技术有限公司

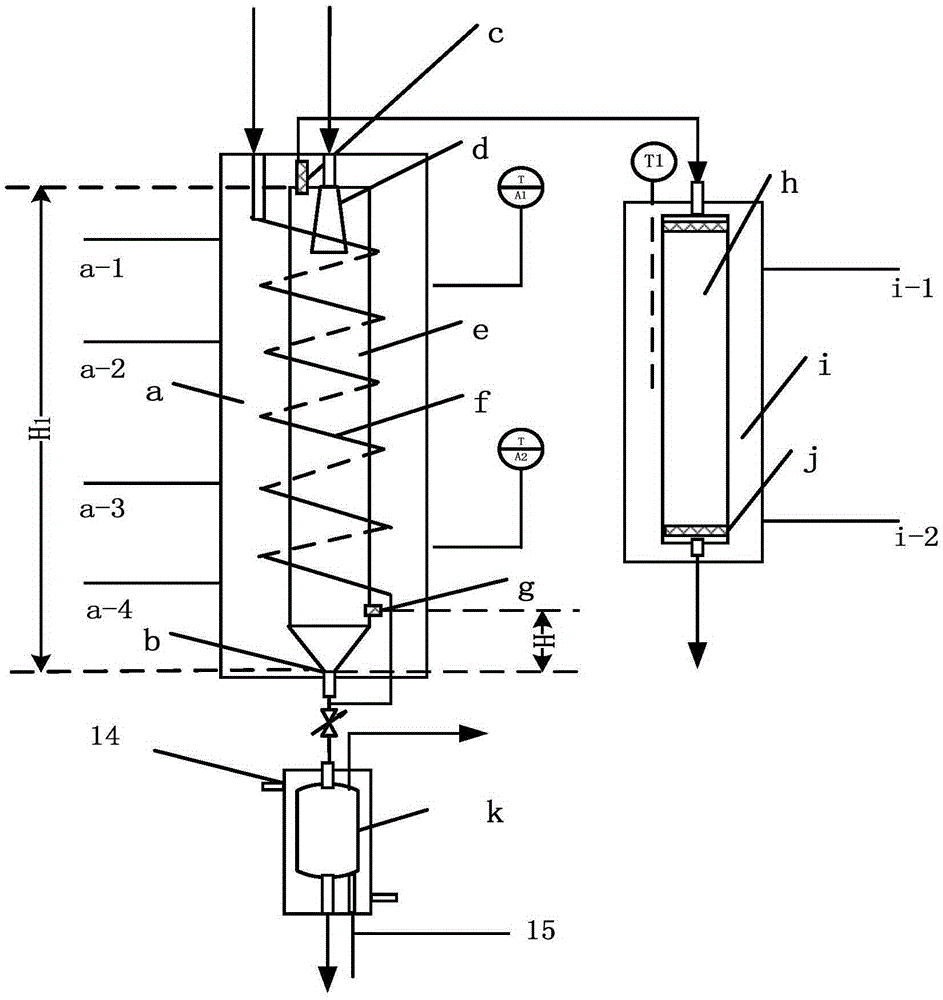

Method and device for preparing active carbon and byproducts of combustion gas and tar through conversion of coal in supercritical water

ActiveCN105349183AStable temperatureUniform temperatureGaseous fuelsWorking-up tarSolubilityMethanation

Provided are a method and device for preparing active carbon and byproducts of combustion gas and tar through conversion of coal in supercritical water. In the method, by utilization of characteristics of high extraction solubility and extremely strong mass and heat transferring performances of a supercritical water high-pressure environment, coal is employed as a raw material to prepare active carbon, high-heating-value gas and tar, and a technology for integration of pyrolysis, gasification and extraction of coal by utilization of supercritical water is achieved. A vertical supercritical water reactor is employed and a catalytic reactor is matched. The supercritical water reactor is mainly aimed to the extraction process and the gasification process, and the matched catalytic reactor is aimed to the methanation process. The method and device have advantages of high thermal efficiency and good economical efficiency.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Low-water-content dehydrated sludge direct supercritical water gasification processing apparatus and method

ActiveCN102730917AImprove liquidityReduce cloggingSludge treatmentHydrogen productionSludgeGas phase

In prior arts of sludge processing, water is added for preparing slurry for improving the sludge fluidity, such that the processing efficiency of the dehydrated sludge is reduced. Aiming against the technical problem, the invention provides a low-water-content dehydrated sludge direct supercritical water gasification processing apparatus and a corresponding method. The method is characterized in that: before the dehydrated sludge is directly subjected to supercritical water gasification processing, the sludge is pre-liquefied by using a liquefaction apparatus, such that the sludge fluidity is improved, and a part of the inorganic substances in the sludge is settled. Therefore, subsequent pumping and supercharging can easily be carried out, a blocking risk in pipelines is reduced, sludge processing efficiency is substantially improved, and equipment utilization rate is substantially improved. Also, gas-phase products and heat in the product can be effectively recovered and utilized, such that energy utilization rate is improved, and processing cost is reduced.

Owner:HOHAI UNIV

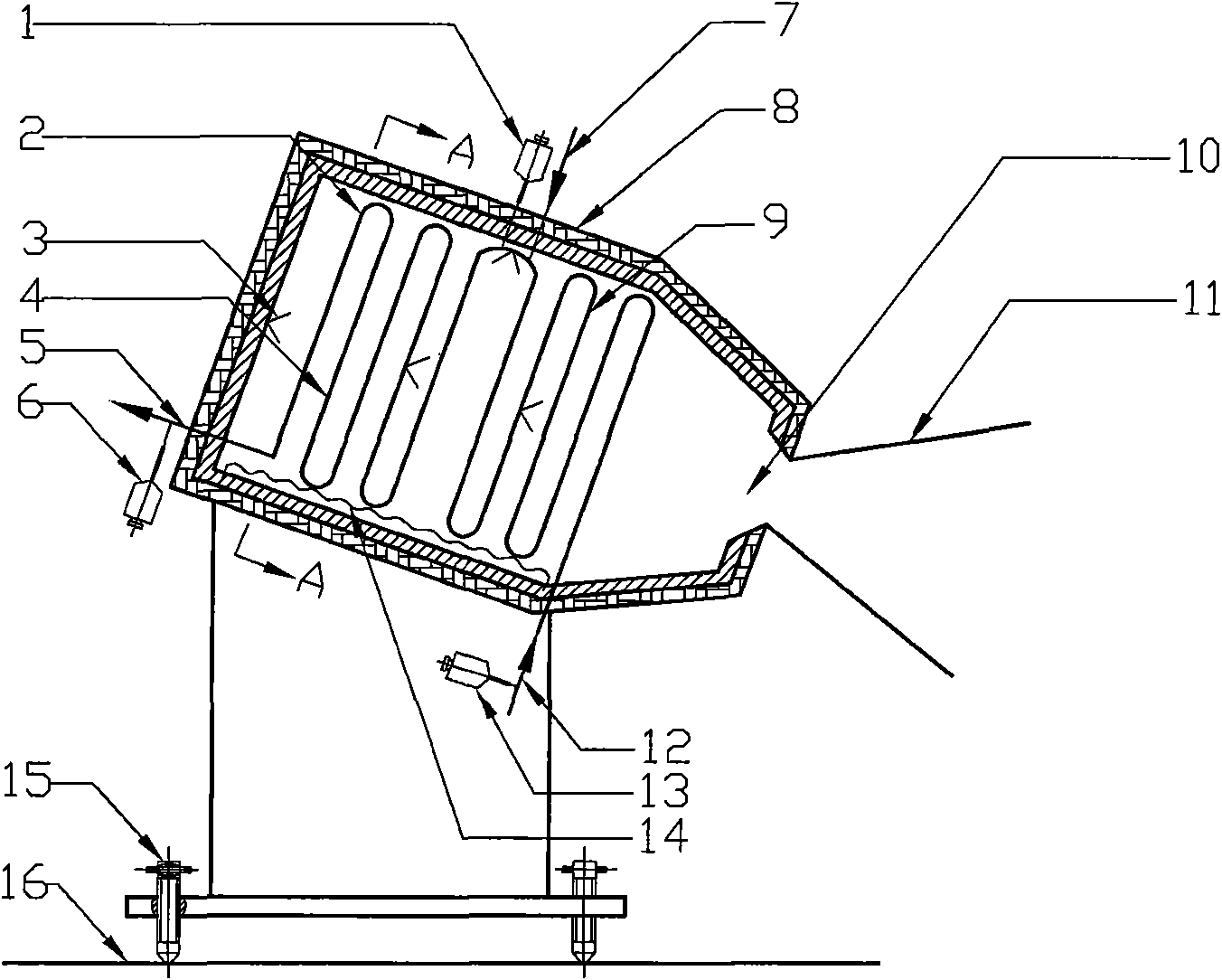

System and method for producing hydrogen by collecting solar energy in multi-plate mode and coupling biomass supercritical water gasification

ActiveCN102126704AEasy to operateNo pollution in the processEnergy inputHydrogen productionProcess engineeringEngineering

The invention relates to a system and a method for producing hydrogen by collecting solar energy in a multi-plate mode and coupling biomass supercritical water gasification. The system comprises a cavity-type solar energy absorption reactor used for absorbing the heat of the solar energy to drive biomass supercritical water gasification hydrogen producing reaction, a preheater used for providing heat for preheating water when the irradiance of the solar energy is not enough, or the fluctuation is larger, and a heat exchanger used for recovering heat and improving the transformation efficiencyof the system energy. The method comprises the following steps: adopting multi-plate light condenser tracking and focusing solar energy for providing the heat source; preheating the high-pressure biomass materials to the temperature of 180-240 DEG C; recovering and reacting by a heat exchanger; introducing the high-temperature liquid heat into the preheater; mixing the high-temperature and high-pressure preheating water at the inlet of a solar energy absorption reactor in a certain proportion, and rapidly heating the materials to supercritical water gasification hydrogen manufacturing. The system and method provided by the invention are beneficial for realizing hydrogen production in high efficiency by focusing solar energy and thermally coupling biomass supercritical water gasification with low cost in large scale.

Owner:陕西中核交大超洁能源技术有限公司

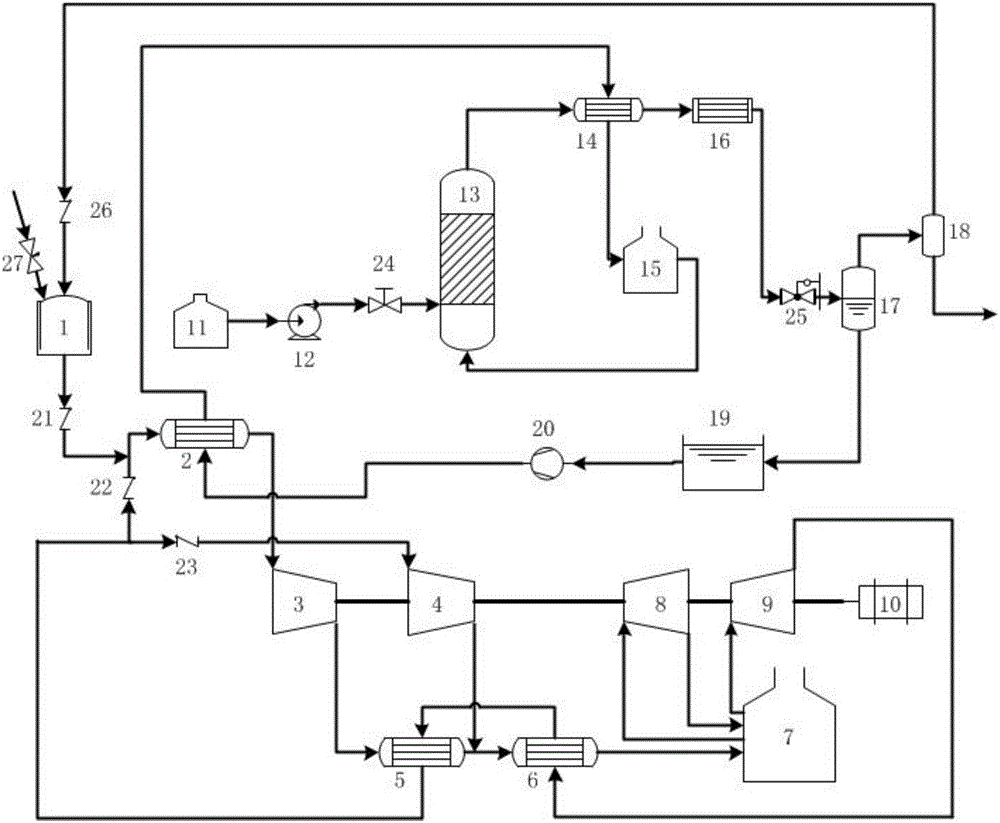

Supercritical water gasification and supercritical carbon dioxide Brayton cycle joint production system

ActiveCN105971679AReliable supplyRealize comprehensive utilizationEnergy inputSteam engine plantsBrayton cycleReaction system

The invention discloses a supercritical water gasification and supercritical carbon dioxide Brayton cycle joint production system which comprises a supercritical water gasification coal or biomass or organic waste reaction system and a supercritical carbon dioxide Brayton cycle power generation system. Dioxide carbon generated in a supercritical water gasification system is used for supplementation of dioxide carbon in the Brayton cycle system, the cost is reduced, effective utilization and clean conversion of coal, biomass and organic waste are conducted, waste heat in the supercritical carbon dioxide Brayton cycle power generation system is used for preheating preheated water in the supercritical water gasification system, and therefore the heat efficiency of the system is improved. By means of the supercritical water gasification and supercritical carbon dioxide Brayton cycle joint production system, a new idea is provided for coupling application of the supercritical water gasification system and the supercritical Brayton cycle power generation system.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

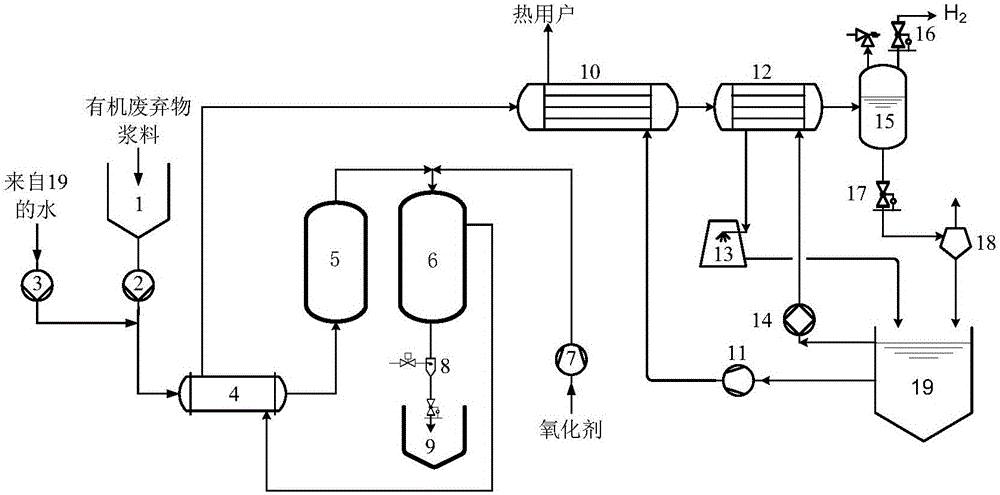

Two-step organic waste treatment system and method based on supercritical/subcritical water technology

ActiveCN106010662ASafe conversionEfficient conversionSludge treatmentHydrogen separationEnvironmental engineeringEngineering

The invention discloses a two-step organic waste treatment system and method based on supercritical / subcritical water technology. The two-step organic waste treatment system comprises a subcritical hydrolysis reactor, a supercritical water gasification reactor, a material conveying apparatus communicated with the bottom of the subcritical water gasification reactor, an oxidizing agent apparatus, a residue discharging apparatus, a material heat exchanger, a backheating apparatus and a product collection apparatus. Organic waste is hydrolyzed into micromolecular products through a subcritical hydrolysis reaction, so requirements on subsequent gasification reaction conditions are lowered, and harmless treatment of organic waste is realized; organic waste is completely converted into clean energy like H2 by supercritical water gasification, so the goal for sustainable efficient recycling of organic waste is achieved; an oxidizing agent is added in the reaction process of supercritical water, so an in-situ heat source is provided for gasification, a gasification rate is increased and energy consumption is reduced; and through directional adjustment and control of technological parameters of subcritical hydrolysis and supercritical water gasification, cooperative effect of the two-step method can be realized, and the gasification conversion rate of organic waste is greatly improved.

Owner:HUNAN UNIV

Biomass supercritical water gasification and multi-plate focusing heat supply coupling hydrogen production device and method

ActiveCN101597027AIncrease independenceOvercome CorrosivitySolar heating energyHydrogenSolubilityHigh energy

The invention discloses a biomass supercritical water gasification and multi-plate focusing heat supply coupling hydrogen production device and a method; wherein the device adopts a cavity absorber to realize efficient absorption of solar energy, adopts a coil type distribution to cause the structure of a reactor to be compact and strengthen heat transmitter in the reactor, and adopts a multi-plate solar energy condenser to realize high-accuracy automatic tracking of the sun and provide a solar energy source with high focusing ratio and high energy current density for biomass supercritical water gasification hydrogen production, thus realizing direct solar thermolysis supercritical water and biomass hydrogen production. The hydrogen production method provided by the invention utilizes the characteristics of water of high solubility, high diffusivity and the like in supercritical state to realize complete efficient gasification of biomass, so as to generate hydrogen rich gas; and meanwhile, reaction temperature required by solar energy thermochemistry circulation hydrogen production is reduced to be lower than 600 DEG C from more than 1500 DEG C, thus greatly reducing direct solar hydrogen production cost and realizing a renewable energy source hydrogen production system.

Owner:陕西中核交大超洁能源技术有限公司

Method for recovering ammonia and synthesis gas from coking wastewater

ActiveCN103145287AIncrease COD concentrationImprove utilizationHydrogen separationMultistage water/sewage treatmentWater storage tankCo2 absorption

The invention discloses a method for recovering ammonia and synthesis gas from coking wastewater. The method comprises the following steps: (1) entering coking wastewater and a certain amount of alkali into an ammonia evaporator; passing the fluid on the top of the ammonia evaporator through a stronger ammonia water storage tank by virtue of a dephlegmator and a condenser orderly to achieve recovery of ammonia, and entering bottom fluid into a wastewater concentrator; (2) entering the fluid on the top of the wastewater concentrator into a deep treatment section via a heat exchanger, entering the bottom fluid into a supercritical water gasification reactor through a compressor and a heating furnace orderly, and meanwhile, and entering oxygen into the supercritical water gasification reactor via an oxygen compressor; (3) entering the fluid gasified by the supercritical water into s a gas-liquid separator through the heat exchanger and a reducing valve orderly; and (4) entering the bottom fluid of the gas-liquid separator into the deep treatment section, entering the top fluid into a CO2 absorption tower, and meanwhile, diluting a part of fluid in the stronger ammonia water storage tank is together with dilution water in a diluted ammonia water storage tank, and then entering into the CO2 absorption tower via a centrifugal pump, recovering the synthesis gas from the top of the tower, and recycling the ammonium carbonate solution at the bottom of the tower.

Owner:XI AN JIAOTONG UNIV

Comprehensive utilization system and process for hydrogen production by gasification of oil shale refining integrated associated coal

ActiveCN104152166AHigh calorific valueHigh economic valueHydrogen separation using solid contactTreatment with hydrotreatment processesBrown coalCombustion

The invention discloses a comprehensive utilization system and process for hydrogen production by gasification of oil shale refining integrated associated coal. The system comprises an oil shale dry distillation unit, a shale oil-gas separation unit, a shale oil hydrogenation upgrading unit and a separator which are sequentially connected and further comprises a combustion furnace, a coal supercritical water gasification unit, a heat exchanger, a hydrogen purification unit and a construction material production unit. According to the comprehensive utilization system and process disclosed by the invention, oil shale fragments discarded from the oil shale dry distillation unit and excess residual coal gas provide heat to the coal supercritical water gasification reaction, the coal resources with relatively high calorific value and high economic value for maintaining the coal supercritical water gasification reaction are saved, shale associated brown coal can be utilized in an integrated mode to produce high-economic-value hydrogen and the allocation of resources is optimized and meanwhile, the economic efficiency of the process is improved.

Owner:SOUTH CHINA UNIV OF TECH

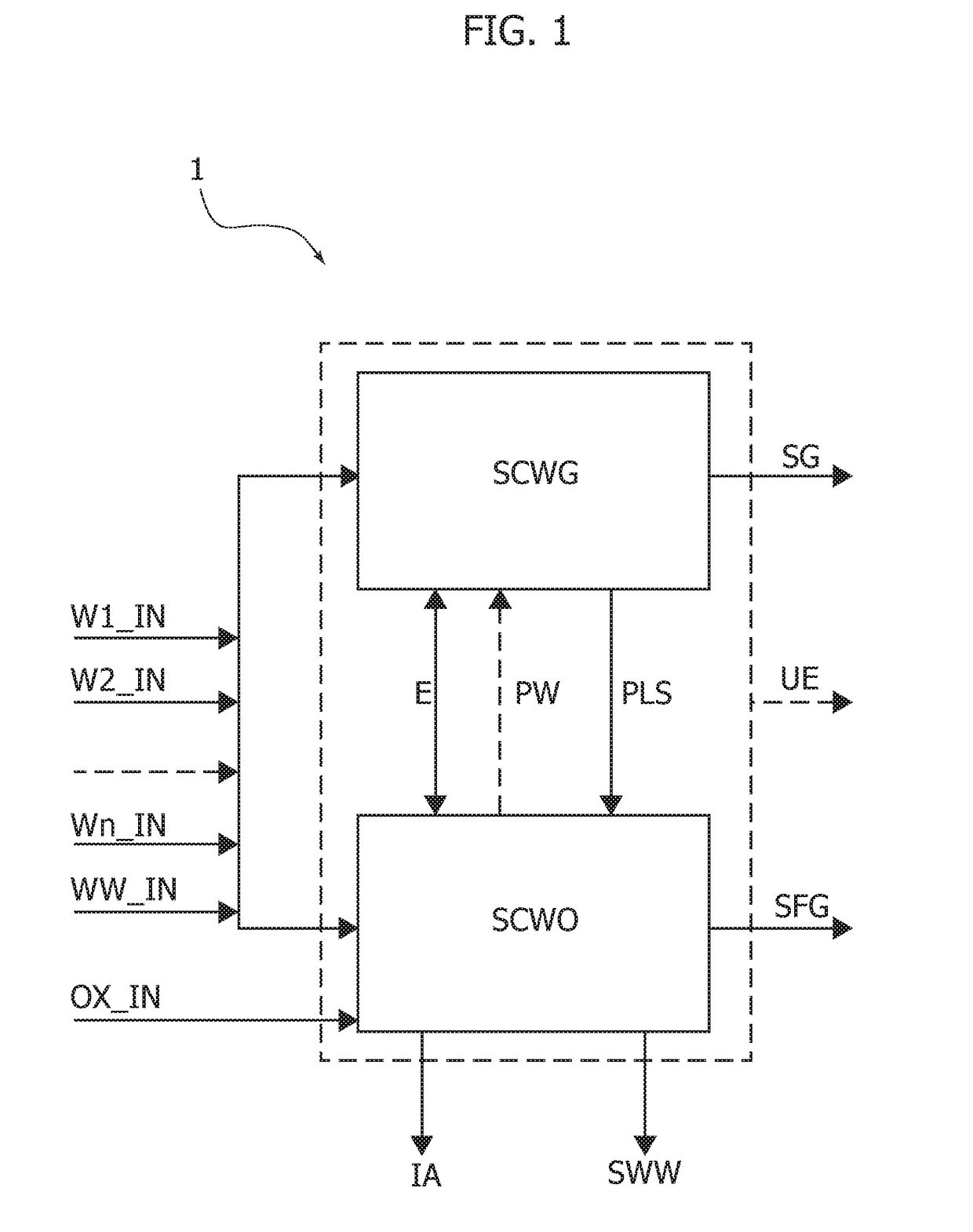

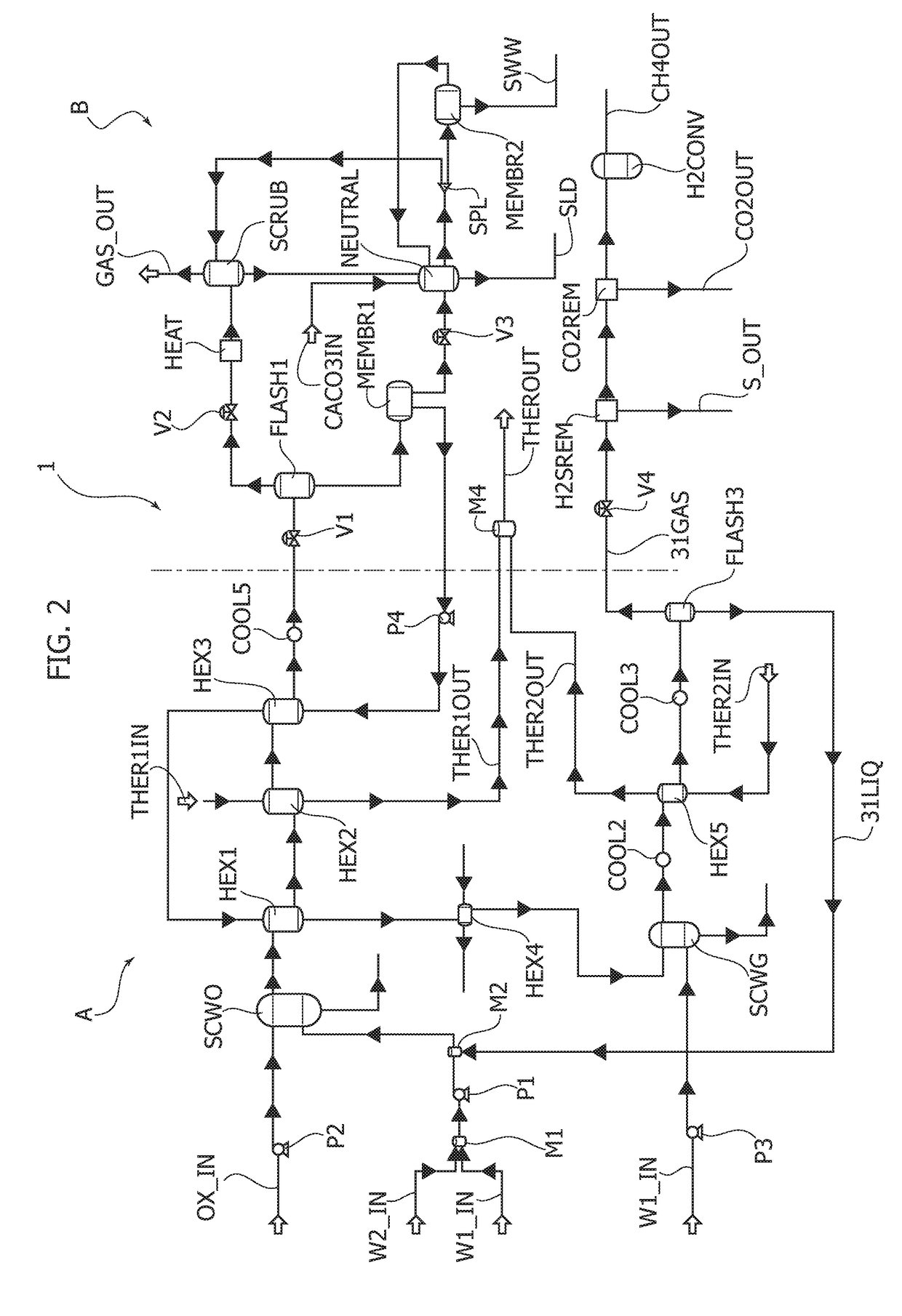

Plant for waste disposal and associated method

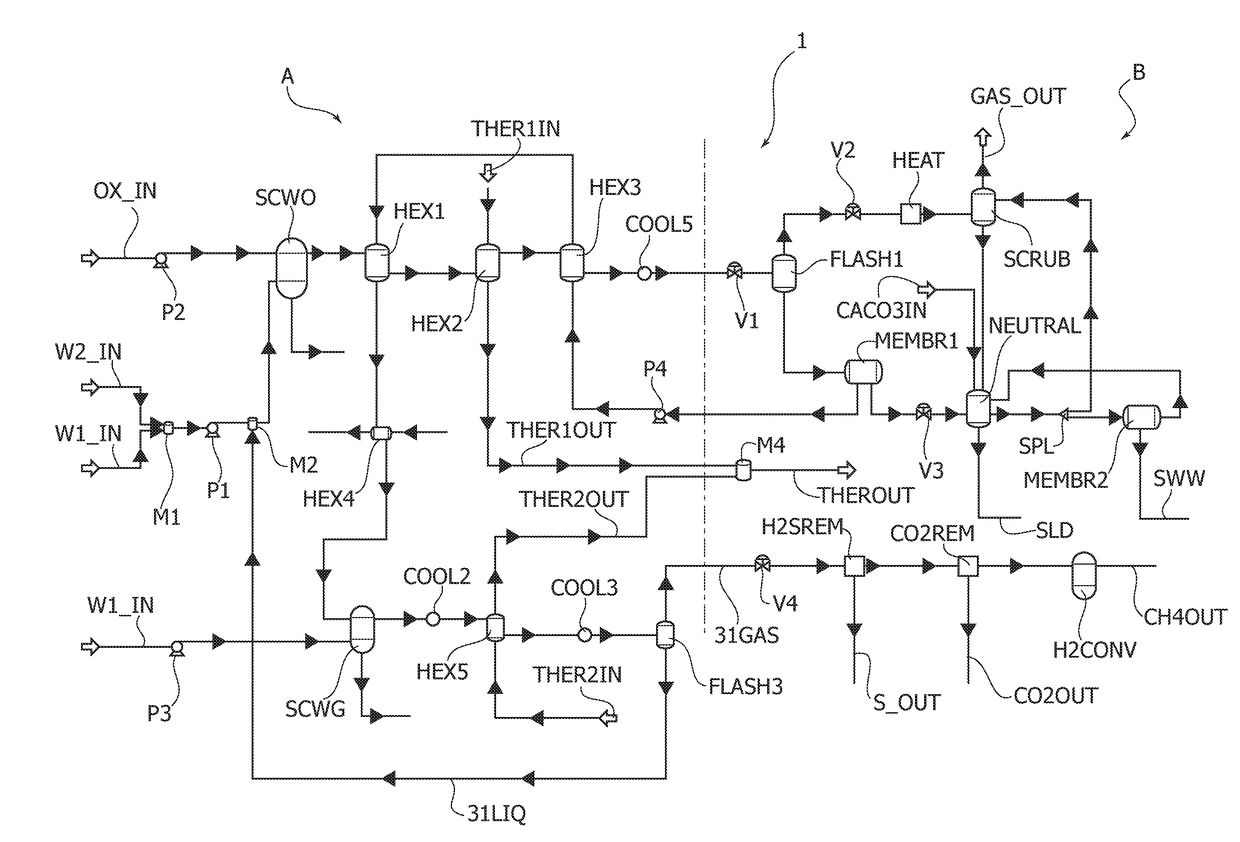

ActiveUS20180117561A1Improve energy efficiencyMinimal environmental impactWaste water treatment from quariesLiquid degasificationEnvironmental engineeringSupercritical water oxidation

A plant for the disposal of wastes includes a supercritical water oxidation reactor, a supercritical water gasification reactor, and a feeding system configured for feeding at least two organic currents of wastes to the supercritical water oxidation reactor and supercritical water gasification reactor and configured for feeding at least one aqueous flow within said plant. The feeding system is configured for feeding the at least one aqueous current with a series flow through the supercritical water oxidation reactor and supercritical water gasification reactor. The feeding system is configured for feeding the at least two organic currents of wastes with a parallel flow through the supercritical water oxidation reactor and supercritical water gasification reactor and so as to selectively feed each of the organic currents of wastes to the supercritical water oxidation reactor or to the supercritical water gasification reactor.

Owner:ARCHIMEDE

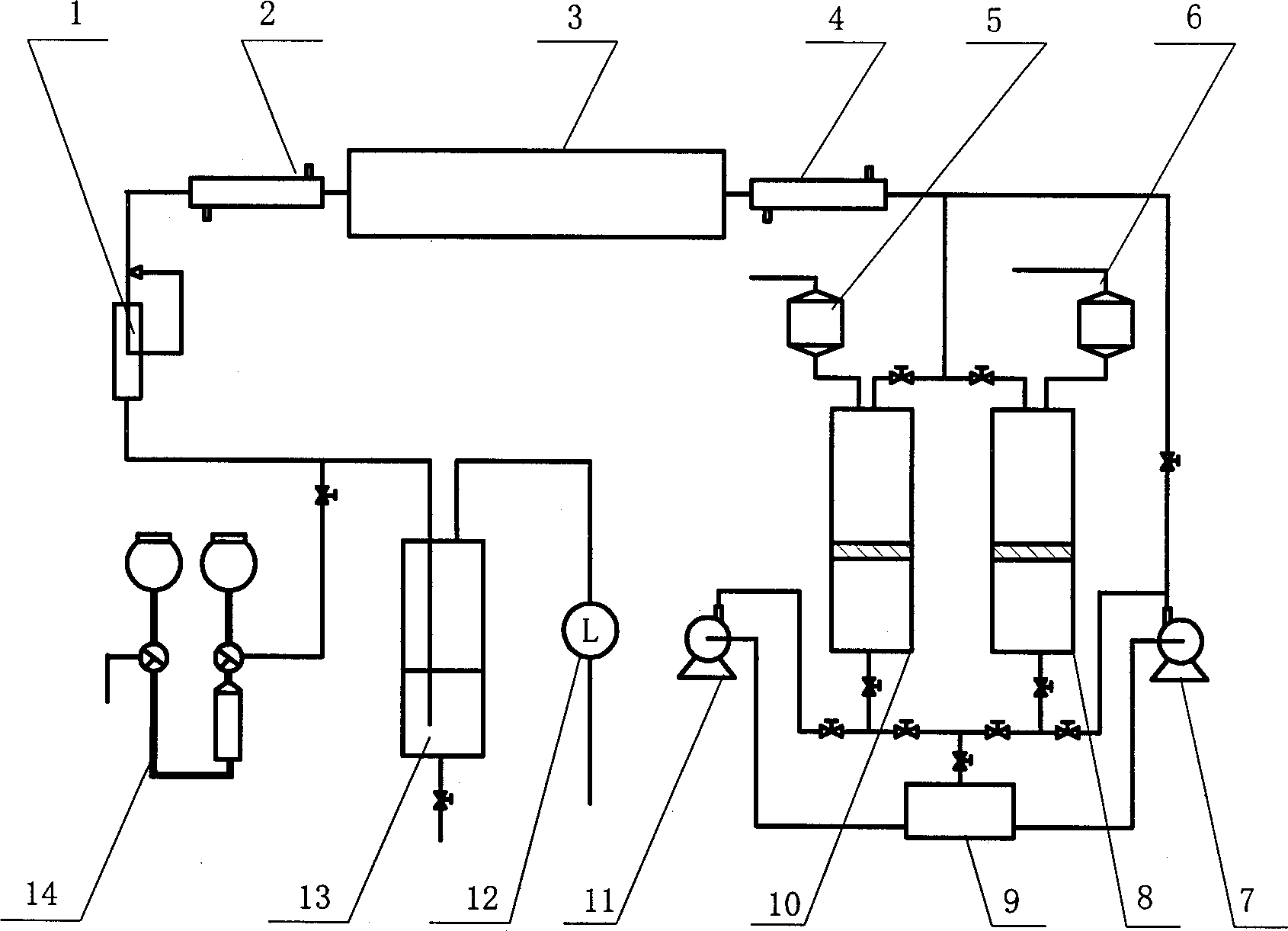

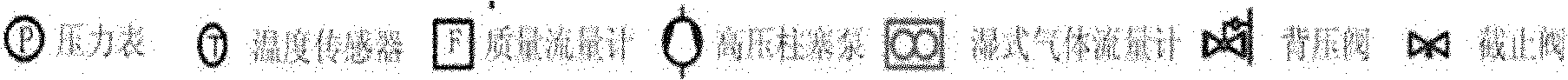

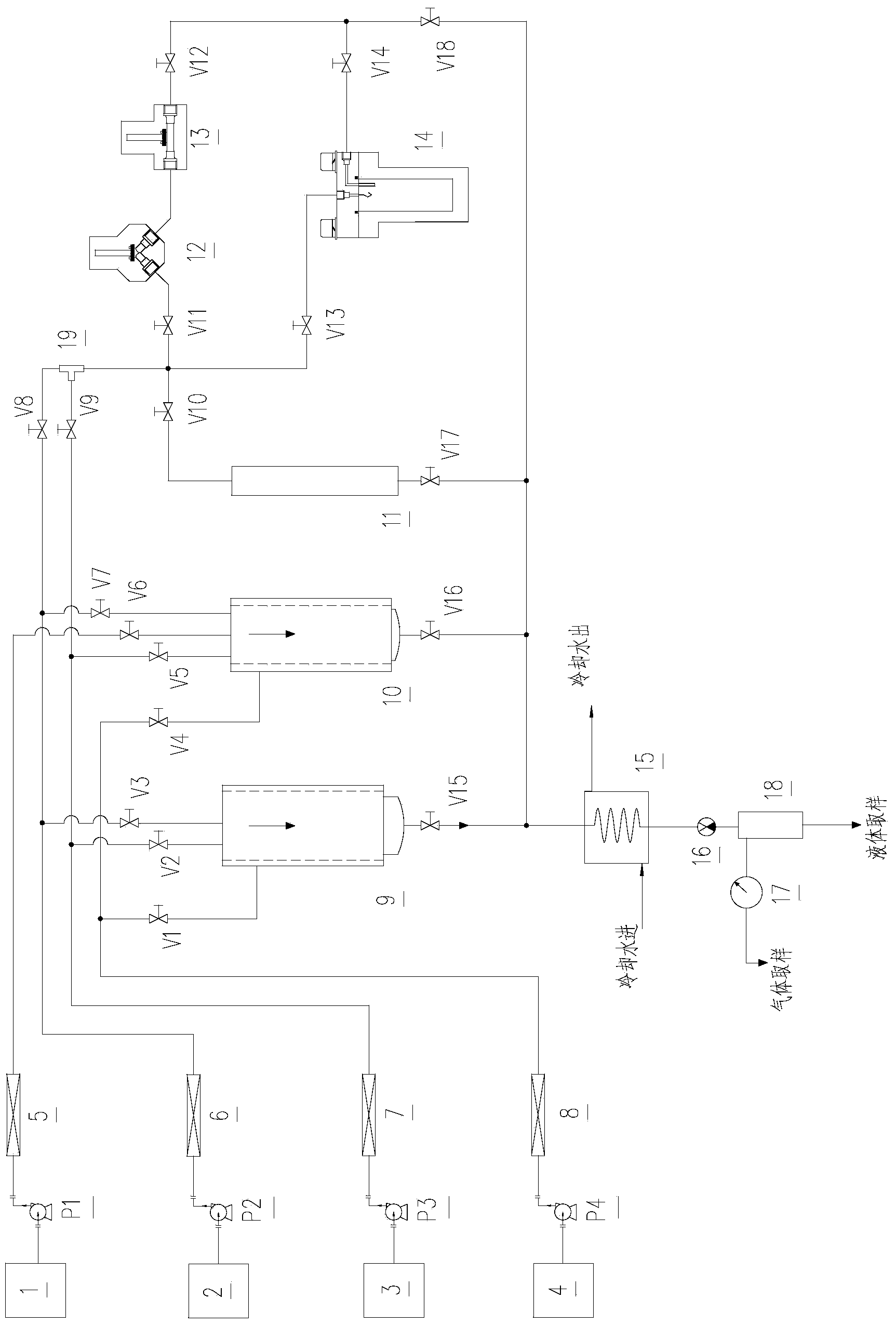

Multifunctional supercritical water technical experimental system

InactiveCN103771549ARealize the experimental research functionSludge treatment by oxidationByproduct vaporizationCombustionSludge

The invention discloses a multifunctional supercritical water technical experimental system which integrates an evaporation wall type reactor, a cold wall type reactor, a tubular reactor, an evaporation wall type hydrothermal combustion reactor, a cold wall type hydrothermal combustion reactor and a flow induced corrosion reactor, and can be used for conducting experiment researches on gasification, oxidation and partially oxidation of supercritical water in different reactors for municipal sludge and organic wastewater, and can be further used for conducting experiment researches on flow induced corrosion of materials for municipal sludge and organic wastewater. Compared with the prior art, the system is good in integration, comprehensive in function and simple and convenient to operate.

Owner:XI AN JIAOTONG UNIV

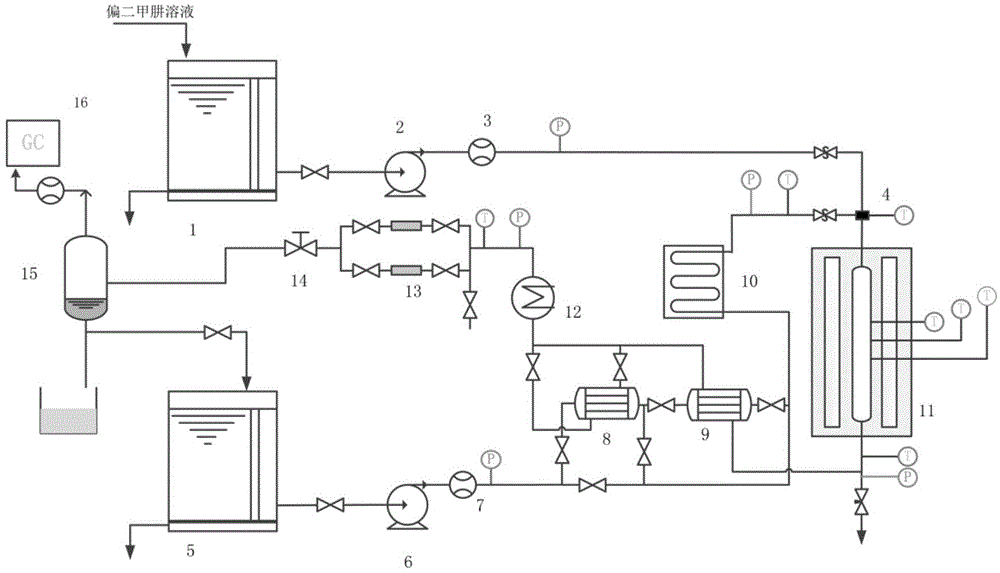

Continuous device for gasifying unsymmetrical dimethylhydrazine waste liquid with supercritical water

ActiveCN104628059AHigh removal rateReduce the concentration of ammonia nitrogenHydrogenMultistage water/sewage treatmentLiquid wasteUnsymmetrical dimethylhydrazine

The invention discloses a continuous device for gasifying unsymmetrical dimethylhydrazine waste liquid with supercritical water. The device comprises an unsymmetrical dimethylhydrazine storage tank, a mixer, a water tank, a preheating system and a reactor, wherein the outlet of the unsymmetrical dimethylhydrazine storage tank is connected with the first inlet of the mixer; the outlet of the water tank is connected with the second inlet of the mixer; the outlet of the mixer is connected with the inlet of the reactor, the water in the reactor is supercritical and the supercritical water and unsymmetrical dimethylhydrazine are reacted in the reactor for recycling. Compared to a kettle-type reactor, by the continuous device for gasifying unsymmetrical dimethylhydrazine waste liquid with supercritical water, the temperature of the reaction materials can be rapidly raised to a predetermined temperature, the carbon gasification rate and COD removal rate are further increased and the concentration of ammonia nitrogen in produced liquid is reduced.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT +2

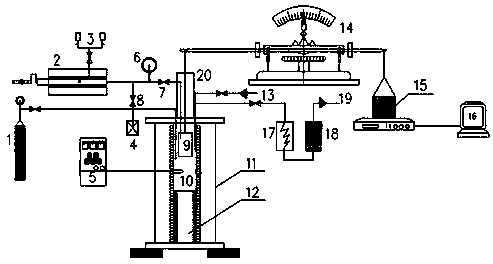

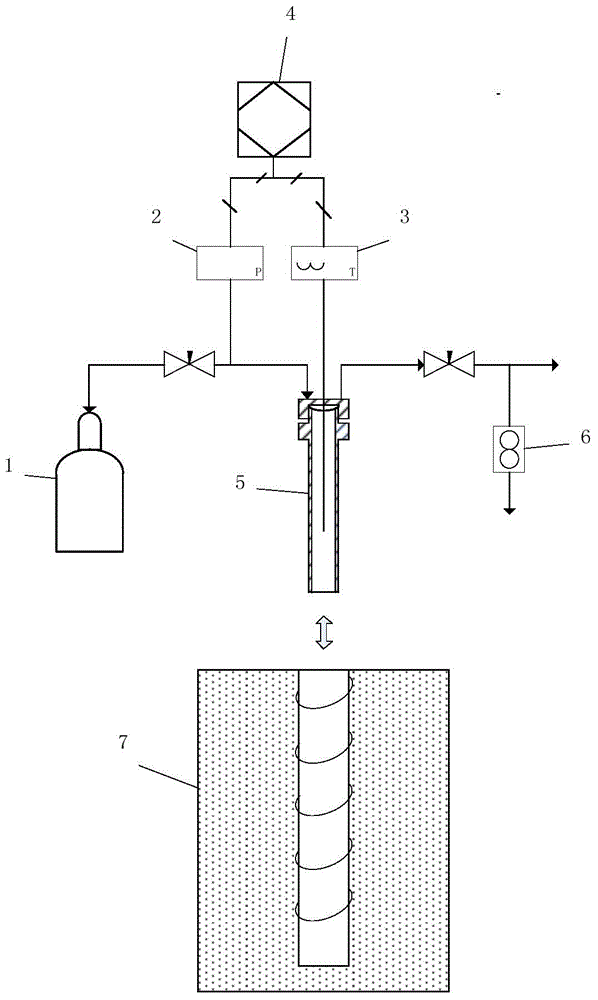

Thermogravimetric characteristic analysis system for massive test specimen supercritical water gasification

InactiveCN103712877AAdjustable and controllable pressureAdjustable and controllable temperatureMaterial weighingExperimental researchWater storage tank

The invention discloses a thermogravimetric characteristic analysis system for massive test specimen supercritical water gasification. The system comprises an electronic balance, a main reaction kettle and a heating furnace, wherein a material bucket is suspended in the main reaction kettle; the material bucket is suspended at one end of the electronic balance, and a balancing bucket is suspended at the other end of the electronic balance, and is connected with a computer; the main reaction kettle and the heating furnace are sealed bodies. The system also comprises an inert gas source connected with the main reaction kettle, a high-pressure pump and a de-ionized water storage tank, wherein de-ionized water enters the high-pressure pump, and enters the main reaction kettle after being pressurized; the material bucket is made from a steel wire mesh. According to the system, the shortcoming that thermogravimetric characteristic analysis and researches can be made by a conventional device only under a normal pressure condition is overcome; in addition, thermogravimetric experimental researches on a supercritical water gasification process of a massive test specimen (being more than 100 grams) can be made, and equipment technologies for organic solid waste gasification reaction mechanisms and kinetic researches are expanded.

Owner:ZHEJIANG UNIV OF TECH

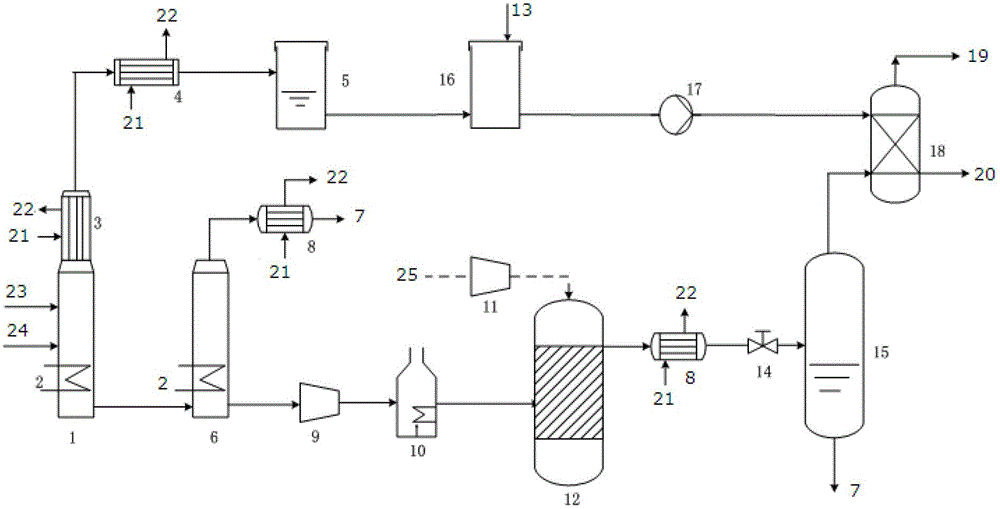

Energy gradient utilization system and method for supercritical water gasification hydrogen production process

PendingCN111171875ARelease fullyEfficient use ofGasification processes detailsBulk chemical productionCombustionEngineering

The invention discloses an energy gradient utilization system and method for a supercritical water gasification hydrogen production process. The system comprises a supercritical hydrothermal combustion reactor and a supercritical water gasification reactor. A bottom outlet of the supercritical water gasification reactor is connected to an inlet of a gas-phase separator through a hot fluid side ofa first preheater, a hot fluid side of a temperature regulator and a pressure regulator. A bottom outlet of the gas-phase separator is connected to a top inlet of the supercritical hydrothermal combustion reactor through a hot fluid side of a first heat regenerator, a booster pump and a cold fluid side of a second preheater. The bottom center of the supercritical hydrothermal combustion reactor iscommunicated with the supercritical water gasification reactor through a flow guide piece. An outlet of a water feeding pump and a cold fluid side outlet of the first heat regenerator are both divided into two paths, provide cold fluid respectively and finally send the cold fluid to a first inlet of a mixer. An outlet of the mixer is connected with an efficient cooling jacket, an outlet of the efficient cooling jacket is connected with an inlet of a steam turbine through a temperature and pressure regulator, and an outlet of the steam turbine is connected with an inlet of the water feeding pump. According to the invention, comprehensive gradient utilization of pressure energy and heat energy in the coal gasification hydrogen production process is achieved.

Owner:XI AN JIAOTONG UNIV

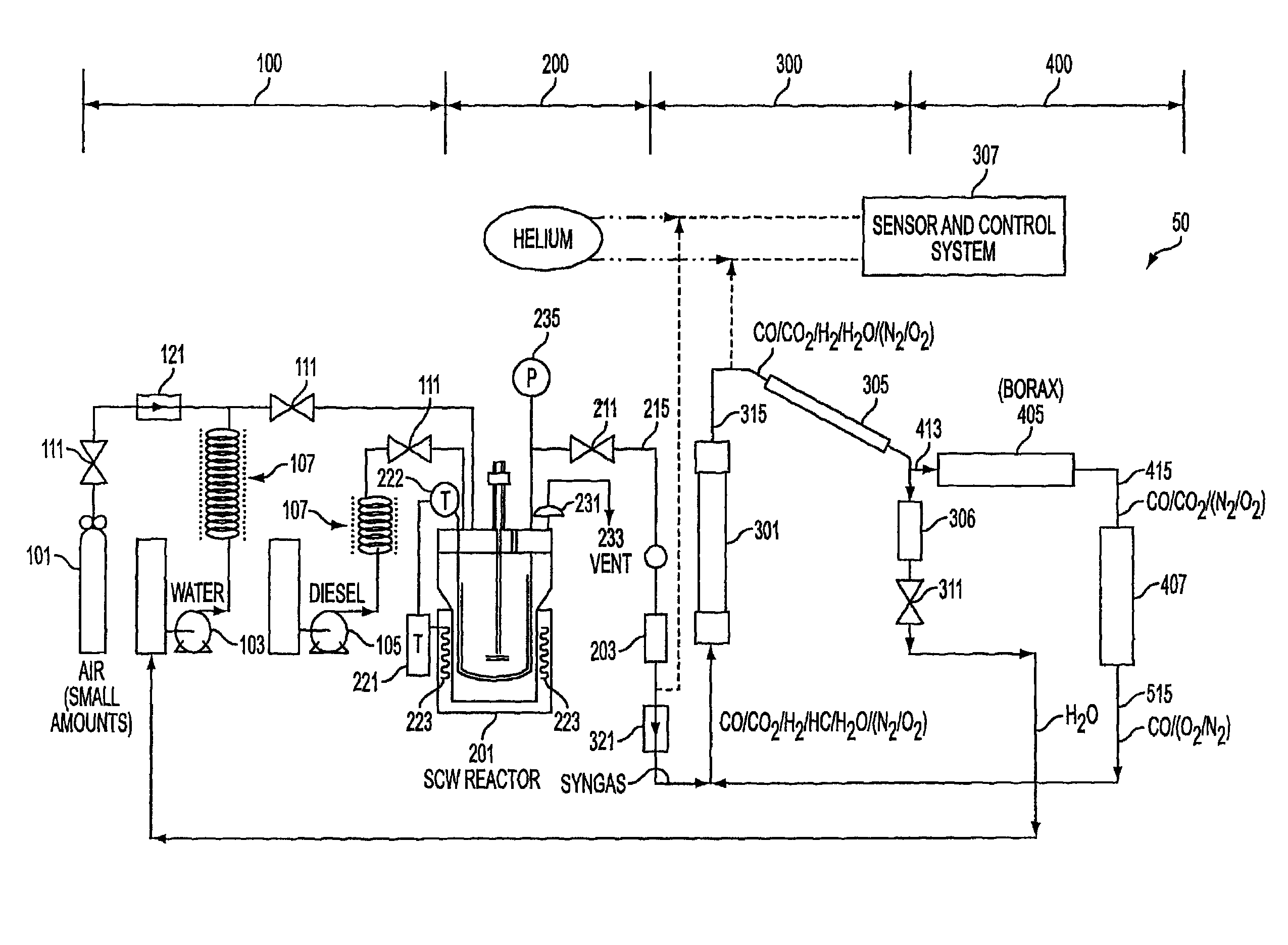

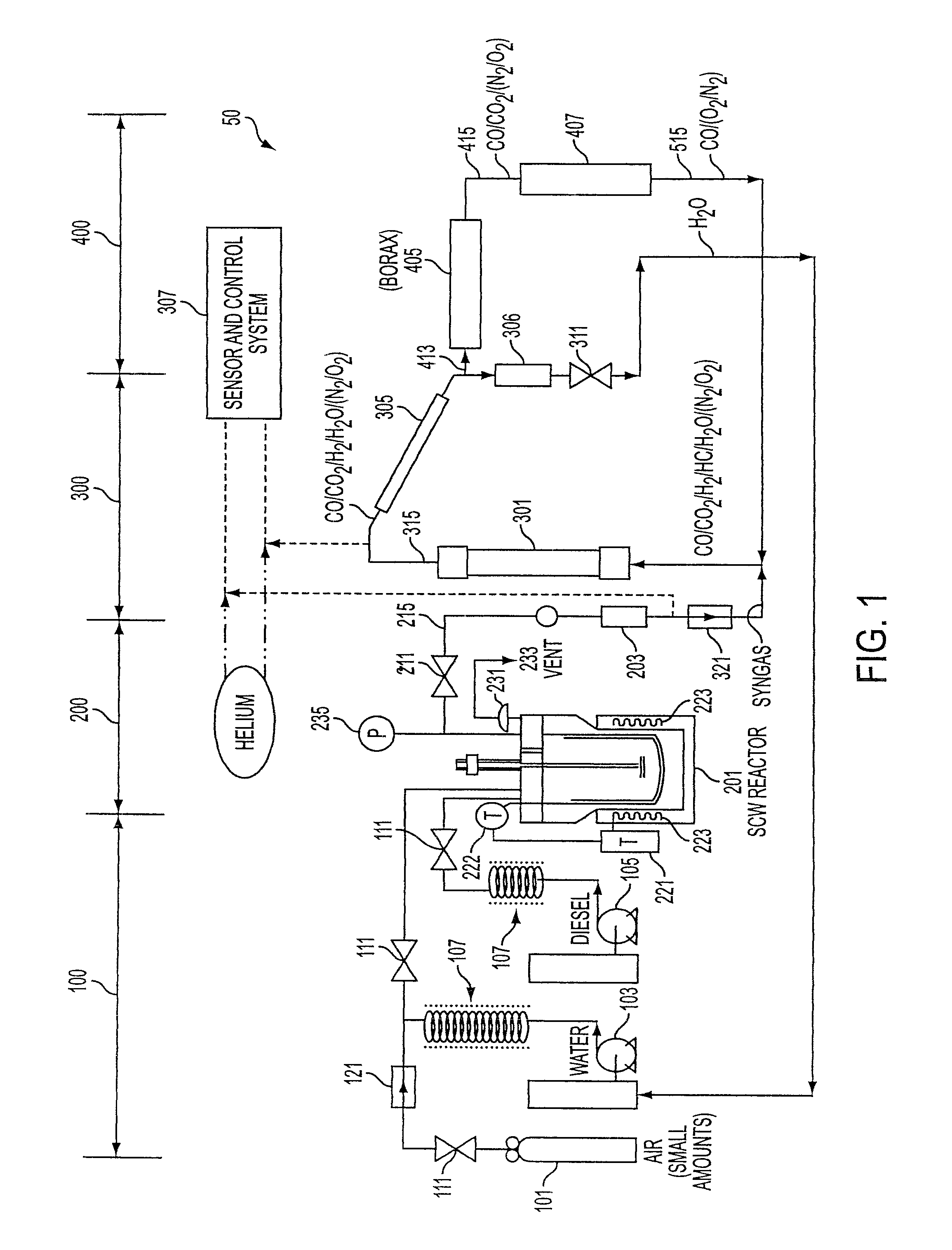

Methods for supercritical water reformation of fuels and generation of hydrogen using supercritical water

Methods for using supercritical water to convert hydrocarbons, particularly hydrocarbon fuels such as diesel fuel, jet fuel, or gasoline, into carbonaceous gases and hydrogen. The synthesis gas stream generated by the fuel reforming reaction can then be further refined to increase hydrogen content, and the resultant hydrogen can be utilized to power fuel cells.

Owner:DRS SUSTAINMENT SYST

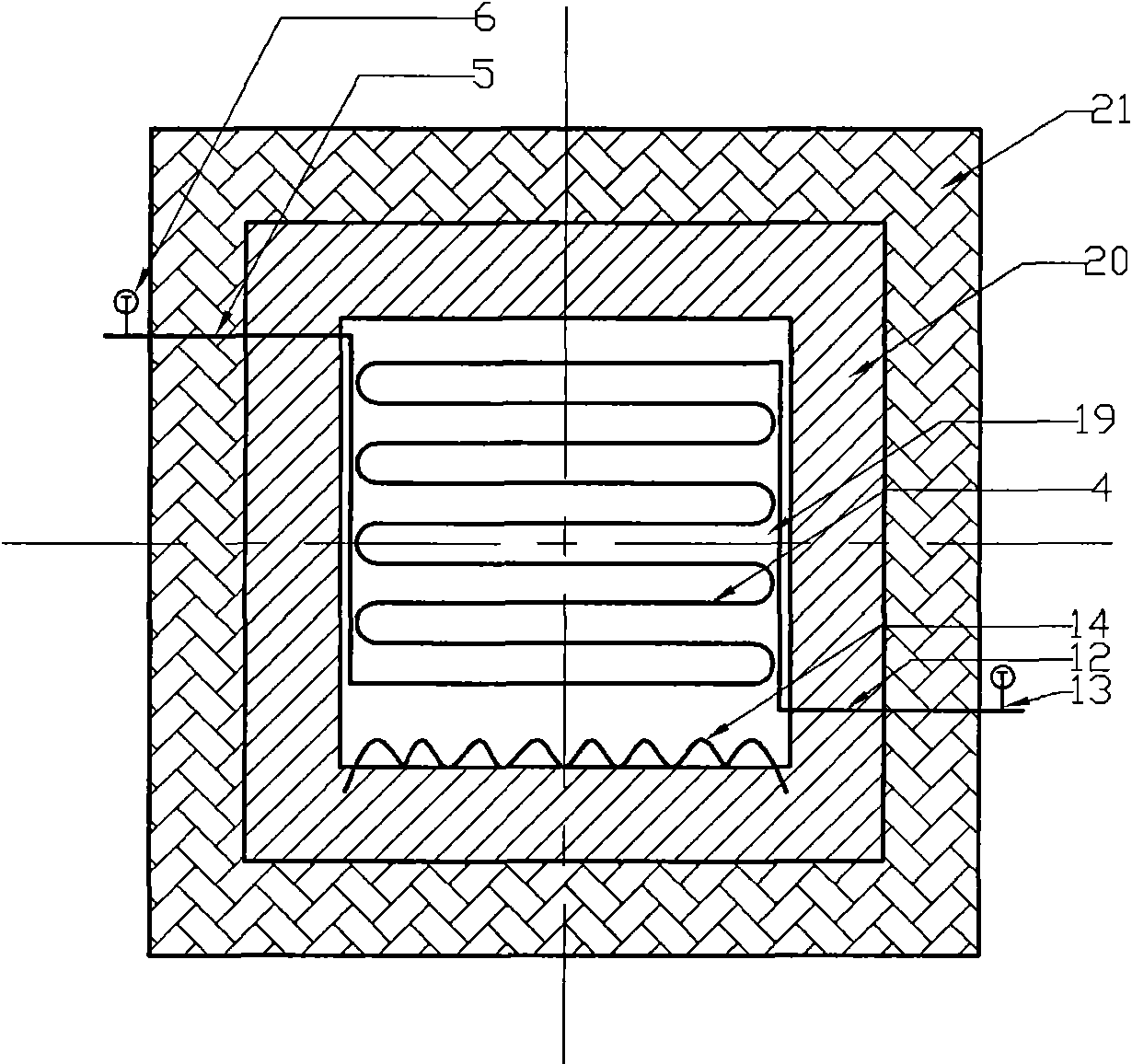

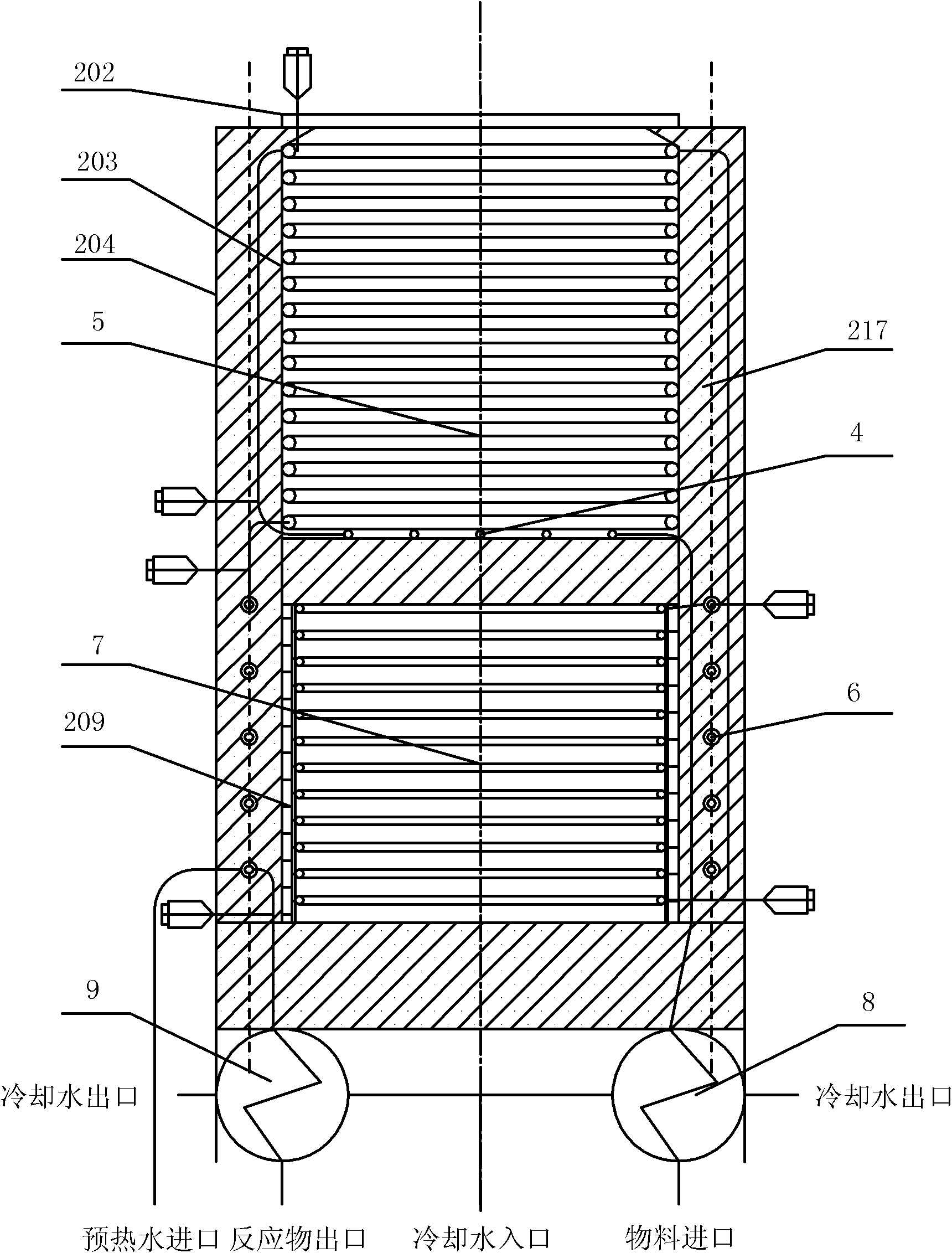

Supercritical water gasification hydrogen production and heat absorption reactor for multi-disk solar heat-collecting coupling biomass

ActiveCN102115030ASmall temperature fluctuationsReduce heat lossHydrogen productionBulk chemical productionHigh energyCoupling

The invention discloses a supercritical water gasification hydrogen production and heat absorption reactor for a multi-disk solar heat-collecting coupling biomass, which comprises a cavity type solar absorption reactor, a first cooler and a second cooler, wherein the cavity type solar absorption reactor comprises an endothermic reaction cavity and a pre-heated water heating cavity, inner cavity walls of the endothermic reaction cavity and the pre-heated water heating cavity are provided with insulating layers, an opening at the upper end of the endothermic reaction cavity is sealed by silica glass, a pipe flow reactor is arranged in the endothermic reaction cavity, and the bottom of the endothermic reaction cavity is provided with a material preheater; the pre-heated water heating cavity is internally provided with a pre-heated water heater, a crawler-type electric heater is used for heating, and a heat storage medium is filled in the pre-heated water heating cavity; and a screw shelltype high-pressure heat exchanger is wound outside the pre-heated water heating cavity. The supercritical water gasification hydrogen production and heat absorption reactor has the advantages of small temperature fluctuation in the solar absorption cavity, high biomass supercritical water gasification rate, high energy comprehensive utilization efficiency and the like, and is beneficial to the realization of efficient, low-cost and massive hydrogen production through supercritical water gasification of focused solar heat coupling biomass.

Owner:陕西中核交大超洁能源技术有限公司

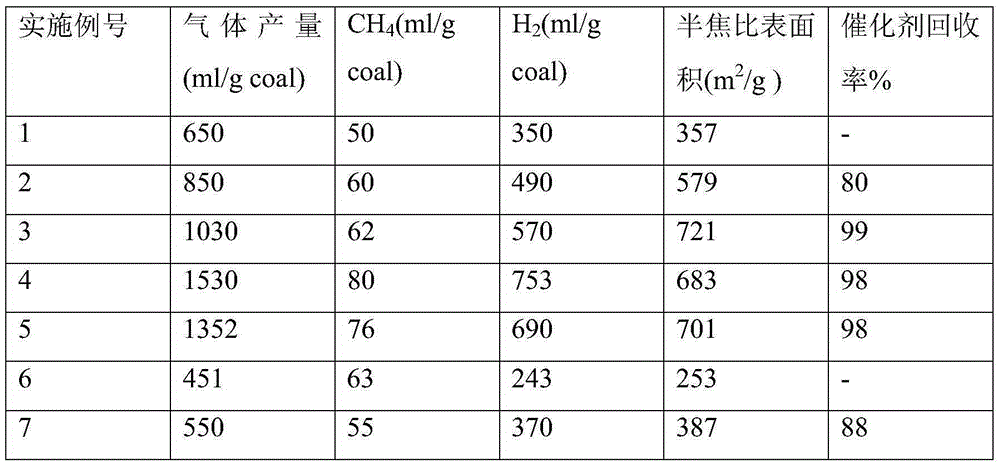

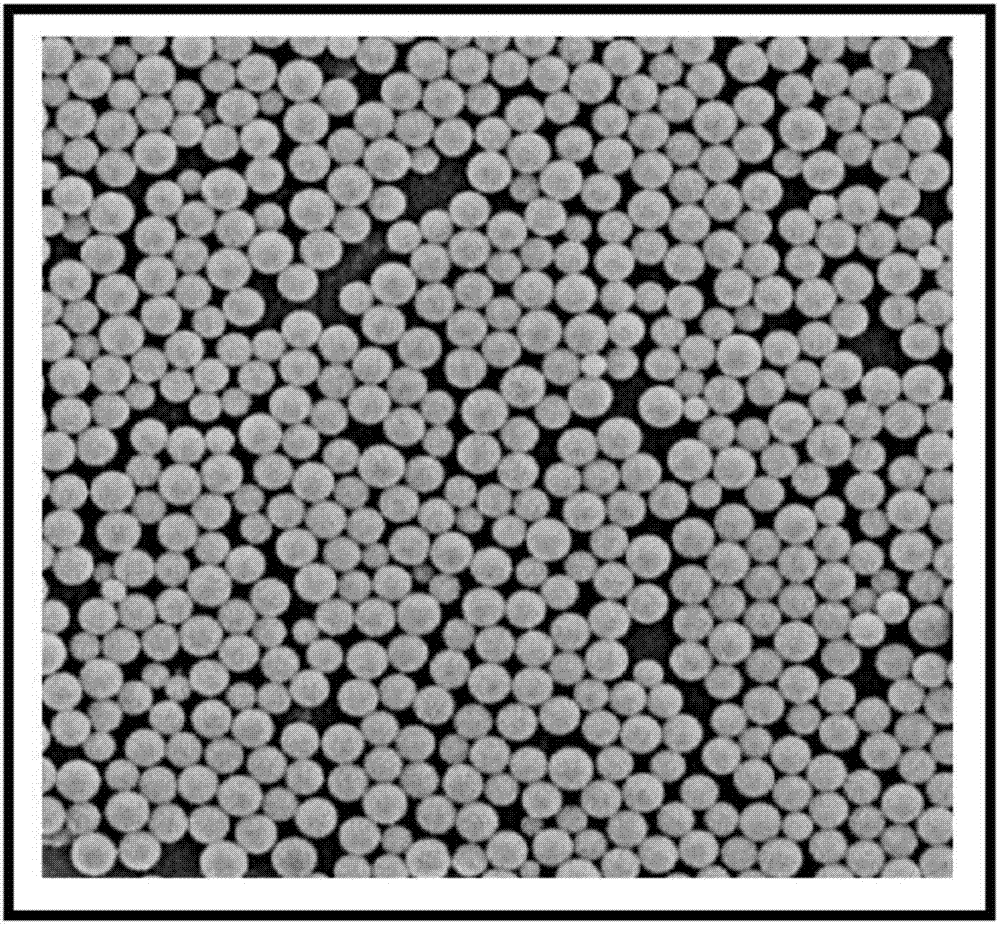

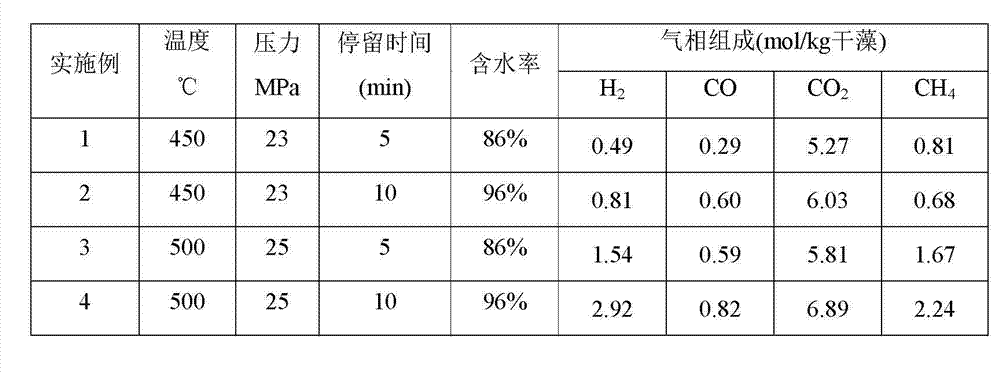

Spherical titanium dioxide catalyst and application thereof to preparation of hydrogen through supercritical water gasification by taking cyanobacteria as raw material

ActiveCN107311226AUniform particle sizeEasy to preparePhysical/chemical process catalystsHydrogen productionResource utilizationGas phase

The invention discloses a spherical titanium dioxide catalyst and application thereof to preparation of hydrogen through supercritical water gasification by taking cyanobacteria as a raw material. The spherical titanium dioxide catalyst is prepared by the following steps: dissolving titanium sulfate and urea in an isopropyl alcohol-water solution with the volume concentration of 25-35% at first, then performing hydrothermal reaction for 14-16 h at 170-190 DEG C, and at last, performing centrifugation, washing and drying, wherein the molar concentration of titanium sulfate is 1.8-2.2 mol / L, and the molar concentration of urea is 1-2 times of that of titanium sulfate. The prepared spherical titanium dioxide can serve as a catalyst to be used for preparing hydrogen through supercritical water gasification by taking cyanobacteria as the raw material, so that, not only is the hydrogen output efficiency greatly improved, but also the concentration of hydrogen in a gaseous phase is greatly increased, and catalytic selectivity in preparation of hydrogen is achieved. The spherical titanium dioxide catalyst and the method can be used for treating and utilizing bloom-forming cyanobacteria, so that not only harmless treatment of cyanobacteria but also efficient resource utilization is realized.

Owner:安徽绿泰环保科技有限公司

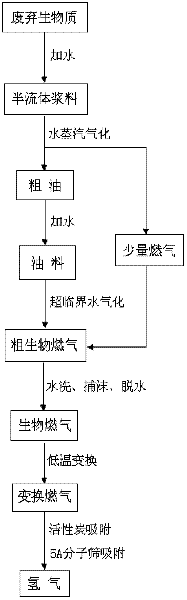

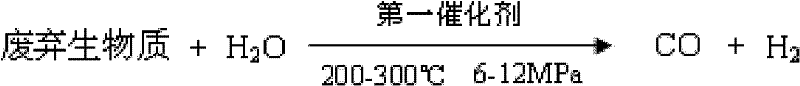

Method for preparing hydrogen by utilizing waste biomass

InactiveCN102653393AReduce pollutionReduce manufacturing costHydrogen separation using solid contactCombustible gas catalytic treatmentRare-earth elementWater vapor

Owner:北京雷恩新材料科技有限公司

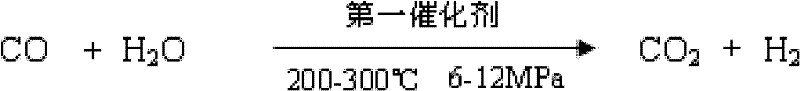

Material grading-preheating and over-temperature protection system and method for supercritical water gasification and hydrogen production

PendingCN111234876AAchieve harmless treatmentAchieve zero emissionsTemperature control without auxillary powerHydrogen separationEngineeringSlurry

A material grading-preheating and over-temperature protection system for supercritical water gasification and hydrogen production comprises a material gradient preheating unit, which comprises a blending storage tank, a slurry high pressure delivery pump, a slurry pre-heater, a flow distributor, and a self-heating gasification furnace; a separation unit, which comprises a temperature regulator, apressure regulator, a high-pressure gas separator and a high-pressure solid-liquid separator; and an over-temperature protection unit, which comprises a flow regulator and a temperature regulator. Gasification raw materials and hot recycled water are mixed and preheated in the blending storage tank; then the mixture enters the slurry pre-heater, is preheated and heated, then enters the self-heating gasification furnace, and is heated by the heat released by reactions carried out in the upper part of the self-heating gasification furnace; and three-stage gradient preheating is completed. The gasification product from the slurry pre-heater is subjected to temperature adjustment and pressure adjustment, then gas separation and solid-liquid separation are performed, the liquid phase is returned to the raw material blending step, and after temperature adjustment, medium-temperature cooling water is introduced into the cooling wall of a self-heating gasification furnace to prevent over-temperature. The system and method can improve the gasification rate and hydrogen yield, self-heating balance of the system is realized; safe, stable, and efficient operation is guaranteed; the energy consumption and cost are reduced; and zero emission of pollutants is realized.

Owner:XI AN JIAOTONG UNIV

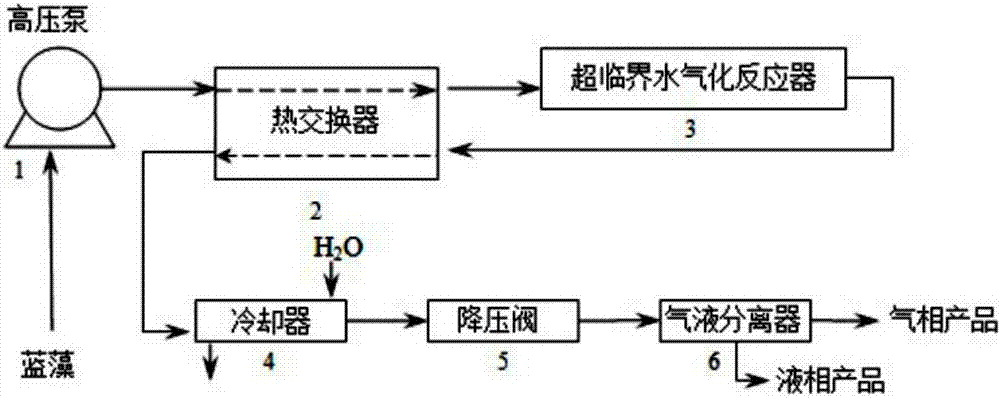

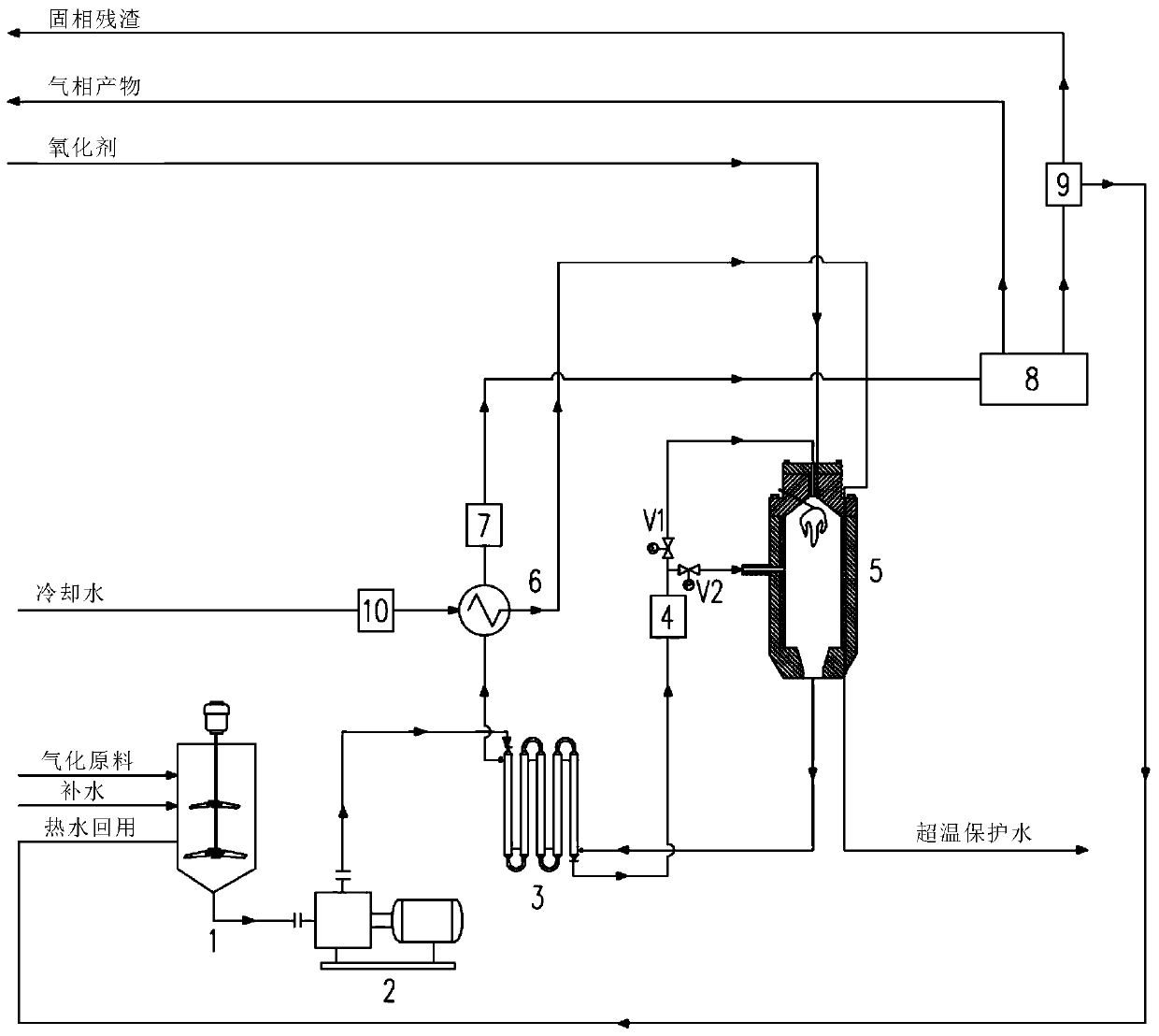

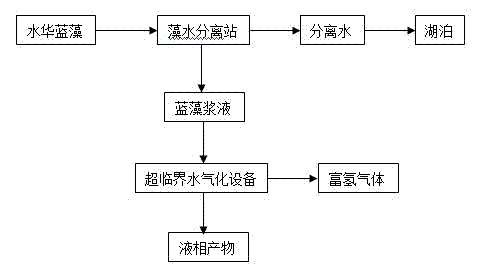

Hydrogen production method by supercritical water gasification using bloom-forming cyanobacteria as raw material

InactiveCN102765697AEasy to handleSimple processHydrogen productionBulk chemical productionNew energyHigh water content

The invention provides a device and a method for producing hydrogen by direct supercritical water gasification of bloom-forming cyanobacteria, according to the characteristics that the bloom-forming cyanobacteria suspension has high water content, and forms into supercritical water under high temperature and high pressure, and that organic matters in the cyanobacteria suspension can form combustible gas rich in hydrogen. The device and the method provided by the invention can realize direct supercritical water gasification reaction on the salvaged bloom-forming cyanobacteria, so as to obtain hydrogen; the process is simple and requires no secondary dehydration or water addition; the produced new energy of hydrogen can be reused; the reaction time is greatly shortened to realize efficient and fast treatment on bloom-forming cyanobacteria; and the treatment process does not require addition of an oxidizing agent, and has significantly reduced treatment cost compared with supercritical water oxidation treatment. Therefore, the method overcomes technical problems in an existing bloom-forming cyanobacteria treatment, such as long anaerobic digestion time, incomplete treatment, low treatment efficiency due to large water content in the bloom-forming cyanobacteria suspension and complication caused by addition of a dehydration step, and at the same time gives consideration to energy transformation and utilization.

Owner:HOHAI UNIV

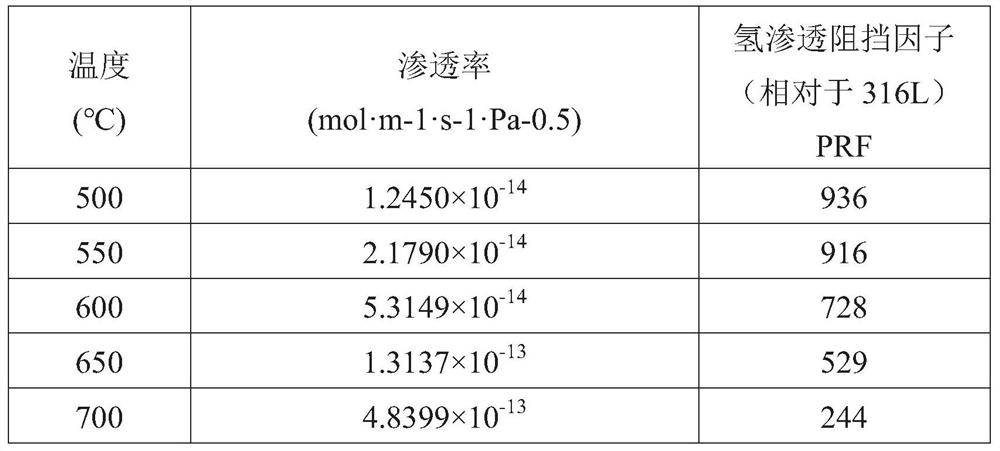

Anti-corrosion and anti-hydrogen permeation coating and preparation method thereof

PendingCN114686814AImproved hydrogen barrier performanceOvercome the defect of poor corrosion resistanceVacuum evaporation coatingSputtering coatingNitrogen oxidesHigh entropy alloys

The coating comprises a stainless steel base body, a high-entropy alloy transition layer and a high-entropy alloy ceramic layer which are sequentially arranged, the high-entropy alloy transition layer and the high-entropy alloy ceramic layer are sequentially and alternately overlaid for 1-10 times, the high-entropy alloy transition layer is made of AlCrCoFeTi or AlCrNbTiZr high-entropy alloy, and the high-entropy alloy ceramic layer is made of AlCrCoFeTi or AlCrNbTiZr high-entropy alloy. And the high-entropy alloy ceramic layer is a nitride, an oxide or a nitrogen oxide of an AlCrCoFeTi or AlCrNbTiZr alloy. The coating structure formed by alternately overlapping the high-entropy alloy transition layers and the high-entropy alloy ceramic layers is adopted, and the binding force and thermal shock resistance of the coating and the stainless steel substrate are improved. A medium-frequency magnetron sputtering method is selected for the high-entropy alloy transition layer; and the high-entropy alloy ceramic layer adopts an intermediate-frequency reactive sputtering method. The corrosion-resistant and hydrogen-permeation-resistant coating has excellent corrosion resistance and hydrogen permeation resistance, and is especially suitable for the field of supercritical water gasification hydrogen production.

Owner:GRIMAT ENG INST CO LTD

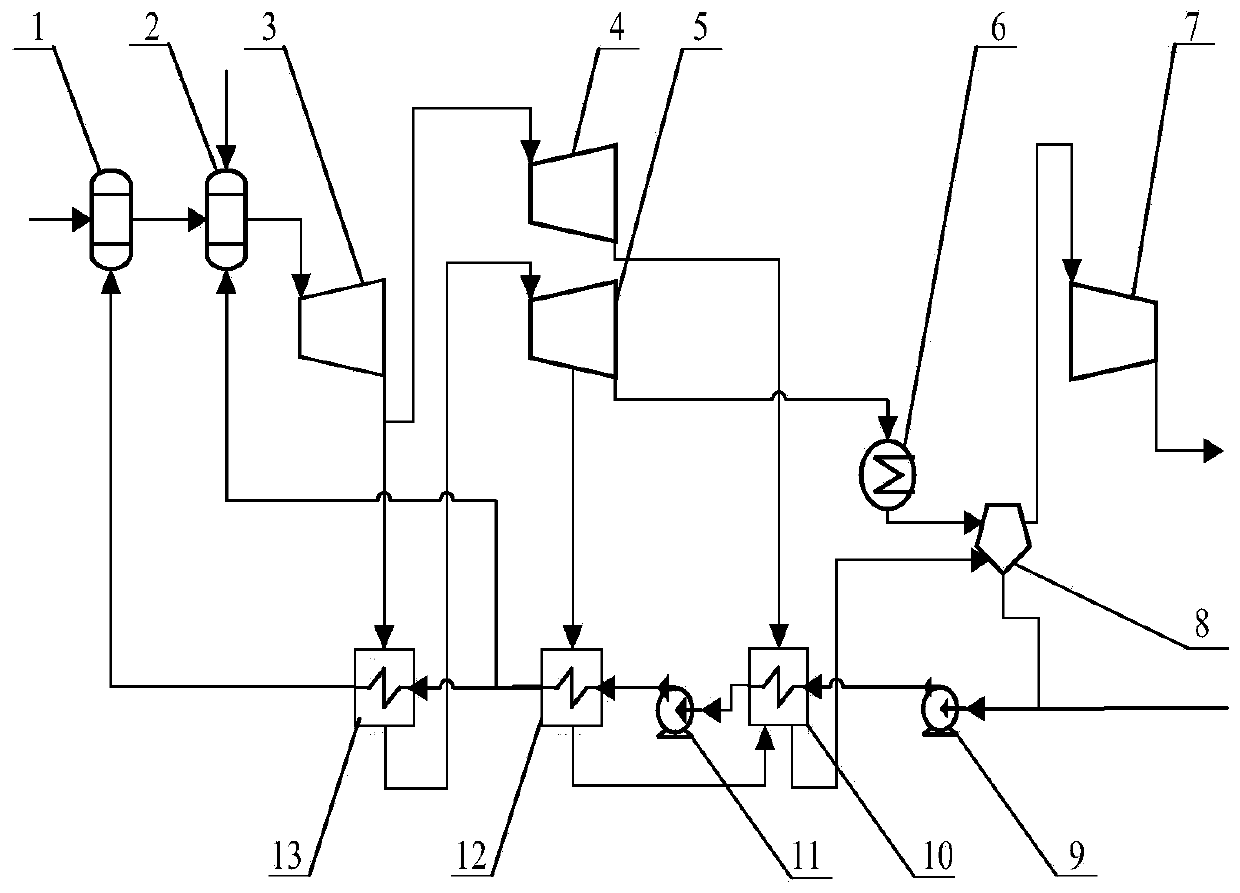

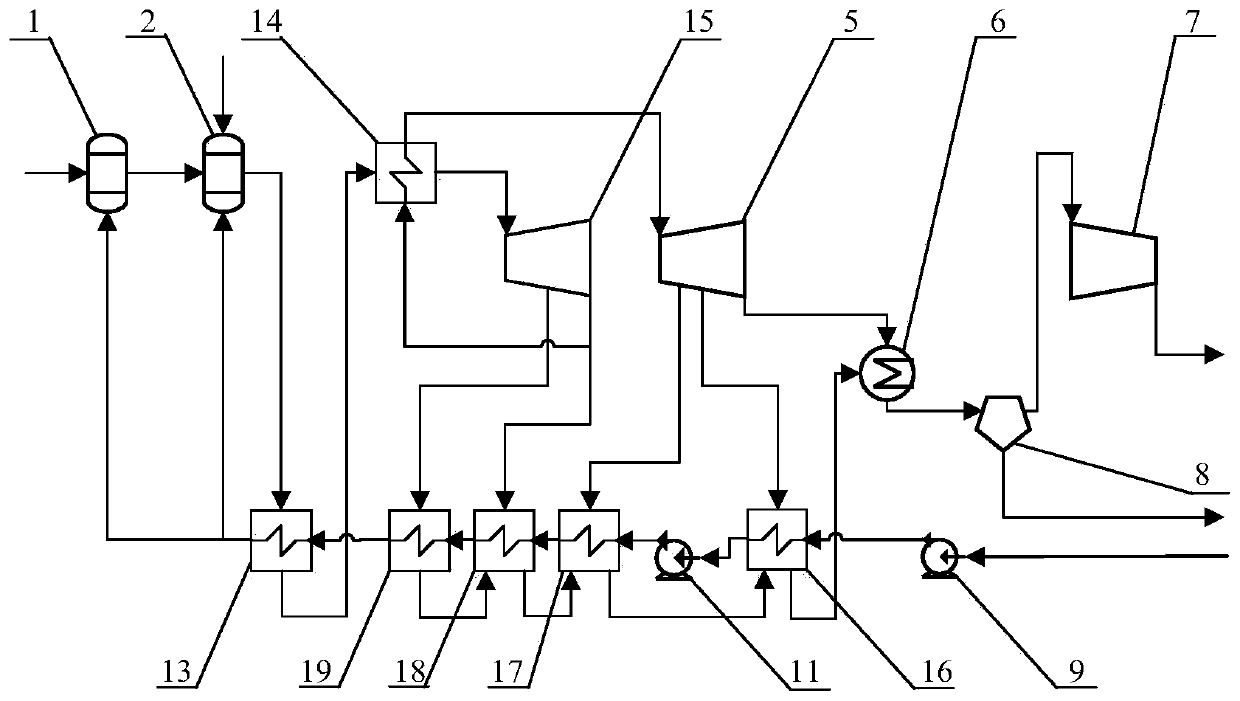

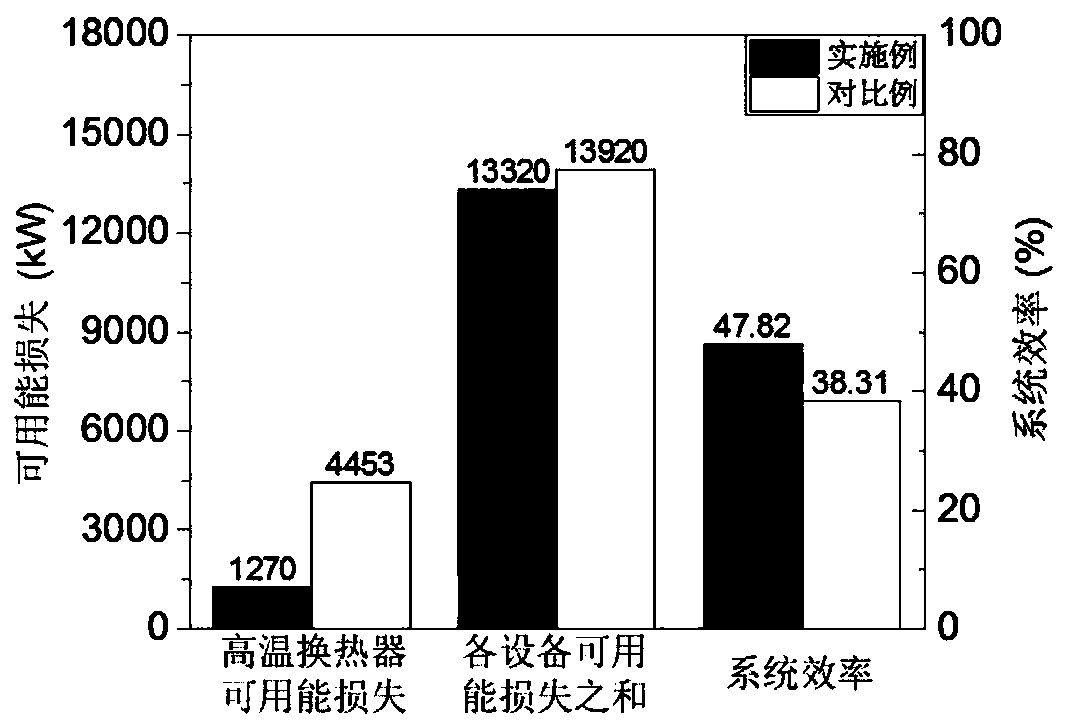

Coal supercritical water gasification power generation system capable of controlling available energy loss and working method

ActiveCN111412022AReduce usable energy lossReduce mass flow rateCombination enginesSteam engine plantsVapor–liquid separatorEngineering

The invention discloses a coal supercritical water gasification power generation system capable of controlling the available energy loss and a working method. The system comprises a supercritical water gasification reactor, an oxidation reactor, a condenser, a gas-liquid separator, a compressor, a plurality of turbines, a heat exchanger and a water pump. The coal supercritical water gasification power generation system is characterized in that supplied water entering the water side of the high-temperature heat exchanger is shunted, meanwhile a high-temperature working medium entering the steamside of the heat exchanger is shunted, heat exchange is conducted through the working medium subjected to high-pressure turbine temperature reduction and decompression, the irreversibility of the heat exchanger is reduced, and the power generation efficiency of the system is improved; meanwhile, a supercritical water gasification technology is adopted, so that generation of atmospheric pollutantsis avoided, carbon dioxide trapping is facilitated, and the cleanliness of coal utilization is achieved. The coal supercritical water gasification power generation system is beneficial to developmentand improvement of the coal clean power generation technology, and energy safety is guaranteed.

Owner:XI AN JIAOTONG UNIV

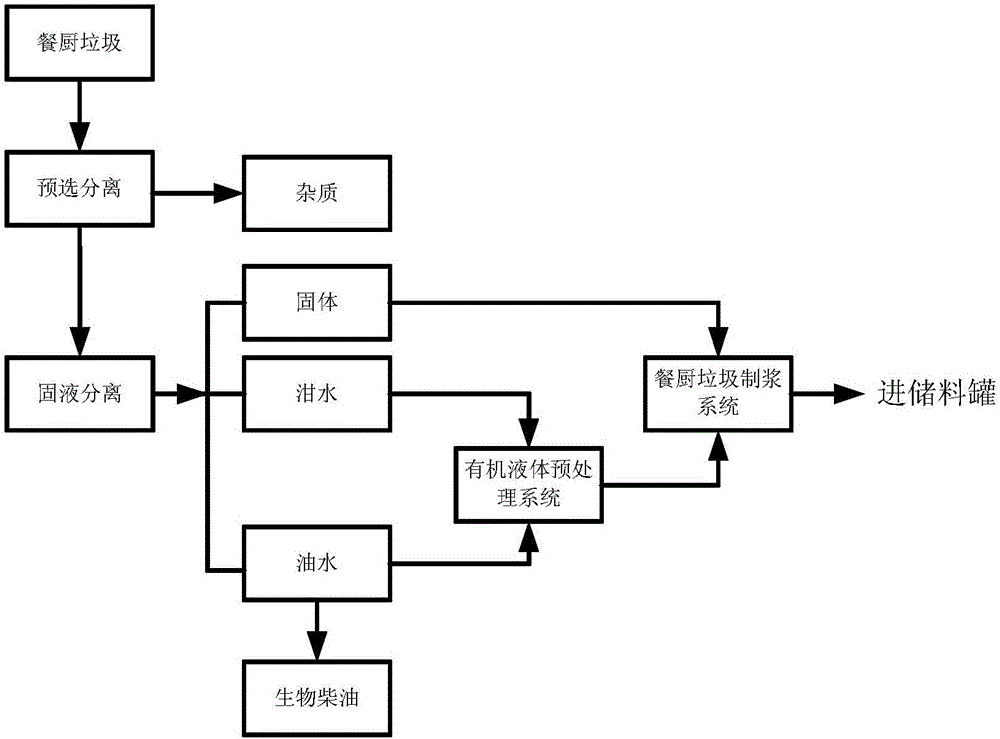

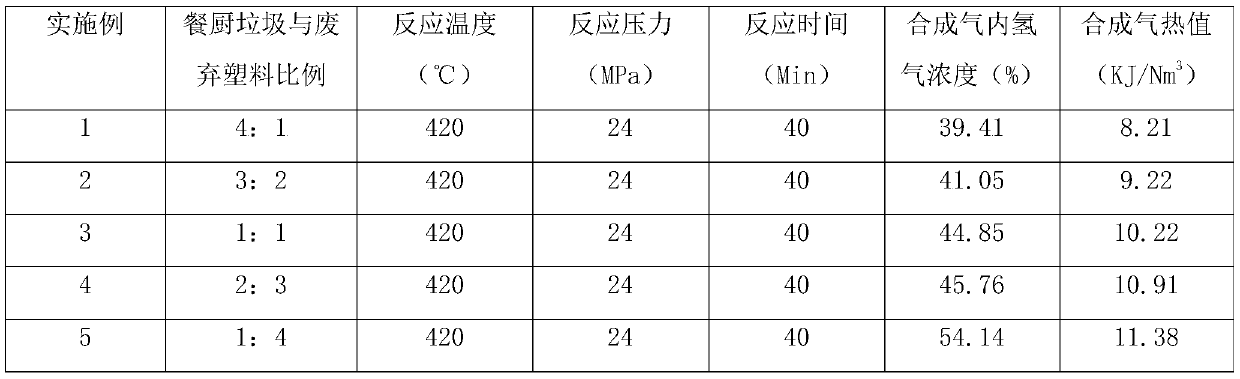

Combined method for treating kitchen waste and waste plastics to prepare hydrogen-rich fuel gas

InactiveCN110643392AEasy to handleIncrease the concentration of hydrogenGaseous fuelsGasification processes detailsSyngasAir pump

Owner:ZHEJIANG UNIV OF TECH

Supercritical water coal gasification device and method

PendingCN110283625AEfficient use ofOmit the compression processEnergy inputBulk chemical productionElectrolysis of waterCoal slurry

The invention discloses a supercritical water coal gasification device, and a method. The supercritical water coal gasification device comprises a water electrolysis unit, a gasification reactor, a waste heat recovery unit, and a deslagging unit; the water electrolysis unit is arranged at the middle lower part of the supercritical water coal gasification device, and is used for electrolysis of water into hydrogen gas and oxygen gas; hydrogen gas is directly introduced into an outlet of the gasification reactor through a pipeline for mixing with a gasification product, and oxygen gas is introduced into the gasification reactor directly; supercritical water coal slurry and high temperature water are introduced into the gasification reactor for gasification reaction with oxygen gas provided by the water electrolysis unit, pollutants such as sulfur and heavy metals are precipitated to the bottom of the reactor with coal ash, and are discharged through the deslagging unit; gasification reaction products are discharged through the top of the reactor, is mixed with the hydrogen gas from the water electrolysis unit, and then is delivered into the waste heat recovery unit with the hydrogen gas, is cooled, and then is discharged out from the supercritical water coal gasification device. The supercritical water coal gasification device is capable of realizing coal clean high efficiency conversion; synthetic gas heat value is high; and compared with conventional coal gasification method, the advantages are that: the structure is simple, and economical and environment protection performance is excellent.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method for gasifying unsymmetrical dimethylhydrazine waste liquor through supercritical water

ActiveCN104628062AImprove qualitySimple structureWater contaminantsWater/sewage treatment by heatingTemperature controlRoom temperature

The invention discloses a method for gasifying unsymmetrical dimethylhydrazine waste liquor through supercritical water. The method comprises the following steps of adding an unsymmetrical dimethylhydrazine water solution to a reaction kettle; heating a temperature-controlled electric furnace, and carrying out leakage detection on the reaction kettle by using high-pressure argon at the same time; after the temperature inside the temperature-controlled electric furnace reaches preset temperature and is stable, placing the reaction kettle into the temperature-controlled electric furnace for heating; controlling and regulating the heating power of the temperature-controlled electric furnace by utilizing a K-shaped armoured thermocouple inside the temperature-controlled electric furnace so as to change the heating rate inside the reaction kettle; after the temperature inside the reaction kettle reaches the preset temperature, keeping constant temperature, and reacting unsymmetrical dimethylhydrazine with supercritical water which is positioned in the reaction kettle and heated and pressurized to a supercritical state; after the reaction is finished, taking the reaction kettle out of the temperature-controlled electric furnace, and reducing to room temperature; and opening a gas collecting valve to collect a gaseous sample to complete the gasification of the unsymmetrical dimethylhydrazine waste liquor. The process can be carried out in a continuous supercritical water fixed bed device or an intermittent reaction kettle. A device is simple in structure, low in operation cost and high in COD removal rate.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com