Hydrogen production method by supercritical water gasification using bloom-forming cyanobacteria as raw material

A technology of supercritical water gasification and water bloom cyanobacteria, which is applied in the field of resources and environment, can solve the problems of long time-consuming anaerobic digestion, increased dehydration steps, and low processing efficiency, and achieves simple, fast and efficient processing methods, rapid processing, and reduced processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

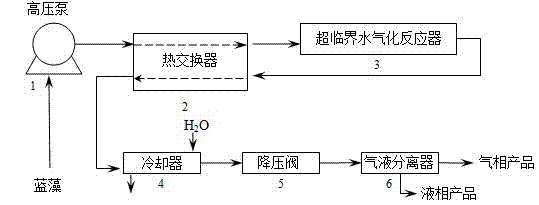

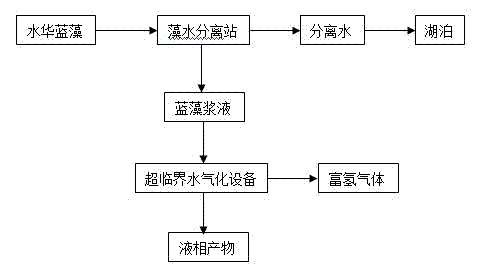

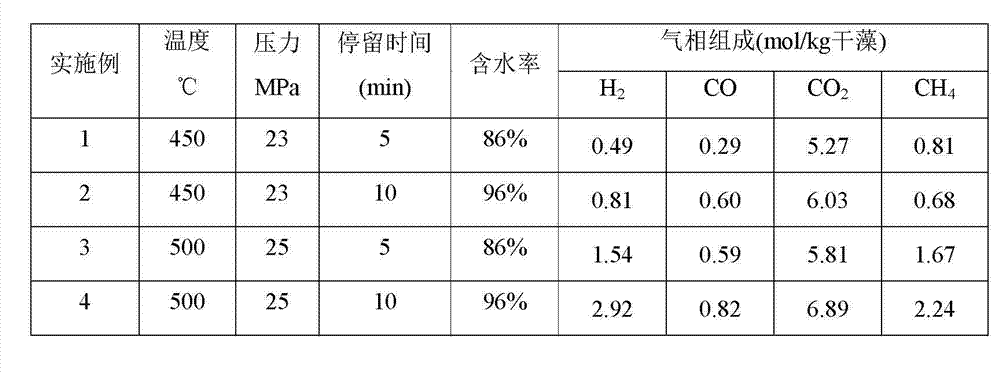

[0026] The cyanobacteria liquid salvaged from Taihu Lake and entering the algae-water separation station, with a water content of 96%, is directly injected into a supercritical water reactor preheated to a temperature of 450°C through a high-pressure pump, and after reacting for 5 to 10 minutes, it passes through a heat exchanger , cooler, pressure reducing valve, gas-liquid separator, etc. to separate the gas-liquid products, and the gas-phase product components are shown in Table 1.

Embodiment approach 2

[0028] The cyanobacteria liquid salvaged from Taihu Lake and entering the algae-water separation station is further dehydrated and concentrated by the dehydration device, and the water content is reduced to 86%. It is directly injected into the supercritical water reactor pre-heated to a temperature of 450°C through a high-pressure pump , after reacting for 5 to 10 minutes, separate the gas-liquid products through heat exchangers, coolers, pressure reducing valves, gas-liquid separators, etc., see the specific process flow figure 2 . Controlling different reaction parameter conditions, the gas phase product components are shown in Table 1.

Embodiment approach 3

[0030] The difference from Embodiment 1 is that the temperature and pressure of the supercritical water reactor are increased to 500°C and 25MPa. The gas-liquid products were separated, and the gas-phase product components are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com