Anti-corrosion and anti-hydrogen permeation coating and preparation method thereof

A coating and anti-hydrogen technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of poor corrosion resistance and inability to meet the anti-corrosion and anti-hydrogen permeation performance requirements of supercritical water reactor materials , to achieve the effect of strong corrosion resistance, good high temperature stability and oxidation resistance, high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

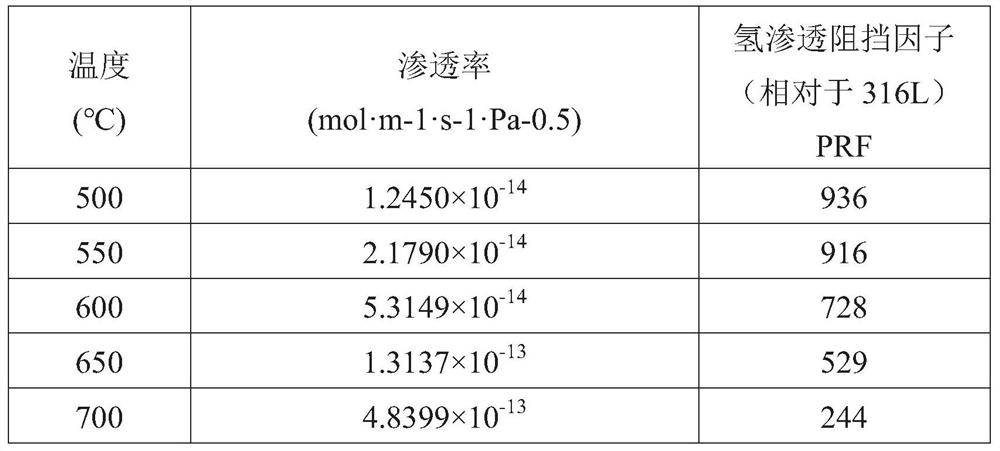

Examples

Embodiment 1

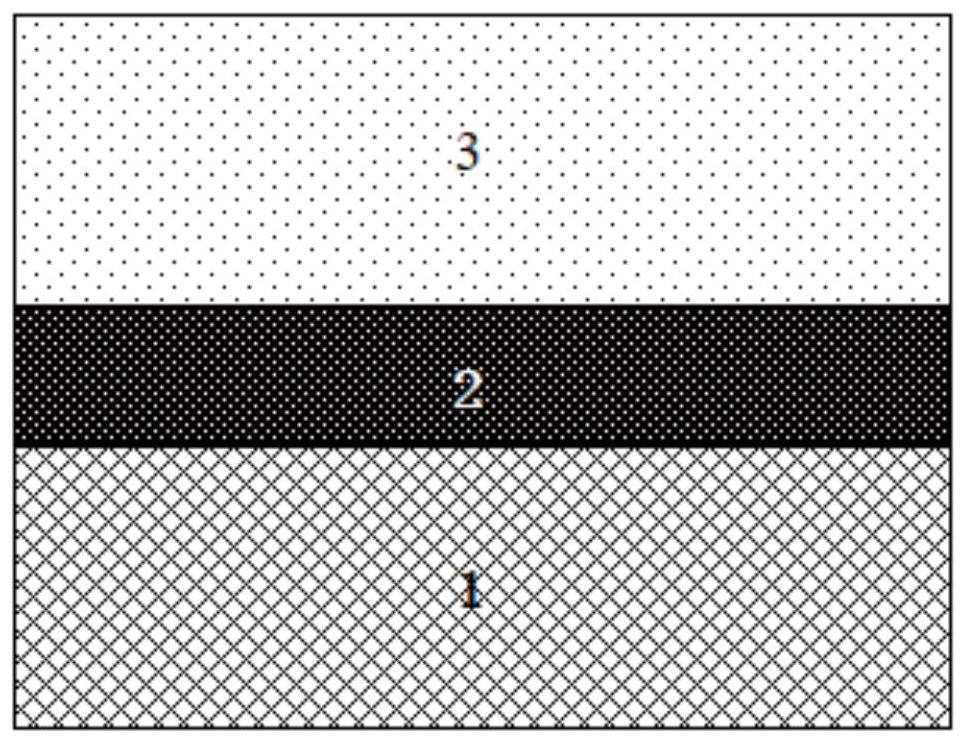

[0030] 1. Preparation of 316L / AlCrCoFeTi / AlCrCoFeTiO anti-corrosion and anti-hydrogen permeation coating

[0031] 1) Select 316L stainless steel as the substrate, polish one side of the 316L stainless steel substrate to a roughness of 2 μm, and use a high-entropy alloy AlCrCoFeTi target with a diameter of 100 mm for sputtering.

[0032] 2) Use mechanical pump and molecular pump to vacuumize the magnetron sputtering chamber in turn until the vacuum degree reaches 2.0×10 -3 Pa.

[0033] 3) Pour in the working gas Ar gas, control the air flow rate to 20sccm, adjust the sputtering pressure to 0.5Pa, the sputtering current to 0.5A, the target-base distance during sputtering to be 100mm, and to obtain AlCrCoFeTi with a thickness of 100nm after 30min sputtering High-entropy alloy transition layer.

[0034] 4) Control the Ar gas flow to be 20sccm, feed oxygen, the flow rate is 10sccm, adjust the sputtering pressure to be 0.5Pa, the sputtering current to be 0.5A, the target-base dist...

Embodiment 2

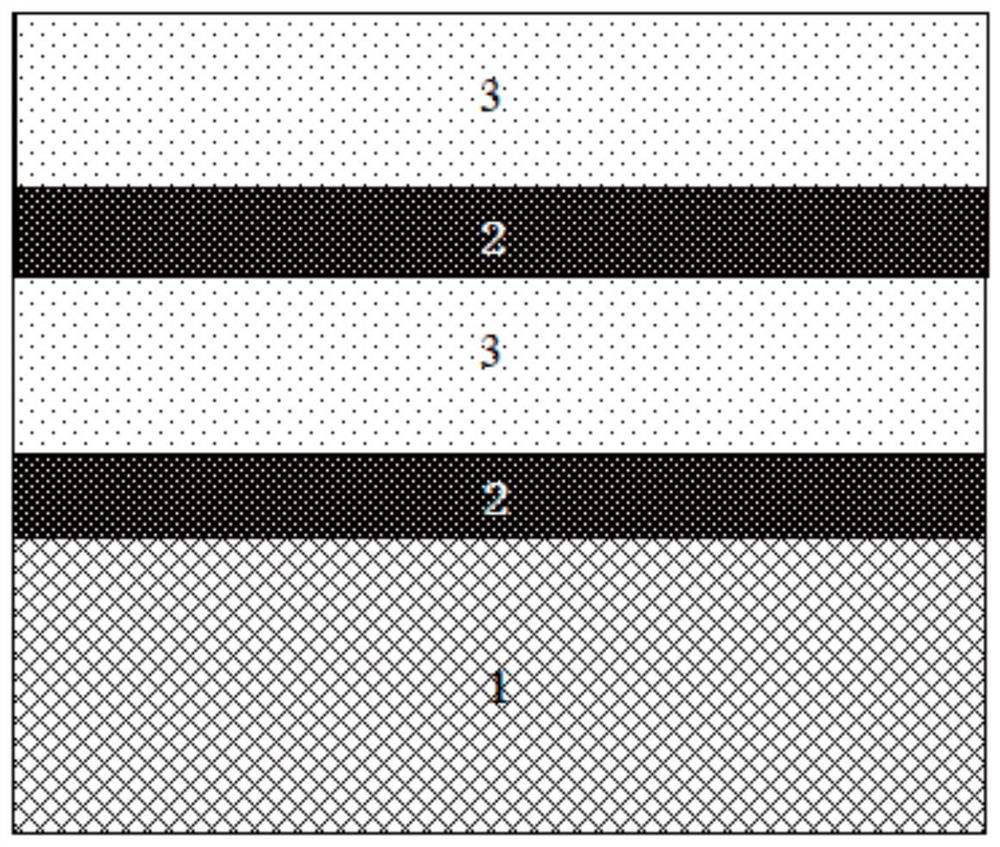

[0045] 1. Preparation of 316L / AlCrNbTiZr / AlCrNbTiZrNO / AlCrNbTiZr / AlCrNbTiZrNO anti-corrosion and anti-hydrogen penetration coating

[0046] 1) Select 316L stainless steel as the substrate, polish one side of the 316L stainless steel substrate to a roughness of 2 μm, and use a high-entropy alloy AlCrNbTiZr target with a diameter of 100 mm for sputtering.

[0047] 2) Use mechanical pump and molecular pump to vacuumize the magnetron sputtering chamber in turn until the vacuum degree reaches 2.0×10 -3 Pa.

[0048] 3) Pour in the working gas Ar gas, control the air flow rate to be 25sccm, adjust the sputtering gas pressure to 0.5Pa, the sputtering current to be 0.5A, the target base distance during sputtering to be 120mm, and to obtain AlCrNbTiZr with a thickness of 100nm after 20min sputtering High-entropy alloy transition layer.

[0049] 4) Control the flow of Ar gas to 25sccm, and feed O 2 and N 2 , the flow rate is 10sccm, the sputtering pressure is adjusted to 0.5Pa, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com