Dispersed hydrogen barrier coating on inner wall of high temperature vacuum heat collecting tube and preparation method thereof

A vacuum heat collector tube and coating technology, applied in the field of solar thermal utilization, to achieve the effects of high bonding strength, controllable thickness, and excellent hydrogen resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

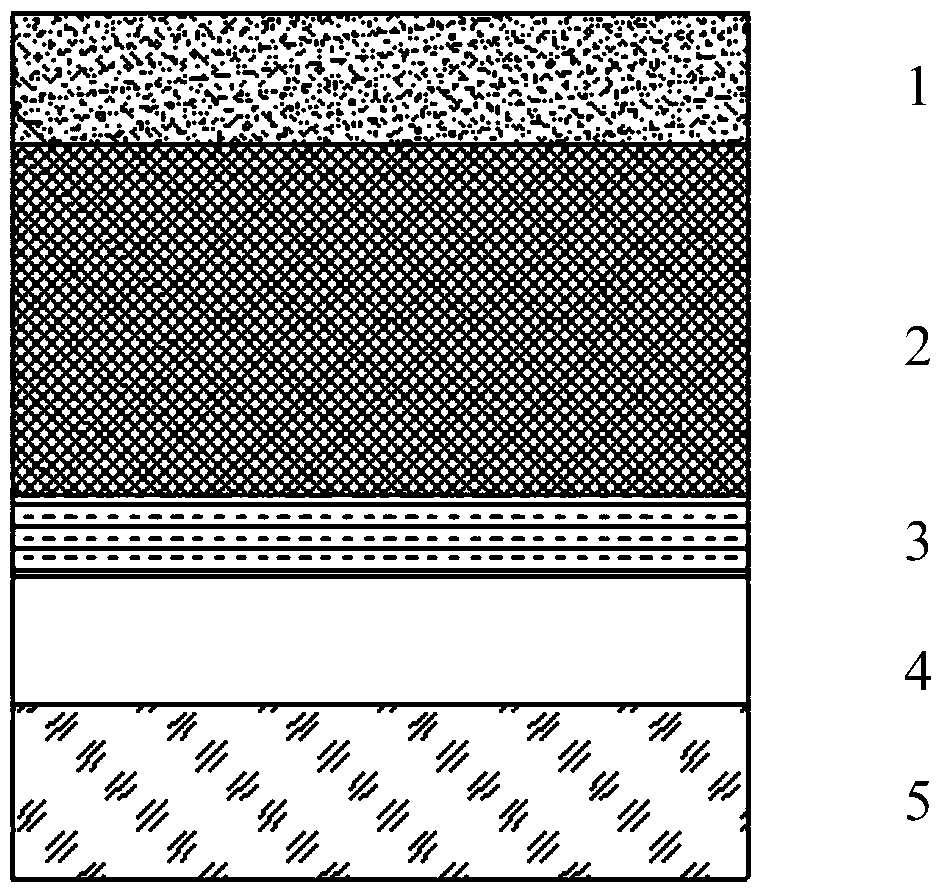

Image

Examples

Embodiment 1

[0026] (1) Polish the inner surface of the stainless steel tube to a roughness of 1 μm;

[0027] (2) Using metal-organic chemical vapor deposition technology to prepare Al on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 / Cr 2 o 3Diffusion coating; the reaction source adopts aluminum organic reaction source and chromium organic reaction source, and the specific process parameters are: aluminum reaction source temperature 150°C, aluminum reaction source reaction time 30min; chromium reaction source temperature 120°C, chromium reaction source reaction time 20min, Carrier gas H 2 The flow rate is 200ml / min. By controlling the heating temperature of the aluminum reaction source and the reaction time, the Al 2 o 3 become the main phase.

[0028] (3) Finally, Al with a thickness of about 0.5 μm is obtained 2 o 3 / Cr 2 o 3 Dispersion coating, in which the main phase Al 2 o 3 The content is about 70w%.

[0029] Determination of Al 2 o 3 / Cr 2...

Embodiment 2

[0031] (1) Polish the inner surface of the stainless steel tube to a roughness of 0.5 μm;

[0032] (2) Using metal-organic chemical vapor deposition technology to prepare Al on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 / Cr 2 o 3 Diffusion coating; the reaction source adopts aluminum organic reaction source and chromium organic reaction source, and the specific process parameters are: aluminum reaction source temperature 150°C, reaction time 50min; 2 The flow rate is 200ml / min.

[0033] (3) Finally, Al with a thickness of about 1 μm is obtained 2 o 3 / Cr 2 o 3 Dispersion coating, in which the main phase Al 2 o 3 The content is about 80w%.

[0034] Determination of Al 2 o 3 / Cr 2 o 3 Diffusion coating at 400°C H 2 Permeability, hydrogen barrier performance increased by 250 times.

Embodiment 3

[0036] (1) Polish the inner surface of the stainless steel tube to a roughness of 0.3 μm;

[0037] (2) Using metal-organic chemical vapor deposition technology to prepare Al on the inner surface of high-temperature vacuum heat collector tubes 2 o 3 / Cr 2 o 3 Diffusion coating; the reaction source adopts aluminum organic reaction source and chromium organic reaction source, and the specific process parameters are: aluminum reaction source temperature 200°C, reaction time 60min; 2 The flow rate is 200ml / min.

[0038] (3) Finally, Al with a thickness of about 3 μm is obtained 2 o 3 / Cr 2 o 3 Dispersion coating, in which the main phase Al 2 o 3 The content is about 90w%.

[0039] Determination of Al 2 o 3 / Cr 2 o 3 Diffusion coating at 400°C H 2 Permeability, hydrogen barrier performance increased by 300 times.

[0040] Al of the present invention 2 o 3 / Cr 2 o 3 The dispersion coating is prepared by the metal-organic chemical vapor deposition method. By deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com