Patents

Literature

49results about How to "Excellent hydrogen resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

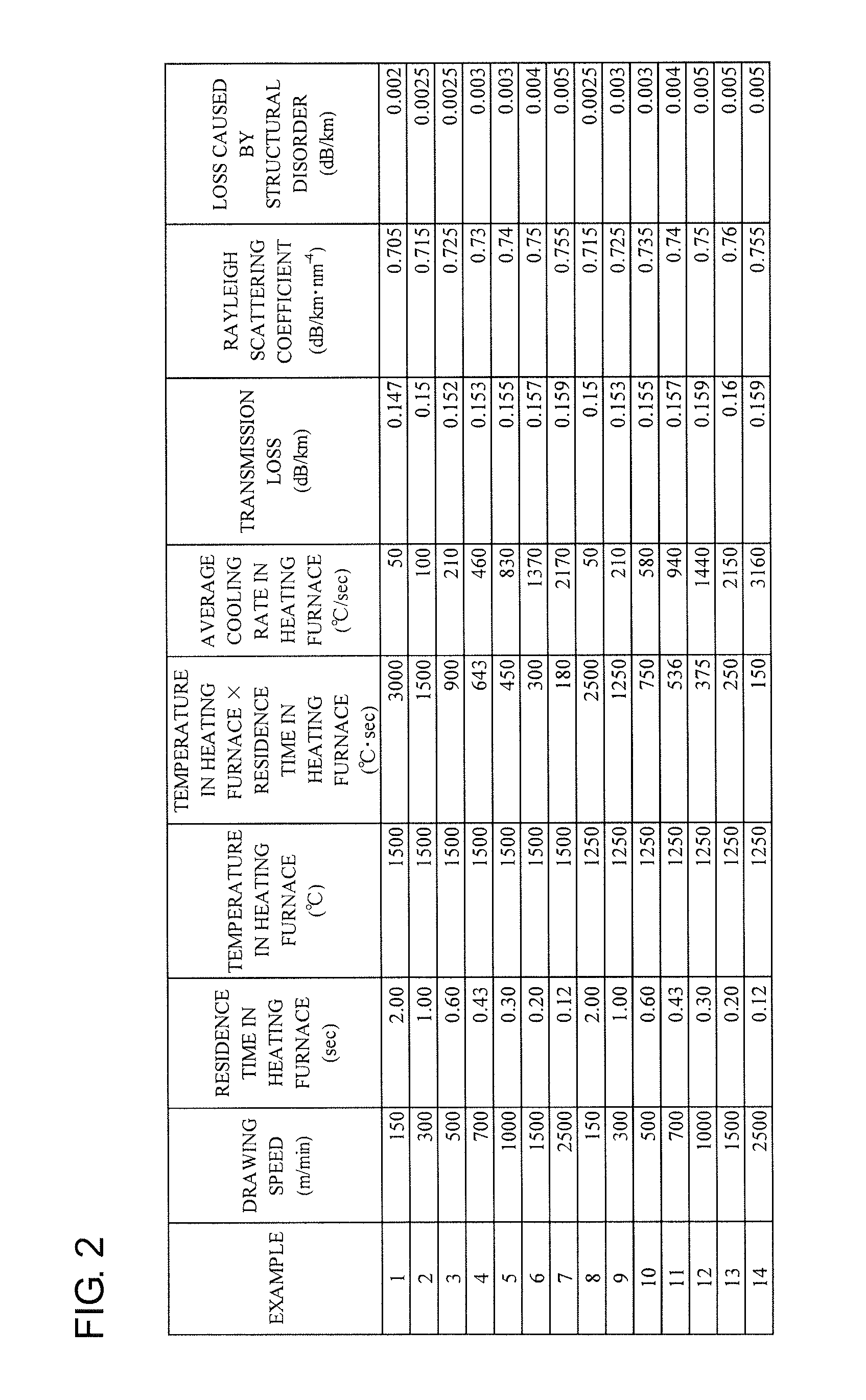

Optical fiber and a method for manufacturing same

InactiveUS20050259932A1Reduce defectExcellent propertyOptical fibre with multilayer core/claddingGlass fibre drawing apparatusProduction rateDopant

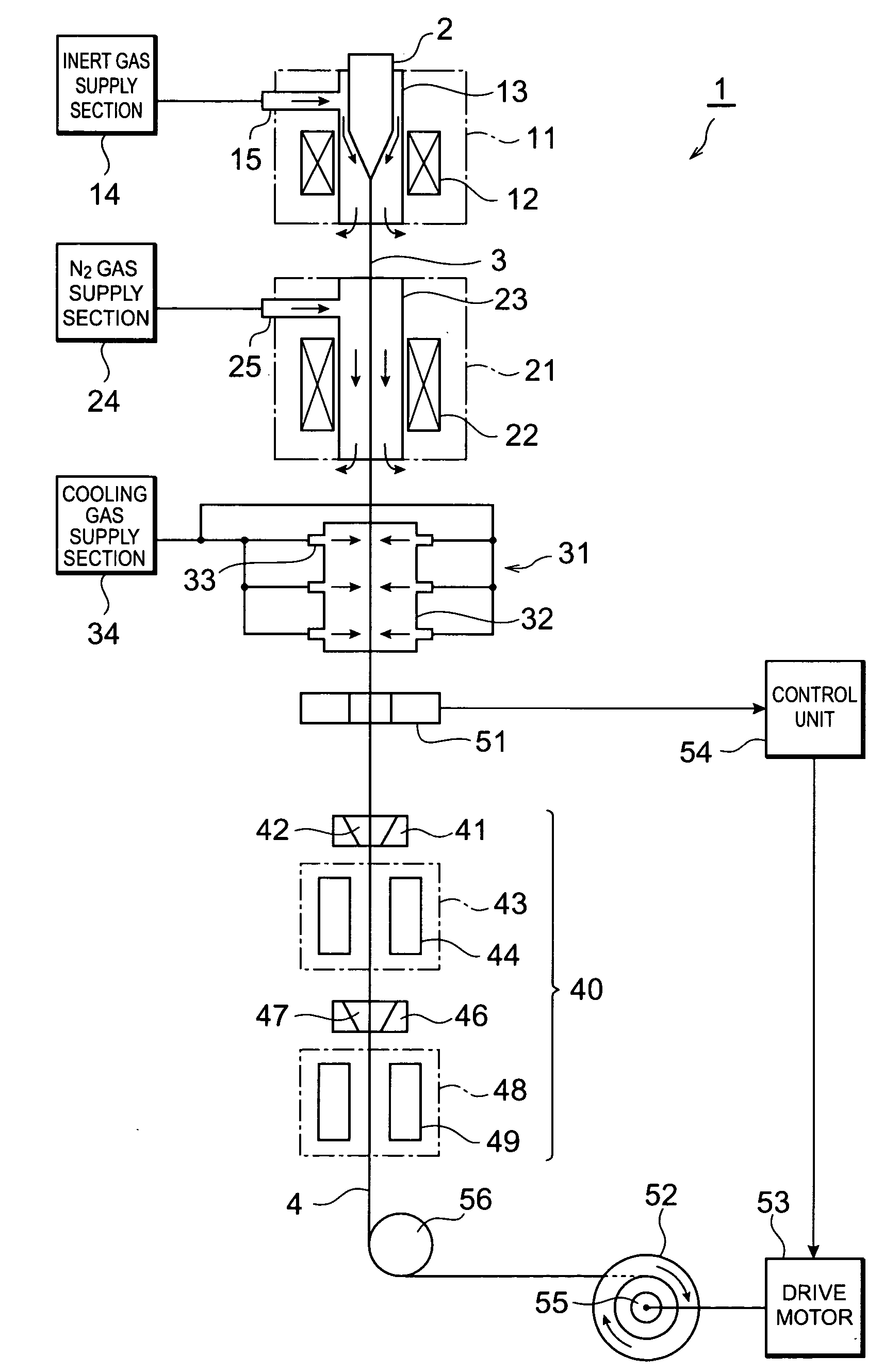

There is prepared an optical fiber preform 2 whose core region is doped with Ge in such a quantity of dopant that the relative refractive-index difference [Ge] expressed in % with respect to pure SiO2 satisfies the condition [Ge]≧0.3%, where upon after being heat drawn with a drawing furnace 11 into an optical fiber 3, the optical fiber 3 is annealed in a heating furnace 21 downstream of the drawing furnace 11 under a condition that the cooling speed is 2000° C. / second or less, and the period of annealing time is equal to or longer than the relaxation time. Further, the annealed optical fiber 3 is introduced into a cooling means 31 at an entry temperature of 700° C. or more, and the optical fiber 3 is forcibly cooled by the cooling means 31. As a consequence, there are achieved an optical fiber and a method of fabricating the same capable of fabricating the optical fiber having a reduced Rayleigh scattering loss as well as excellent hydrogen-resisting property with favorably high productivity.

Owner:SUMITOMO ELECTRIC IND LTD

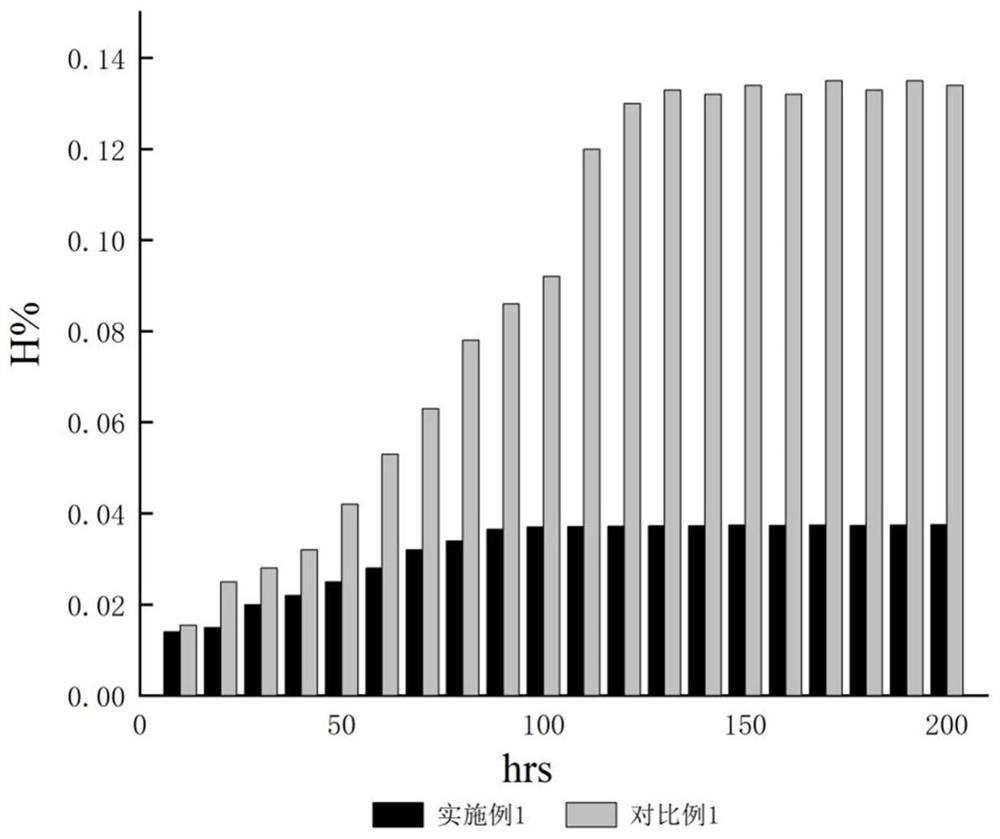

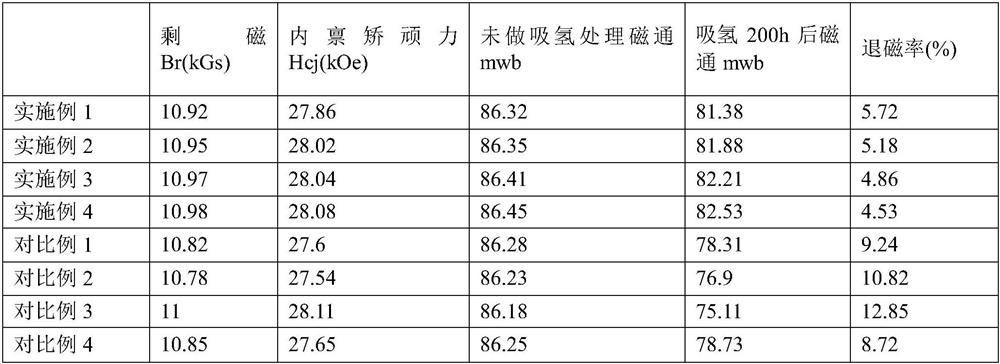

Rare earth element sintered magnet and method for producing rare earth element sintered magnet

ActiveUS20050028890A1Incur damageResistance can be maintainedInorganic material magnetismSolid state diffusion coatingRare-earth elementSintered magnets

Owner:SHIN ETSU CHEM IND CO LTD

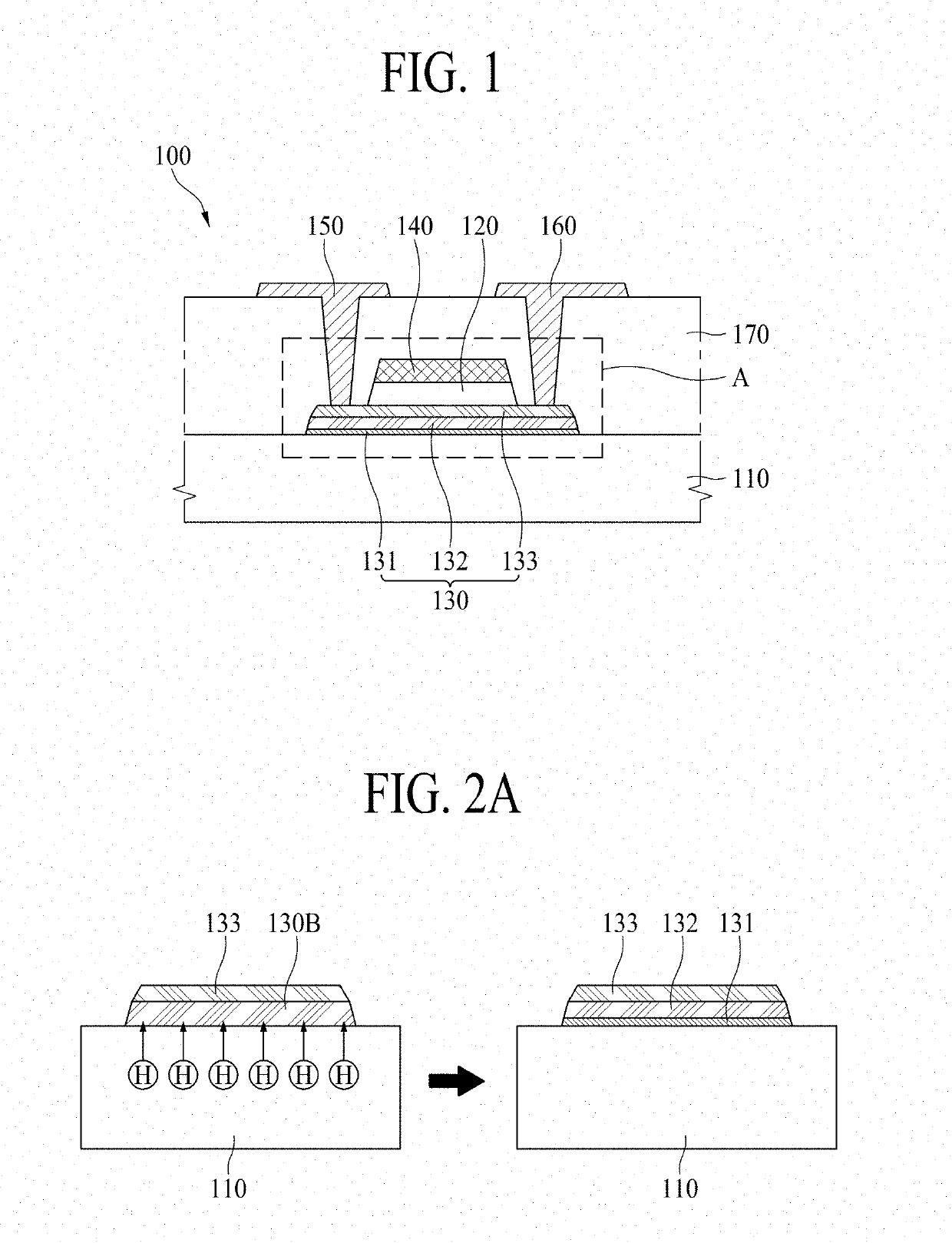

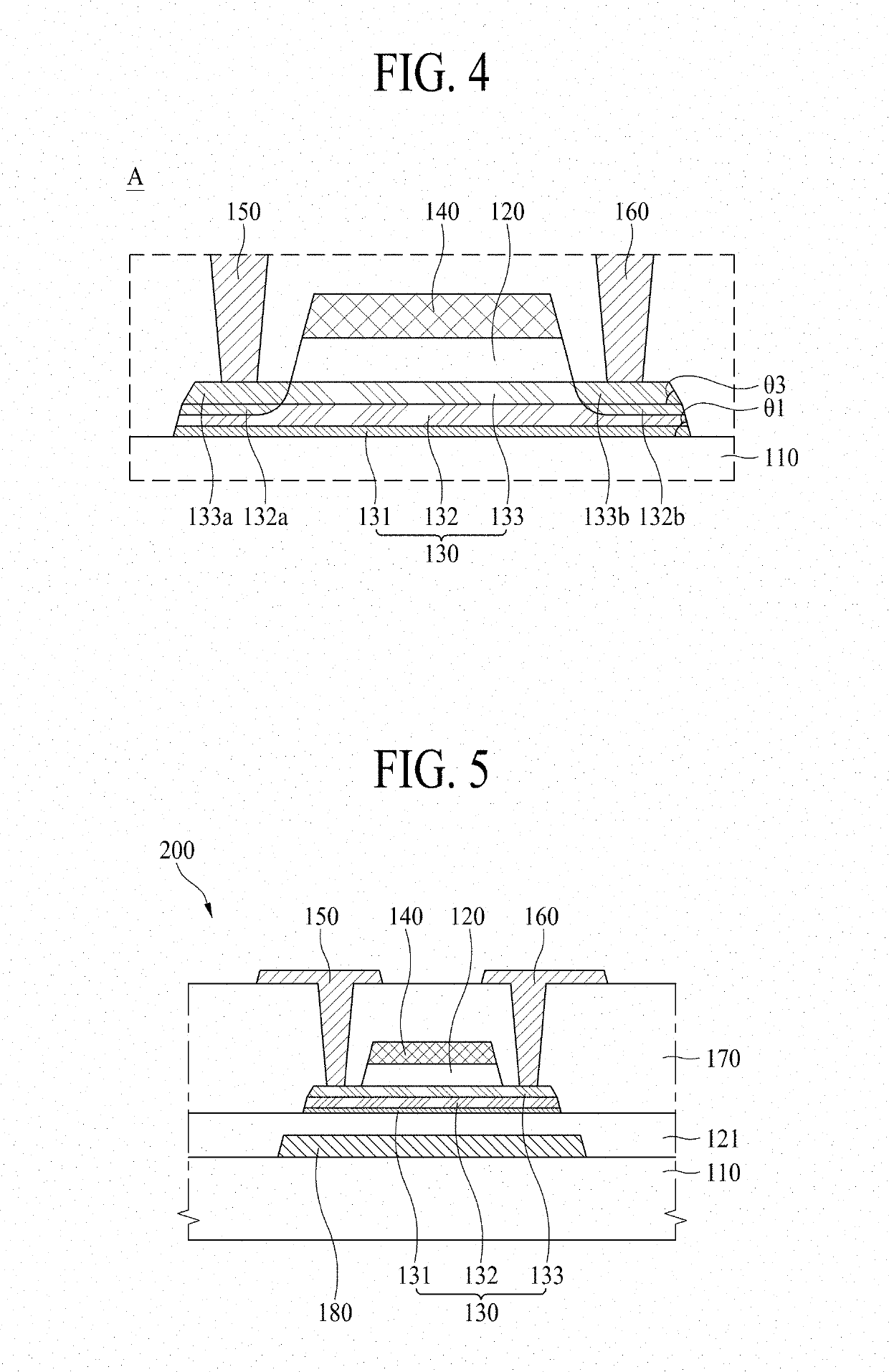

Thin-film transistor having hydrogen-blocking layer and display apparatus including the same

ActiveUS20190140101A1Excellent hydrogen resistanceNot to damageTransistorSolid-state devicesHydrogen concentrationOptoelectronics

A thin-film transistor is disclosed. The thin-film transistor includes an oxide semiconductor layer disposed on a substrate, a gate electrode disposed so as to overlap at least a portion of the oxide semiconductor layer and isolated from the oxide semiconductor layer, a source electrode connected to the oxide semiconductor layer, and a drain electrode connected to the oxide semiconductor layer and spaced apart from the source electrode, wherein the oxide semiconductor layer includes a first sub layer disposed on the substrate, a second sub layer disposed on the first sub layer, and a third sub layer disposed on the second sub layer, the second sub layer has larger resistance than the first sub layer and the third sub layer and lower carrier concentration than the first sub layer and the third sub layer, the first sub layer has higher hydrogen concentration than the second sub layer and the third sub layer, and each of the first sub layer and the second sub layer has crystallinity.

Owner:LG DISPLAY CO LTD

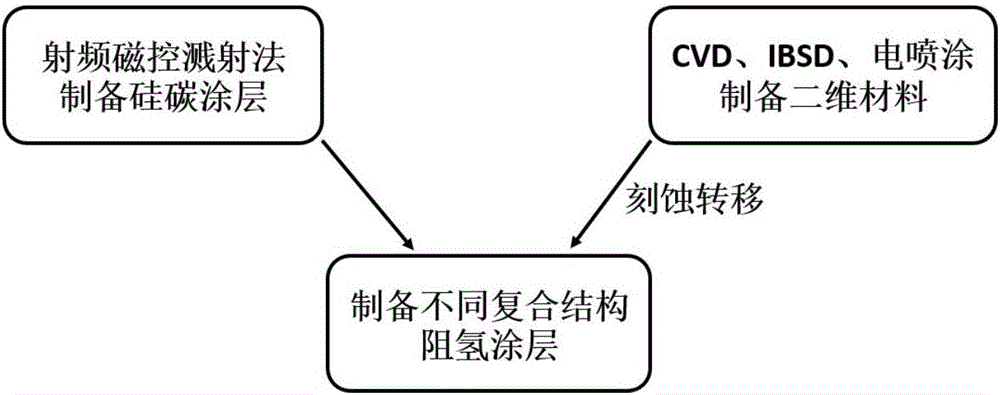

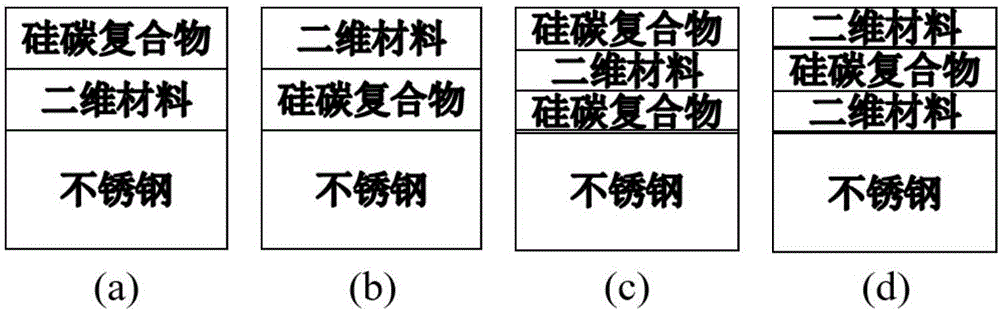

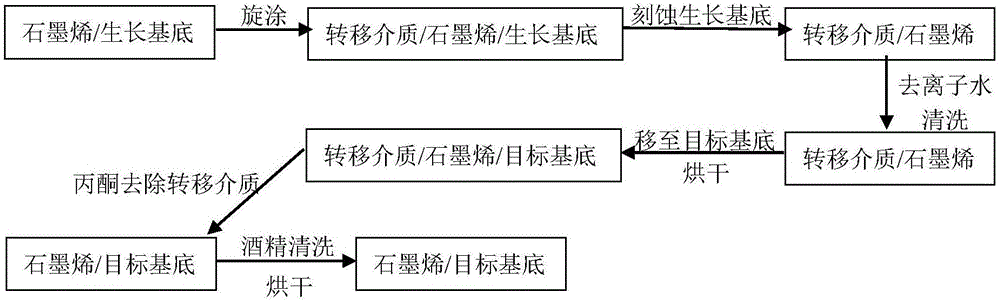

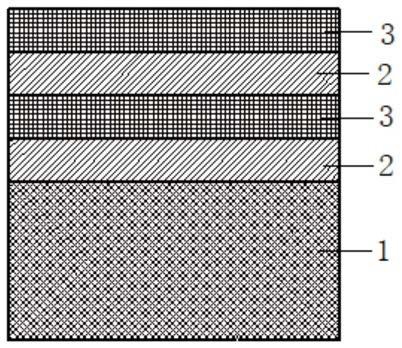

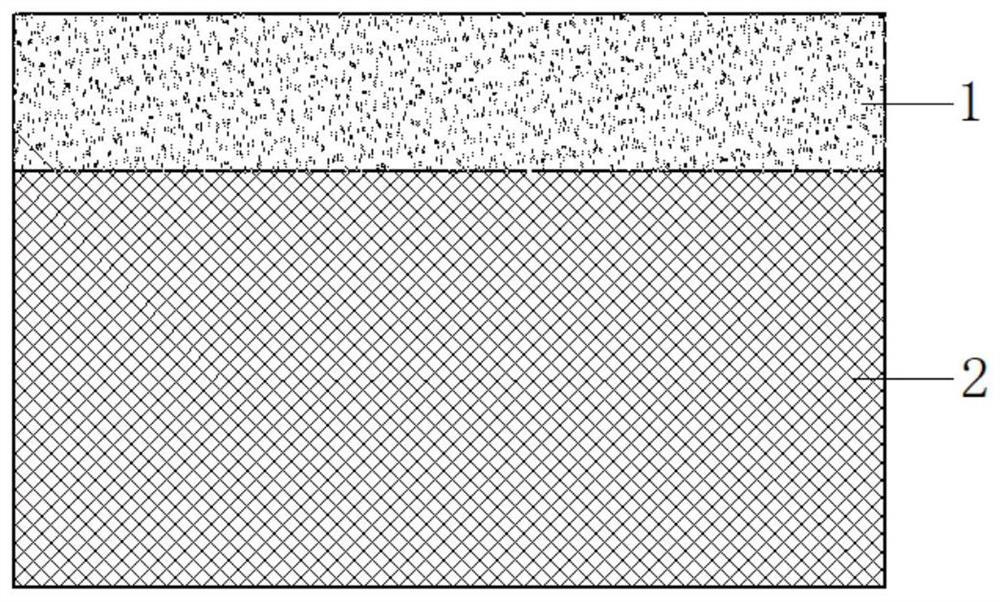

Two-dimensional material adjusting and controlling silicon-carbon composite structure hydrogen resisting coating and preparing method thereof

InactiveCN106283052AExcellent hydrogen resistanceSuperimposed coating processCarbon compositesHydrogen

The invention discloses a two-dimensional material adjusting and controlling silicon-carbon composite structure hydrogen resisting coating. The two-dimensional material adjusting and controlling silicon-carbon composite structure hydrogen resisting coating is characterized in that a coating structure comprises a silicon-carbon compound and a two-dimensional material; a two-dimensional material coating is formed by stacking graphene of a two-dimensional structure or hexagonal boron nitride of a two-dimensional structure or molybdenum disulfide of a molybdenum disulfide layer by layer, the layer number ranges from 1 to 10, and the thickness of the two-dimensional material coating ranges from 0.34 nm to 28 nm; and the silicon-carbon compound is formed by sputtering a silicon carbide target material, and the thickness of the silicon-carbon compound ranges from 0.5 micron to 2 microns. A preparing method of the two-dimensional material adjusting and controlling silicon-carbon composite structure hydrogen resisting coating includes the step that the two-dimensional material is prepared by adopting a chemical vapor deposition (CVD) technology and an ion beam sputtering deposition (IBSD) technology and with the combination of an etching transferring technology. A composite coating technology is adopted and has a hydrogen resisting effect superior to that of a single coating; introduction of the two-dimensional material is brought forwards for the first time on the basis of an original silicon-carbon compound hydrogen resisting coating; and by the adoption of an existing technological method, composite structures of different forms are designed and prepared, and the layer number is taken into consideration.

Owner:BEIHANG UNIV

Rare earth element sintered magnet and method for producing rare earth element sintered magnet

ActiveUS7438768B2Incur damageResistance can be maintainedInorganic material magnetismSolid state diffusion coatingRare-earth elementSintered magnets

Owner:SHIN ETSU CHEM IND CO LTD

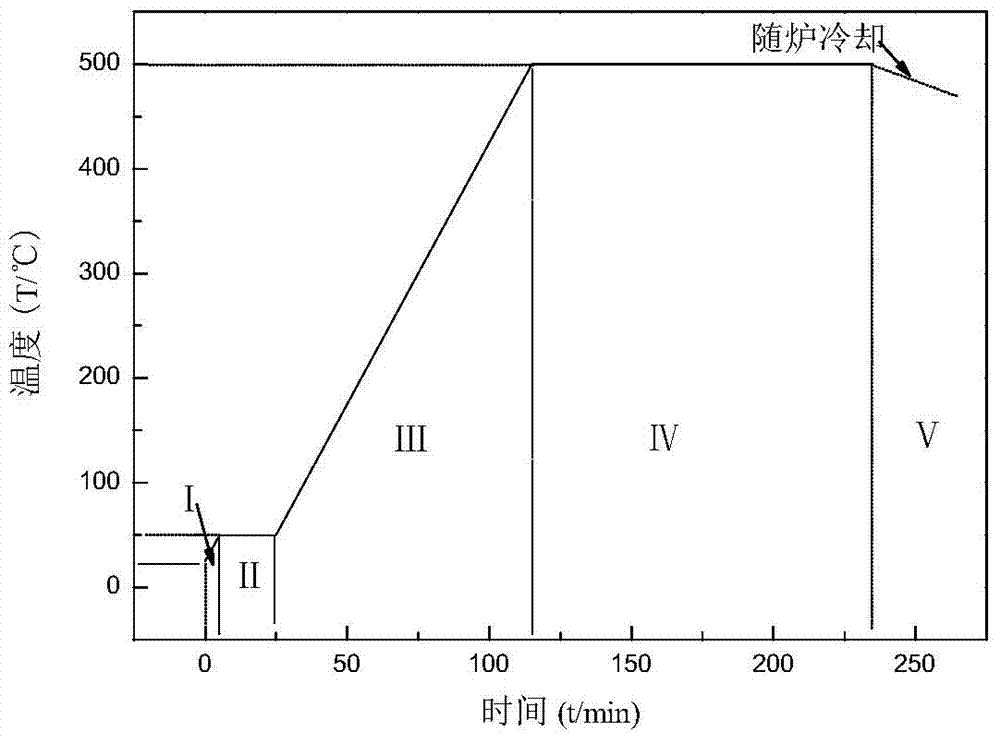

Hydrogen-resistance permeation layer on surface of metal hydride and preparation method thereof

ActiveCN107043907APrevent hydrogen releaseEasy to operateSolid state diffusion coatingSource materialRoom temperature

The invention relates to a preparation method for a hydrogen-resistance permeation layer on the surface of metal hydride. According to the preparation method for the hydrogen-resistance permeation layer on the surface of the metal hydride, source materials containing carbon oxygen or nitrogen oxygen or carbon-nitrogen oxygen are sealed in a reaction vessel with metal hydride matrices, the pressure is controlled between 1.010<5> Pa-101 kPa, and the temperature is controlled to rise from the room temperature to 200-900 DEG C; the carbon oxygen or the nitrogen oxygen or the carbon-nitrogen oxygen is diffused to the surfaces of the metal hydride matrices and conducted in-situ reactions with metal elements of the matrices; and the dense and continuous composite hydrogen-resistance permeation layer which contains the carbon oxygen or the nitrogen oxygen or the carbon-nitrogen oxygen can be obtained after cooling. The hydrogen-resistance permeation layer is tightly combined with the matrices, is moderate in thickness, has an excellent hydrogen-resistance performance and can effectively prevent the hydrogen desorption of the metal hydride when used at the temperature of 200-900 DEG C. The hydrogen-resistance permeation layer on the surface of the metal hydride and the preparation method thereof are simple in operation, high in adaptability, and are not restricted by shapes and structures of complex matrices.

Owner:有研资源环境技术研究院(北京)有限公司

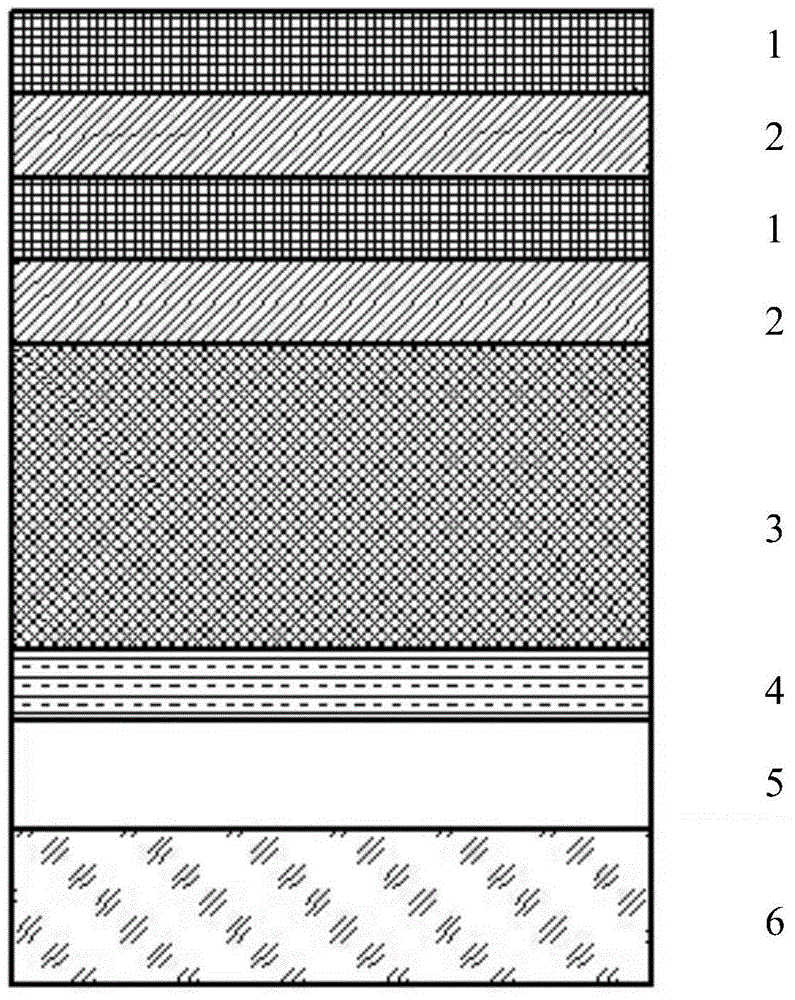

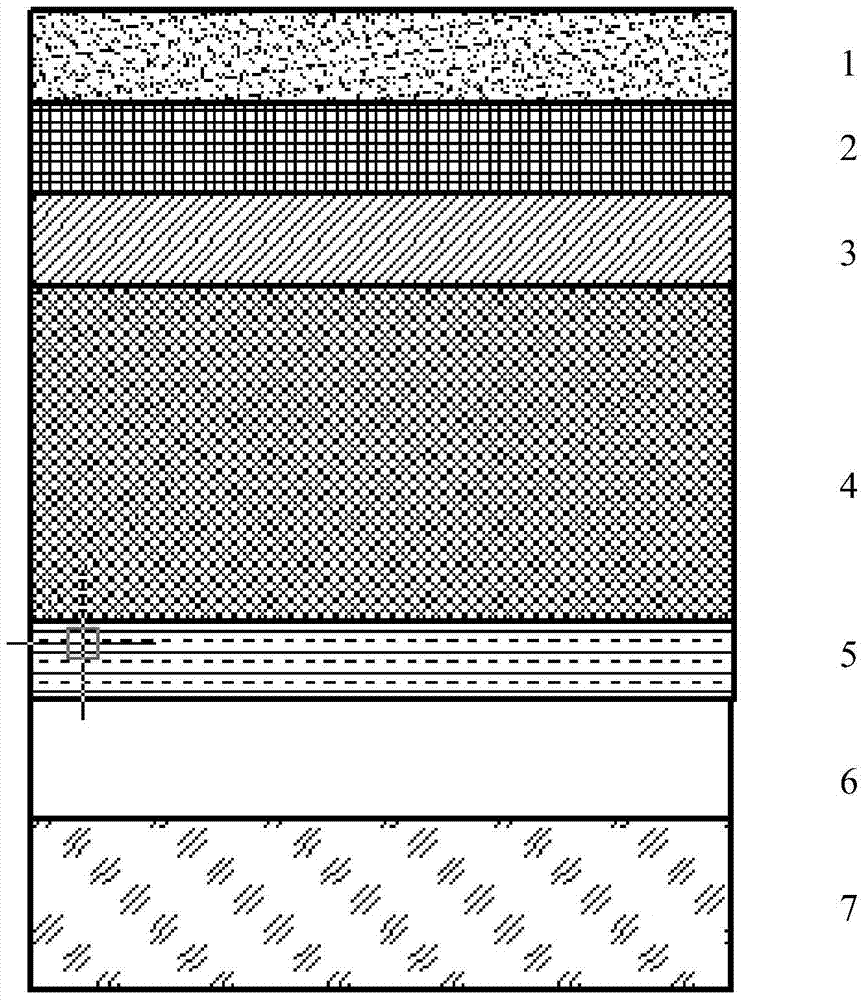

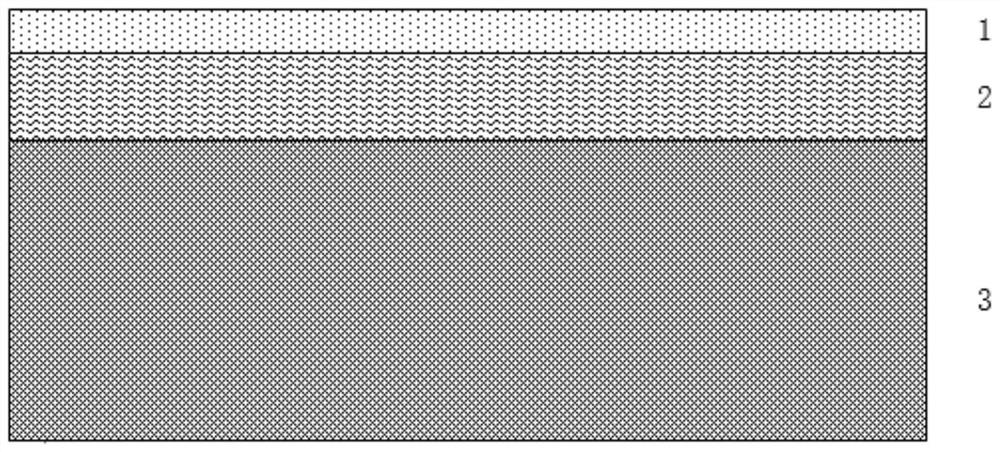

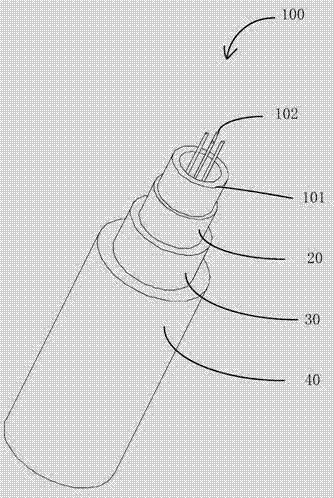

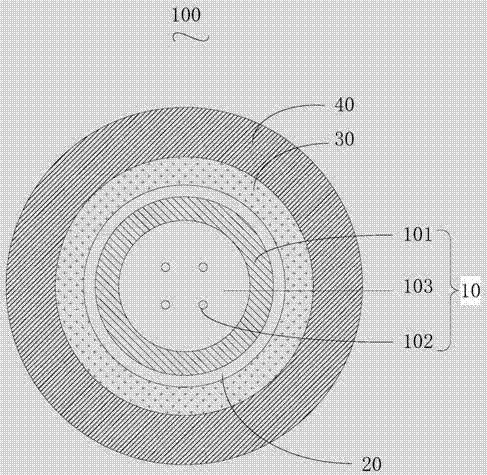

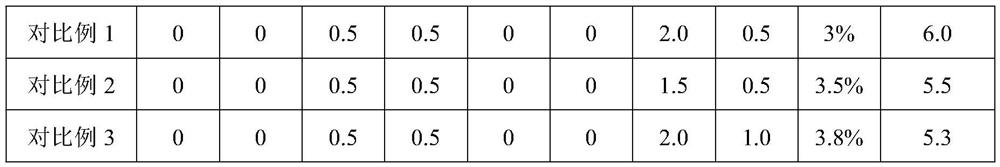

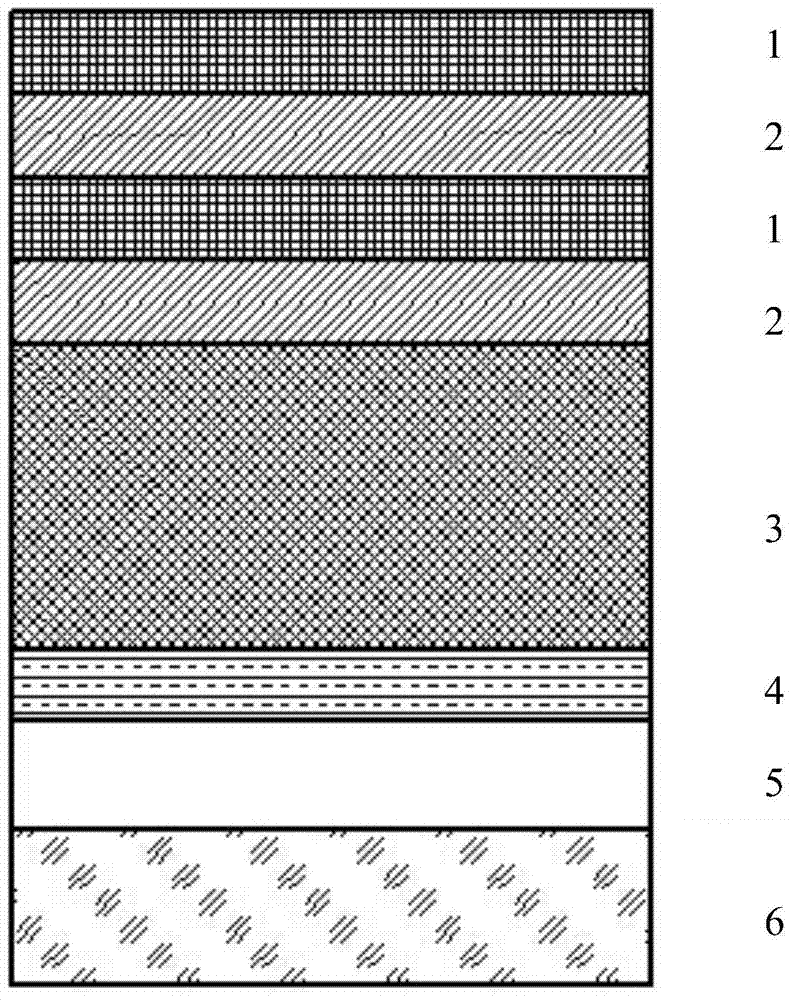

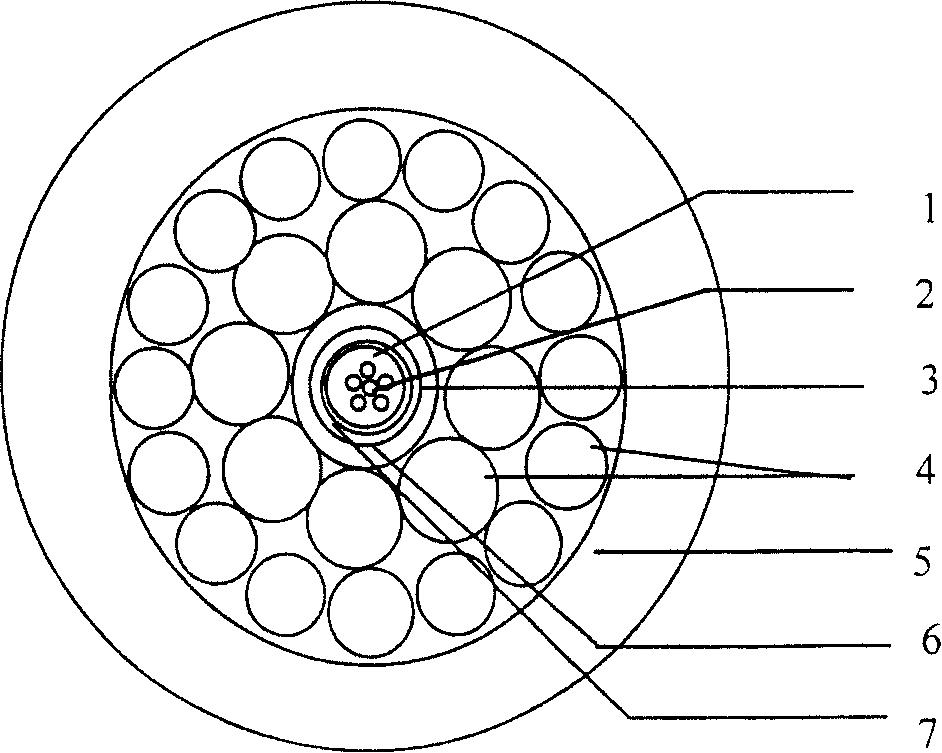

Cable and manufacture method thereof

ActiveCN103033894AGuaranteed transmission performanceHigh tensile strengthFibre mechanical structuresFiberHydrogen

The invention provides a cable which comprises at least one optical fiber (1), a fiber paste layer (2), a first protective layer (3), a hydrogen blocking layer (4) and a second protective layer (5), wherein the fiber paste layer (2), the first protective layer (3), the hydrogen blocking layer (4) and the second protective layer (5) are sequentially wrapped on the surface of the optical fiber (1) from inside to outside. The invention further provides a manufacture method of the cable. The method includes: sequentially forming the fiber paste layer (2), the first protective layer (3), the hydrogen blocking layer (4) and the second protective layer (5) on the surface of the optical fiber (1) from inside to outside. The cable has excellent hydrogen blocking performance and can meets the requirements of being used in severe environment under wells.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Y2O3/Al2O3 composite gradient hydrogen resistant coating and preparation method thereof

ActiveCN105666956AImprove compactnessThickness is easy to controlLaminationLamination apparatusHydrogenHydrogen permeation

The invention relates to an Y2O3 / Al2O3 composite gradient hydrogen resistant coating and a preparation method thereof. The coating is used for resisting hydrogen permeation in a high-temperature vacuum collector tube. The composite gradient hydrogen resistant coating is composed of the stainless steel tube and an Y2O3 / Al2O3 composite coating which is applied on an inner surface of the stainless steel tube. The composite coating is prepared through a metal-organic chemical vapor deposition method, wherein an Al2O3 coating and an Y2O3 coating are deposited repeatedly on the inner surface to form the multilayer Y2O3 / Al2O3 composite gradient hydrogen resistant coating being 0.1-20 [mu]m in thickness. The coating is in a multilayer alternated structure with the most inner layer being Al2O3 and the most outer layer being Y2O3. The hydrogen resistant coating is strong in combination strength with a substrate, is simple in preparation process and is low in cost, and is improved in hydrogen resistant performance by more than 200 times.

Owner:GRIMAT ENG INST CO LTD

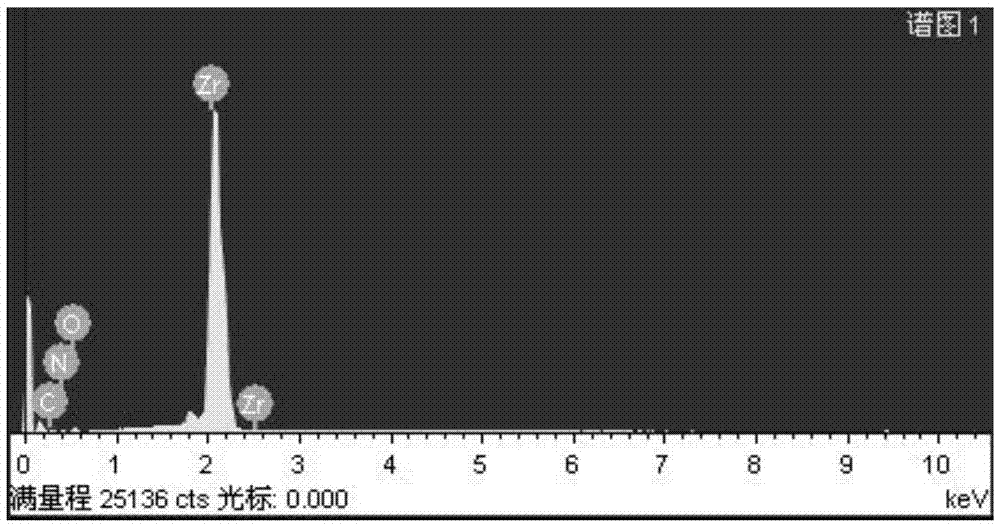

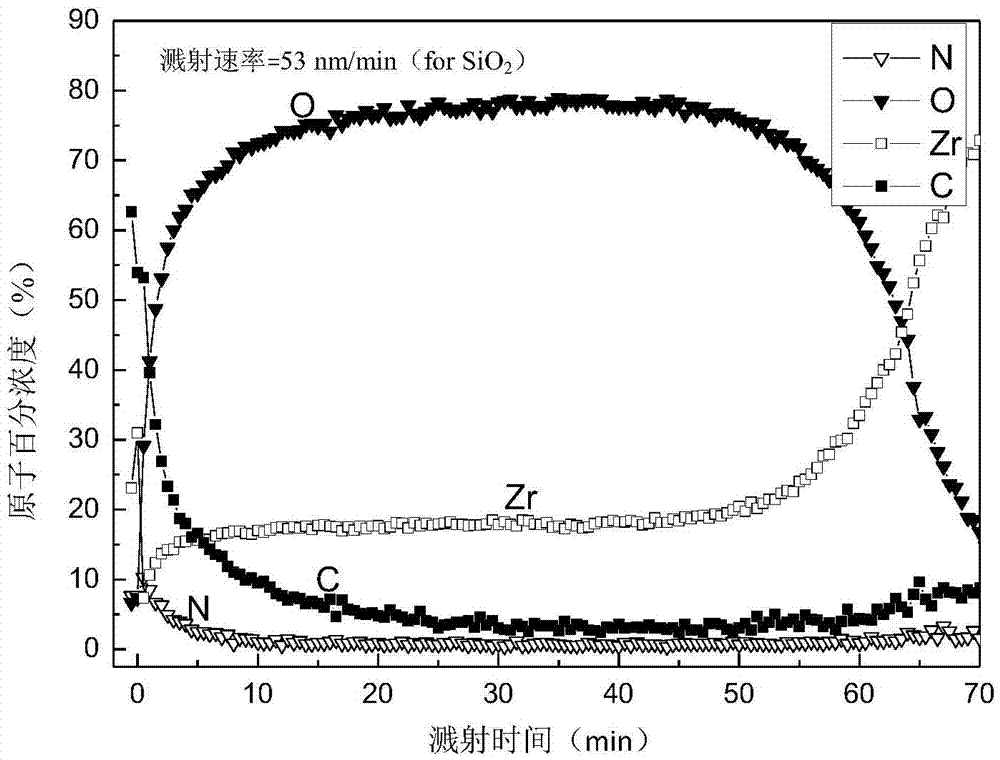

Surface protection method for zirconium hydride

ActiveCN103484844AExcellent hydrogen resistanceUniform thicknessSolid/suspension decomposition chemical coatingZirconium hydrideHydrogen

The invention relates to a method for preparing a hydrogen-permeation resistant coating on the surface of zirconium hydride. The method particularly adopts the technical scheme that an in situ oxidization method for the preparation of a bottom layer is adopted, a sol-gel method is adopted and a nanometer oxide coating is prepared on the bottom layer, and finally an oxide coating with a composite structure is obtained. The method includes the following steps: firstly, the zirconium hydride is subjected to in situ oxidization in an oxidizing gas, so as to prepare a zirconia bottom layer, then the zirconium hydride is placed in a zirconium oxychloride precursor sol, and the sol is solidified and sintered through adopting a segmented heat processing technology. Through the adoption of the method, the prepared composite coating on the surface of the zirconium hydride is tightly combined with a base body, and is proper in thickness, excellent in thermal shock resistance and better in high-temperature oxidation resistance.

Owner:INNER MONGOLIA UNIV OF TECH

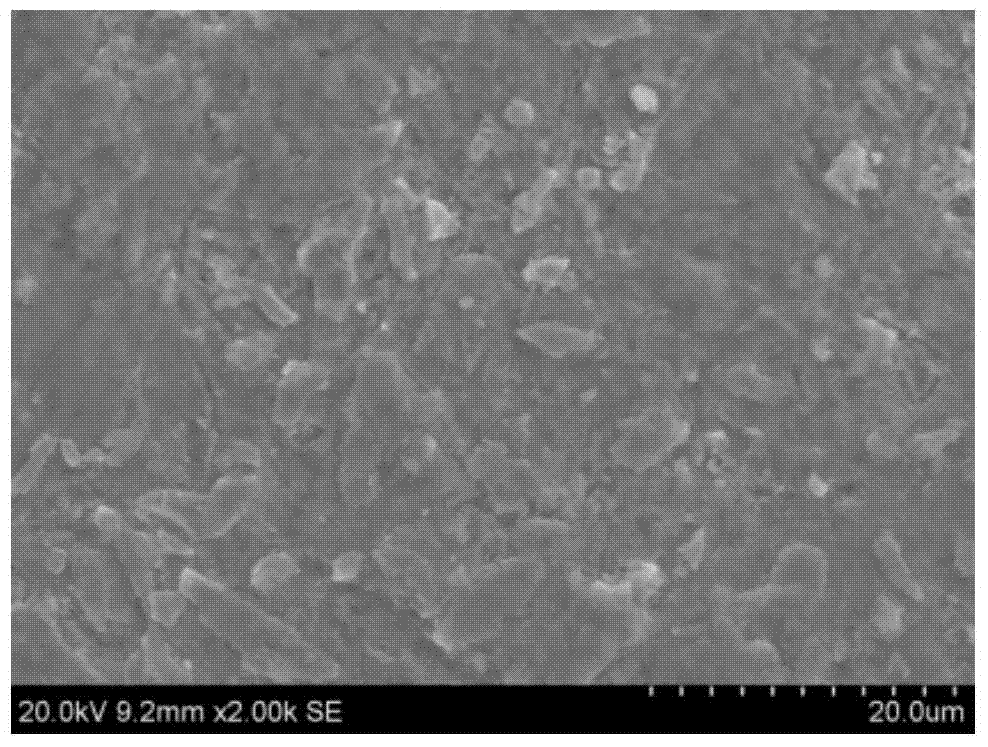

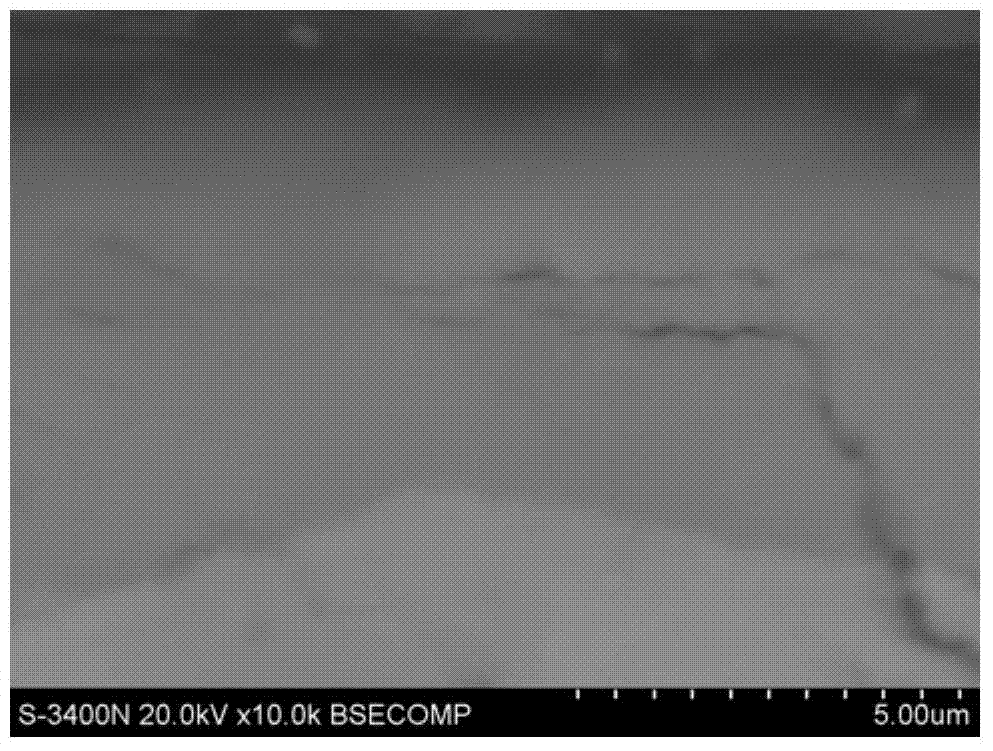

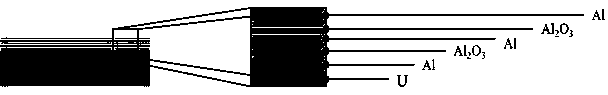

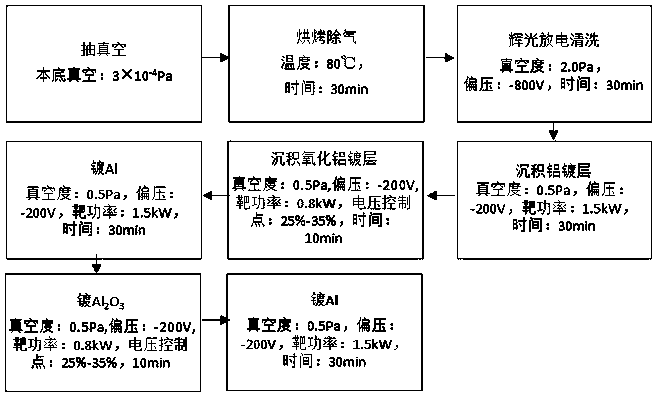

Metal uranium surface water-blocking hydrogen-blocking Al/Al2O3 composite plating layer and preparing method thereof

ActiveCN110670040AReduce defectsImprove densification performanceVacuum evaporation coatingSputtering coatingHydrogen permeationAluminium oxides

The invention discloses a metal uranium surface water-blocking hydrogen-blocking Al / Al2O3 composite plating layer and a preparing method thereof. The purpose is to develop the corrosion-resistant plating layer which has high density and particularly can effectively block water and hydrogen penetration so as to solve the problem about surface corrosion of metal uranium materials. The composite plating layer uses uranium as a base body and is formed by alternately depositing an Al plating layer and an Al2O3 plating layer. According to the composite plating layer and the preparing method, the aluminum oxide plating layer has a function of closing pores of the aluminum plating layer, and the following effects are achieved, wherein on one hand, introduction of the aluminum oxide plating layer prevents continuous growth of columnar grains of the aluminum plating layer, so that penetrating holes and defects in the plating layer are greatly reduced, the compactness of the plating layer is improved, and the number of permeation channels of corrosive media such as water and hydrogen is significantly reduced; and on the other hand, aluminum oxide is of a dense structure, is stable in performance and low in hydrogen permeability and can more effectively block penetration of small atomic size corrosion media such as hydrogen, and the protection performance of the plating layer on the base body is improved. It is determined that the composite plating layer can effectively block penetration of environmental atmospheres such as the water and the hydrogen on the uranium.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Solid lubricant

The solid lubricating agent contains MoS2, and is characterized by that it also contains (wt%) 0.3%-3% of Ca-S dispersing agent, 0.15-2% of ZnDTP antioxidant, 0.25%-2% of PIB tack producer, 0.15%-2% of SI-P antiform additive, and 0.15%-2% of P.P cleaning agent. It not only can reduce friction and wear, but also can greatly prolong the service life of parts, and can save fuel and engine oil, and can reduce discharge of tail gas, and can remove dampness and rust from parts to protect parts. Said solid lubricating agent possesses excellent high temp. resistant and high pressure resistant properties, can be used in the machine with explosive friction, and possesses excellent lubricating action at high and low temp. environments.

Owner:太红花 +1

a y 2 o 3 / al 2 o 3 /cr 2 o 3 Composite gradient hydrogen barrier coating and preparation method thereof

ActiveCN105667009BGrowth enablerImprove compactnessLaminationLamination apparatusHydrogenHydrogen permeation

The invention relates to an Y2O3 / Al2O3 / Cr2O3 composite gradient hydrogen resistant coating and a preparation method thereof. The hydrogen resistant coating is used for resisting hydrogen permeation on a stainless steel structural member, especially resisting the hydrogen permeation on an inner stainless steel tube in a solar energy high-temperature vacuum collector tube. The composite gradient hydrogen resistant coating is composed of the stainless steel tube and an Y2O3 / Al2O3 / Cr2O3 composite coating which is applied on an inner surface of the stainless steel tube. The composite coating is prepared through a metal-organic chemical vapor deposition method, wherein a Cr2O3 coating, an Al2O3 coating and an Y2O3 coating are successively deposited to form the Y2O3 / Al2O3 / Cr2O3 composite gradient hydrogen resistant multilayer coating being 0.1-20 [mu]m in thickness. The hydrogen resistant coating is strong in combination strength with a substrate, is simple in preparation process and is low in cost, and is improved in hydrogen resistant performance by more than 300 times.

Owner:GRIMAT ENG INST CO LTD

Corrosion-resistant shake-proof hammer and surface treatment technique thereof

InactiveCN106011690AWeight increaseGood shock absorptionDevices for damping mechanical oscillationsPressure inorganic powder coatingCorrosion resistantSurface finishing

The invention discloses a corrosion-resistant shake-proof hammer and a surface treatment technique thereof and relates to the technical field of shake-proof hammers of power transmission equipment. The corrosion-resistant shake-proof hammer is composed of, by mass, 0.35%-0.87% of carbon, 0.75%-2.58% of silicon, 12.25%-15.87% of chromium, 3.6%-5.3% of nickel, 0.8%-1.2% of molybdenum, 5.2%-12.6% of manganese, 0.005%-0.009% of niobium, 2.3%-3.5% of aluminum, 3%-8% of copper and the balance ferrum. The corrosion-resistant shake-proof hammer has the advantages of being large in density and good in shake-proof effect; and by spraying a surface coating on the shake-proof hammer, the corrosion resistance and abrasion resistance of the shake-proof hammer are remarkably improved, and thus the service life of the shake-proof hammer is remarkably prolonged.

Owner:安徽固齐线路器材有限公司

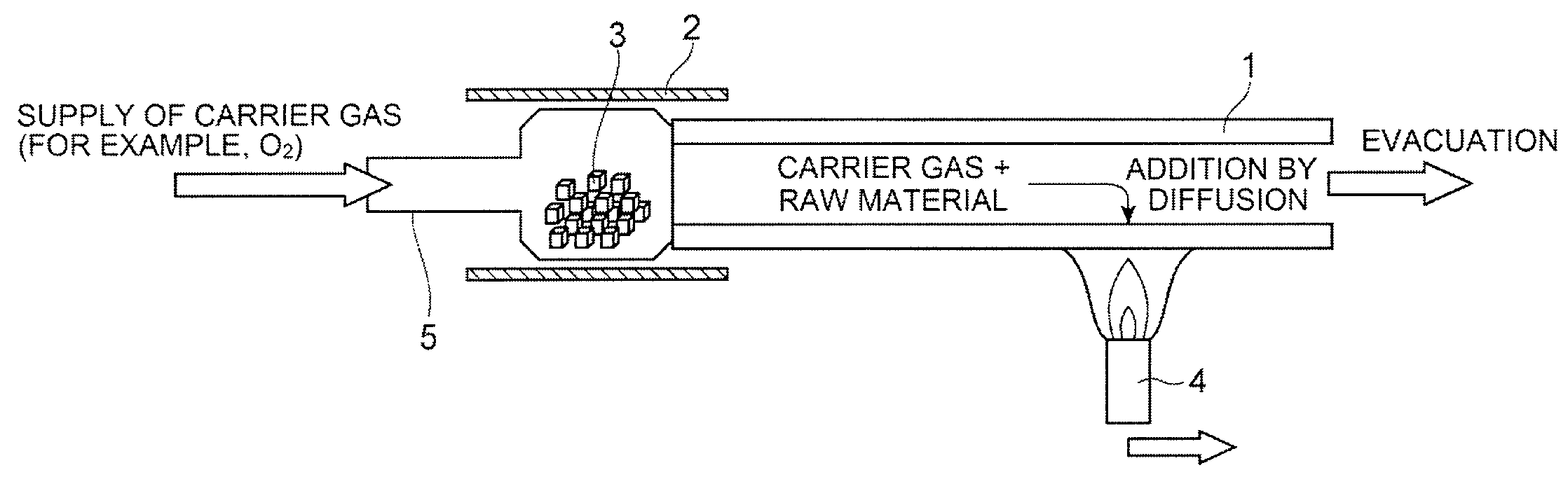

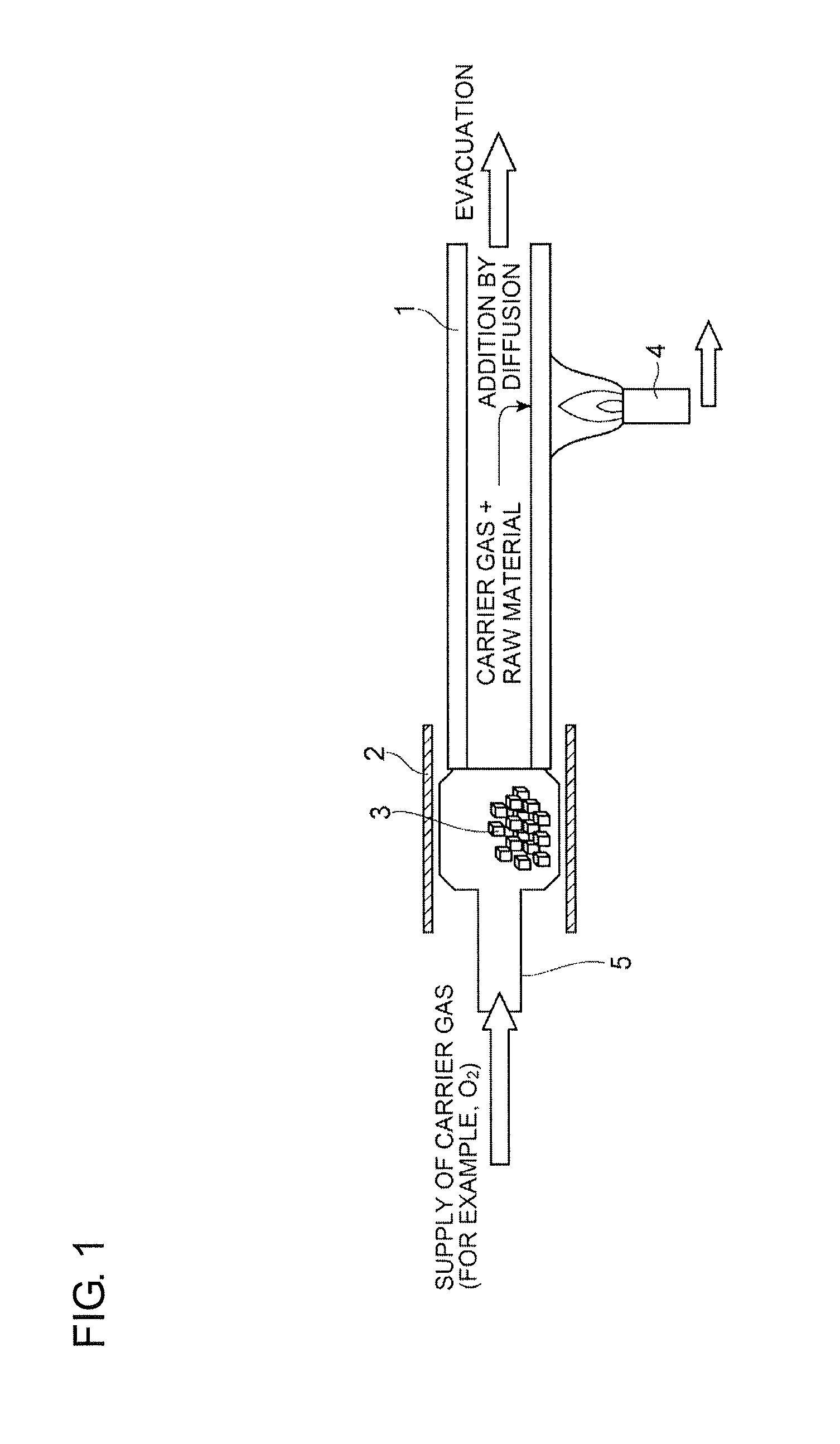

Optical fiber manufacturing method and optical fiber

ActiveUS9527765B2Excellent hydrogen resistanceGlass optical fibreGlass fibre drawing apparatusHydrogenHeating furnace

There is provided a method for producing a low-loss alkali metal-doped silica core optical fiber having excellent hydrogen resistance. The method for producing the optical fiber according to the present invention includes a drawing step of drawing an optical fiber preform in a drawing furnace to produce a silica glass-based optical fiber including a core region containing an alkali metal with an average concentration of 0.5 atomic ppm or more and a cladding region that surrounds the core region and a heating step of heating the optical fiber in a heating furnace through which the optical fiber drawn from the drawing furnace passes.

Owner:SUMITOMO ELECTRIC IND LTD

A kind of high bonding strength aluminum oxide resistance to hydrogen permeation and corrosion resistance insulation layer and its preparation method and application

ActiveCN108914111BThickness is easy to controlImprove compactnessVacuum evaporation coatingSputtering coatingSpray coatingSS - Stainless steel

The invention relates to a high-binding-strength aluminum oxide resistance to hydrogen permeation and corrosion-resistant insulating layer and a preparation method and application thereof. The coating can be prepared by cold spraying, chemical vapor deposition, magnetron sputtering, thermal spraying and other methods on the surface of the substrate to prepare a layer of iron-chromium-aluminum alloy mixed in a certain proportion, and then obtain a thickness of 0.05-1μm by thermal oxidation. α‑Al is dense and has good bonding strength with the substrate, and has excellent hydrogen permeation resistance effect 2 o 3 Oxide layer, the temperature of the substrate during all operations can be controlled below 800°C. In addition to excellent hydrogen permeation resistance, strong self-healing ability and corrosion resistance and insulation ability, the hydrogen permeable layer provided by the present invention has the biggest outstanding advantage of excellent bonding strength with the substrate. The hydrogen-resistant coating can be used as a hydrogen-permeable barrier layer for stainless steel structural parts, especially for a hydrogen-permeable barrier layer on the surface of fusion reactor inner cladding components.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

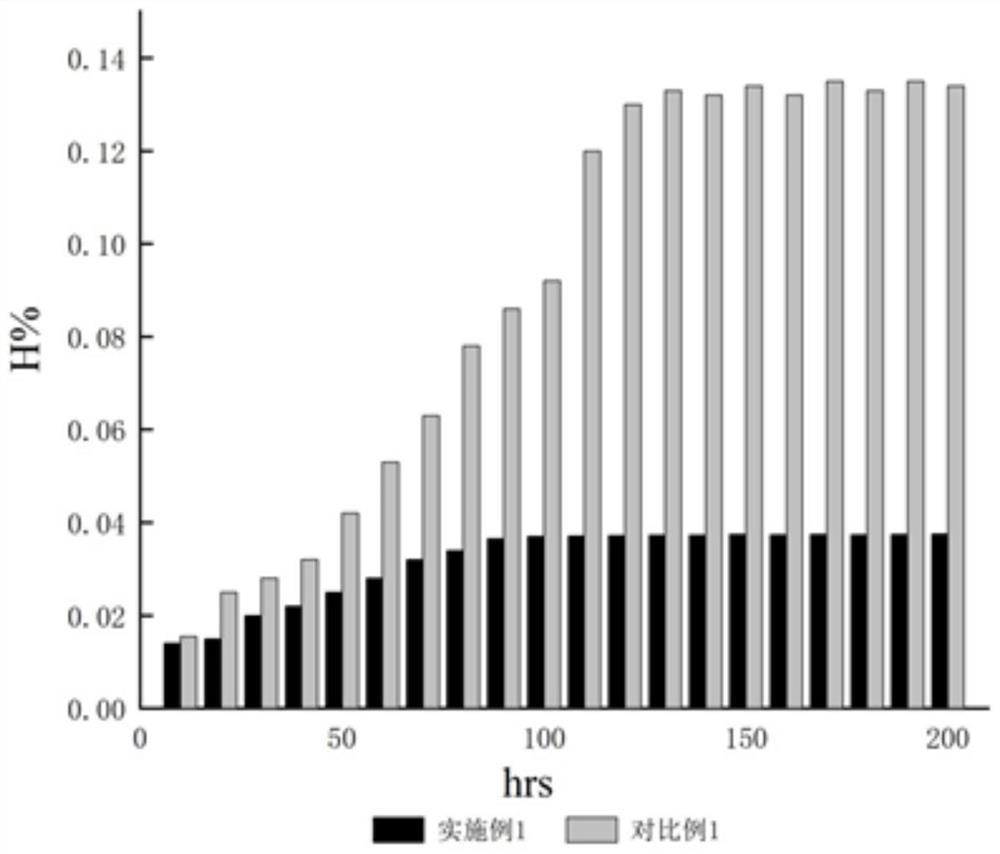

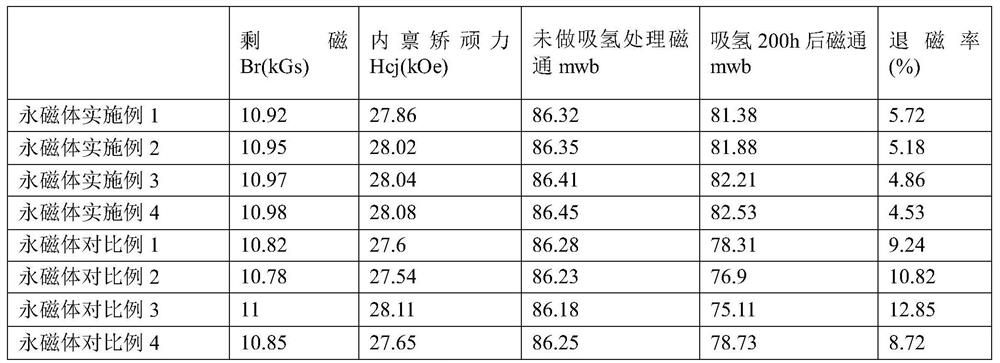

Preparation method of samarium-cobalt permanent magnet suitable for high-temperature and high-pressure pure hydrogen environment

ActiveCN113451038AImprove hydrogen resistanceHigh densityInductances/transformers/magnets manufactureMetallurgySamarium

The invention relates to the field of permanent magnet materials, and discloses a preparation method of a samarium-cobalt permanent magnet suitable for a high-temperature and high-pressure pure hydrogen environment. The method comprises steps of (1) smelting, (2) crushing treatment and jet milling, (3) magnetic field orientation forming and cold isostatic pressing, (4) performing sintering, solid solution and aging treatment on the body, and (5) cleaning the surface of the samarium-cobalt magnet, and sequentially plating the surface of the samarium-cobalt magnet with a base body plating layer, an AlCrZnN plating layer and a DyNiAl plating layer. The plating layer prepared on the surface of the samarium-cobalt permanent magnet through the magnetron sputtering method is good in binding property and compactness and has excellent hydrogen resistance and high temperature resistance, and what is guaranteed is that the samarium-cobalt permanent magnet material is used in the high-temperature and high-pressure pure hydrogen environment.

Owner:HANGZHOU PERMANENT MAGNET GRP

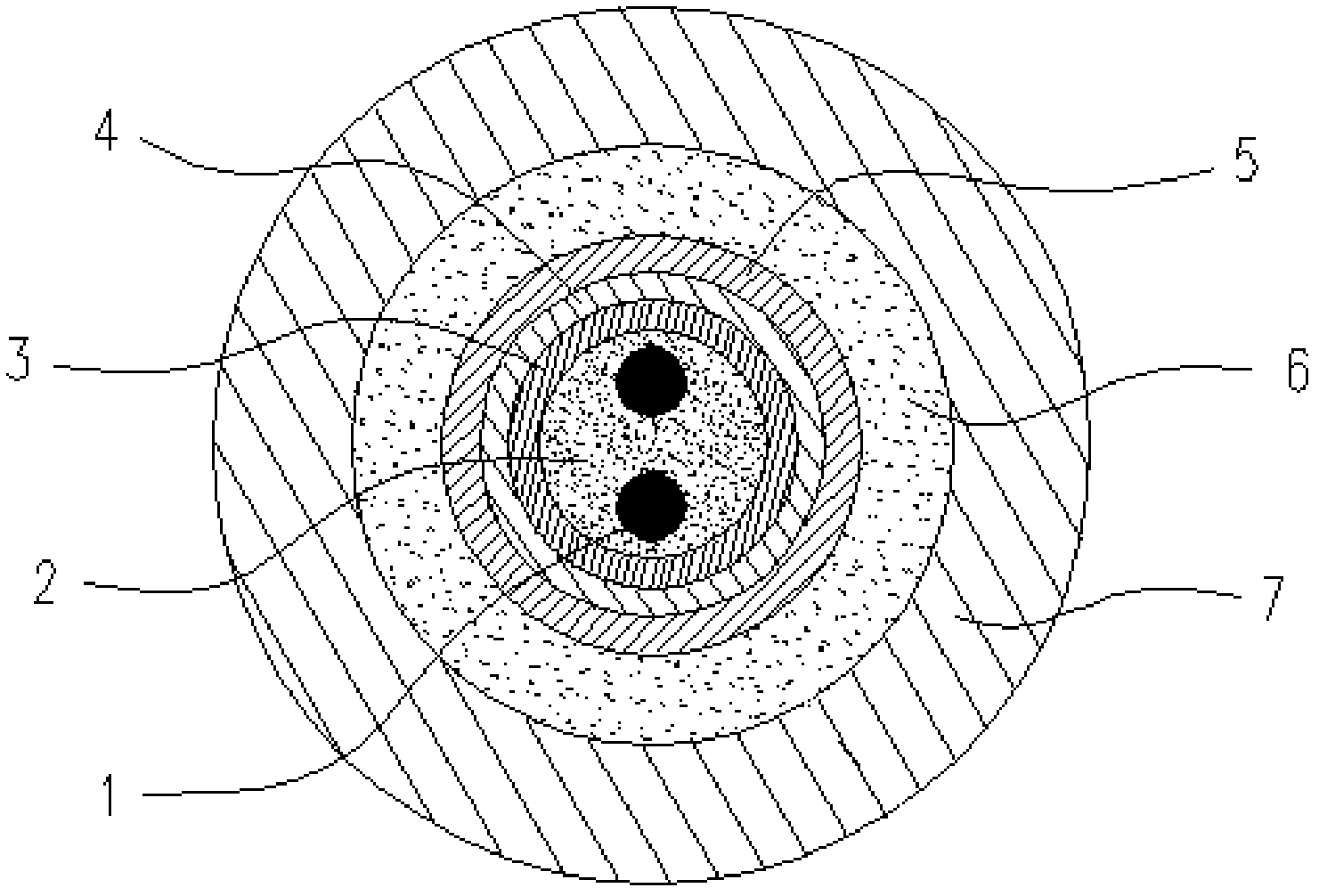

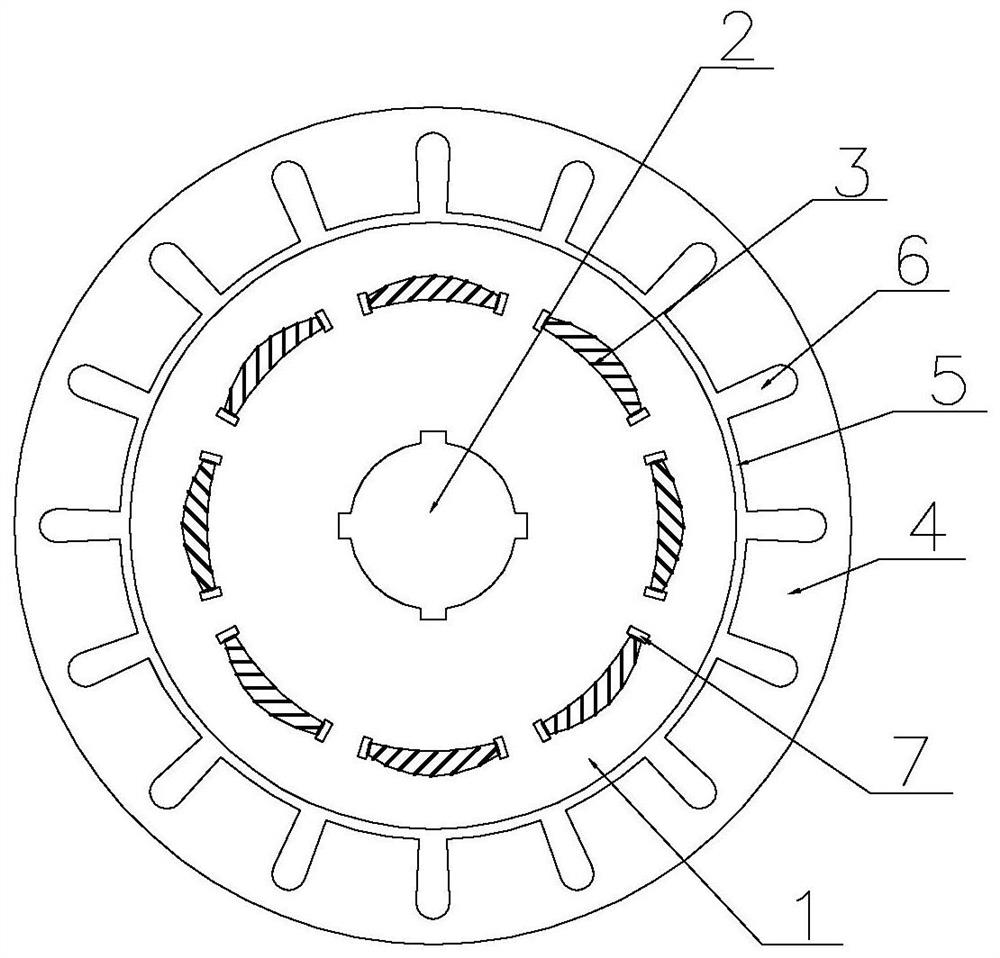

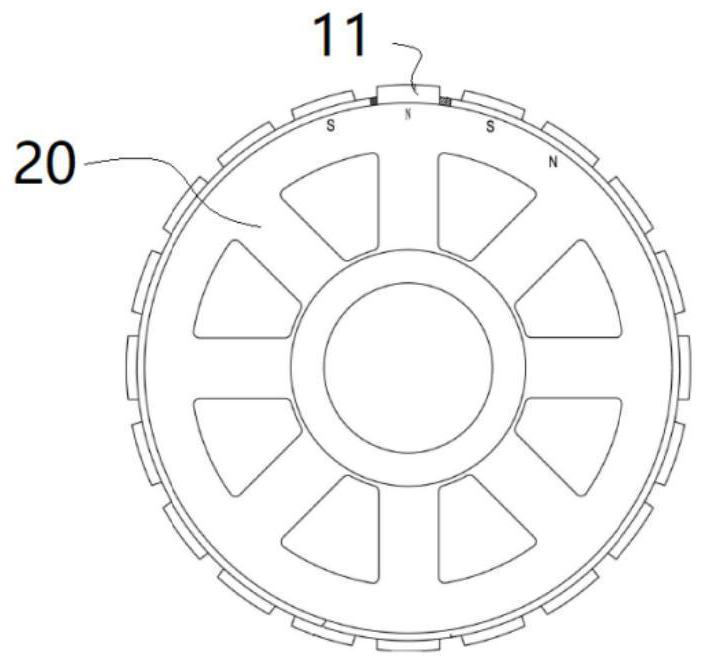

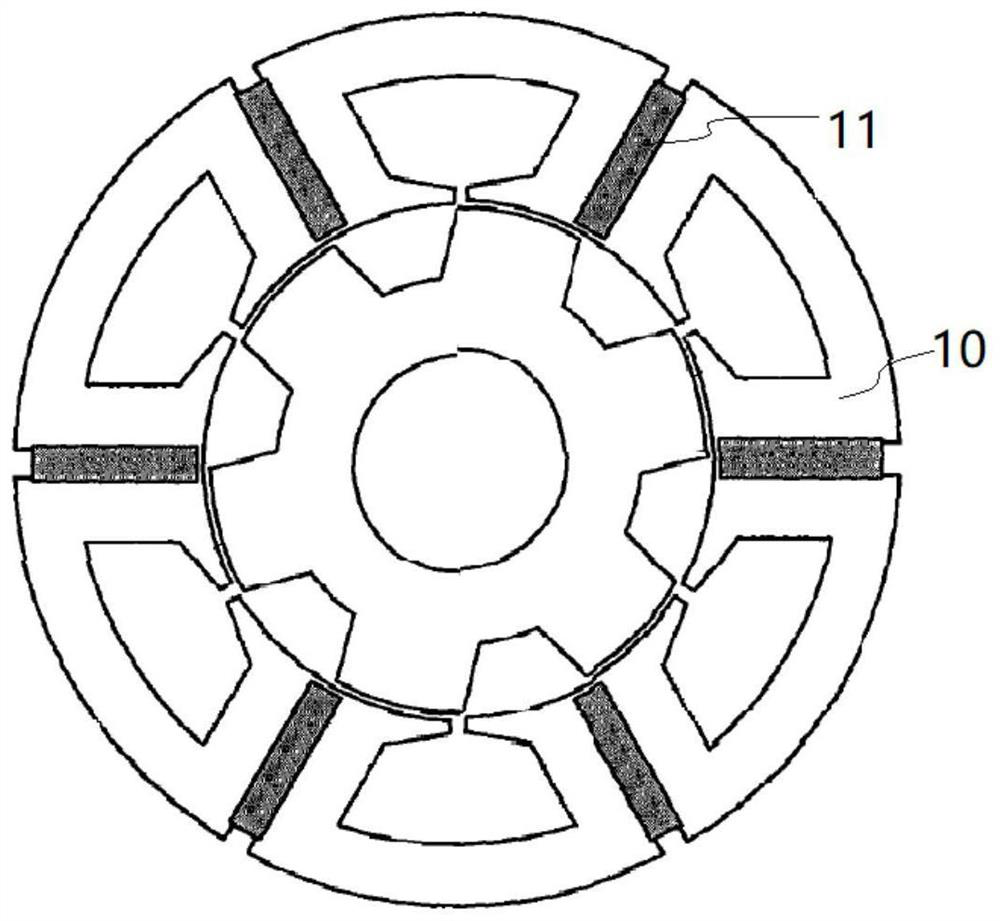

High-temperature-resistant and hydrogen-resistant samarium-cobalt permanent magnet motor

ActiveCN113539606AImprove hydrogen resistanceHigh densityMagnetic circuit rotating partsPermanent magnetsElectric machineStator coil

The invention relates to the field of permanent magnet materials, and discloses a high-temperature-resistant and hydrogen-resistant samarium-cobalt permanent magnet motor which comprises a rotor body (1); a rotor spline shaft (2), assembled at the axis of the rotor body; a plurality of samarium cobalt permanent magnets (3) which are uniformly embedded in the rotor body; a stator body (4), arranged on the outer side of the circumferential surface of the rotor body; an air gap (5), formed between the rotor body and the stator body; and a plurality of stator coils (6), uniformly embedded in the inner circumferential surface of the stator body. According to the permanent magnet motor, the samarium cobalt permanent magnets with excellent hydrogen resistance and high temperature resistance are adopted, so that the use of the permanent magnet motor in a high-temperature and high-pressure pure hydrogen environment is ensured.

Owner:HANGZHOU PERMANENT MAGNET GRP

Photoelectric composite cable and manufacturing method thereof

InactiveCN107240459AImprove use reliabilityExtended service lifeStrip/foil conductorsSurveyInsulation layerThermal expansion

The invention provides a photoelectric composite cable for an oil well. The photoelectric composite cable comprises an optical unit, a conductive layer, a high-temperature resistant insulation layer and an external steel pipe, wherein the conductive layer wraps a surface of the optical unit and is formed by laser continuous welding, the high-temperature resistant insulation layer is formed outside the conductive layer by continuous extrusion, and the external steel pipe wraps the high-temperature resistant insulation layer. In the photoelectric composite cable, the optical unit and the conductive layer are of a coaxial structure, the space in the pipe of the photoelectric composite cable is effectively utilized, so that an optical fiber can have an enough space and the extra length of the optical fiber can be extended to be adaptive to thermal expansion extension of the optical cable or external tensile stress; and meanwhile, the thickness of the insulation layer outside the conductive layer can also be increased, and the insulativity of the conductive layer can be improved. The invention also provides a manufacturing method of the photoelectric composite cable.

Owner:ZHONGTIAN ELECTRIC POWER OPTICAL CABLES CO LTD

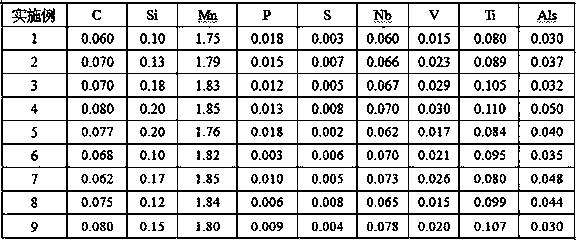

Nb-V-Ti composite reinforced high-strength wear-resistant tank steel plate and production method

The invention discloses an Nb-V-Ti composite reinforced high-strength wear-resistant tank steel plate and a production method, and belongs to the technical field of metallurgy. The steel plate comprises, by mass, 0.06% to 0.08% of C, 0.10% to 0.20% of Si, 1.75% to 1.85% of Mn, P being less than or equal to 0.018%, S being less than or equal to 0.008%, 0.060% to 0.070% of Nb, 0.015% to 0.030% of V,0.080% to 0.110% of Ti, 0.030% to 0.050% of Als and the balance Fe and inevitable impurity elements. The production method comprises procedures of vanadium extraction from vanadium-containing molteniron, semisteel smelting, LF refining, continuous casting, heating, rough rolling, finish rolling and curling. The steel plate provided in the invention has good wear resistance performance and excellent mechanical properties, weight reduction of a tank body can be realized, a transportation capacity is increased and transportation cost is reduced.

Owner:HEBEI IRON AND STEEL

Composite proton conductive ceramic electrolyte film as well as preparation method and application thereof

ActiveCN111313069AHigh bonding strengthImprove compactnessChemical vapor deposition coatingFuel cellsThin membraneChemical vapor deposition

The invention discloses a composite proton conductive ceramic electrolyte film as well as a preparation method and application thereof. The film is formed on the surface of a ceramic tube and is a composite film formed by alternately compounding multiple layers of film materials SrCe<1-x>Yb<x>O<3-alpha> and SrCe<1-x>Er<x>O<3-alpha>, the innermost layer is the SrCe<1-x>Yb<x>O<3-alpha> film, and theoutermost layer is the SrCe<1-x>Er<x>O<3-alpha> film. The preparation method comprises the following steps: (1) carrying out ultrasonic cleaning on the surface of the ceramic tube for 15-30 minutes,and drying; and (2) sequentially and alternately forming a SrCe<1-x>Yb<x>O<3-alpha> film and a SrCe<1-x>Er<x>O<3-alpha> film on the surface of the ceramic tube by adopting a metal organic chemical vapor deposition technology, and finally obtaining the multi-layer SrCe<1-x>Yb<x>O<3-alpha> / SrCe<1-x>Er<x>O<3-alpha> composite proton conductive ceramic electrolyte film. According to the preparation method, the preparation of the composite proton conductive ceramic electrolyte film alternately formed by SrCe<1-x>Yb<x>O<3-alpha> and SrCe<1-x>Er<x>O<3-alpha> is realized on the surface of the ceramic tube for the first time, and the film is good in combination with a matrix, high in compactness, uniform, stable and excellent in hydrogen resistance.

Owner:GRIMAT ENG INST CO LTD

Microalloyed steel with good resistance to hydrogen for the cold-forming of machine parts having high properties

ActiveUS9194018B2Improve mechanical propertiesExcellent hydrogen resistanceWashersNutsCold formedMachine parts

The steel according to the invention is characterized in that, in order to keep its weight content of molybdenum below 0.45%, its chemical composition, besides the iron and the inevitable residual impurities that result from the smelting of the steel, corresponds to the following analysis, given as percentages by weight:0.3≦C %≦0.50.20≦Mo %<0.450.4≦Mn %≦1.00.4≦Cr %≦2.00.04≦Ni %≦0.80.02≦Nb %≦0.0450.03≦V %≦0.300.02≦Ti %≦0.05, with Ti>3.5 N0.003≦B %≦0.005%S %≦0.015P %≦0.015,and optionally 0.05≦Si %≦0.20; Al %≦0.05 and N %≦0.015.By cold forming a hot-rolled wire rod resulting from continuous casting, it is possible to obtain, after heat treatment, “ready-to-use” coined parts, such as cap screws for example for the automotive industry, that offer a tensile strength from 1200 to more than 1500 MPa while having a good hydrogen embrittlement resistance, and this with a specially controlled “raw material” production cost.

Owner:ARCELORMITTAL GANDRANGE

Optical fiber preform, optical fiber and method for manufacturing optical fiber

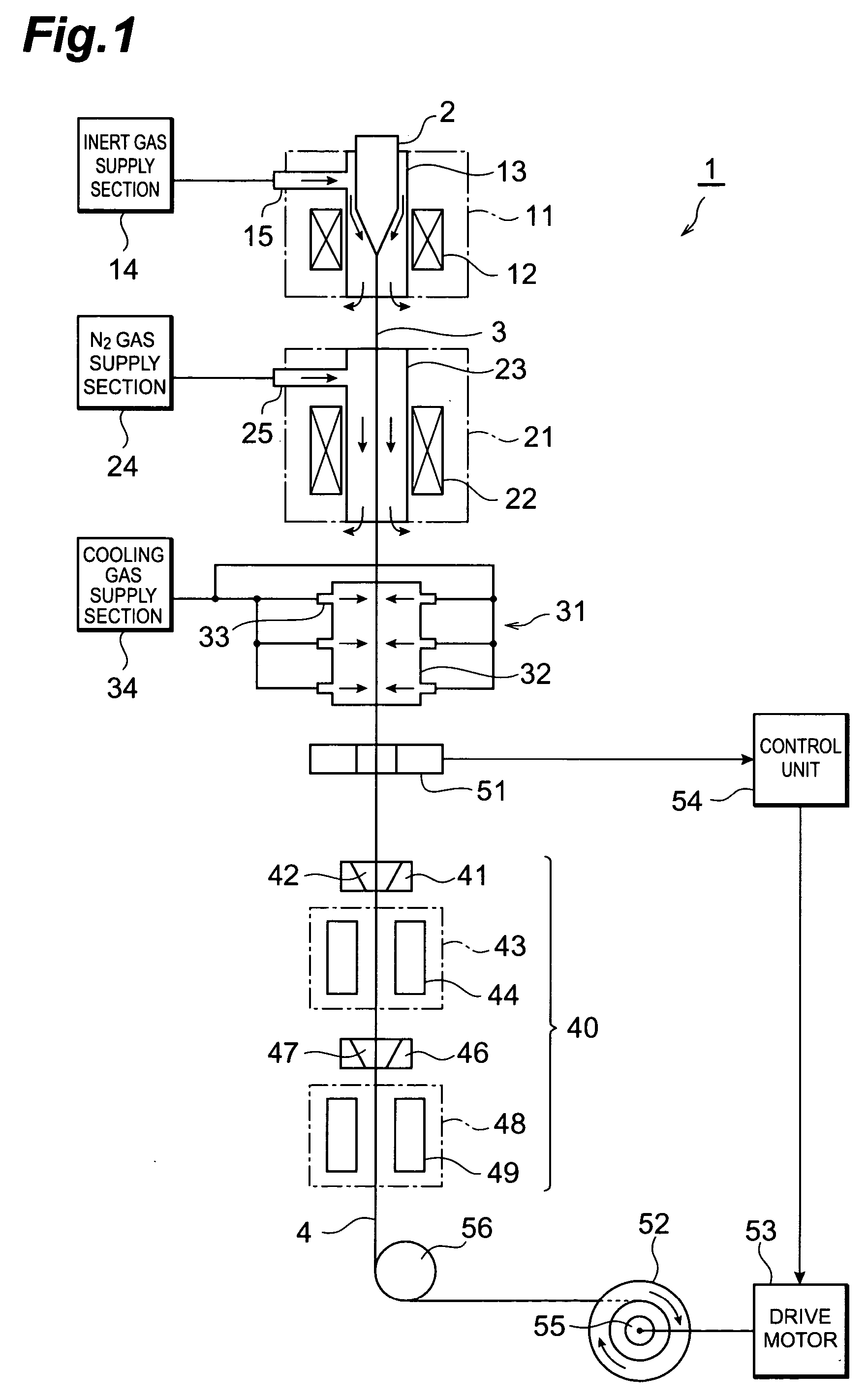

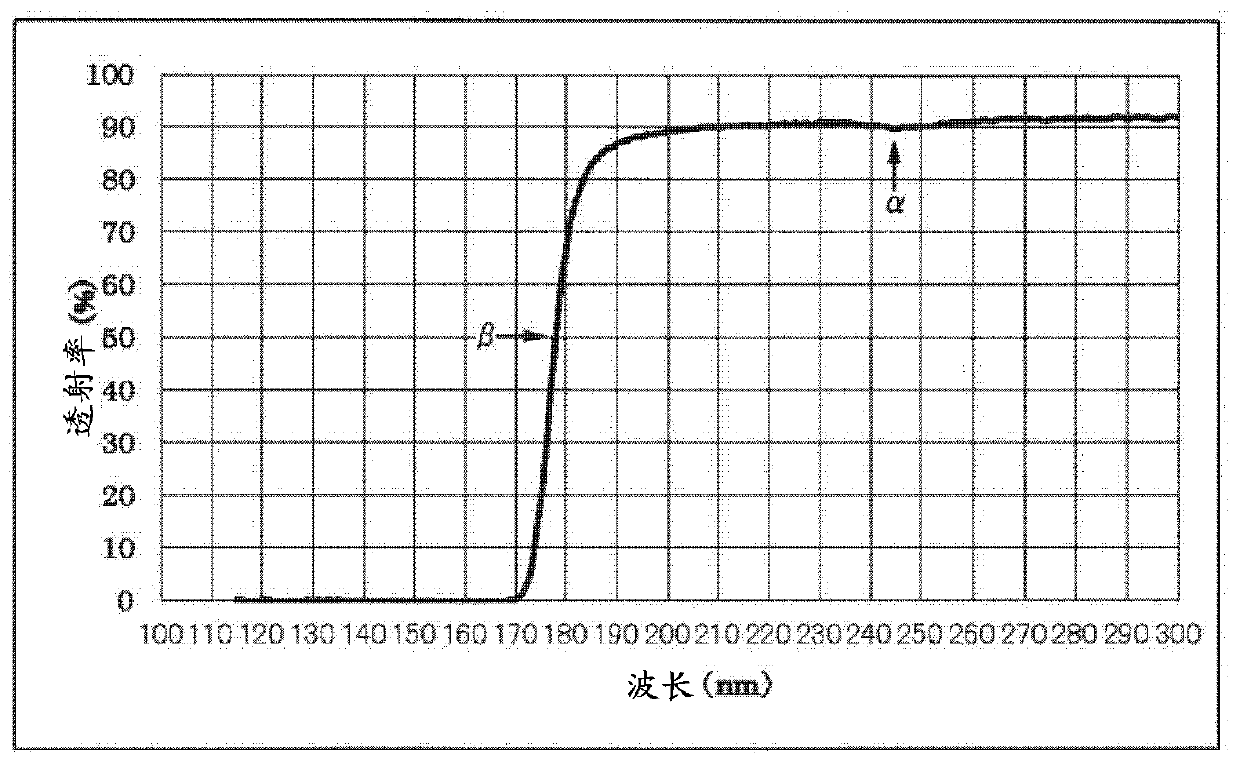

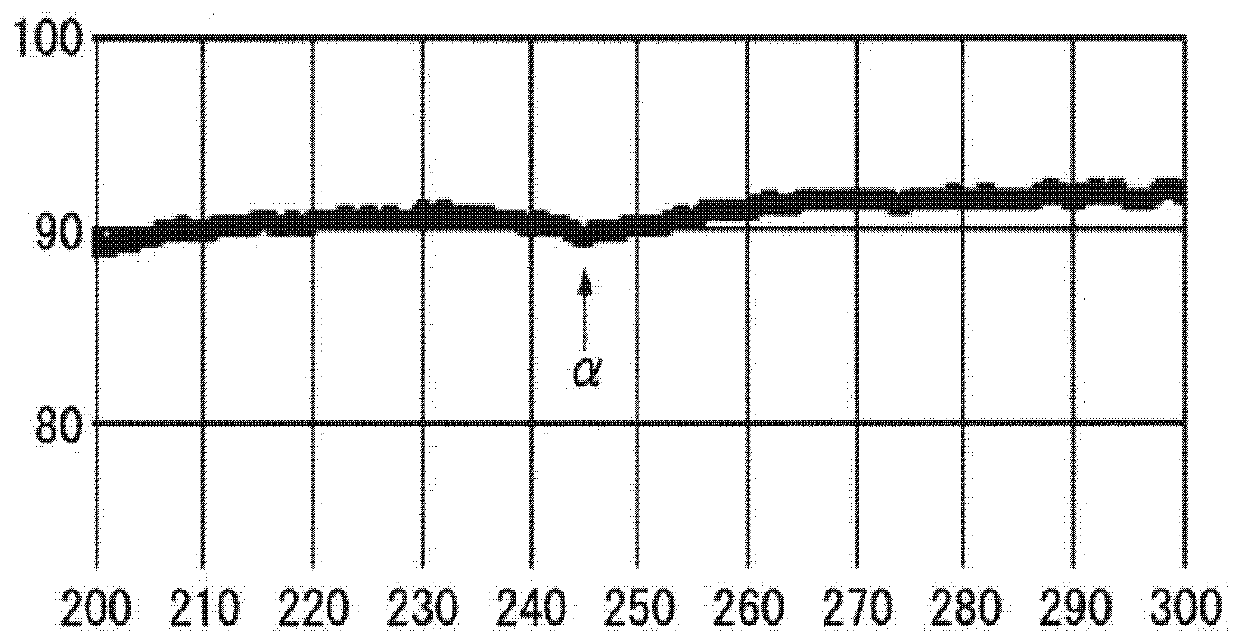

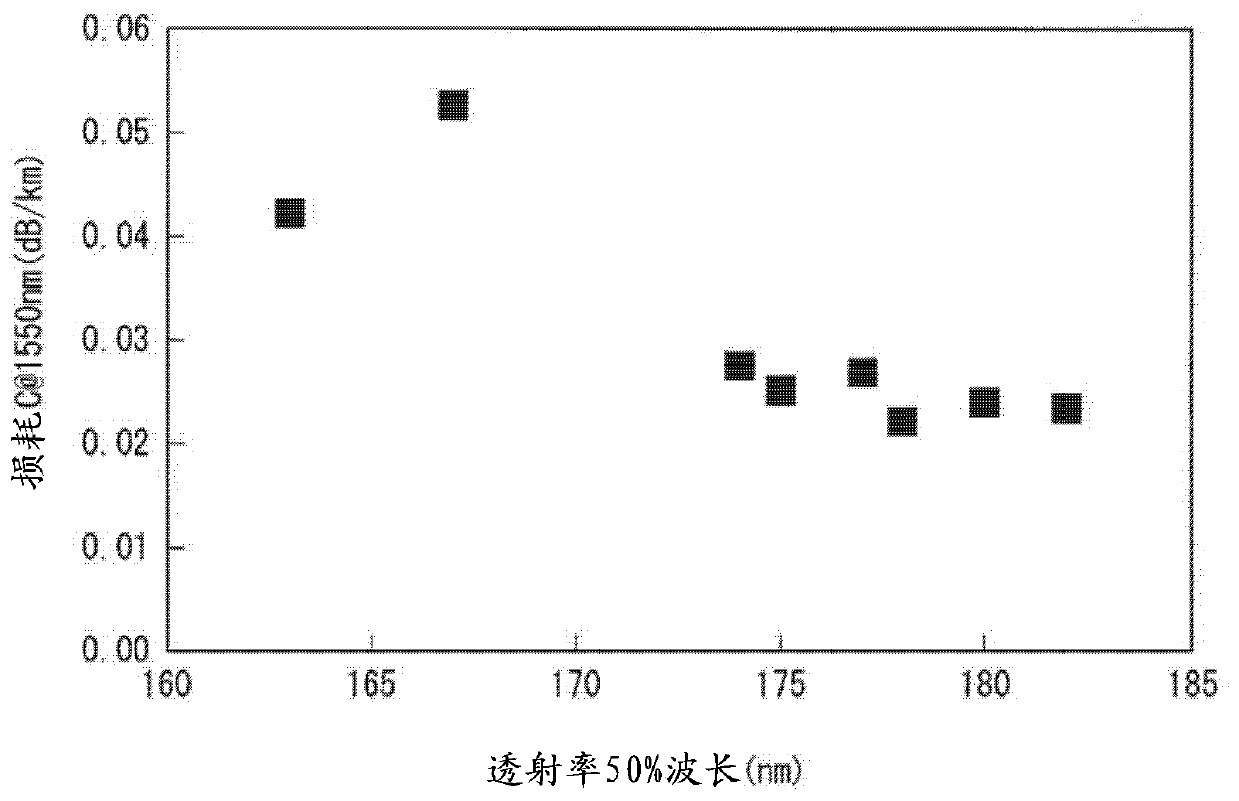

ActiveCN106604899BInhibitionReduce transmission lossGlass optical fibreGlass making apparatusTransmittanceMaterials science

The present invention provides an optical fiber preform having a core made of Ge-free silica glass, wherein the core has at least one of the following characteristics (1) and (2) in spectrometry: (1 ) has an absorption peak at a wavelength of 240nm to 255nm; (2) the wavelength at which the ultraviolet transmittance is below 50% is greater than 170nm.

Owner:FUJIKURA LTD

Hydrogen resistant motor based on rare earth permanent magnet

ActiveCN111313571BImprove hydrogen resistanceExcellent hydrogen resistanceMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePermanent magnet motor

Owner:南京安德海睿智能科技有限公司

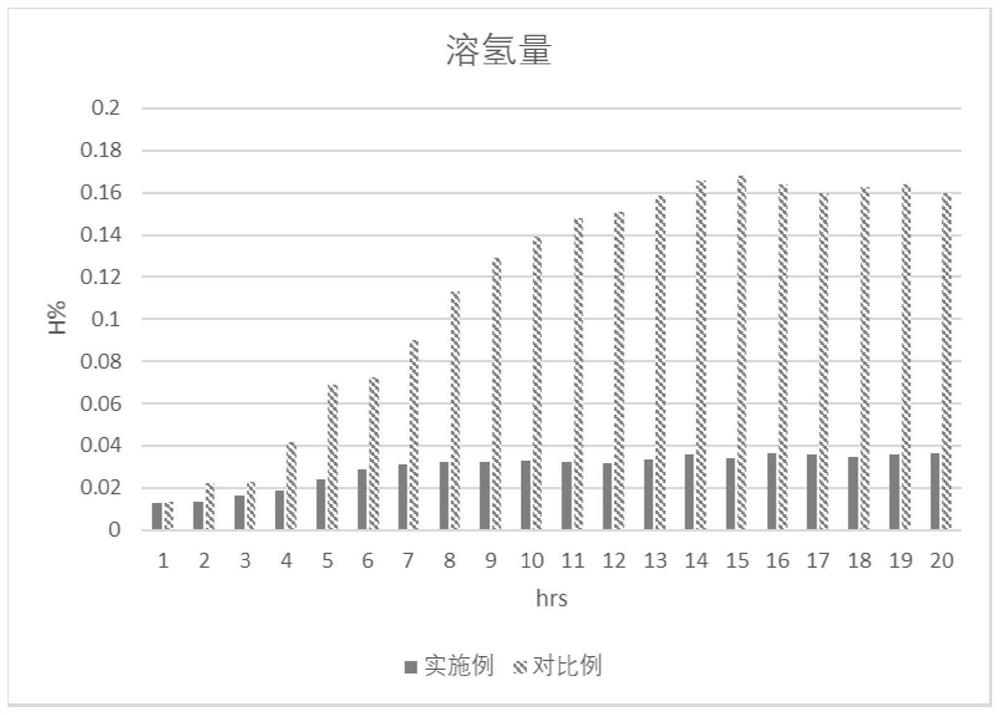

Anti-hydrogen material and preparation method thereof

The invention provides an anti-hydrogen material and a preparation method thereof, and the preparation method comprises the following steps: (1) controlling the content of dissolved hydrogen in molten steel to be 8-20 ppm during smelting, and when the content of Ca is lower than 5 * 10 <-12 > ppm, adding Mg into the molten steel until the content reaches 5 * 10 <-6 >-7 * 10 <-5 > ppm; (2) reducing the hydrogen content in the molten steel to 3 ppm or below by adopting an AOD furnace and a VD furnace; (3) carrying out secondary remelting by adopting electroslag; (4) the electroslag ingot is forged, the initial forging temperature ranges from 1140 DEG C to 1250 DEG C, the final forging temperature ranges from 900 DEG C to 1050 DEG C, and the forging heating rate ranges from 80 DEG C / h to 100 DEG C / h; and (5) hot rolling is conducted after cogging, the heating temperature during hot rolling ranges from 1120 DEG C to 1250 DEG C, the initial rolling temperature ranges from 1080 DEG C to 1180 DEG C, and the final rolling temperature ranges from 900 DEG C to 1050 DEG C. The obtained material is excellent in hydrogen resistance, low in hydrogen content and oxygen content, low in inclusion content and excellent in room temperature performance.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

a y 2 o 3 / al 2 o 3 Composite gradient hydrogen barrier coating and preparation method thereof

ActiveCN105666956BGrowth enablerImprove compactnessLaminationLamination apparatusSS - Stainless steelHydrogen permeation

The invention relates to an Y2O3 / Al2O3 composite gradient hydrogen resistant coating and a preparation method thereof. The coating is used for resisting hydrogen permeation in a high-temperature vacuum collector tube. The composite gradient hydrogen resistant coating is composed of the stainless steel tube and an Y2O3 / Al2O3 composite coating which is applied on an inner surface of the stainless steel tube. The composite coating is prepared through a metal-organic chemical vapor deposition method, wherein an Al2O3 coating and an Y2O3 coating are deposited repeatedly on the inner surface to form the multilayer Y2O3 / Al2O3 composite gradient hydrogen resistant coating being 0.1-20 [mu]m in thickness. The coating is in a multilayer alternated structure with the most inner layer being Al2O3 and the most outer layer being Y2O3. The hydrogen resistant coating is strong in combination strength with a substrate, is simple in preparation process and is low in cost, and is improved in hydrogen resistant performance by more than 200 times.

Owner:GRIMAT ENG INST CO LTD

a y 2 o 3 /cr 2 o 3 Composite gradient hydrogen barrier coating and preparation method thereof

ActiveCN105644058BGrowth enablerImprove compactnessLaminationLamination apparatusSS - Stainless steelChemical vapor deposition

The invention relates to a Y2O3 / Cr2O3 composite gradient anti-hydrogen coating layer and a preparation method thereof. The coating layer can be applied in hydrogen permeation resistance of a high-temperature vacuum heat collecting pipe. The Y2O3 / Cr2O3 composite gradient anti-hydrogen coating layer is composed of a stainless steel pipe and a Y2O3 / Cr2O3 composite coating layer applied on the inner surface of the stainless steel pipe. The composite coating layer is prepared by a metal-organic chemical vapor deposition method; by repeated deposition of chromium oxide and yttrium oxide coating layers, the multilayered Y2O3 / Cr2O3 composite gradient anti-hydrogen coating layer with the thickness of 0.1-20 [mu]m is obtained; the coating layer is composed of a multilayer alternative structure with the innermost layer of chromium oxide and the outermost layer of yttrium oxide. The anti-hydrogen coating layer has high bonding strength with a matrix; the preparation technology is simple and the cost is low; and the anti-hydrogen performance can be enhanced by more than or equal to 150 times.

Owner:GRIMAT ENG INST CO LTD

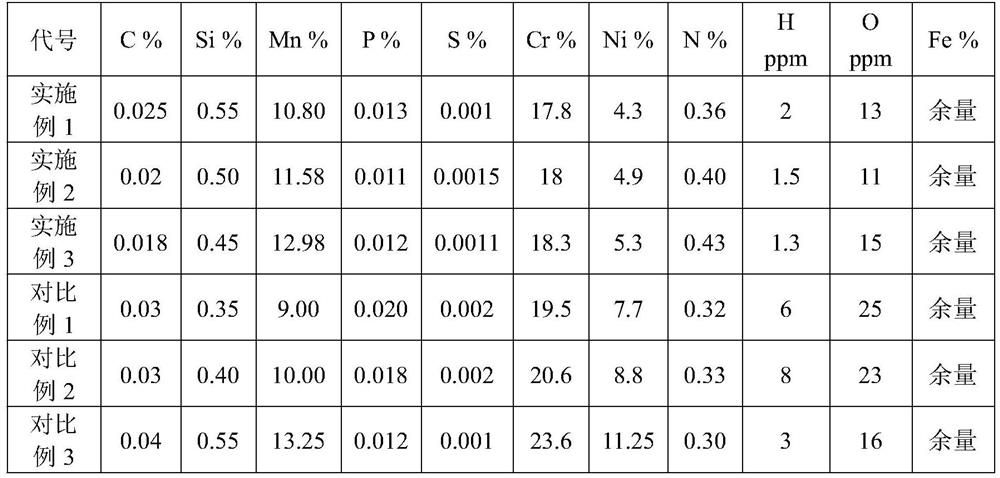

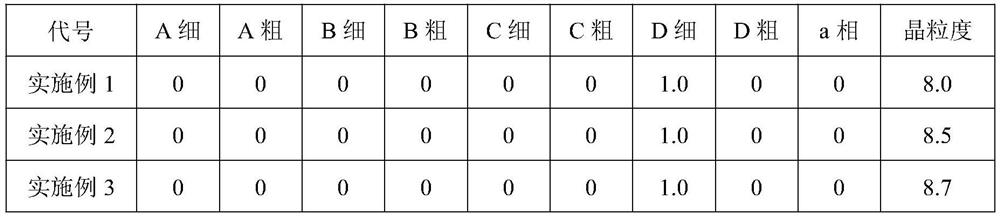

High-Mn austenitic stainless steel for hydrogen having excellent weldability, welded joint using same, device for hydrogen using same, and method for producing welded joint

ActiveUS11225705B2Non optimalEconomical efficiencyArc welding apparatusFurnace typesManganeseSS - Stainless steel

This austenitic stainless steel contains, by mass %: C: 0.3% or less, Si: 0.1% to 1.5%, Mn: 5.5% to 20%, P: 0.050% or less, S: 0.005% or less, Cr: 10% to 20%, Ni: 4.0% to 12%, N: 0.40% or less, Cu: 4.0% or less, O: 0.02% or less, and either one or both of Ca: 0.01% or less and Al: 0.3% or less, with a remainder being Fe and inevitable impurities, and the following Formula (1) is satisfied.[Ni]+[Cu]+12.93[C]+1.11[Mn]+0.72[Cr]+0.88[Mo]−0.27[Si]+7.55[N]≥29.3 Formula (1)

Owner:NIPPON STEEL STAINLESS STEEL CORP

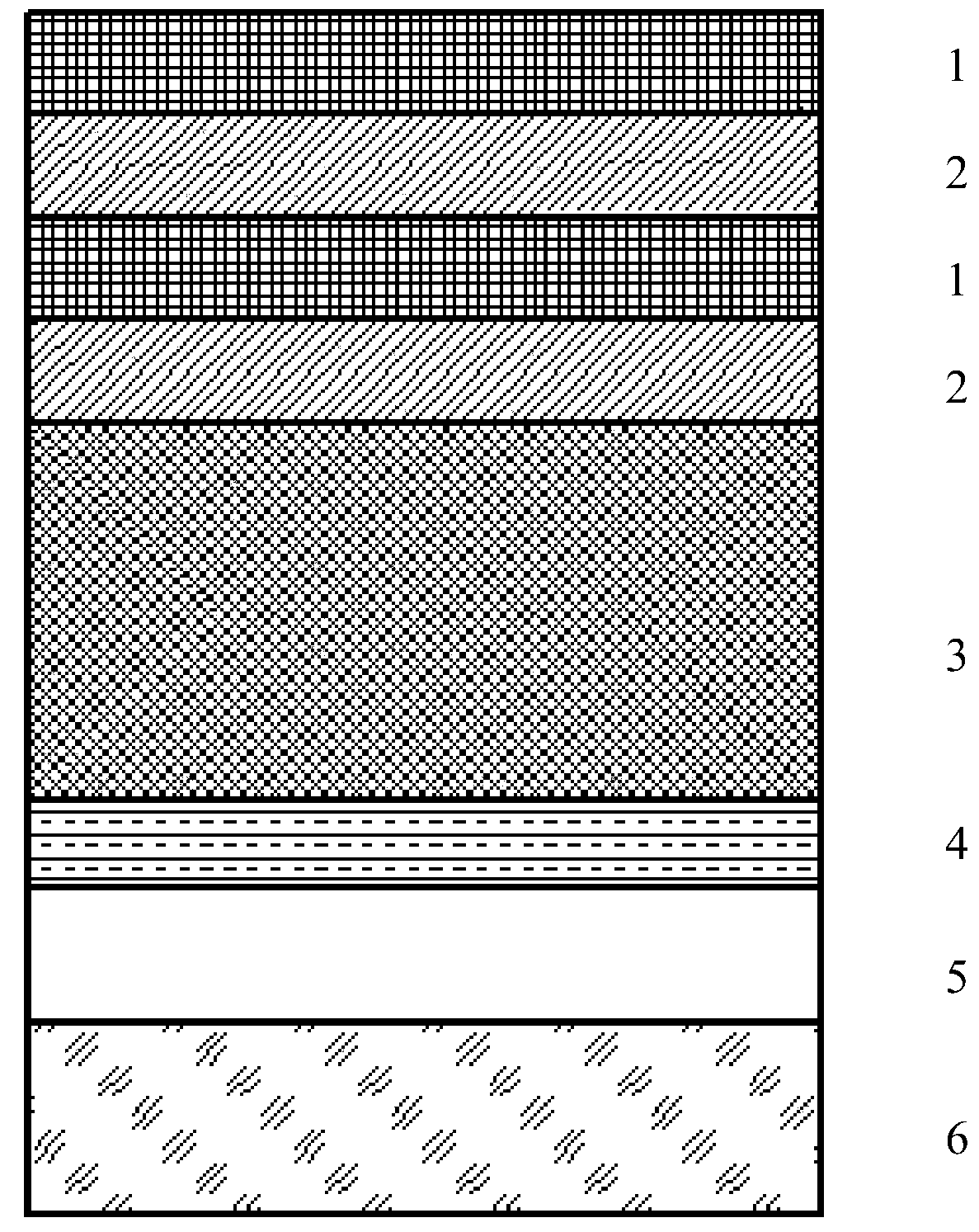

Non-universal optical unit of submarine photoelectric composite cable and making method thereof

ActiveCN100392464CReasonable designCompact structureFibre mechanical structuresOcean bottomHigh intensity

The present invention relates to a submarine photoelectric composite cable non-universal type optical unit and its manufacture method. Its structure includes the following several portions: several optical fibres, plastic tube, stainless steel tube, water-proof material, high-strength armouring steel wire and external protective layer. Said invention also provides the concrete steps of its manufacture method.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

A kind of disperse proton conductive ceramic electrolyte film and preparation method thereof

ActiveCN111313068BHigh bonding strengthImprove compactnessChemical vapor deposition coatingFuel cellsOrganic reactionChemical vapor deposition

The invention discloses a dispersed proton conductive ceramic electrolyte membrane and a preparation method thereof. The film is formed on the surface of the ceramic tube and is made of film material SrCe 1‑x Yb x o 3‑α and SrCe 1‑ x Er x o 3‑α composed of dispersed thin films, in which SrCe 1‑x Yb x o 3‑α Main phase, SrCe 1‑x Er x o 3‑α Dispersed in the main phase. The preparation method comprises the following steps: (1) ultrasonically cleaning the surface of the ceramic tube for 15-30 min, and drying; (2) simultaneously depositing SrCe on the surface of the ceramic tube by metal-organic chemical vapor deposition technology. 1‑x Yb x o 3‑α and SrCe 1‑x Er x o 3‑α , the metal reaction sources are Yb organic reaction source and Er organic reaction source respectively, and the carrier gas is H 2 ; By adjusting the reaction source temperature and reaction time to make SrCe 1‑x Yb x o 3‑α phase becomes the main phase, and finally a dispersed proton-conducting ceramic electrolyte film is obtained. The film of the present invention has the characteristics of high bonding strength with the substrate, high compactness, uniformity and stability, and excellent hydrogen resistance performance, and can be applied to solid oxide fuel cells, electrolysis of water for efficient production of hydrogen, synthesis of ammonia under normal pressure, separation and purification of hydrogen, etc. aspect.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com