A kind of disperse proton conductive ceramic electrolyte film and preparation method thereof

A technology of ceramic electrolyte and proton conduction, which is applied in the direction of circuits, fuel cells, electrical components, etc., can solve problems such as the difficulty in preparing high-performance proton conduction ceramic electrolyte films, and achieve the effects of high density, controllable thickness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) ZrO with a length of 60mm, an outer diameter of 15mm and a wall thickness of 2mm 2 Ultrasonic cleaning of ceramic tube surface for 15 minutes, drying;

[0025] (2) Simultaneous deposition of SrCe on the surface of ceramic tubes by metal-organic chemical vapor deposition technology 1-x Yb x o 3-α and SrCe 1-x Er x o 3-α The reaction source uses ytterbium acetylacetonate and erbium acetylacetonate, and the specific process parameters are: Yb reaction source temperature 450°C; Er reaction source temperature 420°C, Yb reaction source reaction time 30min; Er reaction source reaction time 20min, carrier gas H 2 The flow rate is 200mL / min.

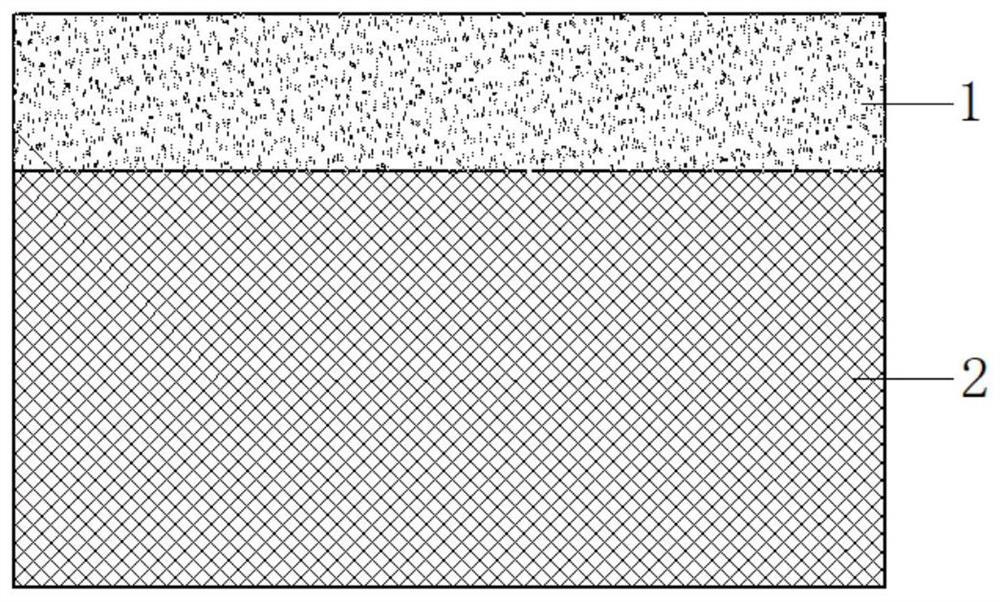

[0026] (3) SrCe with a thickness of about 0.5 μm is finally obtained 1-x Yb x o 3-a / SrCe 1-x Er x o 3-α dispersed film, in which the main phase SrCe 1-x Yb x o 3-α The content accounts for about 70%, the film layer is uniform and dense, and has good bonding force with the substrate;

[0027] Determination of SrCe by AC...

Embodiment 2

[0029] (1) ZrO with a length of 60mm, an outer diameter of 15mm and a wall thickness of 2mm 2 Ultrasonic cleaning of ceramic tube surface for 15 minutes, drying;

[0030] (2) Simultaneous deposition of SrCe on the surface of ceramic tubes by metal-organic chemical vapor deposition technology 1-x Yb x o 3-α and SrCe 1-x Er x o 3-α The reaction source adopts ytterbium acetylacetonate and erbium acetylacetonate, and the specific process parameters are: Yb reaction source temperature 350°C; Er reaction source temperature 320°C, Yb reaction source reaction time 30min; Er reaction source reaction time 20min, carrier gas H 2 The flow rate is 100mL / min.

[0031] (3) SrCe with a thickness of about 1.5 μm is finally obtained 1-x Yb x o 3-a / SrCe 1-x Er x o 3-α dispersed film, in which the main phase SrCe 1-x Yb x o 3-α The content accounts for about 70%, the film layer is uniform and dense, and has good bonding force with the substrate;

[0032] Determination of SrCe by ...

Embodiment 3

[0034] (1) ZrO with a length of 60mm, an outer diameter of 15mm and a wall thickness of 2mm 2 Ultrasonic cleaning of ceramic tube surface for 15 minutes, drying;

[0035] (2) Simultaneous deposition of SrCe on the surface of ceramic tubes by metal-organic chemical vapor deposition technology 1-x Yb x o 3-α and SrCe 1-x Er x o 3-α The reaction source uses ytterbium acetylacetonate and erbium acetylacetonate, and the specific process parameters are: Yb reaction source temperature 650°C; Er reaction source temperature 620°C, Yb reaction source reaction time 30min; Er reaction source reaction time 20min, carrier gas H 2 The flow rate is 400mL / min.

[0036] (3) SrCe with a thickness of about 8.5 μm is finally obtained 1-x Yb x o 3-a / SrCe 1-x Er x o 3-α dispersed film, in which the main phase SrCe 1-x Yb x o 3-α The content accounts for about 80%, the film layer is uniform and dense, and has good bonding force with the substrate;

[0037] Determination of SrCe by AC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com