Patents

Literature

32results about How to "Reduce defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

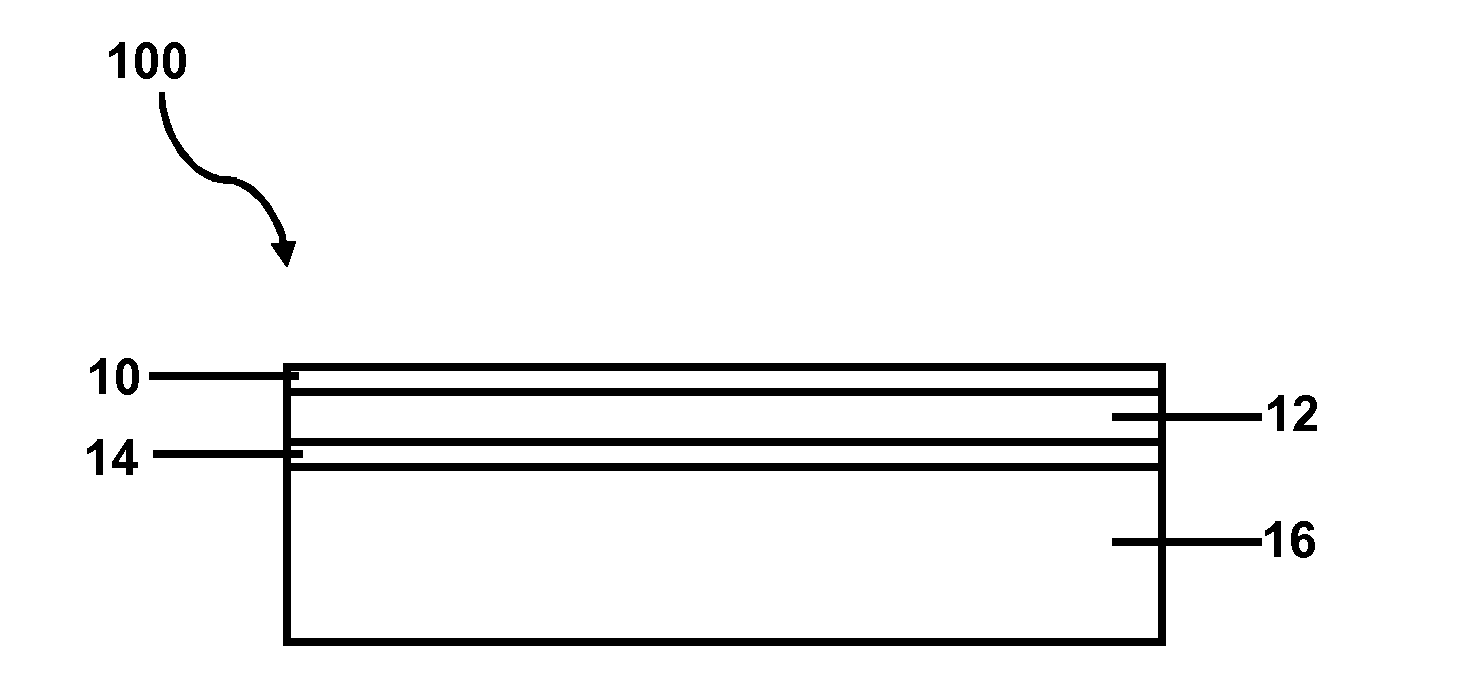

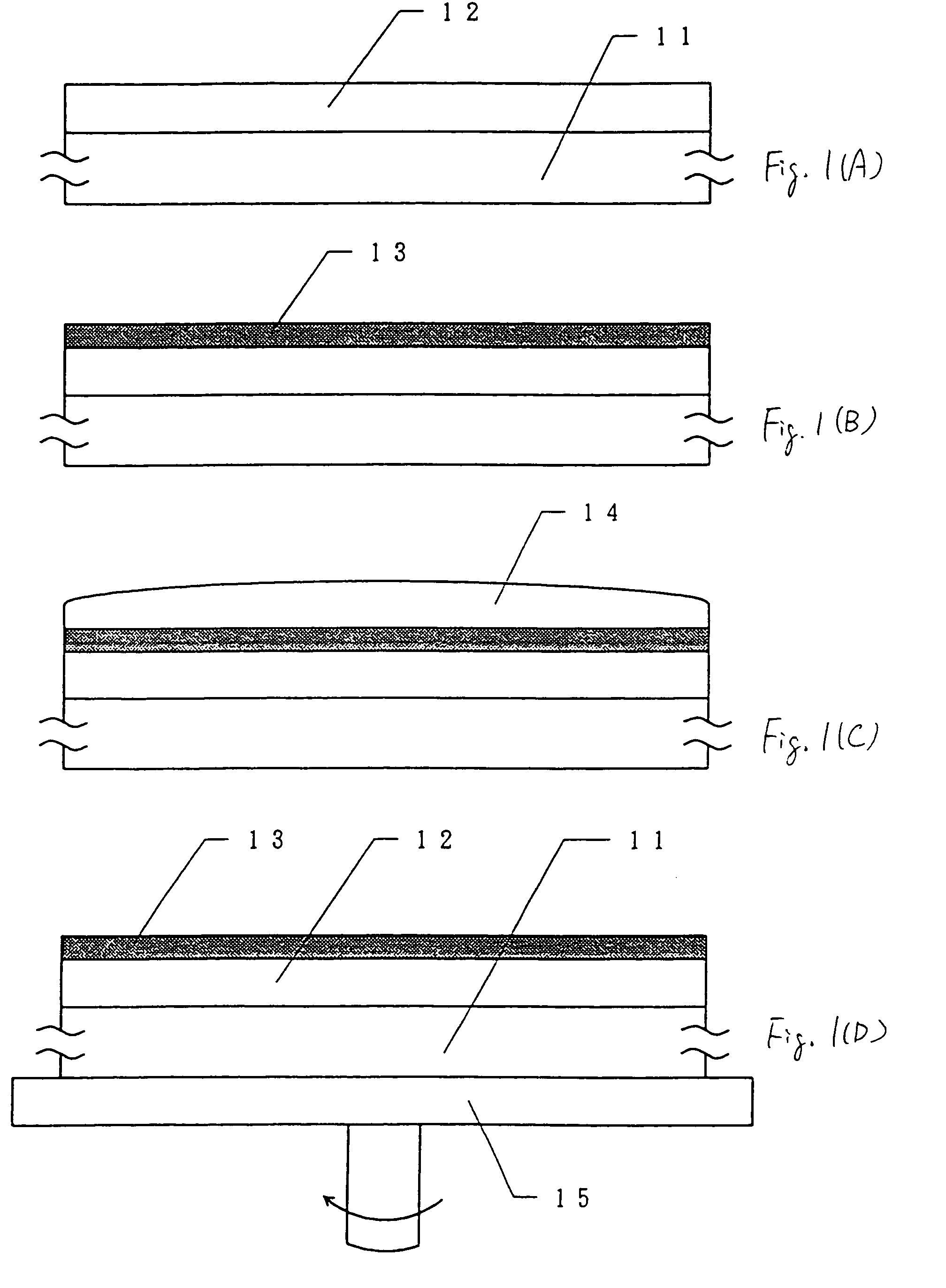

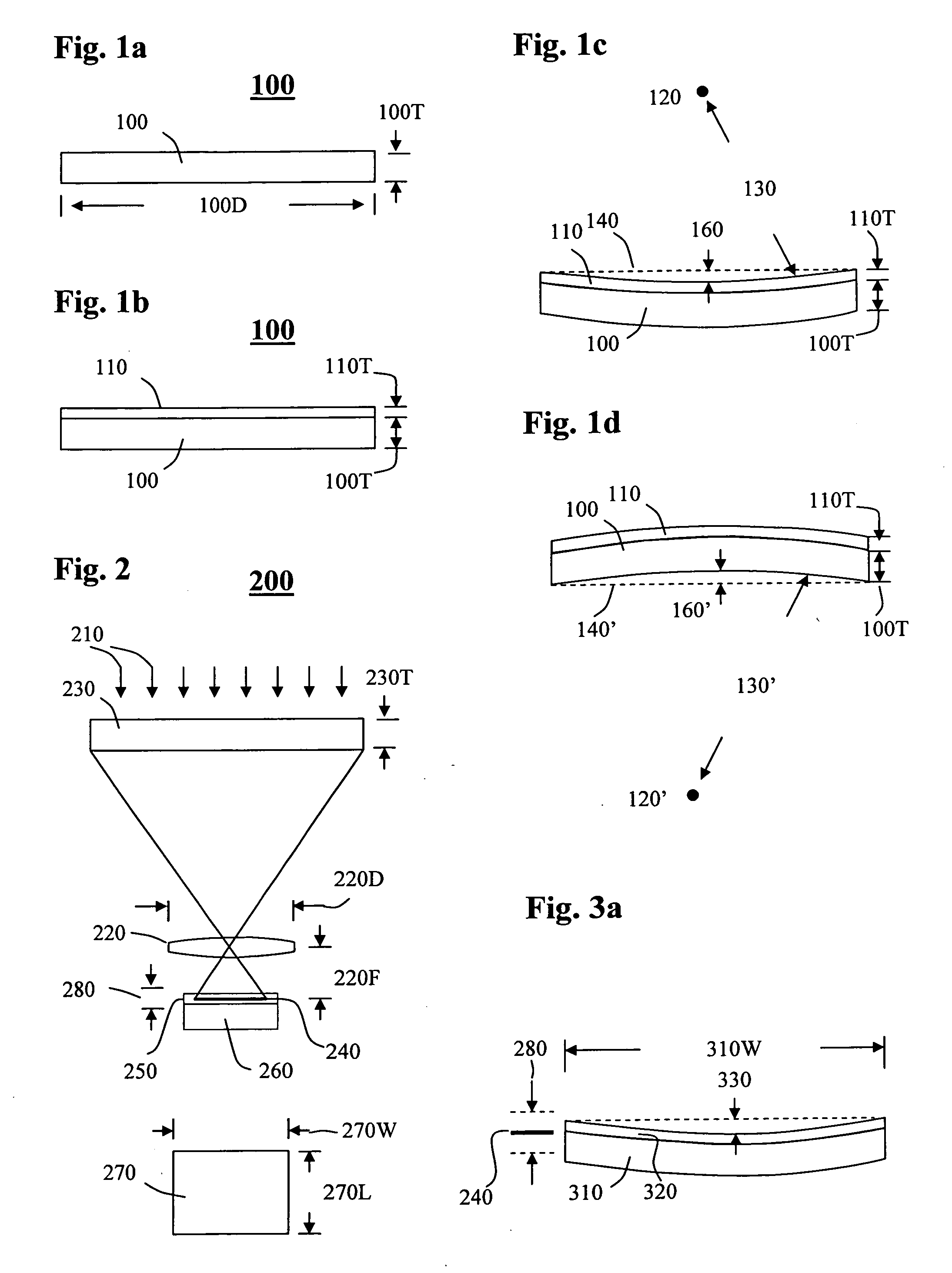

Glass laminated articles and layered articles

ActiveUS20090297806A1Reduce defectIncrease clarityRecord information storageLight beam reproducingElectrochromic devicesPolymer science

Laminated articles and layered articles, for example, low alkali glass laminated articles and layered articles useful for, for example, electrochromic devices are described.

Owner:CORNING INC

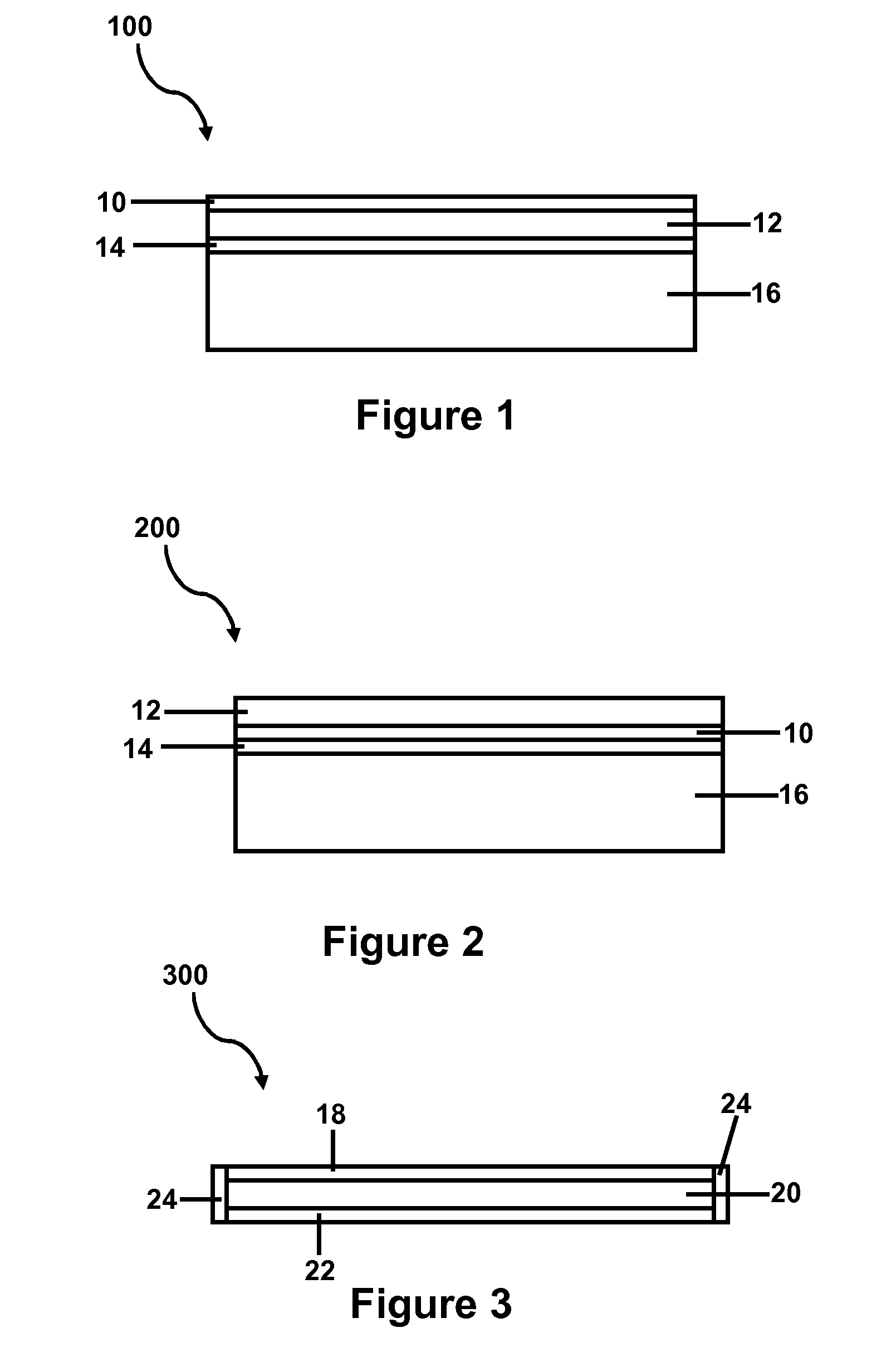

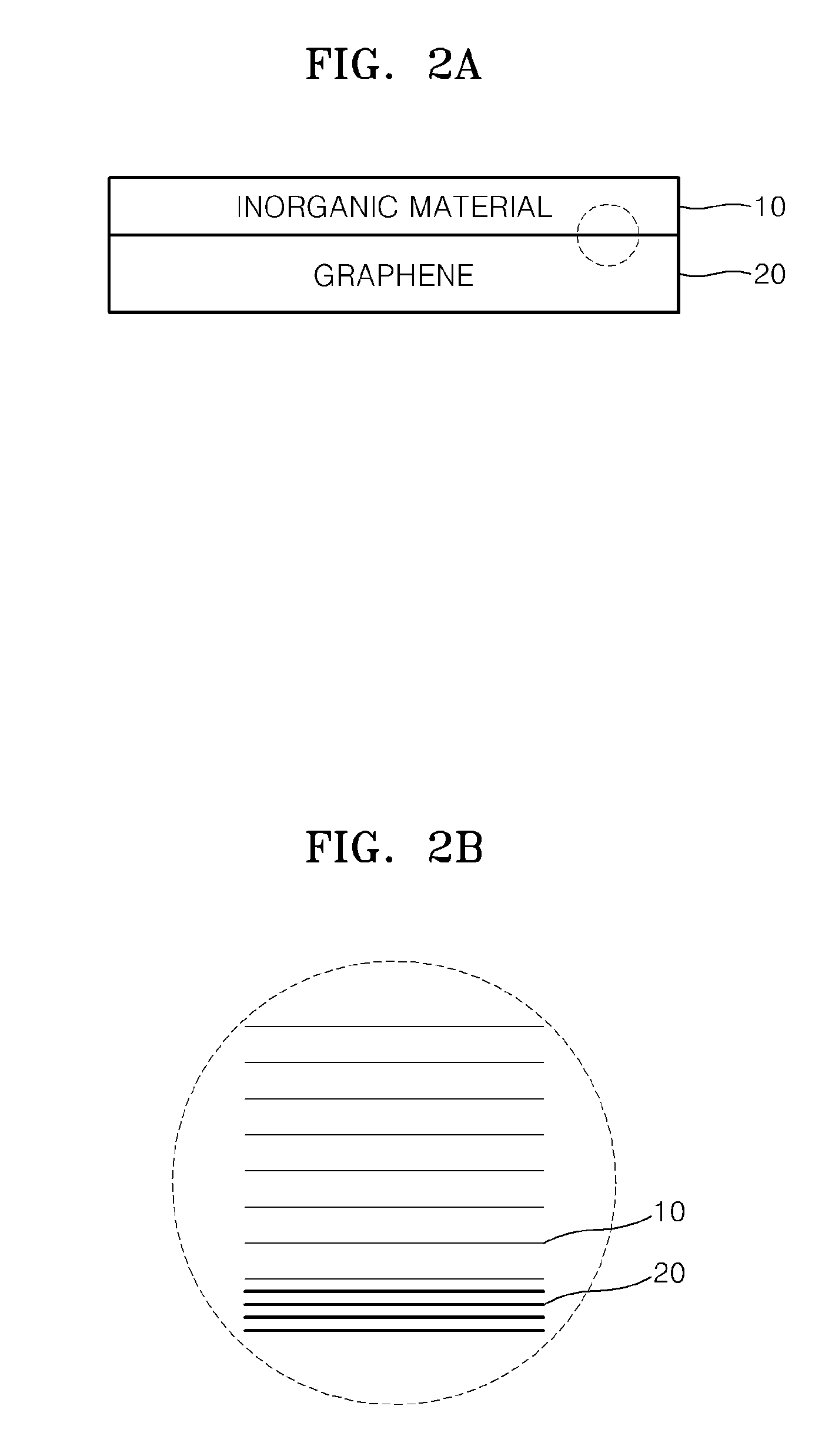

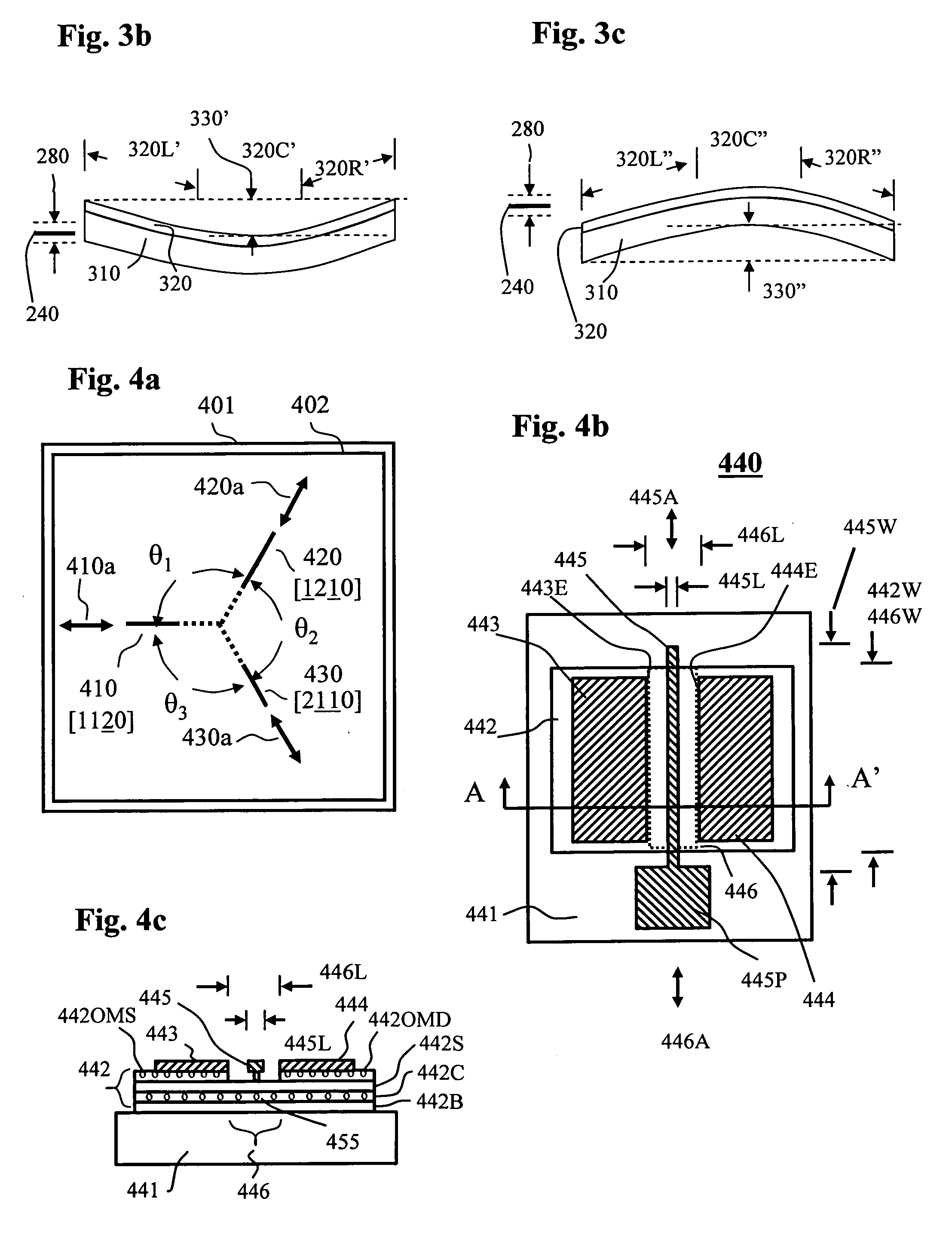

Material including graphene and an inorganic material and method of manufacturing the material

ActiveUS20110129675A1Reduce defectLow costMaterial nanotechnologyLayered productsCrystal planeCrystal system

A material including: graphene; and an inorganic material having a crystal system, wherein a crystal plane of the inorganic material is oriented parallel to the (0001) plane of the graphene. The crystal plane of the inorganic material has an atomic arrangement of a hexagon, a tetragon, or a pentagon.

Owner:SAMSUNG ELECTRONICS CO LTD +1

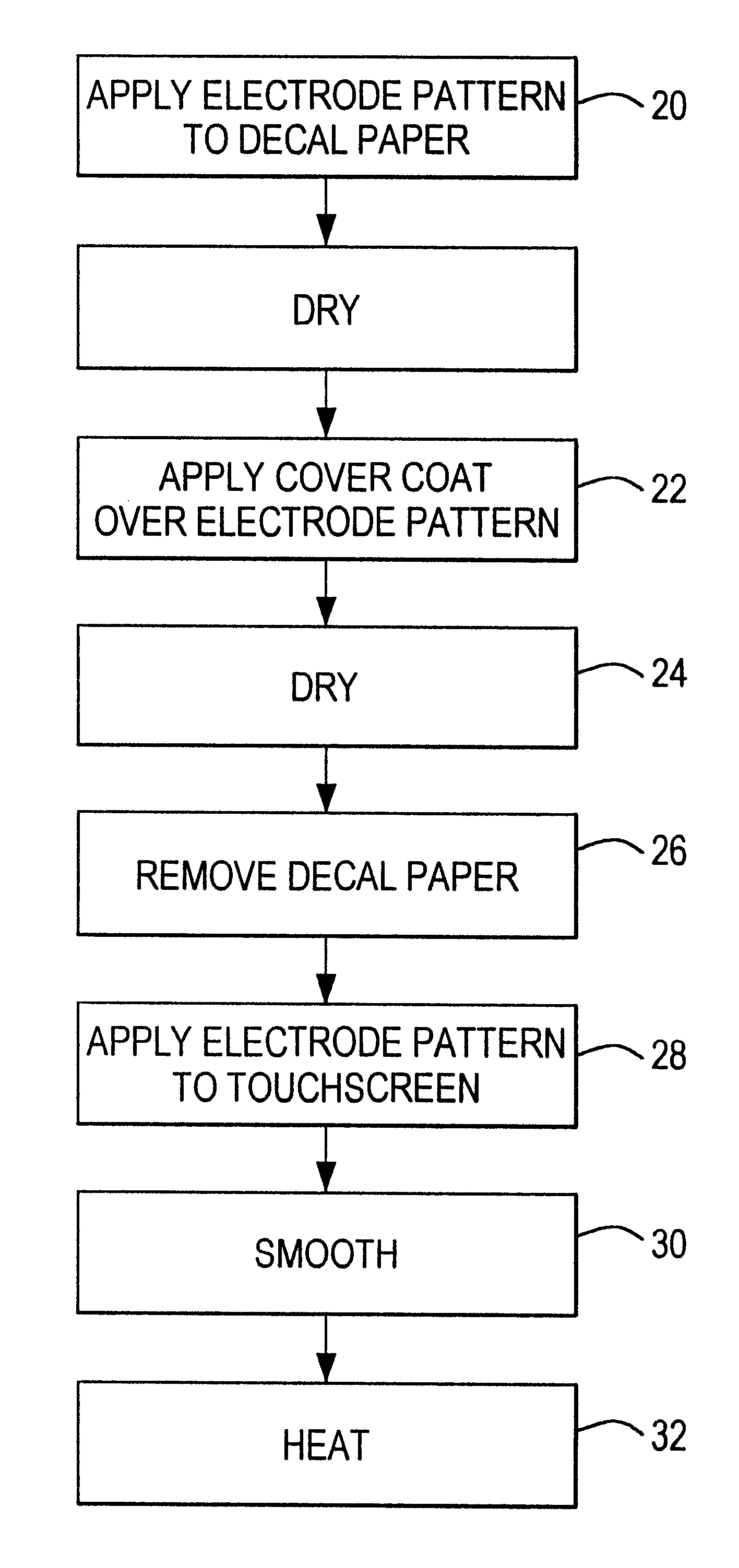

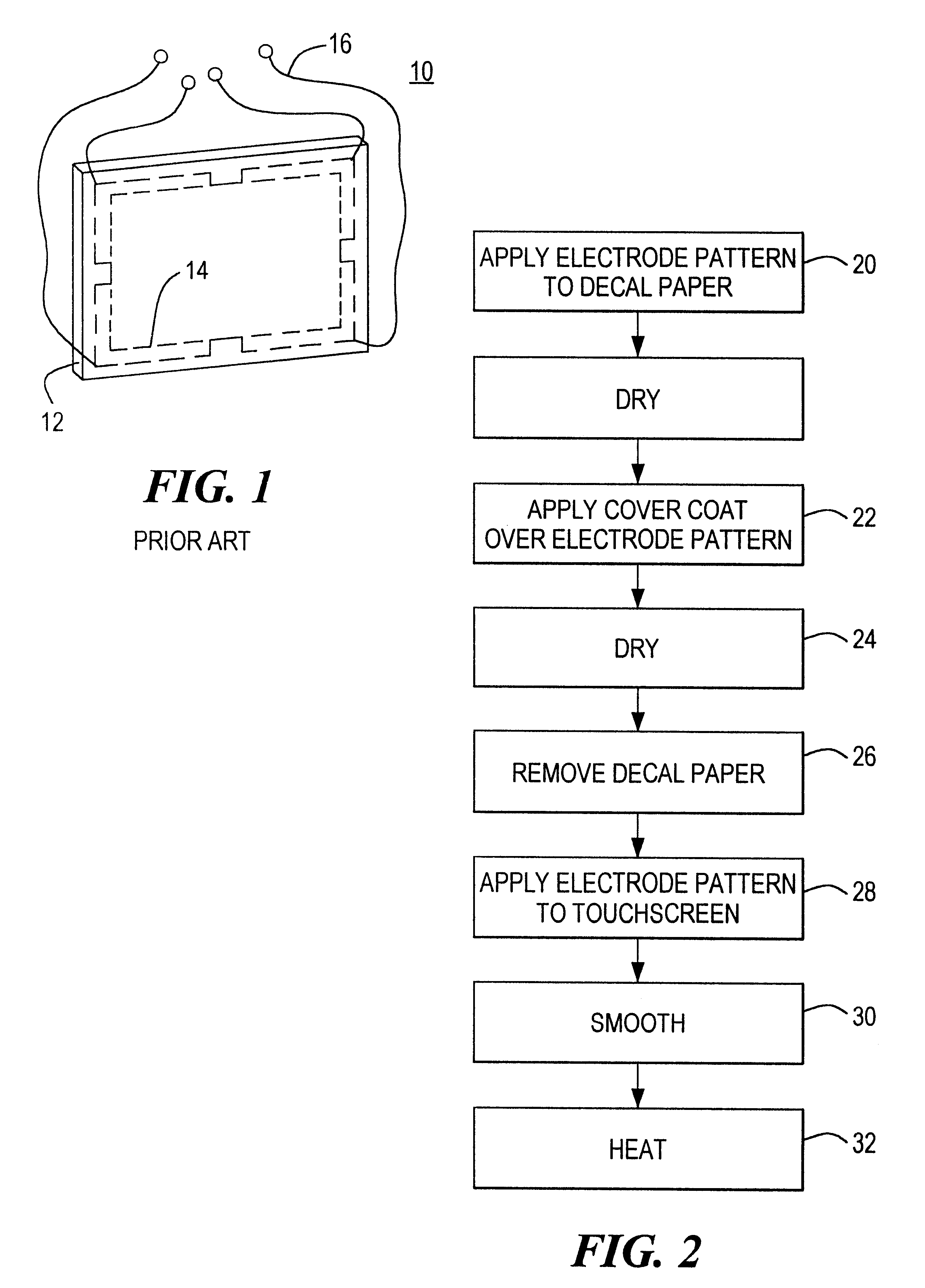

Method of applying an edge electrode pattern to a touch screen and a decal for a touch screen

InactiveUS6280552B1Reduce defectImprove qualityLine/current collector detailsLamination ancillary operationsEngineeringTouchscreen

A method of applying an edge electrode pattern to a touch screen panel including printing an edge electrode pattern on decal paper; applying a cover coat over the electrode pattern; removing the decal paper; and transferring the edge electrode pattern to a touch screen panel. A decal to be used in accordance with this method.

Owner:3M INNOVATIVE PROPERTIES CO

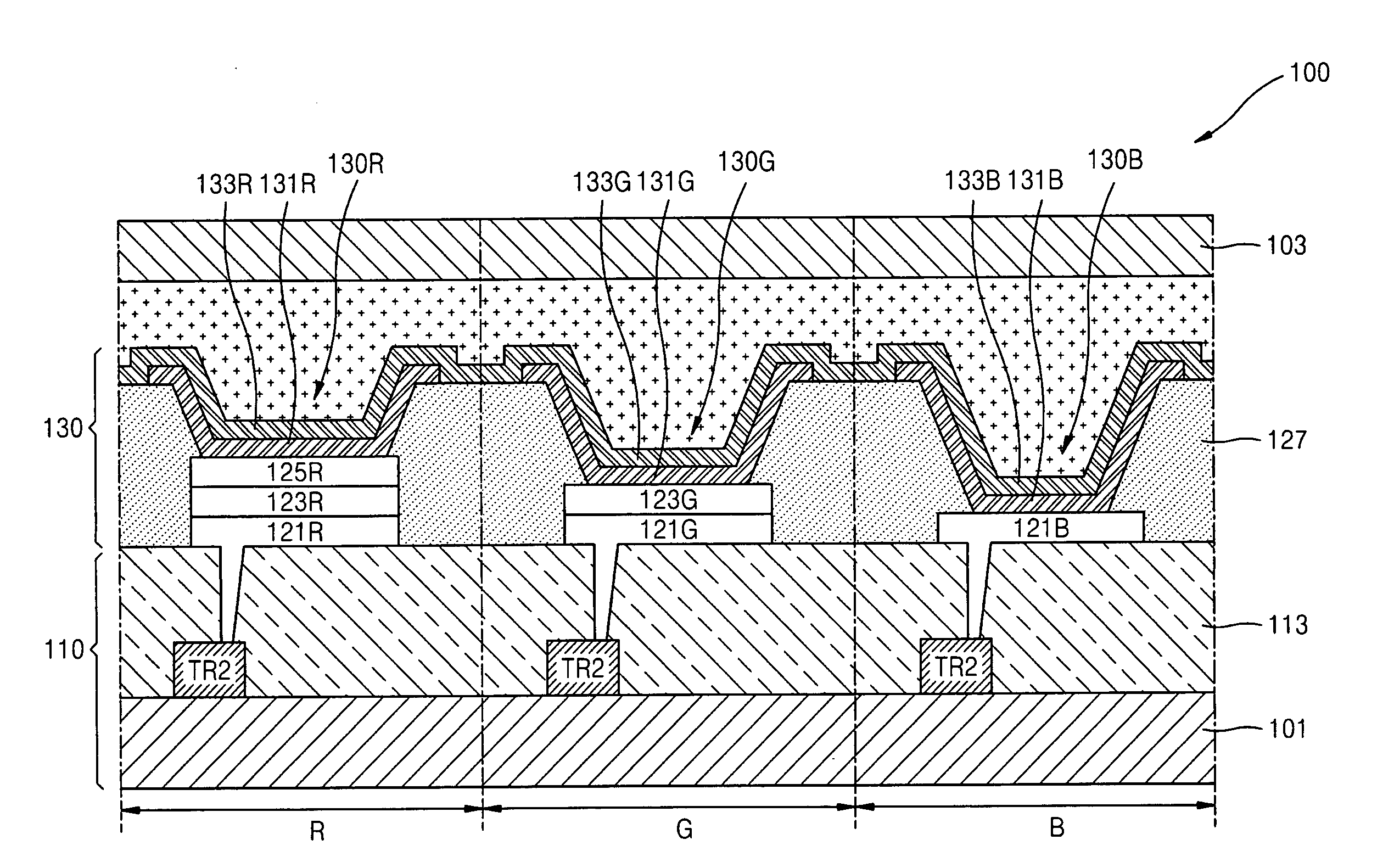

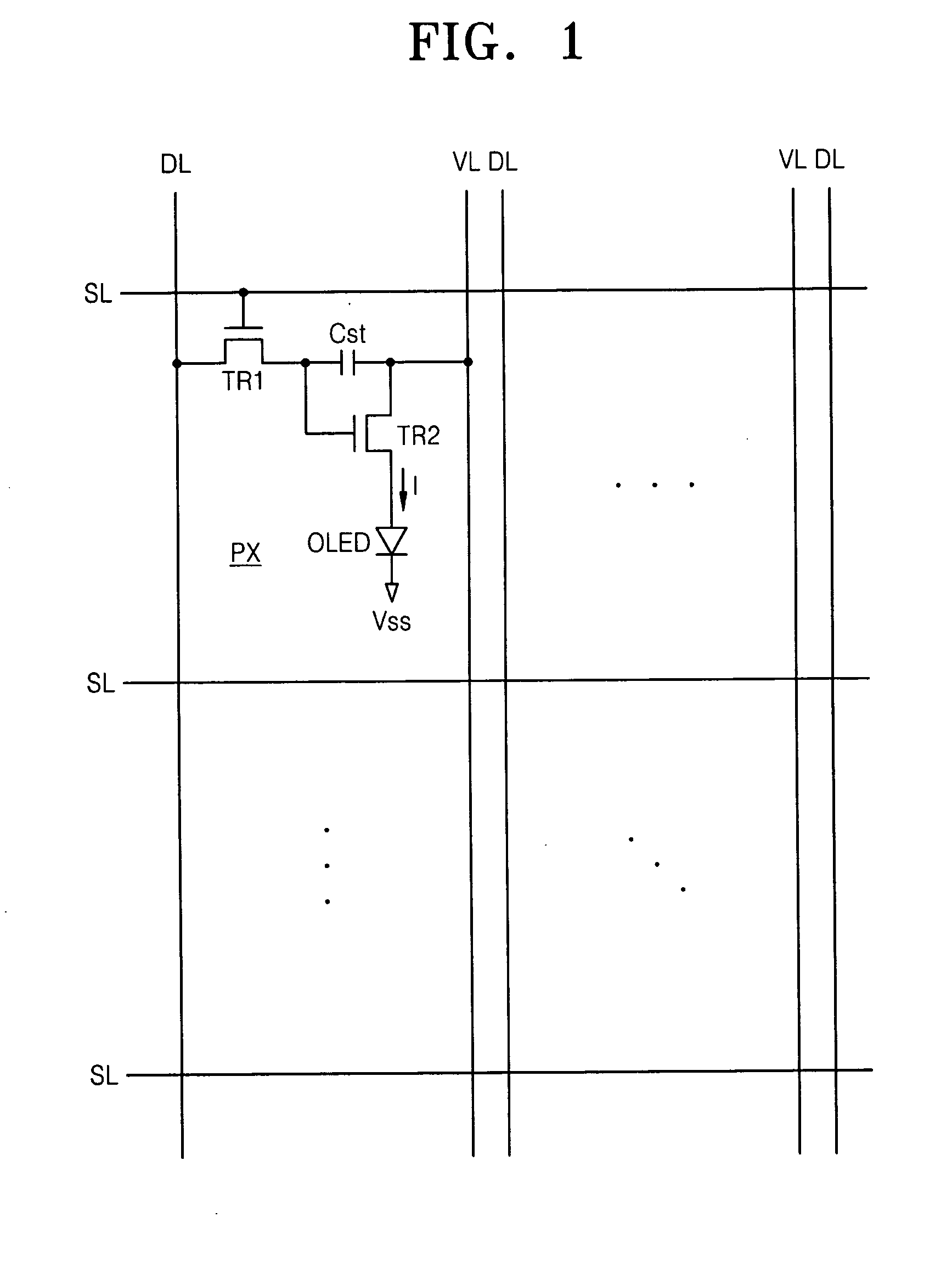

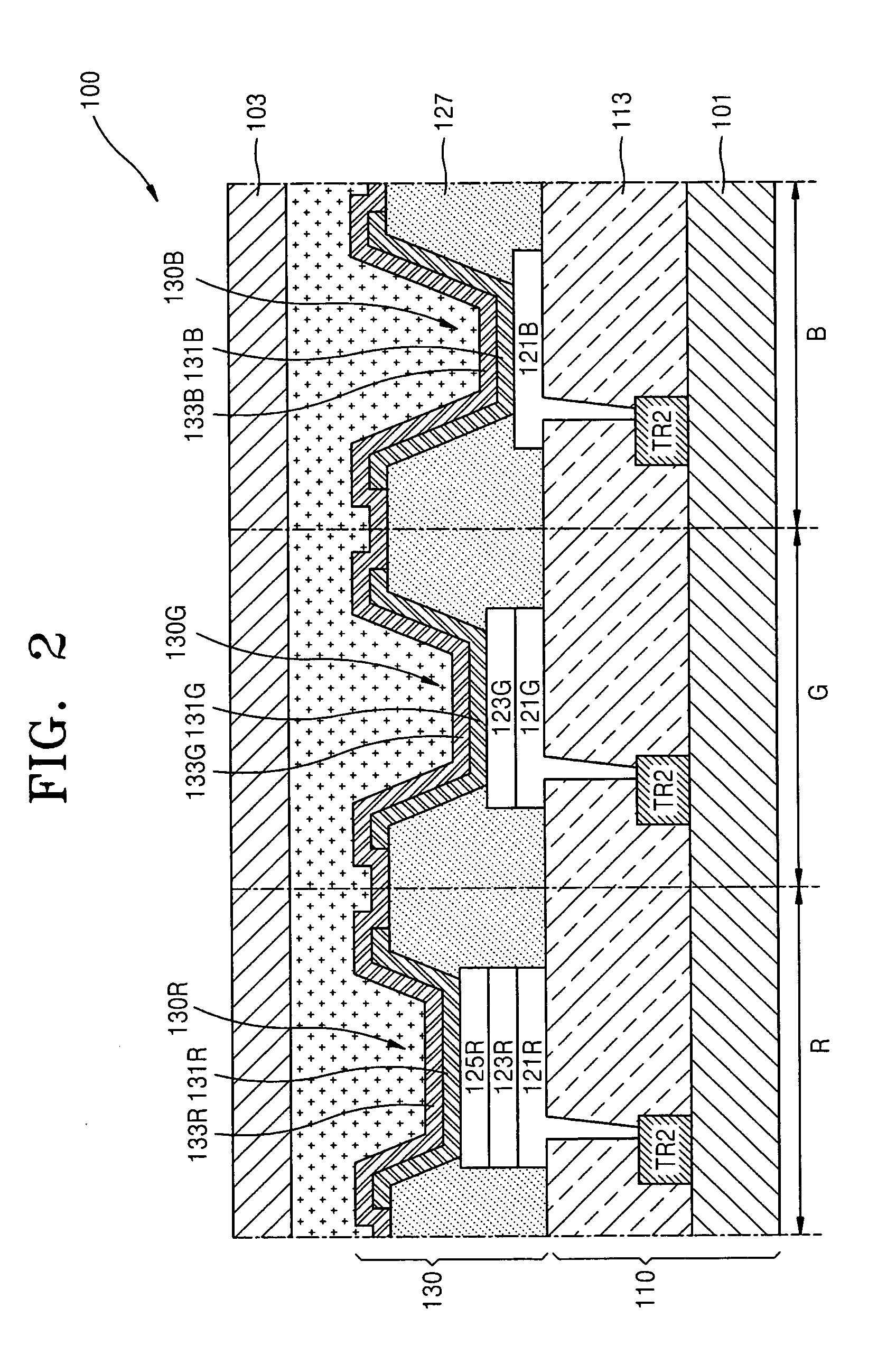

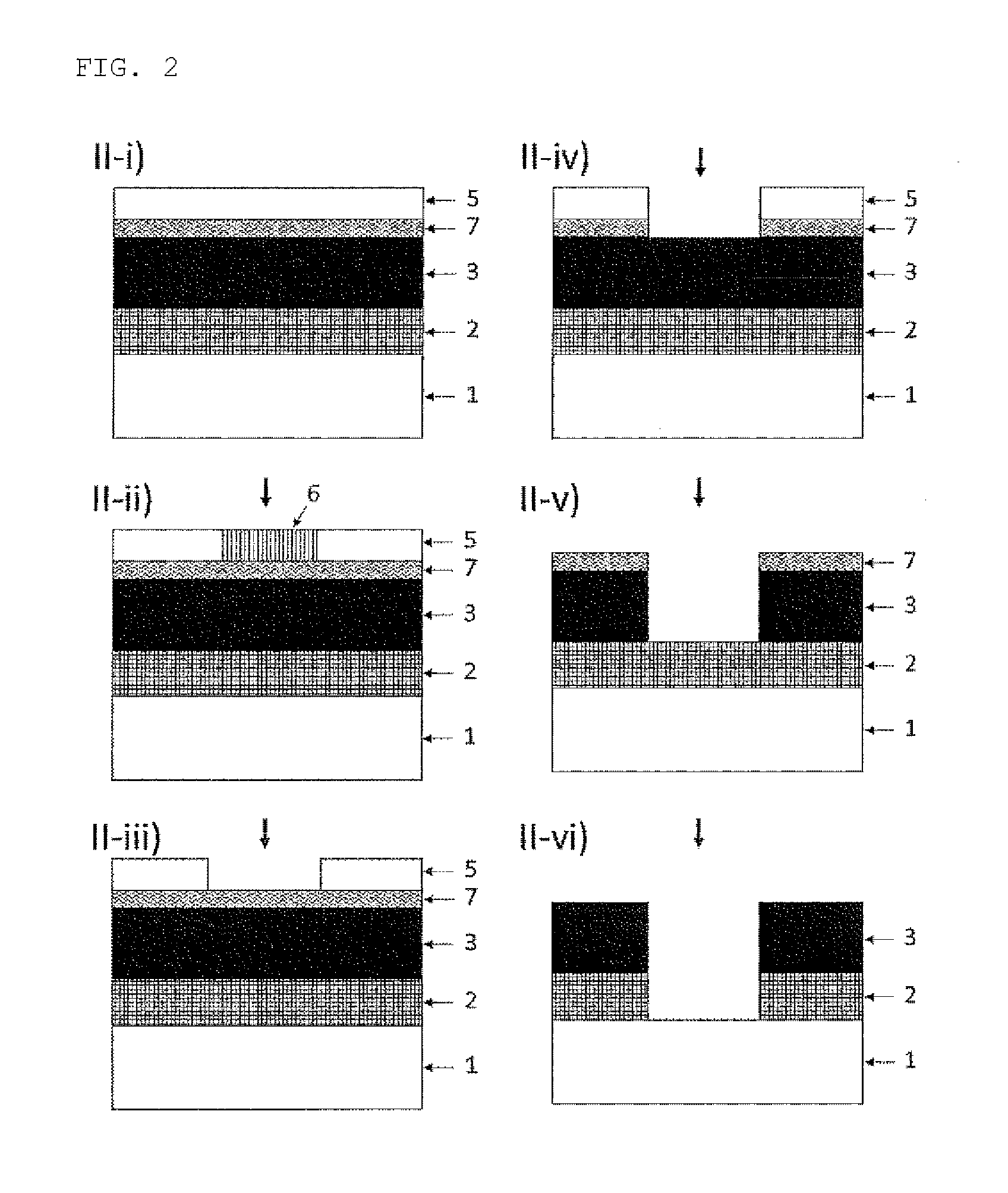

Method of manufacturing organic light emitting display device

InactiveUS20110229994A1Reduce defectImprove productivitySolid-state devicesSemiconductor/solid-state device manufacturingAshingDisplay device

A method of manufacturing an organic light emitting display device includes providing a substrate, the substrate including a first electrode on which a first photosensitive layer is formed, a second electrode on which a second photosensitive layer is formed, and an exposed third electrode, coating an organic layer on the substrate, and carrying out an ashing process to remove the organic layer and the second photosensitive layer and to partially remove the first photosensitive layer so as to avoid exposing the upper surface of the first electrode.

Owner:SAMSUNG DISPLAY CO LTD

Method of making laminate structures for mechanical activation

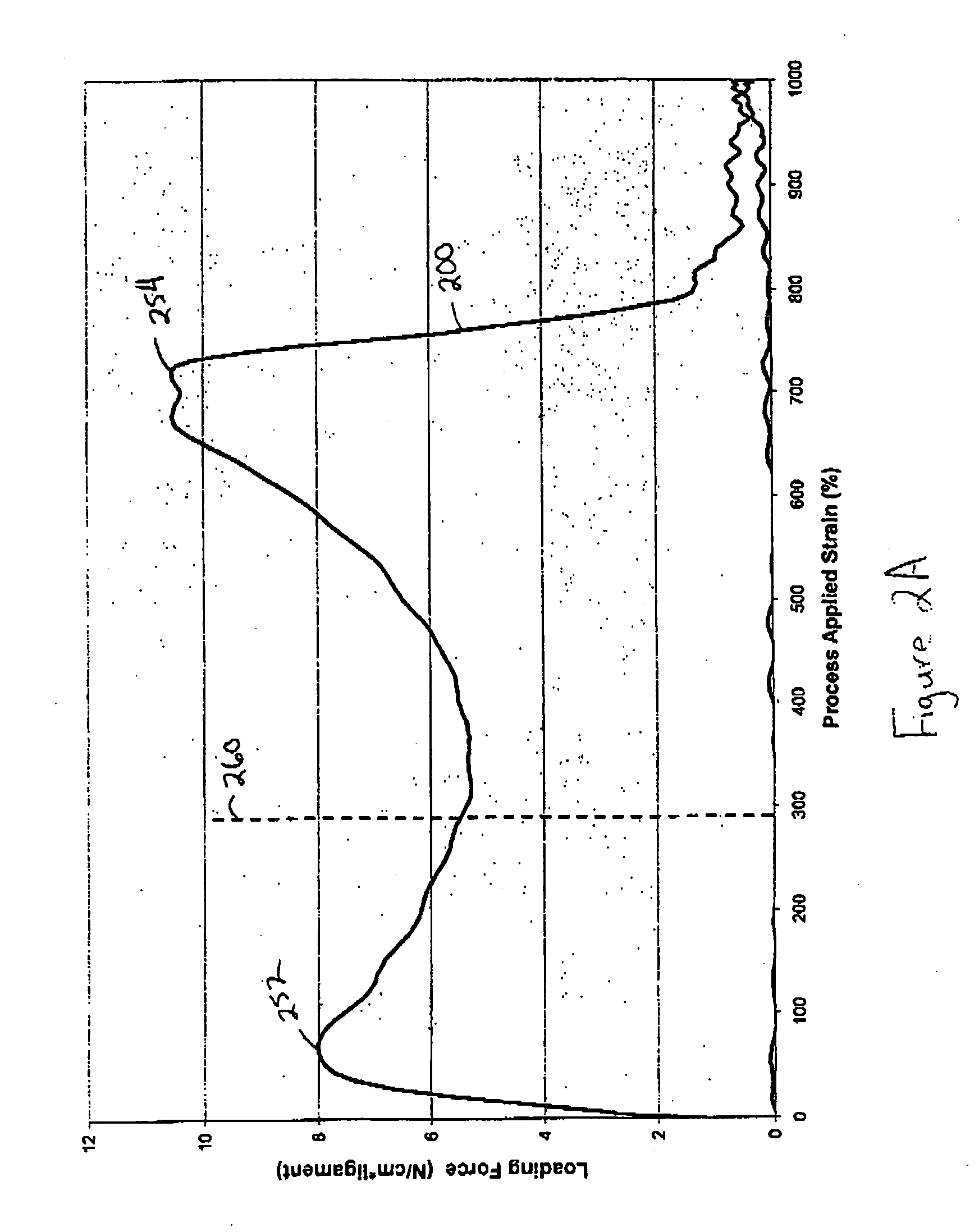

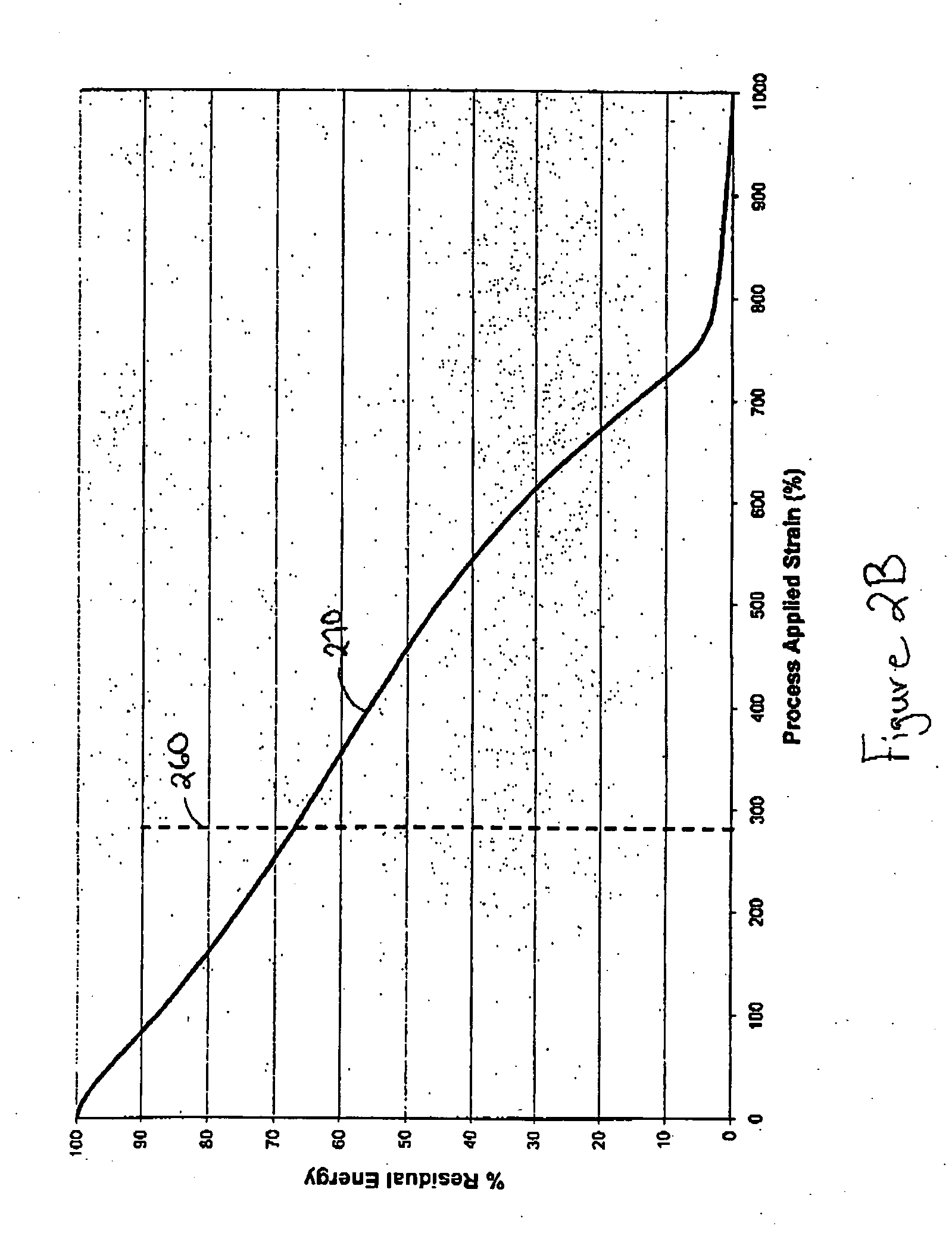

InactiveUS20070202767A1Reduce defectReduce defectsSynthetic resin layered productsLaminationStrain rateAdhesive

A method for producing a stretch laminate includes forming an intermediate stretch laminate. Forming the intermediate stretch laminate includes providing a first substrate and attaching an elastic film to a surface of the first substrate via an adhesive. The first substrate and the elastic film are in a face to face orientation. The intermediate stretch laminate has a residual energy of greater than or equal to 50% at a predetermined applied strain. The method of forming the stretch laminate further includes mechanically activating the intermediate stretch laminate at a strain rate of at least 100 s−1.

Owner:THE PROCTER & GAMBNE CO

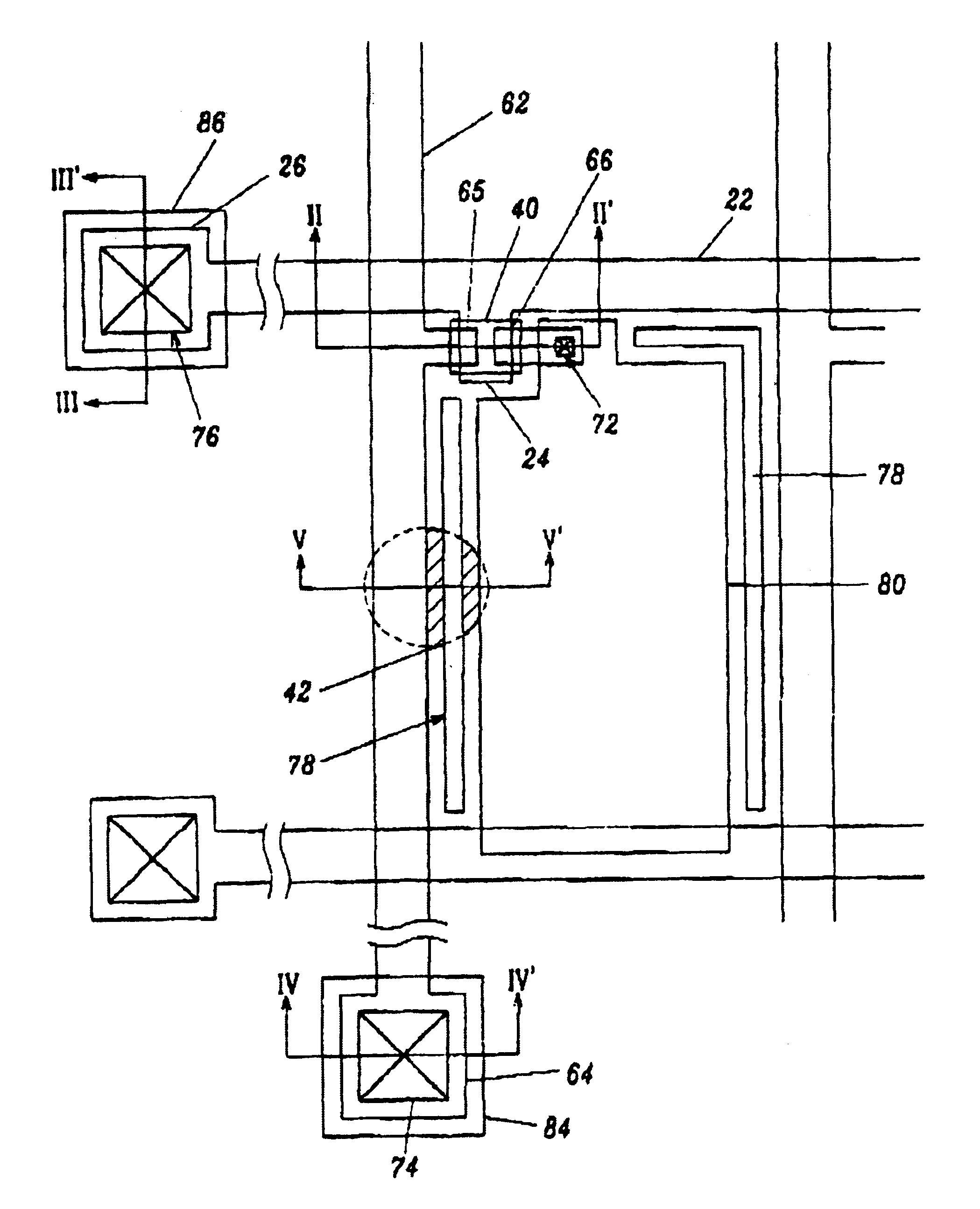

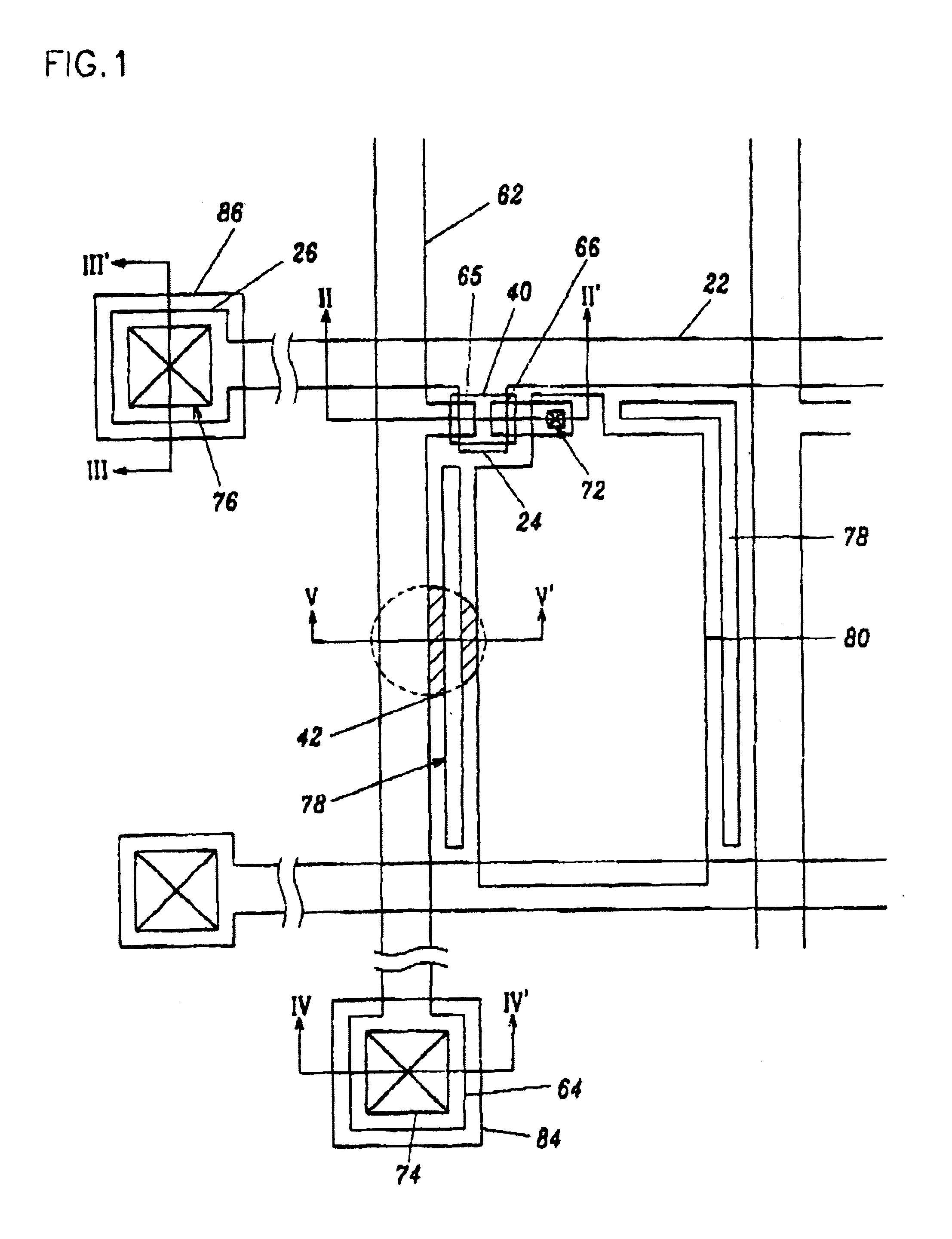

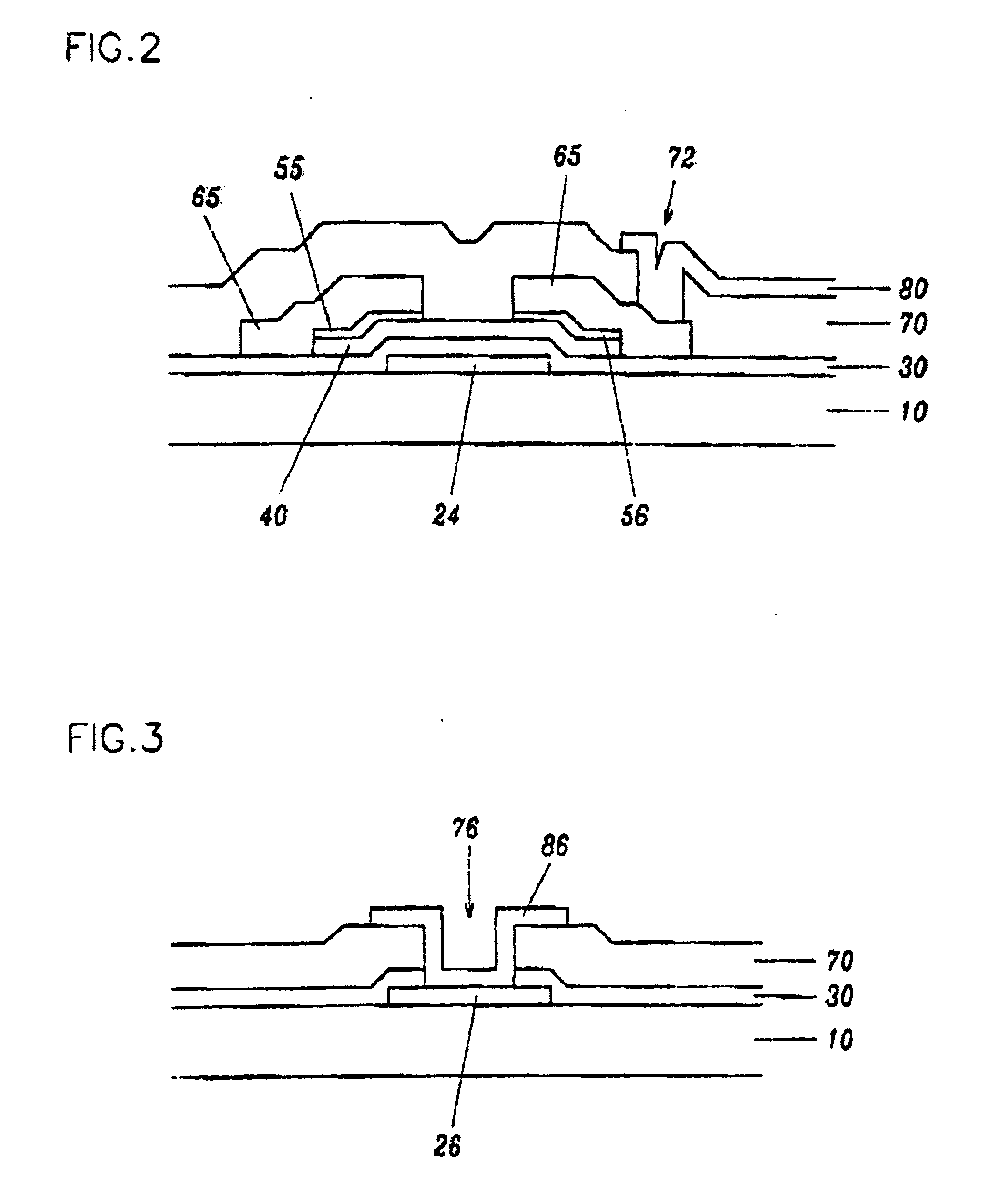

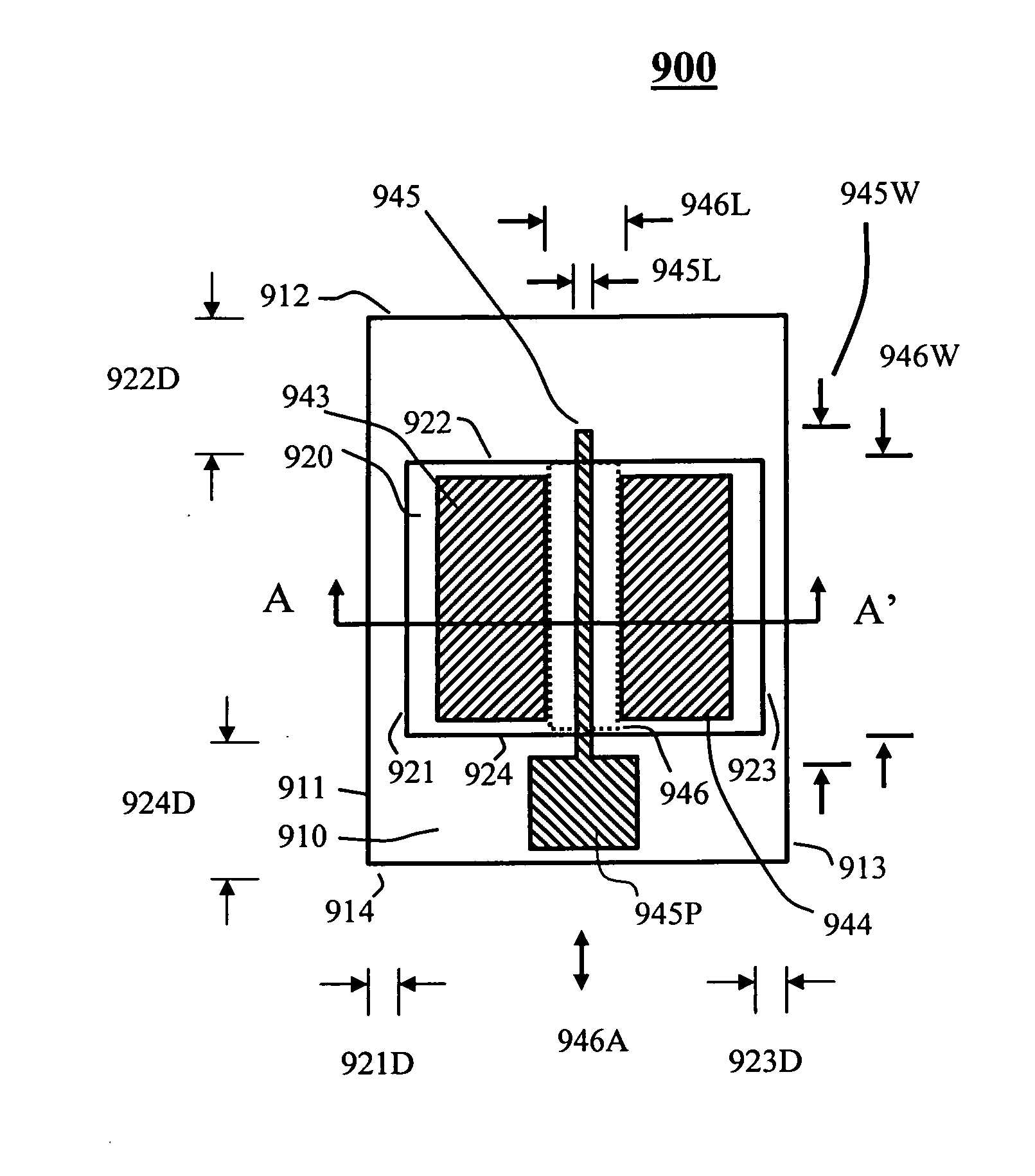

Thin film transistor array panel for a liquid crystal display

InactiveUS6900854B1Reduce defectReduce pixel defectsSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceLiquid-crystal display

A gate wire including a gate line extending in the horizontal direction, and a gate electrode is formed on an insulating substrate. A gate insulating layer is formed on the gate wire and covers the same. A semiconductor pattern is formed on the gate insulating layer 30, and formed on the semiconductor pattern are a data wire having a date line in the vertical direction, a source electrode, a drain electrode separated from the source electrode opposite the source electrode with respect to the gate electrode, and an align pattern located on both sides of the data line. A passivation layer is formed on the data wire and the align pattern, and has contact holes exposing the drain electrode and an opening exposing the substrate between the data line and the align pattern. Here, the align pattern adjacent to the data line is exposed through the opening, and the semiconductor pattern and the gate insulating layer are under-cut. A pixel electrode connected to the drain electrode through the contact hole is formed on the passivation layer. Here, the opening is located between the data line and the pixel electrode. In this structure, misalignment occurring in the manufacturing process of a thin film transistor panel for a liquid crystal display is minimized, and stitch defects are prevented by uniformity forming a coupling capacitance between the data line and the pixel electrode. Shorts between the data line and the pixel electrode are prevented by forming the opening between the data line and the pixel electrode.

Owner:SAMSUNG DISPLAY CO LTD

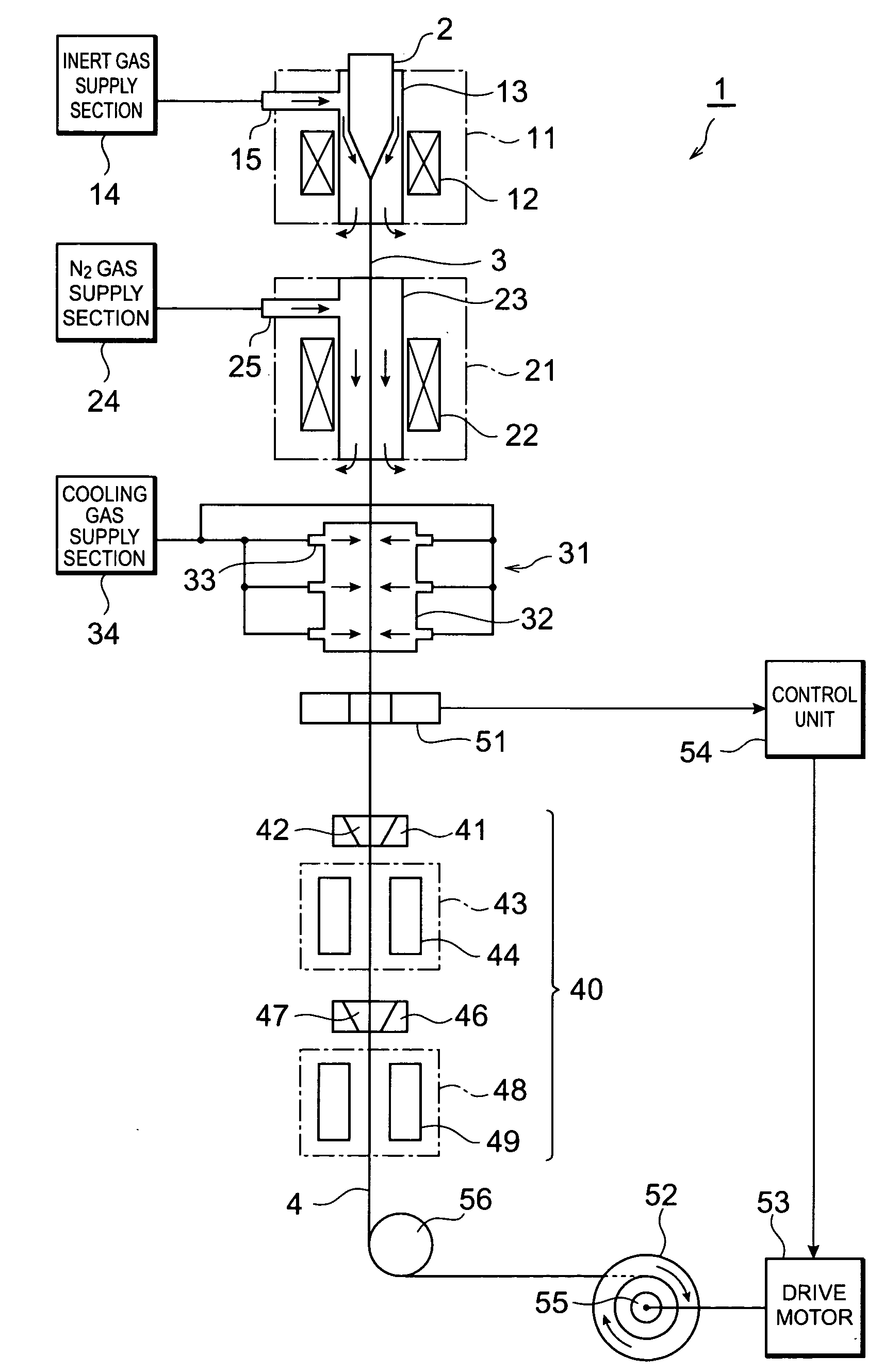

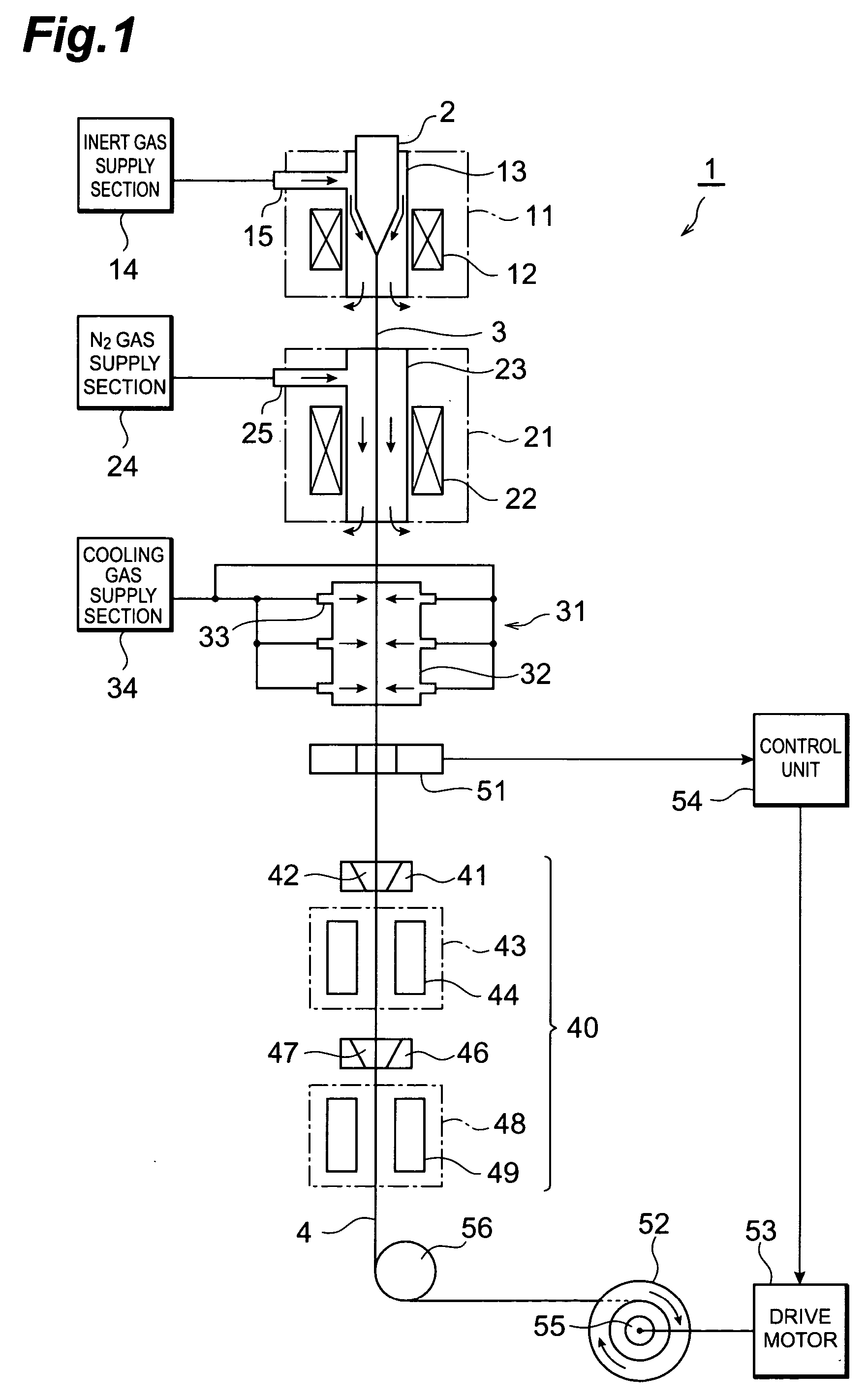

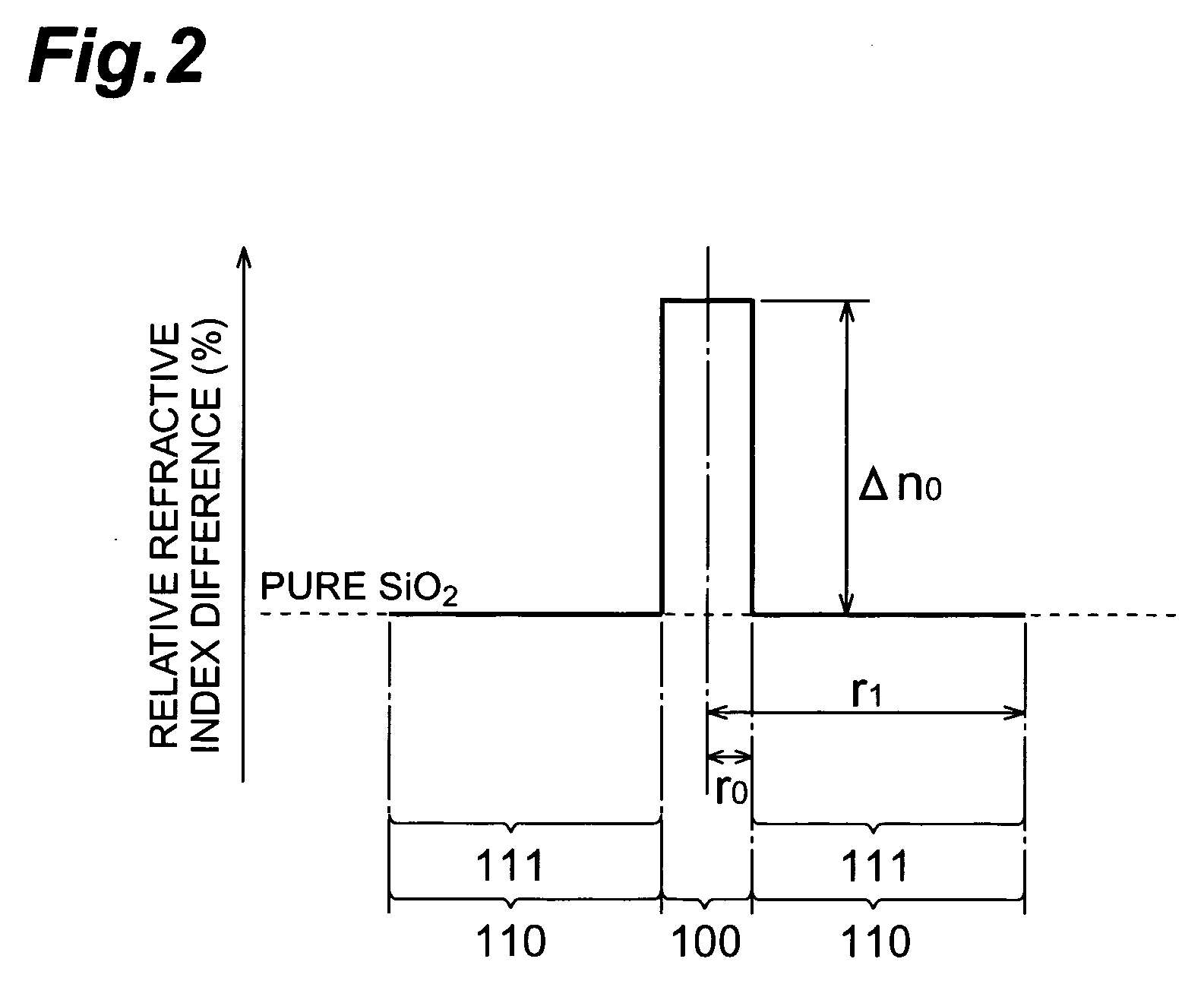

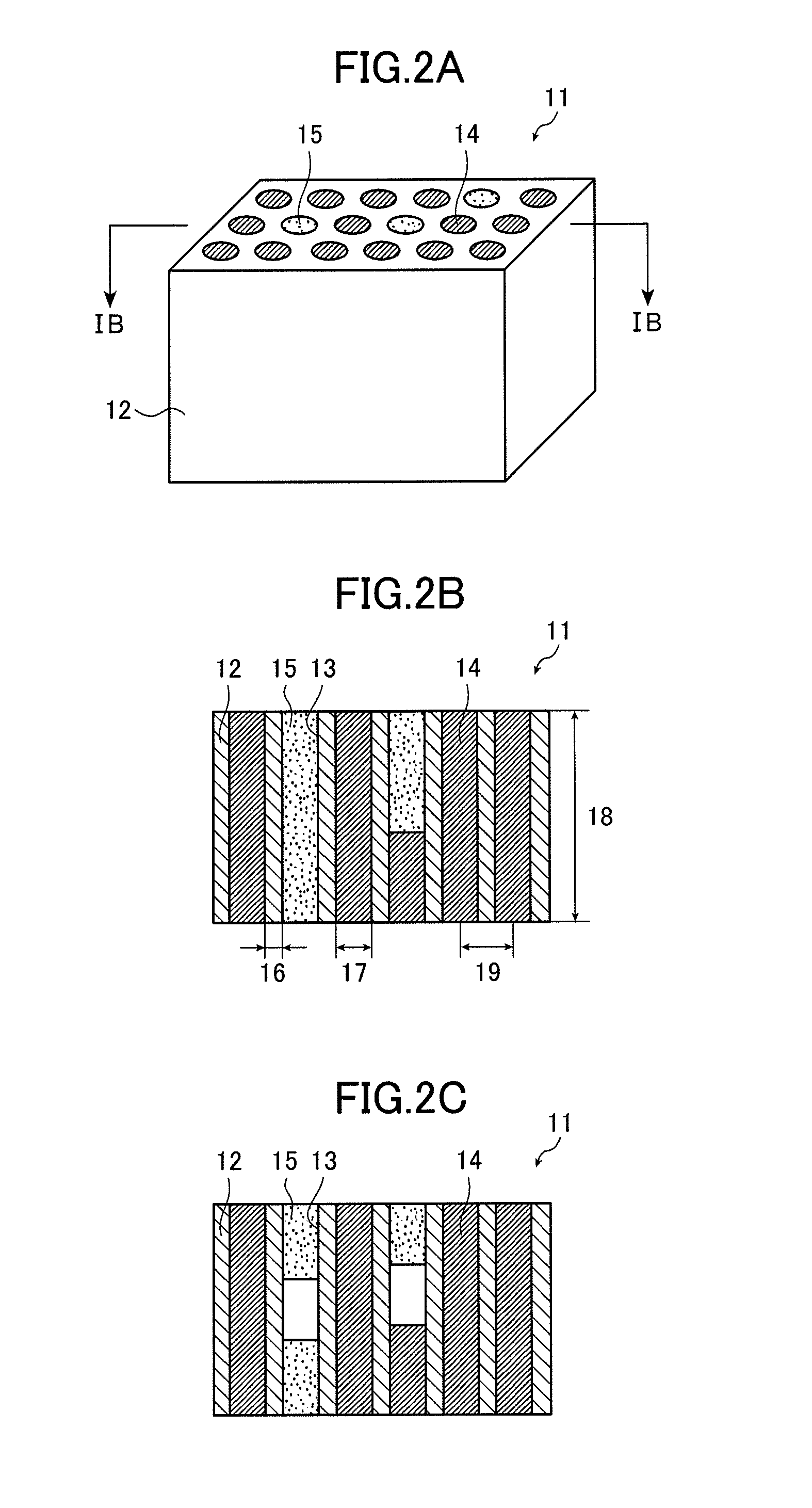

Optical fiber and a method for manufacturing same

InactiveUS20050259932A1Reduce defectExcellent propertyOptical fibre with multilayer core/claddingGlass fibre drawing apparatusProduction rateDopant

There is prepared an optical fiber preform 2 whose core region is doped with Ge in such a quantity of dopant that the relative refractive-index difference [Ge] expressed in % with respect to pure SiO2 satisfies the condition [Ge]≧0.3%, where upon after being heat drawn with a drawing furnace 11 into an optical fiber 3, the optical fiber 3 is annealed in a heating furnace 21 downstream of the drawing furnace 11 under a condition that the cooling speed is 2000° C. / second or less, and the period of annealing time is equal to or longer than the relaxation time. Further, the annealed optical fiber 3 is introduced into a cooling means 31 at an entry temperature of 700° C. or more, and the optical fiber 3 is forcibly cooled by the cooling means 31. As a consequence, there are achieved an optical fiber and a method of fabricating the same capable of fabricating the optical fiber having a reduced Rayleigh scattering loss as well as excellent hydrogen-resisting property with favorably high productivity.

Owner:SUMITOMO ELECTRIC IND LTD

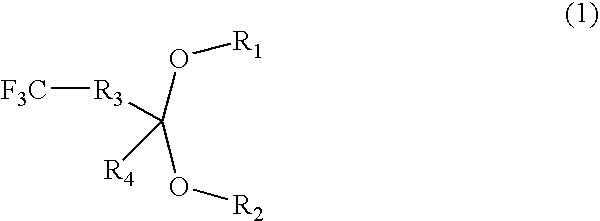

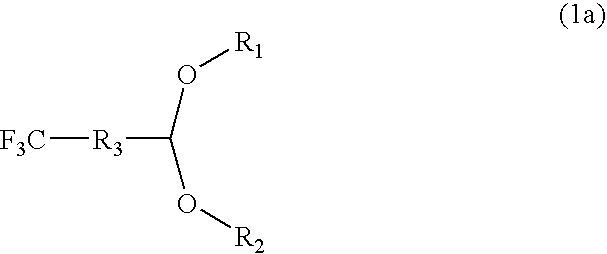

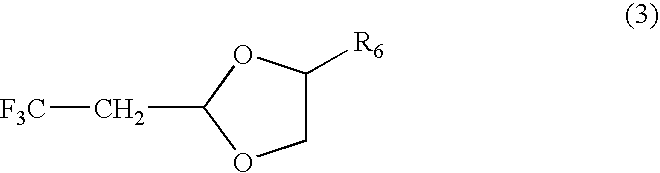

Fluorine-containing polymer coating composition, method for forming fluorine-containing polymer film using coating composition, and method for forming photoresist or lithographic pattern

InactiveUS20070105044A1Reduce defectHigh resolutionOrganic chemistryPhotosensitive materialsSolventResist

There is provided a means for forming a protective film of a fluorine-containing polymer composition excellent in smoothness and adhesiveness on a photoresist. Moreover, there is provided a means for removing the protective film without impairing the underlying photoresist. A polymer coating composition obtainable by dissolving a fluorine-containing polymer compound in a solvent comprising a fluorinated acetal having a specific structure is applied on a photoresist and dried to form a protective film. The fluorinated acetal having the specific structure is suitable as a solvent for being brought into contact with a fluorine-containing polymer film, peeling the film, and forming a photoresist or a lithographic pattern.

Owner:CENT GLASS CO LTD

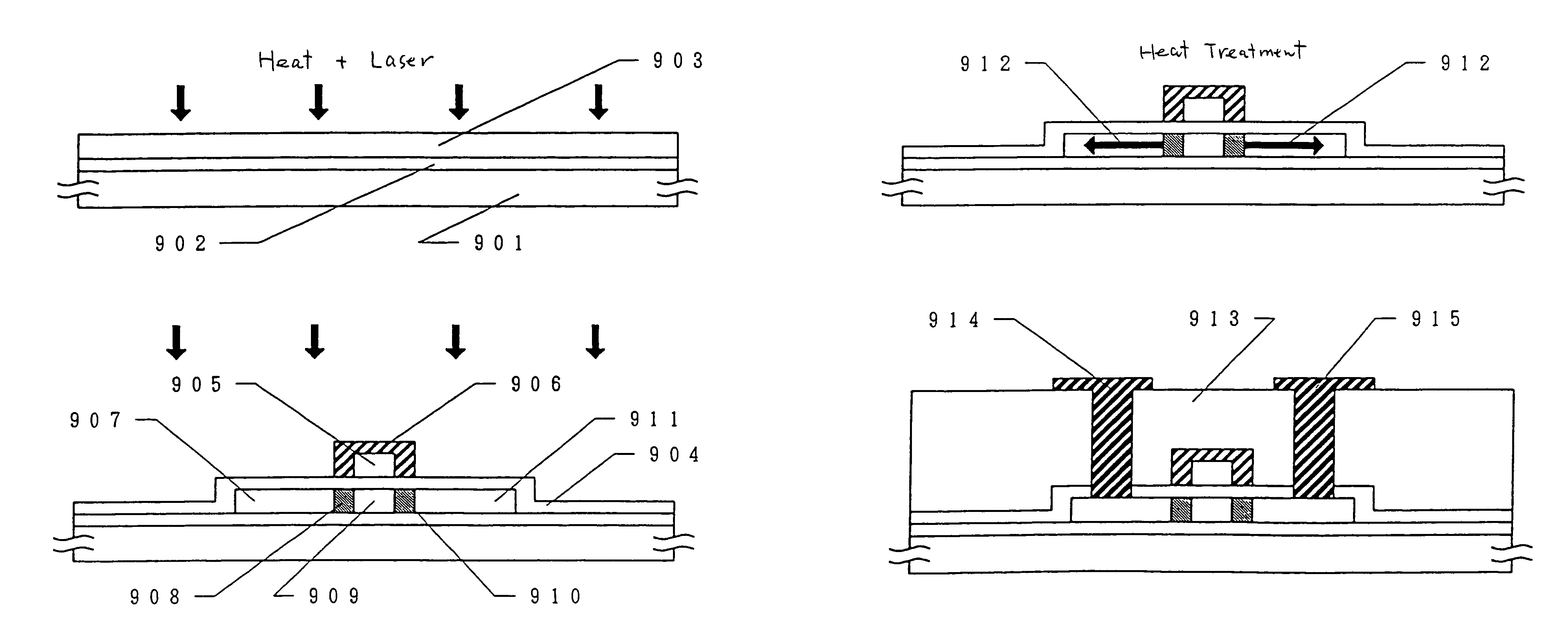

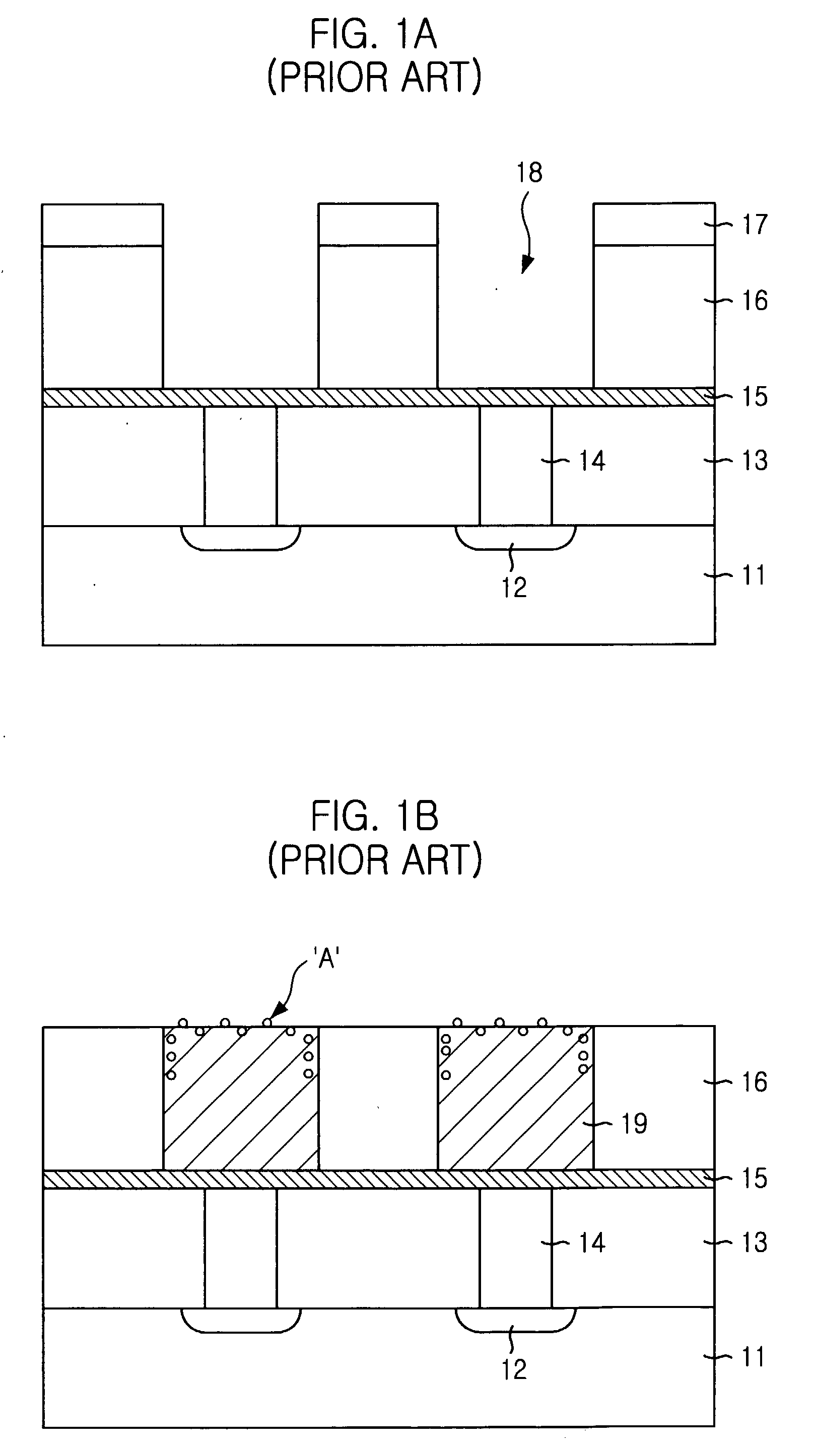

Method for fabrication of field-effect transistor to reduce defects at MOS interfaces formed at low temperature

InactiveUS6905920B2Reduce defectImprove characteristicTransistorSemiconductor/solid-state device manufacturingEngineeringField-effect transistor

A method for the fabrication of a field-effect transistor wherein after forming a semiconductor layer serving as an active layer on a substrate, the substrate temperature is set at no higher than 100° C., a gate insulating film is formed on the semiconductor layer. Then, the gate insulating film is heat treated in an atmosphere containing water. By heat treating in the atmosphere containing water, OH bonds in the vicinity of the insulating film interface are reduced and, therefore, the CV characteristic thereof is improved.

Owner:138 EAST LCD ADVANCEMENTS LTD

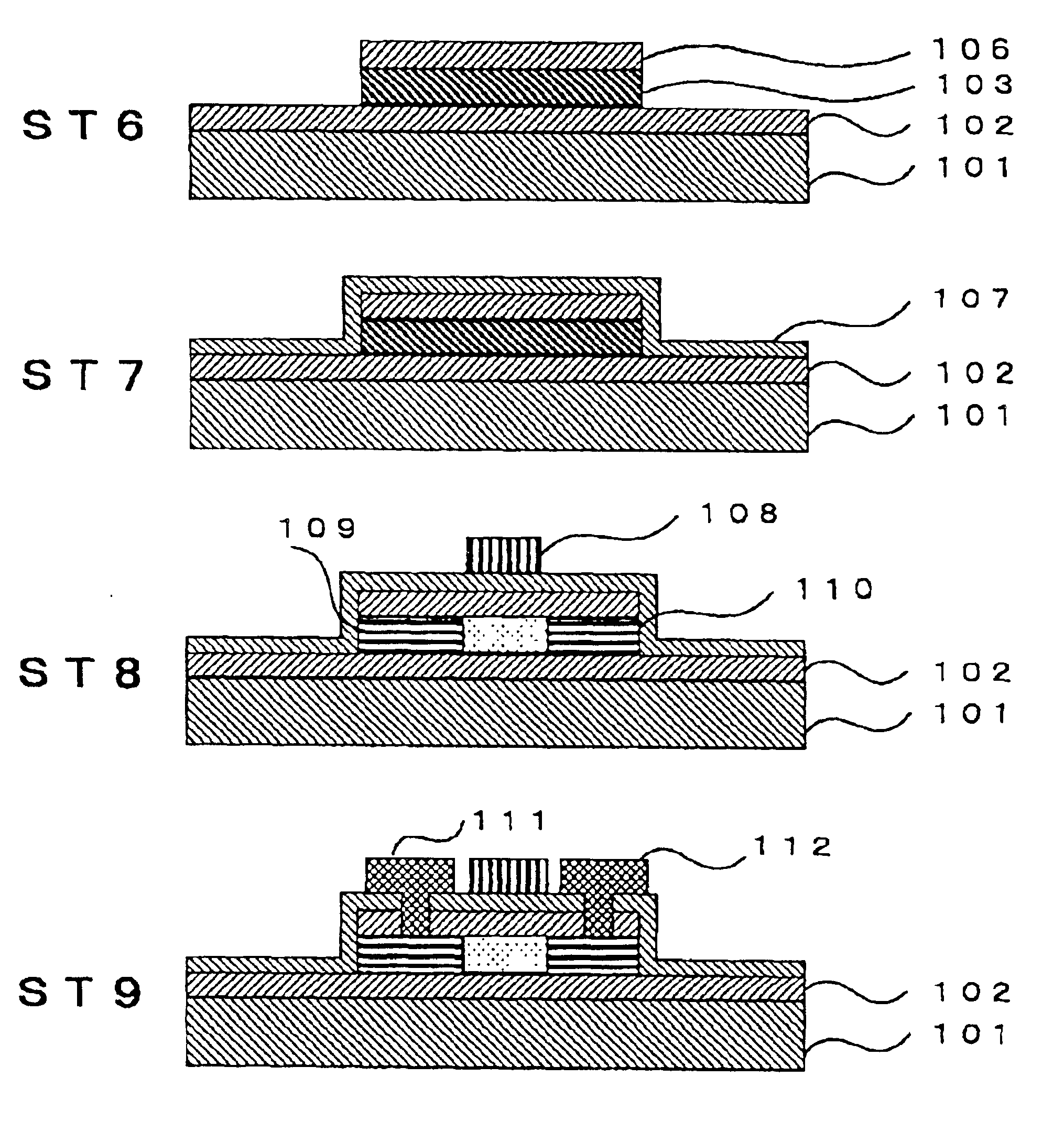

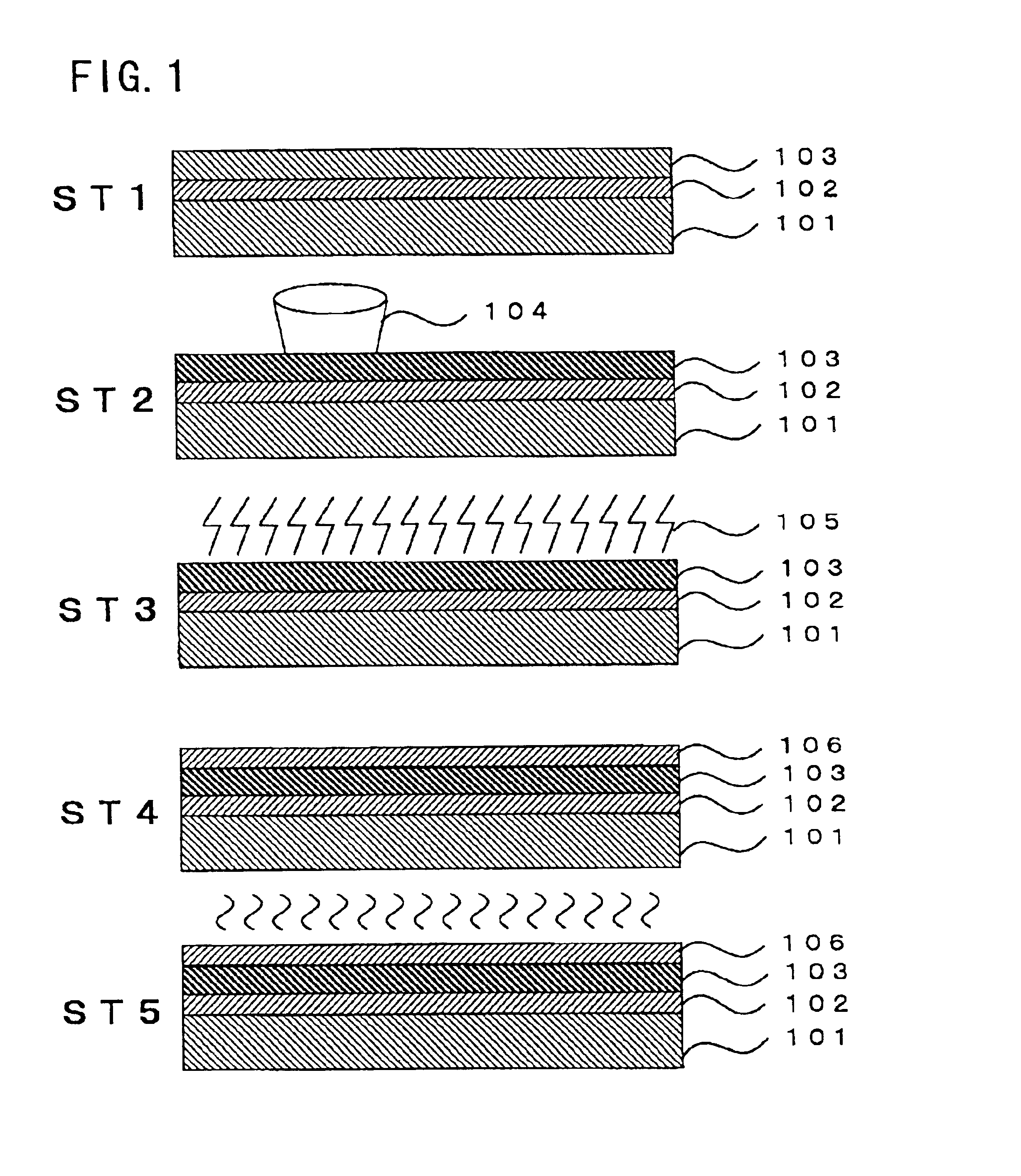

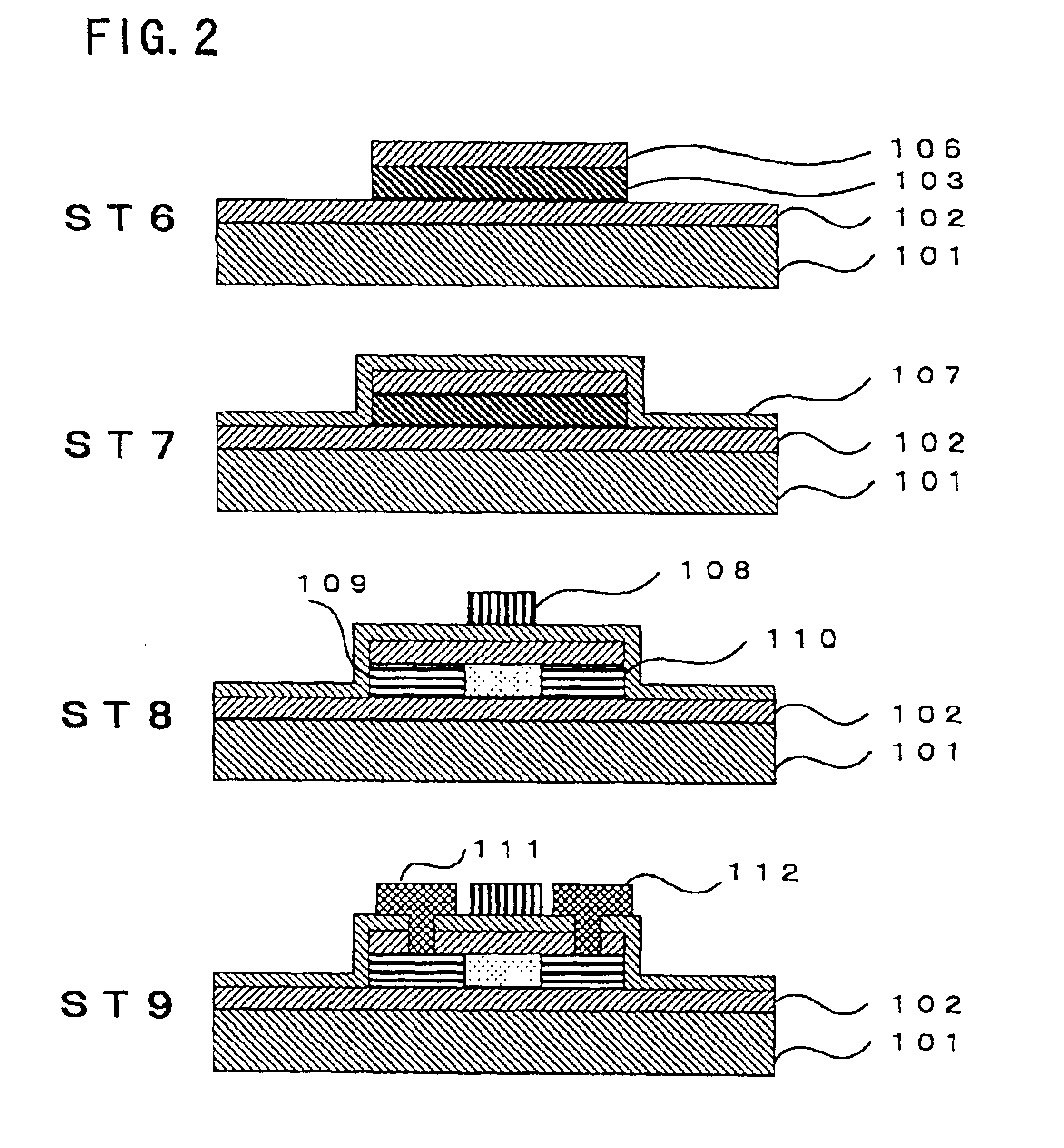

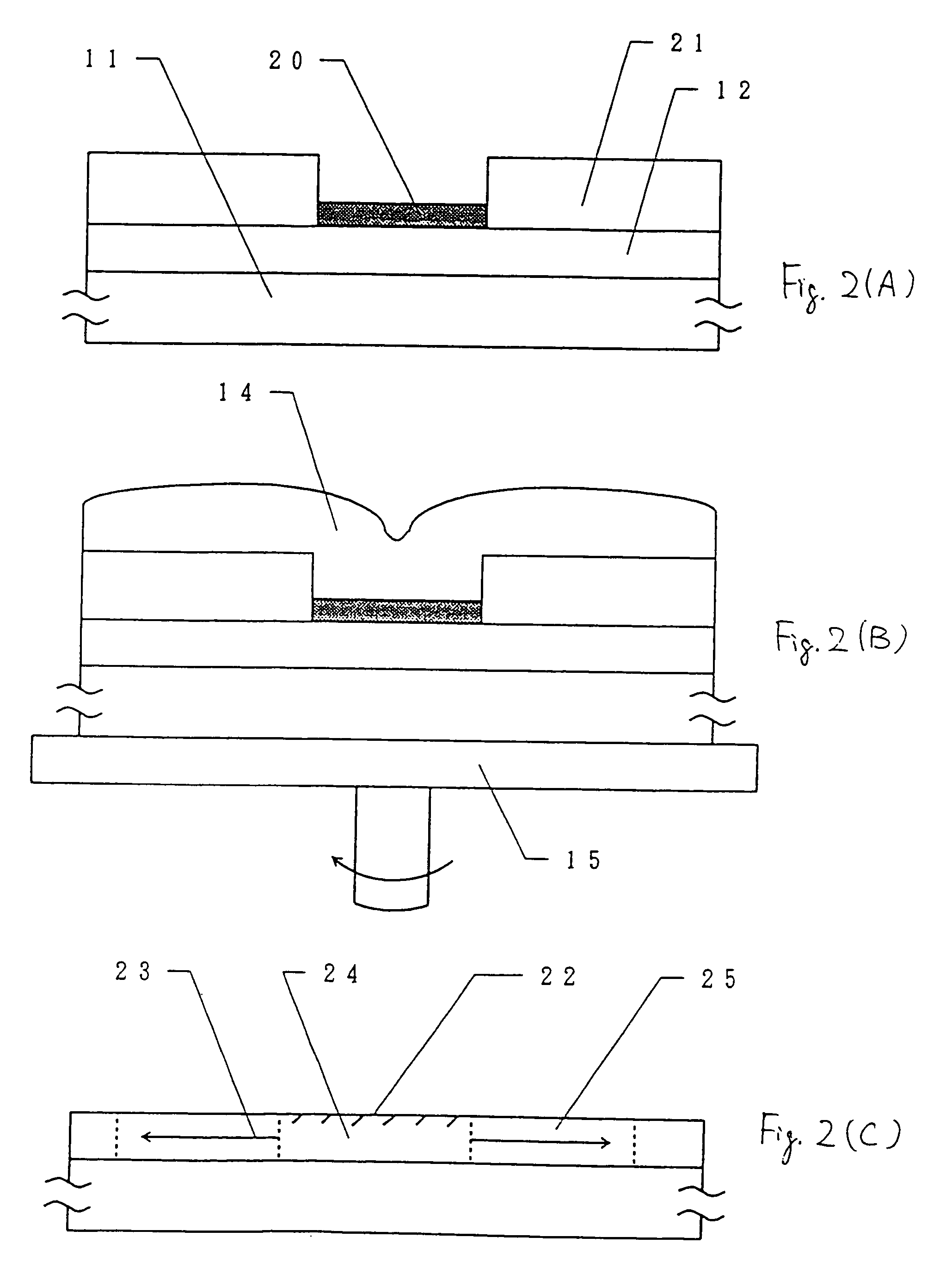

Method of fabricating a semiconductor device utilizing a catalyst material solution

InactiveUS7186601B2Improve crystallization ratioReduce defectTransistorRadiation applicationsLaser lightThin oxide

A very thin oxide film is formed on an amorphous silicon film that is formed on a glass substrate, and an aqueous solution such as an acetate solution added with a catalyst element such as nickel by 10 to 200 ppm (adjustment needed) is dropped thereon. After the structure is held in this state for a predetermined period, spin drying is performed by using a spinner. A crystalline silicon film is obtained by subjecting the structure to a heat treatment of 550° C. and 4 hours and then to laser light irradiation. A crystalline silicon film having a smaller defect concentration is obtained by further performing a heat treatment of 550° C. and 4 hours.

Owner:SEMICON ENERGY LAB CO LTD

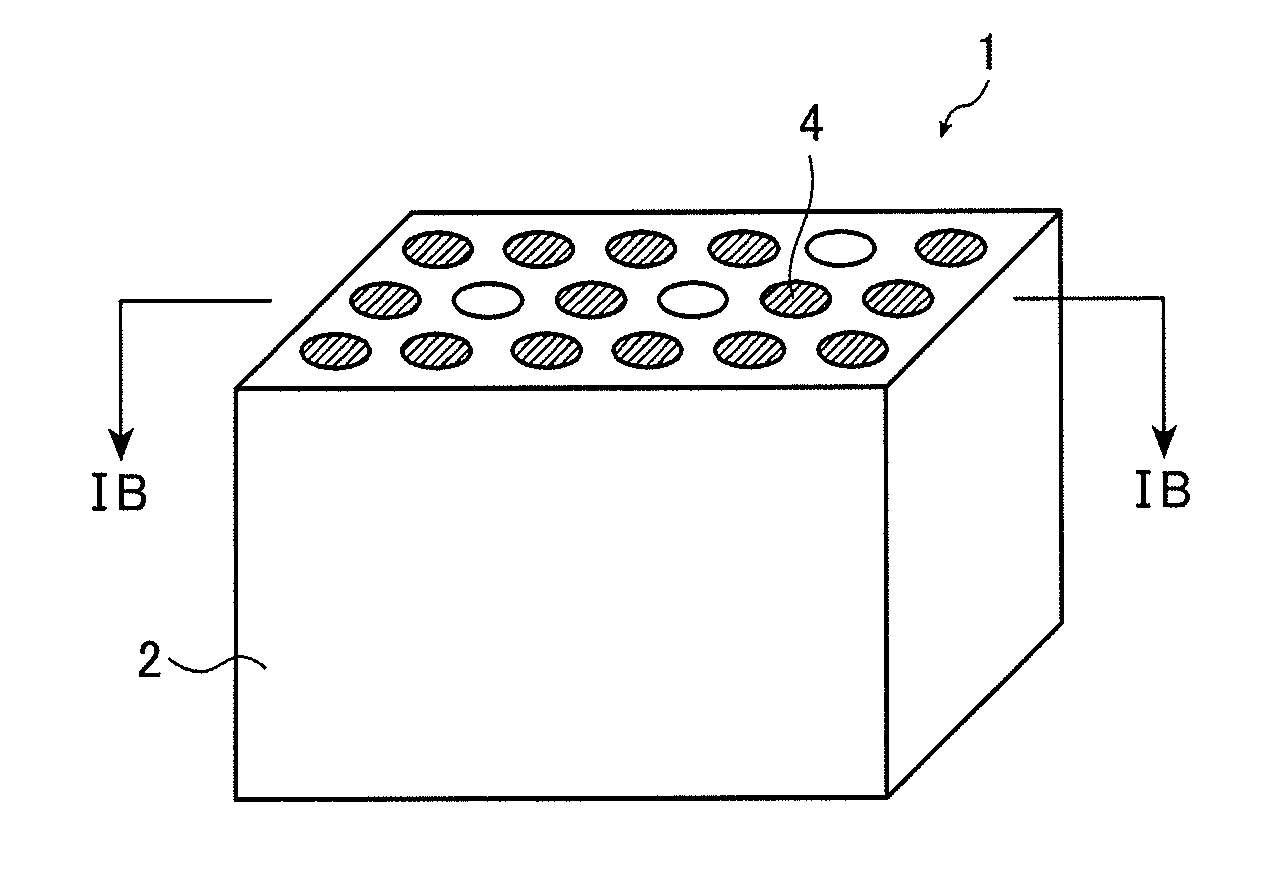

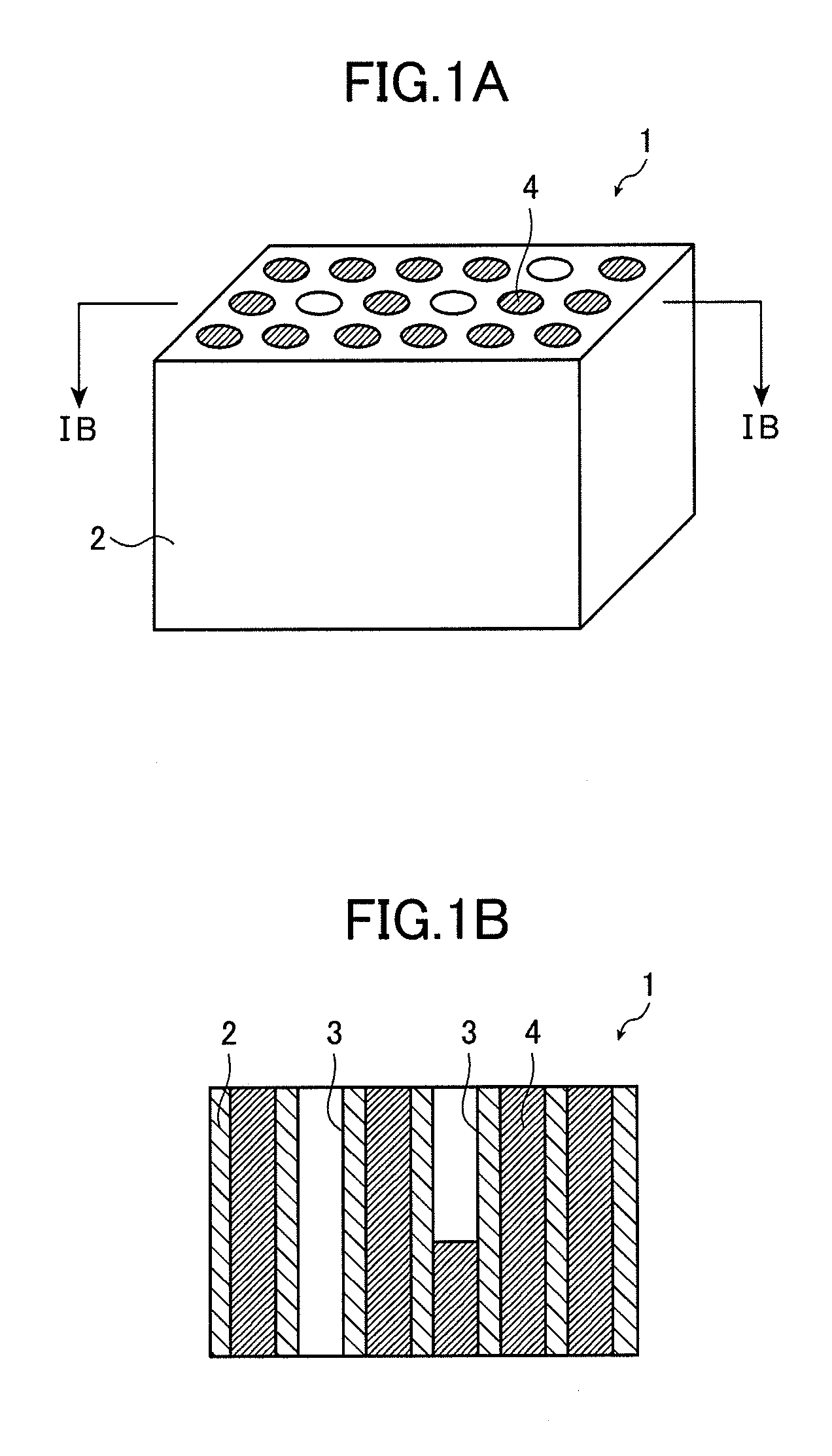

Microstructure and microstructure production method

InactiveUS20110311800A1Reduce defectEasy to produceAnodisationNon-insulated conductorsMetal alkoxideMagnesium

A microstructure enabling provision of an anisotropic conductive member capable of reducing wiring defects and a method of producing such microstructure. The microstructure includes through-holes formed in an insulating matrix and filled with a metal and an insulating substance. The through-holes have a density of 1×106 to 1×1010 holes / mm2, a mean opening diameter of 10 nm to 5000 nm, and a mean depth of 10 μm to 1000 μm. The sealing ratio of the through-holes as attained by the metal alone is 80% or more, and the sealing ratio of the through-holes as attained by the metal and the insulating substance is 99% or more. The insulating substance is at least one kind selected from the group consisting of aluminum hydroxide, silicon dioxide, metal alkoxide, lithium chloride, titanium oxide, magnesium oxide, tantalum oxide, niobium oxide, and zirconium oxide.

Owner:FUJIFILM CORP

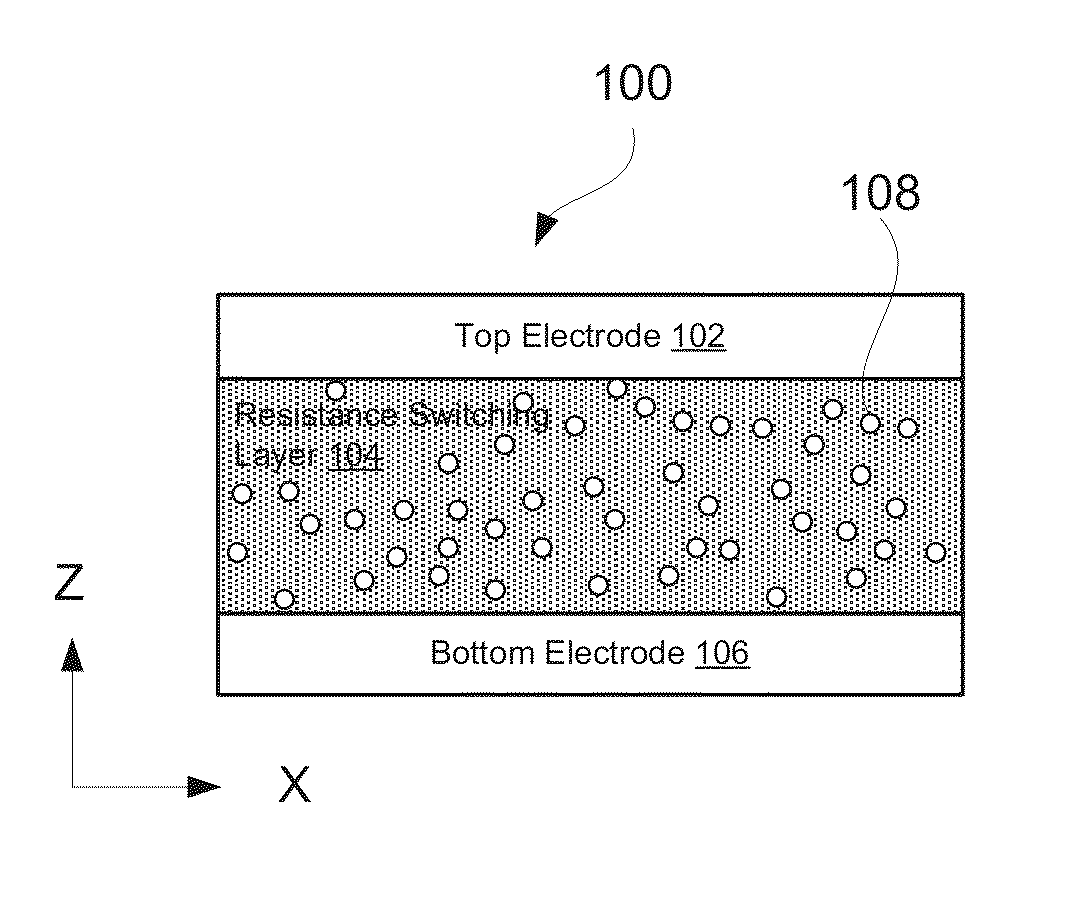

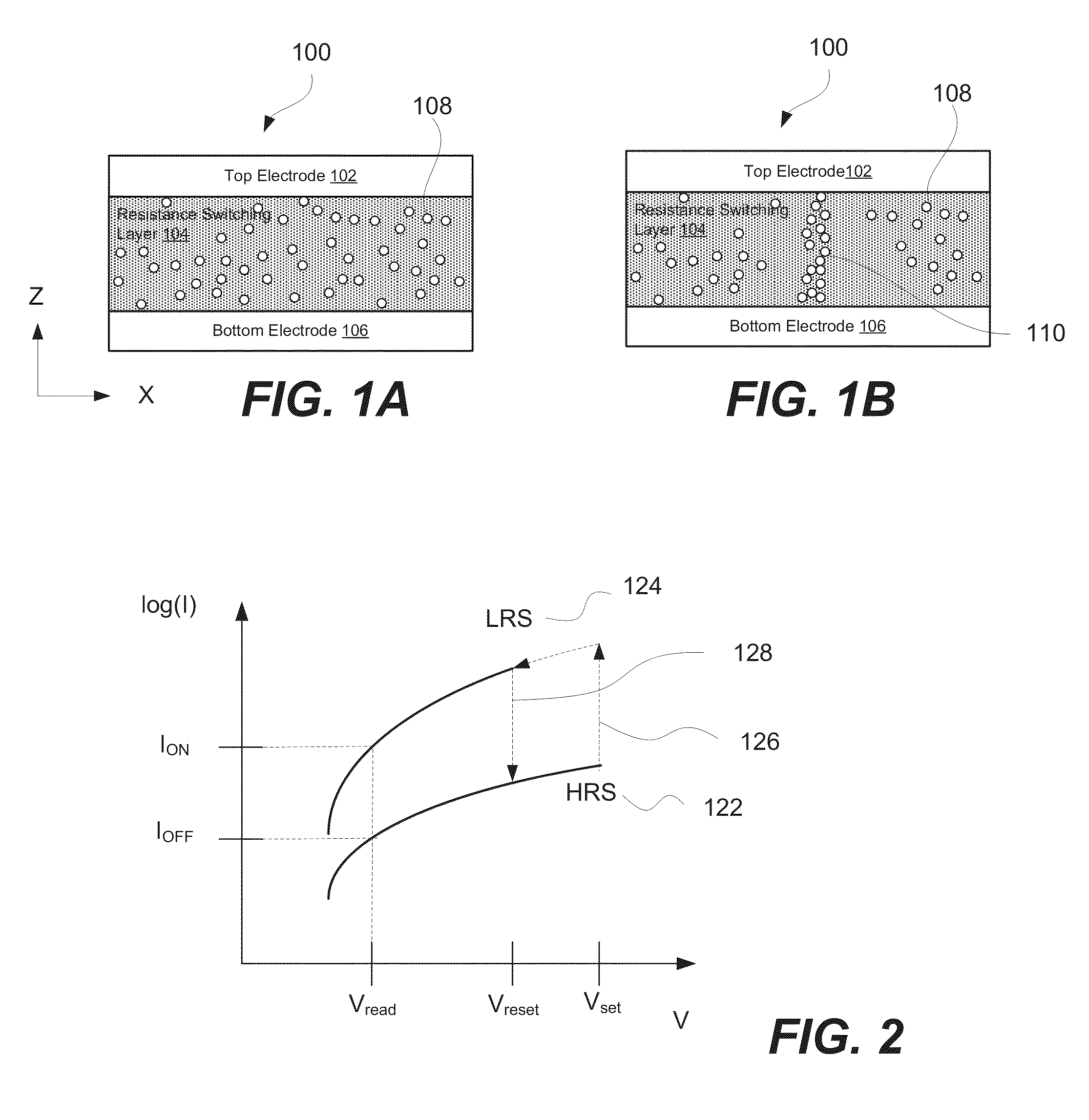

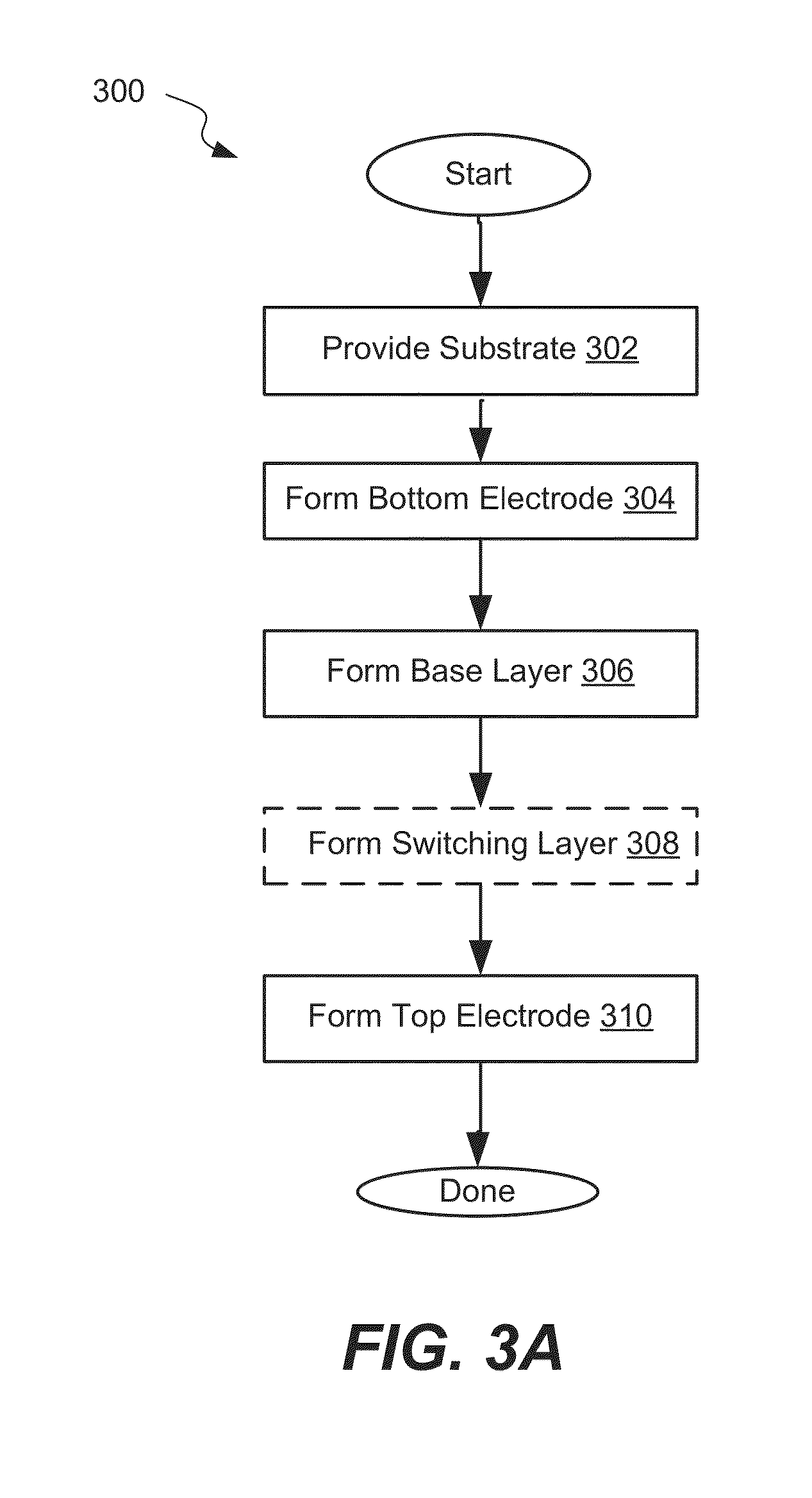

Resistive Switching Layers Including Hf-Al-O

ActiveUS20140175361A1Reduce defectReduce layeringSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesOptoelectronicsNitrogen

Provided are resistive random access memory (ReRAM) cells having switching layers that include hafnium, aluminum, oxygen, and nitrogen. The composition of such layers is designed to achieve desirable performance characteristics, such as low current leakage as well as low and consistent switching currents. In some embodiments, the concentration of nitrogen in a switching layer is between about 1 and 20 atomic percent or, more specifically, between about 2 and 5 atomic percent. Addition of nitrogen helps to control concentration and distribution of defects in the switching layer. Also, nitrogen as well as a combination of two metals helps with maintaining this layer in an amorphous state. Excessive amounts of nitrogen reduce defects in the layer such that switching characteristics may be completely lost. The switching layer may be deposited using various techniques, such as sputtering or atomic layer deposition (ALD).

Owner:SANDISK TECH LLC +2

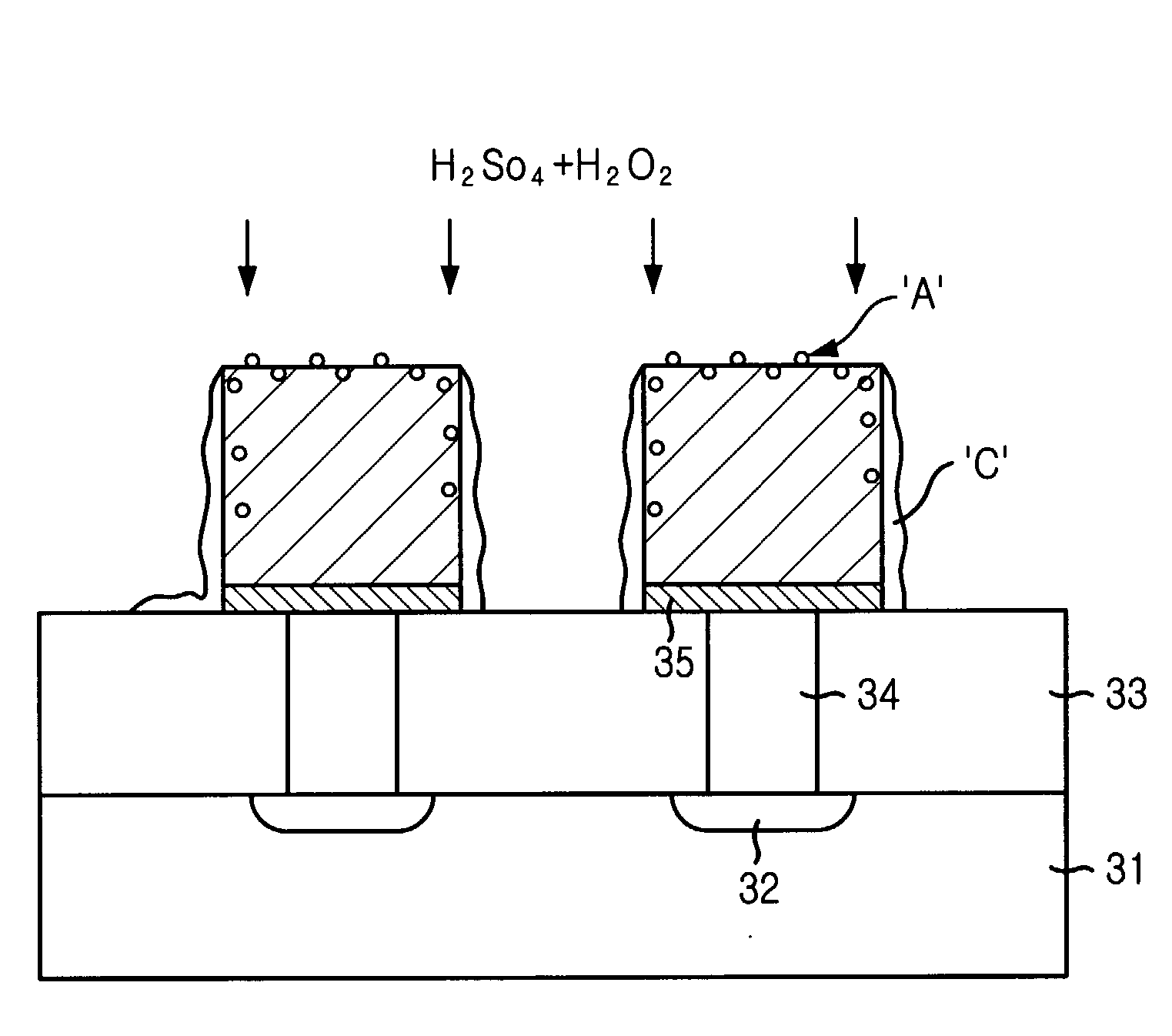

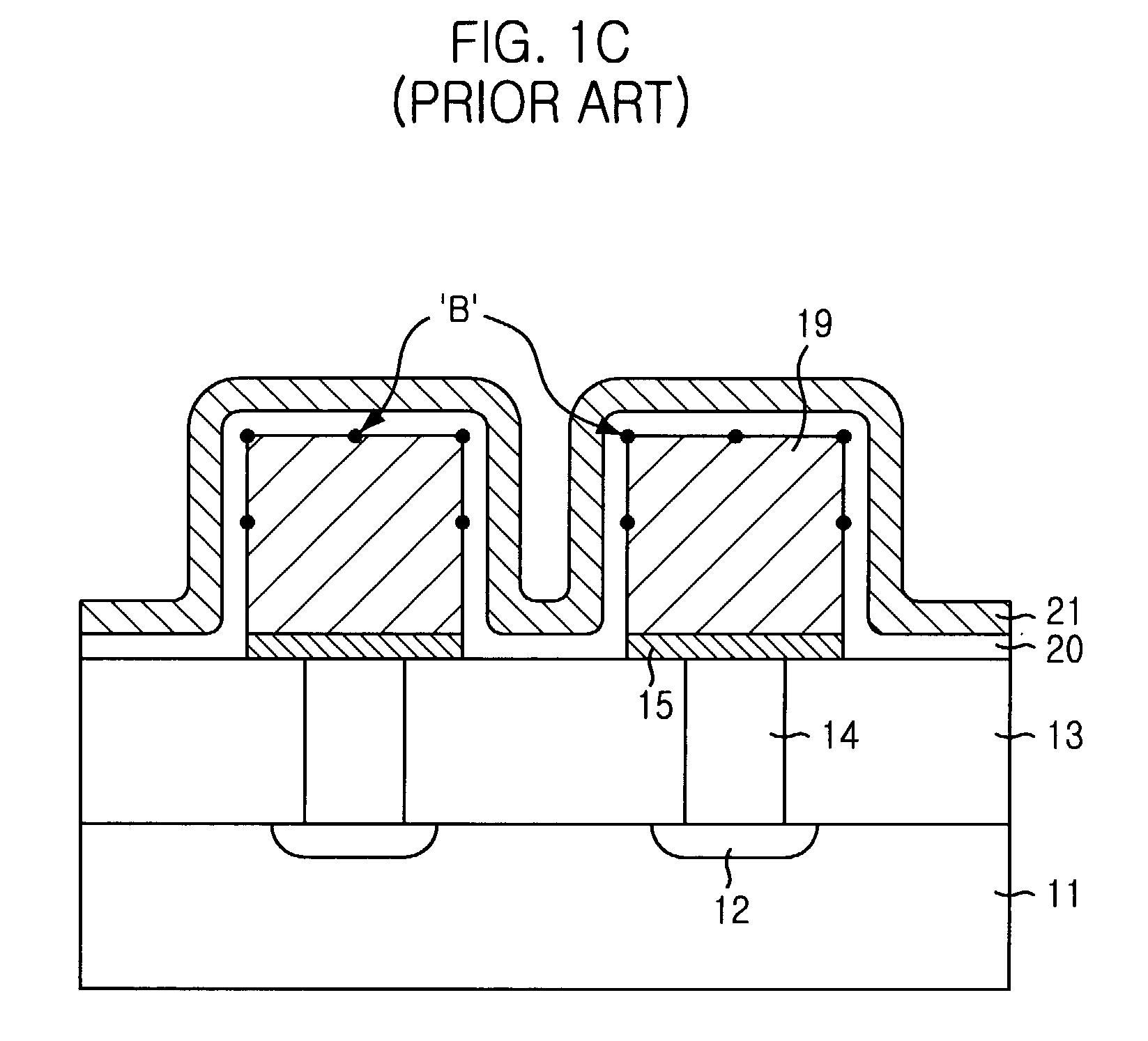

Method for fabricating a capacitor

InactiveUS20030040162A1Improve electrical characteristicReduce defectTransistorSemiconductor/solid-state device manufacturingSemiconductorDielectric layer

Disclosed is a method for fabricating a capacitor, comprising the steps of forming a bottom electrode on the semiconductor substrate by an electro chemical deposition (ECD) technique, performing a wet-cleaning process for removing impurities of a surface of the bottom electrode, forming a dielectric layer on the bottom electrode and forming a top electrode on the dielectric layer.

Owner:SK HYNIX INC

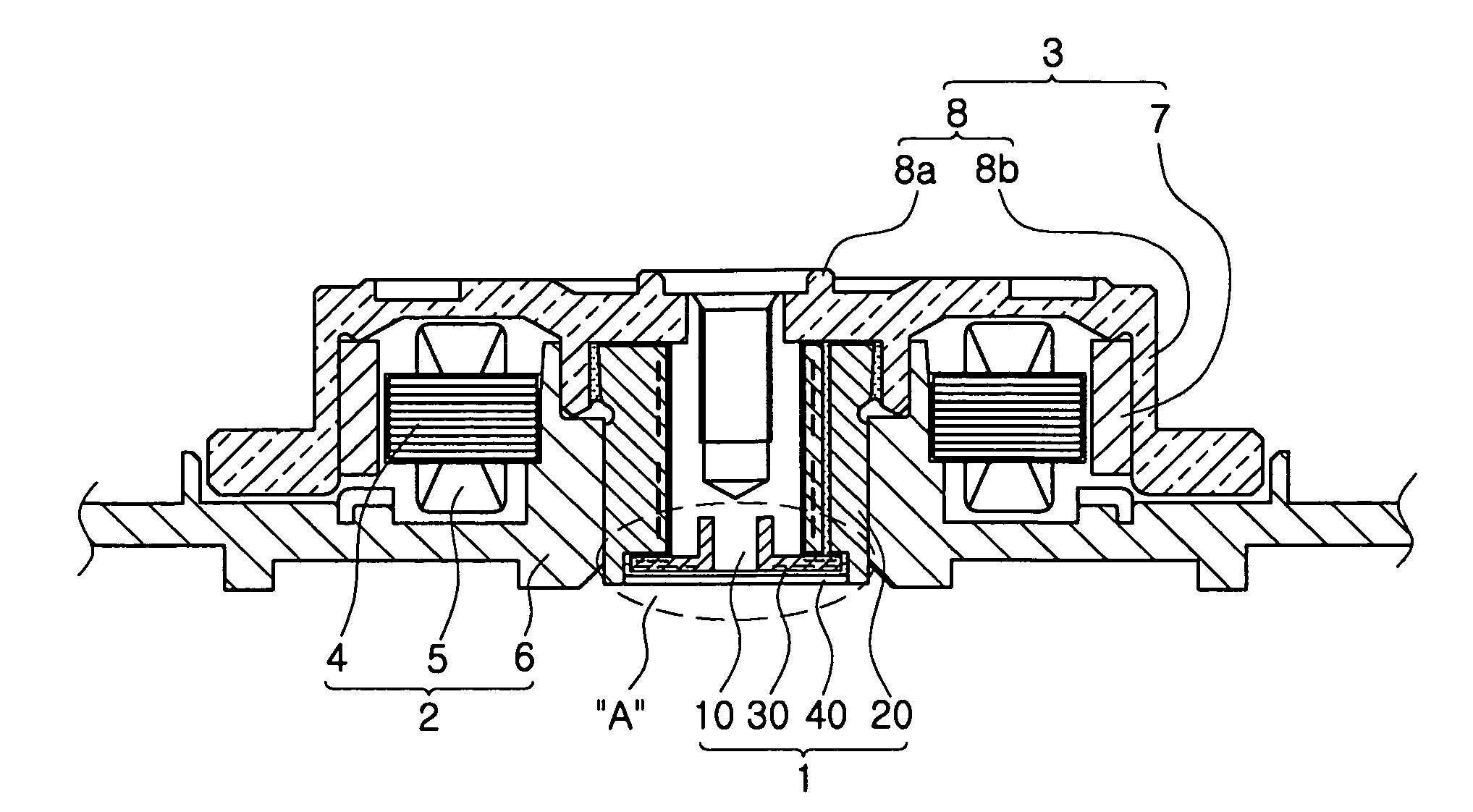

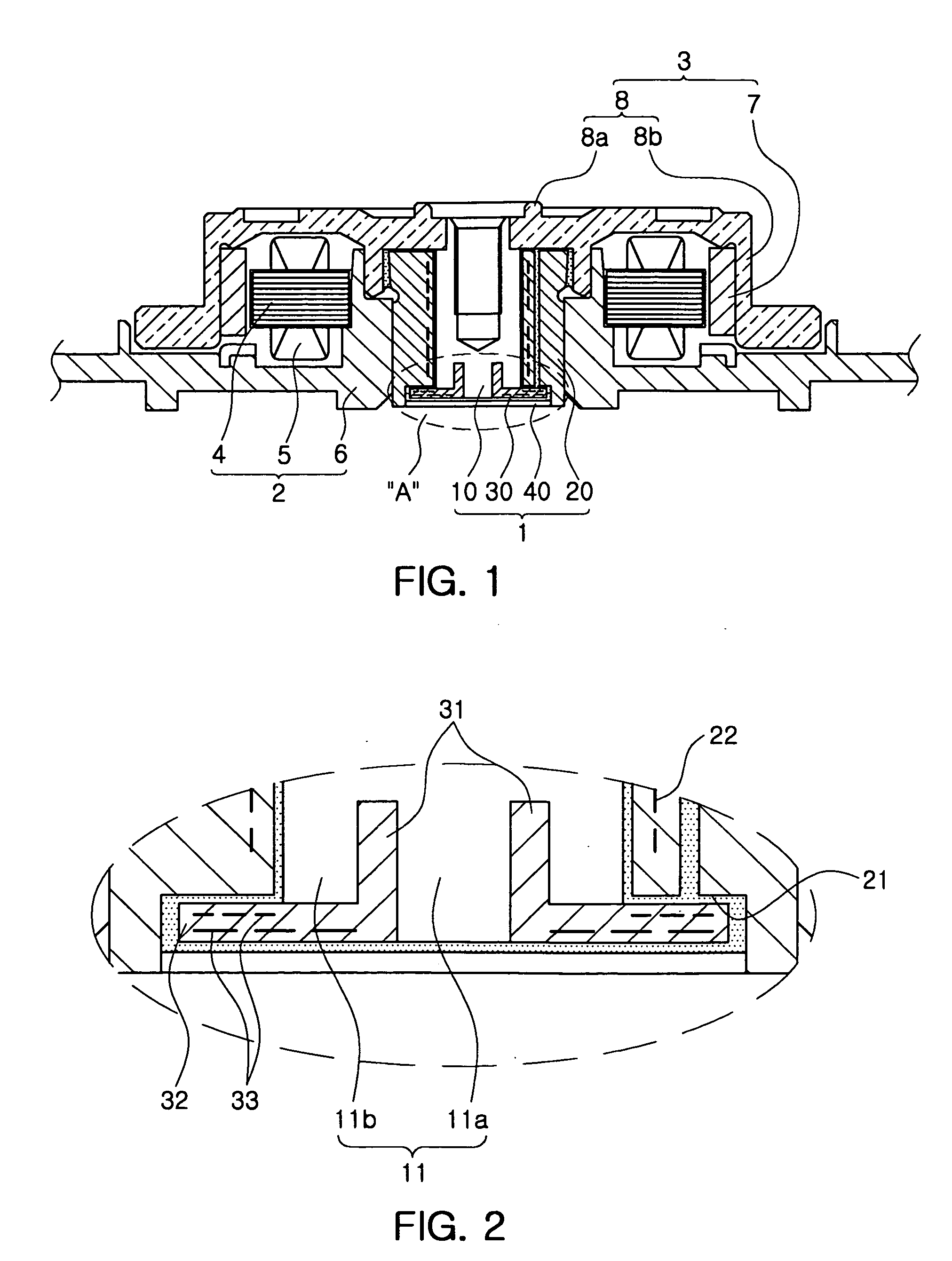

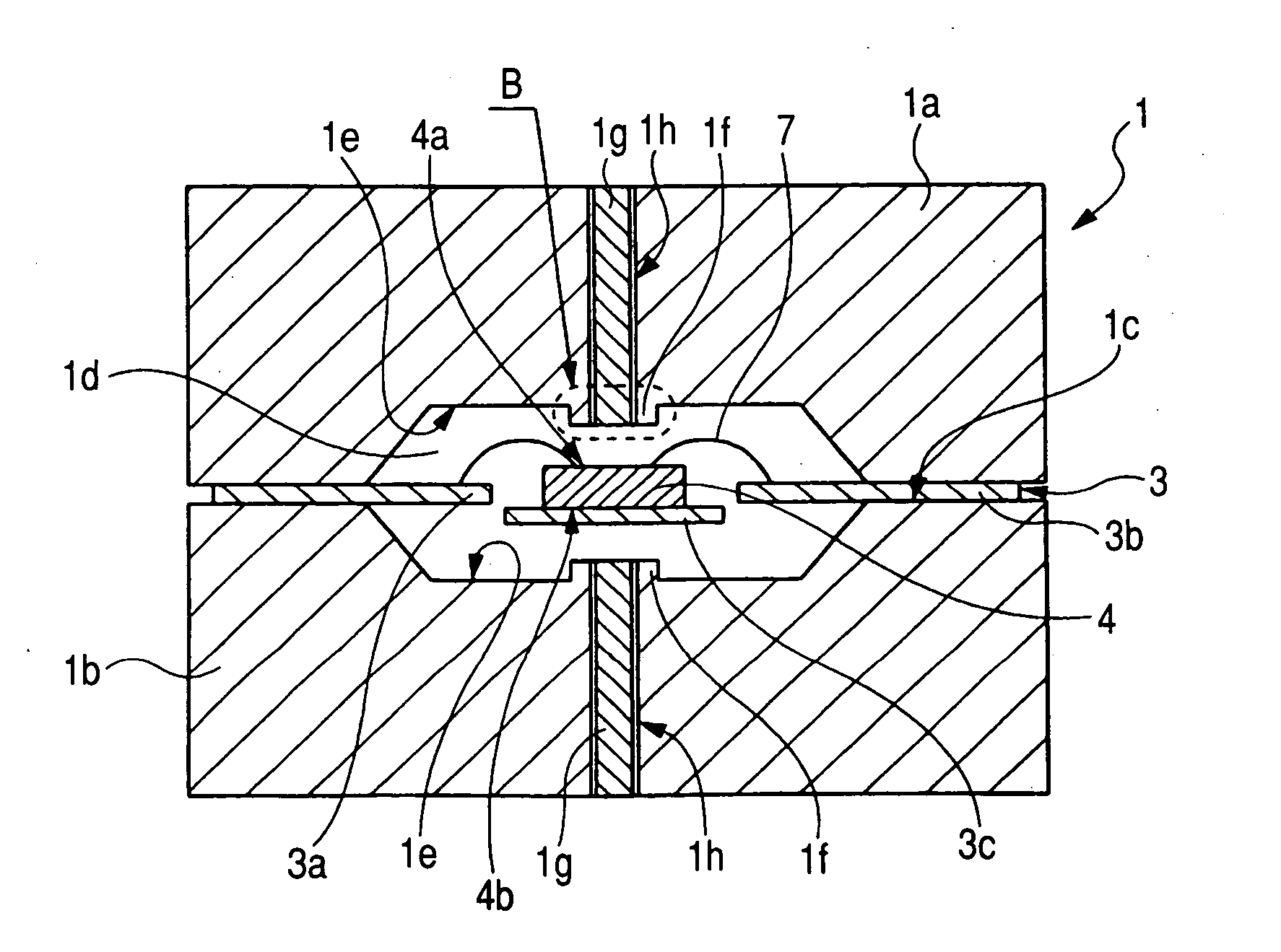

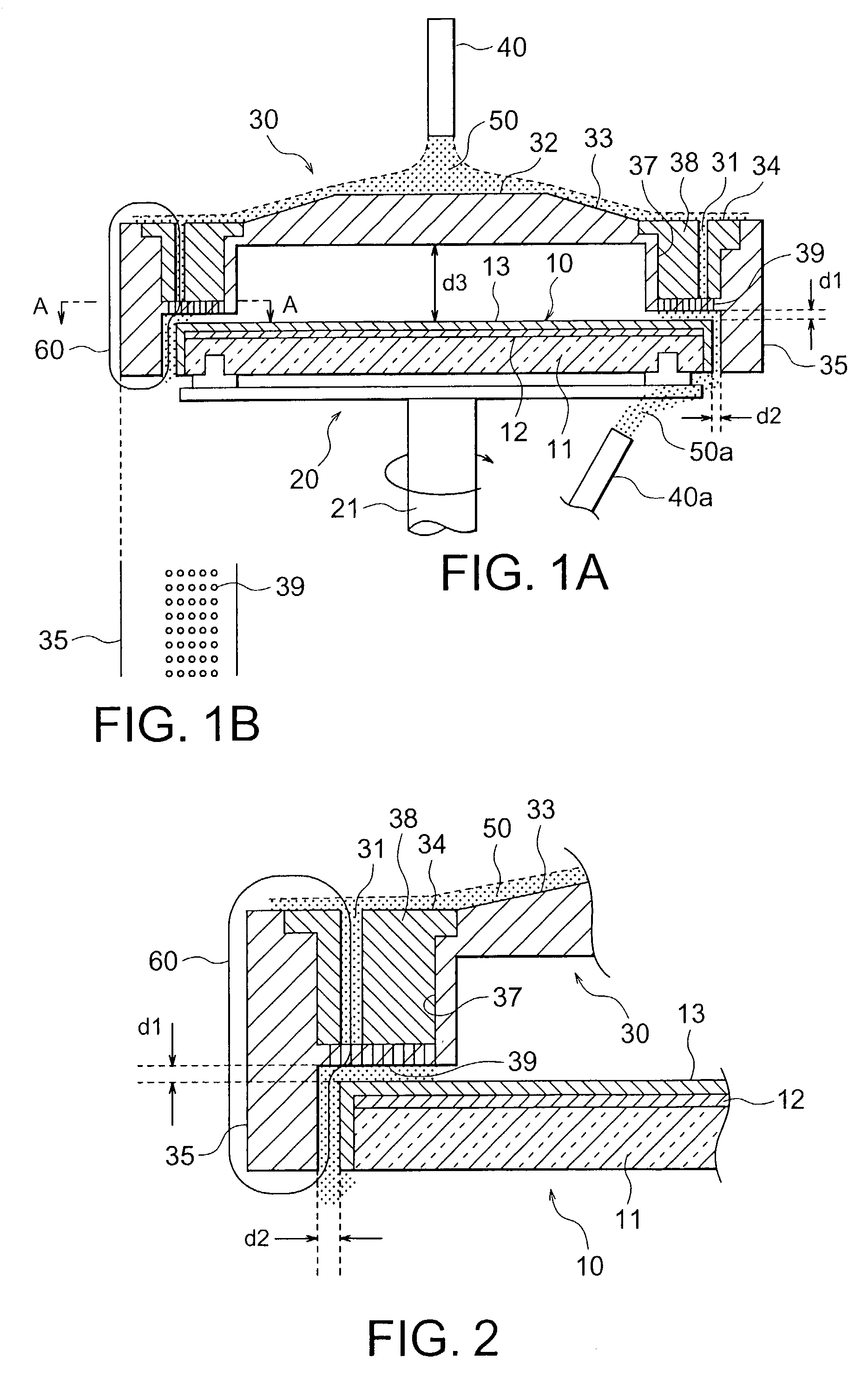

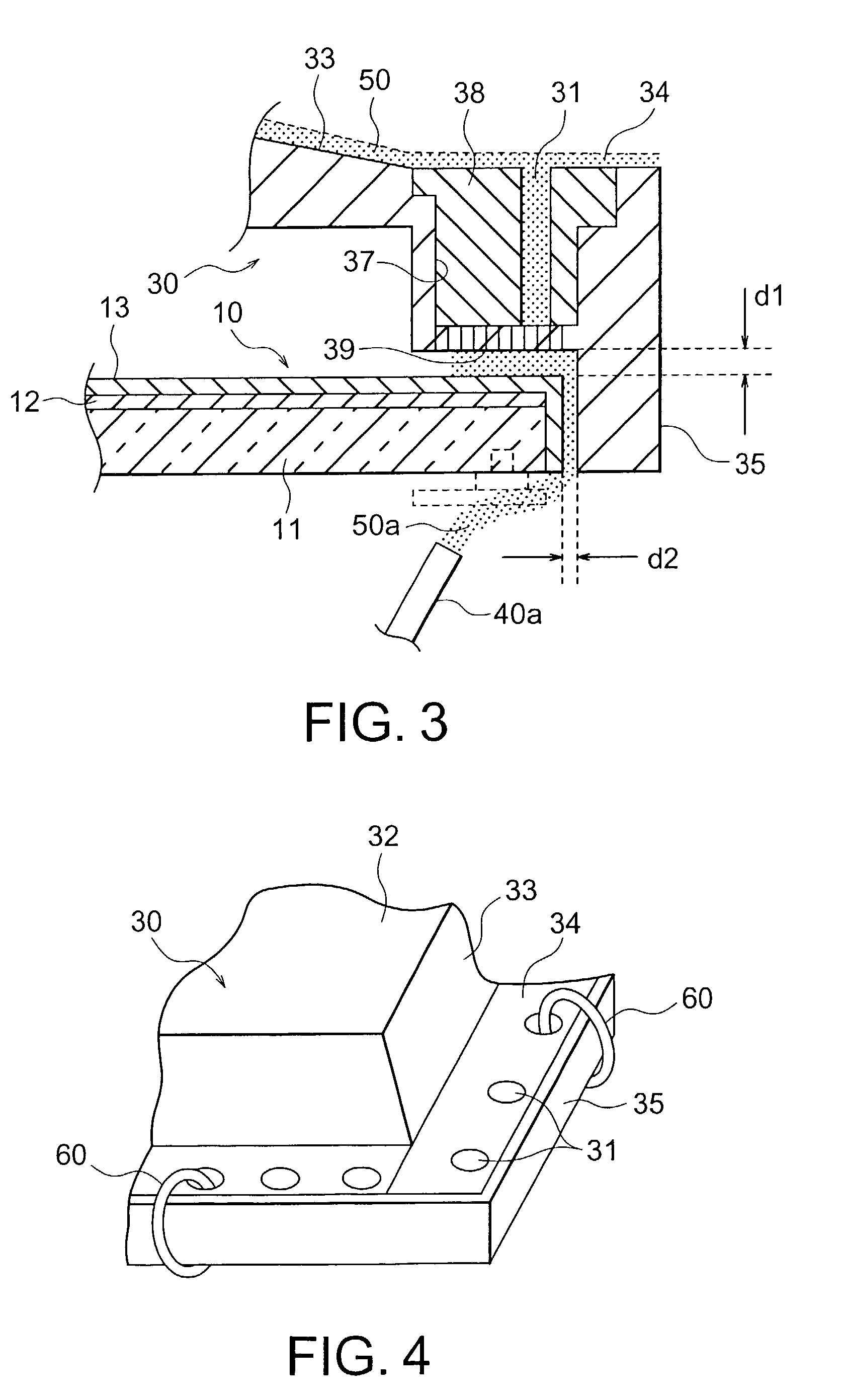

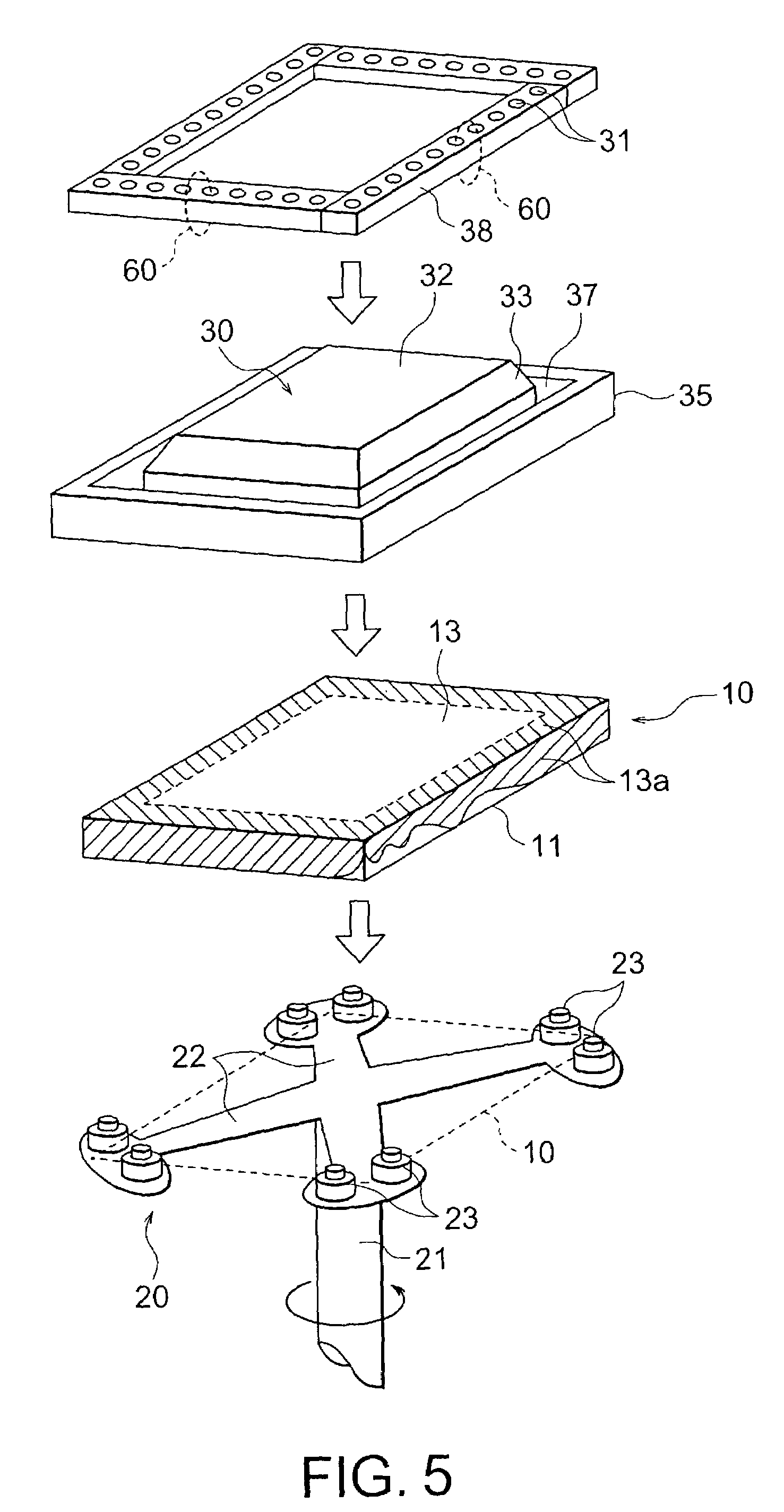

Hydrodynamic bearing assembly and motor including the same

There is provided a hydrodynamic bearing assembly including: a sleeve having a shaft inserted thereinto and supported thereby; a thrust plate coupled to one end of the shaft; an extension part formed at the thrust plate to be extended in an axial direction so as to be coupled to the shaft; and a coupling part formed at the shaft to contact an inner surface of the extension part so as to be coupled to the extension part.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

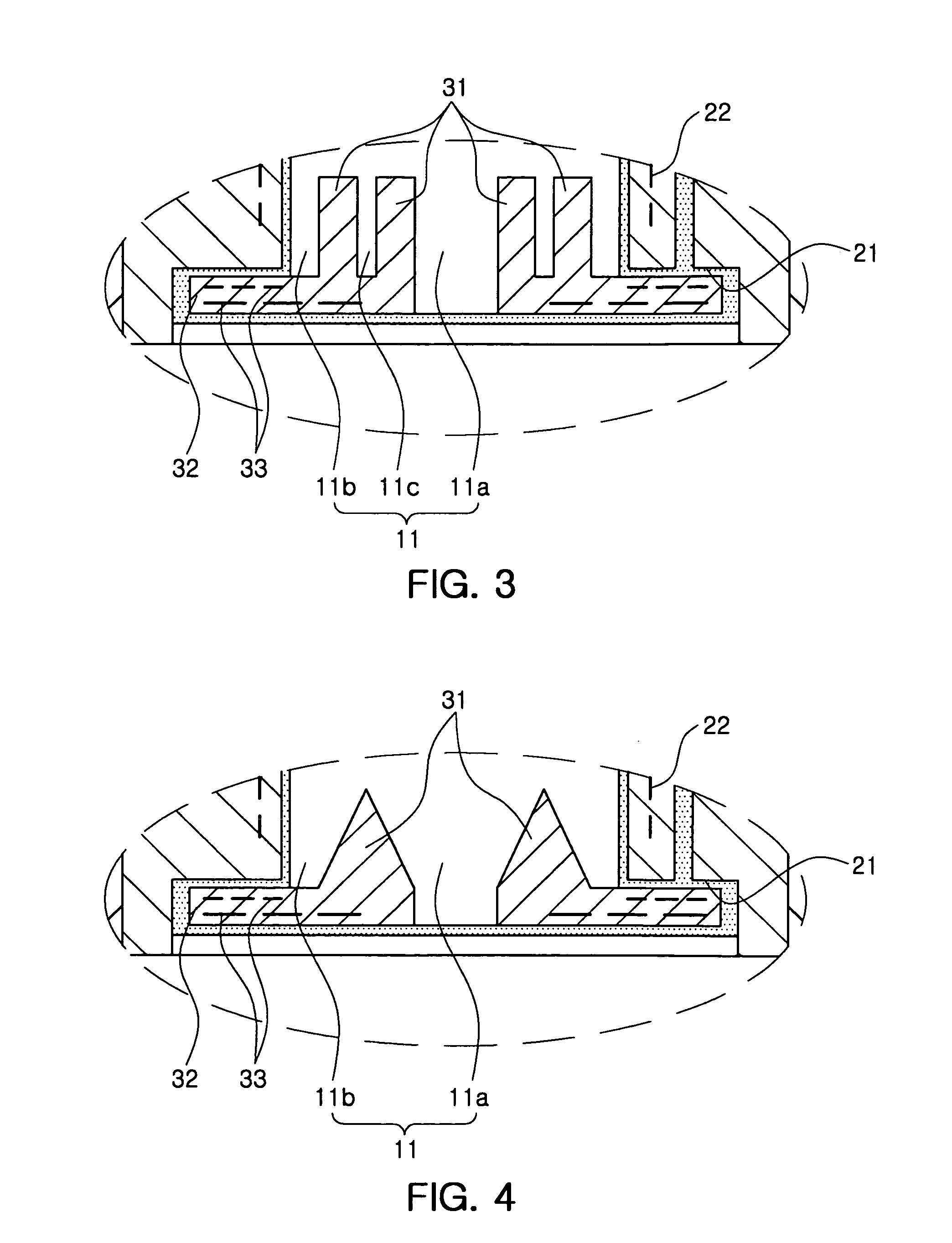

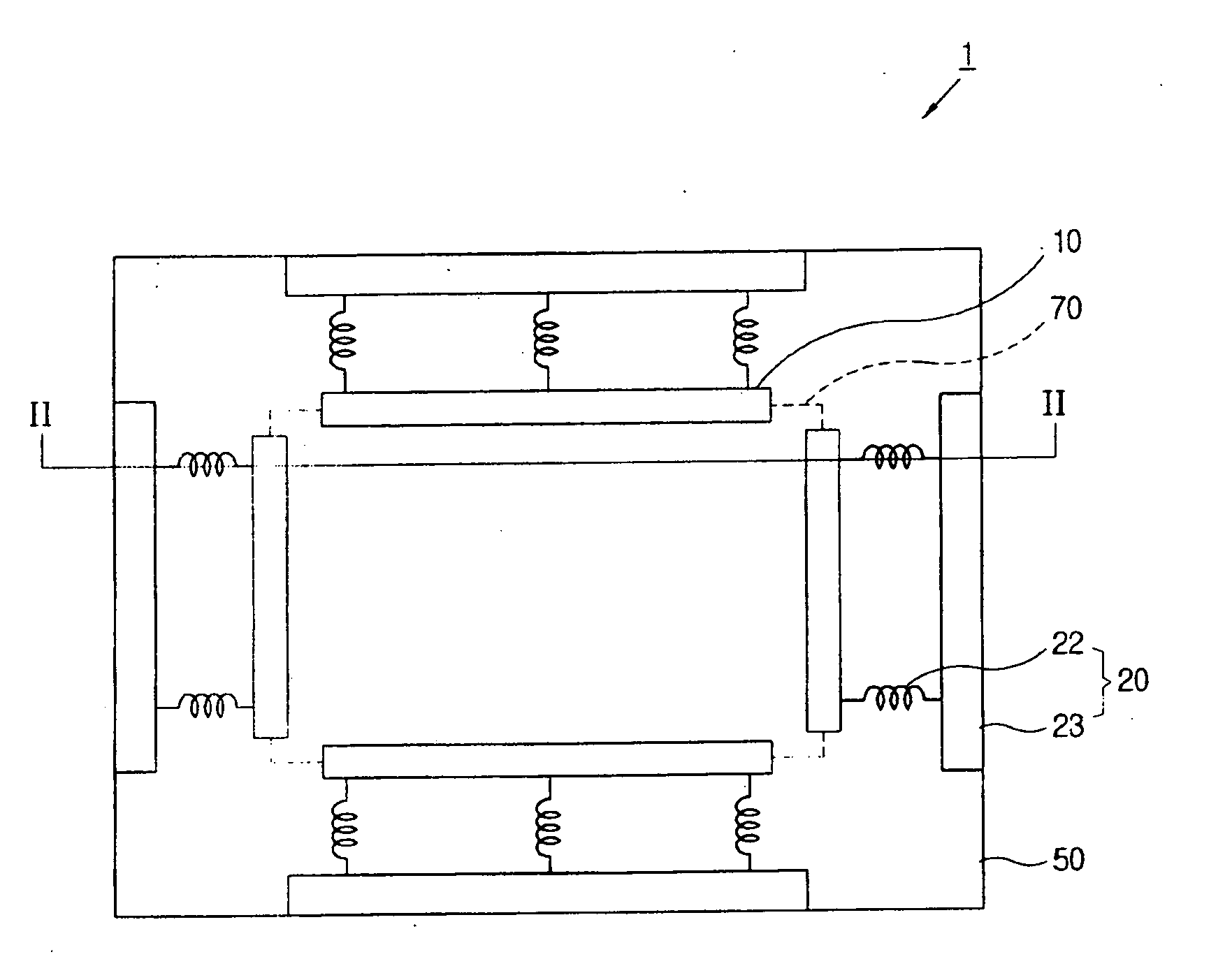

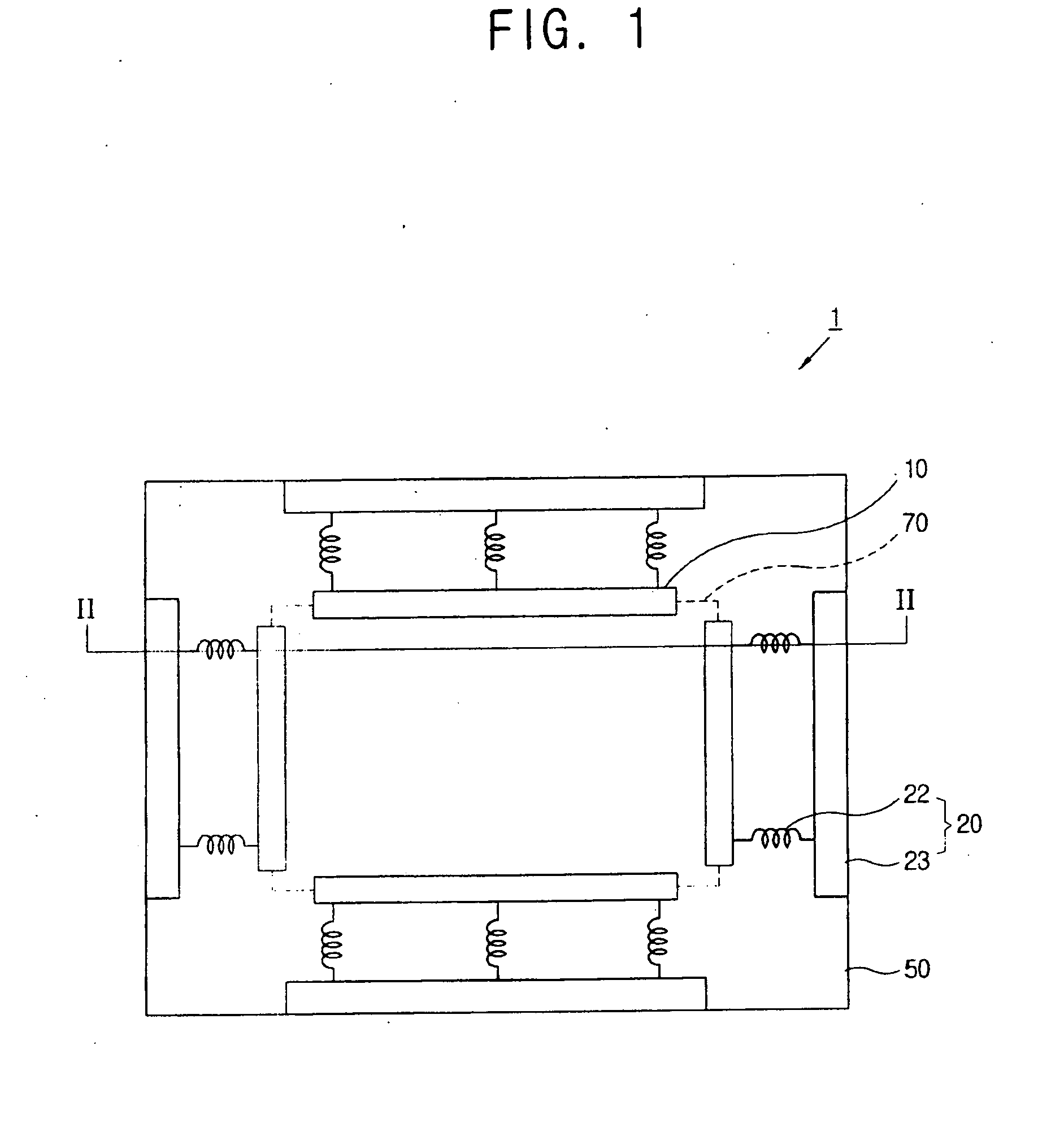

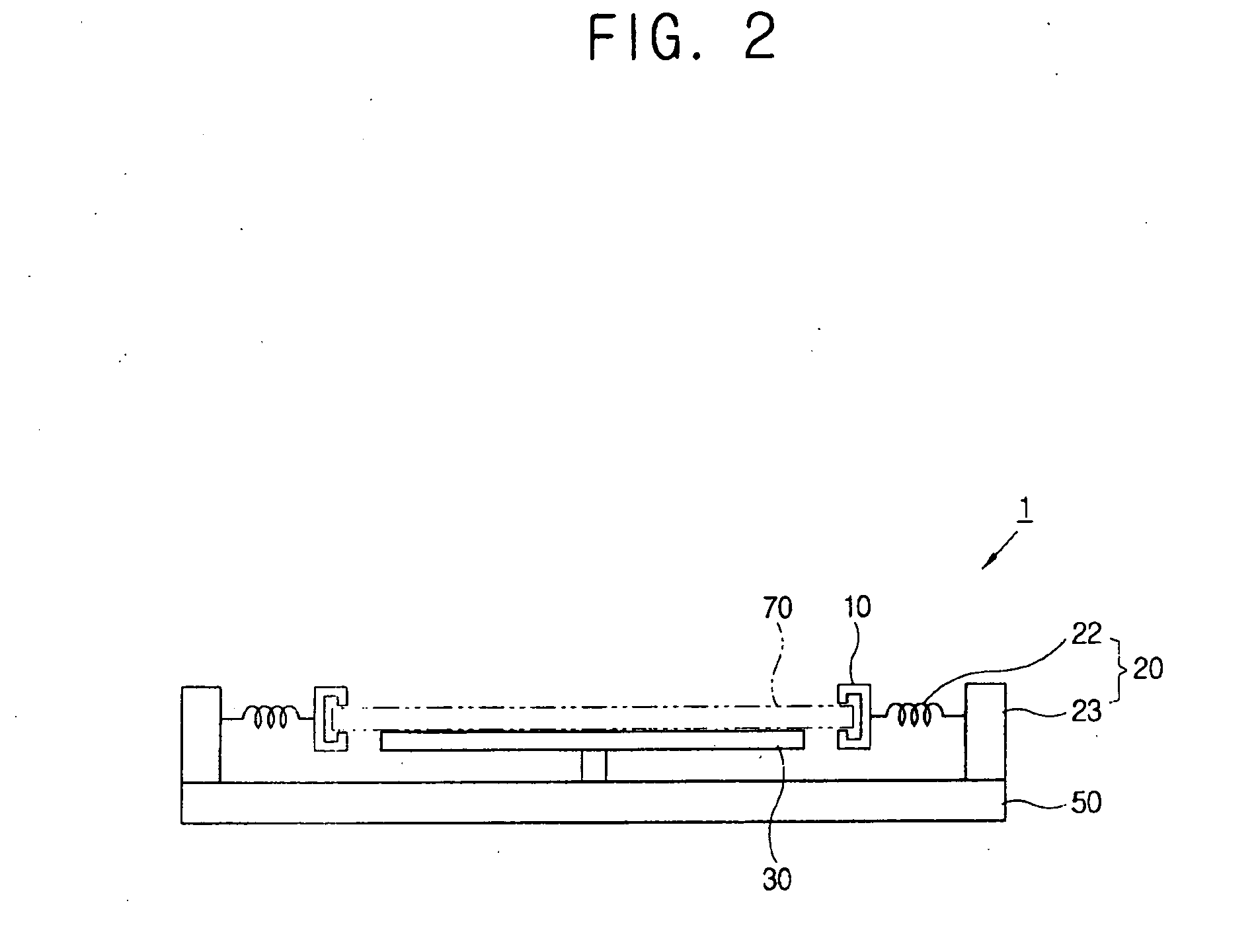

Apparatus and method for manufacturing a display device substrate

InactiveUS20070224717A1Reduce defectReduce defectsSolid-state devicesSemiconductor/solid-state device manufacturingTension memberBiomedical engineering

An apparatus and method for manufacturing a display device substrate are provided. In one embodiment, the apparatus comprises a clamp for clamping an edge of a plastic substrate, and a tension member applying tension along a surface of the plastic substrate by interacting with the clamp to strain the plastic substrate. Advantageously, the flexible plastic substrate is substantially prevented from deflecting in a manufacturing process thereby reducing defects in the display device substrate.

Owner:SAMSUNG DISPLAY CO LTD

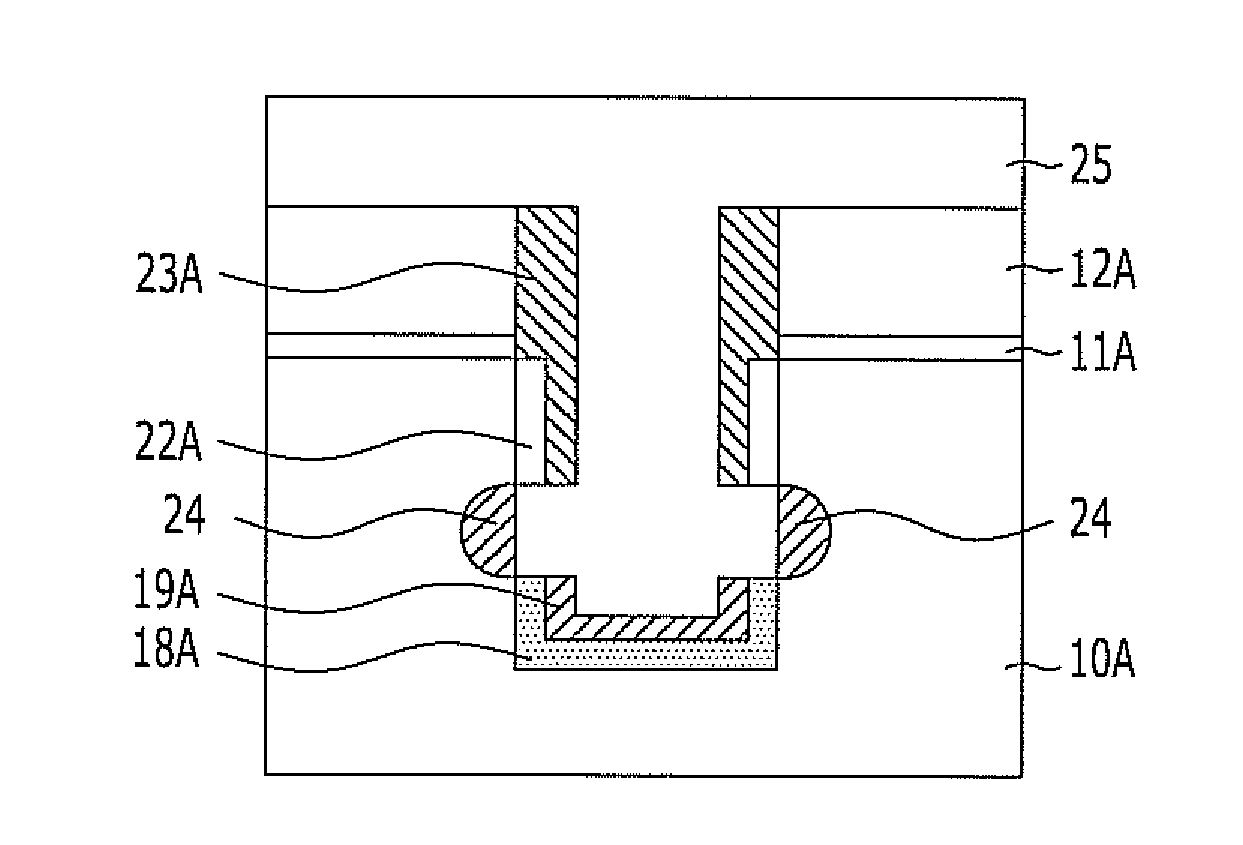

Method of manufacturing a semiconductor device

ActiveUS20060043641A1Reduce defectImproved yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Improvement in the yield of a semiconductor device is aimed at. When extruding a molded body with the ejector pin which performs advance-or-retreat movement at the projecting portion which projects from this bottom face in the bottom face of a mold cavity corresponding to the surface and the mounting side of a molded body after forming a molded body, depressed portions being formed in the surface and the mounting side by projecting portions, they can extrude. When accumulating molded bodies themselves in the baking step after a resin molding step and performing bake, by arranging the resin burr which furthermore withdrew from the surface and the mounting side in the depressed portion, bake can be performed in the condition that the accumulated molded bodies are stuck. Therefore, the form of deformation of a warp etc. of each molded body or a lead frame, can be made uniform, and, as a result, improvement in the yield of QFP (semiconductor device) is aimed at.

Owner:RENESAS ELECTRONICS CORP

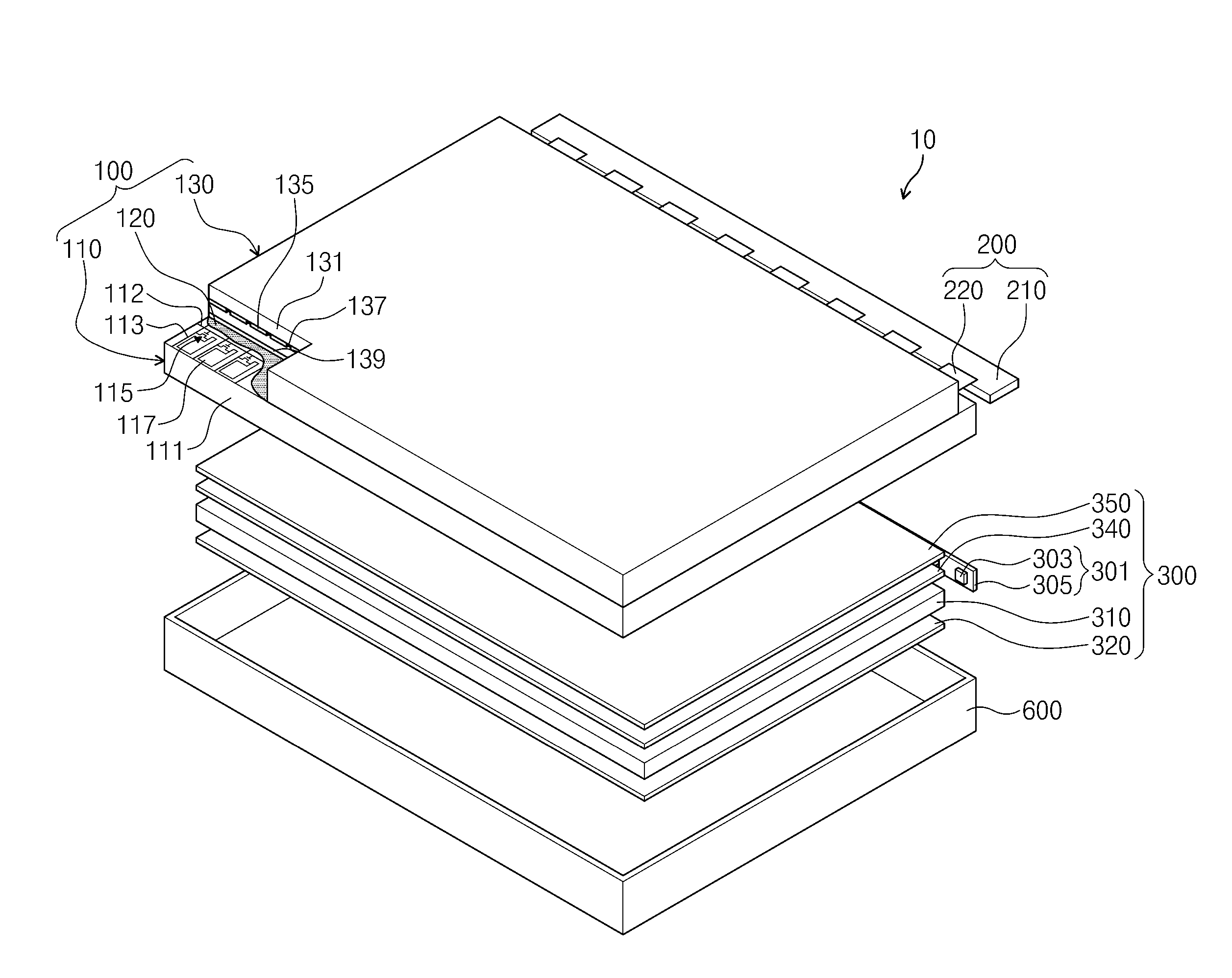

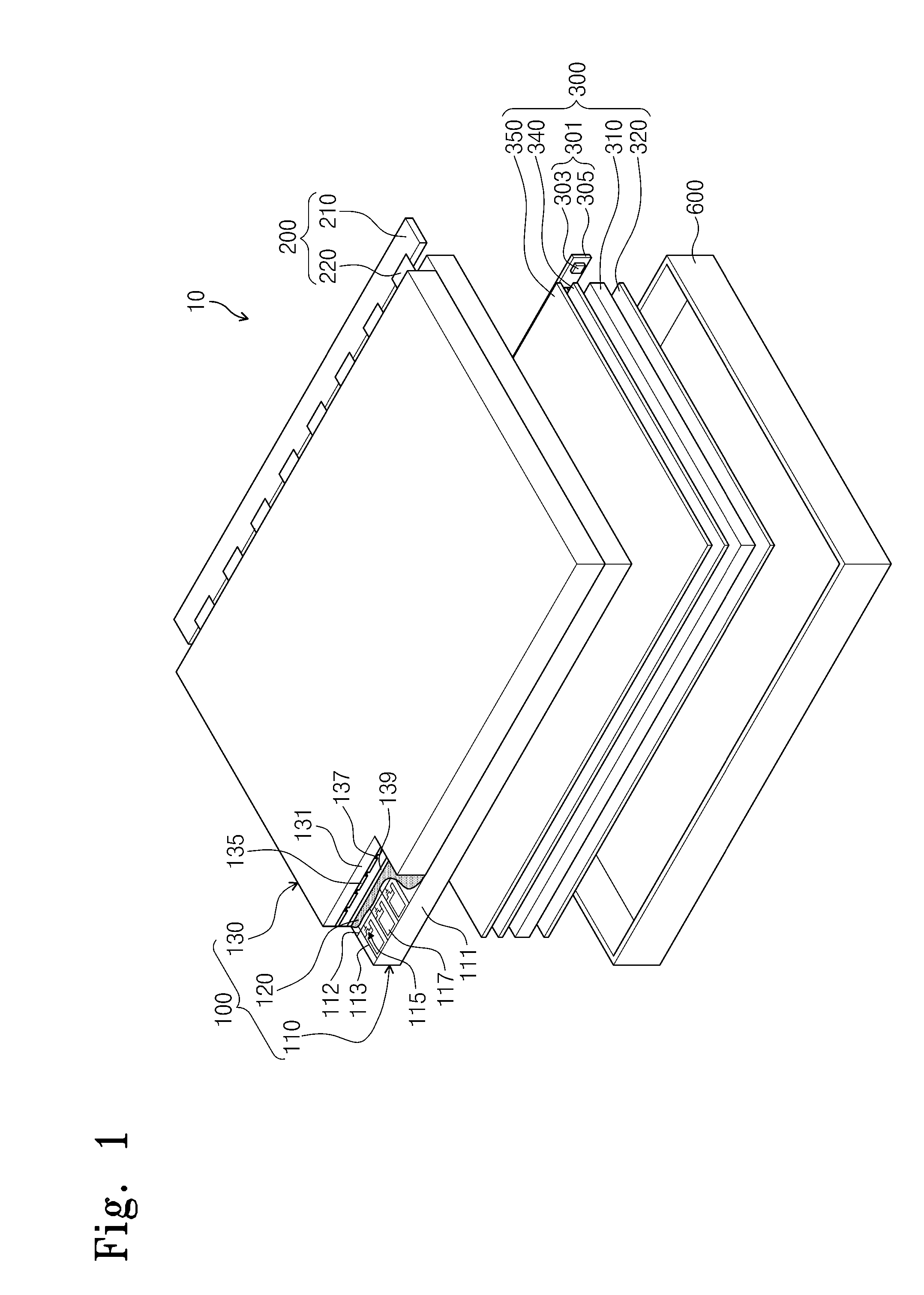

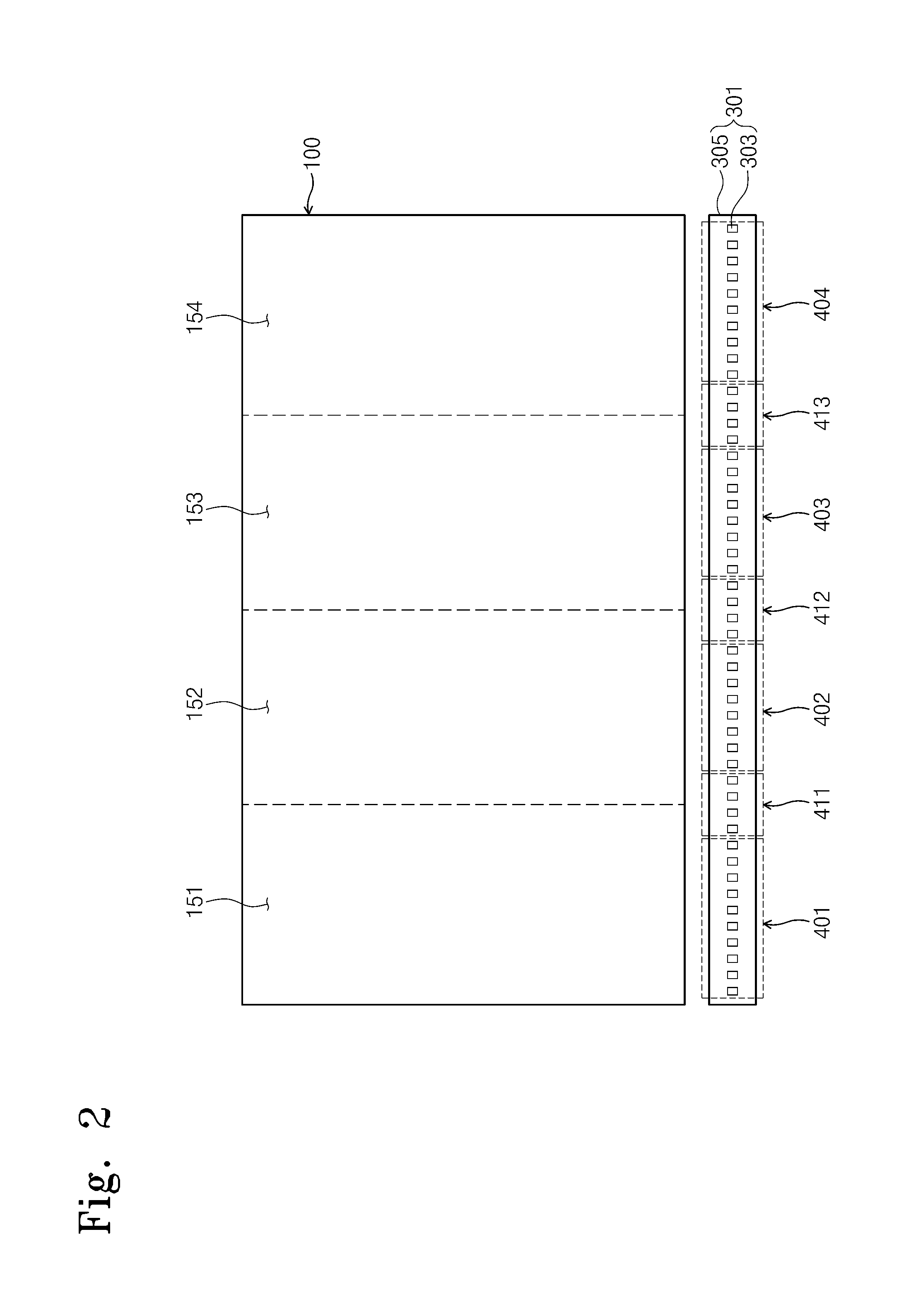

Display apparatus including sub-light source groups

ActiveUS20110037685A1Decrease brightness differenceReduce defectStatic indicating devicesOptical light guidesLight sourceBrightness perception

A display apparatus includes; a display panel which displays an image using a light, wherein the display panel is divided into a plurality of display areas corresponding to the image, a plurality of main-light source groups which each have a plurality of light sources, wherein the main-light source groups are arranged respectively corresponding to the display areas to provide the light thereto, a power source circuit is connected to each main-light source groups to provide a corresponding driving power to each of the main-light source groups, and a plurality of sub-light source groups, each of which is arranged between two adjacent main-light source groups and wherein each sub-light group receives the driving power applied to each of the two main-light source groups adjacent thereto to provide a light corresponding to an average brightness of the two adjacent main-light source groups to a border area between two adjacent display areas.

Owner:SAMSUNG DISPLAY CO LTD

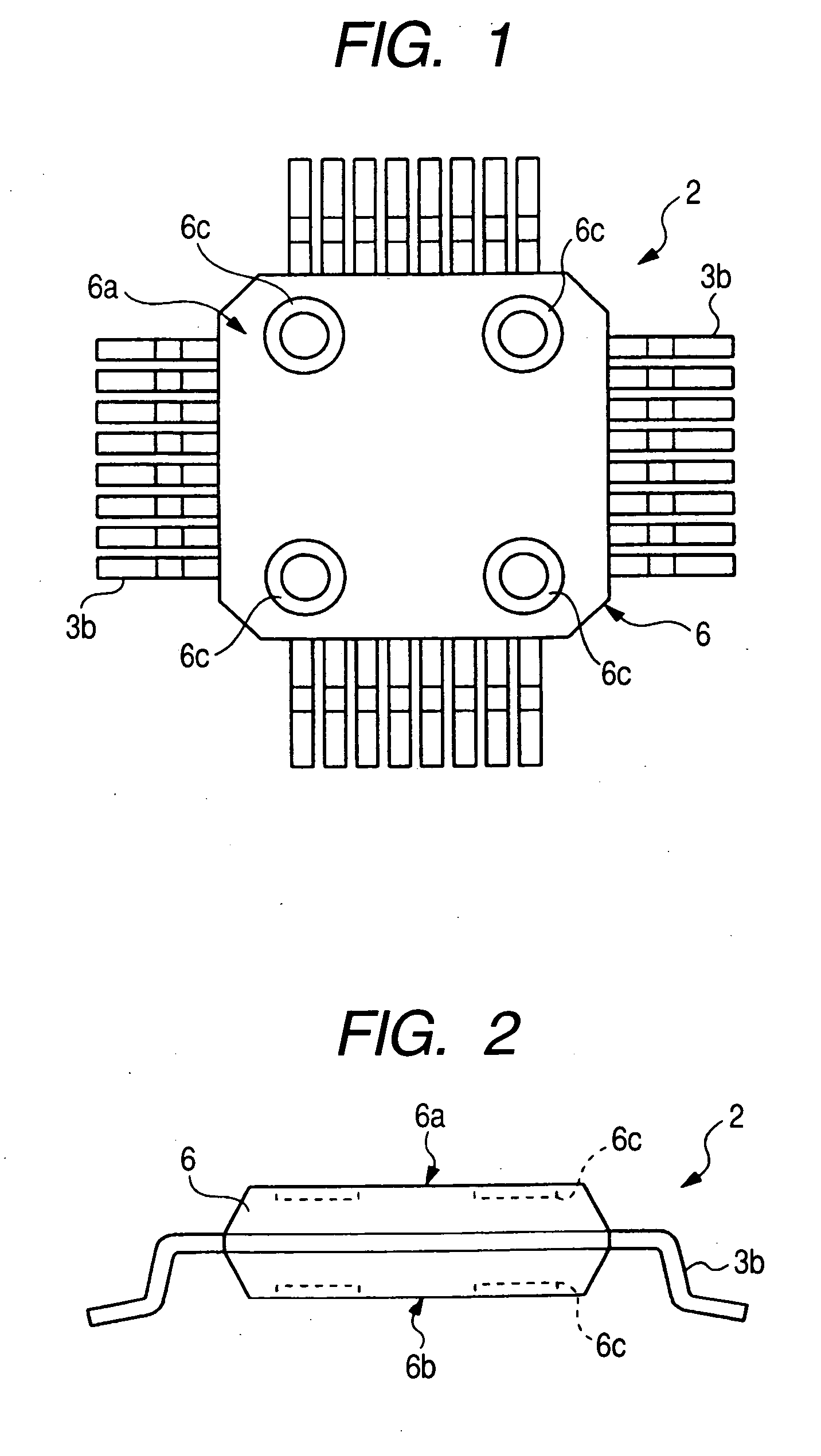

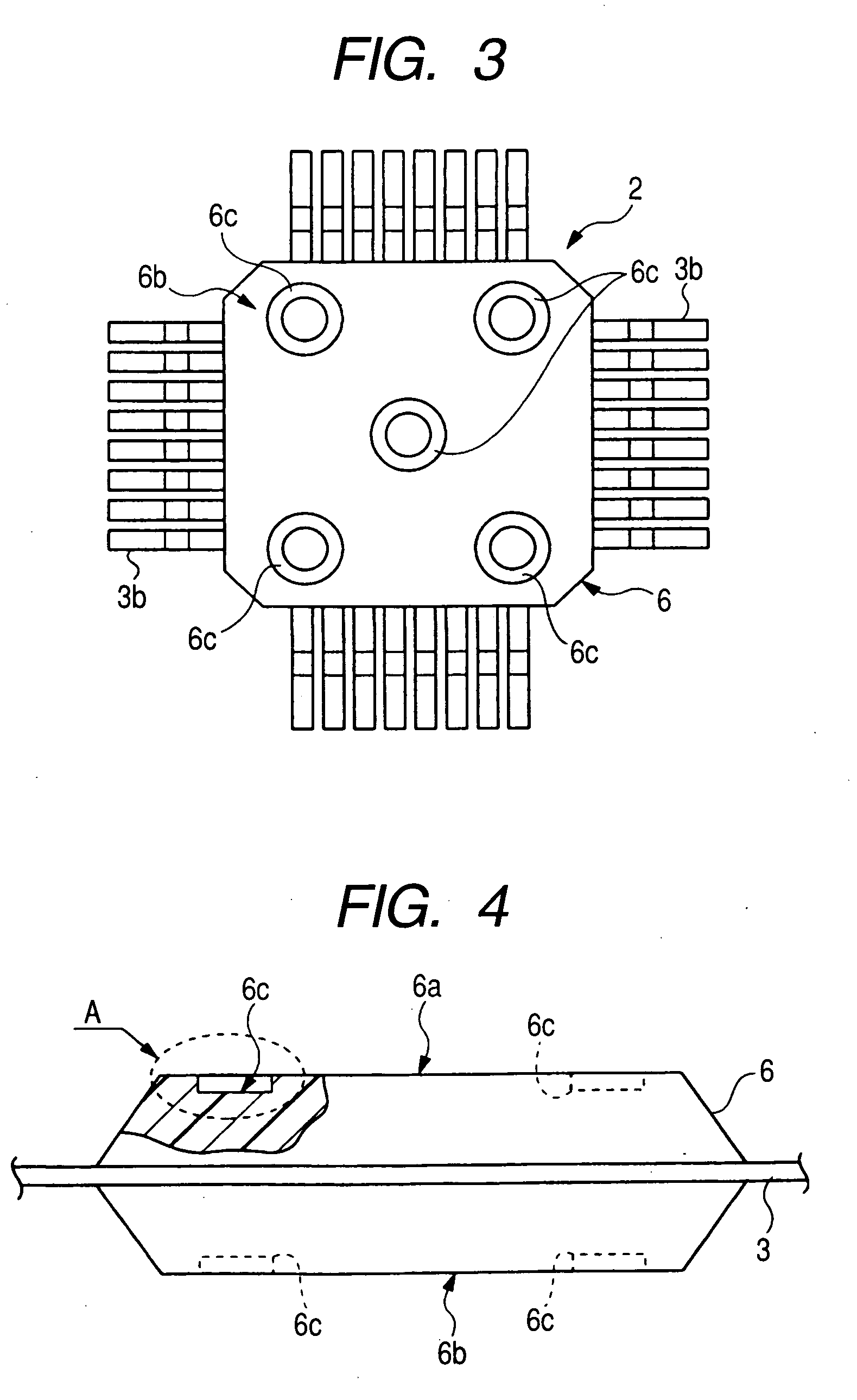

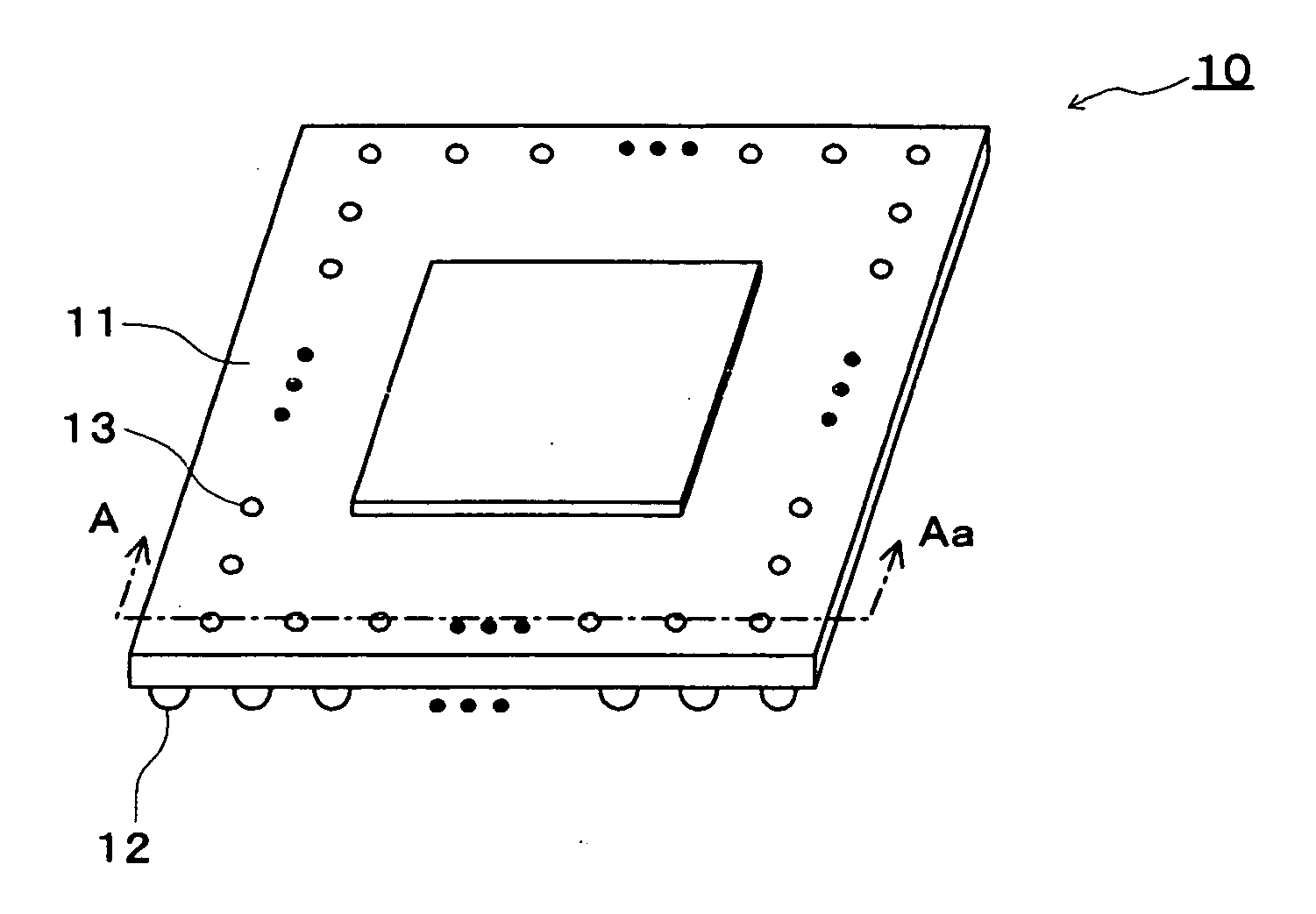

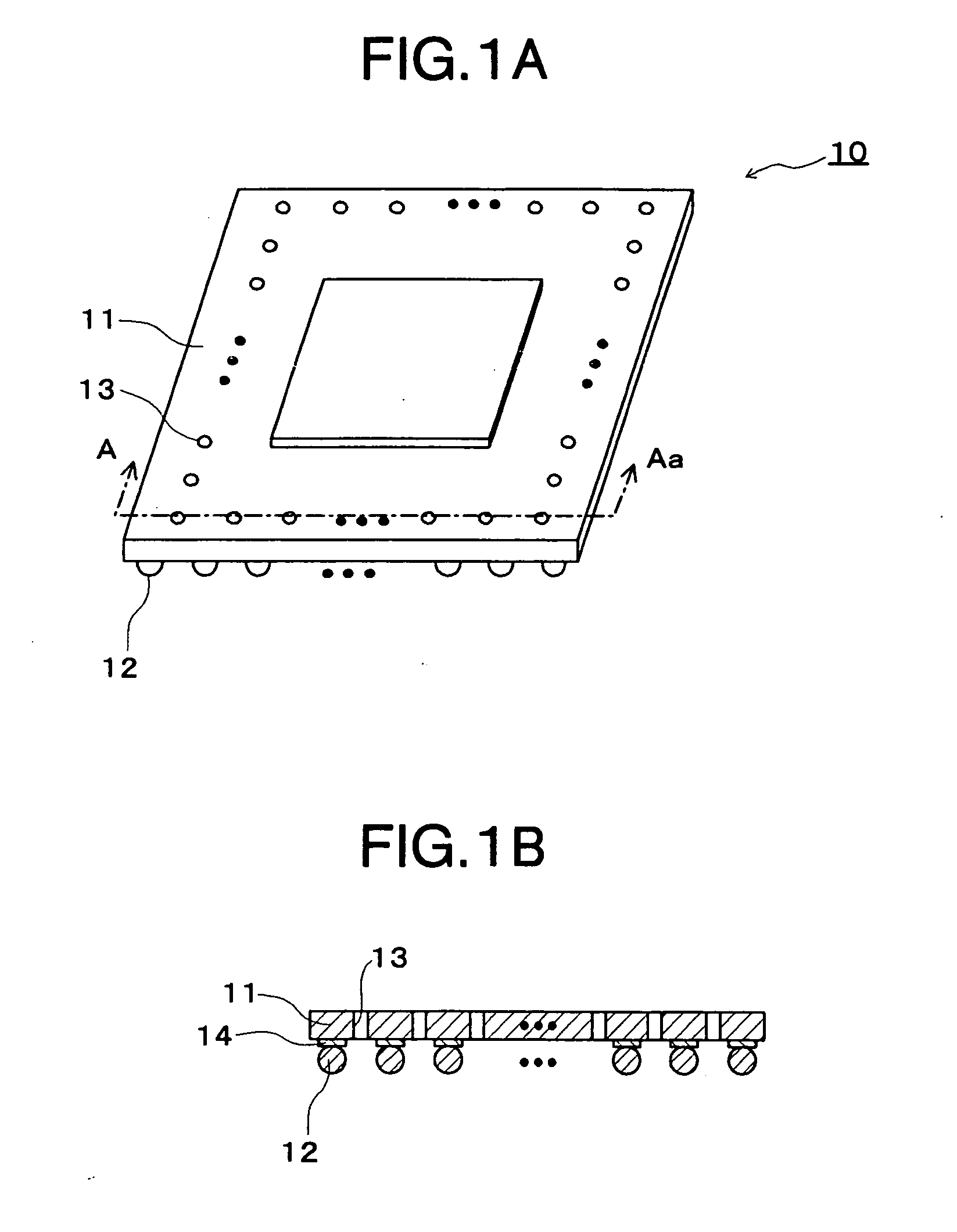

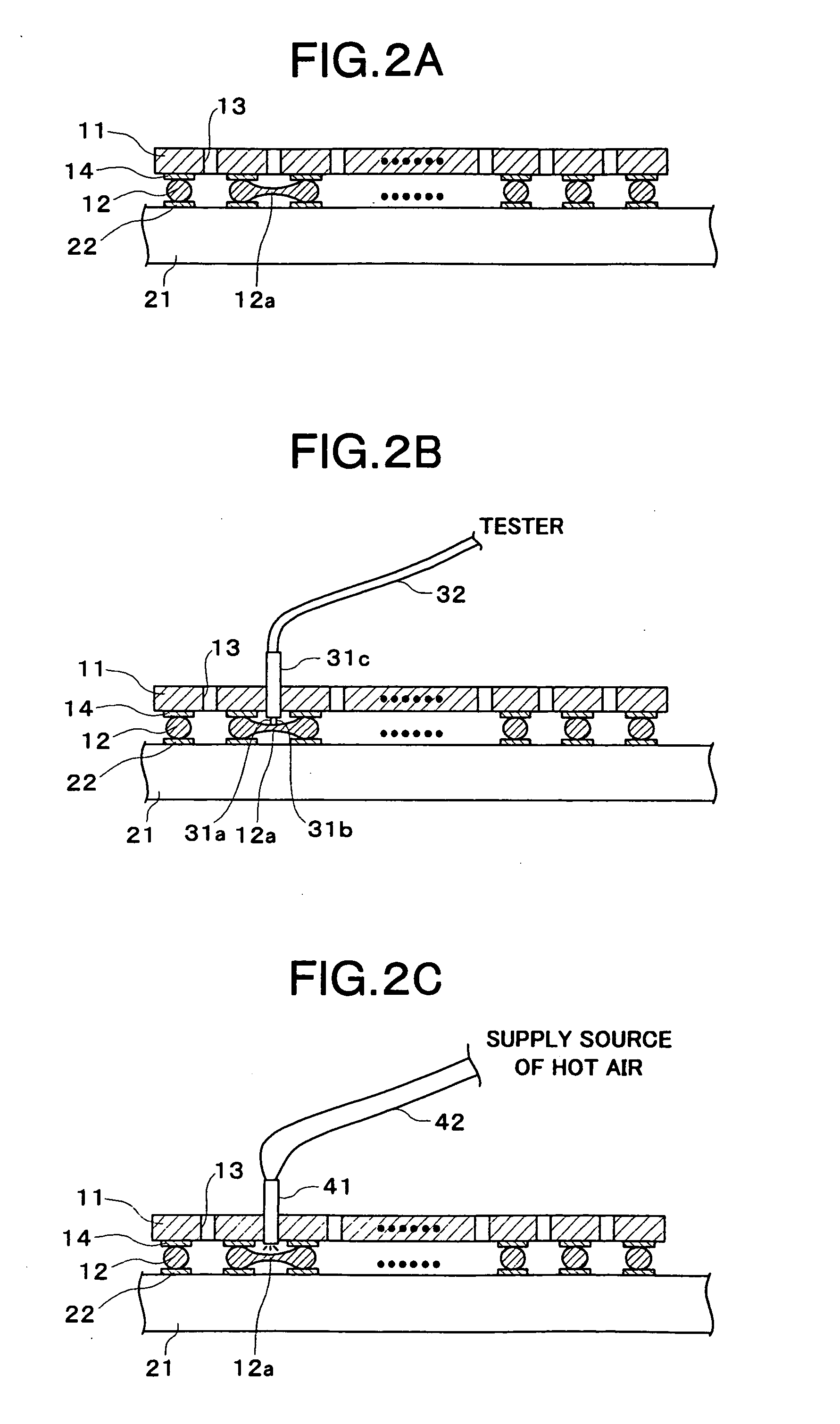

IC package, inspection method of IC package mounting body, repairing method of IC package mounting body, and inspection pin for IC package mounting body

InactiveUS20050211979A1Reduce defectEasily detectPrinted circuit assemblingSemiconductor/solid-state device testing/measurementExternal connectionInspection method

Disclosed is an IC package including an interpose substrate and lands for external connection disposed on a face of the interpose substrate in a grid pattern, the interpose substrate having a penetration hole on at least a position between the lands for external connection disposed in a grid pattern. Besides, there are disclosed an inspection method of an IC package mounting body mounting this IC package, a repairing method of an IC package mounting body mounting this IC package, and an inspection pin for an IC package mounting body used for such an inspection.

Owner:KK TOSHIBA

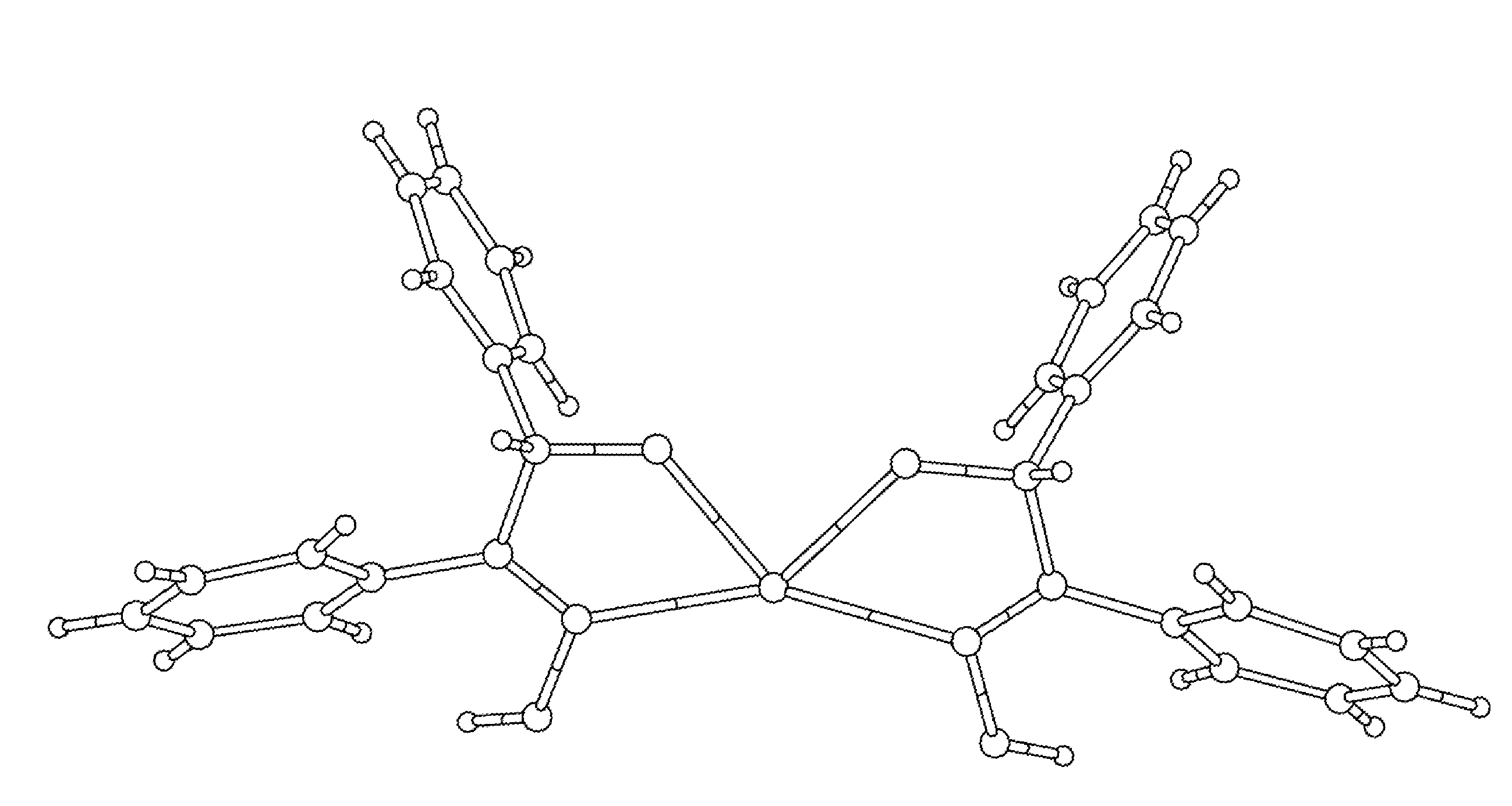

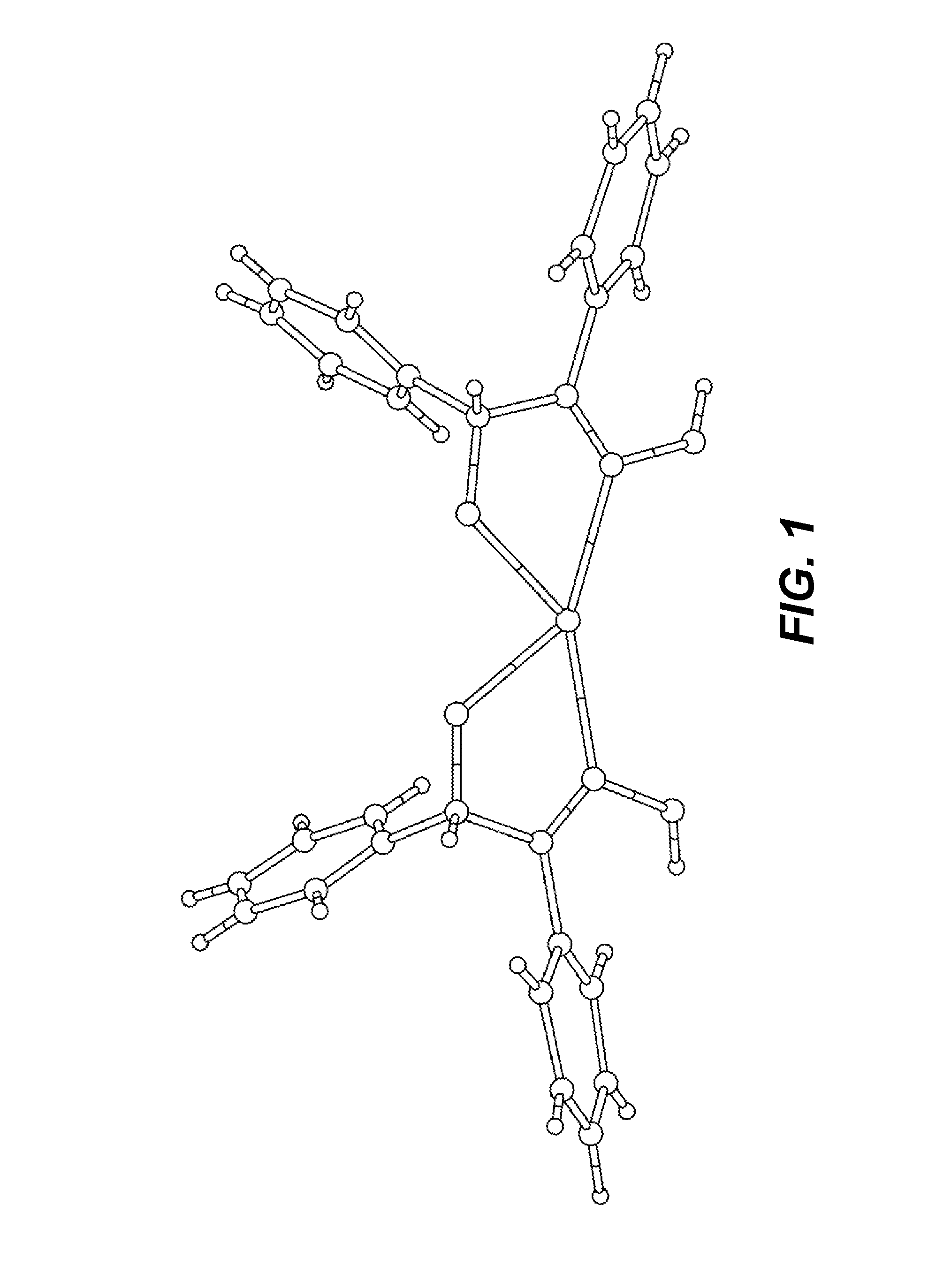

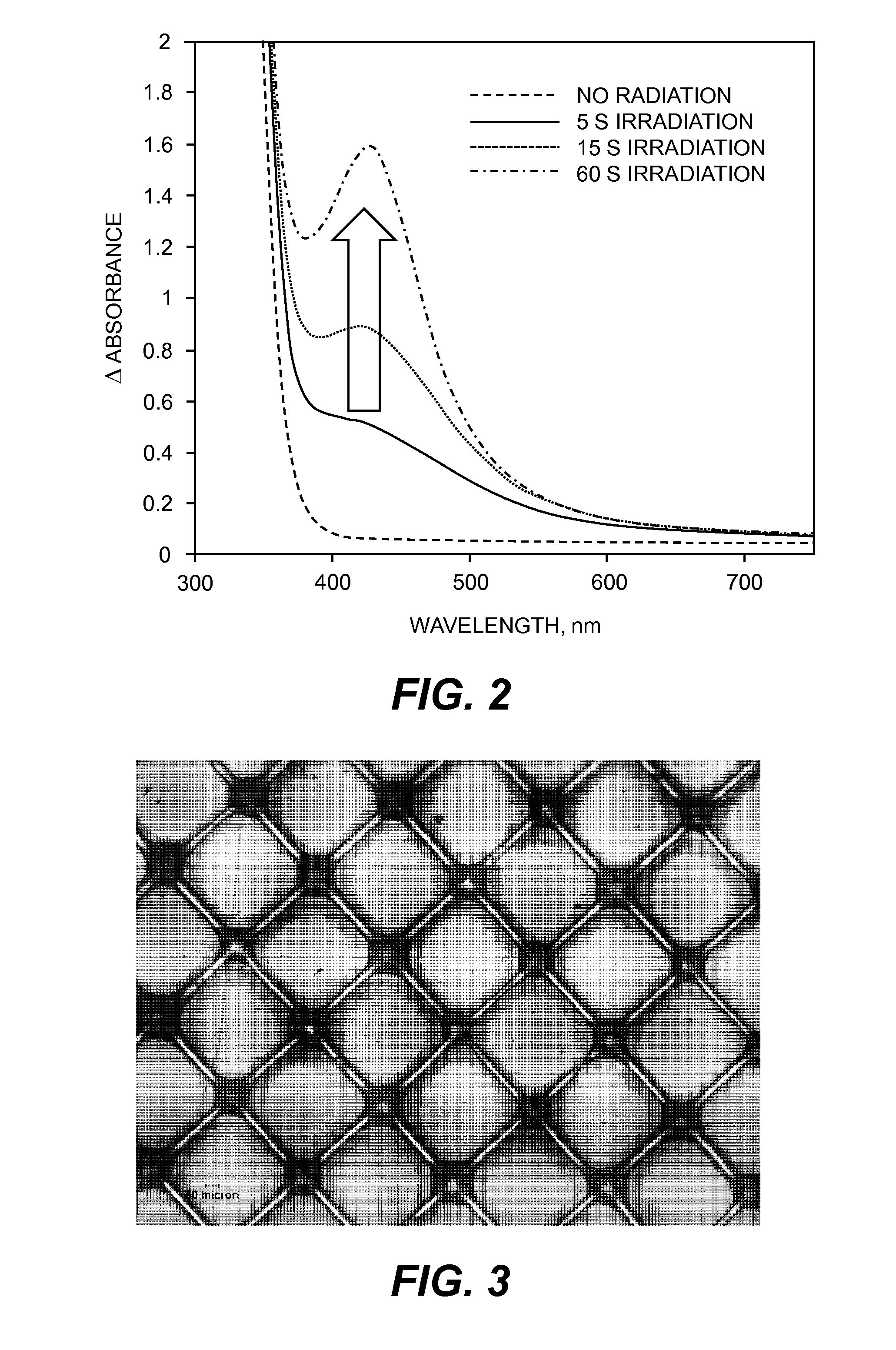

Metal catalytic composition with silver-oxime complex

ActiveUS20160167021A1Reduce errorReduce defectOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectroless platingElectrically conductive

A non-aqueous metal catalytic composition includes (a) a complex of silver and an oxime comprising reducible silver ions in an amount of at least 2 weight %, (b) a silver ion photoreducing composition in an amount of at least 1 weight %, and (c) a photocurable component, a non-curable polymer, or a combination of a photocurable component and a non-curable polymer. This non-aqueous metal catalytic composition can be used to form silver metal particles in situ during suitable reducing conditions. The silver metal can be provided in a suitable layer or pattern on a substrate, which can then be subsequently subjected to electroless plating to form electrically-conductive layers or patterns for use in various articles or as touch screen displays in electronic devices.

Owner:EASTMAN KODAK CO

Method of manufacturing a mask blank and a mask, the mask blank and the mask, and useless film removing method and apparatus

InactiveUS7226705B2Reduce defectAccurate exposureSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusSolventEngineering

In a method of removing a useless film formed along a circumferential portion of a substrate, so as to provide a removed portion, a cover member is covered over the substrate to supply a solvent to the useless portion through solvent supply holes. The circumferential portion which has the removed portion and a non-removed portion serves to provide an identification code or the like for identifying the substrate. The solvent supply holes are formed in a solvent guide member which is exchangeably attached to a peripheral portion of the cover member. The substrate may be either a mask blank or a mask that has the identification pattern formed by removing the useless film by the above-mentioned method.

Owner:HOYA CORP

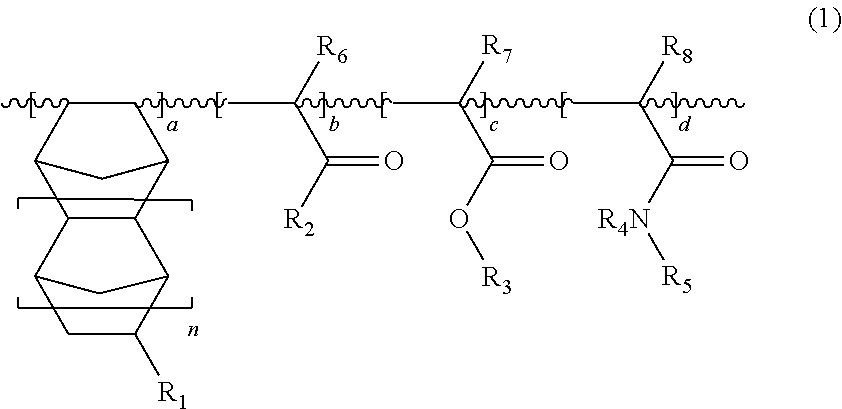

Water-soluble resin composition and method of forming fine patterns by using the same

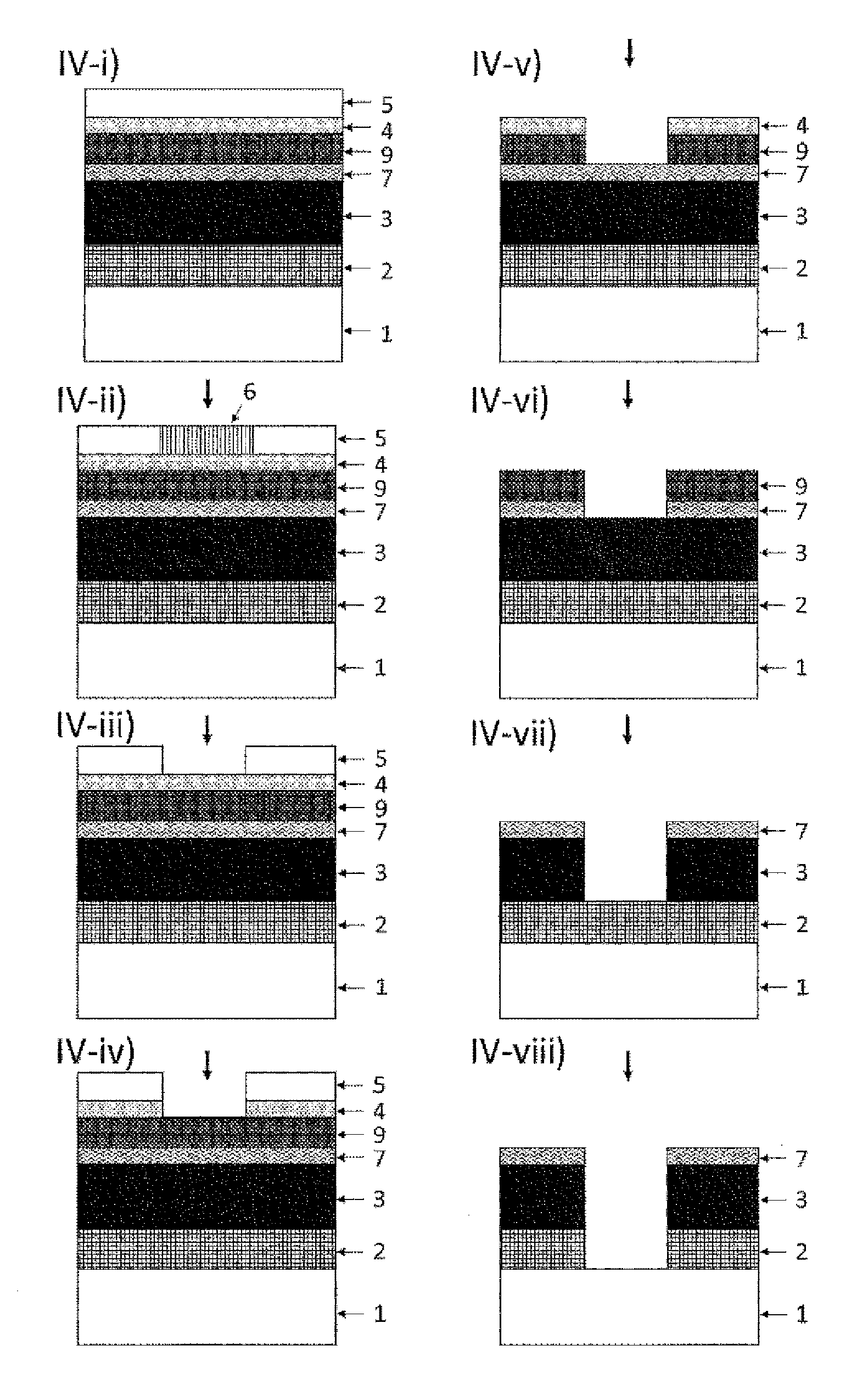

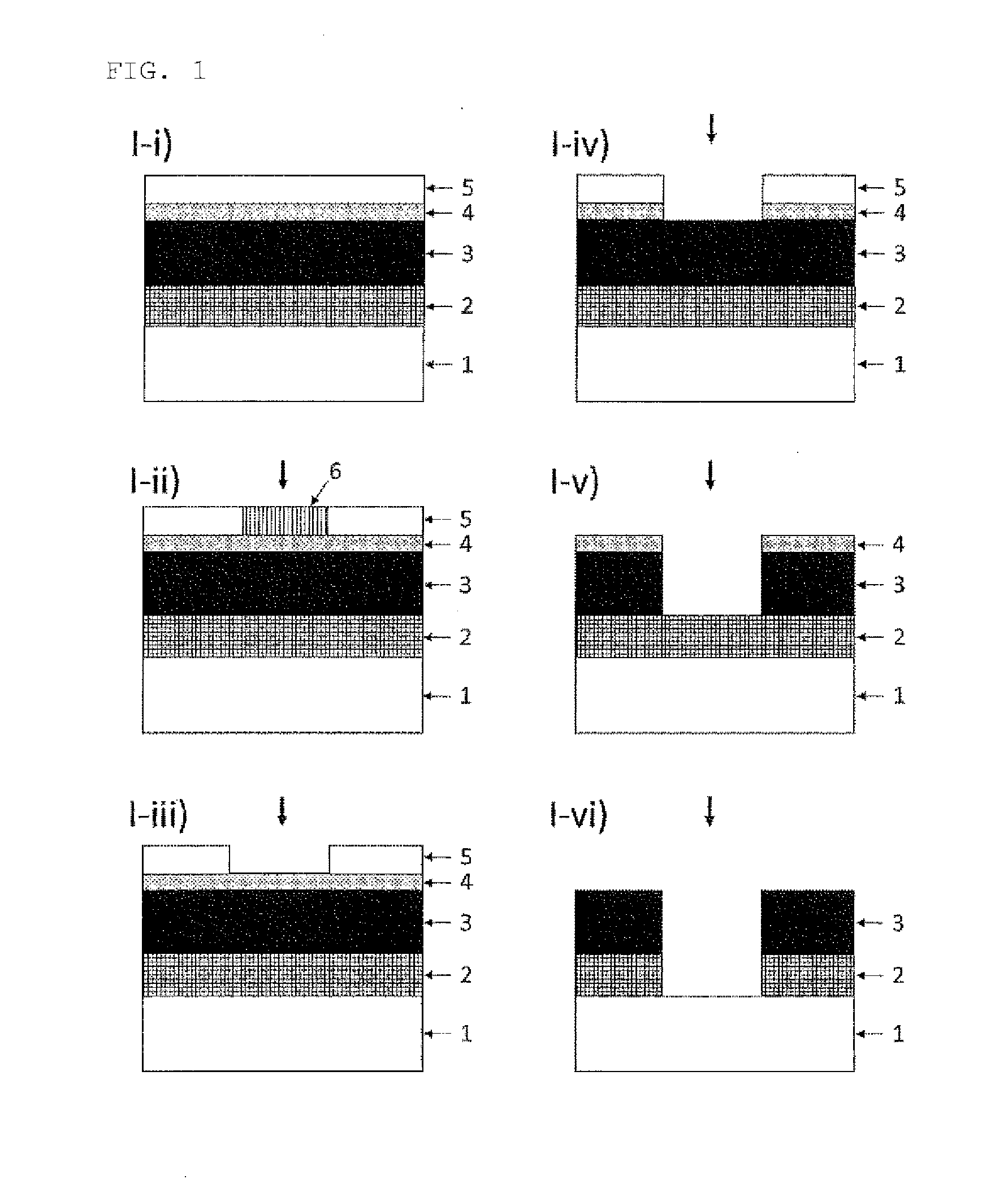

InactiveUS20120189963A1Reduce defectIncrease miniature and stabilitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusSolventWater soluble polymers

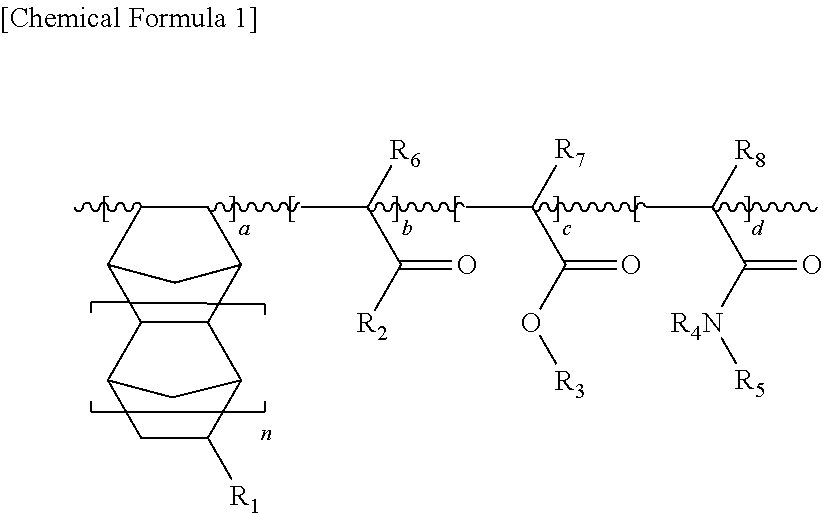

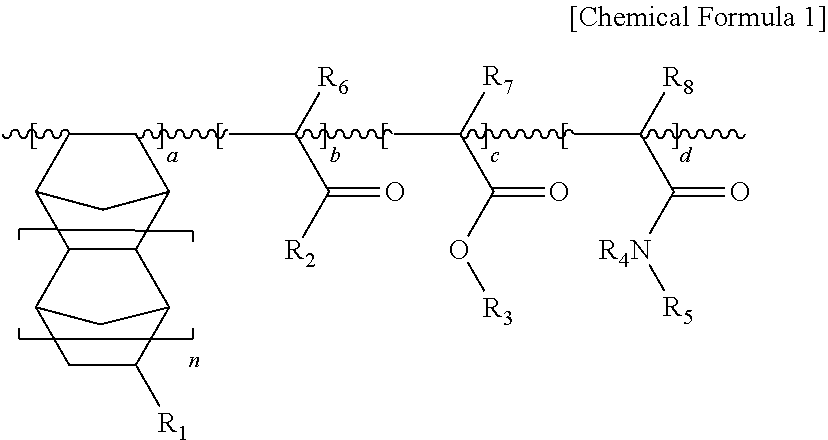

A water-soluble resin composition for forming fine patterns comprising water-soluble polymer represented by Chemical Formula 1 as below and the first water-soluble solvent, is coated and heated on a photoresist layer having at least one contact hole to reduce a size of the at least one contact hole.(In Chemical Formula 1,each of R1, R2, R3 and R5 independently represents an alkyl group of C1-30 or an cyclo alkyl group of C3-30 which respectively have one selected from the group consisting of hydrogen, an ether group, an ester group, a carbonyl group, an acetal, an epoxy group, a nitril group, an amine group, and an aldehyde group;each of R4, R6, R7 and R8 independently represents hydrogen or a methyl group;n represents an integer of 0 to 5;a represents a real number of 0.05 to 0.5;each of b, c and d respectively represents a real number of 0 to 0.7; anda+b+c+d=1)

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Resist under layer film composition and patterning process

ActiveUS20160342088A1Reduce defectGood filling propertySemiconductor/solid-state device manufacturingCoatingsResistPolymer chemistry

The present invention provides a resist under layer film composition containing a novolak resin having a repeating unit shown by the formula (1),wherein R represents a group containing one or more fluorine atoms. There is provided a resist under layer film composition that is excellent in filling property, generates little outgas, and has excellent dry etching resistance and heat resistance.

Owner:SHIN ETSU CHEM IND CO LTD

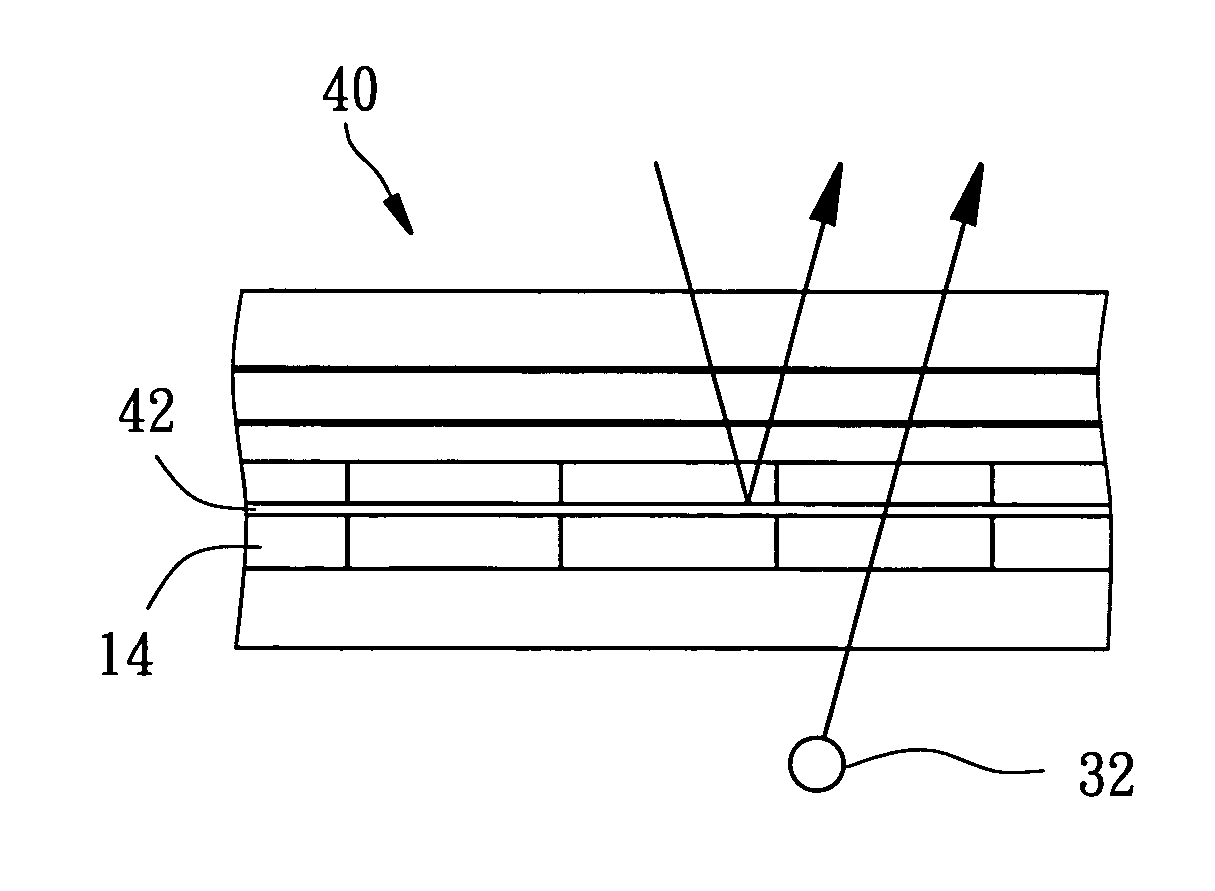

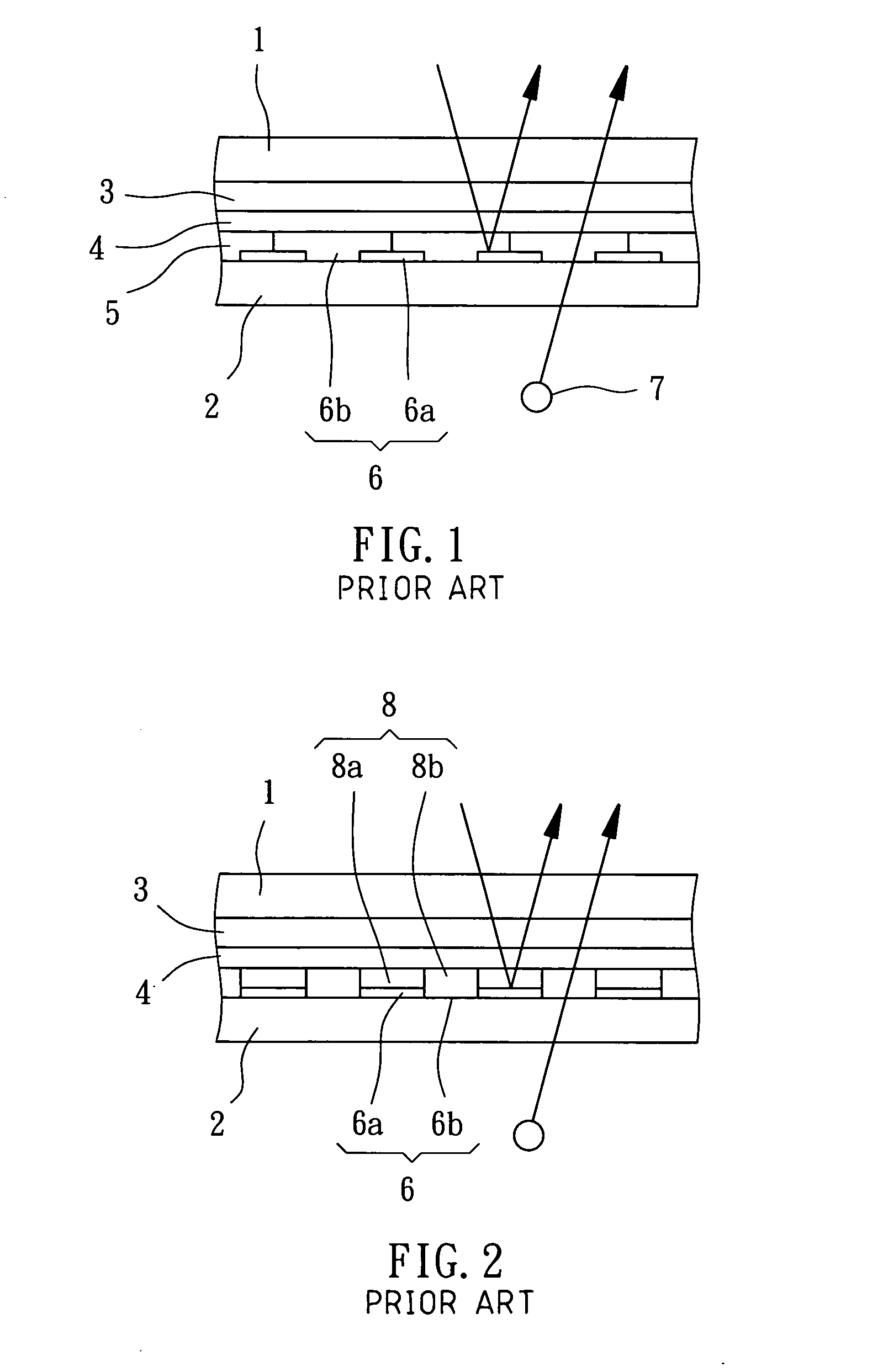

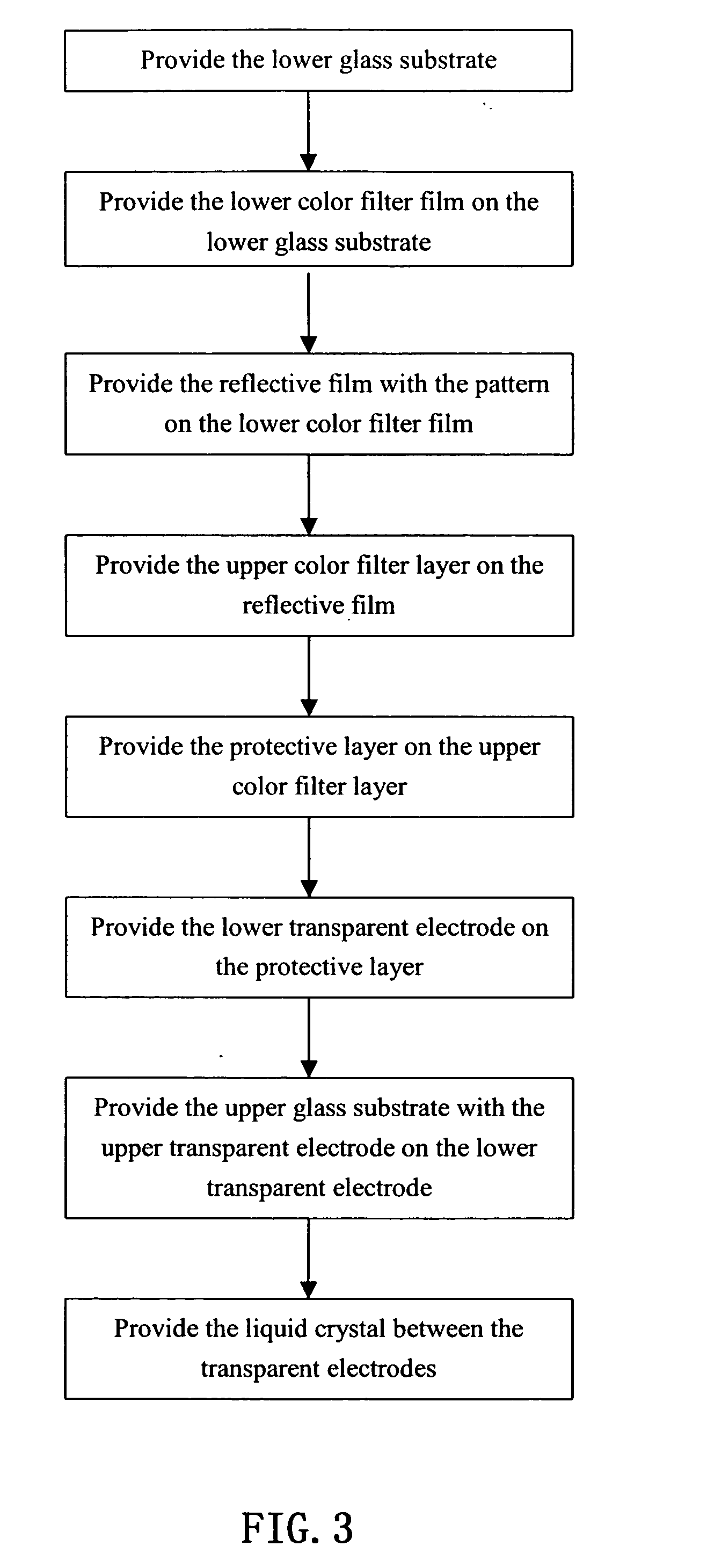

Apparatus of liquid crystal display for compensating chromaticity of reflected light and the method of fabrication

InactiveUS20060017868A1Reduce defectEasily alignNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal penal has a lower color filter film, a reflective film, an upper color filter film, a protective layer (with or without), a lower transparent electrode and an upper glass substrate with an upper transparent electrode on a bottom thereof stacked on the on a lower glass substrate in sequence. And then, a liquid crystal layer is provided in between the upper and the lower transparent electrode. The liquid crystal penal of the present invention provides a higher color intensity and a greater luminance.

Owner:WINTEK CORP

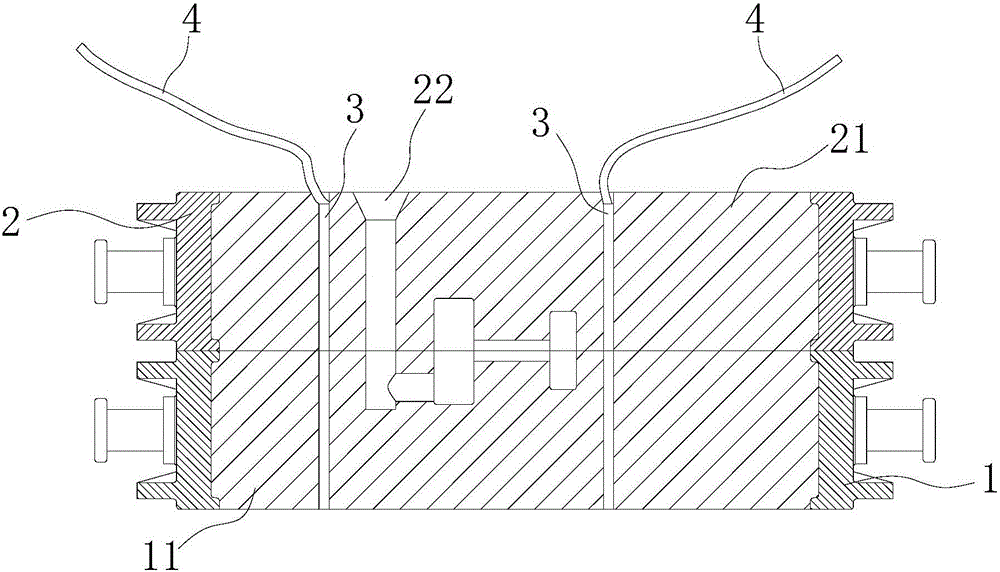

Rapid casting mold cooling method

InactiveCN106180579ASpeed up coolingGrain refinementFoundry mouldsFoundry coresCasting moldRapid casting

The invention discloses a rapid casting mold cooling method. The method comprises the following steps of production technology preparing, material preparing, sand making, modeling, drawing, mould assembling mold casting, melting, pouring cooling and shaking out after curing. According to the rapid casting mold cooling method, ventilation channels are manufactured in the casting modeling process, compressed air is blown in during pouring to conduct manual strengthened cooling, the casting cooling speed is increased, and a very good effect is achieved for relieving the sand mold heat effect; defects of a casting due to molding sand heating can be reduced, and therefore generation of defects of blade parts is reduced. Cooling is conducted while pouring is conducted, the grain of the casting is refined, the mechanical performance of the casting is also improved to a certain degree, the quality of the casting is improved, and especially the quality of partition plate blades for an H type compressor is obviously improved; and through the batched trial manufacturing, the partition plate casting produced by adopting the method for blowing the compressed air in the pouring process is subjected to nondestructive testing after grinding, and the quality situation meets the requirement and is greatly improved compared with original partition plate castings.

Owner:HANGZHOU STEAM TURBINE CASTING & FORGING

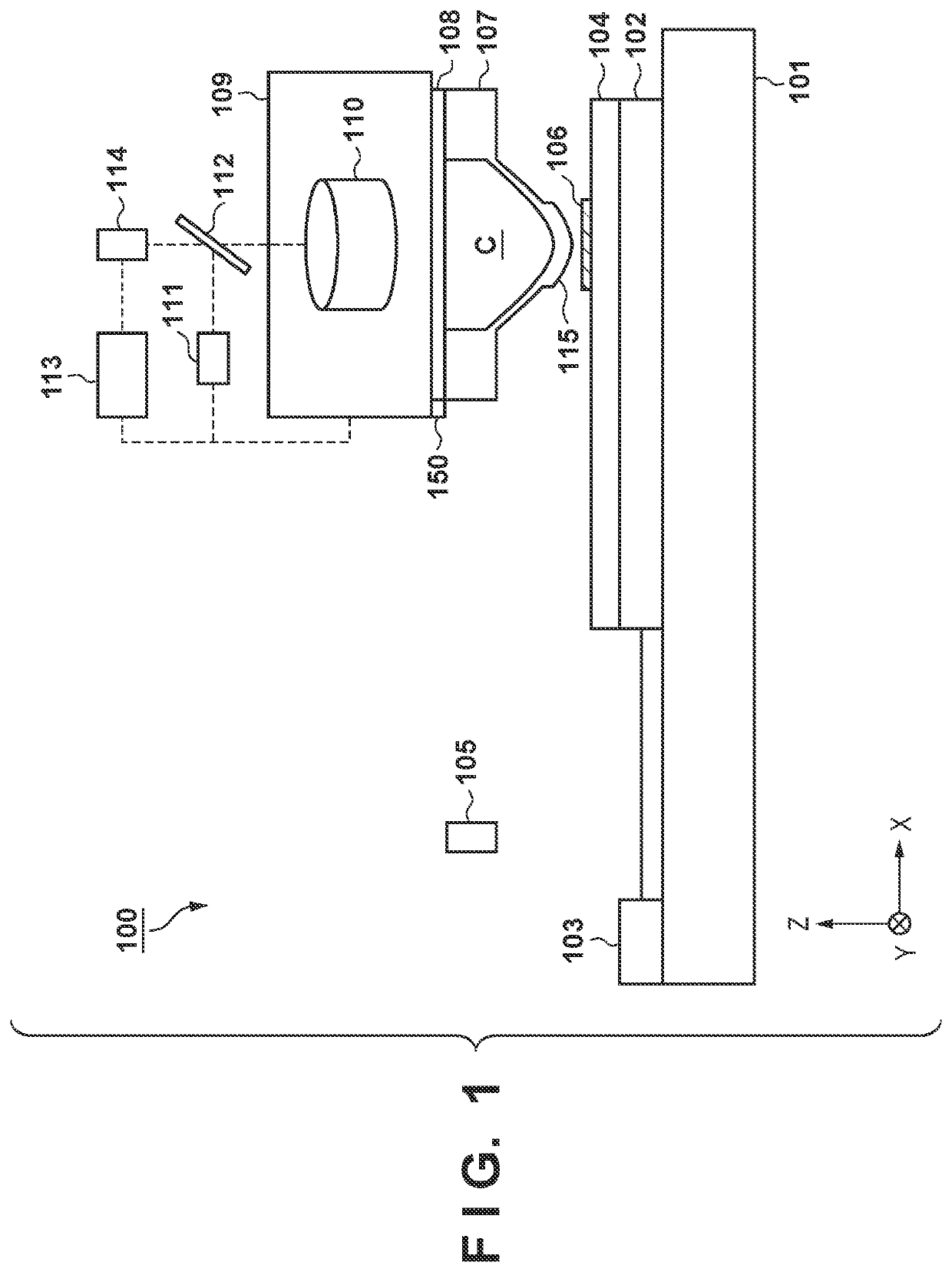

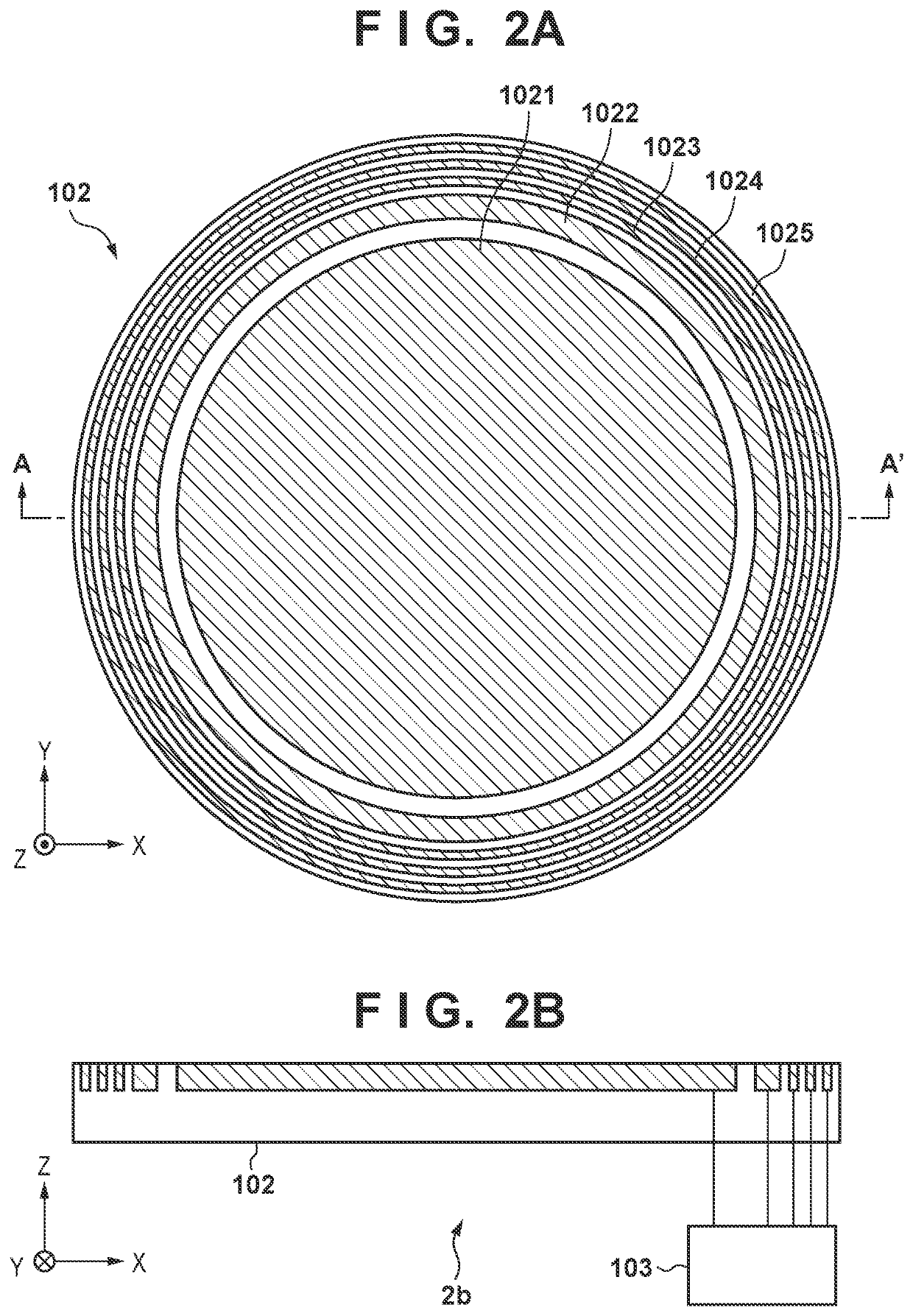

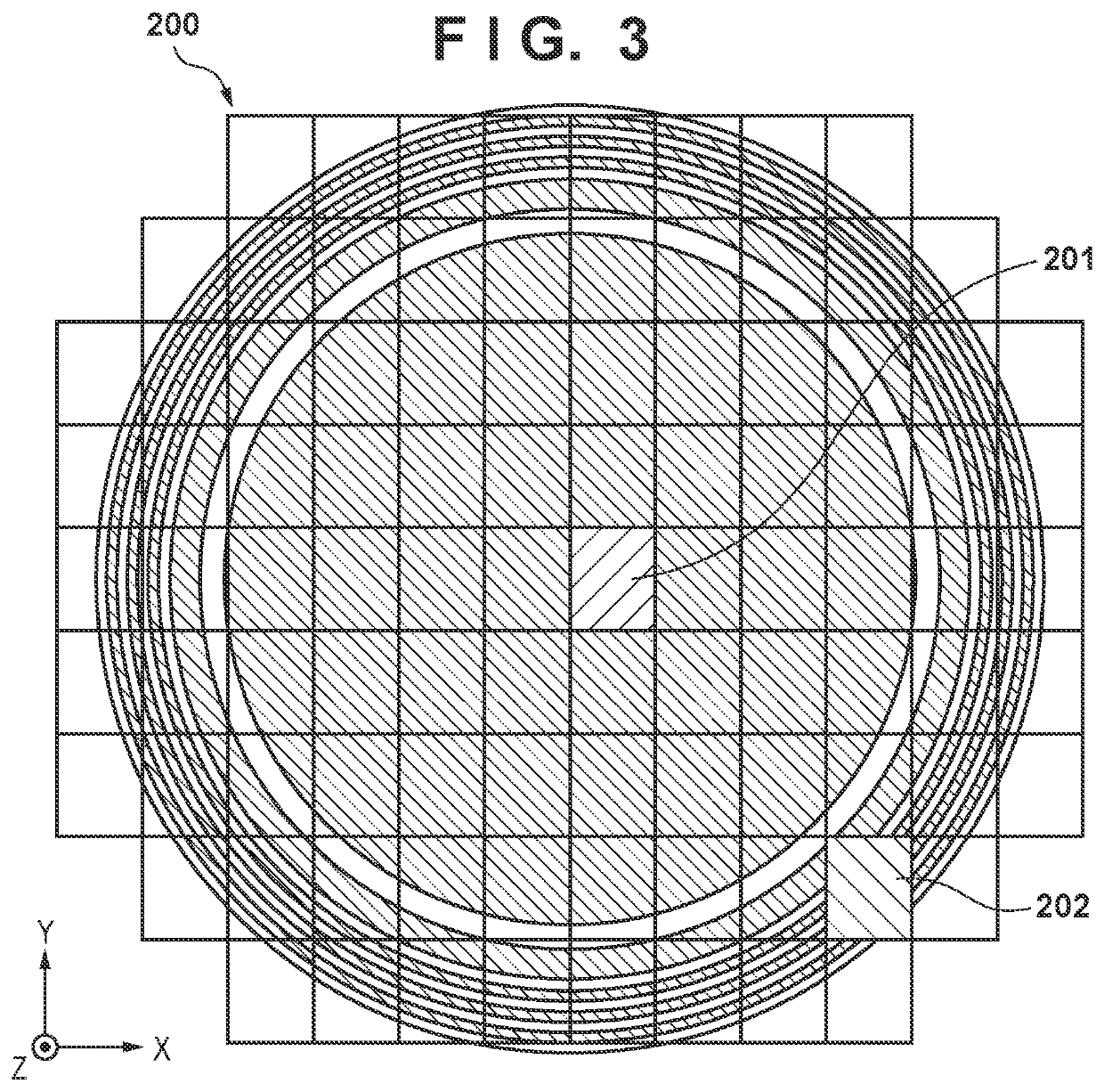

Forming apparatus and method of manufacturing article

ActiveUS20200387067A1Reduce defectIncrease service lifePhotomechanical apparatusSemiconductor/solid-state device manufacturingManufacturing engineeringMechanical engineering

Owner:CANON KK

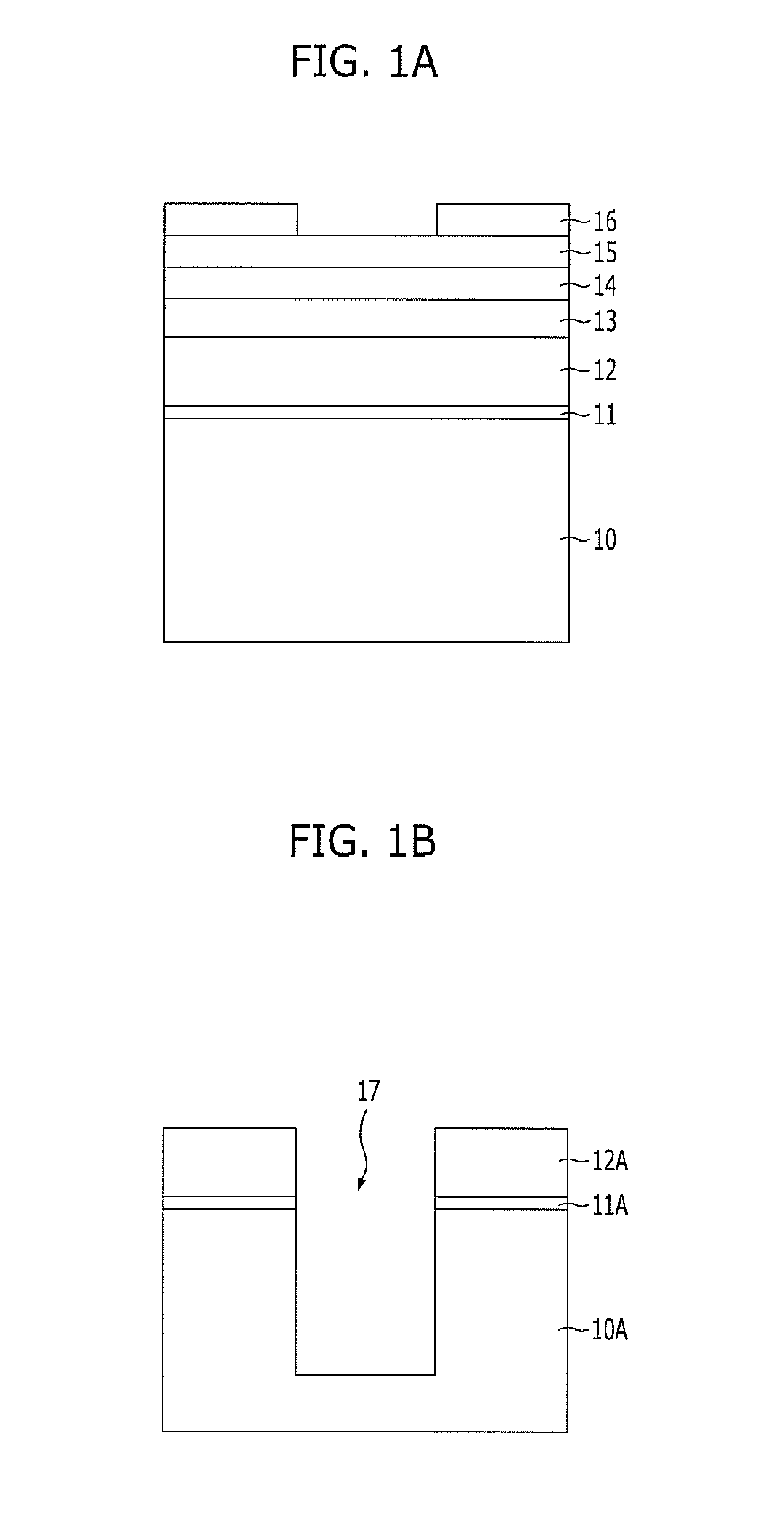

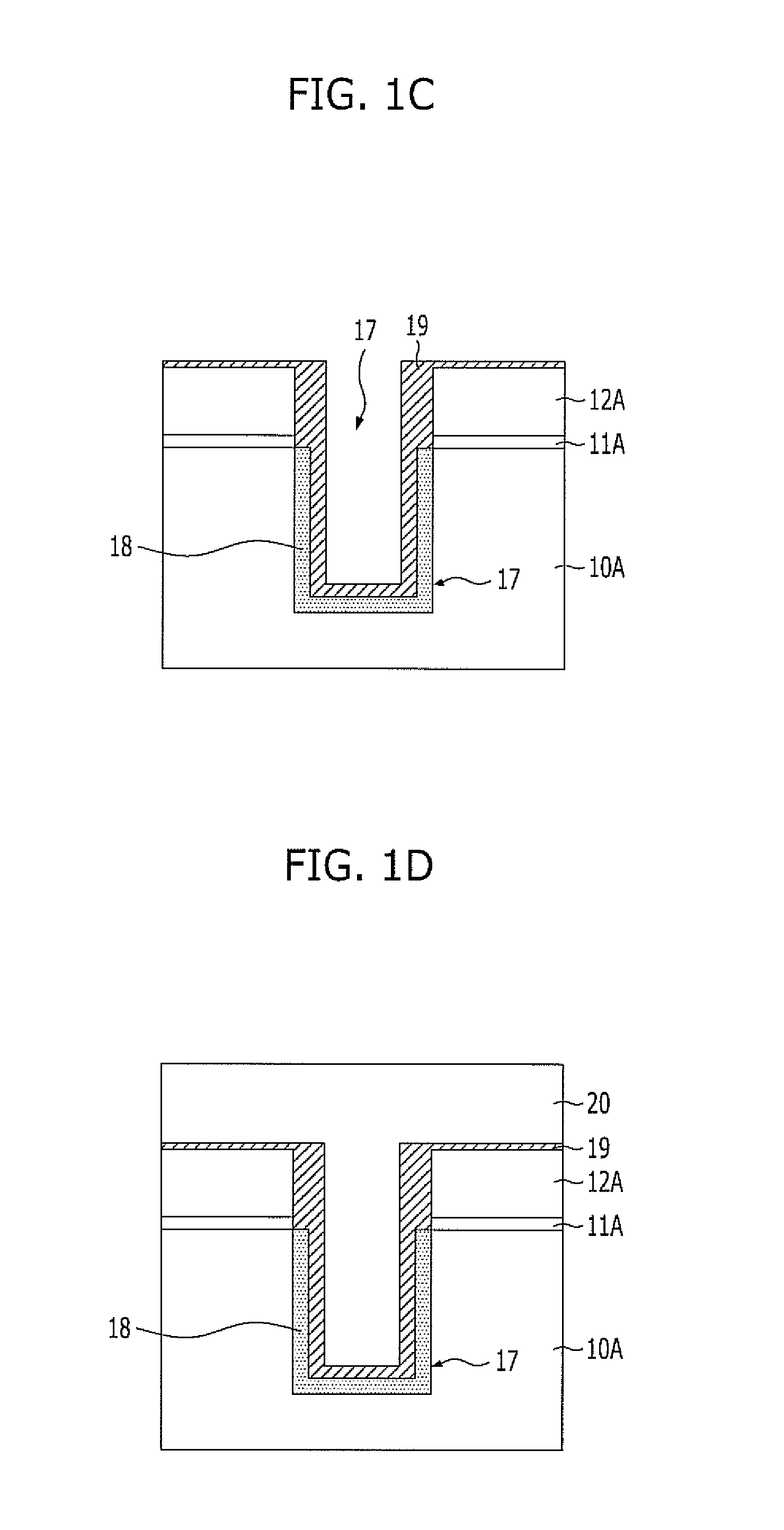

Doping method for semiconductor device

InactiveUS20110027964A1Reduce defectSemiconductor/solid-state device manufacturingSemiconductor devicesDopantSemiconductor

A doping method for a semiconductor device includes forming a trench in a semiconductor substrate, forming a doped layer doped with a dopant over the undoped layer, and forming a doped region into which the dopant is diffused, wherein the doped region is a portion of the semiconductor substrate in contact with the doped layer.

Owner:SK HYNIX INC

High Electron Mobility Transistors and Integrated Circuits with Improved Feature Uniformity and Reduced defects for Microwave and Millimetre Wave Applications

InactiveUS20150372096A1Improve critical dimension uniformityReduce defectTransistorSolid-state devicesPhysicsIntegrated circuit

High mobility transistors and microwave integrated circuits with an improved uniformity of the width of the smallest of features, an increased lithographic yield and reduced defects in the active components are provided. Before and during fabrication, a first grooving process is performed to partially or completely remove composite epitaxial layers in the field lanes to reduce the initial bow to be smaller than DOF range and to improve the uniformity of the critical dimension. A second grooving process may also be performed to remove composite epitaxial layers in the dicing lanes to further improve the uniformity of the width of the smallest features for the devices and circuits to be made.

Owner:SHIH ISHIANG +3

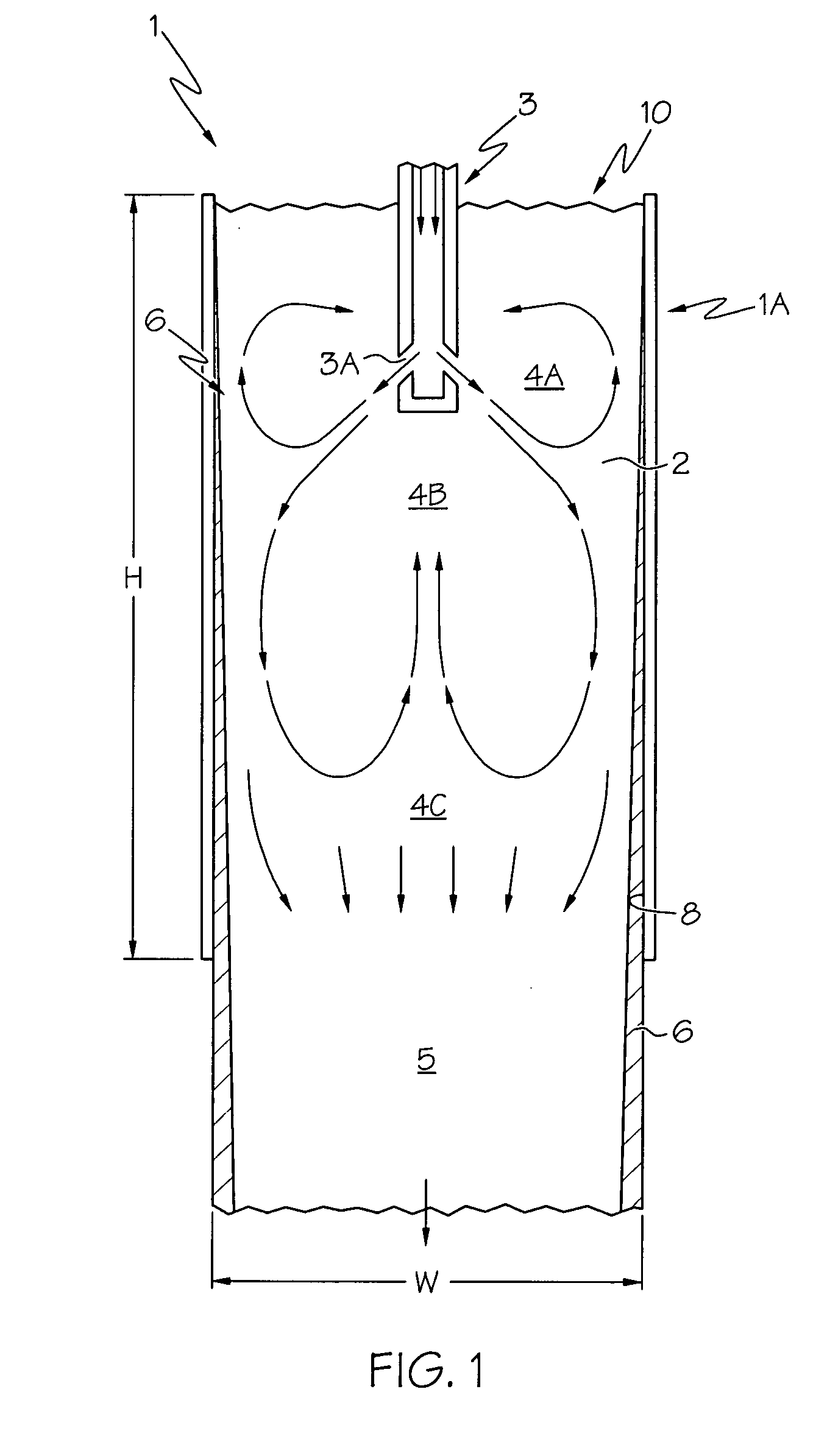

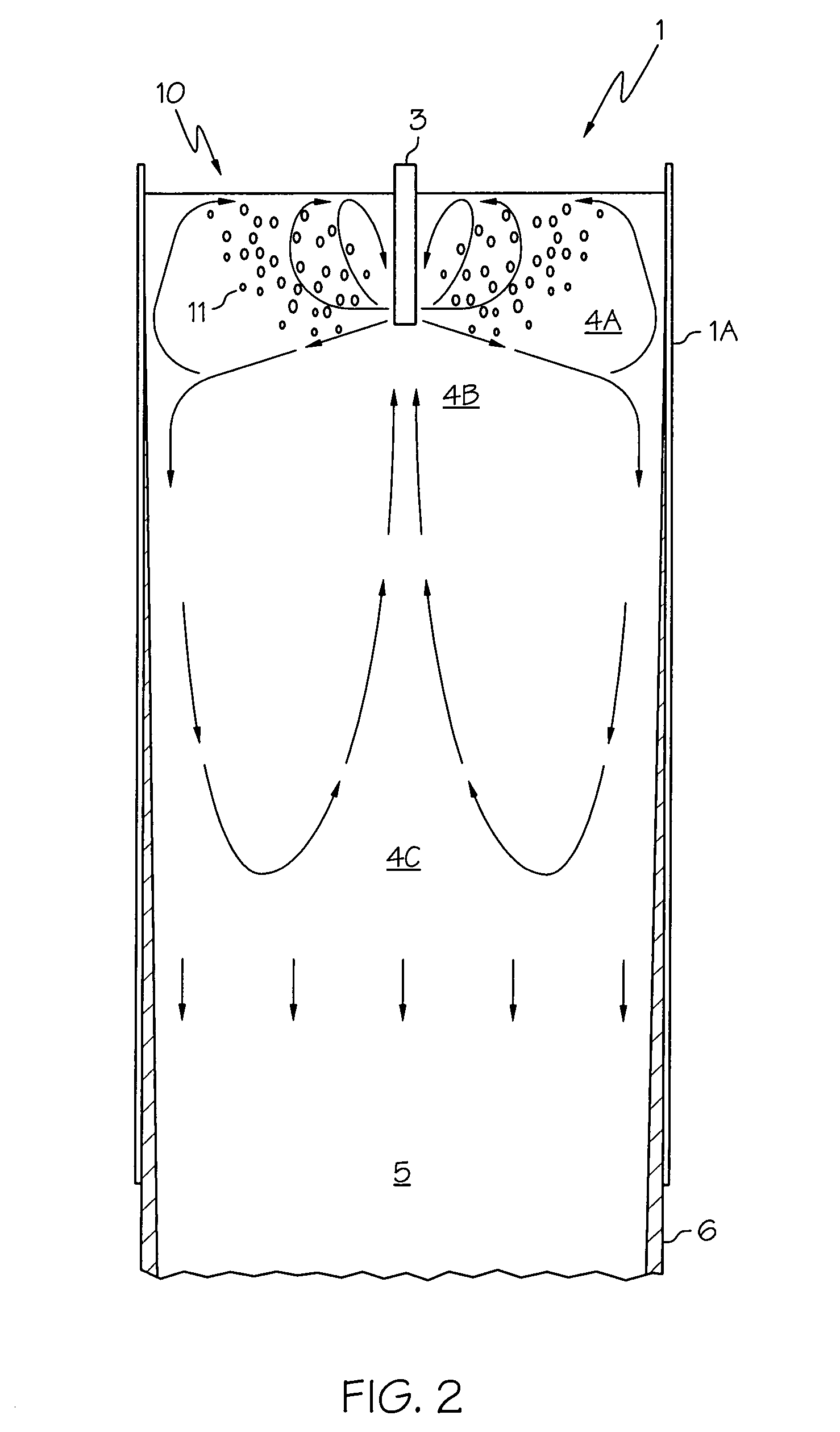

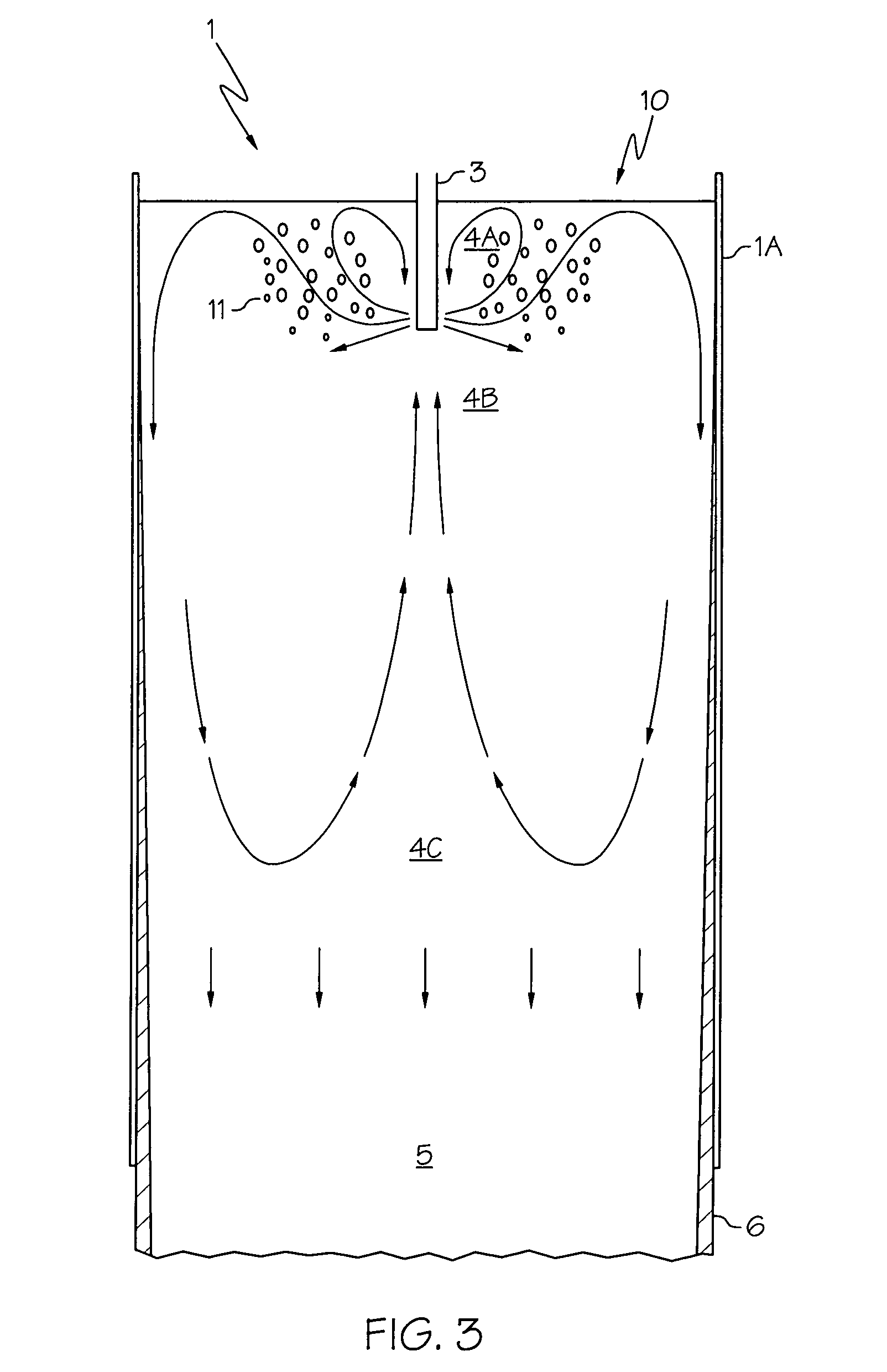

Method and apparatus for melt flow control in continuous casting mold

InactiveUS20060118272A1Reduce sliver and other defectReduce defectMelt-holding vesselsSlagMolten metal

A method and apparatus for continuous casting of metal. The flow of molten metal is altered to eliminate or reduce the transfer of entrained mold flux slag and non-metallic particles to the vicinity of solidifying metal near the mold walls, thereby resulting in significantly reduced sliver and related defects. Flow modifier members are placed such that their larger surface is more aligned with the larger dimension of the interior volume of the vessel in which the member is placed. In a particular form, the members may be shaped as rectangular plates and placed substantially parallel to the longer interior wall of the vessel.

Owner:THE OHIO STATE UNIV RES FOUND

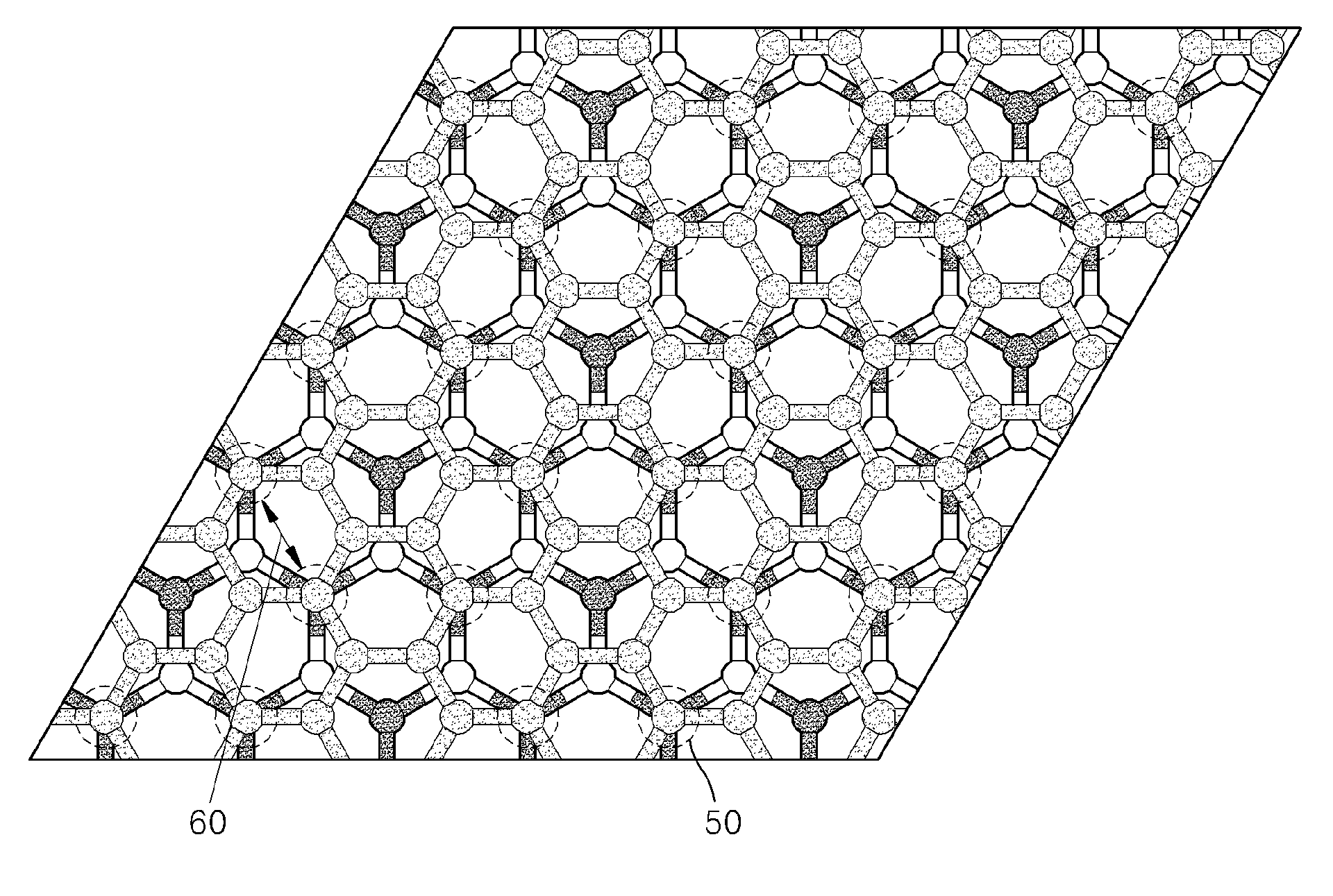

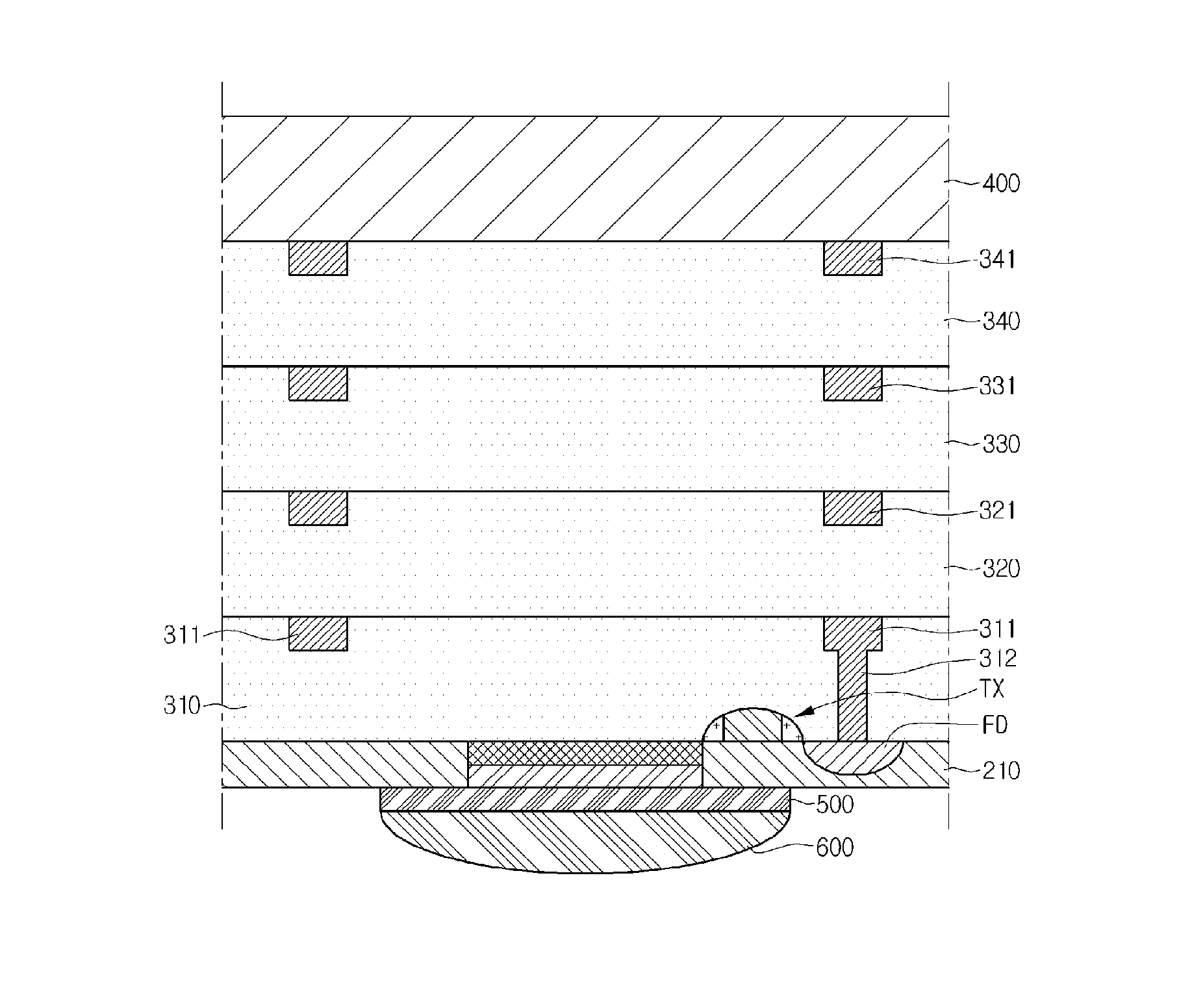

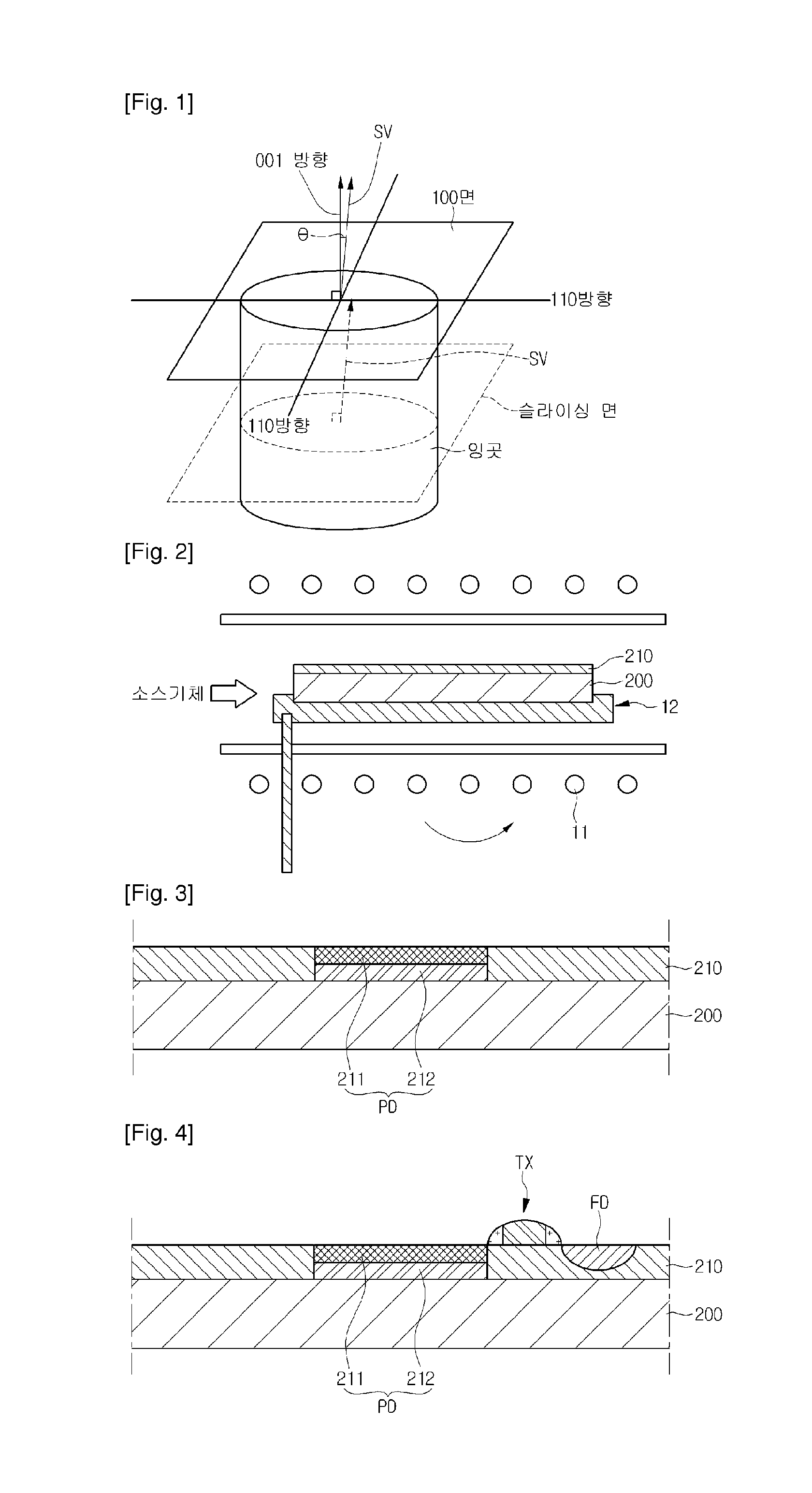

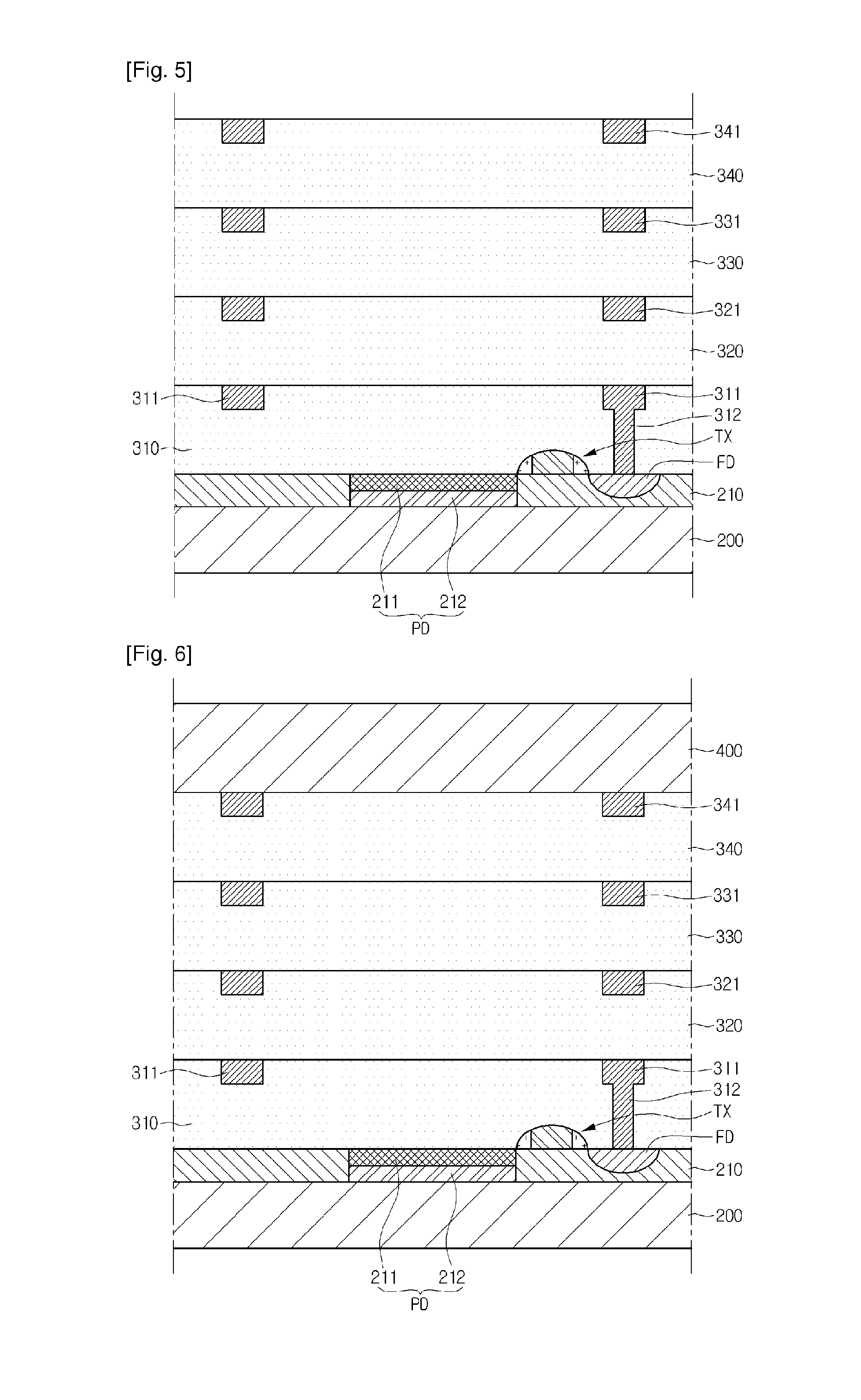

Image sensor and method for manufacturing the same

InactiveUS20150014754A1Reduce defectImprove sense efficiencySolid-state devicesSemiconductor/solid-state device manufacturingImage sensorCrystal orientation

Provided are an image sensor and a method of manufacturing the same. The image sensor includes a support substrate, a wire layer disposed under the support substrate, an epitaxial layer disposed under the wire layer, and a photodiode disposed in the epitaxial layer. The epitaxial layer has an off angle of about 0.3° to about 1.5° with respect to a [001] crystal orientation.

Owner:LG SILTRON

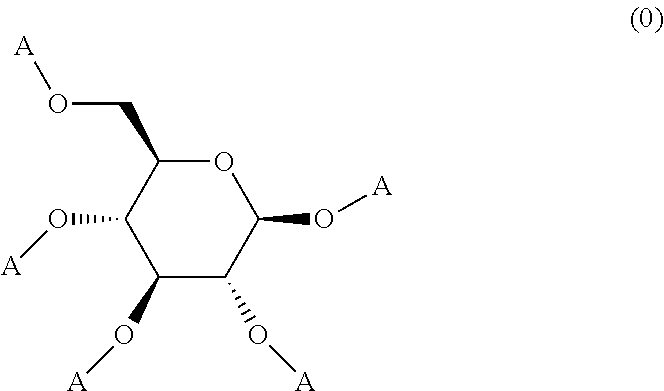

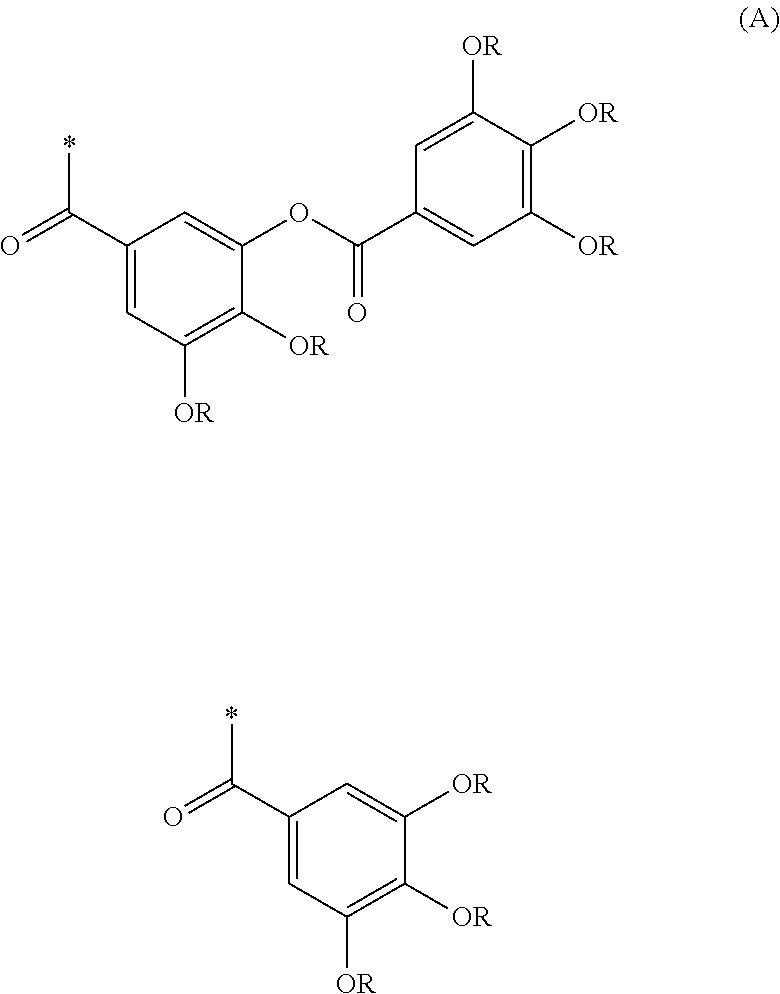

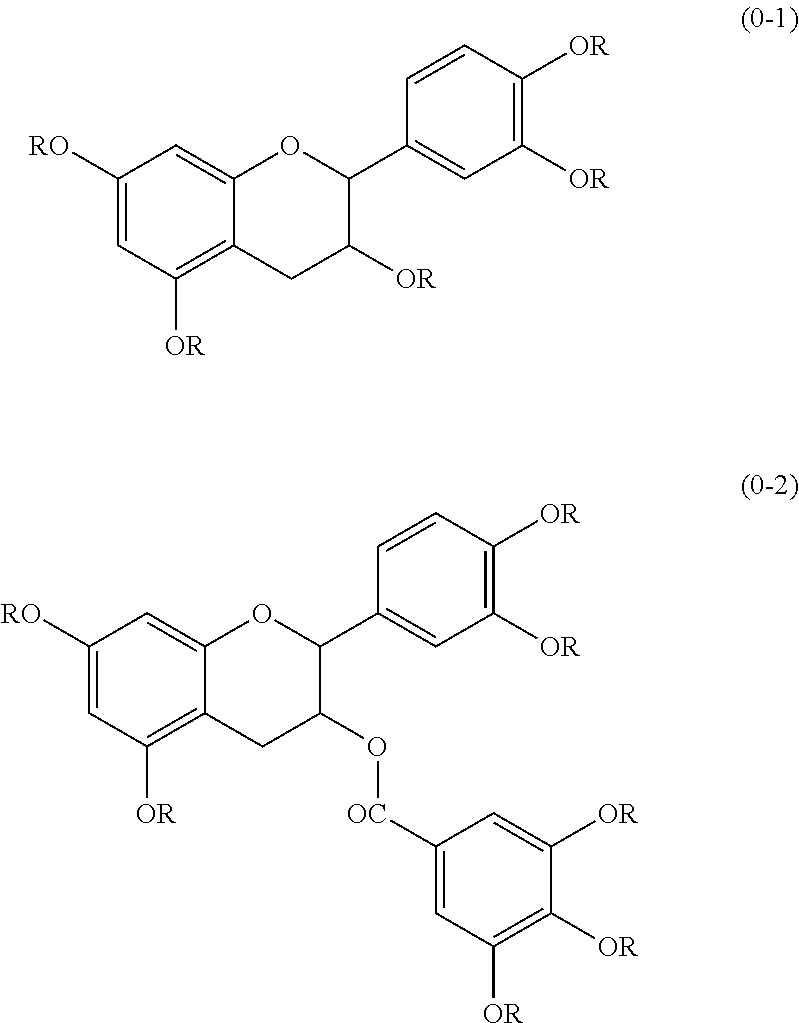

Resist composition and pattern formation method using same, compound and resin

InactiveUS20210063880A1Reduce defectGood stabilityEsterified saccharide compoundsSugar derivativesComposite materialChemical compound

The present invention provides a resist composition comprising one or more tannin compounds selected from the group consisting of a tannin comprising at least one acid dissociation reactive group in the structure and a derivative thereof, and a resin obtained using the tannin or the derivative as a monomer, and a pattern formation method using the same, a compound and a resin.

Owner:KANSAI UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com