Hydrodynamic bearing assembly and motor including the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

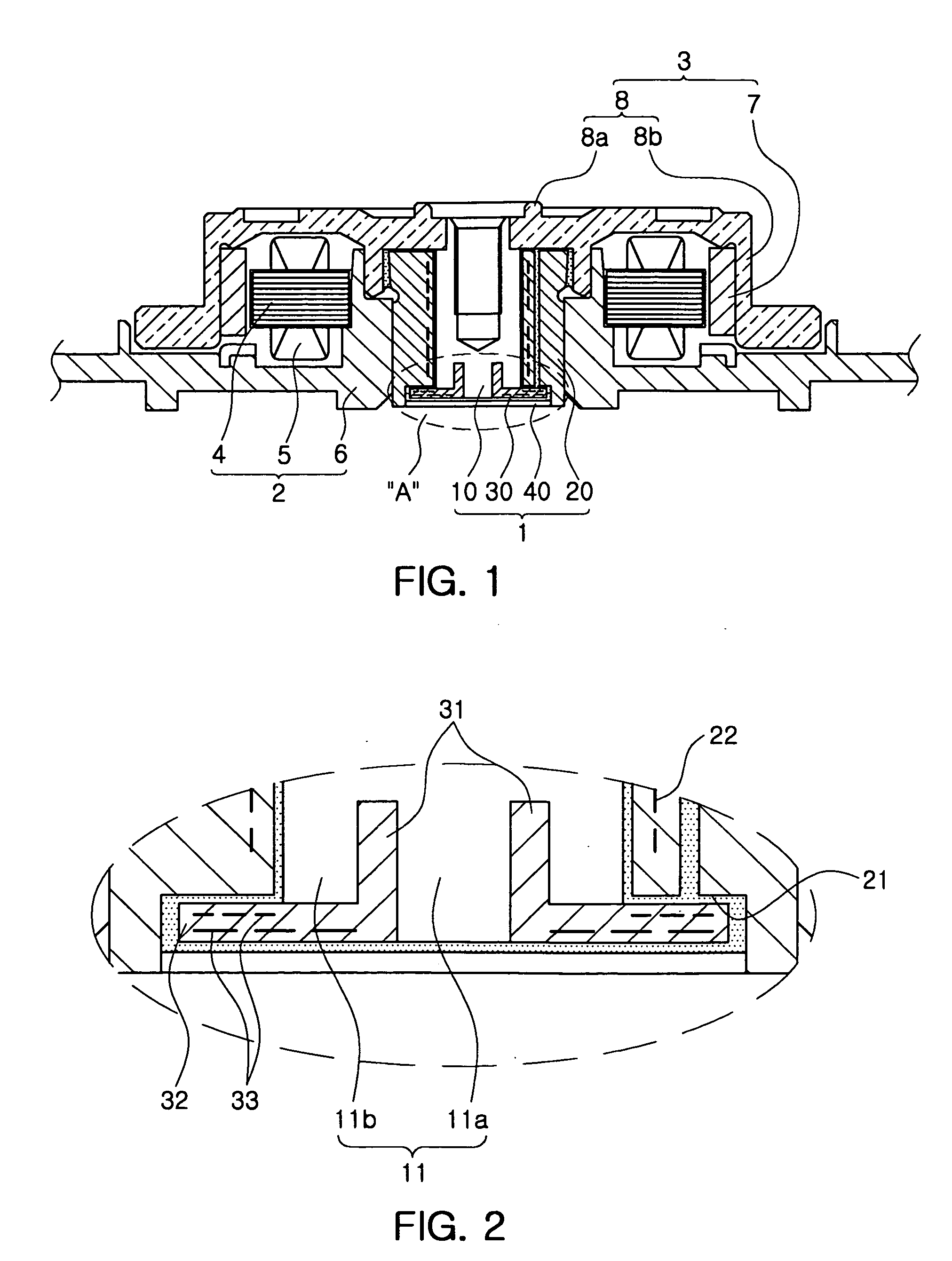

[0073]FIG. 3 is a cross-sectional view schematically showing a modified thrust plate according to an exemplary embodiment of the present invention.

[0074]Referring to FIG. 3, only one extension part 31 according to the exemplary embodiment of the present invention may be formed at the thrust plate 30; however, a plurality of extension parts 31 having different diameters may also be formed. That is, the plurality of extension parts 31 having a concentric circle may be formed at the thrust plate 30, such that the coupling part 11 may include a first coupling part 11a contacting an innermost surface of the extension part 31, a second coupling part 11b contacting an outermost surface thereof, and a third coupling part 11c contacting inner / outer surfaces between the innermost and outermost surfaces.

[0075]Therefore, a coupling area between the thrust plate 30 and the shaft 10 may be increased, as compared to the case in which a single extension part 31 is formed.

[0076]Accordingly, the coup...

second embodiment

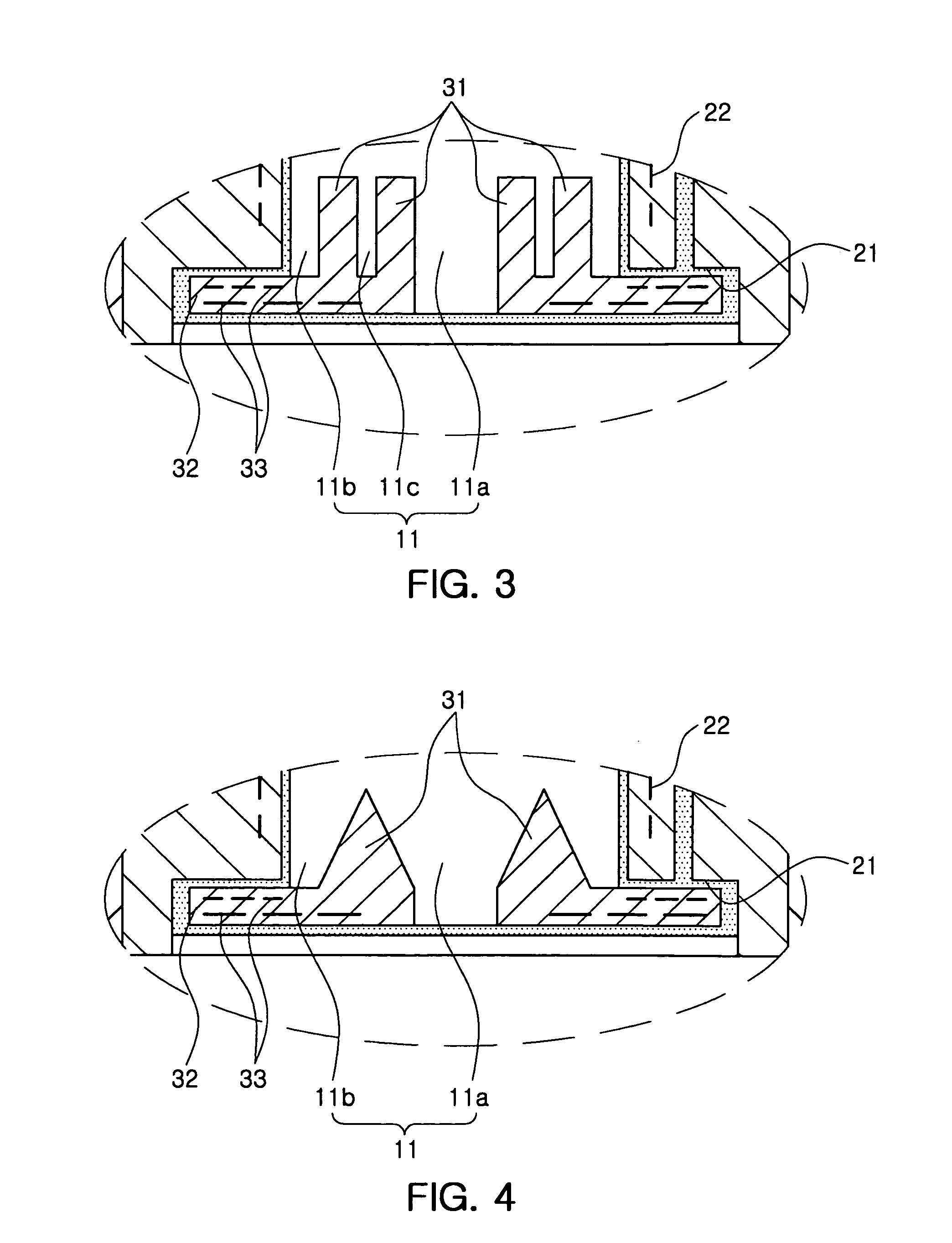

[0077]FIG. 4 is a cross-sectional view schematically showing a modified thrust plate according to an exemplary embodiment of the present invention.

[0078]Referring to FIG. 4, the extension part 31 may be formed horizontally with the axial direction; however, at least one of the inner and outer surfaces of the extension part 31 may also be formed to be tapered. That is, at least one of the inner and outer surfaces of the extension part 31 may be formed to be inclined or may be formed to be curved.

[0079]Therefore, the thrust plate 30 may be inserted into the shaft 10 along a tapered surface of the extension part 31 during the coupling between the thrust plate 30 and the shaft 10, whereby the coupling therebetween is facilitated.

third embodiment

[0080]FIG. 5 is a cut-away perspective view schematically showing a modified thrust plate according to an exemplary embodiment of the present invention.

[0081]Referring to FIG. 5, the extension part 31 may be continuously formed at the thrust plate 30 in the circumferential direction; however, the extension part 31 may also be formed in an interrupted manner in the circumferential direction. That is, a plurality of fan-shaped extension parts 31 may be formed in the circumferential direction.

[0082]Meanwhile, when the extension part 31 is formed in an interrupted manner in the circumferential direction, the coupling part 11 of the shaft 10 may have a shape corresponding to that of the extension part 31.

[0083]Therefore, a advantage in which the thrust plate 30 may completely be dependent on the rotational driving of the shaft 10 is generated.

[0084]That is, the rotational force of the shaft 10 may be transferred to the thrust plate 30 by a structural shape of the extension part 31 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com