Method and apparatus for melt flow control in continuous casting mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

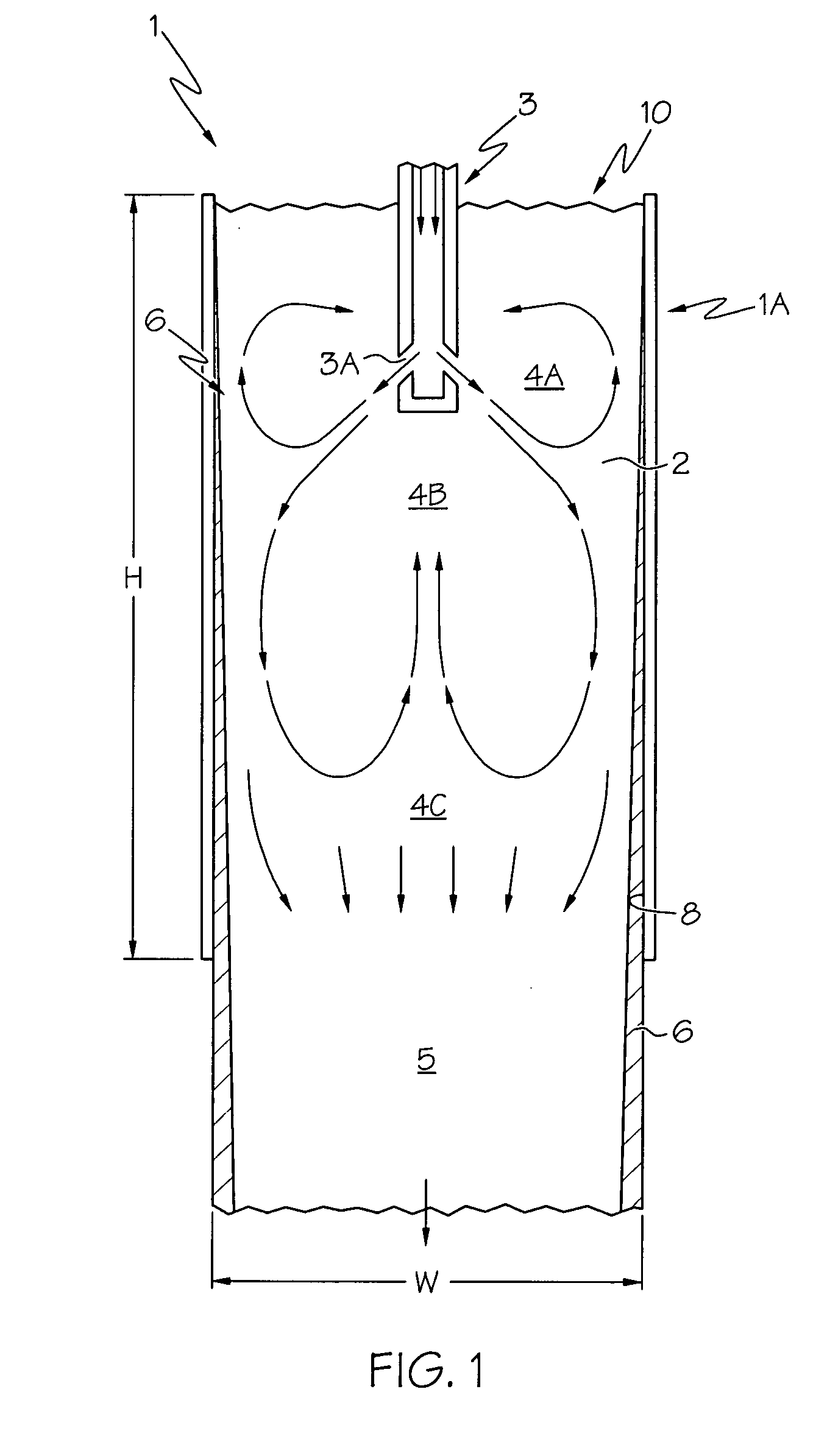

[0032] Referring first to FIG. 1, an elevation view of a conventional continuous casting system showing a general flow pattern in vessel (also referred to as a mold or mold vessel) 1 is shown. Molten metal 2 emerges from discharge ports 3A in SEN 3 and enters the vessel 1, flowing generally along flow lines 4A, 4B and 4C (collectively referred to as flow lines 4). Molten metal 2 then emerges from the vessel 1 as a partially solidified slab 5 in the shape of the vessel 1, which is typically rectangular with a thickness dimension T, height (or length) dimension H and a width dimension W (not presently shown). As the molten metal 2 progresses through the vessel 1, a layer of solidified steel 6 is formed against the interior surfaces 8 of the vessel 1, resulting in the formation of a shell over the freshly cast slab 5. One or more flow modifier members (not presently shown) may be located on either side of the SEN 3, and have traditionally been used to prevent or minimize downward liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com