Method of making laminate structures for mechanical activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Definitions:

[0017] The following terminology is used herein consistent with the plain meaning of the terms with further details provided in the present specification.

[0018] As used herein, the term “absorbent article” refers to devices that absorb and contain body exudates and, more specifically, refers to devices that are placed against or in proximity to the body of a wearer to absorb and contain the various exudates discharged from the body.

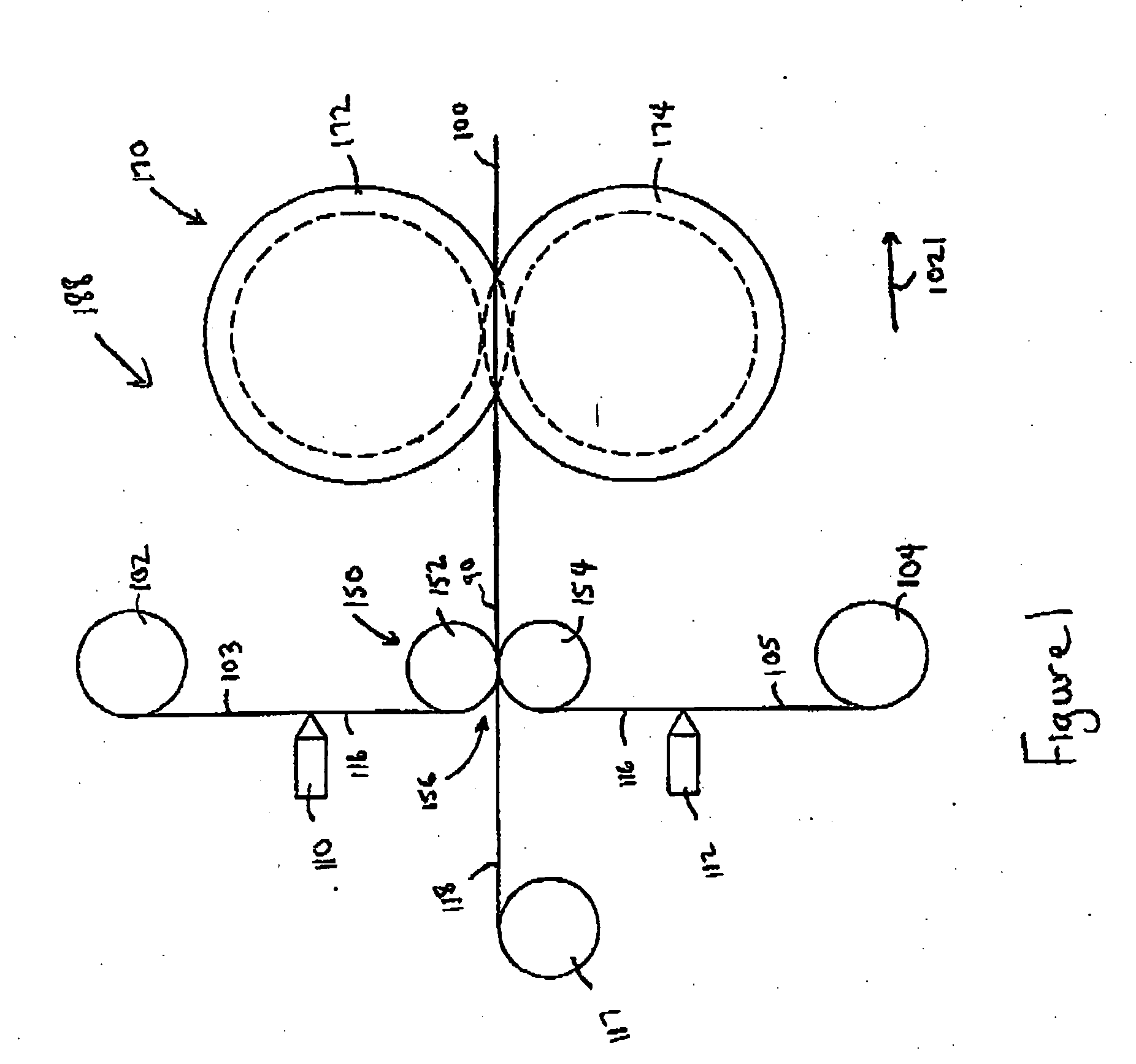

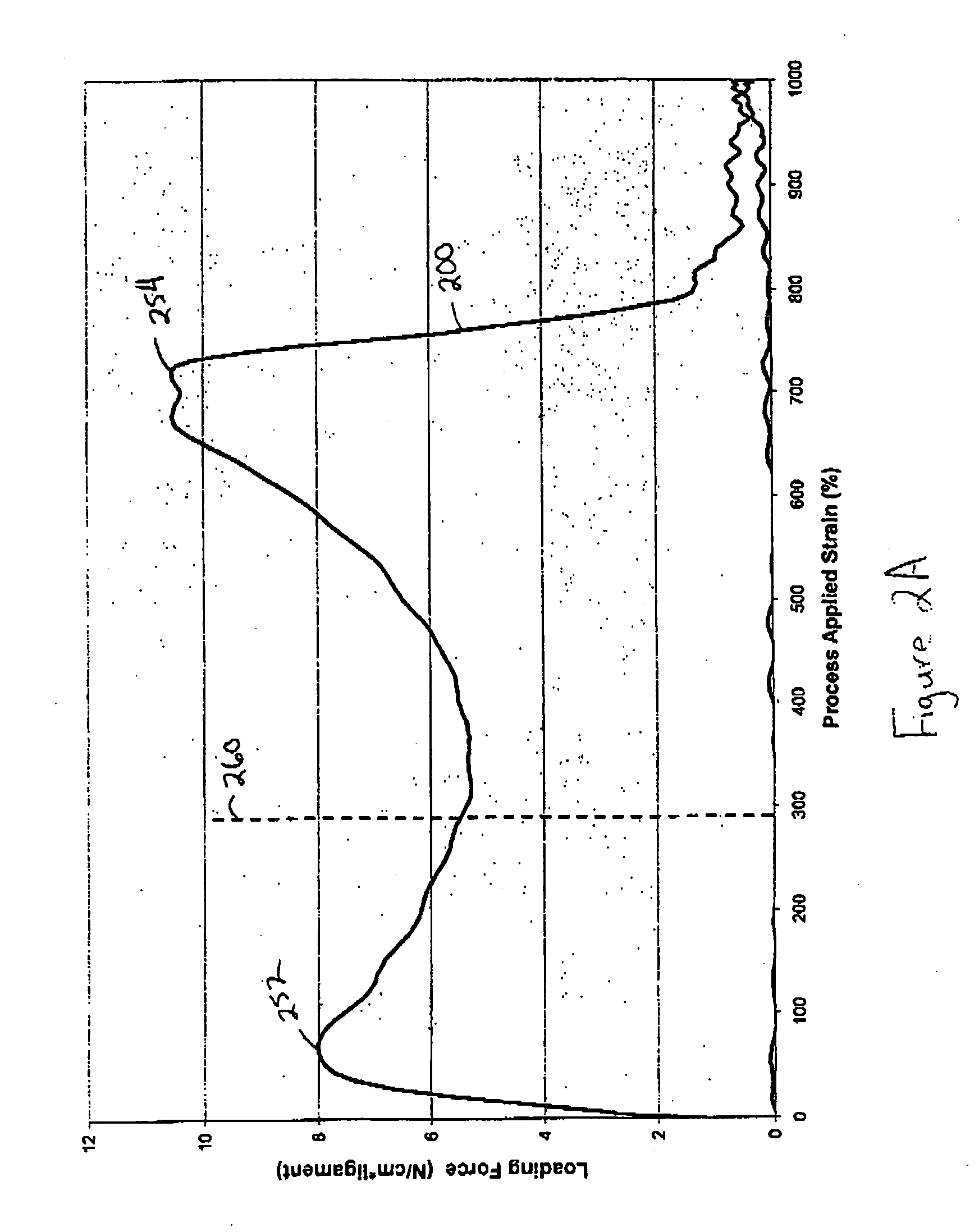

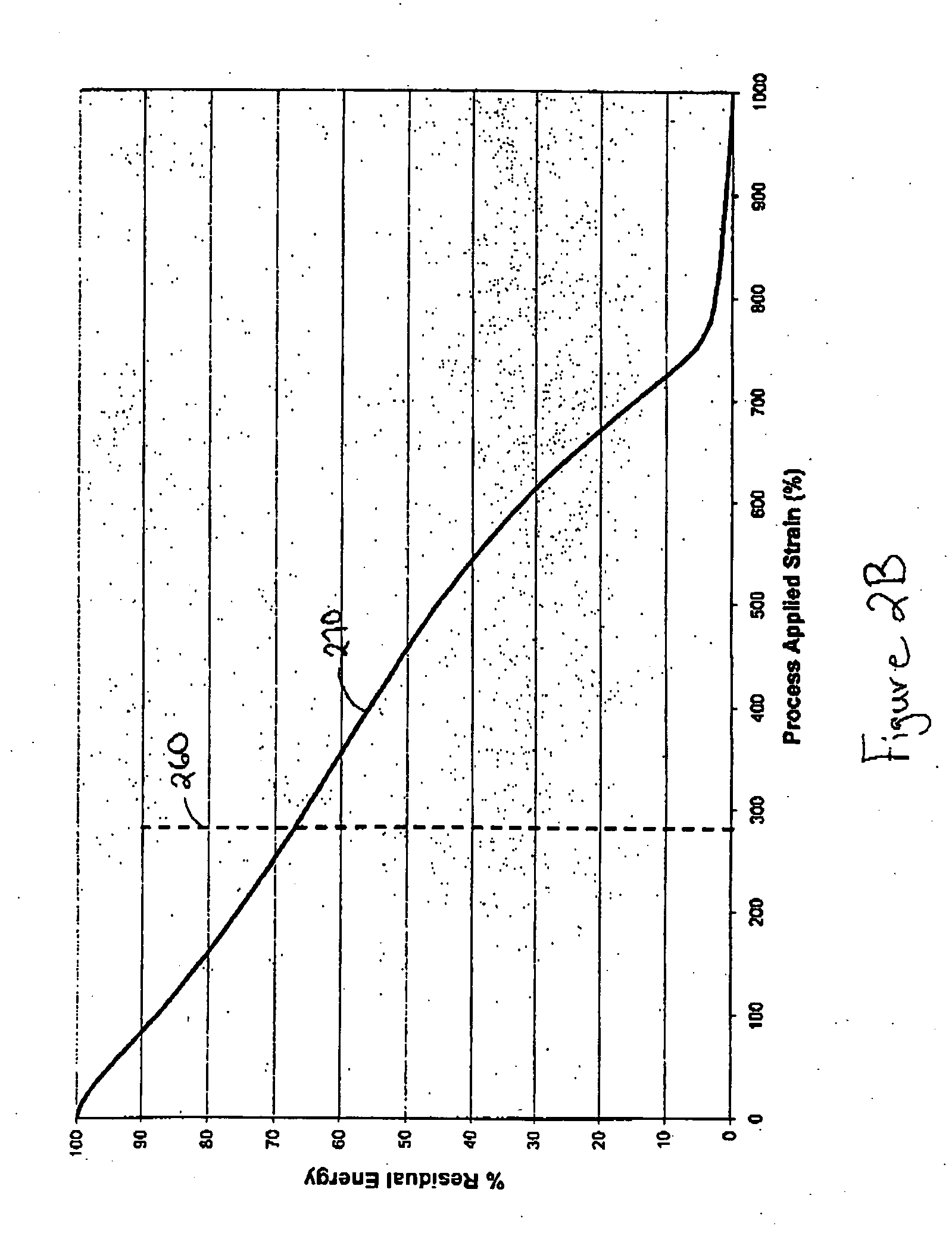

[0019] The terms “activating”, “activation”, or “mechanical activation” refer to the process of making a substrate, or an elastomeric laminate more extensible than it was prior to the process.

[0020]“Basis weight” refers to the weight of a planar material for a given surface area. Basis weight is typically measured in grams per square meter (gsm). The basis weight of a stretch laminate is typically measured while the stretch laminate is in an unstrained configuration.

[0021] The terms “corrugations” or “rugosities” are used to describe hil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com