Rapid casting mold cooling method

A rapid cooling and casting technology, applied in the field of casting, can solve the problems of easy generation of slag inclusions and pores, and achieve the effects of reducing thermal effects, reducing defects, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

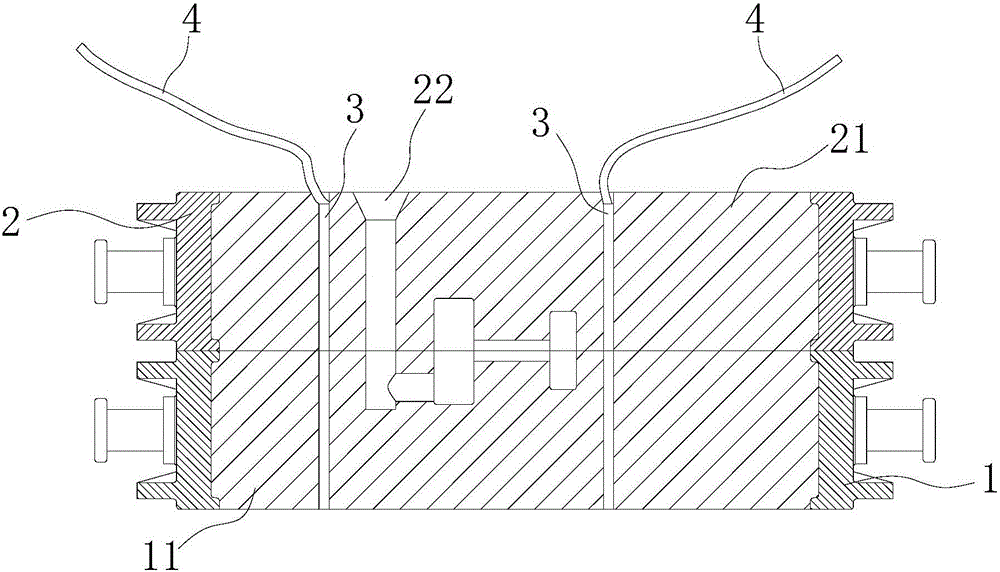

[0042] There are two air passages 3, which are placed on the left and right sides of the pattern.

Embodiment 2

[0044] The quantity of air duct 3 is 4, and is divided into the surroundings of pattern.

[0045] Compared with the castings obtained in Example 1 and Example 2, the cooling rate in Example 2 is more obvious, and the effect of slowing down the heat effect of the casting on the sand mold between the blades and reducing the defects of the blade parts is also more obvious. In addition, the first and second embodiments both adopt the method of cooling while pouring. Compared with the current common method, the crystal grains of the casting are refined, the mechanical properties of the casting are also improved, and the overall quality of the casting is improved.

[0046] The invention provides a rapid cooling method for casting molds, especially for H-type compressors, which significantly improves the quality of the partition blades. Through batch trial production, the H-type compressors are produced by blowing compressed air during the pouring process. Castings are subjected to n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com