Patents

Literature

410 results about "Hydrogen permeation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen permeation is the diffusion of hydrogen ions through the thin metal isolation diaphragms used in pressure transmitters either through interstitial or substitutional (vacancy) mechanisms.

Hydrogen transport membranes

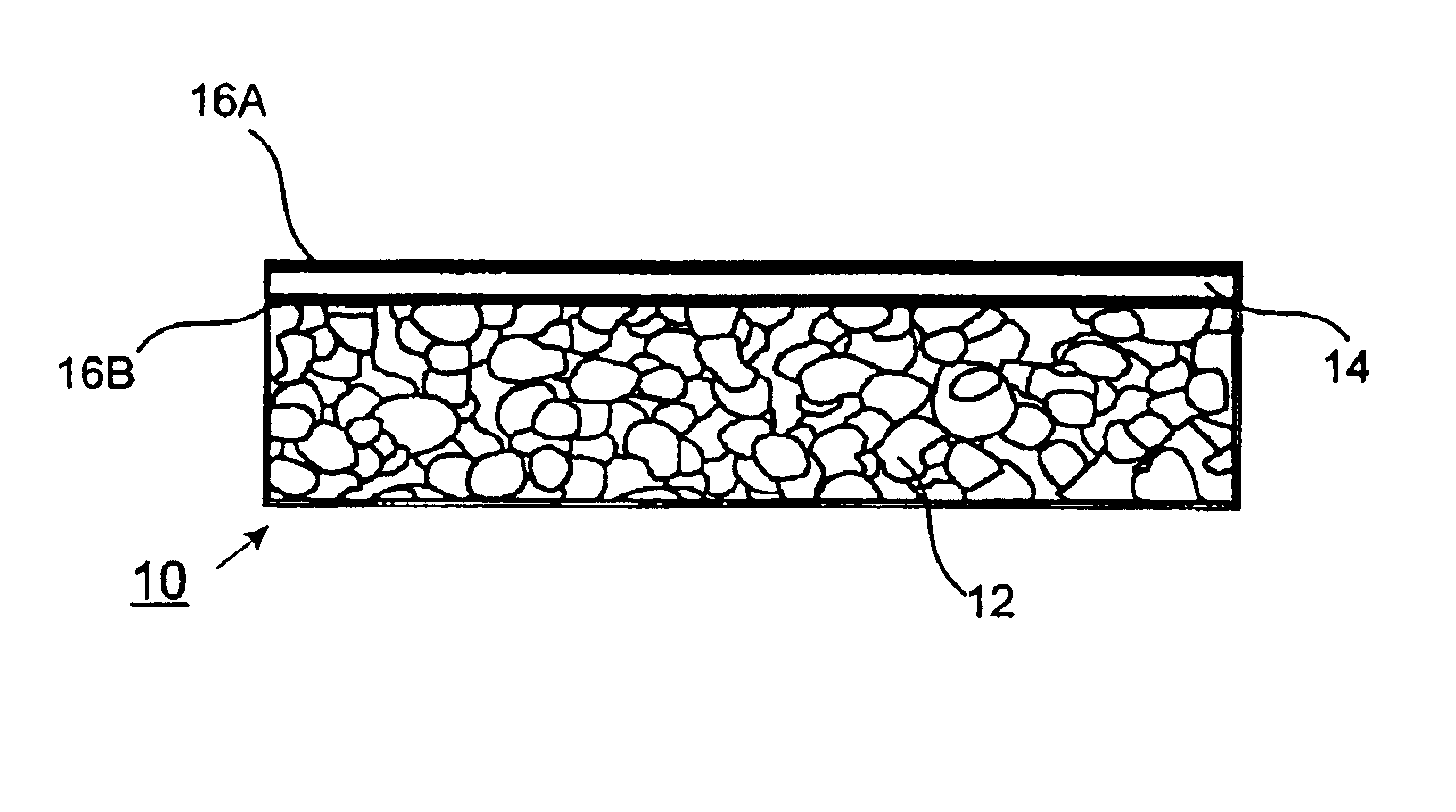

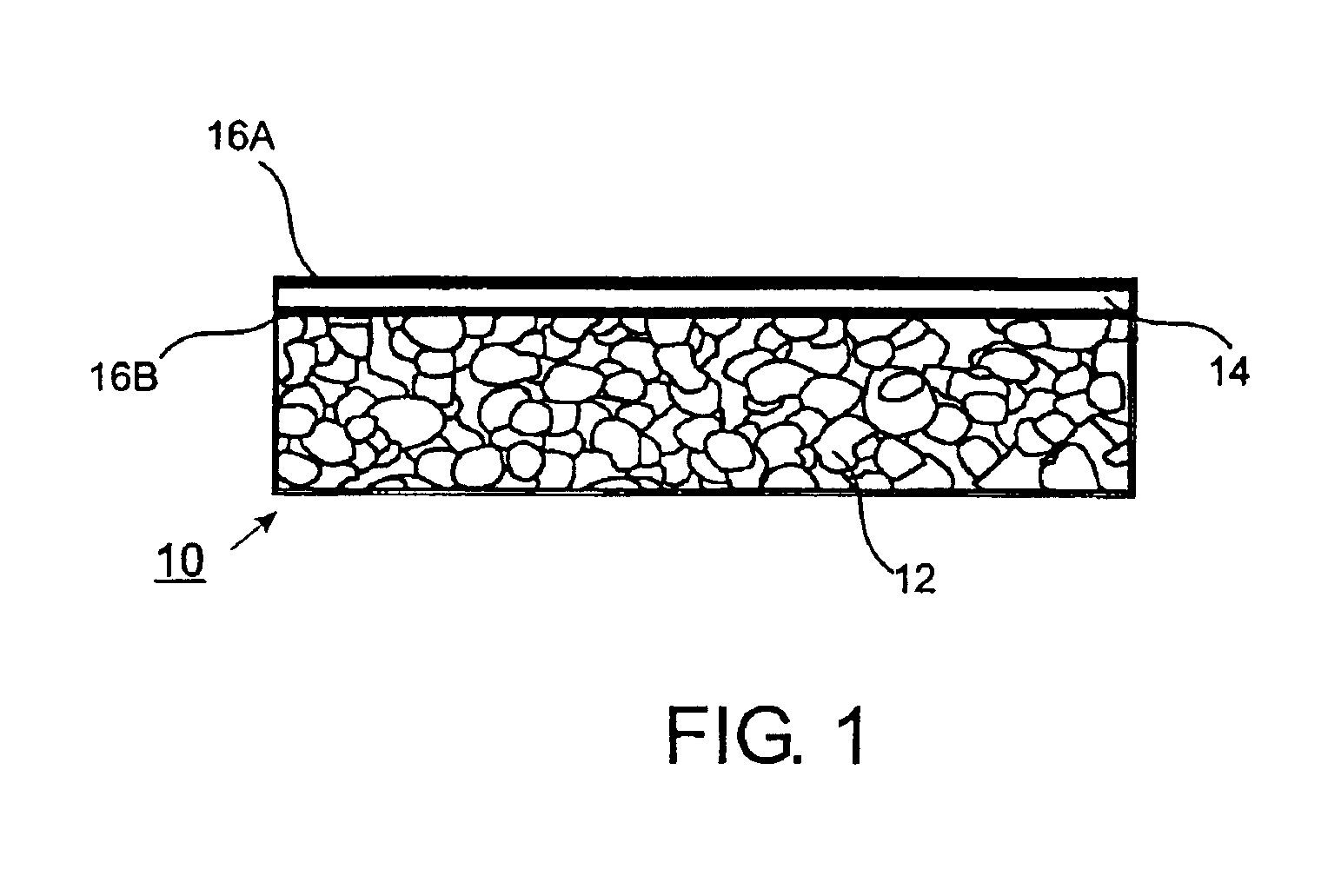

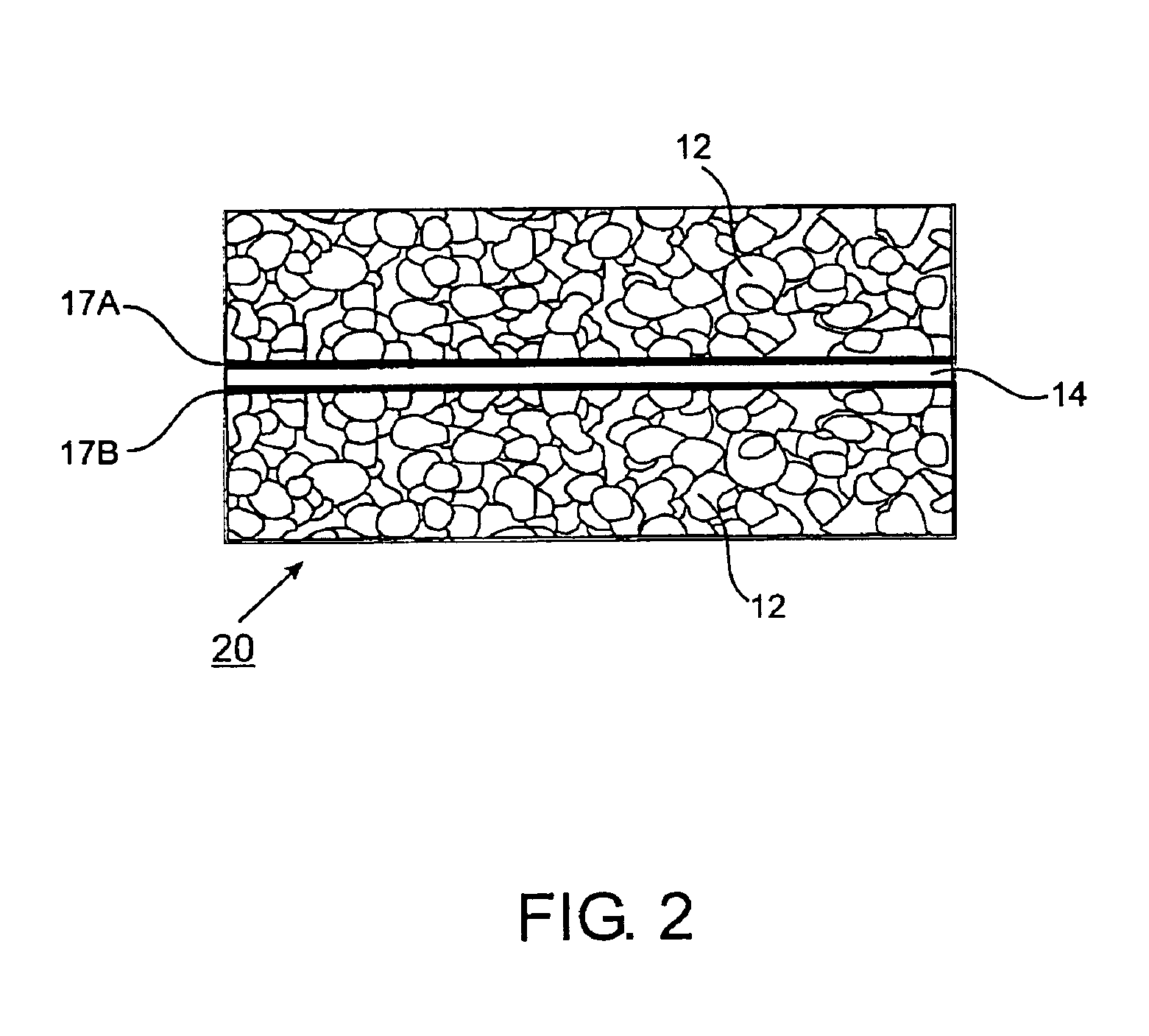

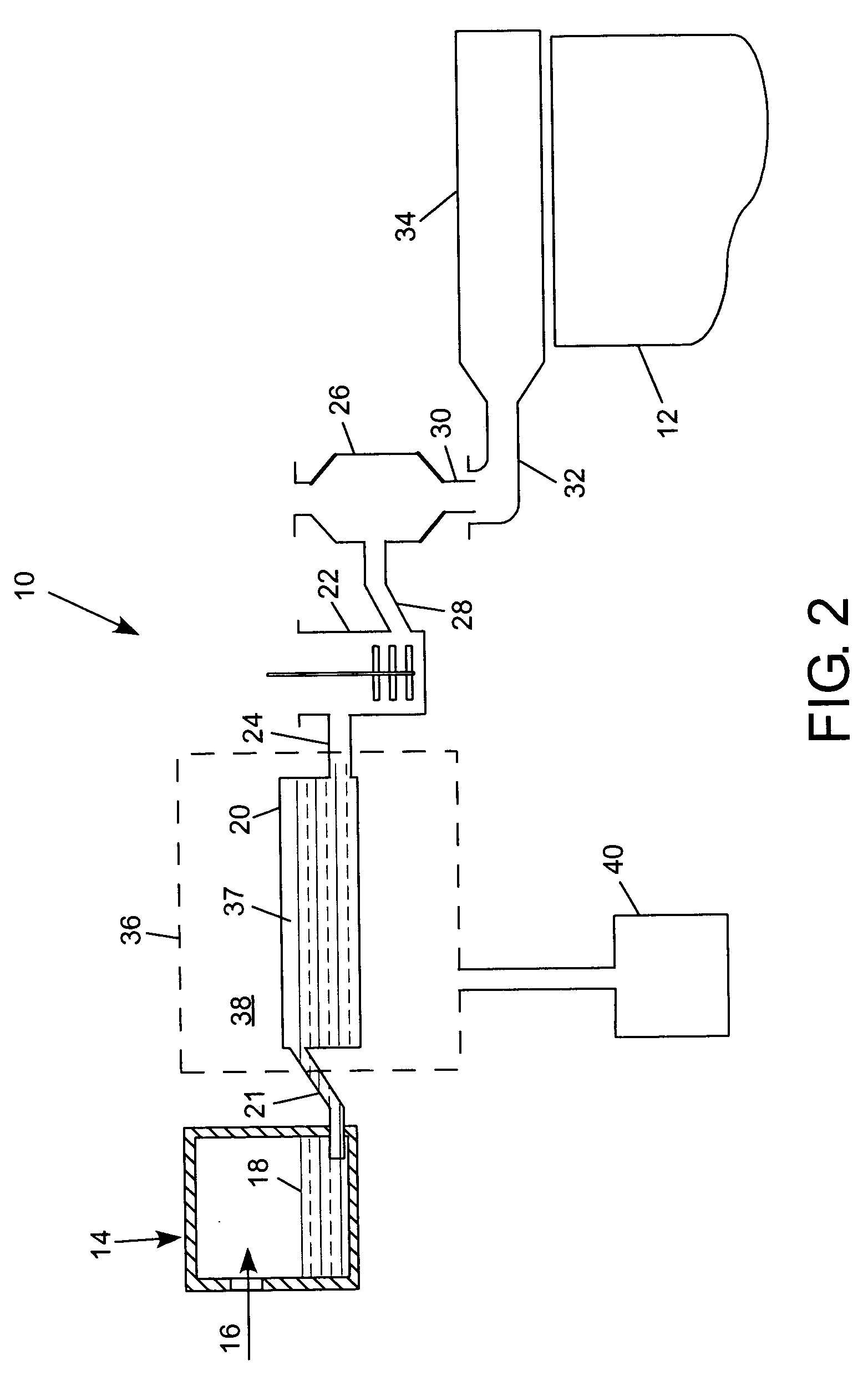

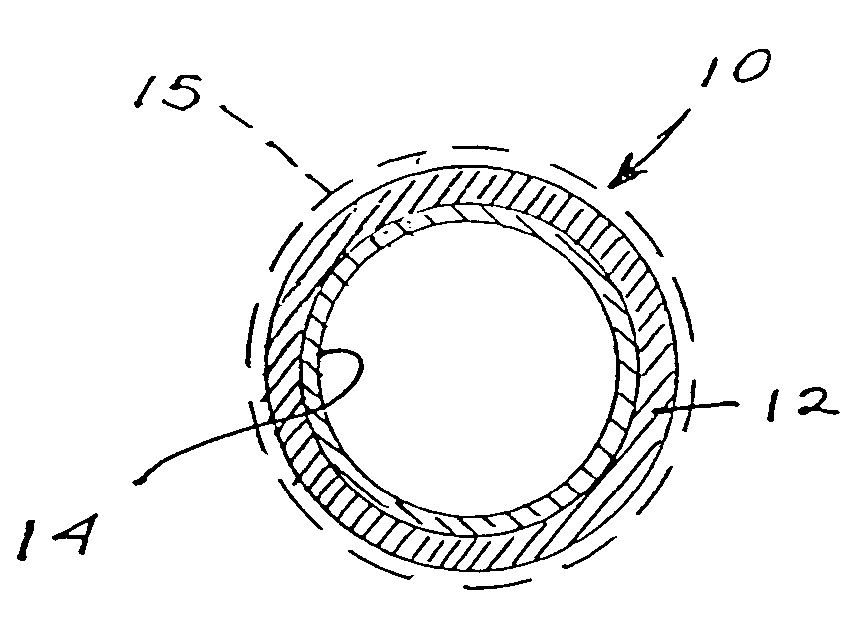

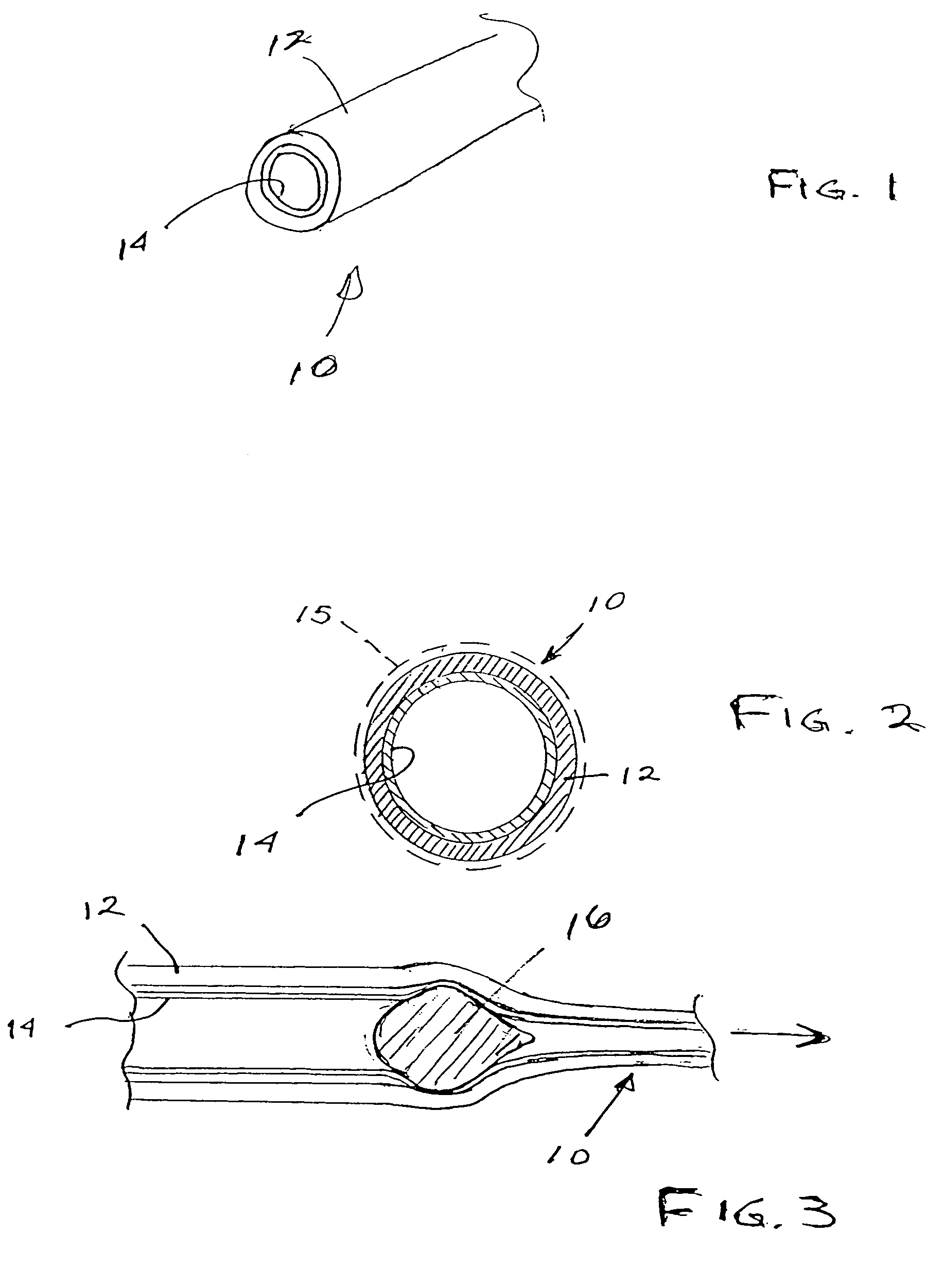

InactiveUS6899744B2Increase ratingsThickness minimizationSemi-permeable membranesMembranesSupport matrixNiobium

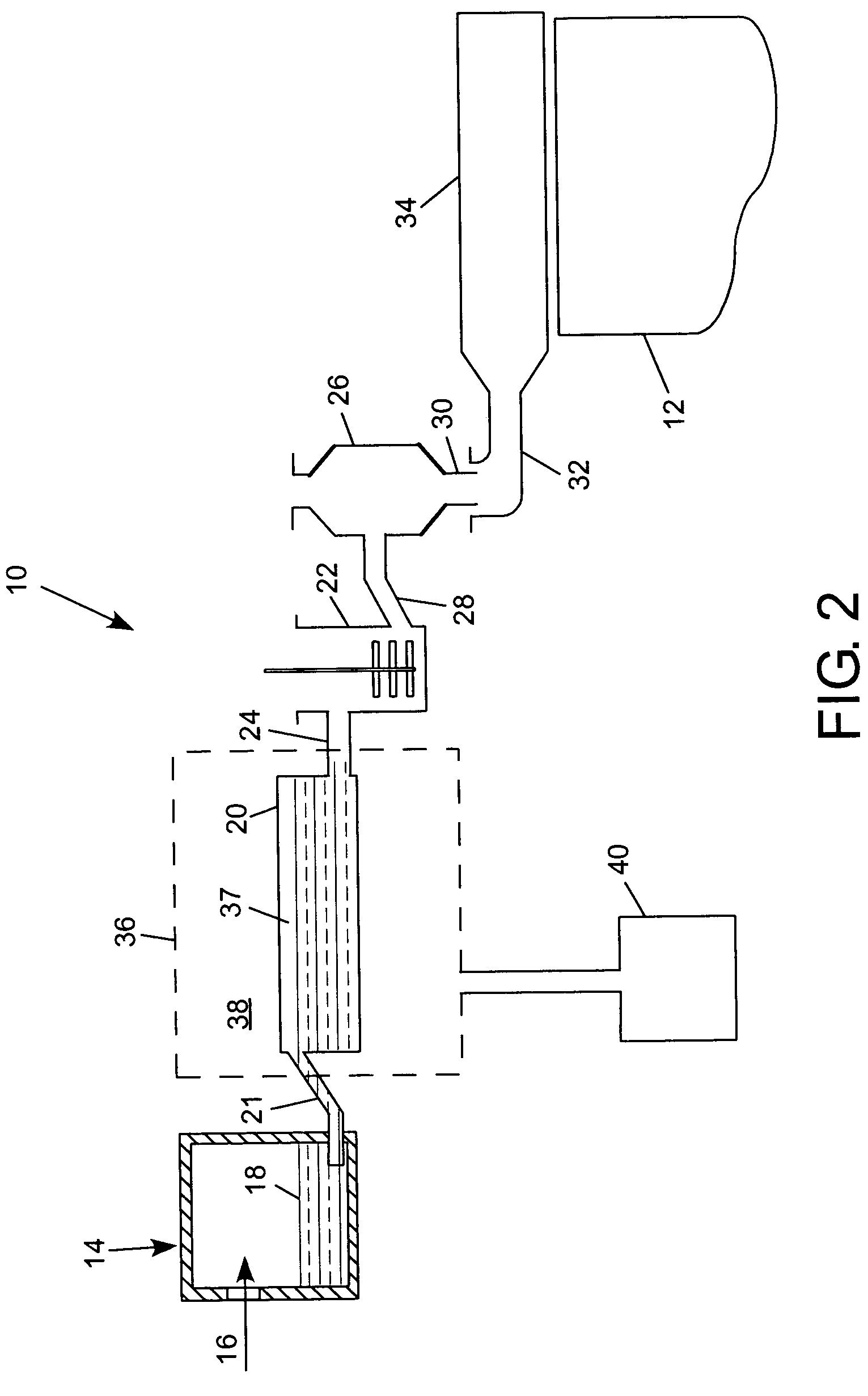

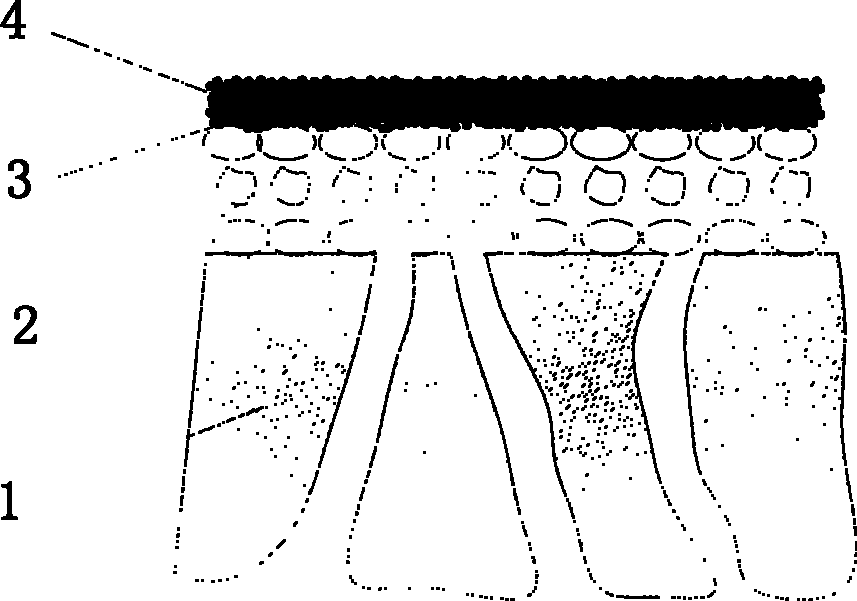

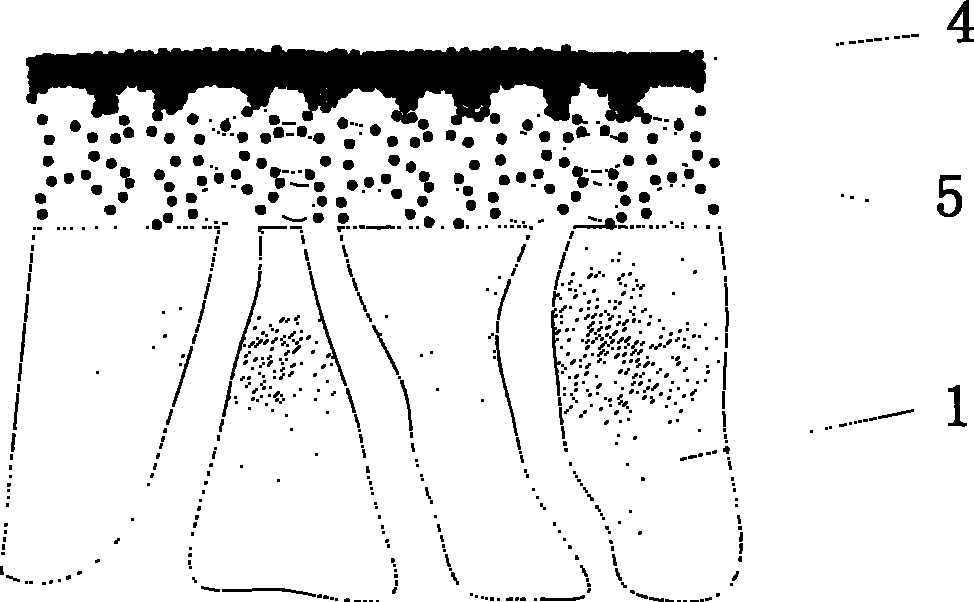

Composite hydrogen transport membranes, which are used for extraction of hydrogen from gas mixtures are provided. Methods are described for supporting metals and metal alloys which have high hydrogen permeability, but which are either too thin to be self supporting, too weak to resist differential pressures across the membrane, or which become embrittled by hydrogen. Support materials are chosen to be lattice matched to the metals and metal alloys. Preferred metals with high permeability for hydrogen include vanadium, niobium, tantalum, zirconium, palladium, and alloys thereof. Hydrogen-permeable membranes include those in which the pores of a porous support matrix are blocked by hydrogen-permeable metals and metal alloys, those in which the pores of a porous metal matrix are blocked with materials which make the membrane impervious to gases other than hydrogen, and cermets fabricated by sintering powders of metals with powders of lattice-matched ceramic.

Owner:ELTRON RES

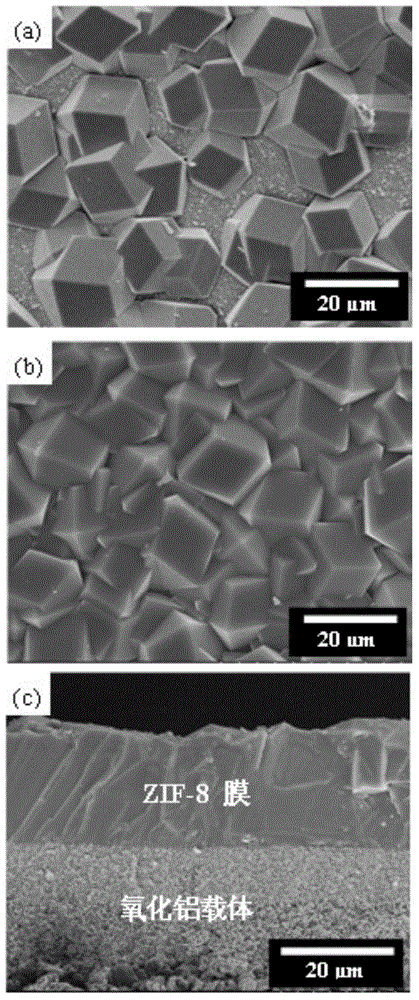

Metal organic framework membrane and preparation method and application thereof

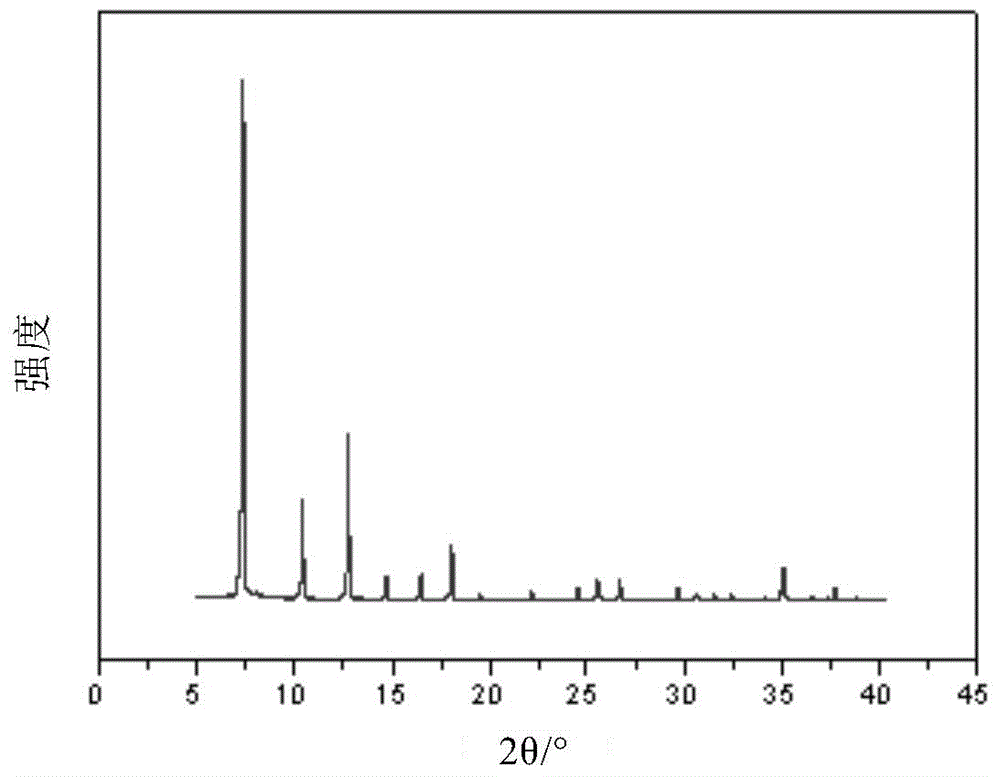

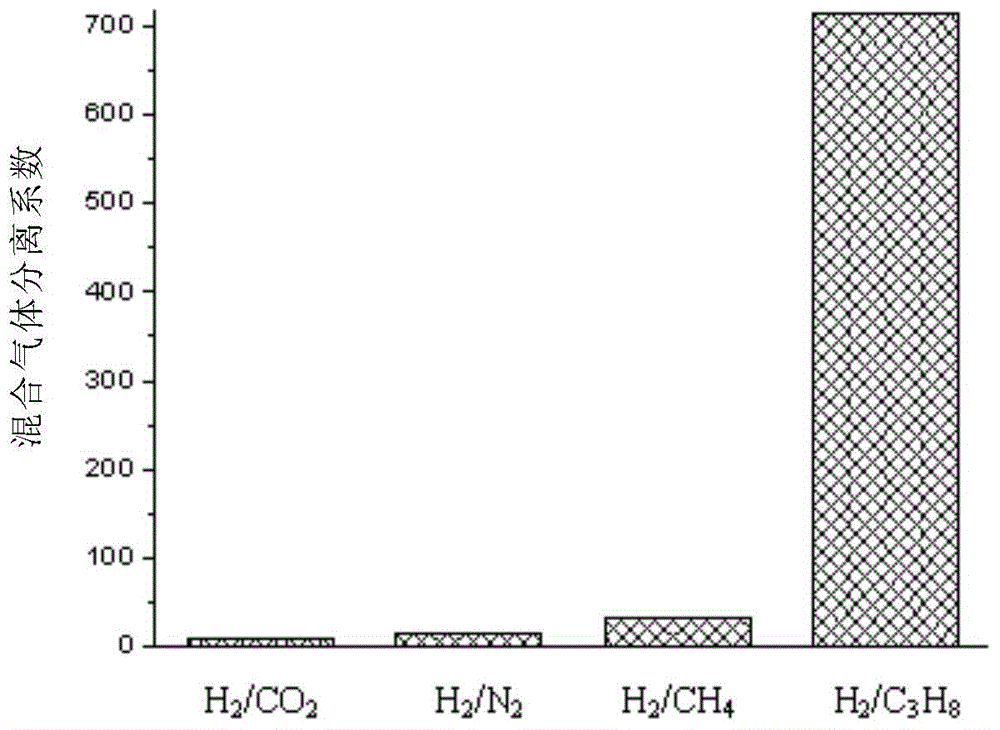

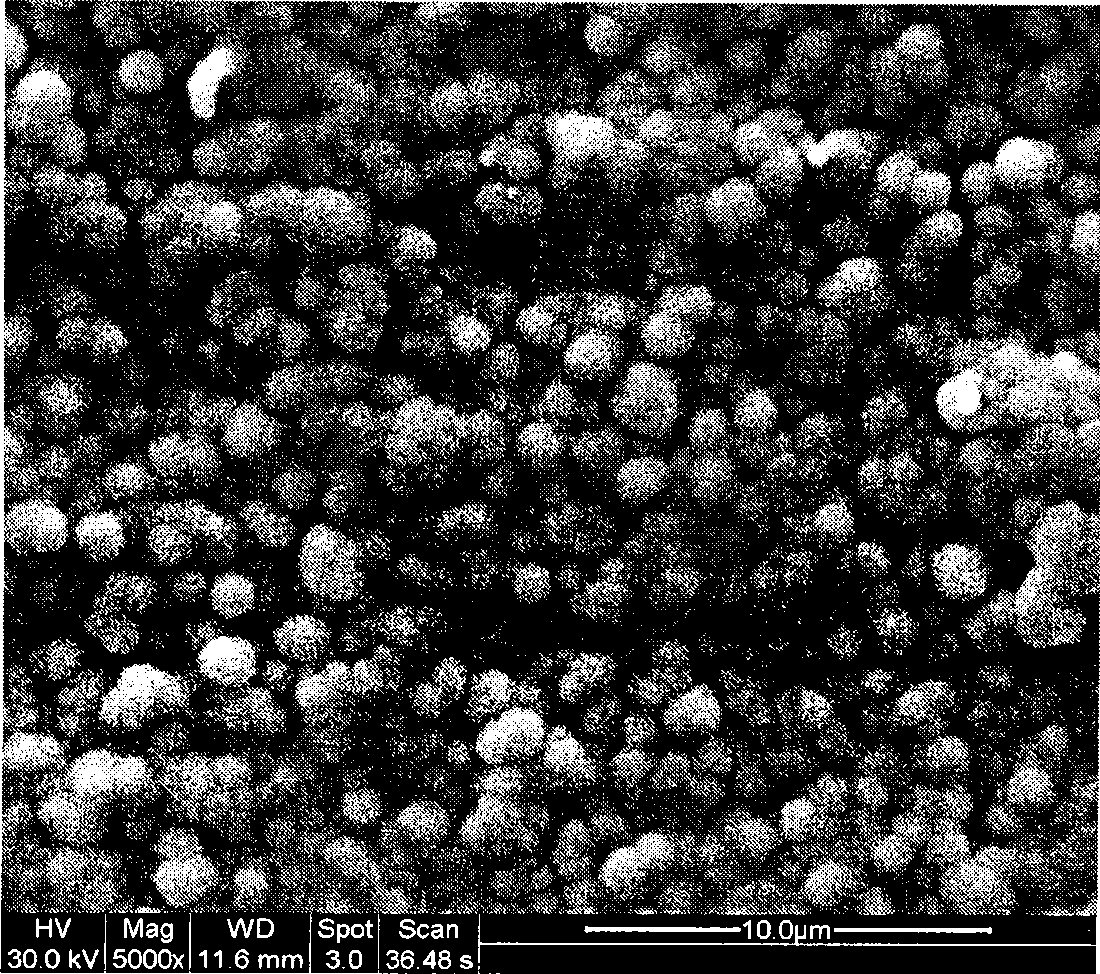

ActiveCN104415670AImprove microstructureEasy to separateSemi-permeable membranesMicrowaveMetal-organic framework

The present invention provides a high-selection hydrogen permeation separation performance metal organic framework membrane for efficient preparation, and especially relates to a zeolite imidazole organic framework membrane, and preparation method of ZIF-8 membrane and a metal organic framework membrane prepared by the method are provided. The method comprises the following steps: using dopamine for functional modification of a solid carrier; and synthesizing the metal organic framework membrane on the surface of the functionally modified solid carrier. By preparation of the metal organic framework membrane by the method, nucleation and growth are greatly enhanced, the prepared metal organic framework membrane is homogeneous and dense, falling-off condition after membrane formation can be significantly improved, and gas separation performance is good; the method has the advantages of mild operation condition, easy industrialized amplification, environment friendliness, and strong applicability. The method can also adopts microwave heating method, the reaction time can be shortened, and the cost of industrial production can be further reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

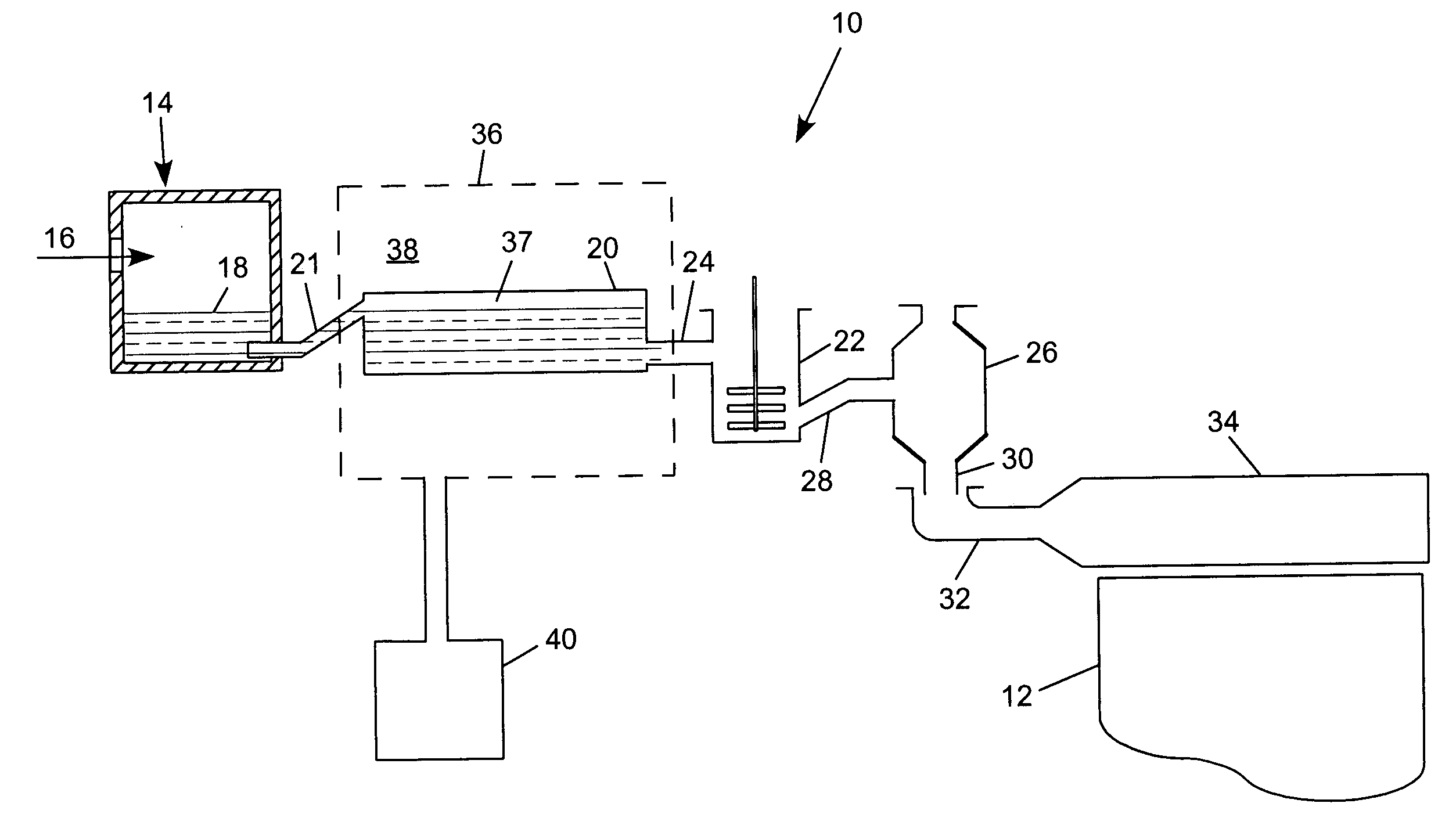

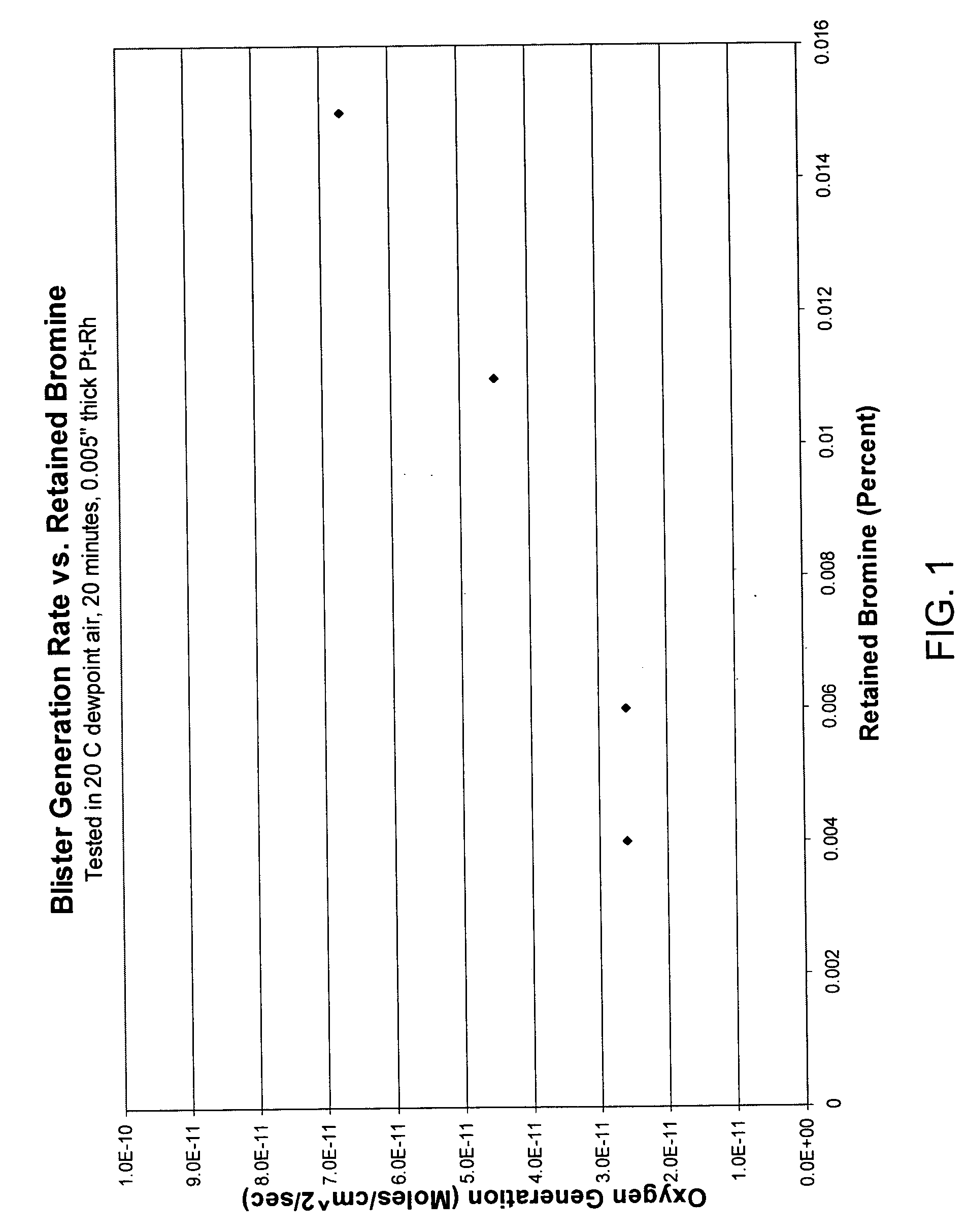

Method of fining glass

InactiveUS20060242995A1Increased hydrogen permeationAvoid formingGlass furnace apparatusGlass vesselAlloy

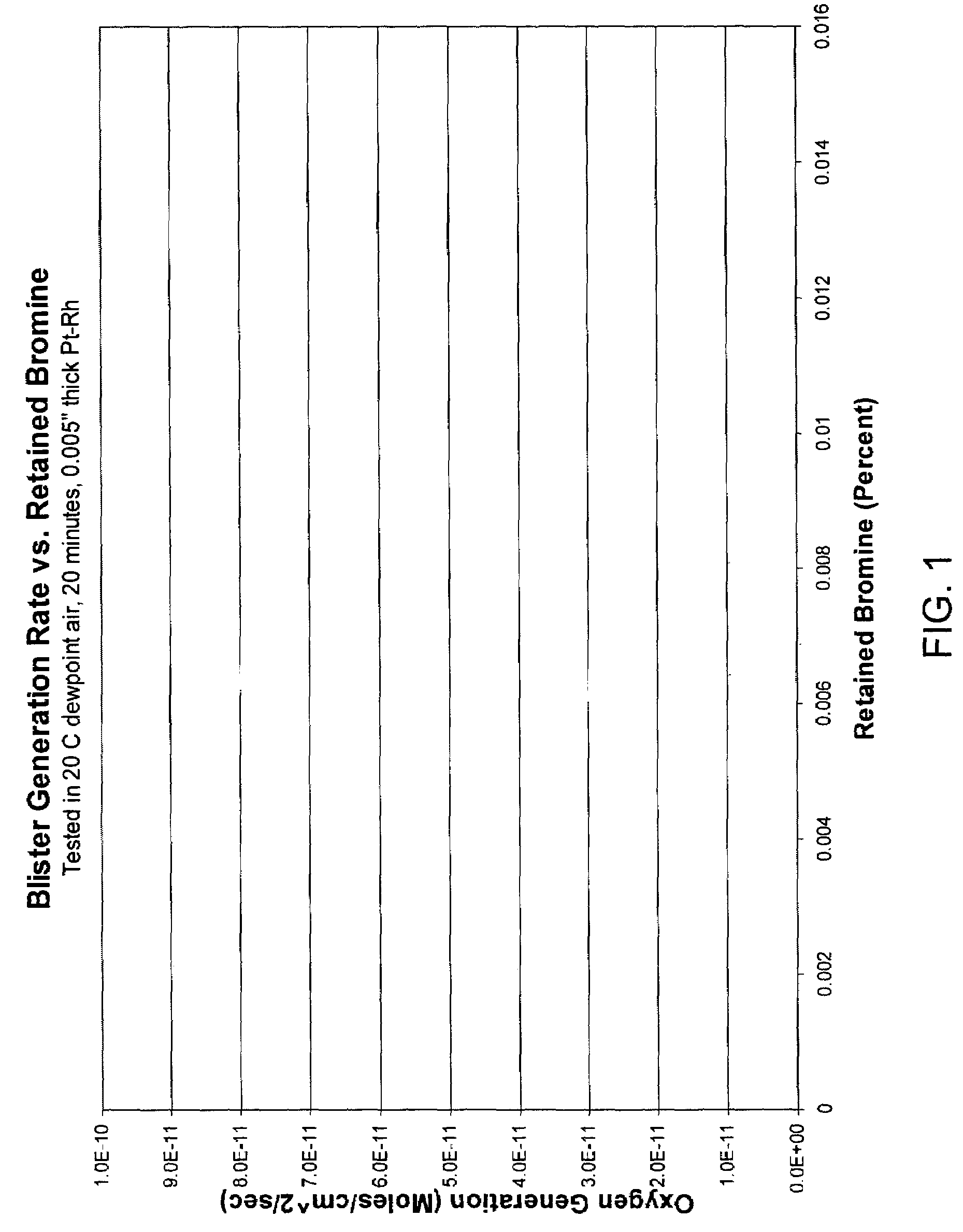

A method of forming an oxide glass including heating a glass melt having a β—OH concentration of at least about 0.35 in a vessel comprising a metal selected from the group consisting of platinum, molybdenum, palladium, rhodium, and alloys thereof, there being an interface present between the vessel and the glass, and controlling a partial pressure of hydrogen in an atmosphere in contact with an outside surface of the vessel in an amount such that hydrogen permeation blisters form in a region of the glass adjacent the glass-vessel interface.

Owner:CORNING INC

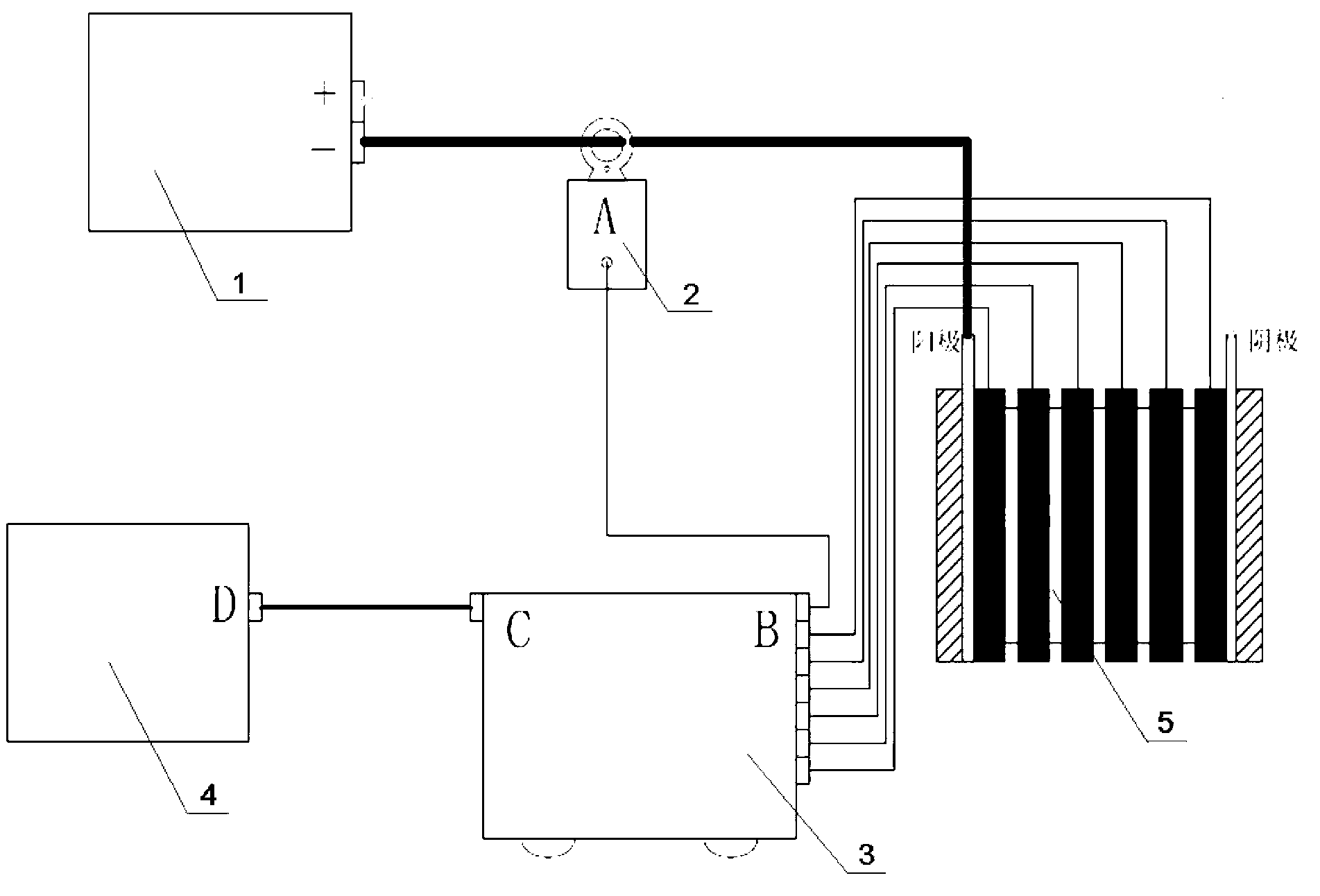

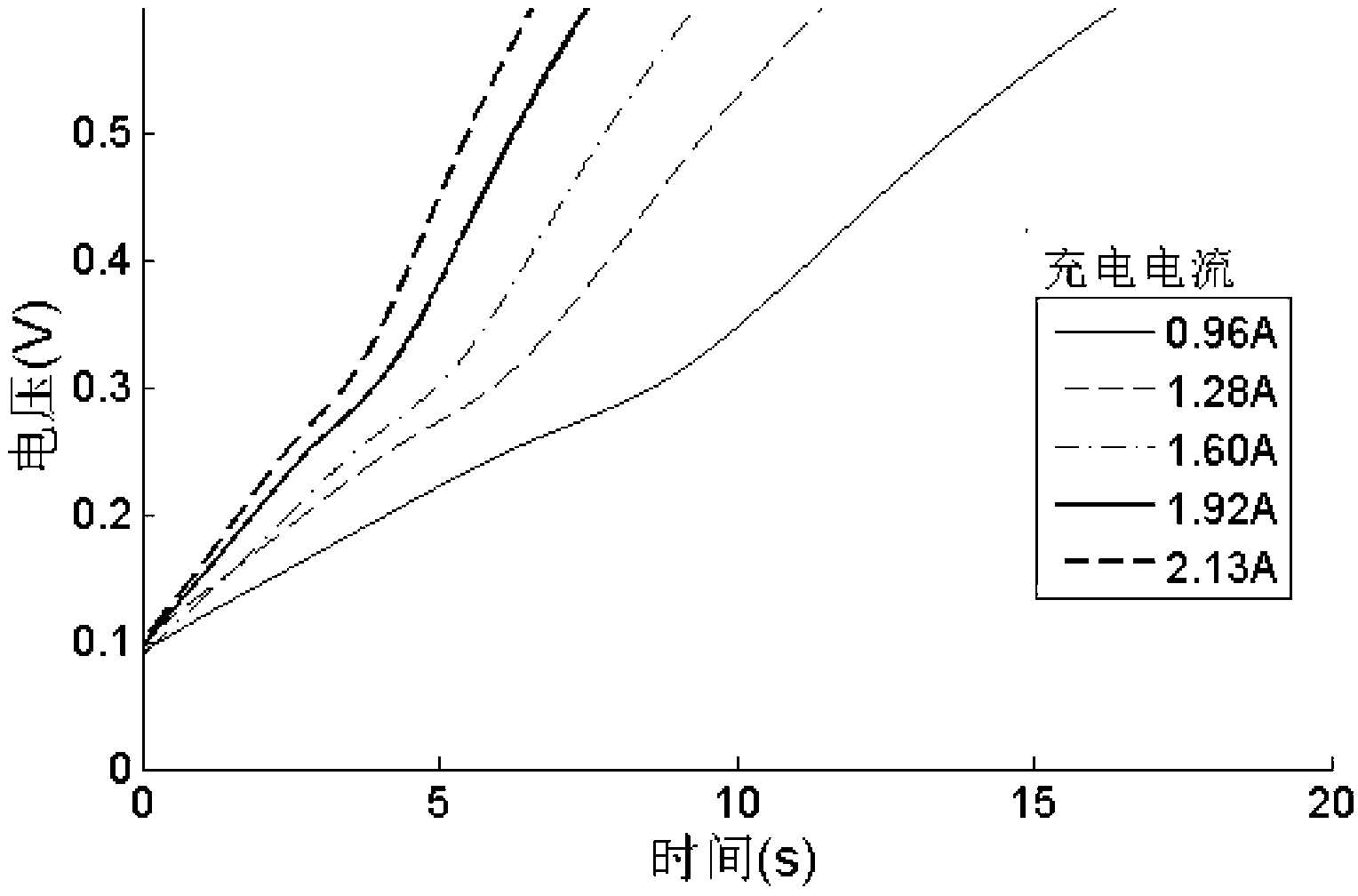

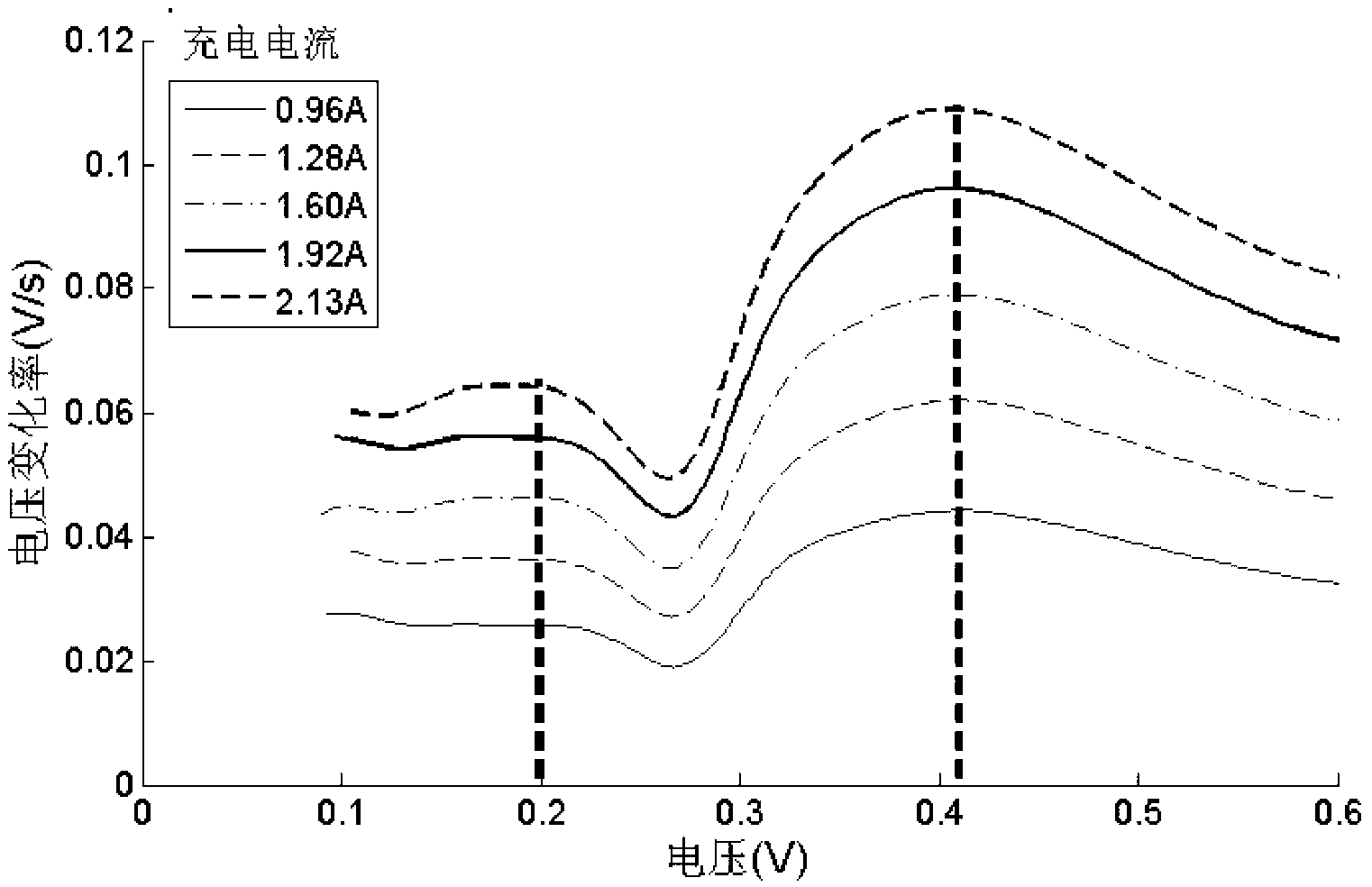

Spot test method and test device for fuel cell stack membrane electrode conditions

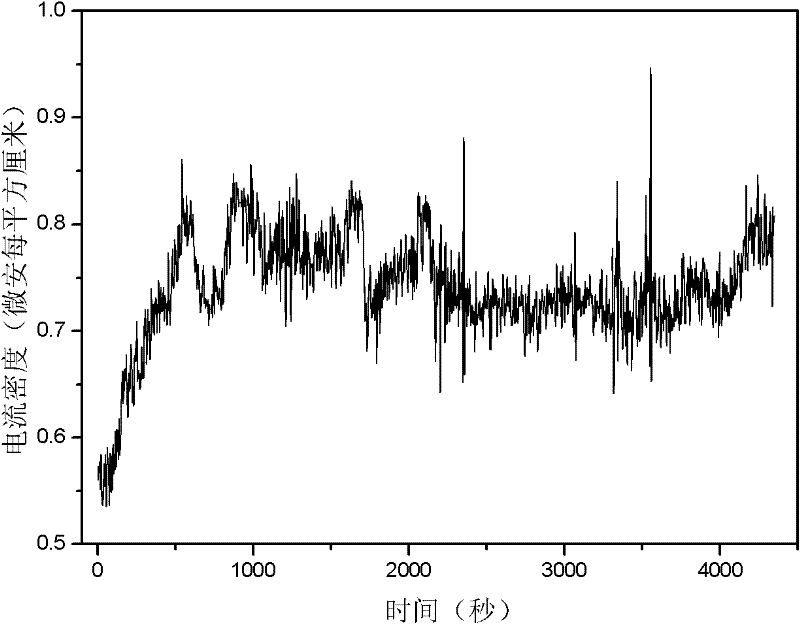

The invention discloses a spot test method and a test device for fuel cell stack membrane electrode conditions. Hydrogen and nitrogen or air are supplied to to-be-tested fuel cells, fuel cell voltage is removed through loads until zero, constant current charging is carried out on the to-be-tested fuel cells by adopting a constant-current power supply, a charging current is measured by a current sensor, current signals of the current sensor and voltage signals of each of the to-be-tested fuel cells are collected by a data collector, converted into digital quantity signals and transmitted to a data processing unit, automatic processing of measured data is achieved through program writing by the data processing unit, and parameters such as catalytic agent effective and active area, double-layer capacitance, hydrogen permeation current and impedance of membrane electrodes of the to-be-tested fuel cells are provided through differential and integral operation on collected voltage data of each fuel cell. The spot test method and the test device for the fuel cell stack membrane electrode conditions are suitable for testing a fuel cell stack or a single fuel cell, and has the advantages of being spot, free of damage, simple and convenient, fast and the like.

Owner:TSINGHUA UNIV

Process For Recovering Hydrogen And Carbon Dioxide

ActiveUS20120121497A1Effective recoveryImprove processing efficiencySolidificationLiquefactionSyngasPhysical chemistry

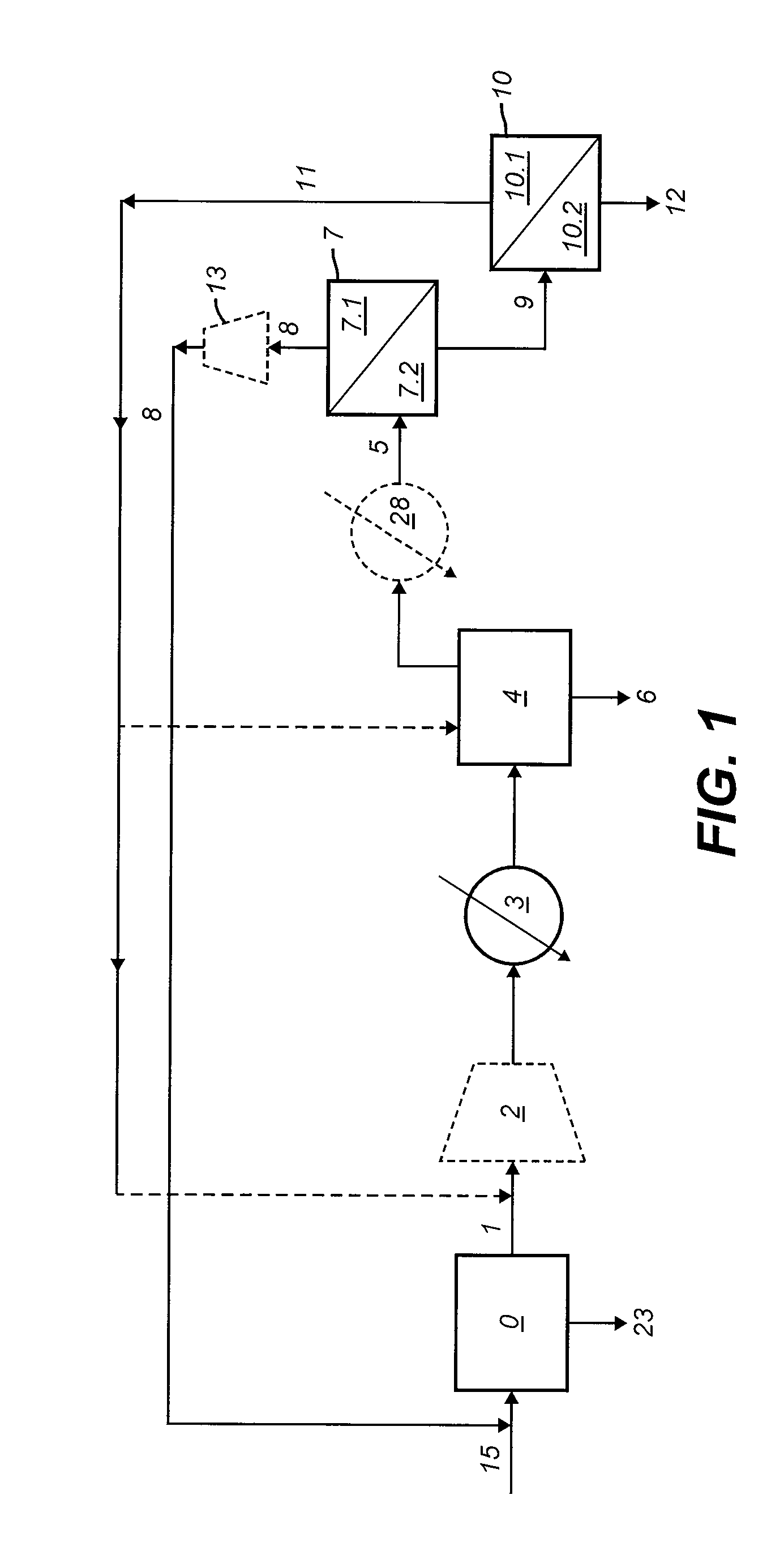

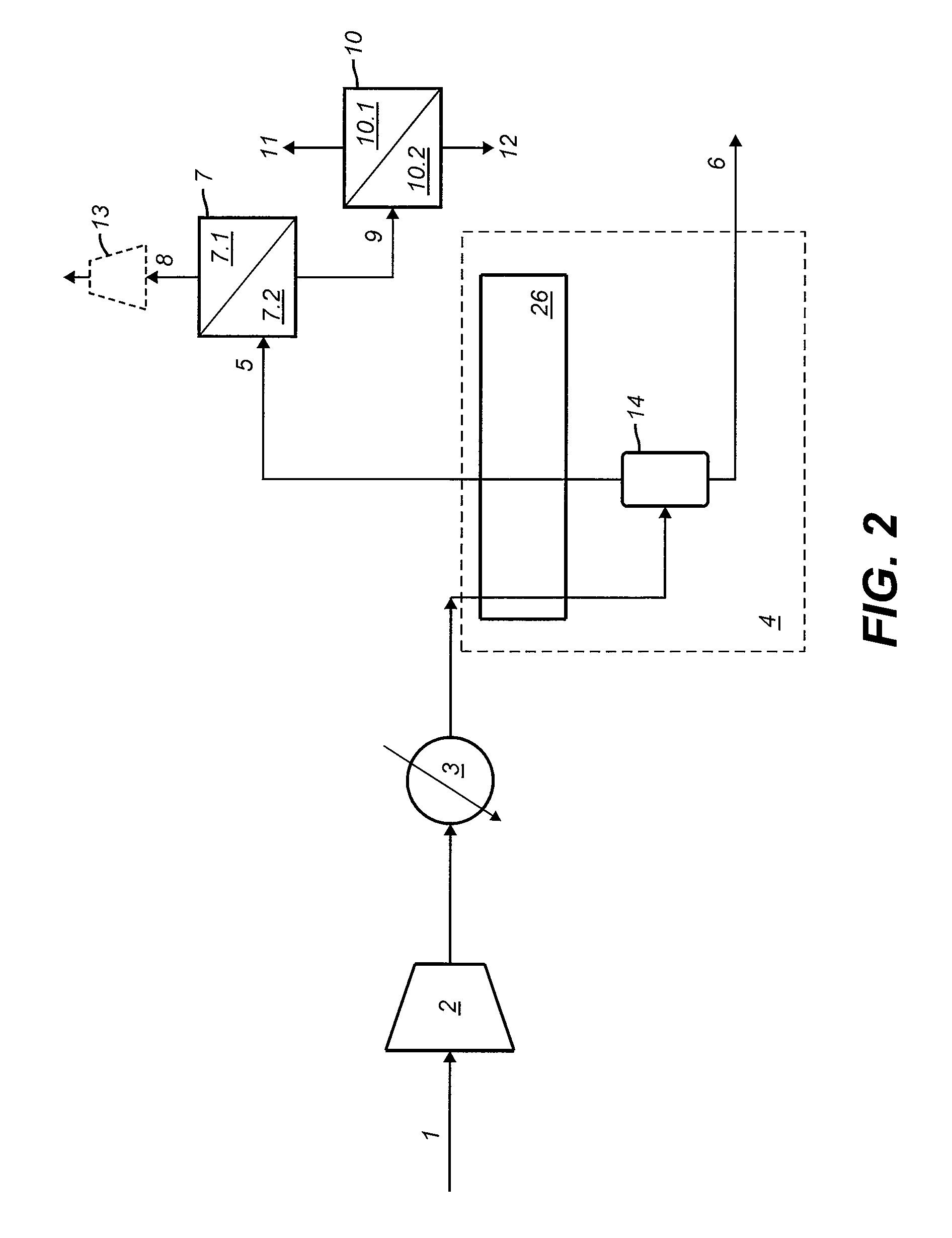

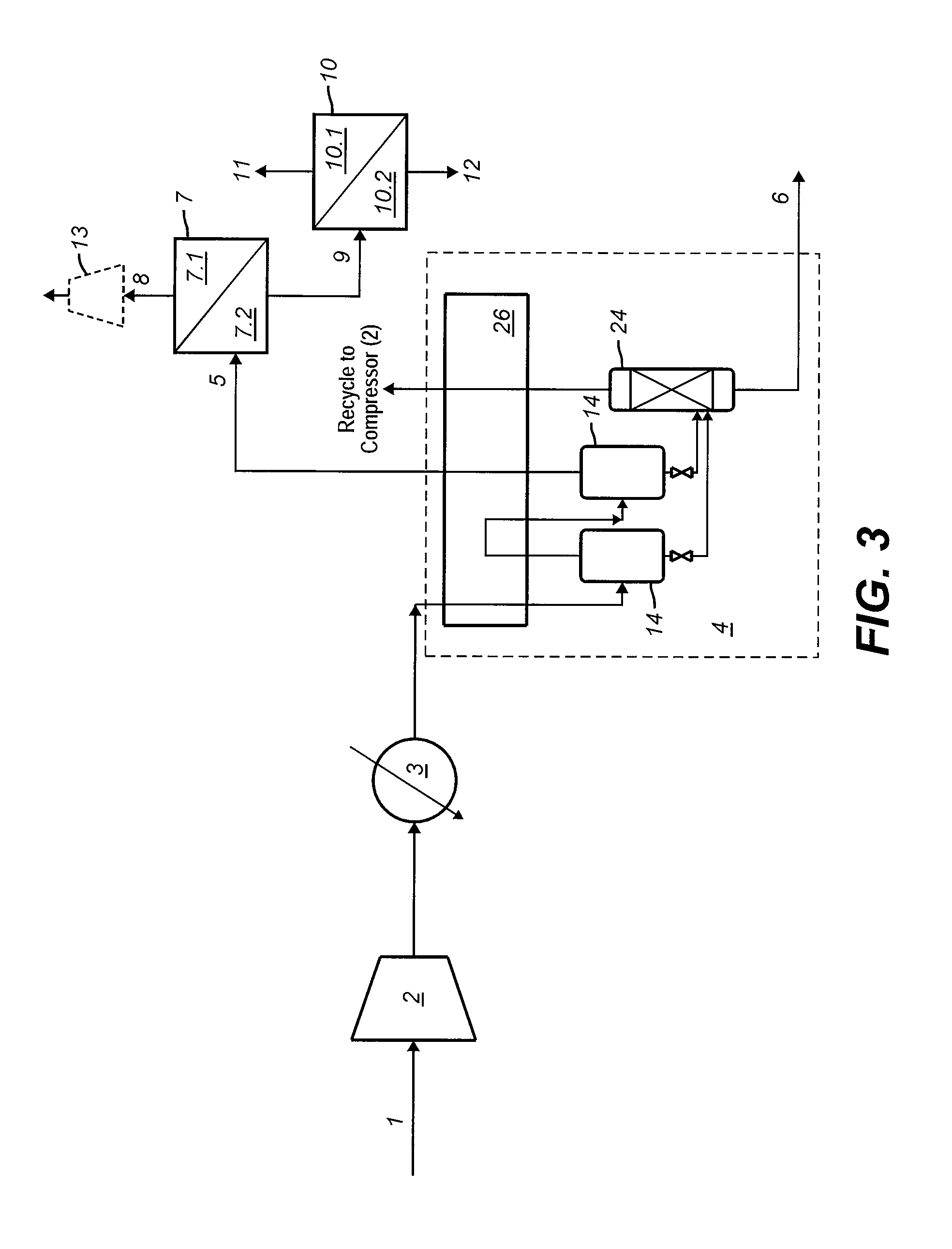

The present invention provides a process for recovering hydrogen and carbon dioxide from a process stream (1) of a process unit (0) wherein the process stream (1) contains at least carbon dioxide, hydrogen and methane. In the process, the process stream (1) is optionally compressing in a first compressor (2) before being cooled in a heat exchanger (3) to a temperature equal to or less than −10° C. Next, the cooled process stream (1) is separated and purified in a carbon dioxide separation unit (4) to produce a carbon dioxide rich liquid stream (6) and a carbon dioxide lean non-condensable stream (5) with the carbon dioxide rich liquid stream (6) being withdrawn as a carbon dioxide product for further use. The carbon dioxide lean non-condensable stream (5) is then withdrawn from the carbon dioxide separation unit (4) and passed through a hydrogen selective membrane separation unit (7) to form a hydrogen rich permeate stream (8) with the remaining components in the carbon dioxide lean non-condensable stream (5) forming a hydrogen lean residue stream (9). The hydrogen lean residue stream (9) is passed through a carbon dioxide selective membrane separation unit (10) to form a carbon dioxide enriched permeate stream (11) with the remaining components in the hydrogen lean residue stream (9) forming a carbon dioxide depleted residue stream (12). The hydrogen rich permeate stream (8) is optionally compressed in a second compressor (13) and recycled for use as a supplemental feed stream in the process unit (0) or in other processes. The carbon dioxide enriched permeate stream (11) is recycled to the process stream (1) prior to the compressor (2) or within the compressor (2) between stages of compression, or to the carbon dioxide separation unit (4) while the carbon dioxide depleted residue stream (12) is withdrawn for further use. The present invention further relates to the use of this process within a hydrogen generation plant to increase recovery of hydrogen and capture equal to or greater than 90% of the carbon dioxide in the syngas stream.

Owner:AIR LIQUIDE LARGE INDS U S LP +1

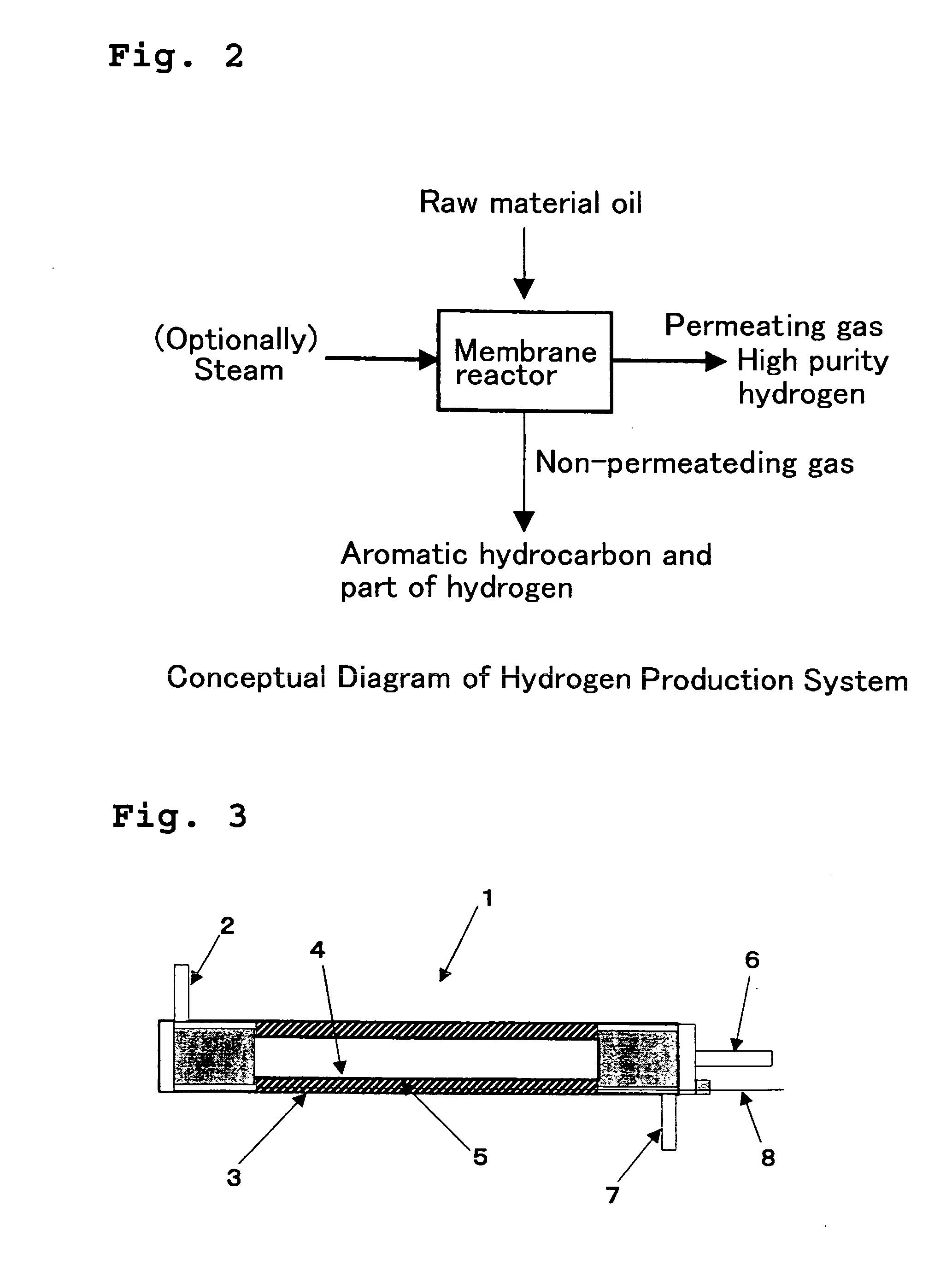

Method for Producing Hydrogen and System Therefor

InactiveUS20080234527A1Efficient productionReduce pressureOrganic chemistry methodsHydrogen/synthetic gas productionDouble tubeDehydrogenation

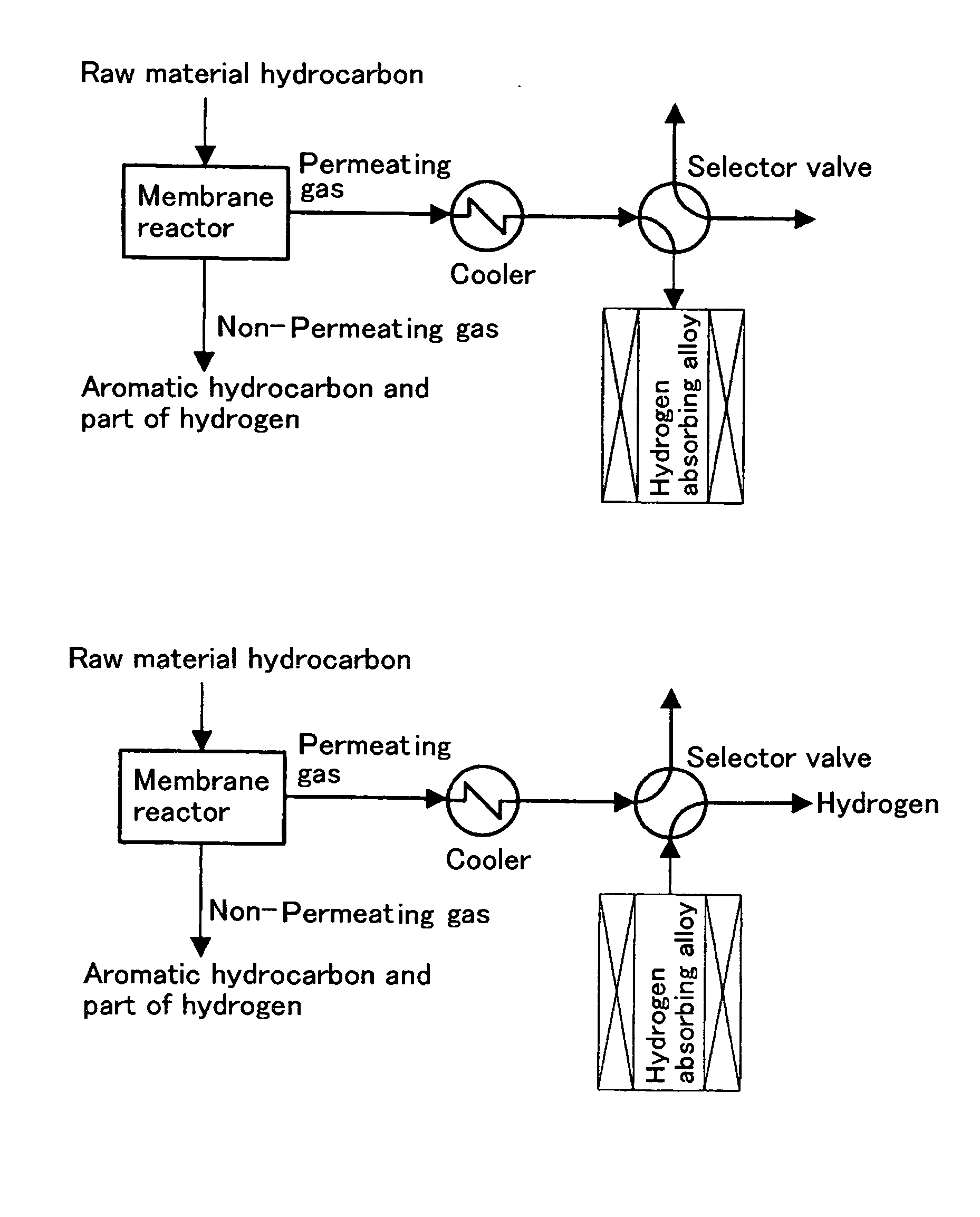

The present invention provides a hydrogen production method capable of producing hydrogen with good efficiency while solving problems such as separation, lower-temperature reaction and heat supply in production of hydrogen by dehydrogenation reaction of raw material oil. Within a reaction tube of a double-tube structure comprising an inner tube composed of a hydrogen separating membrane, a metallic outer tube having a plurality of internal fins, and a metal oxide layer and further a catalyst supported on the fins, hydrocarbon having cyclohexane ring is dehydrogenated to produce hydrogen and aromatic hydrocarbon, and selective membrane separating operation of hydrogen is performed within the reaction system while conducting the dehydrogenation to remove mainly the hydrogen on a permeating side and obtain mainly the aromatic hydrocarbon on a non-permeating side. The other method comprises absorbing at least part of the resulting hydrogen flow to a hydrogen absorbing (storing) alloy to make the pressure on the hydrogen permeating side of the hydrogen separating membrane lower than that on the non-permeating side.

Owner:NIPPON OIL CORP

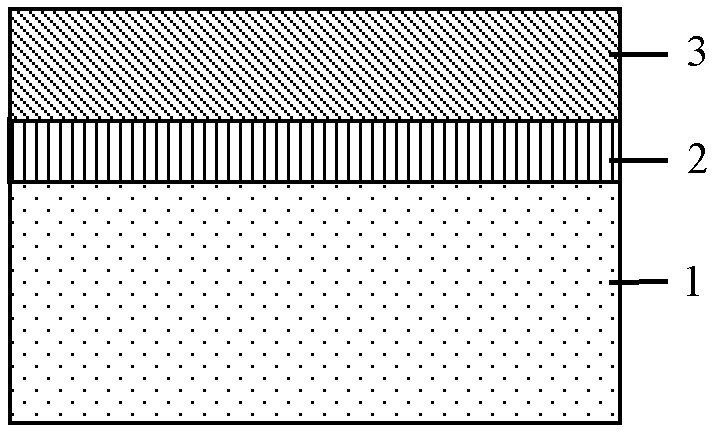

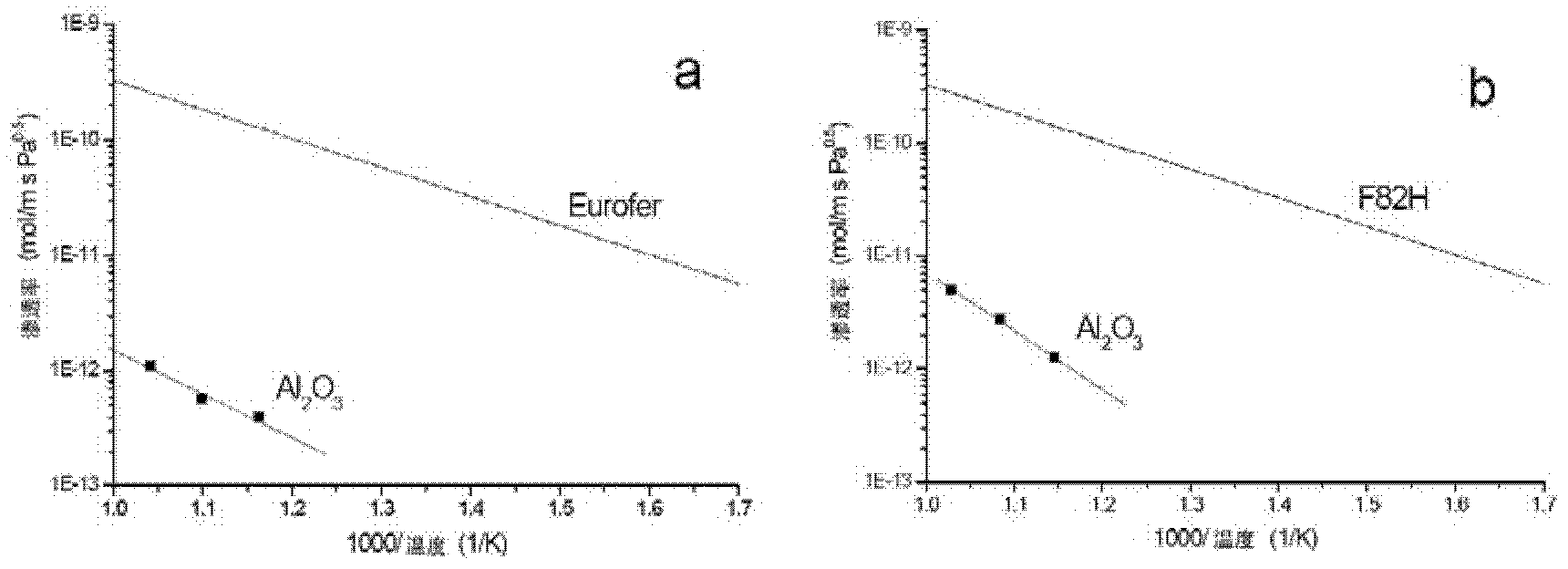

Steel-based hydrogen permeation-resistant composite coating and preparation method for same

InactiveCN103160828AHas hydrogen permeation resistanceHigh bonding strengthSuperimposed coating processHydrogen permeationBinding force

The invention provides a steel-based hydrogen permeation-resistant composite coating and a preparation method for the same. The hydrogen permeation-resistant composite coating is composed of a thermally-grown oxide coating on a steel surface, and a compact aluminium oxide coating on the thermally-grown oxide coating, wherein the thermally-grown oxide coating is obtained by performing controlled oxidation treatment on a steel matrix at 700-1000 DEG C; the aluminium oxide hydrogen permeation-resistant coating is provided on the thermally-grown oxide coating which is provided by the steel matrix; and the high-temperature binding force and the thermal cycle performance of the aluminium oxide coating are improved by a thermally-grown oxide middle transition layer. The aluminium oxide coating prepared by the preparation method provided by the invention is compact in structure, strong in binding force, and excellent in hydrogen permeation resistance and thermal cycle use performance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

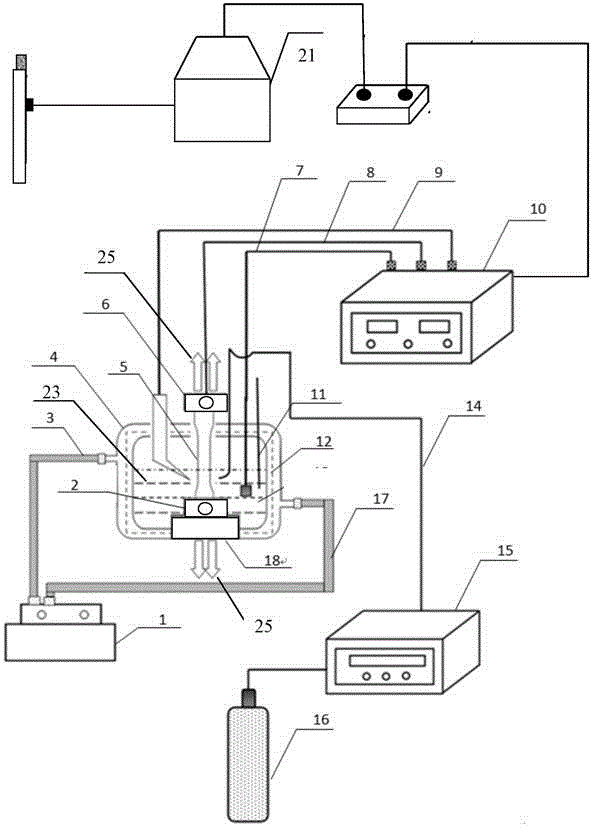

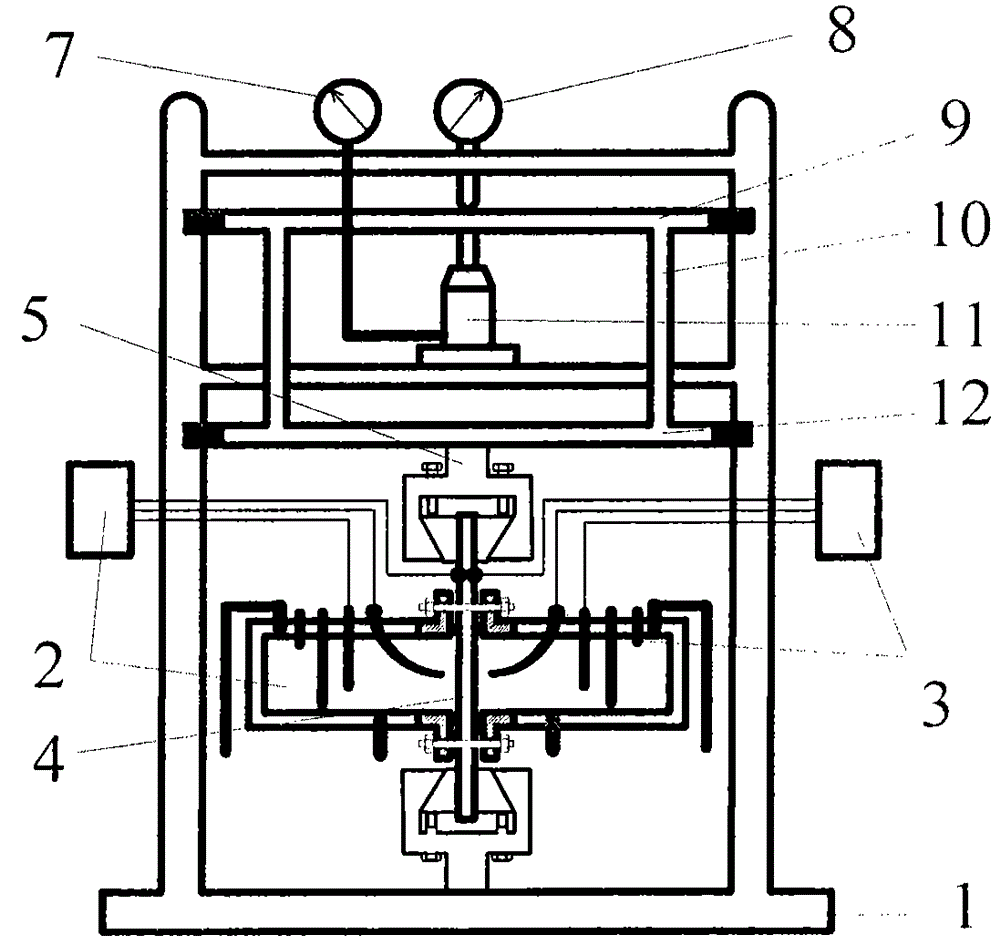

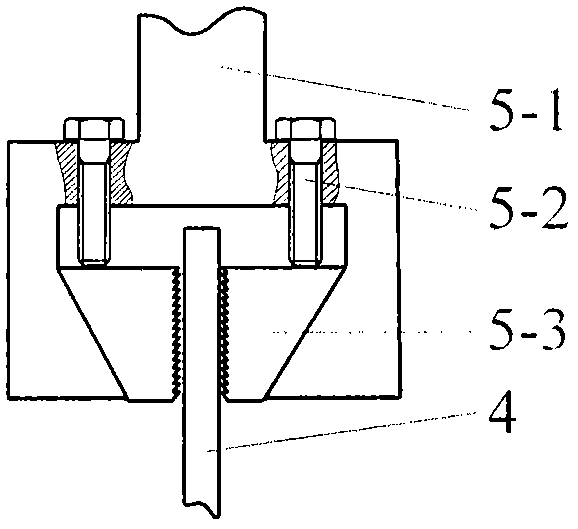

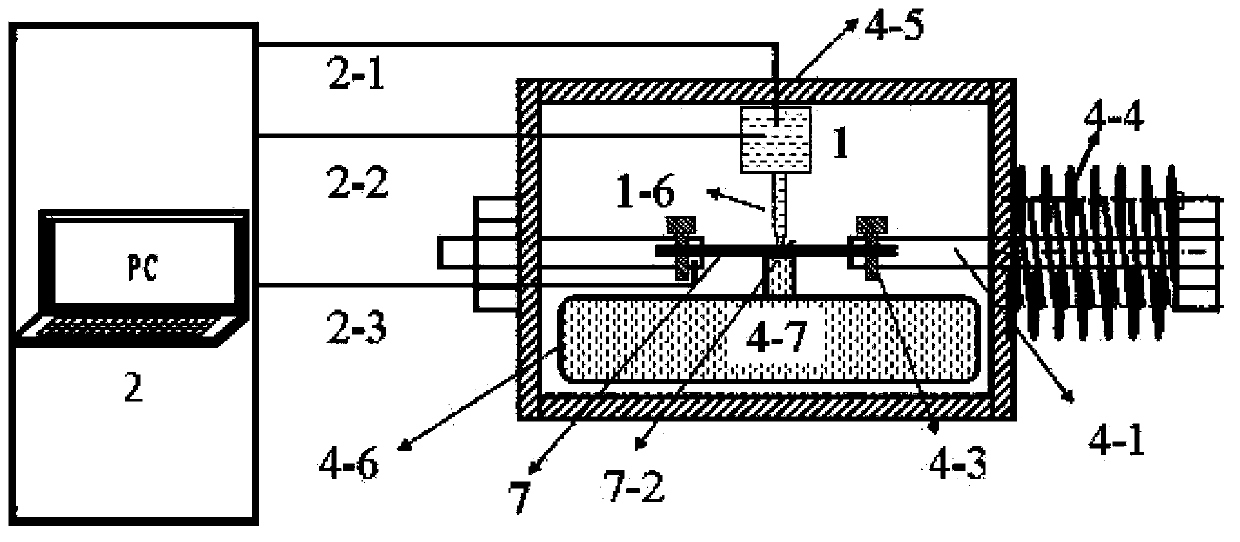

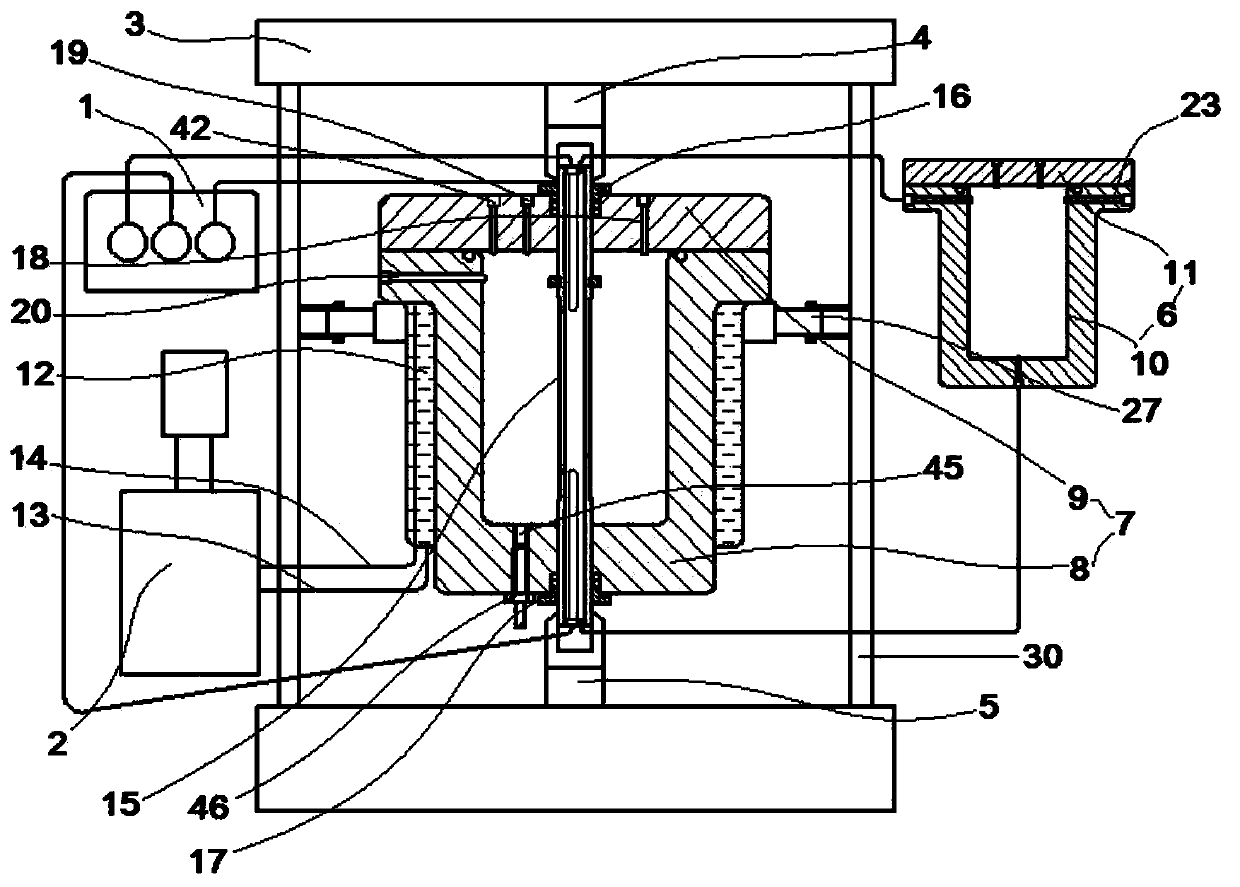

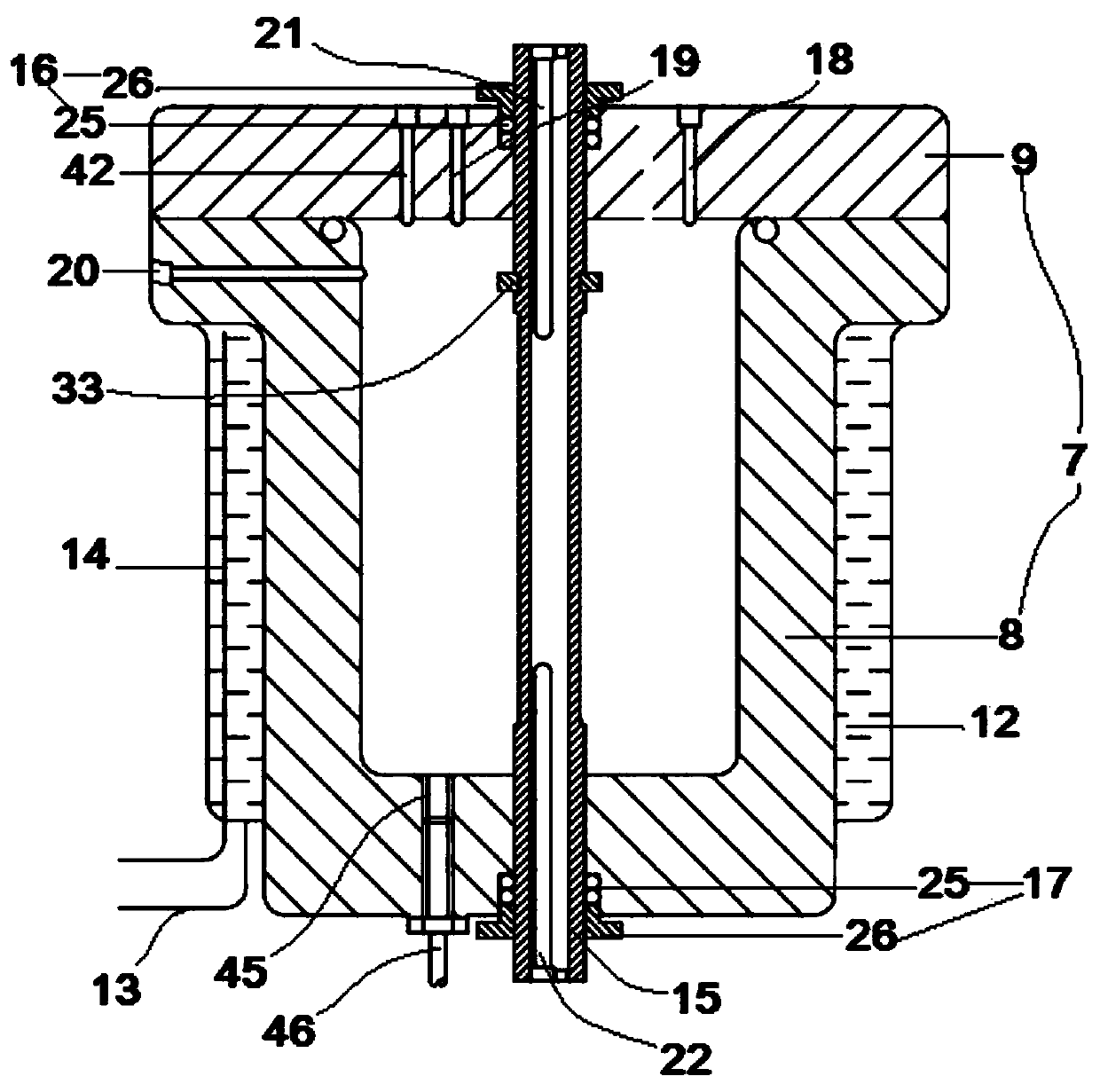

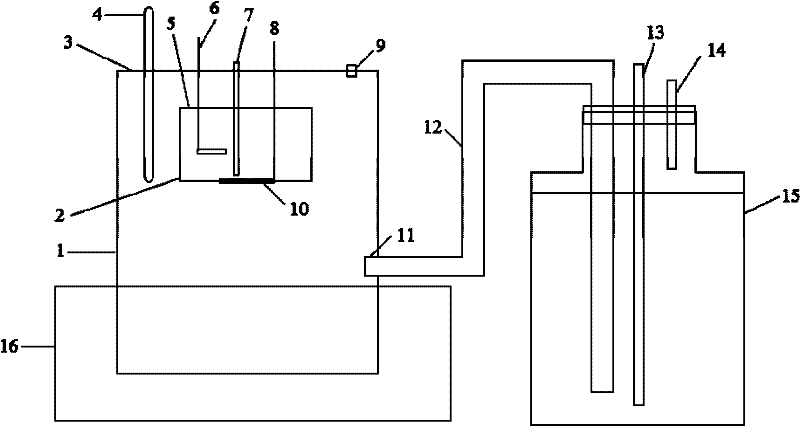

Stress corrosion and hydrogen measuring electrochemical in-situ measurement device under slow strain speed condition

ActiveCN105300874ARealize in situ electrochemical behavior detectionSample size adjustableWeather/light/corrosion resistanceMeasurement deviceMetallic materials

The invention provides a stress corrosion and hydrogen measuring electrochemical in-situ measurement device under a slow strain speed condition. The stress corrosion and hydrogen measuring electrochemical in-situ measurement device comprises an electrochemical work station, an auxiliary electrode, a working electrode, a reference electrode, a stretching test sample, a slow strain stretching machine, a computer, an isolation transformer, a corrosion device and a hydrogen measuring device. The stress corrosion and hydrogen measuring electrochemical in-situ measurement device has the effects that an electrochemical in-situ test can be carried out on stress corrosion and hydrogen permeation respectively under the slow strain speed condition through replacing a corrosion electrolytic tank; the device has the characteristics of adjustable test sample size, in-situ electrochemical measurement, accurate load-displacement readings, simple structure, convenience and flexibility in utilization, simplicity in operation and the like. The device can be used for simultaneously realizing in-situ electrochemical behavior detection of pull stress, corrosive liquid, corrosive gas and temperatures, and can be widely applied to researches of strain speeds, the pull stress, types and concentrations of corrosive media, pH values, temperatures, corrosive gas partial pressure and concentration and influences on corrosion of metal materials by hydrogen brittleness, and a damage evolution rule of materials can be analyzed through electrochemical data.

Owner:CIVIL AVIATION UNIV OF CHINA

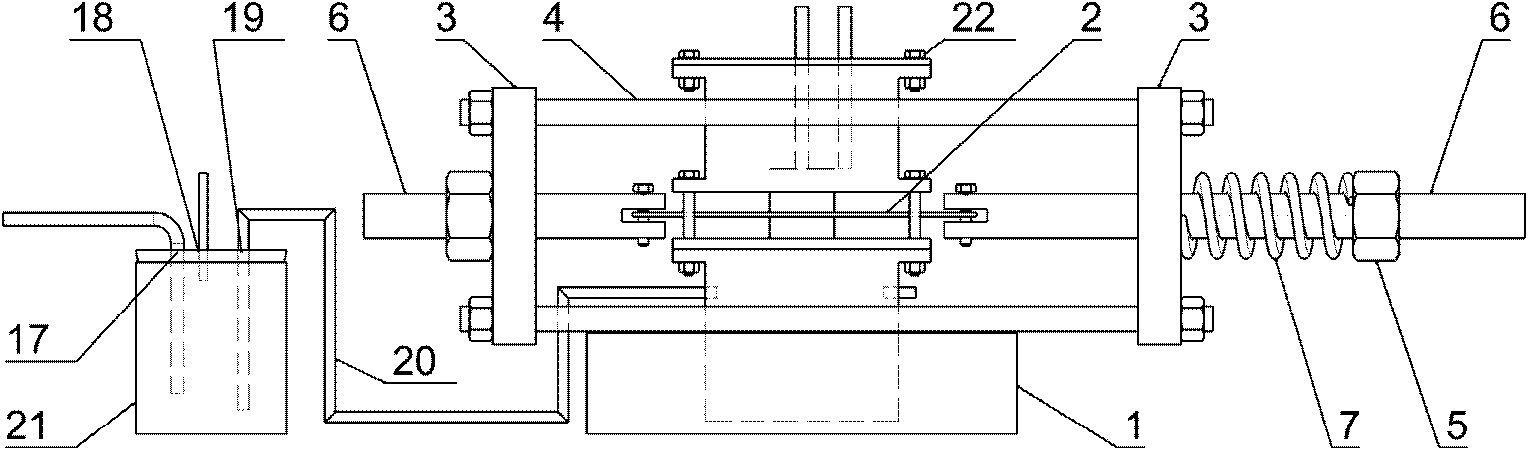

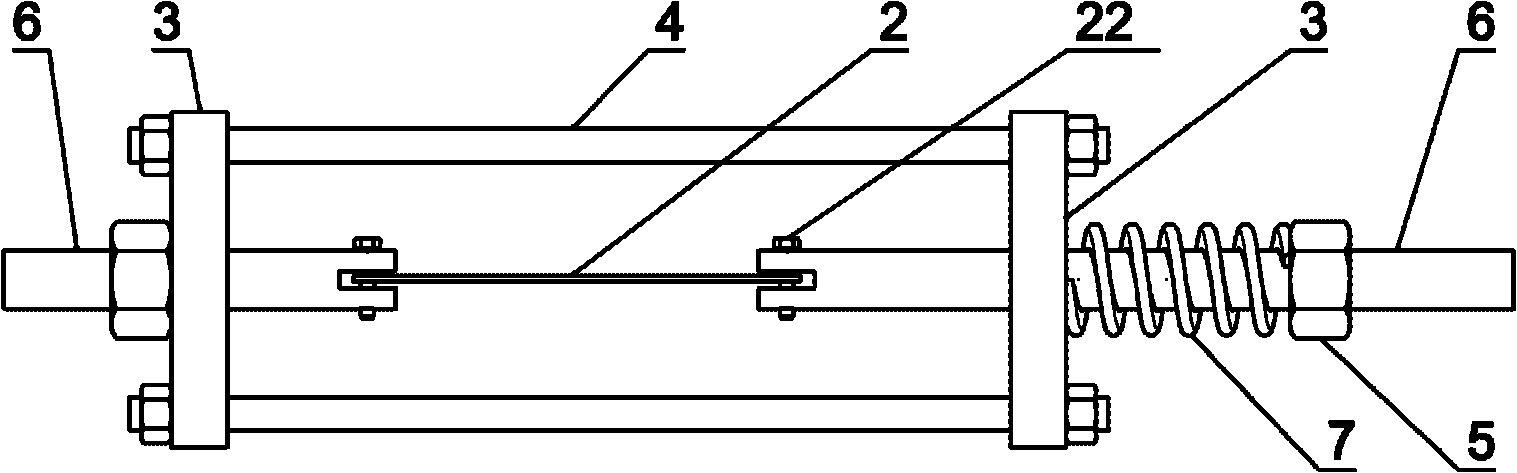

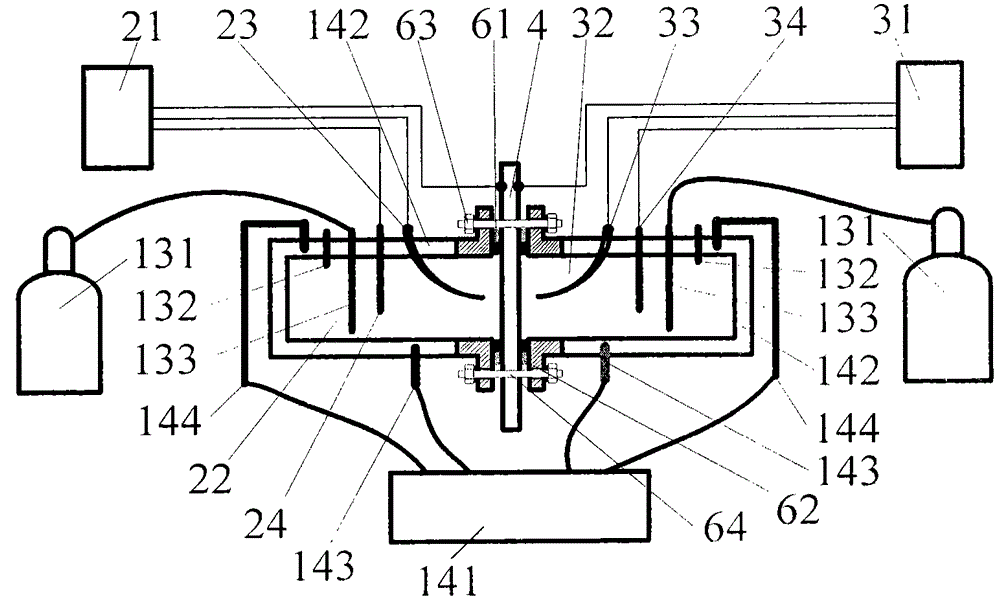

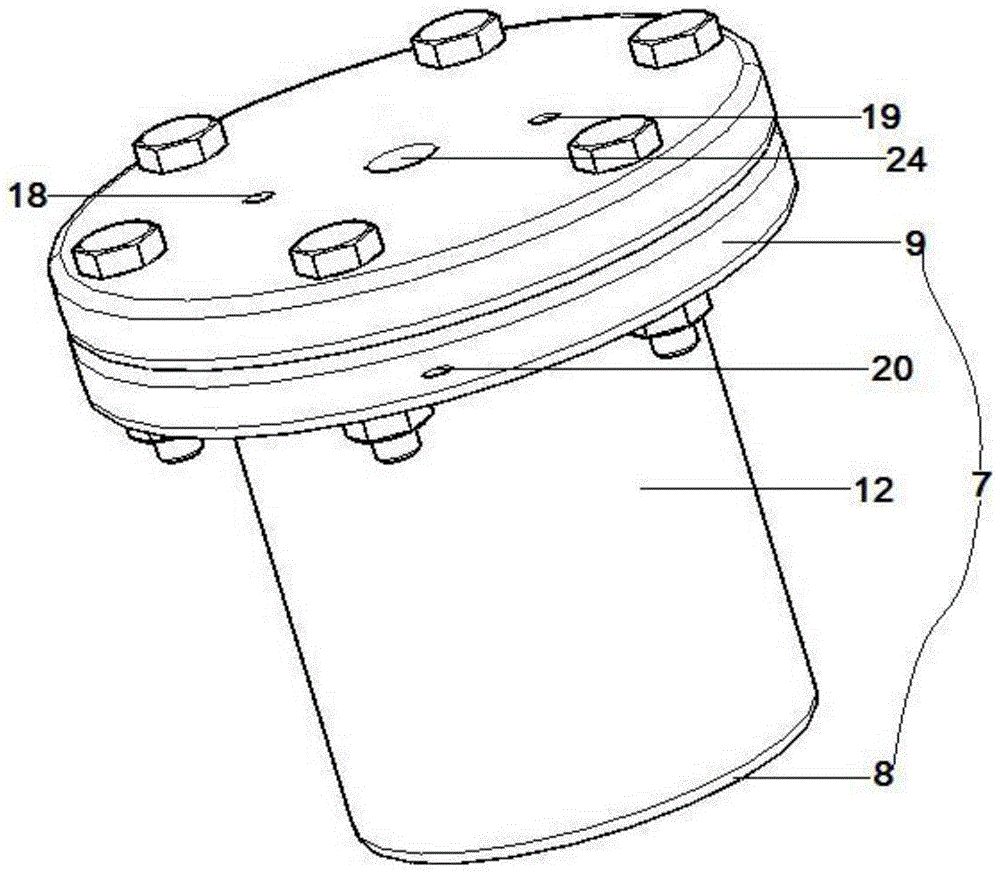

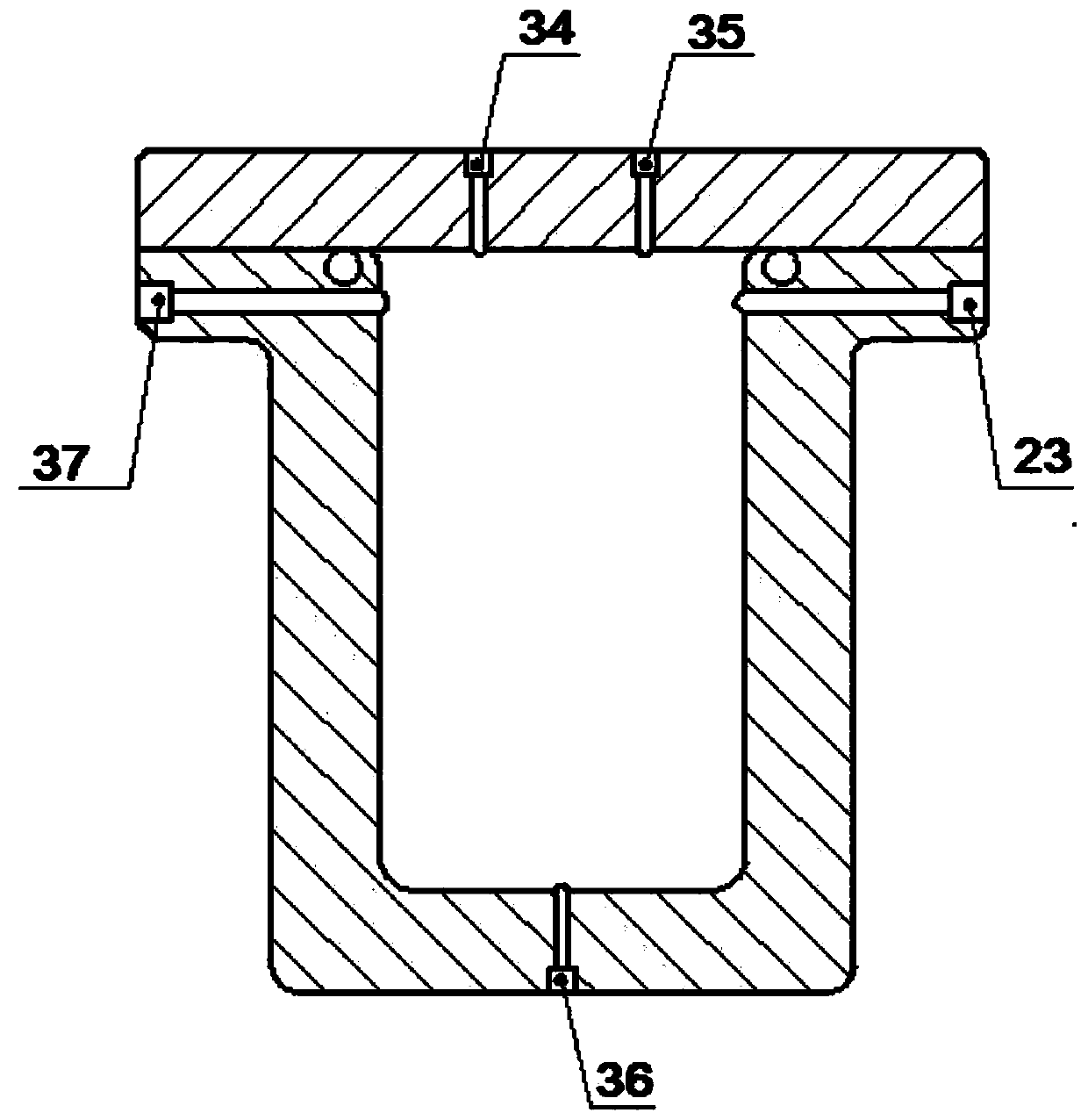

Device and method for researching hydrogen permeation behavior of metal subjected to dead-load pulling stress in gaseous medium

ActiveCN102323308ARealize continuous recordingEasy to operateMaterial electrochemical variablesWater bathsGas cylinder

The invention relates to a device and method for researching the metallic hydrogen permeation behavior, in particular to a device and method for researching the hydrogen permeation behavior of metal subjected to dead-load pulling stress in a gaseous medium, and the device and method are used for researching the interactive influence of pulling stress and a gaseous environment on the metallic hydrogen permeation behavior. The device comprises a heating device, a stretching device, an electrolytic bath and a liquid / gas storage bottle. The method comprises the steps of: nickel-plating a single side of a test piece to be tested, and fixing the test piece between a lower opening of an anode pool and an upper opening of an environmental pool, wherein the nickel-plated layer of the test piece faces the environmental pool; and providing dead-load pulling stress for the test piece by the stretching device. An experimental medium in the anode pool is a NaOH solution. An experimental solution inthe environmental pool forms a gaseous medium environment under the action of water bath. The device and method provided by the invention can be used for researching the hydrogen permeation behavior of a metallic material subjected to dead-load pulling stress in the gaseous medium, the control of the magnitude of the pulling stress and the environment and atmosphere can be realized, and the deficiency that the influence of a stressed state and the gaseous environment on the metallic hydrogen permeation behavior cannot be measured through the traditional electrolytic bath is made up.

Owner:UNIV OF SCI & TECH BEIJING

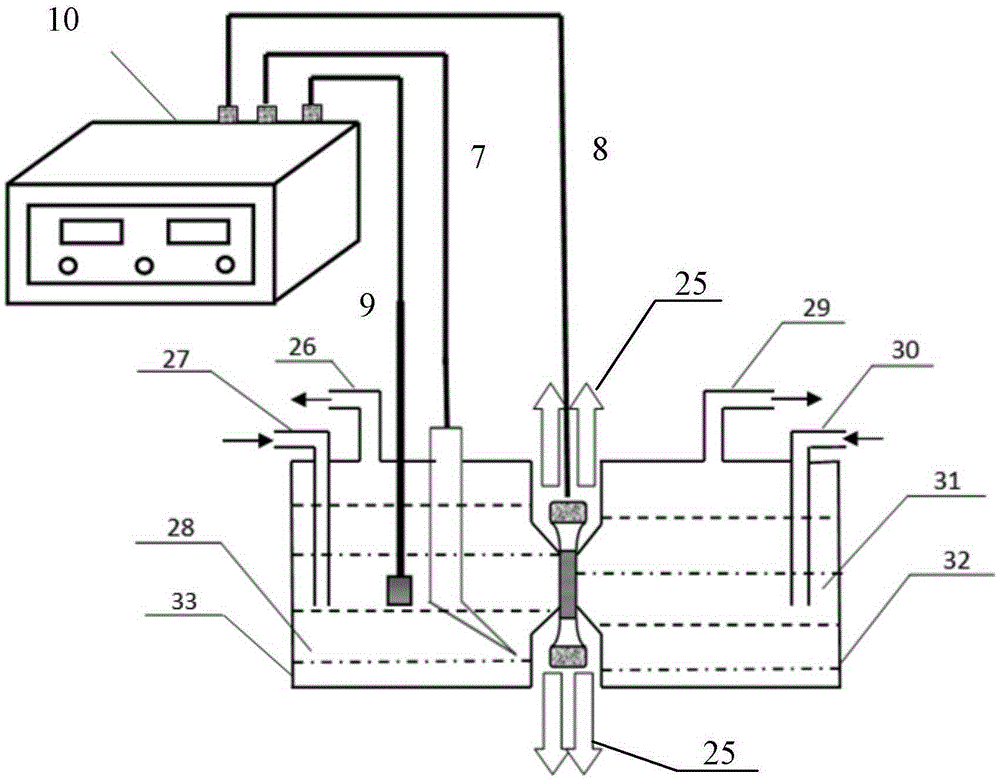

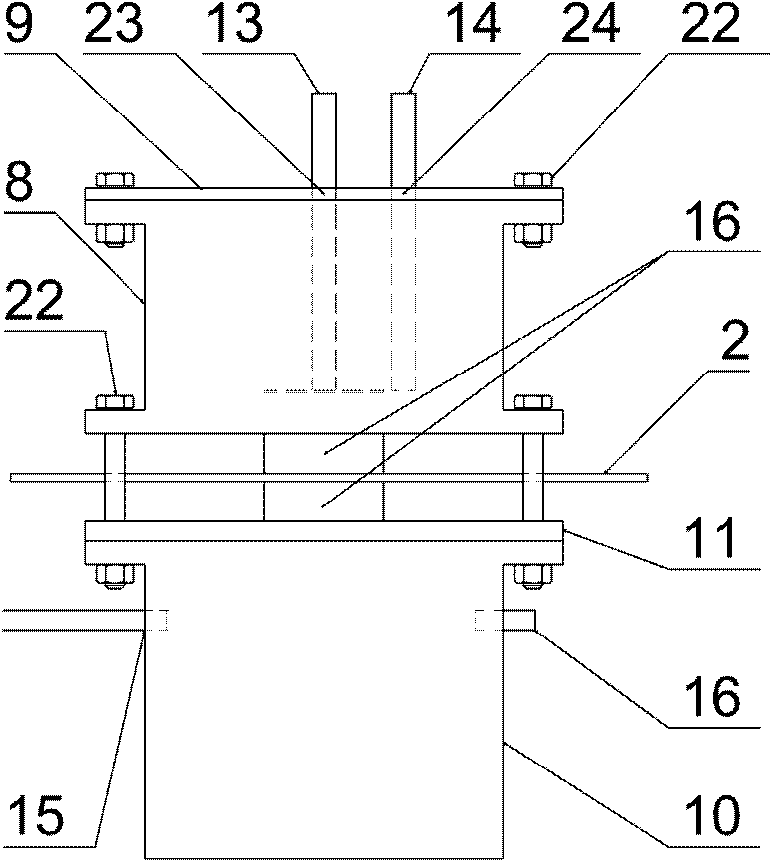

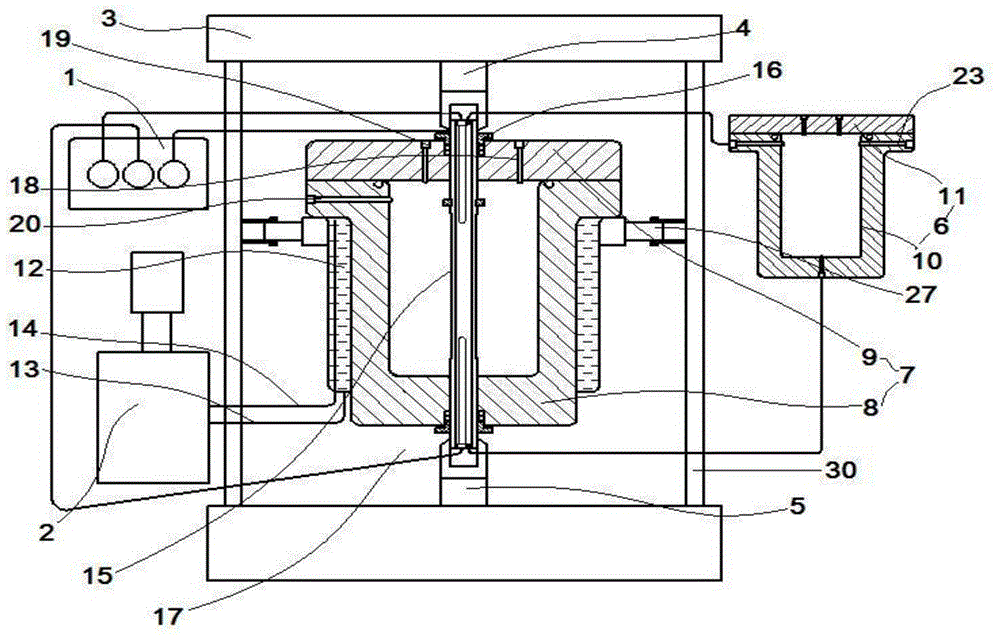

Metal hydrogen permeation behavior research device and method

The invention discloses a metal hydrogen permeation behavior research device and method, the device includes a mechanical loading system, an electrochemical measurement system, a temperature control system and a gas drive system. The loading system provides tensile stress to a specimen by a jack via a middle transfer component. A hydrogen permeation electrolysis pool, a negative pole pool and a positive pole pool are made of nickel base alloy so as to improve the bearing capacity and corrosion resistance, a sealing component is adopted to realize strict sealing between the electrolytic pool and the specimen. An electrolyte solution and a high pressure gas are introduced into the negative pole pool, and a high-voltage reference electrode and an auxiliary electrode are arranged to simulate the mechanical chemical service environment of a metal structure. The metal hydrogen permeation behavior research device can be used for study on hydrogen permeation behavior of a metal structure in high hydrostatic pressure effect deep sea environment and downhole drilling device high pressure environment under the action of tensilc stress-strain effect, and the defect that in the prior art the hydrogen permeation cell can't measure the impact of stress state on metal hydrogen permeation behavior in high pressure environment can be compensated, and by introduction of the temperature control system and the gas drive system, the medium stability can be maintained, and the testing precision is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

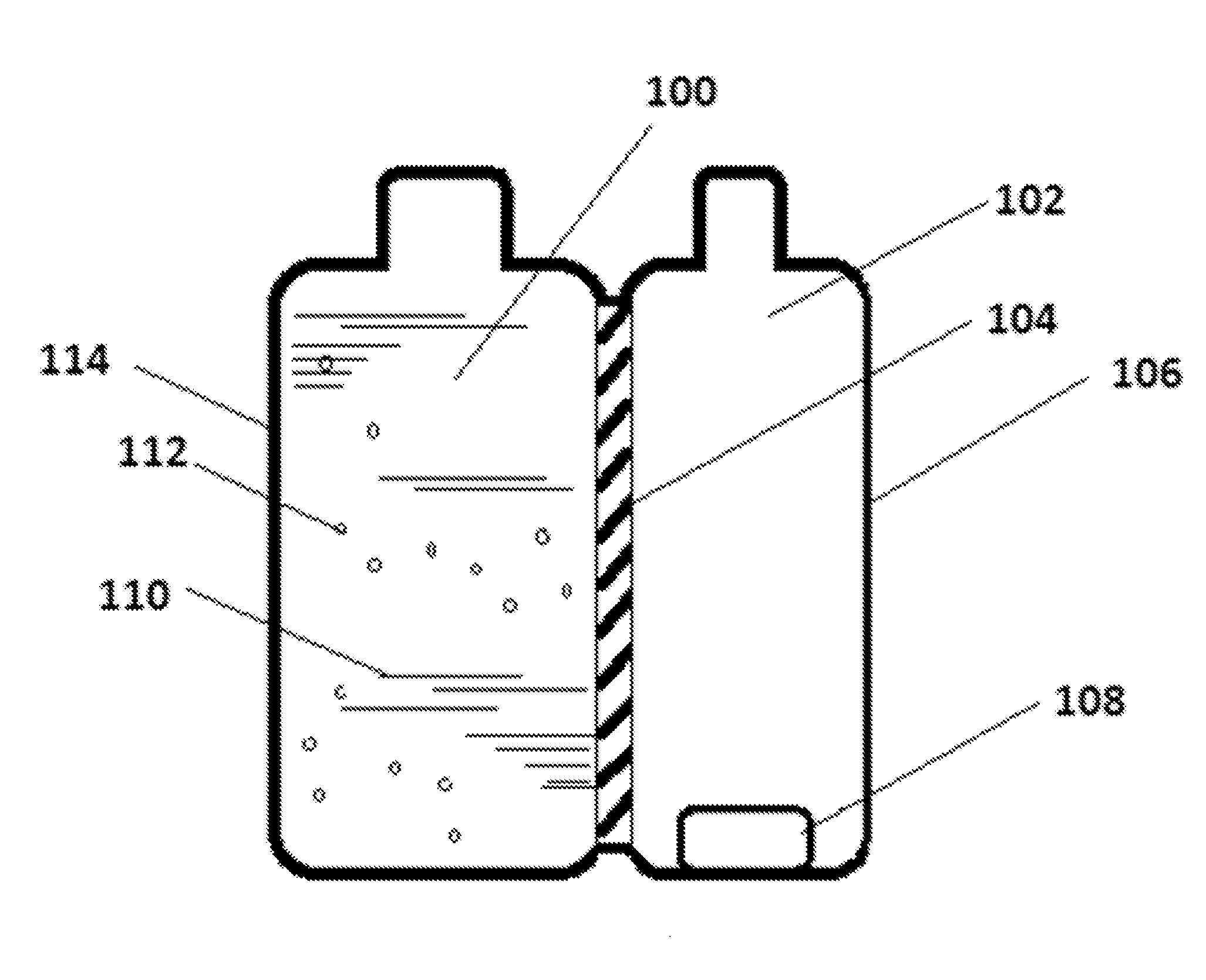

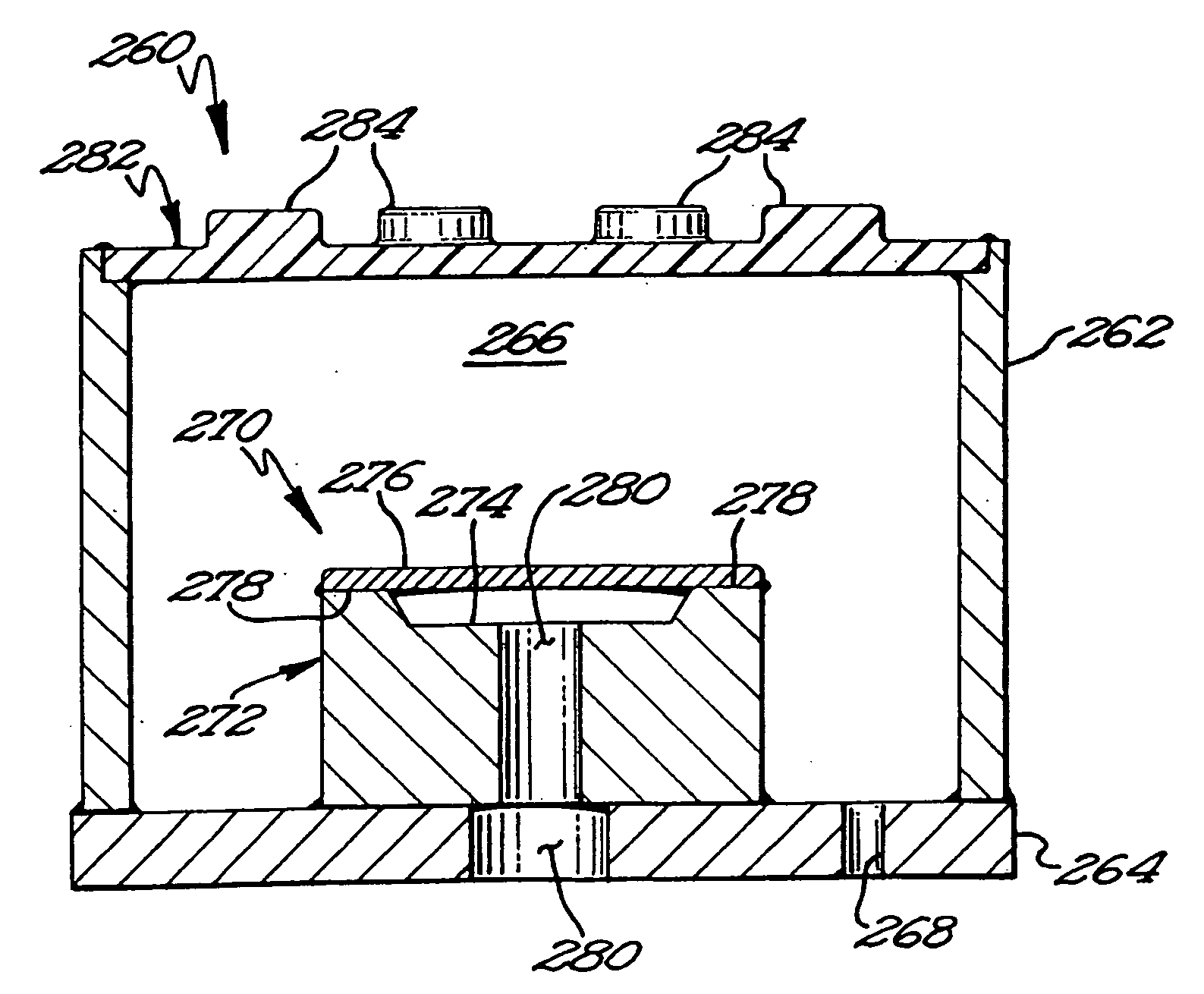

Method and Apparatus to Produce Hydrogen-Rich Materials

InactiveUS20140247689A1Increase the concentration of hydrogenImprove hydrogen permeabilityLighting and heating apparatusUsing liquid separation agentHydrogen concentrationCompound (substance)

Hydrogen molecule (H2) has been indicated as a novel anti-oxidant reagent specifically targeting OH free radicals. This invention discloses the methods and apparatus that can be used to increase the hydrogen concentration in water, in beverages, and in other hydrogen absorbing materials through a sealed hydrogen gas producing chamber made of materials that have good hydrogen permeability and can withhold gas pressure. The disclosed method and apparatus can increase the hydrogen concentration quickly without leaking other chemical by-products of the gas producing system into the treated materials.

Owner:CENTAQUA

High temperature and high pressure corrosion hydrogen permeation kinetic test device and test method thereof

ActiveCN104568726AReduce the amount of experimentsAvoid influenceWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesFatigue loadingEngineering

The invention discloses a high temperature and high pressure corrosion hydrogen permeation kinetic test device and a test method of the device. When the device is used for carrying out fatigue limit measurement, step type fatigue load is applied to material from small to large under the given corrosion condition after hydrogen permeability current is stable; when the hydrogen permeability current is increased along with the increment of the load, the load is proved to cause dislocation movement in the material, so that the load is the fatigue limit of the material in the environment. After the device and the method are adopted, the quantitative relation between a fatigue load state and hydrogen permeation quantity can be measured in situ in an online way in the high pressure hydrogen sulfide corrosion environment, the internal relation between stress and segregation diffusion of hydrogen can be visually expressed, and the characteristics of the mutual relation of multiple data can be established.

Owner:湖州度信科技有限公司

Hydrogen conduit and process for producing same

A conduit for conveying hydrogen under conditions of high temperature and high pressure comprises a clad, seamless tubing having a substrate layer formed of a tough base material that includes iron, chromium, or nickel, or alloys thereof. The tubing further has a thin cladding or surface layer formed of an alloy including at least about 2-10% aluminum, combined with other materials that include at least one of iron and nickel and chromium, in an amount sufficient to make the surface layer capable of resisting hydrogen permeation. The conduit is formed by draw bonding a cladding tube in the substrate tube.

Owner:KINNALLY KEVIN J +1

Niobium alloy and hydrogen permeation membrane produced from it

InactiveUS6800392B2High hydrogen permeation rateReduce riskMembranesSemi-permeable membranesRheniumPlatinum

Owner:W C HERAEUS GMBH

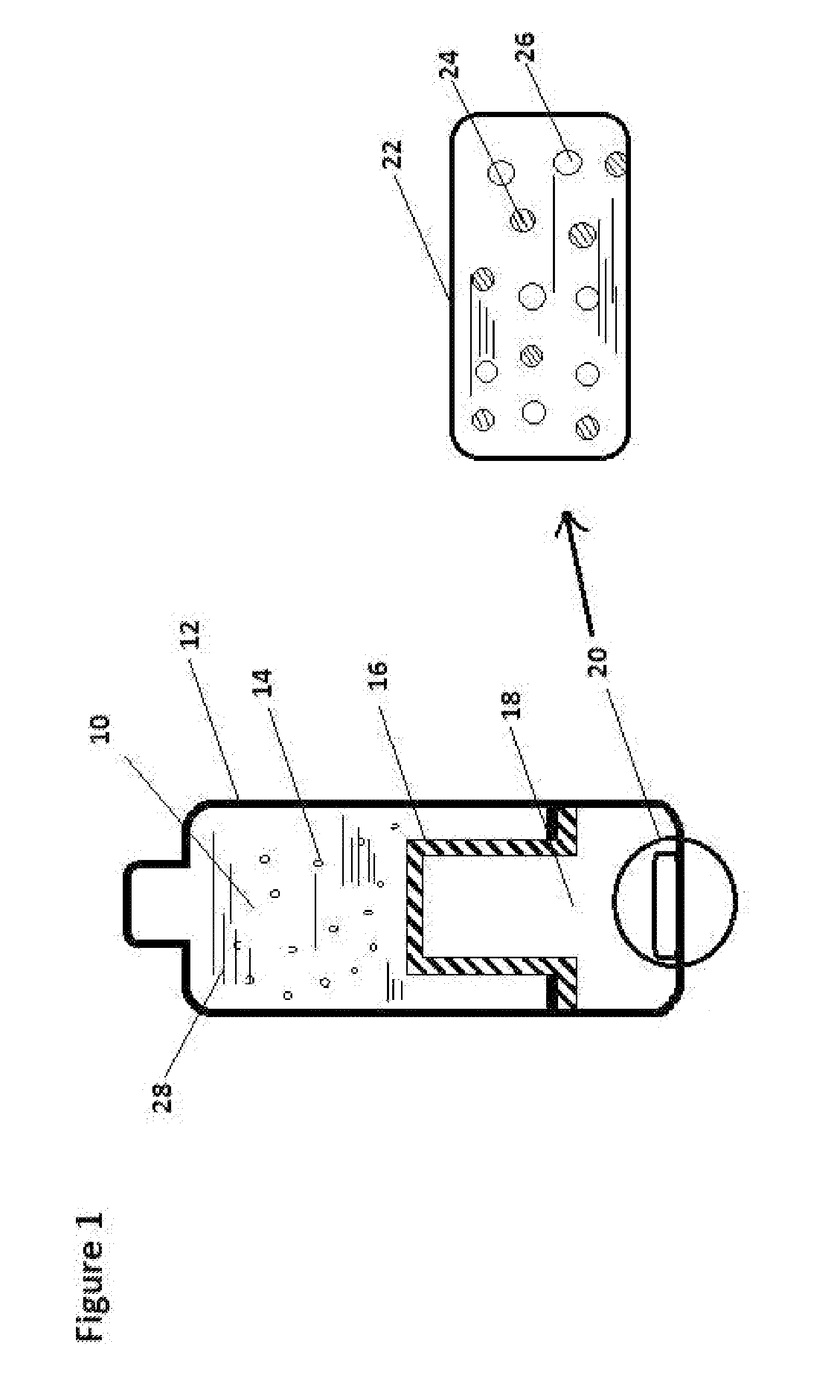

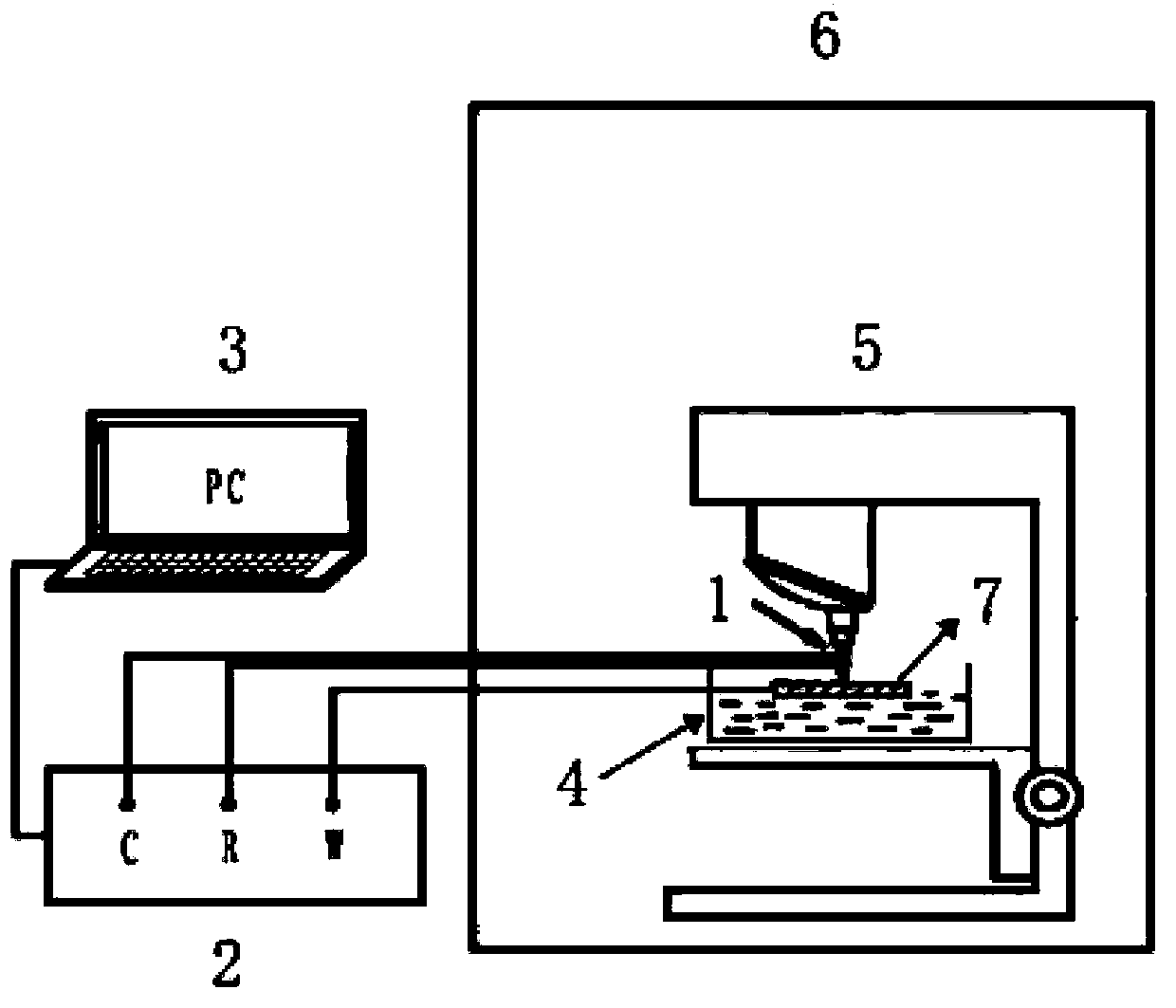

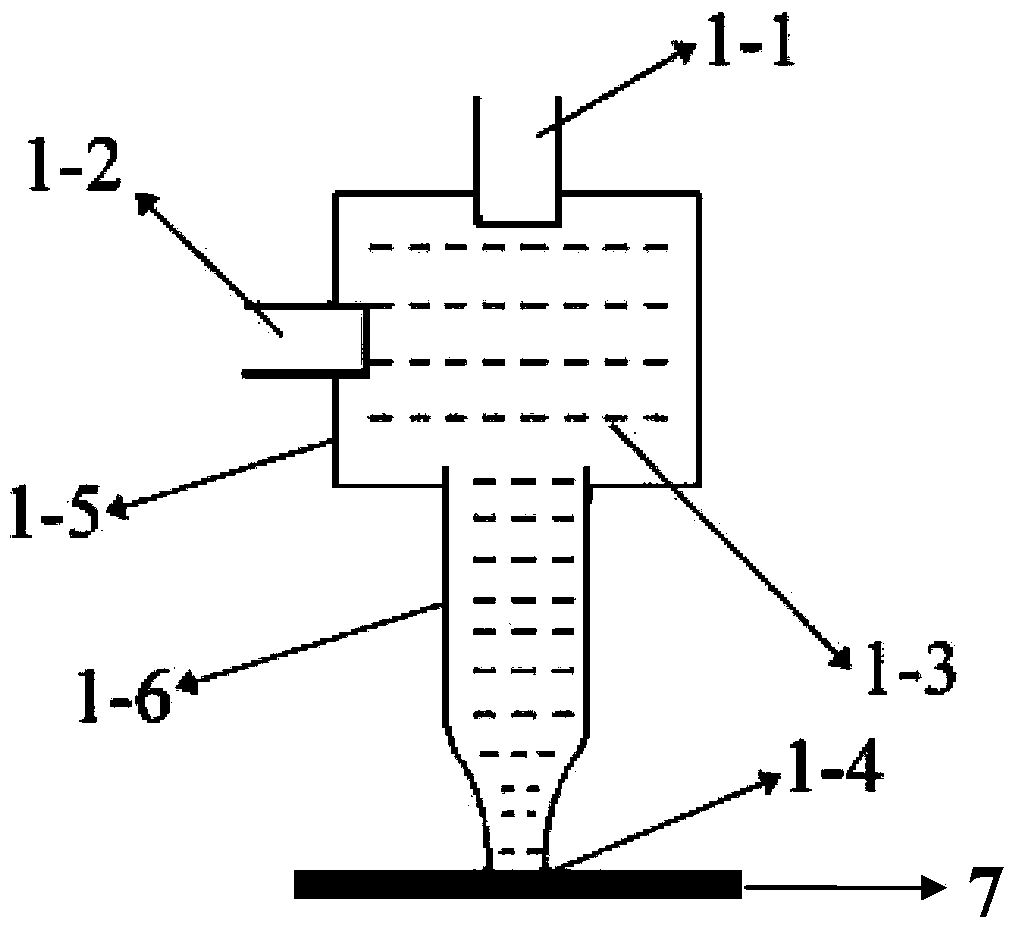

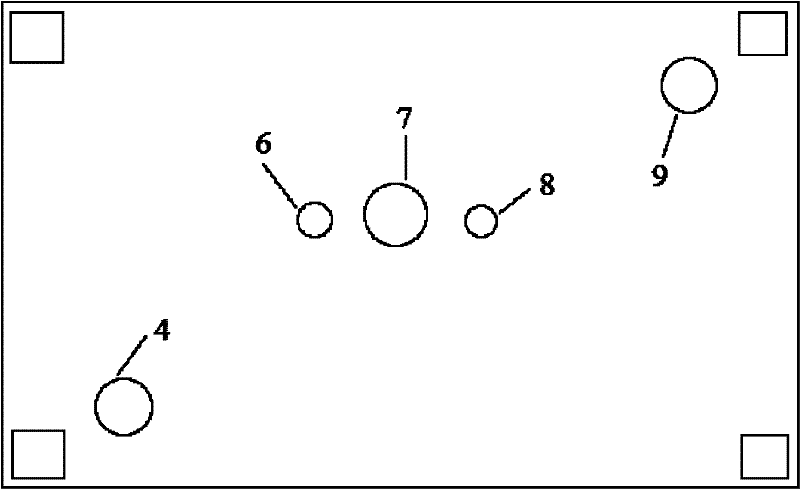

Experimental device for hydrogen permeation behaviors of local areas of metal

InactiveCN103398942AHigh precisionSimple test methodWeather/light/corrosion resistanceStress concentrationHydrogen

The invention provides an experimental device for hydrogen permeation behaviors of local areas of metal. The experimental device comprises a micro-electrolytic tank and a corrosion environment simulating groove, wherein one face of a working test sample is a detection area and the other face of the working test sample is a corrosion area; one end of the micro-electrolytic tank is contacted with a testing area of the working test sample; the corrosion area of the working test sample is contacted with a corrosion medium in the corrosion environment simulating groove; a three-electrode system is composed of a counter electrode, a reference electrode and the working test sample in the micro-electrolytic tank; the counter electrode, the reference electrode and the working test sample are connected with a counter electrode port, a reference electrode port and a working electrode port of an electrochemical work station by leads respectively; the electrochemical work station is connected with a computer by a data line. The invention provides the experimental device for researching the hydrogen permeation behaviors of the local areas of a metal material in a simulated stress corrosion environment and a testing range can reach a micron grade; the experimental device can be applied to the researches on the hydrogen permeation behaviors of specific narrow areas including a stress concentration area, a crack tip area, a welding line area and the like.

Owner:HARBIN ENG UNIV

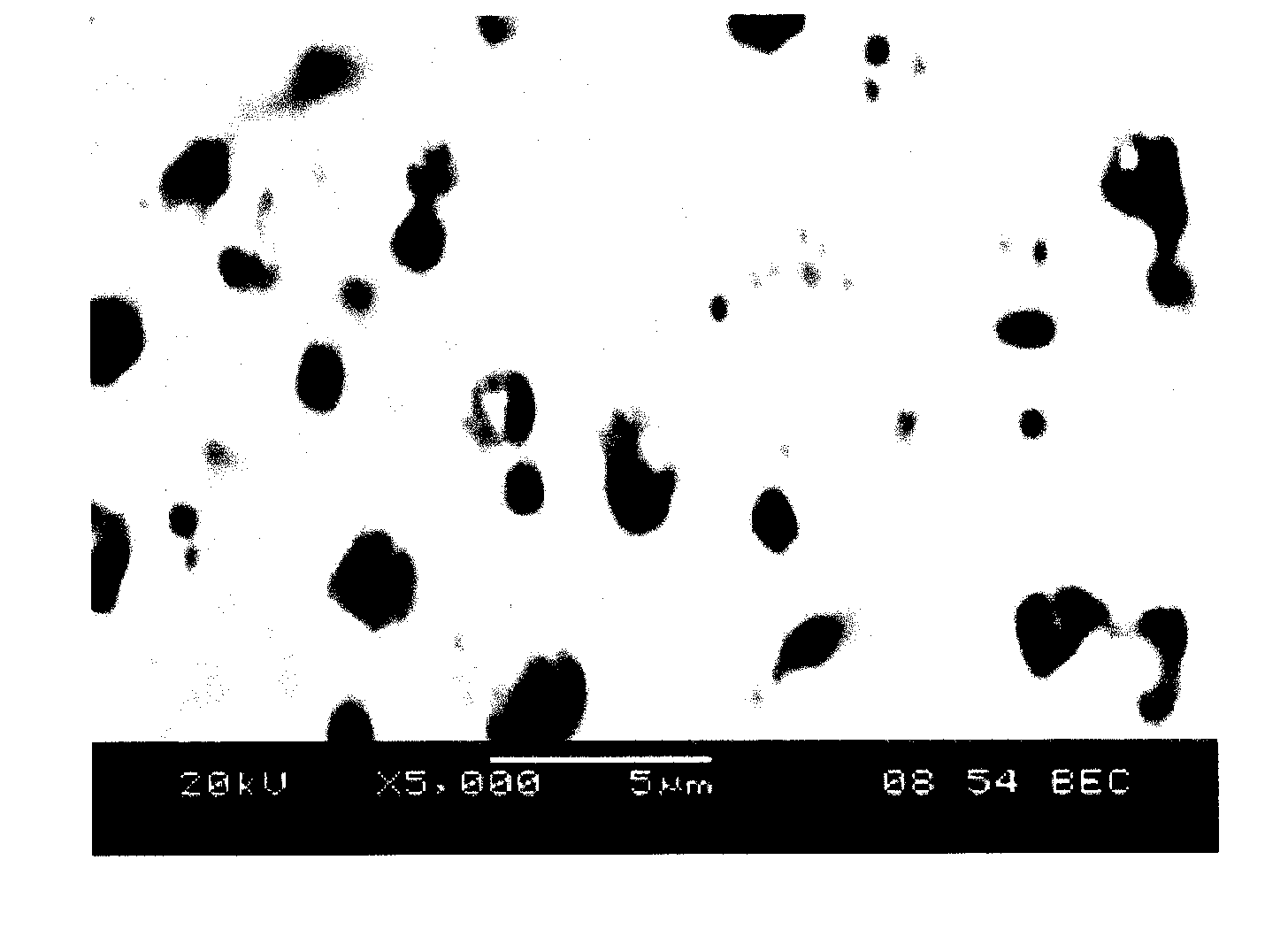

Ceramic mixed protonic/electronic conducting membranes for hydrogen separation

ActiveUS20050194571A1Minimize chemical reactionStability advantageSemi-permeable membranesMembranesProtonHydrogen permeation

A multi-phase mixed protonic / electronic conducting material comprising a proton-conducting ceramic phase and an electron conductive ceramic phase. Under the presence of a partial pressure gradient of hydrogen across the membrane, a membrane fabricated with this material selectively transports hydrogen ions through the protonically conductive ceramic phase and electrons through the electronically conducting ceramic phase, which results in ultrahigh purity hydrogen permeation through the membrane. The material has a high electronic conductivity and hydrogen gas transport is rate-limited by the protonic conductivity of the material.

Owner:COORSTEK INC

Method for preparing hydrogen permeation preventing coating by aluminizing by adopting room temperature fused salt

The invention discloses a method for preparing a hydrogen permeation preventing coating by aluminizing by adopting room temperature fused salt, comprising the following steps of: firstly, carrying out surface treatment of degreasing and oxidation film removing on strain steel matrix with a conventional method; secondly, aluminizing by adopting room temperature fused salt, wherein the room temperature fused salt for aluminizing is a system formed by AlCl3 and organic salt, the organic salt is one of alkyl pyridine halide, alkyl imidazole halide and alkaryl chloration ammonium salt, the mole ratio of the AlCl3 to the organic salt is larger than 1.0 and smaller than or equal to 2.0, the technical parameter for aluminizing by adopting room temperature fused salt is as follows: an aluminum wire as the anode has the temperature of 25-60 DEG C and the current density of 5-30mA / cm<2>, and the plating time is 30-200min; and thirdly, heat treatment to obtain an Fe-Al alloy layer, wherein the technical parameter for heat treatment is as follows: the temperature is 670-750 DEG C, and the time is 30min to 24h; fourthly, oxidation, wherein the technical parameter for oxidation is as follows: the temperature is 670-1050 DEG C, the time is 1-200h, and the oxygen partial pressure is 1.0*10-2 Pa to 2.1*104 Pa. The invention is suitable for preparing tritium permeation preventing coatings on surfaces of special-shaped pieces such as the inner wall of a pipeline, and the like, is suitable for the requirement of large-scale industrialized production, and has a self-healing function.

Owner:ZHEJIANG UNIV +1

Method of fining glass

InactiveUS7475568B2Increased hydrogen permeationAvoid formingGlass furnace apparatusGlass vesselAlloy

A method of forming an oxide glass including heating a glass melt having a β—OH concentration of at least about 0.35 in a vessel comprising a metal selected from the group consisting of platinum, molybdenum, palladium, rhodium, and alloys thereof, there being an interface present between the vessel and the glass, and controlling a partial pressure of hydrogen in an atmosphere in contact with an outside surface of the vessel in an amount such that hydrogen permeation blisters form in a region of the glass adjacent the glass-vessel interface.

Owner:CORNING INC

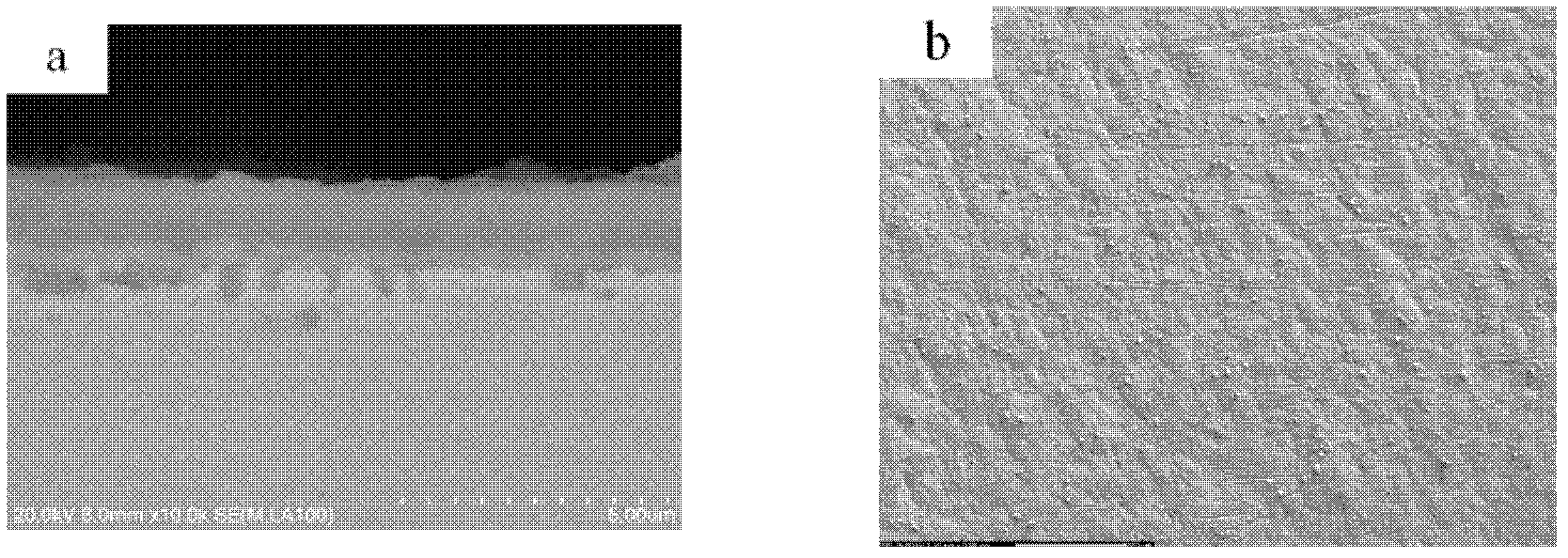

Method for preparing palladium-based composite membranes

ActiveCN101439267AAvoid damageExtended service lifeSemi-permeable membranesHydrogen separationCeramic compositeMetallurgy

The invention relates to a preparation method for a hydrogen permeation palladium compound membrane; at first, nano palladium powder and ceramic powder are added into water; then a dispersant and a thickening agent are added to prepare the mixed slurry material of the nano palladium and the ceramic which is uniformly dispersed and stable; secondly, a macropore ceramic supporter after hanging slurry in the prepared slurry material is put into an atmosphere furnace for forging at a high temperature; the compound material transition membrane layer of the nano palladium and the ceramic with a small aperture is formed on the surface of the macropore ceramic supporter; then an electroless plating method is used to prepare an outer layer ultra thin compact palladium membrane on the compound material transition membrane layer and finally form an integral hydrogen permeation palladium compound membrane comprising the macropore ceramic supporter, the compound material transition membrane layer with the small aperture and the compact palladium layer. The method avoids the fussy steps of normal activation and sensitization, is convenient in operation, and is broad in practicability; moreover, the prepared palladium membrane is more stable under a high temperature.

Owner:NANJING TECH UNIV

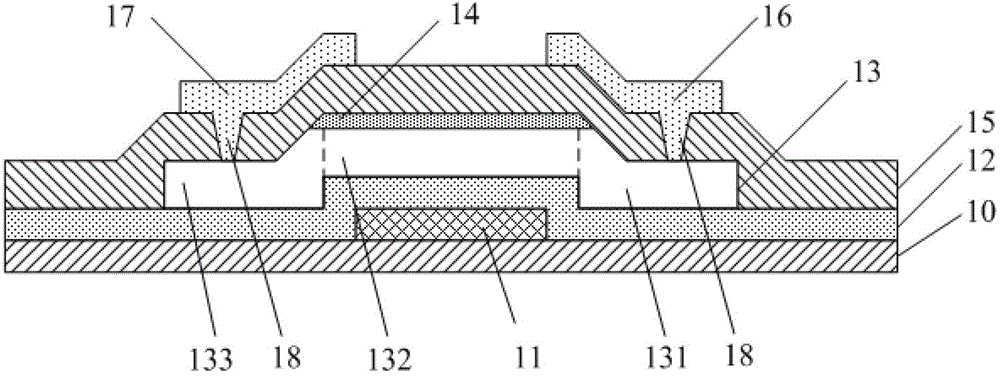

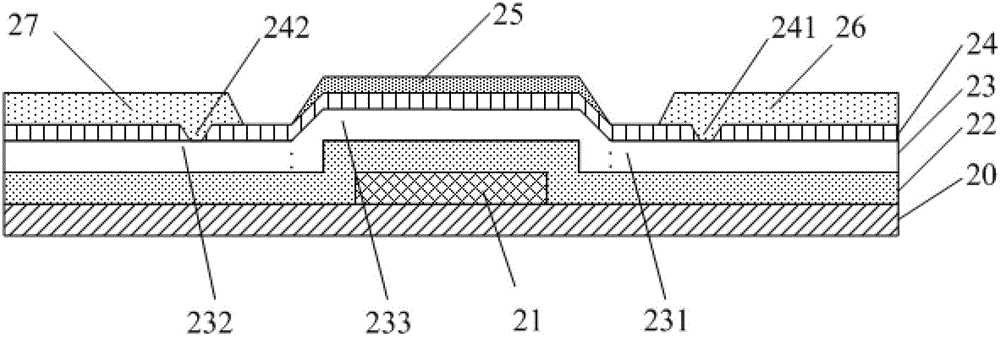

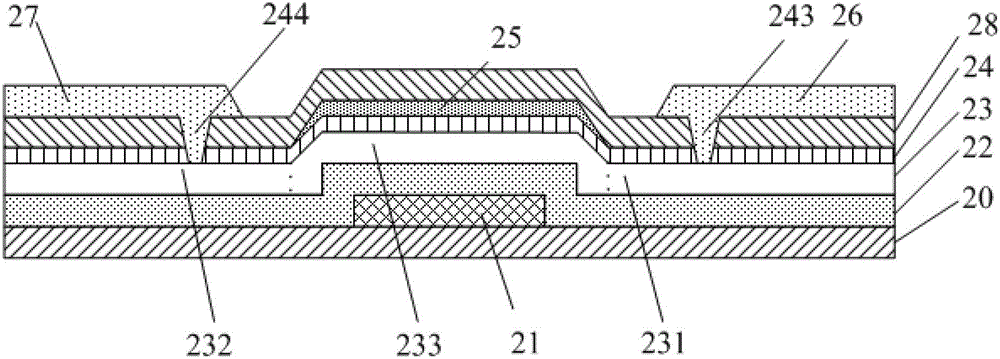

Oxide thin-film transistor with bottom-gate structure and manufacturing method thereof

ActiveCN103915508AWon't enterGuaranteed to be carried out effectivelyTransistorSemiconductor/solid-state device manufacturingHydrogenOxide thin-film transistor

The invention discloses an oxide thin-film transistor with a bottom-gate structure and a manufacturing method of the oxide thin-film transistor. According to the manufacturing method, the oxide thin-film transistor comprises a substrate, a gate electrode, a gate insulating layer, an active layer, a hydrogen permeation layer, an etching barrier layer, a source electrode and a drain electrode; the gate electrode is formed on the substrate; the gate insulating layer is formed on the gate electrode and the substrate, and the gate electrode is covered with the gate insulating layer; the active layer is formed by an oxide semiconductor on the gate insulating layer, the active layer comprises a source region, a drain region and a channel region corresponding to the gate electrode, and the source region and the drain region are doped with hydrogen ions; the hydrogen permeation layer is formed on the active layer and used for controlling the number of the hydrogen ions doped with the source region and the drain region; the etching barrier layer is formed at the position, corresponding to the gate electrode, of the hydrogen permeation layer, and is used for preventing the hydrogen ions from entering the channel region; the source electrode and the drain electrode are electrically connected to the active layer. According to the scheme of the oxide thin-film transistor with the bottom-gate structure and the manufacturing method of the oxide thin-film transistor, the hydrogen permeation layer is arranged, as a result, it is guaranteed that the channel region can be formed, and then it is guaranteed that a TFT device is effective.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

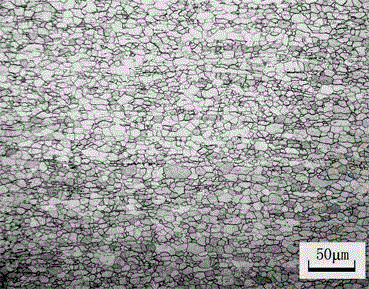

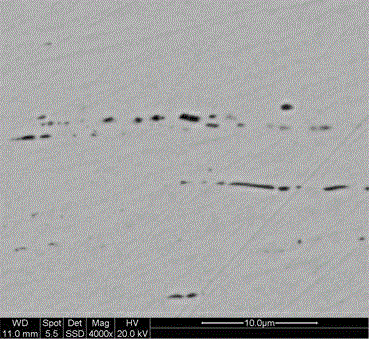

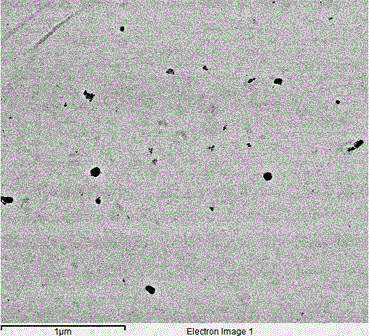

Full-ferrite enamel steel for heat exchanger and production method thereof

The invention relates to a full-ferrite enamel steel for a heat exchanger. The full-ferrite enamel steel comprises the following chemical components in percentages by weight: less than or equal to 0.0050% of C, 0.10-0.50% of Mn, less than or equal to 0.010% of Si, less than or equal to 0.020% of P, 0.015-0.045% of S, less than or equal to 0.010% of Als, 0.010-0.055% of Nb, less than or equal to 0.0030% of B and 0.010-0.050% of O; the production method comprises the following steps of pretreating molten iron, smelting, refining and continuously casting by virtue of a converter; heating the cast blank; carrying out hot rolling; coiling and acid pickling; carrying out cold rolling; annealing; finishing for later use. The microstructure of the enamel steel disclosed by the invention is full ferrite, the grain size of ferrite reaches Grade 11, the main inclusions are long-wire-shaped MnS and granular Mn / Nb composite oxides, the precipitated phases are fine NbC / N and BN particles, Rel is 180-240MPa, the tensile strength is 280-360MPa, the elongation is 36-46%, the hydrogen permeation time of the steel plate is equal to or greater than 25min / mm<2>, no scute burst is caused after enamelling, enamel adhesion strength is greater than A1 level and the pinhole rate is less than 10 / m<2>.

Owner:武汉钢铁有限公司

High temperature and high pressure corrosion hydrogen permeation testing device and method

ActiveCN104568727AReduce the amount of experimentsAvoid influenceWeather/light/corrosion resistanceFatigue loadingCarbon dioxide corrosion

The invention discloses a high temperature and high pressure corrosion hydrogen permeation testing device and method. When fatigue limit is measured, after hydrogen permeation current is stabilized under the given corrosion condition, step type fatigue loads are applied to a test sample material from a smaller one to a larger one, and when the hydrogen permeation current is increased along with increase of the load, dislocation movement inside the test sample material is caused by the load, and the load is considered as the fatigue limit of the test sample material in the environment. The device and the method disclosed by the invention have the characteristics that a quantitative relation between the fatigue load state and the hydrogen permeation amount can be measured in situ on line in a high-pressure carbon dioxide corrosion state, the internal relation between the stress and segregation diffusion of hydrogen can be intuitively reflected, and a mutual relation among multiple data is established.

Owner:ZHEJIANG UNIV OF TECH

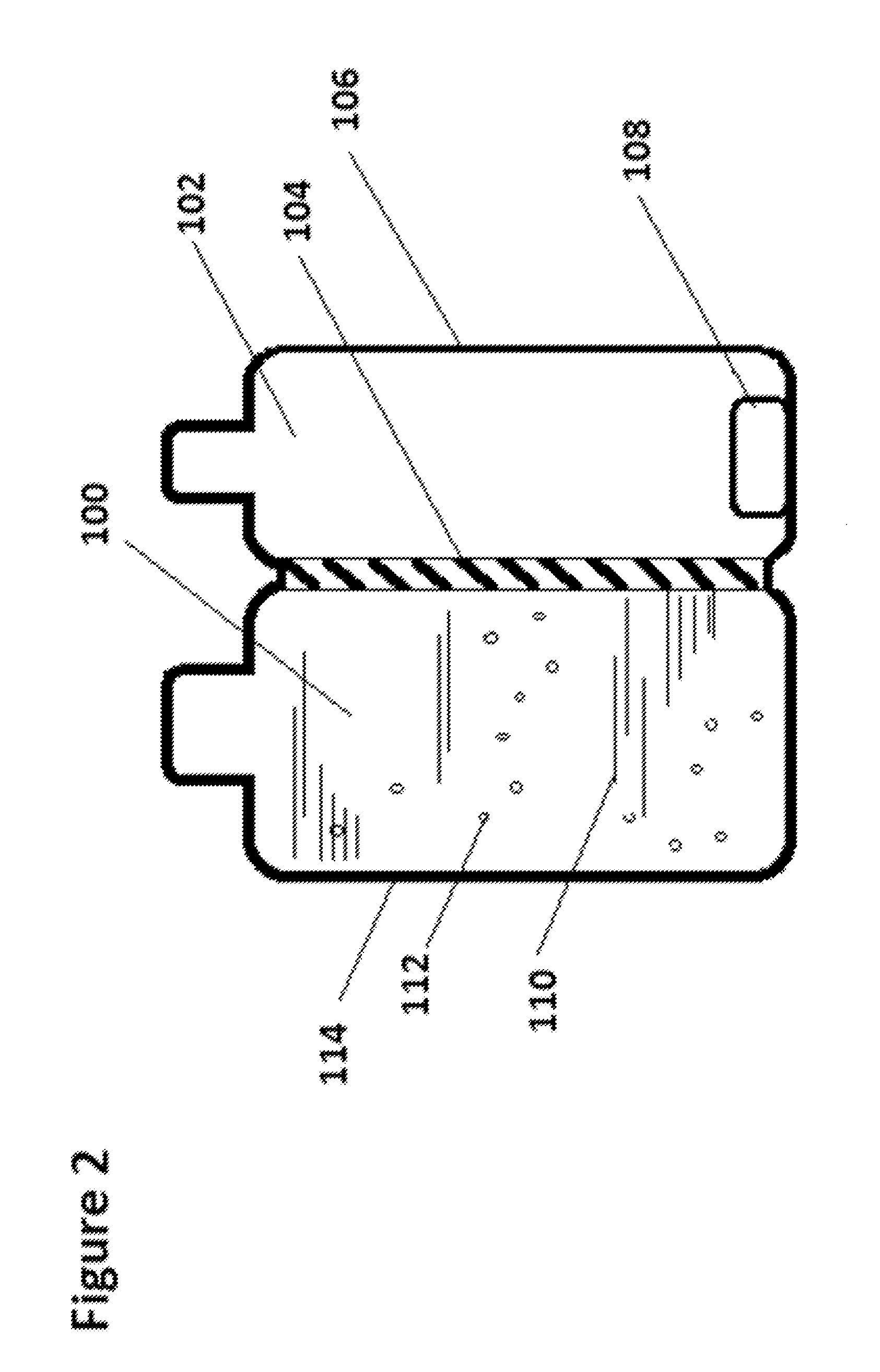

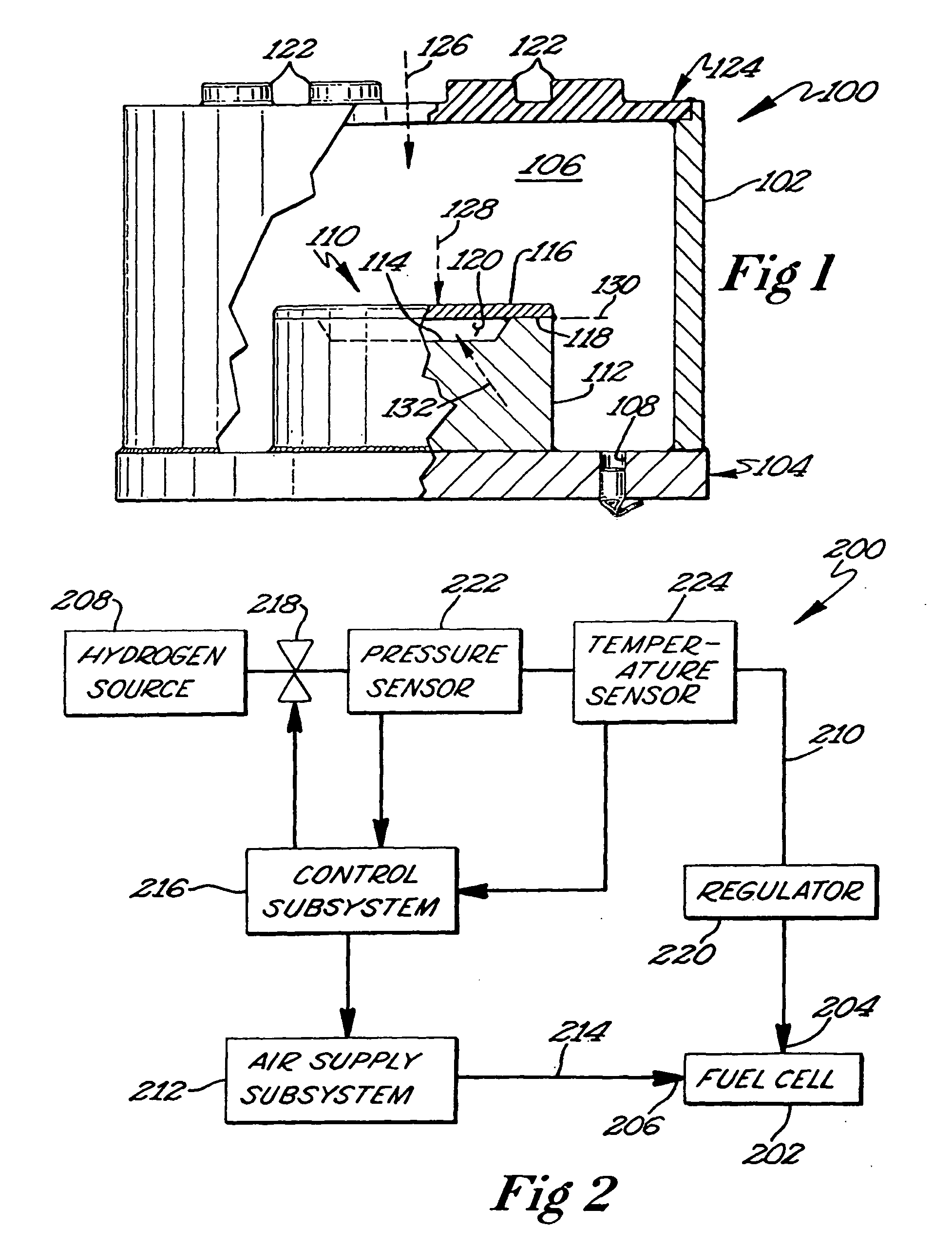

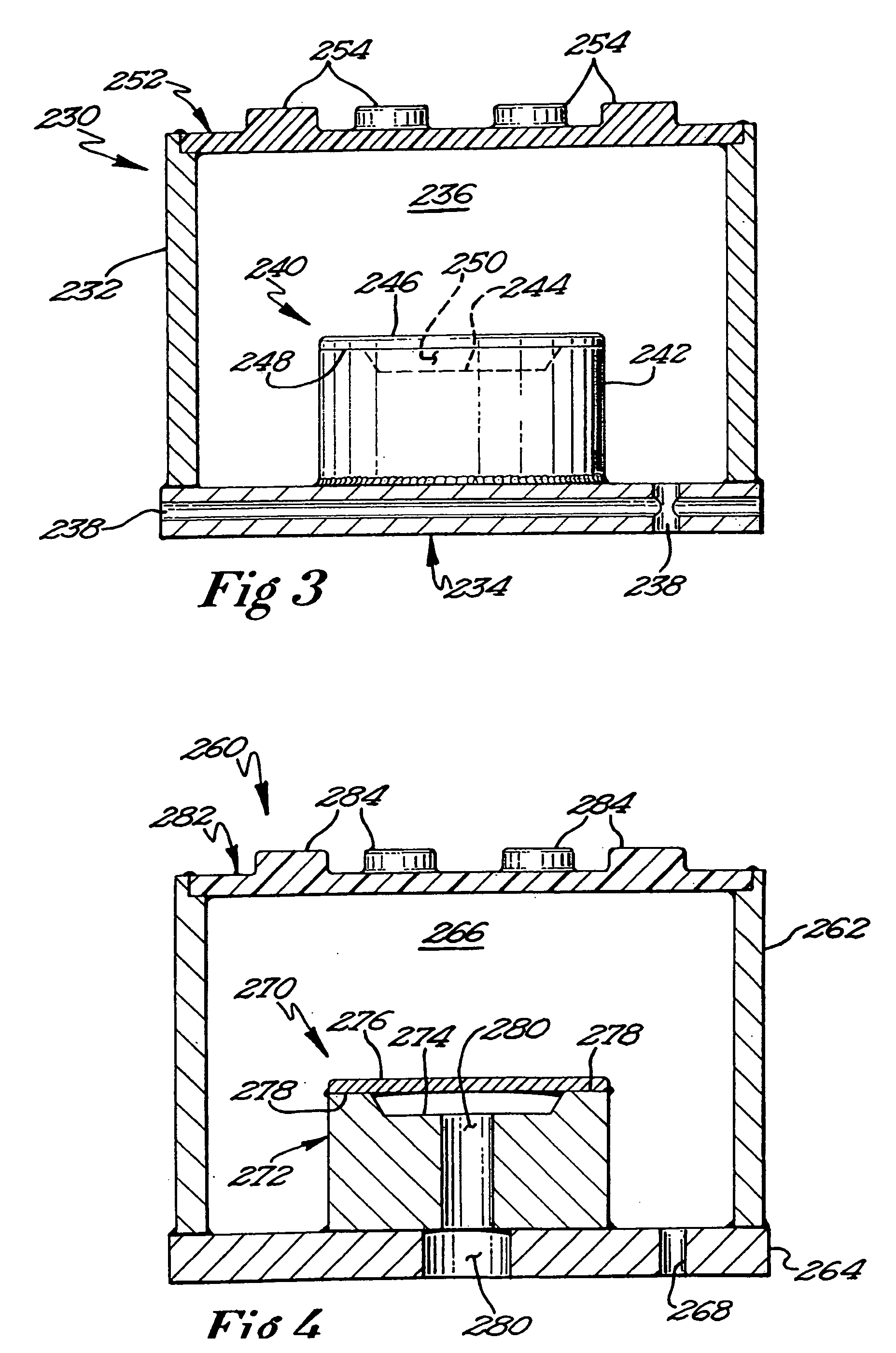

Pressure transducer for gaseous hydrogen environment

ActiveUS20060248958A1Reducing permeation of hydrogenPerformanceFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsHydrogen pressureTransducer

A silicon-based hydrogen pressure sensor module incorporates a low temperature cofired ceramic (LTCC) substrate that shields the cavity formed by the silicon membrane and cell body from hydrogen permeation. A bossed container filled with an oil material is mounted on the substrate and houses a sensor cell. The oil material may be impregnated with a hydrogen getter material.

Owner:DELPHI TECH IP LTD

Cr2O3 and Al2O3 complex gradient hydrogen resistant coating and preparation method and application thereof

ActiveCN104647828AImprove compactnessThickness is easy to controlSolar heating energySolar heat devicesChemical vapor depositionChemistry

The invention relates to a Cr2O3 and Al2O3 complex gradient hydrogen resistant coating and a preparation method and an application thereof. The complex coating is composed of Cr2O3 and Al2O3, and coats stainless steel. The complex coating is prepared by a metal-organic chemical vapor deposition method. By recurrent deposition of aluminium oxide and chromium oxide coatings, a multilayered Cr2O3 and Al2O3 complex gradient hydrogen resistant coating of 0.1-20 microns thick is obtained. The hydrogen resistant coating can be used in hydrogen permeation resistance of a stainless steel structural component. The hydrogen resistant coating has high bonding strength with a matrix; the preparation technology is simple and cost is low; and hydrogen resistance can be enhanced by more than 100 times.

Owner:GRIMAT ENG INST CO LTD

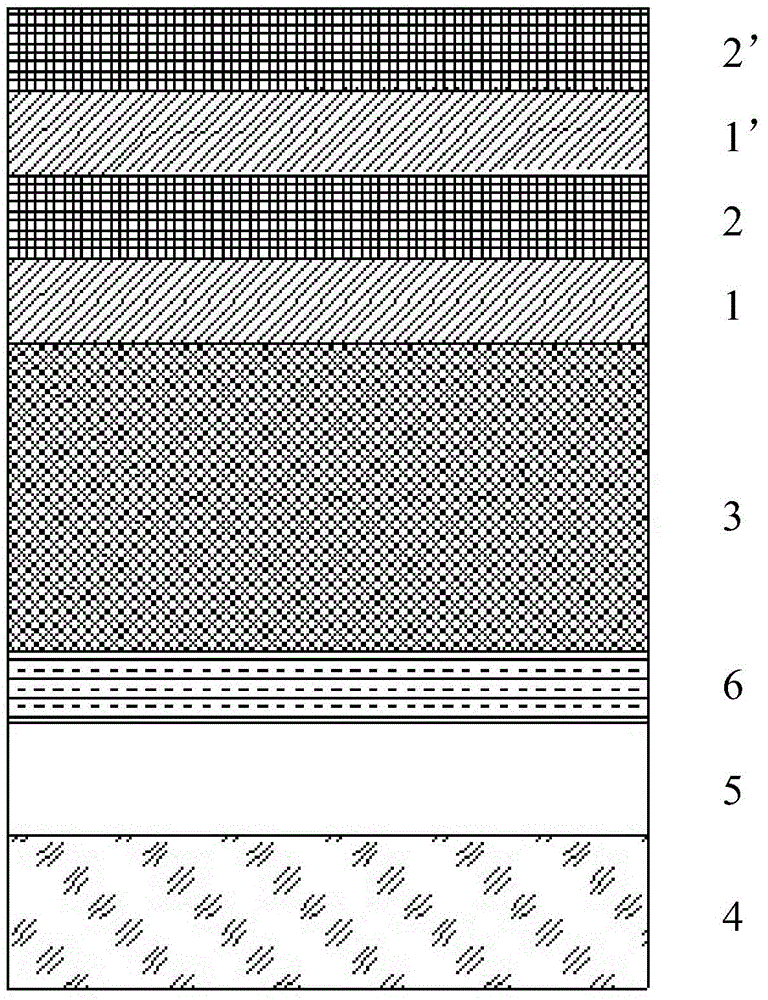

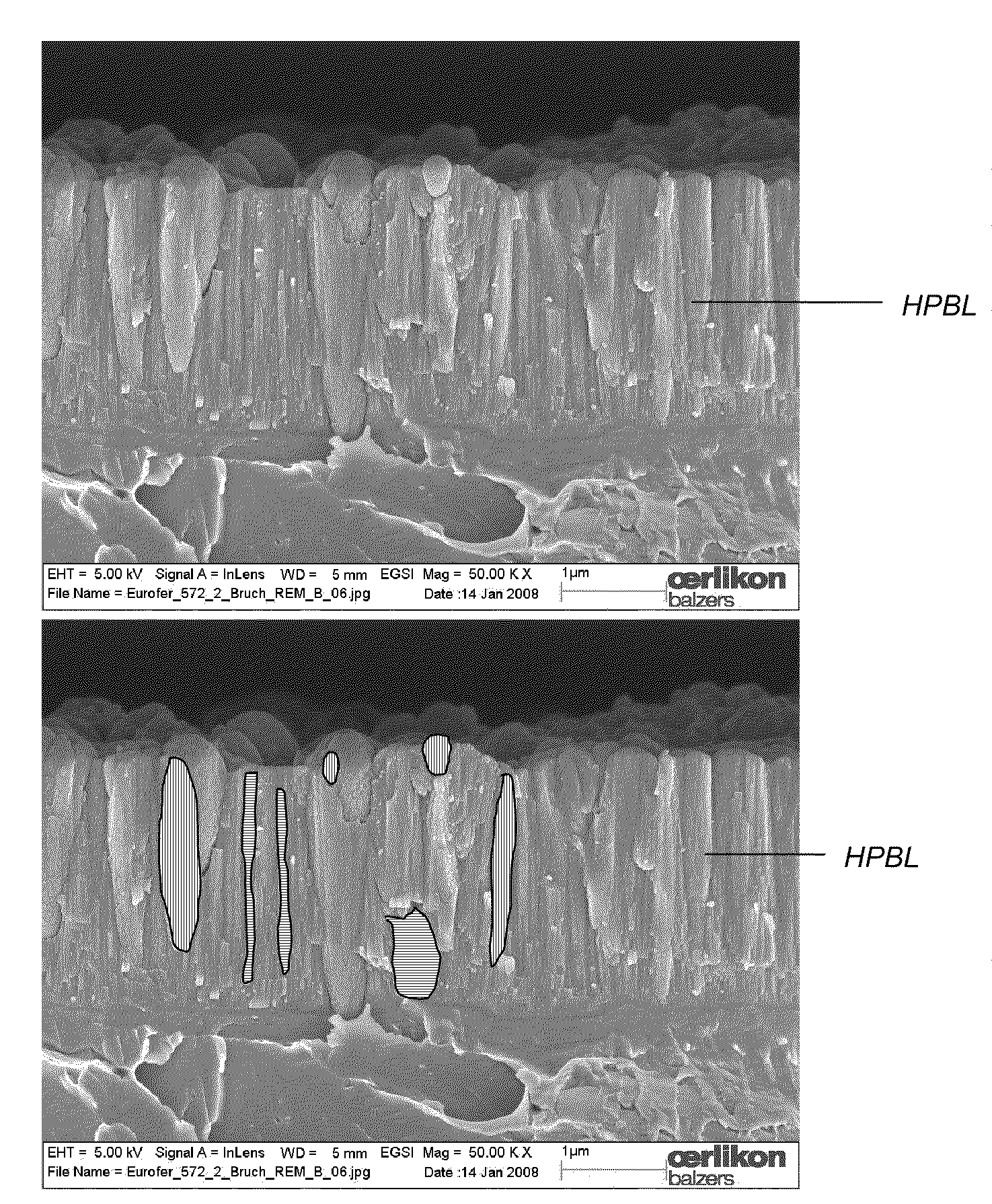

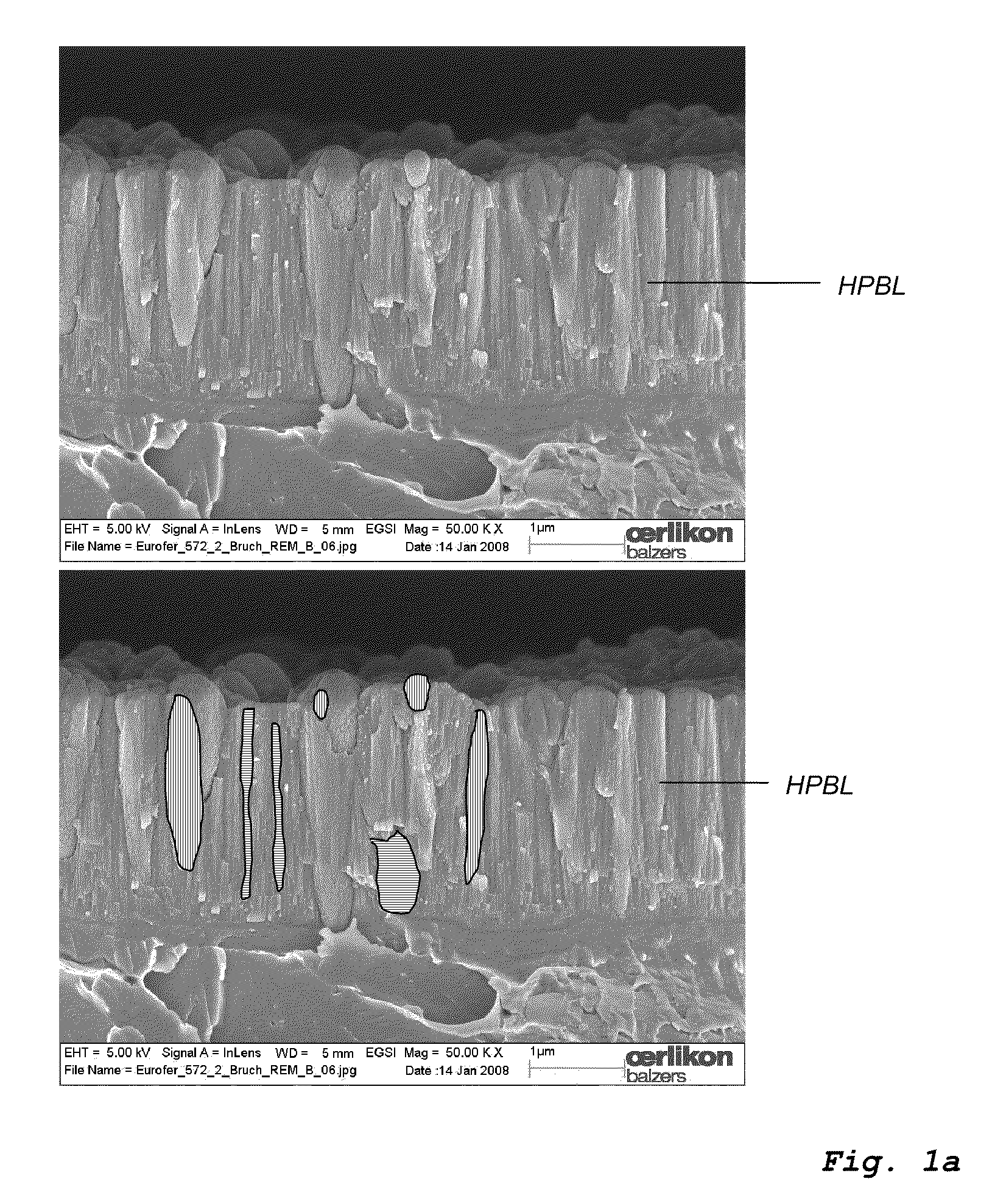

Permeation barrier layer

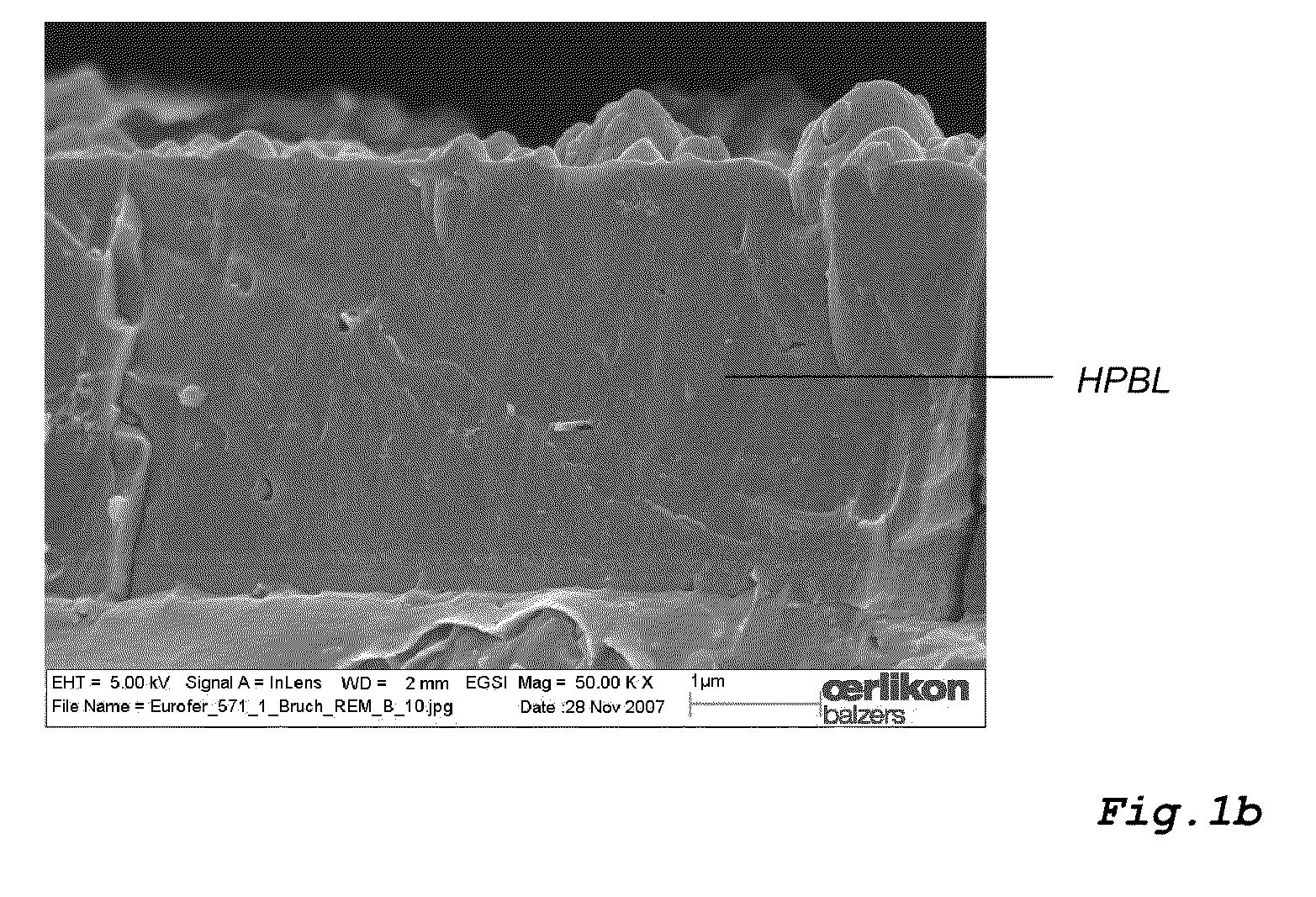

ActiveUS20090191417A1Improve wear resistanceReduce heat transferFinal product manufactureVacuum evaporation coatingGas phaseEvaporation

The method for manufacturing a hydrogen permeation barrier comprises the steps ofa) depositing on a substrate (SUB) a layer system (LS) comprising at least one layer (L1,L2,L3);characterized in that step a) comprises the step ofb) depositing at least one hydrogen barrier layer (HPBL) comprising an at least ternary oxide.The apparatus comprises a sealable volume and a wall forming at least a portion of a boundary limiting said volume, wherein said wall comprises a hydrogen permeation barrier comprising a layer system (LS) comprising at least one layer, wherein said layer system comprises at least one hydrogen barrier layer (HPBL) comprising an at least ternary oxide.Preferably, said at least ternary oxide is substantially composed of Al, Cr and O, and said depositing said at least one hydrogen barrier layer (HPBL) is carried out using a physical vapor deposition method, in particular a cathodic arc evaporation method.Preferably, step a) comprises depositing on said substrate at least one of: an adhesion layer (AdhL), a hydrogen storage layer (HStL), a protective layer (ProtL), in particular a thermal barrier layer (ThBL), a diffusion barrier layer (DBL), an oxidation barrier layer (OxBL), a chemical barrier layer (ChBL), a wear resistance layer (WRL).Excellent hydrogen permeation barrier properties can be achieved, and the layer system can be tailored as required by an envisaged application.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

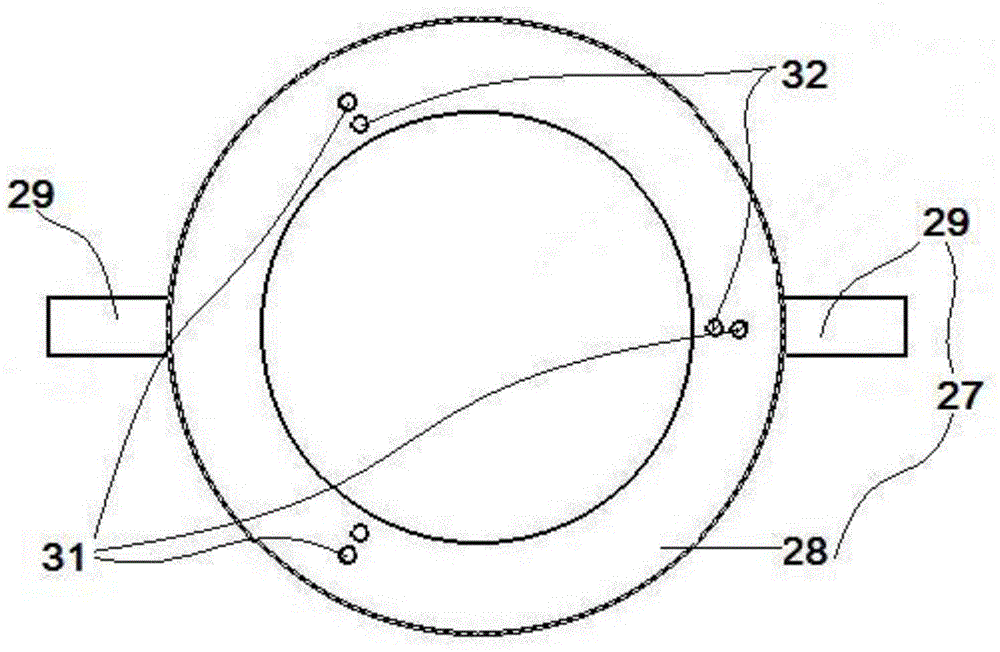

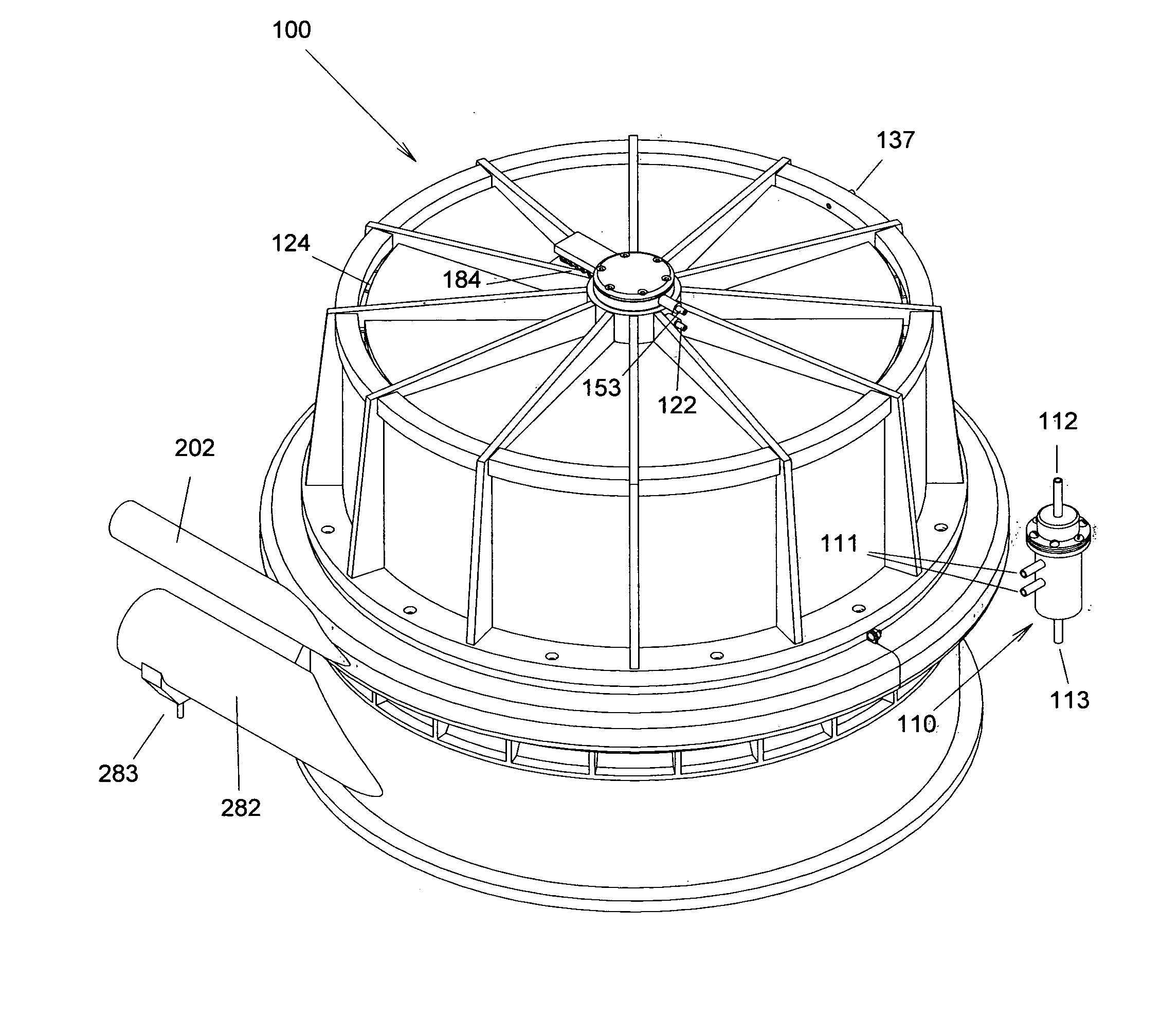

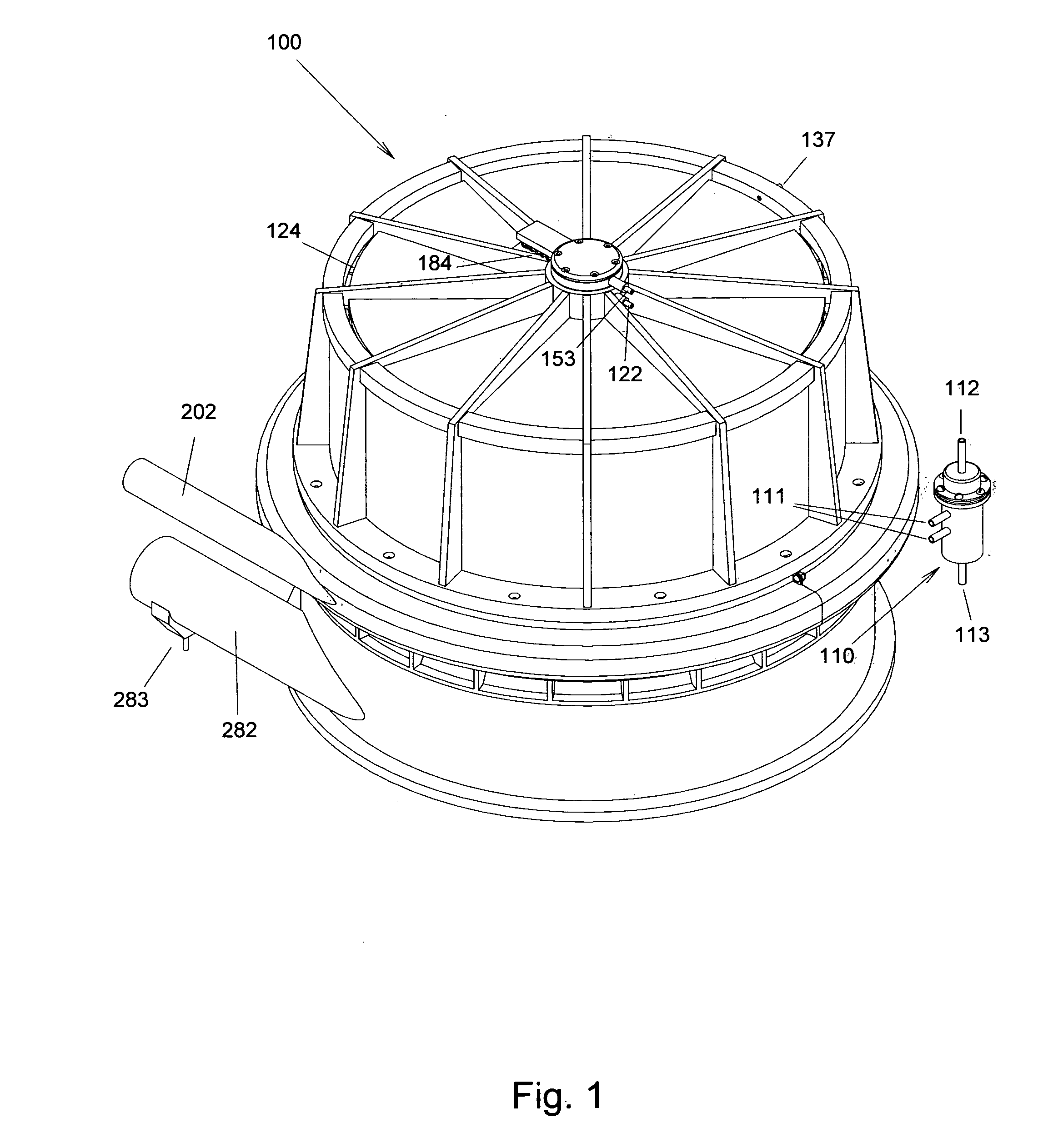

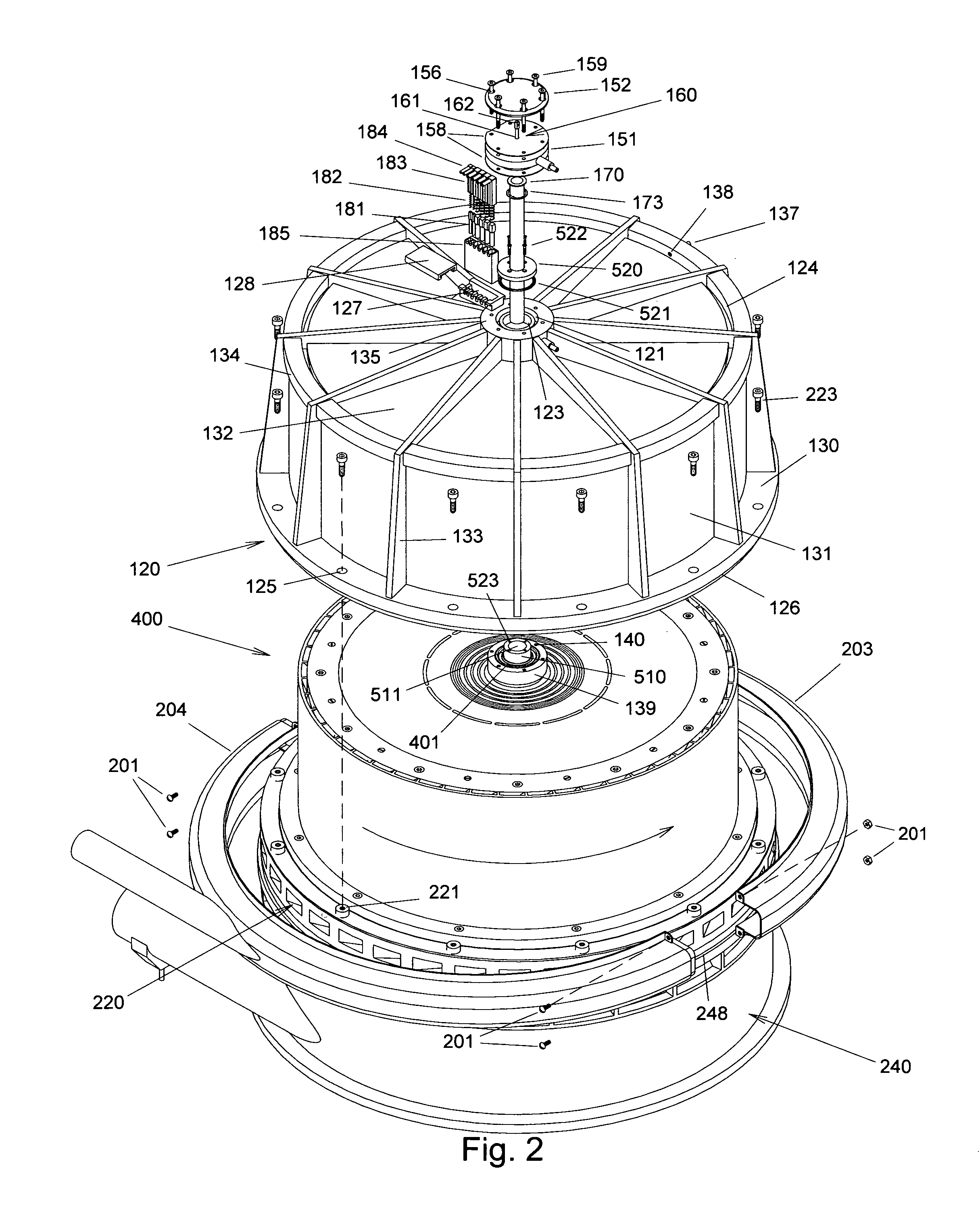

Ion pump and an electrochemical engine using same

InactiveUS20090038315A1Increases activity of ion pumpHigh activitySludge treatmentVolume/mass flow measurementElectrochemistryUltrasonic generator

An ion pump that generates a stream of unbalanced aqueous anions that transit from a cathode surface to a region adjacent to an anode surface. The ion pump works in conjunction with an ultrasound generator that produces standing waves having the intensity to dehydrogenate liquid hydrocarbons at the catalytic anode surface. Current density of the ion pump and frequency of the ultrasound transducer are synchronized according to the rate hydrogen permeates through a membrane. An electrochemical engine uses ion pumps and ultrasound generators to convert liquid hydrocarbon fuel to useful work while recovering hydrogen-depleted carbon from the fuel for recycling, including production of renewable fuel. When carbon is recovered, carbon dioxide is not produced. Tensile stress applied to the ion-pump membranes by rotation, high-frequency pressure waves, and radial acceleration of the interstitial hydrogen are applied in a collective manner that facilitates hydrogen permeation through the ion pump membranes.

Owner:JOHNSON ROBERT PAUL

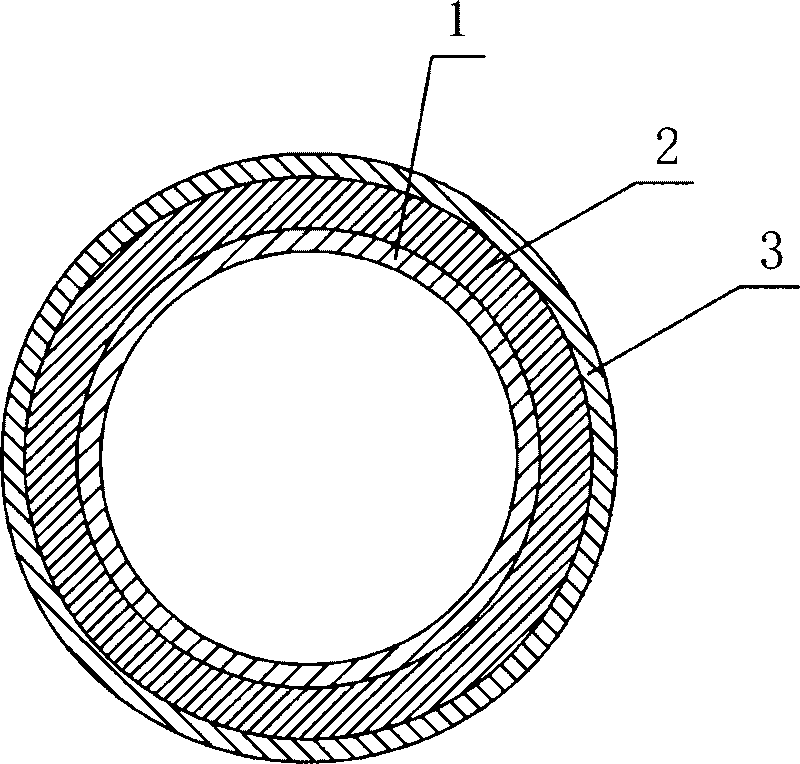

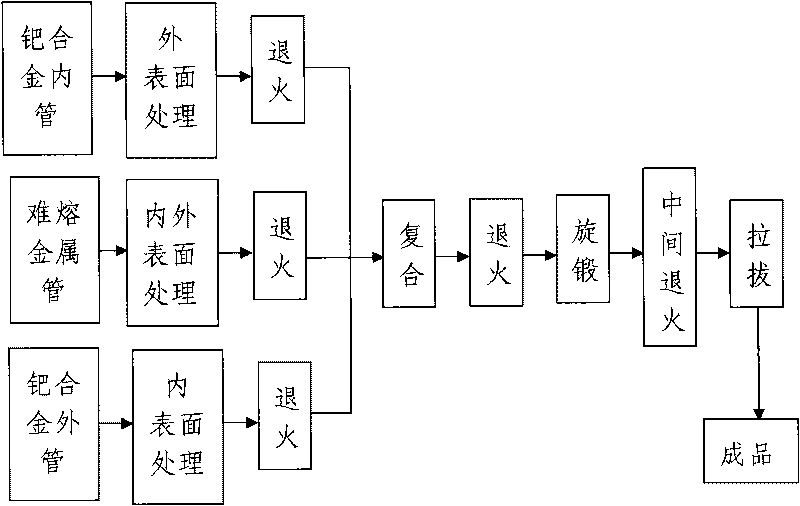

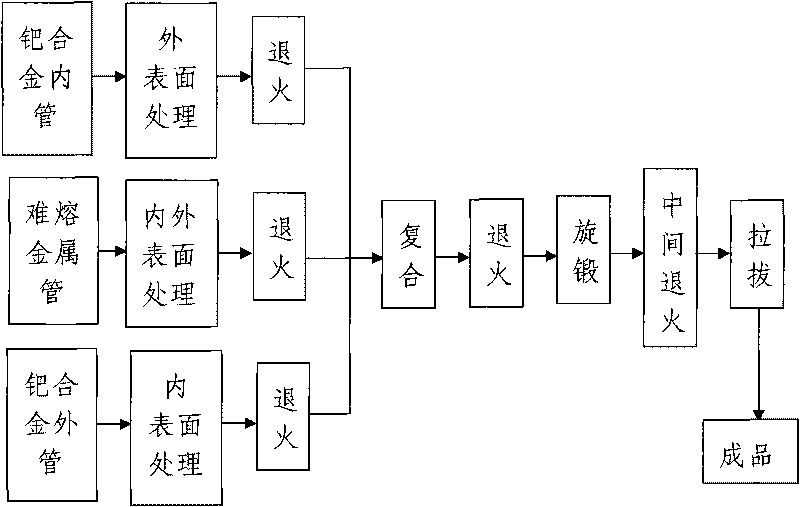

Palladium alloy infusible metal composite pipe and manufacture method thereof

The invention discloses a palladium alloy infusible metal composite pipe and a manufacture method thereof. The palladium alloy infusible metal composite pipe comprises an infusible metal pipe, a palladium alloy inner pipe and a palladium alloy outer pipe, wherein the infusible metal pipe has the hydrogen permeating capability and is made of infusible metal material; the palladium alloy inner pipe and the palladium alloy outer pipe are arranged inside and outside the infusible metal pipe; and the palladium alloy inner pipe, the infusible metal pipe and the palladium alloy outer pipe are coaxially arranged and carry out metallurgical bonding to form a hydrogen permeating composite pipe in the composite ratio of 2-5:4-30:1-3. The manufacture method comprises the following steps of: 1. preparing the pipes; 2. processing the surfaces of the pipes; 3. compounding by an explosion compounding method or a diffusion-welding compounding method and forming a composite pipe blank; and 4. mouldingthe composite pipe. The method has simple steps and convenient implementation, and the prepared palladium alloy infusible metal composite pipe has high performance, not only has the catalysis characteristic and oxidation resistance of palladium alloy on hydrogen, but also has high strength and high selective hydrogen permeation ratio of infusible metal.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

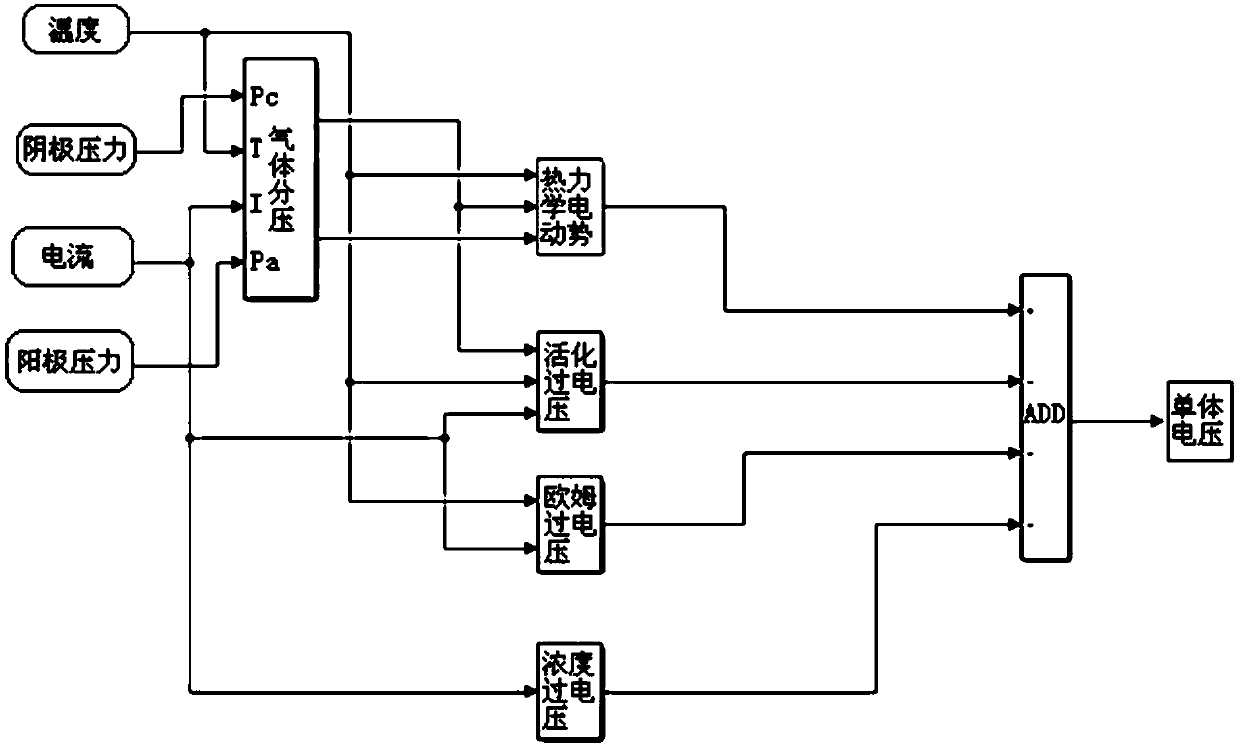

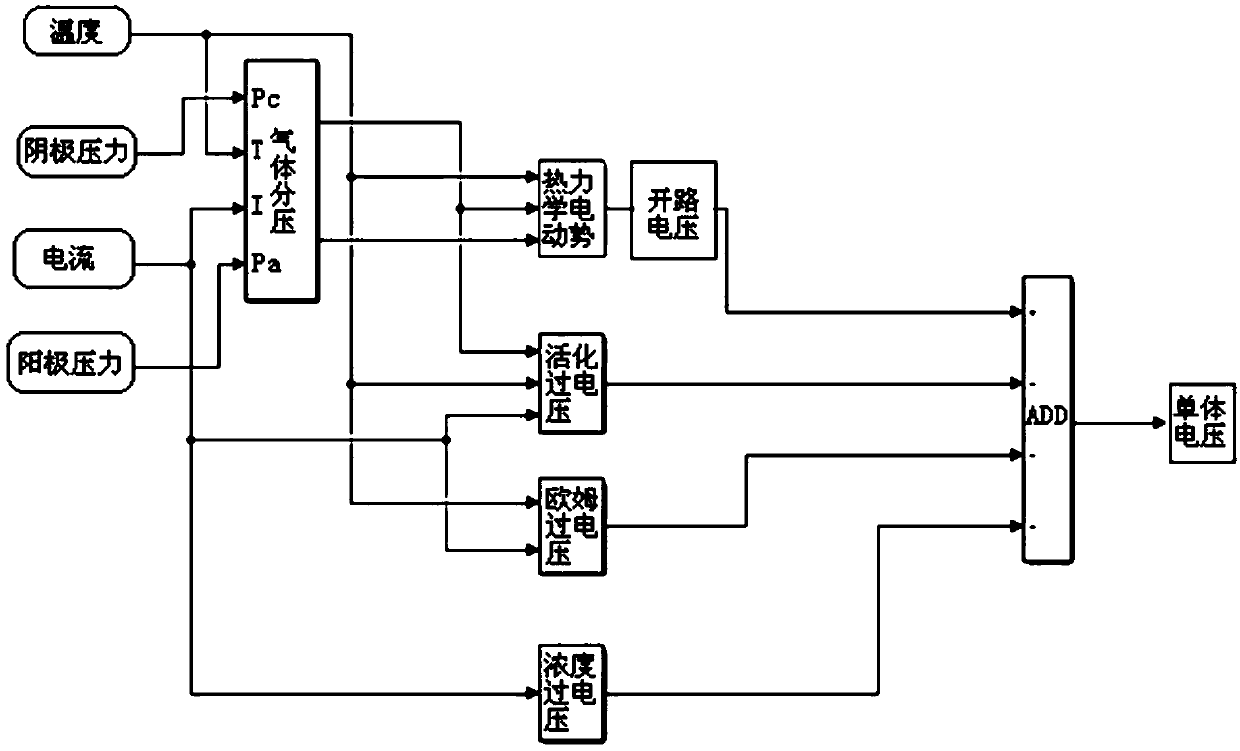

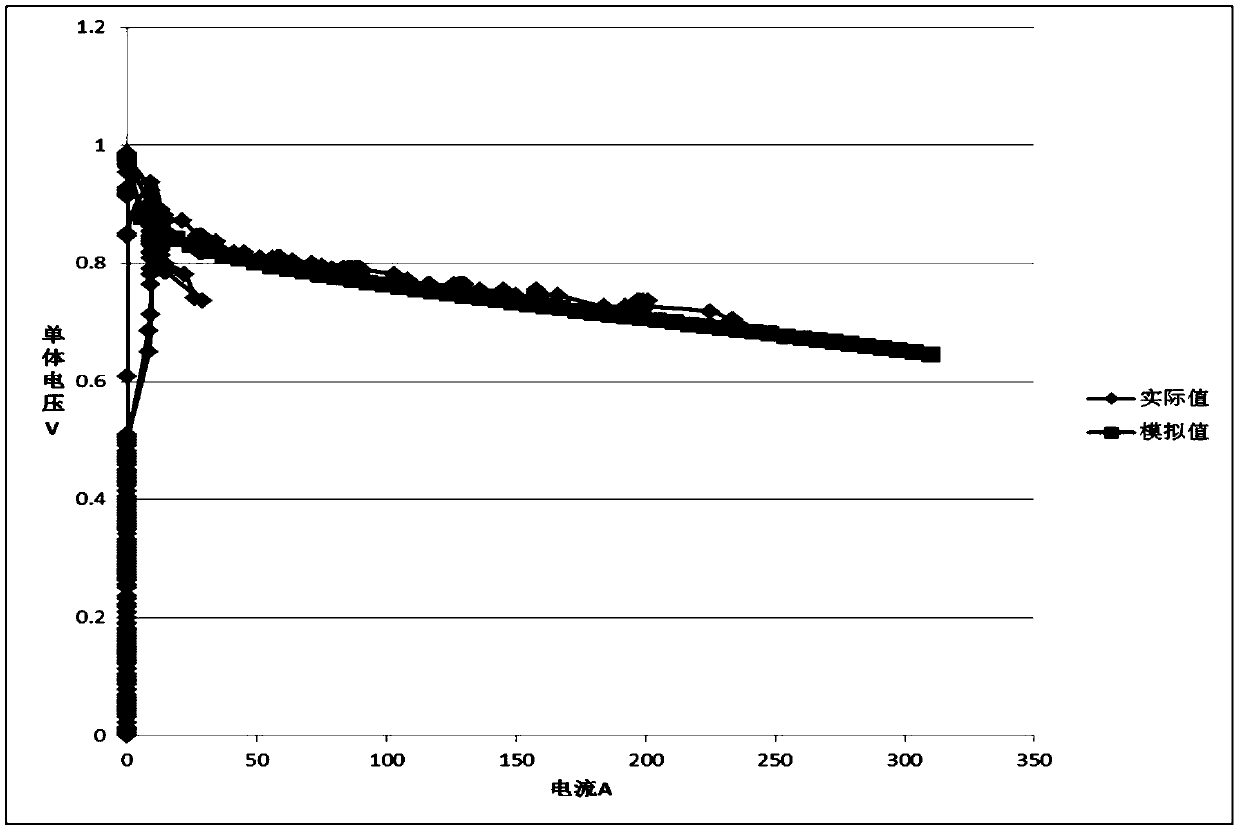

Proton exchange membrane fuel cell modeling method

ActiveCN109657348AThe simulation calculation is accurateReasonably builtSpecial data processing applicationsOvervoltageChemical physics

The invention relates to a proton exchange membrane fuel cell modeling method. The method comprises the steps of activating an overvoltage model act, an ohmic overvoltage model ohmic, a concentrationovervoltage model con and a voltage drop model Eloss caused by internal current / permeation loss. According to the technical scheme, PEMFC voltage loss caused by hydrogen permeation or internal currentis used as a calculation part of the model; Through the PEMFC modeling method provided by the invention, the PEMFC model architecture is more reasonable to build, more conforms to the working mechanism of the proton exchange membrane fuel cell, and the model simulation calculation is more accurate.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A device and method for studying hydrogen permeation behavior of metals in acidic atmospheric medium

ActiveCN102288654AEasy to measureHigh simulationPreparing sample for investigationMaterial electrochemical variablesElectrolytic agentGas phase

The invention relates to a device and a method for research on hydrogen permeation of metal, in particular to a device and a method for research on hydrogen permeation of metal in acidic atmospheric medium with an adjustable pH value. The device comprises an environmental tank, an anode tank and a liquid storage bottle. A specimen to be tested is fixed at an opening at the bottom of the anode tank, and electrolyte in the anode tank adopts NaOH solution. Acidic solution in the environmental tank can form an acidic atmospheric medium environment under a water bath. Three electrodes are connected with corresponding ports of an electrochemical working system through wires. By adopting the device and the method, the hydrogen permeation current of metal materials in the acidic atmospheric medium can be measured, gas-phase components can be controlled, and the relevant defects of the conventional double electrolytic tanks for electrochemical hydrogen permeation can be overcome.

Owner:河北维立方科技有限公司

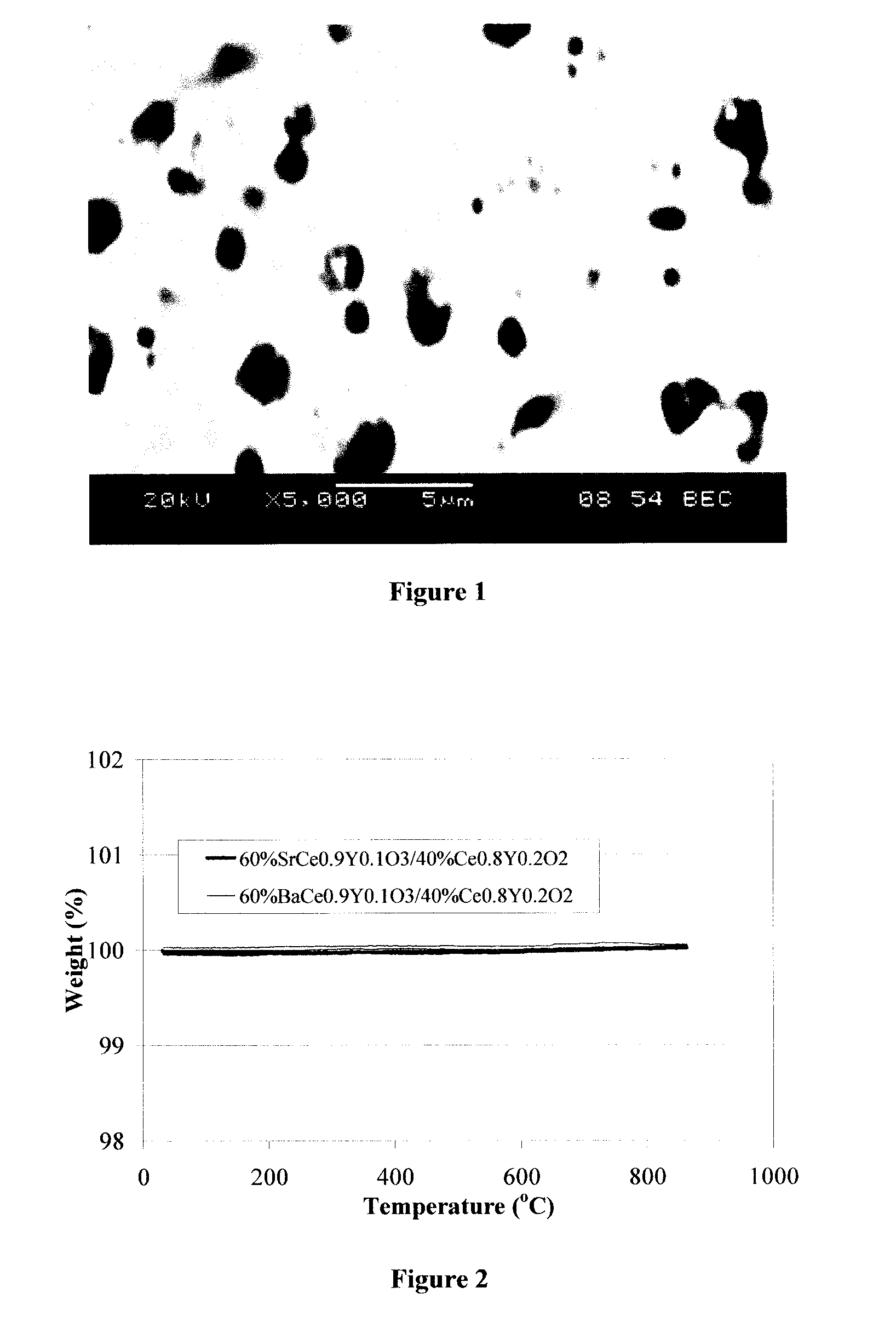

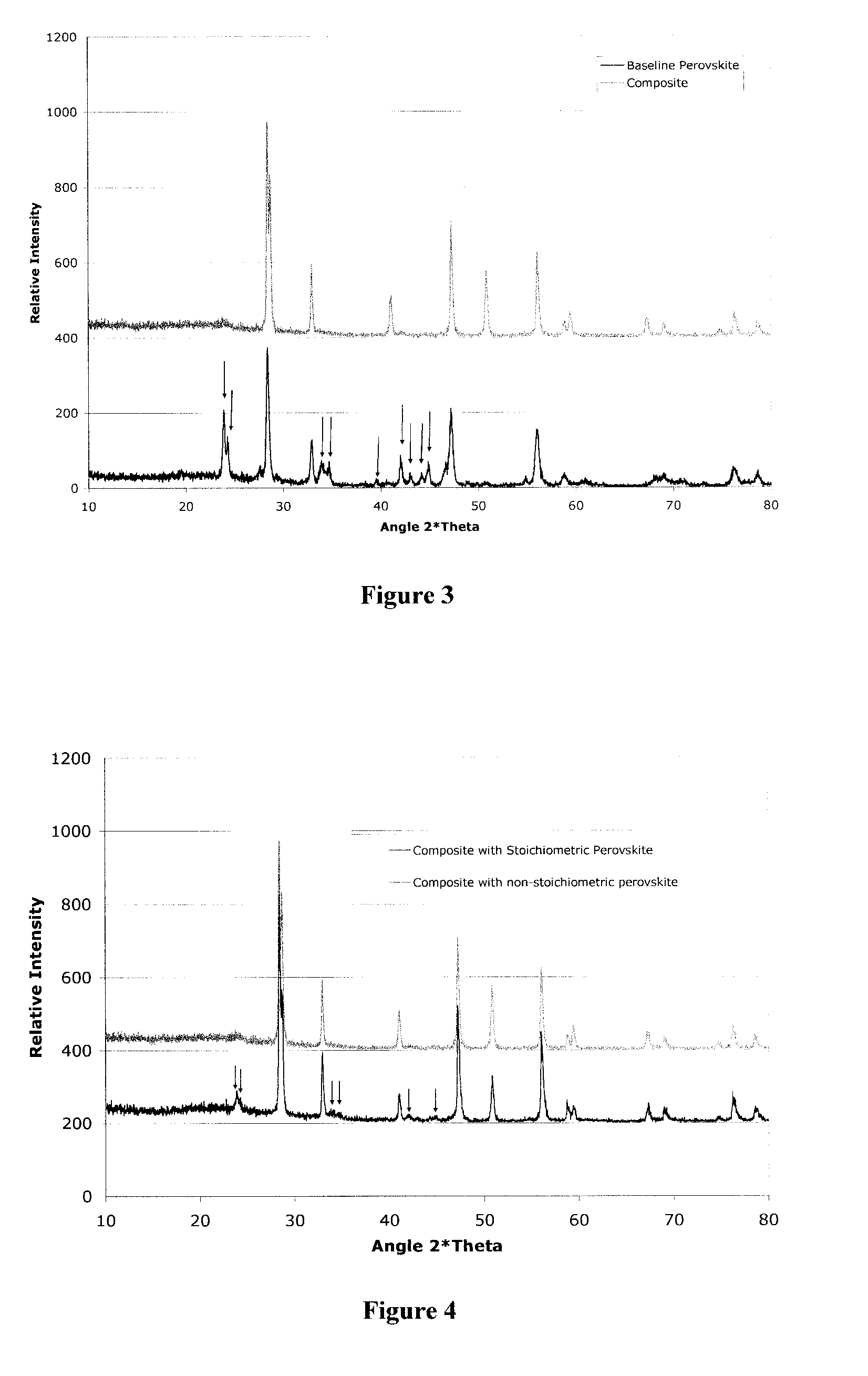

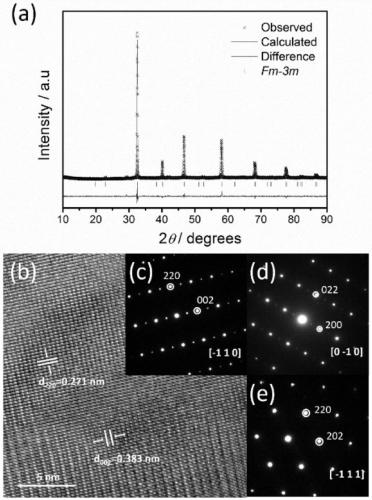

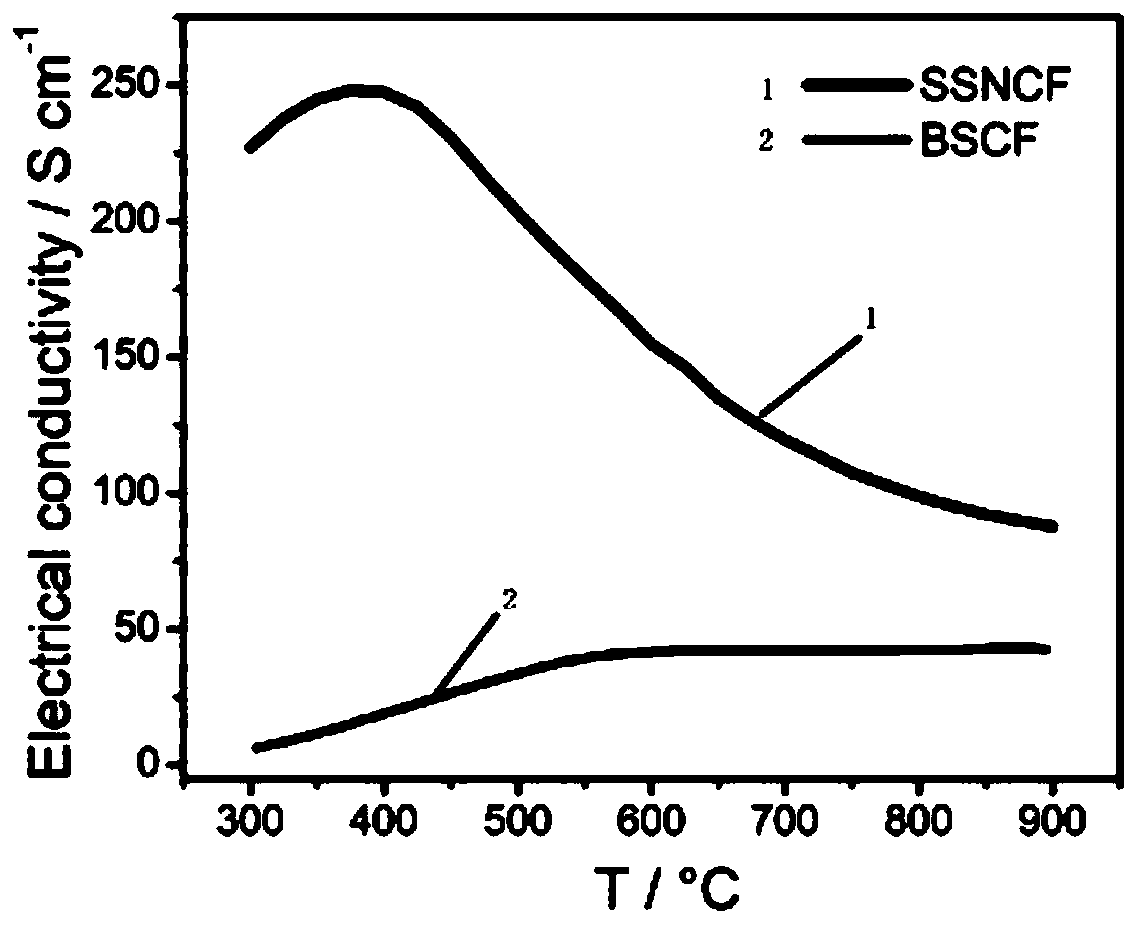

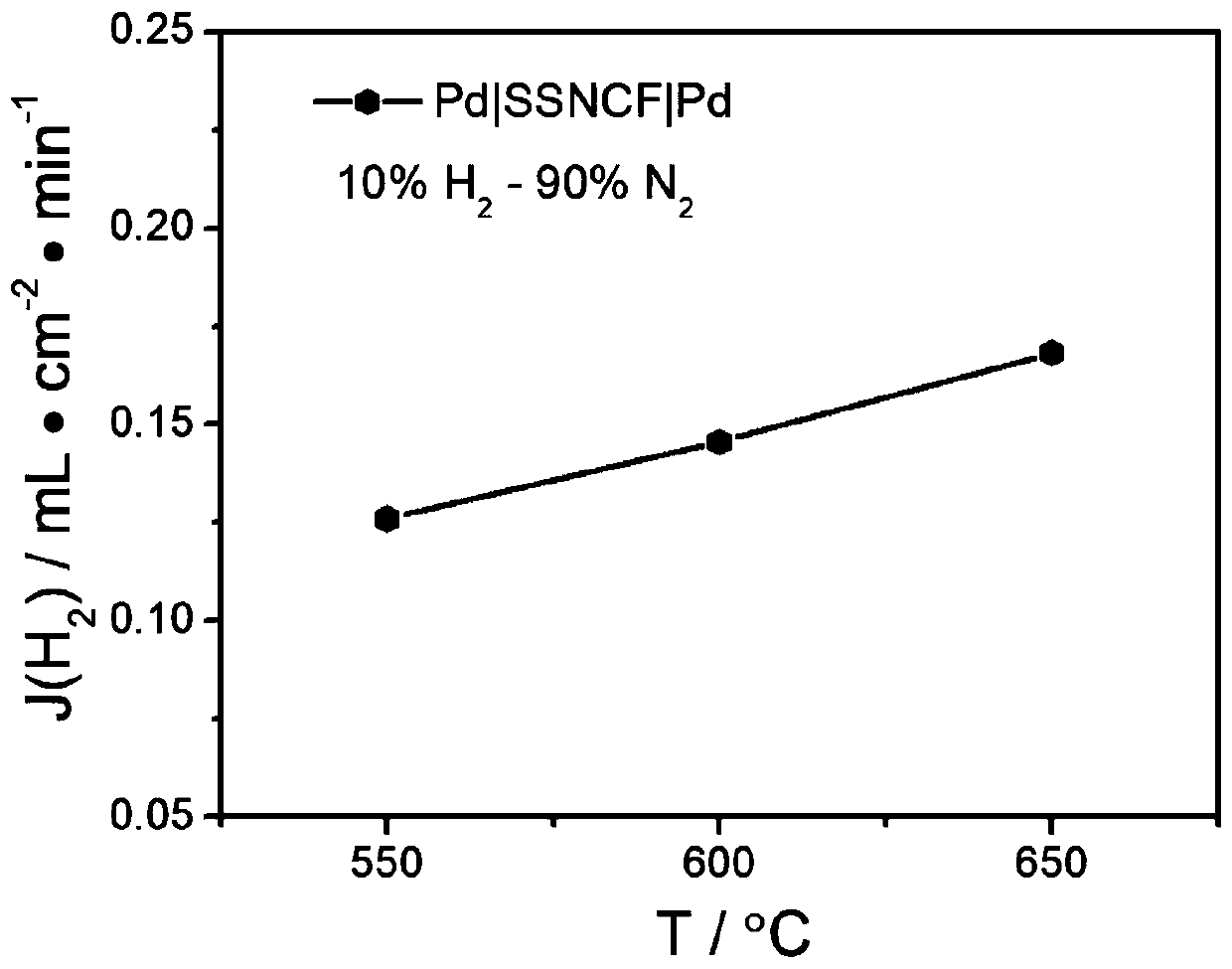

Perovskite mixed conductor material and preparation method thereof

ActiveCN109817997AImprove output performanceCell electrodesCobalt compoundsElectrical conductorOxygen vacancy

The invention relates to a novel oxygen ion, proton and electron mixed conductor solid oxide fuel cell cathode material. The composition molecular formula of the cathode material is Sr2Sc0.1Nb0.1Co1.5Fe0.3O<6-delta> (SSNCF), wherein [delta] represents the content of oxygen vacancies, and the invention belongs to the field of solid oxide fuel cell cathode materials. The cathode material also has excellent proton conductivity under the condition that the cathode material has certain oxygen ion and electron conductivity. The cathode material has proton, oxygen ion and electron mixed conductivity,so that the SSNCF has excellent electrochemical performance on a proton conductor, and correspondingly, the maximum output power at 650 DEG C is up to 840 mW.cm<-2>. Meanwhile, through a hydrogen permeation method, the hydrogen permeation performances of the two materials (SSNCF and Ba0.5Sr0.5Co0.8Fe0.2O<3-delta> (BSCF)) are compared by using an experimental method, the proton conductivity of thetwo materials is compared, and the proton conductivity of the two materials is estimated.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com