Palladium alloy infusible metal composite pipe and manufacture method thereof

A technology of refractory metal and palladium alloy, which is applied in the field of hydrogen permeable composite pipe preparation, can solve the problems of fast corrosion rate, difficult connection with other components, fragile and other problems, and achieves the effects of simple processing steps, improved hydrogen permeability and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

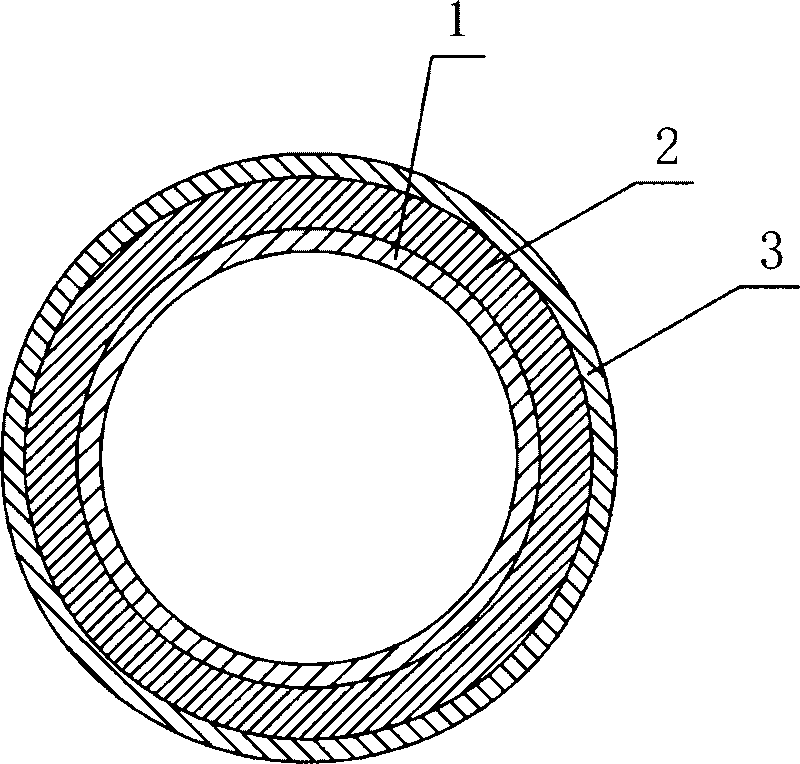

[0044] In this embodiment, the prepared palladium alloy-refractory metal composite tube includes a refractory metal tube 2 made of a refractory metal material with hydrogen permeability and a palladium alloy inner tube arranged on the inside and outside of the refractory metal tube 2 1 and a palladium alloy outer tube 3, the palladium alloy inner tube 1, the refractory metal tube 2 and the palladium alloy outer tube 3 are coaxially arranged and the three are metallurgically combined to form a hydrogen permeable composite tube.

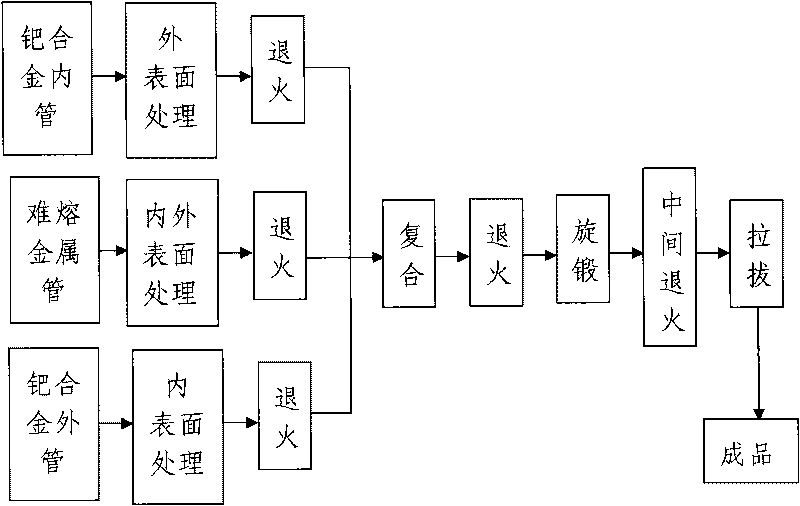

[0045] In this embodiment, when preparing the palladium alloy-refractory metal composite pipe, the following steps are included:

[0046] Step 1. Pipe preparation: determine the wall thickness and length of the palladium alloy inner pipe 1, refractory metal pipe 2 and palladium alloy outer pipe 3 according to the composite ratio. The palladium alloy inner tube 1 is a PdAg20 tube with a diameter of φ15×1mm, the refractory metal tube 2 is a niobium tube ...

Embodiment 2

[0063] In this embodiment, different from Embodiment 1, the composite ratio of the palladium alloy inner tube 1, the refractory metal tube 2 and the palladium alloy outer tube 3 is 2:4:1, and the palladium alloy outer tube 3 The thickness is 5 microns.

[0064] During actual preparation, the difference from Example 1 is that in step 2, the outer surface of the palladium alloy inner tube 1 prepared in step 1, the inner and outer surfaces of the refractory metal tube 2 and the inner surface of the palladium alloy outer tube 3 are respectively carried out. During the grinding process, the roughness of each treated surface reaches 0.3 μm. In step 3011, when the annealing treatment is performed before the explosion compounding, specifically when the refractory metal pipe 2 is annealed, the vacuum degree in the high temperature annealing furnace is 1×10 -2 Pa, the heating temperature is 800°C and the holding time is 90min; when the palladium alloy inner tube 1 and the palladium all...

Embodiment 3

[0066] In this embodiment, different from Embodiment 1, the composite ratio of the palladium alloy inner tube 1, the refractory metal tube 2 and the palladium alloy outer tube 3 is 5:30:3, and the palladium alloy outer tube 3 The thickness is 15 microns.

[0067] During actual preparation, the difference from Example 1 is that in step 2, the outer surface of the palladium alloy inner tube 1 prepared in step 1, the inner and outer surfaces of the refractory metal tube 2 and the inner surface of the palladium alloy outer tube 3 are respectively carried out. During the grinding process, the roughness of each treated surface reaches 0.8 μm. In step 3011, when the annealing treatment is performed before the explosion compounding, specifically when the refractory metal pipe 2 is annealed, the vacuum degree in the high-temperature annealing furnace is 9.9×10 -3 Pa, the heating temperature is 1200°C and the holding time is 30min; when the palladium alloy inner tube 1 and the palladiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com