Method for preparing hydrogen permeation preventing coating by aluminizing by adopting room temperature fused salt

A technology of room temperature molten salt and aluminum plating, which is applied in the field of nuclear technology and application, to achieve the effect of improving coating adhesion, eliminating voids, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Embodiment 1: on the tubular 1Cr18Ni9Ti austenitic stainless steel substrate surface preparation hydrogen permeable coating, the specific steps are as follows:

[0032] 1. Take a cylindrical 1Cr18Ni9Ti austenitic stainless steel substrate sample with a diameter of 60mm, a thickness of 3mm, and a height of 60mm, and first use conventional methods to degrease and remove the oxide film;

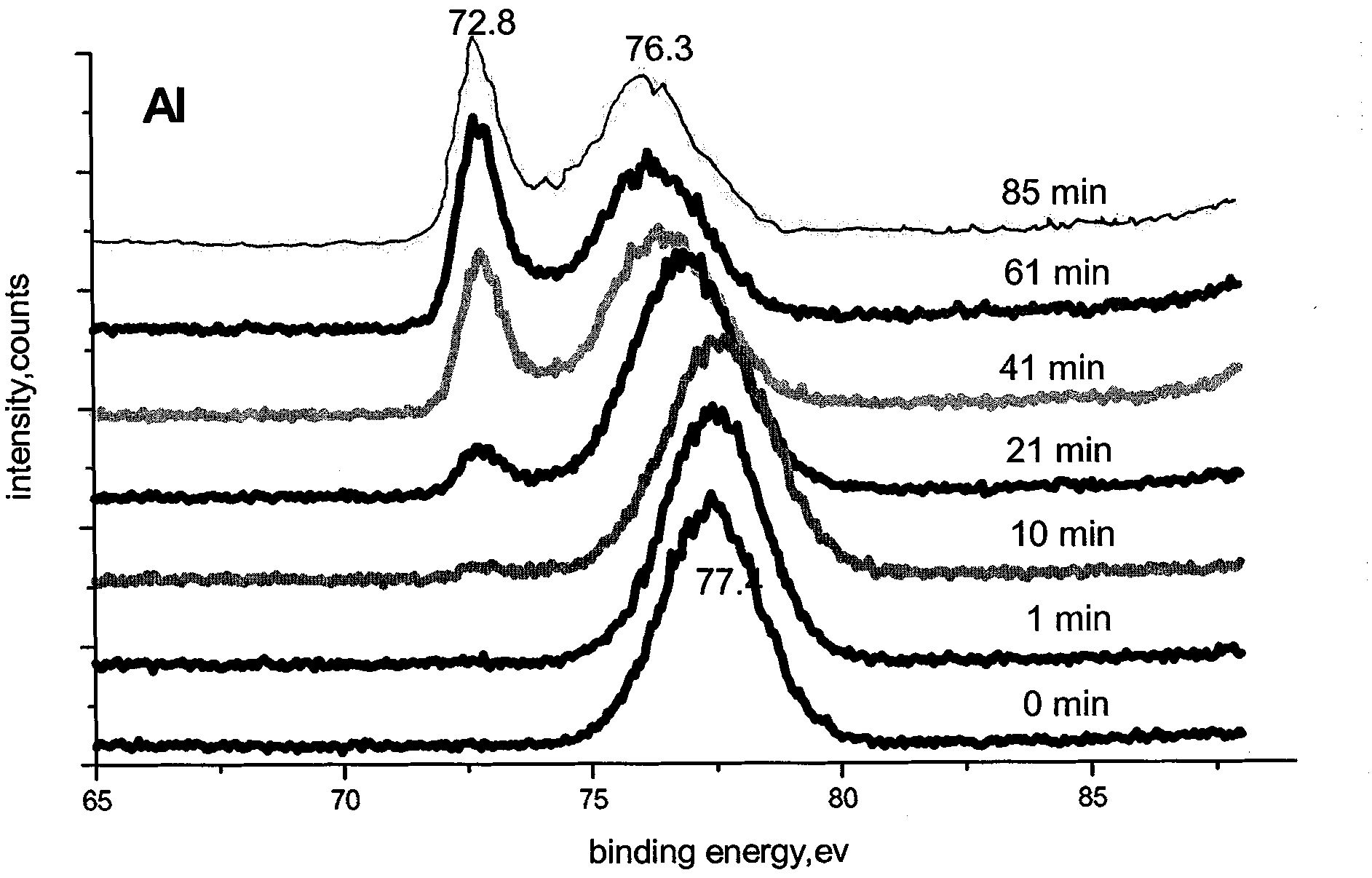

[0033] 2. Put the sample into the AlCl in the argon protection glove box 3 In a solution composed of 1-methyl-3-ethylimidazole chloride (EMIC), where AlCl 3 The molar ratio to 1-methyl-3-ethylimidazole chloride (EMIC) is 2:1. Then carry out aluminum plating at room temperature 25°C, current density 20mA / cm 2 , plating for 50min, to obtain an aluminum coating with a thickness of about 20μm, such as figure 1 As shown, the coating is well bonded to the substrate.

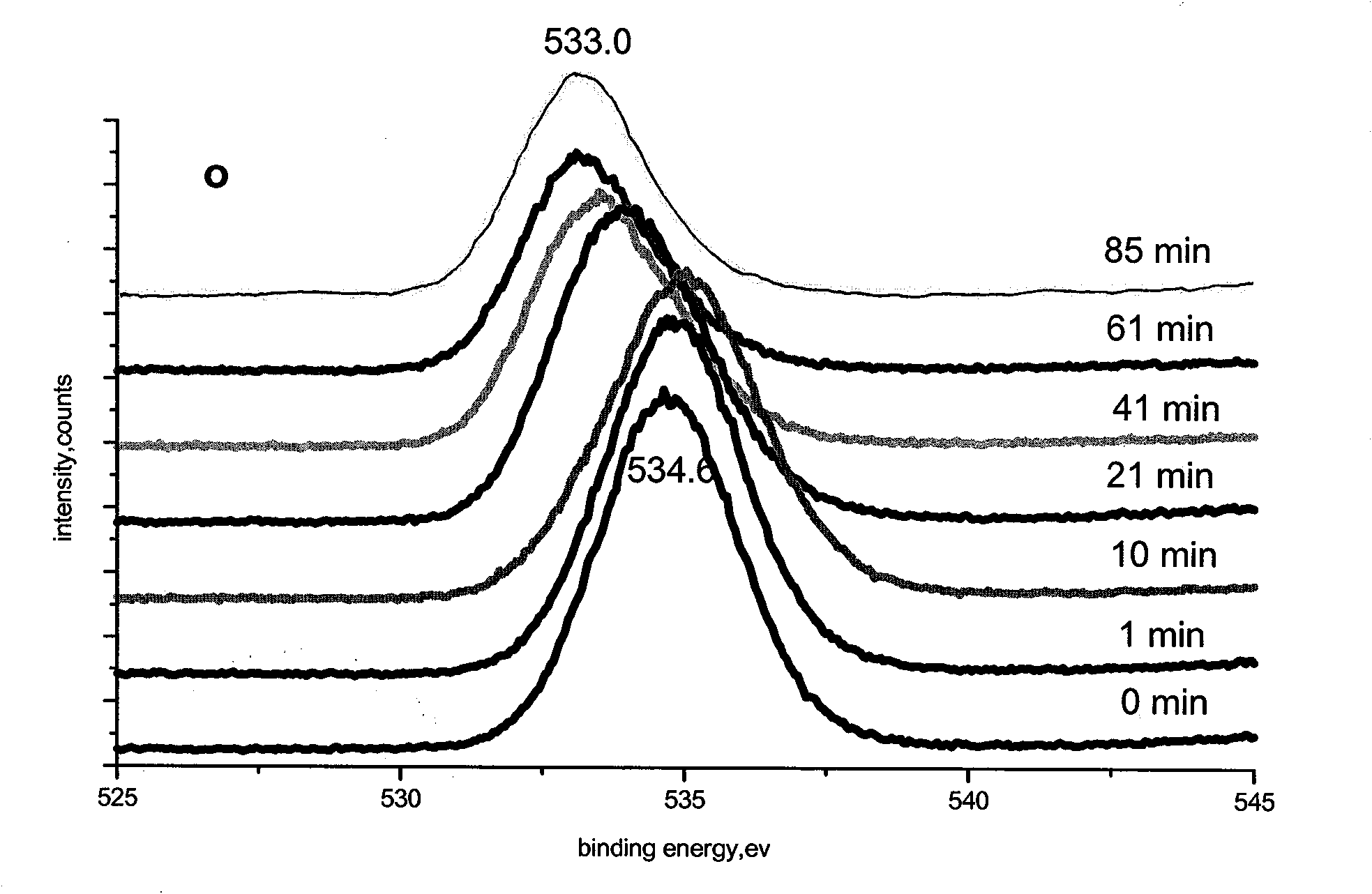

[0034] 3. After plating, the sample is heat-treated in an air furnace at a temperature of 750 ° C and kept for 4 hours to obt...

Embodiment 2

[0037] Embodiment 2: on the surface of the tubular HR-2 austenitic stainless steel substrate, a hydrogen-resistant permeable coating is prepared, and the specific steps are as follows: 1. get a tubular HR-2 austenitic stainless steel substrate sample with a diameter of 60 mm, a thickness of 3 mm, and a height of 60 mm. First, conventional methods are used to degrease and remove the oxide film;

[0038] 2. Put the sample into the AlCl in the argon protective glove box 3 In a solution composed of 1-methyl-3-ethylimidazole chloride (EMIC), where AlCl 3 The molar ratio to 1-methyl-3-ethylimidazole chloride (EMIC) is 2:1. Then aluminum plating is carried out at room temperature 25°C with a current density of 10mA / cm 2 , Plating for 100min, an aluminum coating with a thickness of about 20μm was obtained, and the coating was well bonded to the substrate.

[0039] 3. The sample after plating is heat-treated in an air furnace at a temperature of 750°C and held for 4 hours to obtain ...

Embodiment 3

[0042] Embodiment 3: A hydrogen permeation-resistant coating is prepared on the surface of a tubular HR-2 austenitic stainless steel substrate. The specific steps are as follows:

[0043] 1. Take a tubular HR-2 stainless steel substrate sample with a diameter of 60mm, a thickness of 3mm, and a height of 60mm, and first use conventional methods to degrease and remove the oxide film;

[0044] 2. Put the sample into the AlCl in the argon protective glove box 3 In a solution composed of 1-methyl-3-ethylimidazole chloride (EMIC), where AlCl 3 The molar ratio to 1-methyl-3-ethylimidazole chloride (EMIC) is 2:1. Then carry out aluminum plating at room temperature 25°C, current density 5mA / cm 2 , Plating for 200min, an aluminum coating with a thickness of about 20μm was obtained, and the coating was well bonded to the substrate.

[0045] 3. After plating, the sample is heat-treated in an air furnace at a temperature of 750 ° C and kept for 24 hours to obtain a Fe-Al alloy layer wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com