A LED display screen display calibration system and calibration method

A technology of LED display and display calibration, applied to static indicators, cathode ray tube indicators, instruments, etc., can solve the problems of inconvenient mass production, calibration disorder, troublesome maintenance and operation, etc., to facilitate mass production and reduce bandwidth requirements , The effect of simple maintenance operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

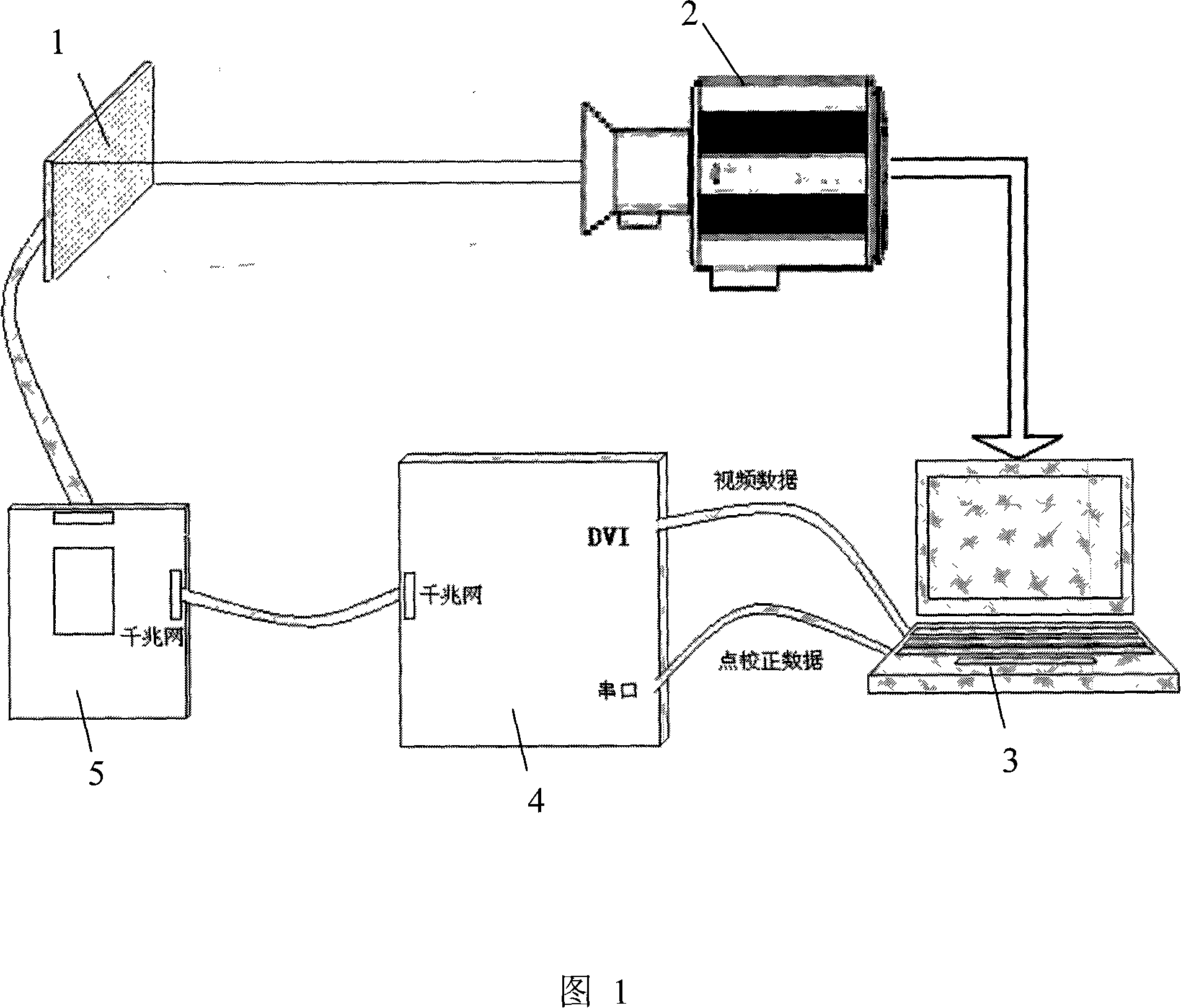

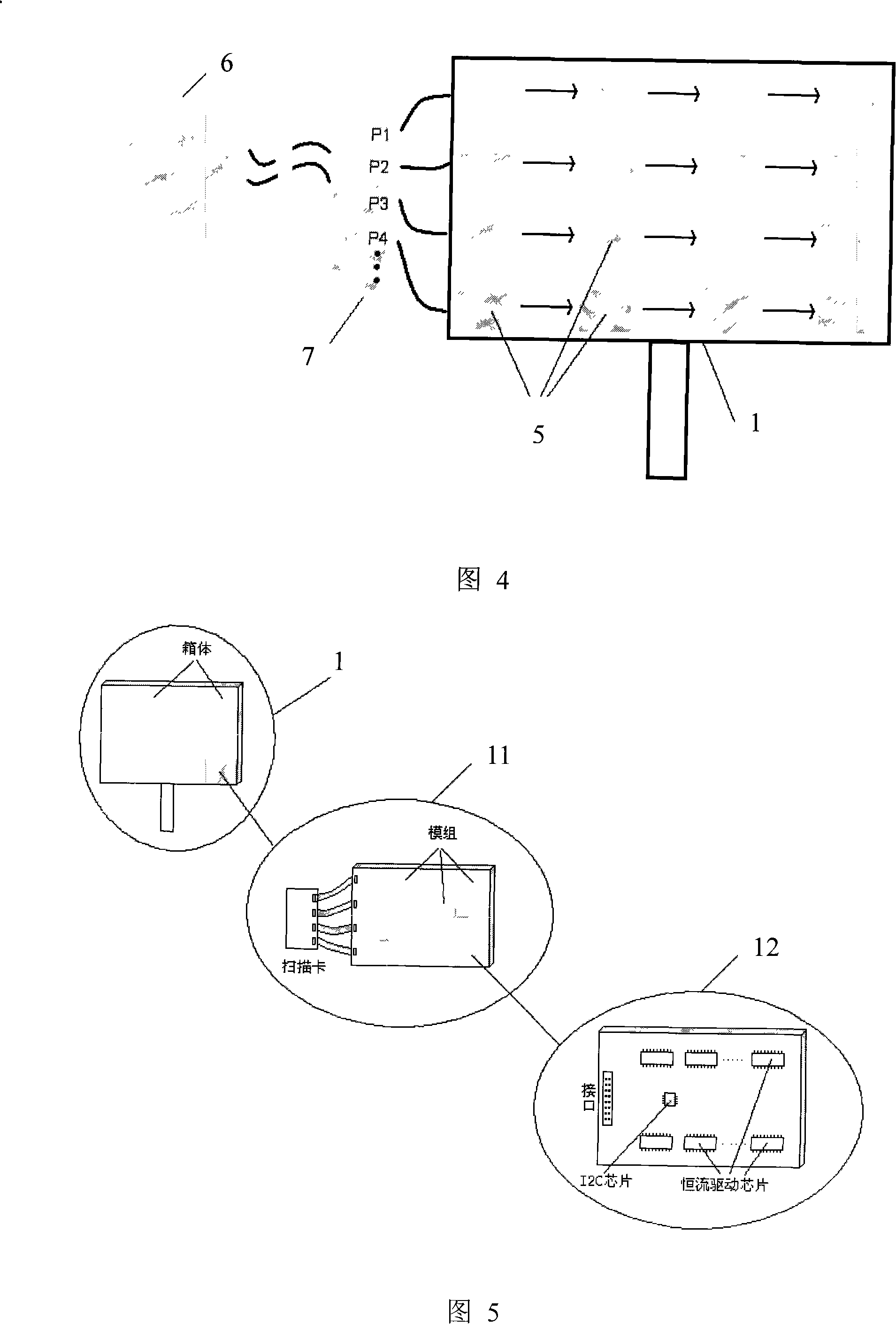

[0051] As shown in FIG. 4 and FIG. 5 , the LED display display correction system of the present invention includes a video acquisition controller 6 , a data distributor 7 , a scan control card 5 and an LED display module 12 .

[0052] Wherein, the video acquisition controller 6 includes a large-scale editable logic array chip connected through a corresponding bus, a DVI image receiving circuit, a Gigabit network communication interface circuit, an optical fiber communication interface circuit, a general serial communication interface and a high-speed memory circuit.

[0053] The data distributor includes a large-scale programmable logic array chip, a Gigabit network communication interface circuit, an optical fiber communication interface circuit and an environment monitoring circuit.

[0054] As shown in Figure 9, the scan control card 5 includes an editable logic array chip (FPGA) 52, a gigabit network communication interface circuit 51, a memory circuit 54, a DC-DC power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com