Patents

Literature

1789 results about "Control card" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

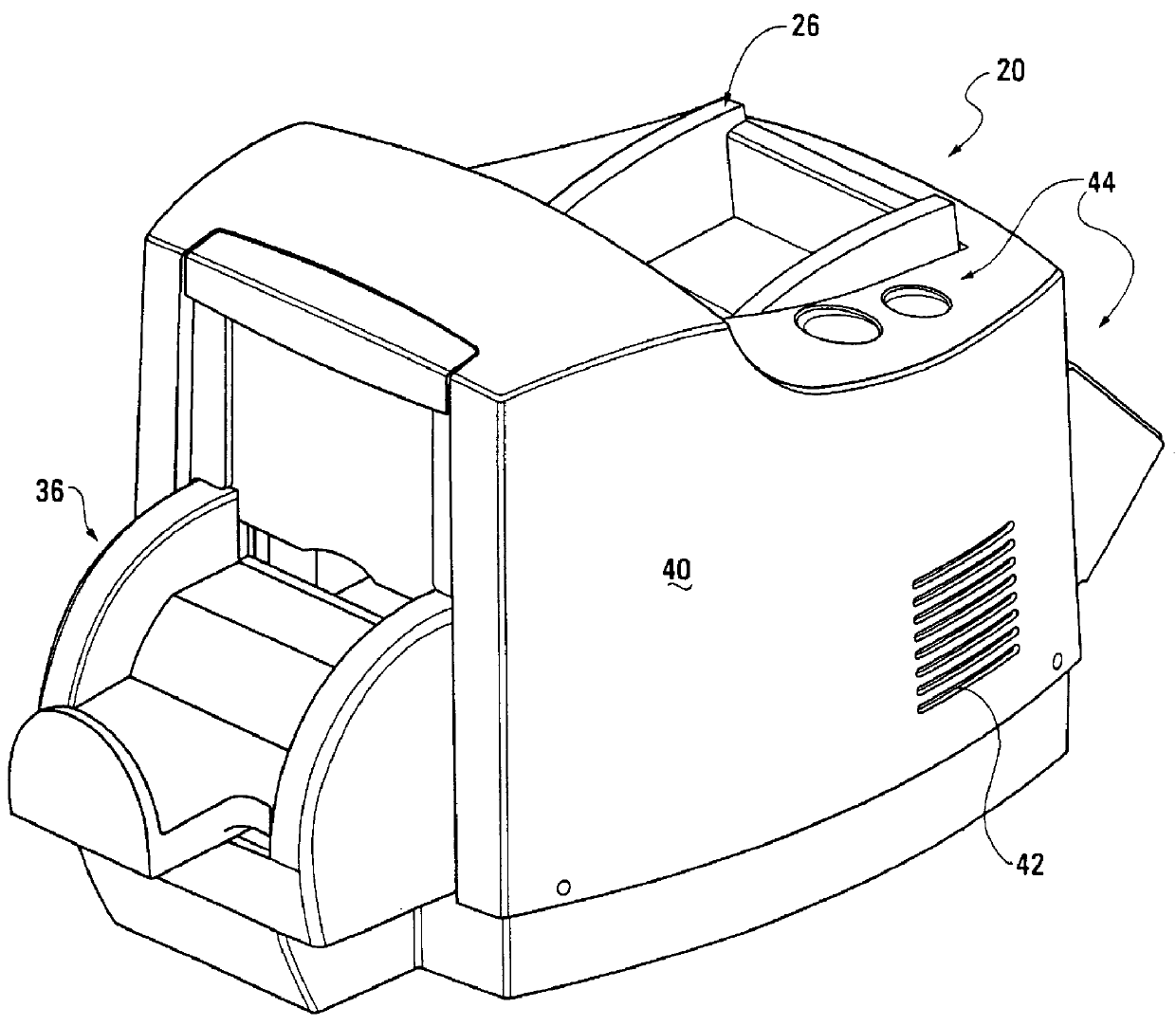

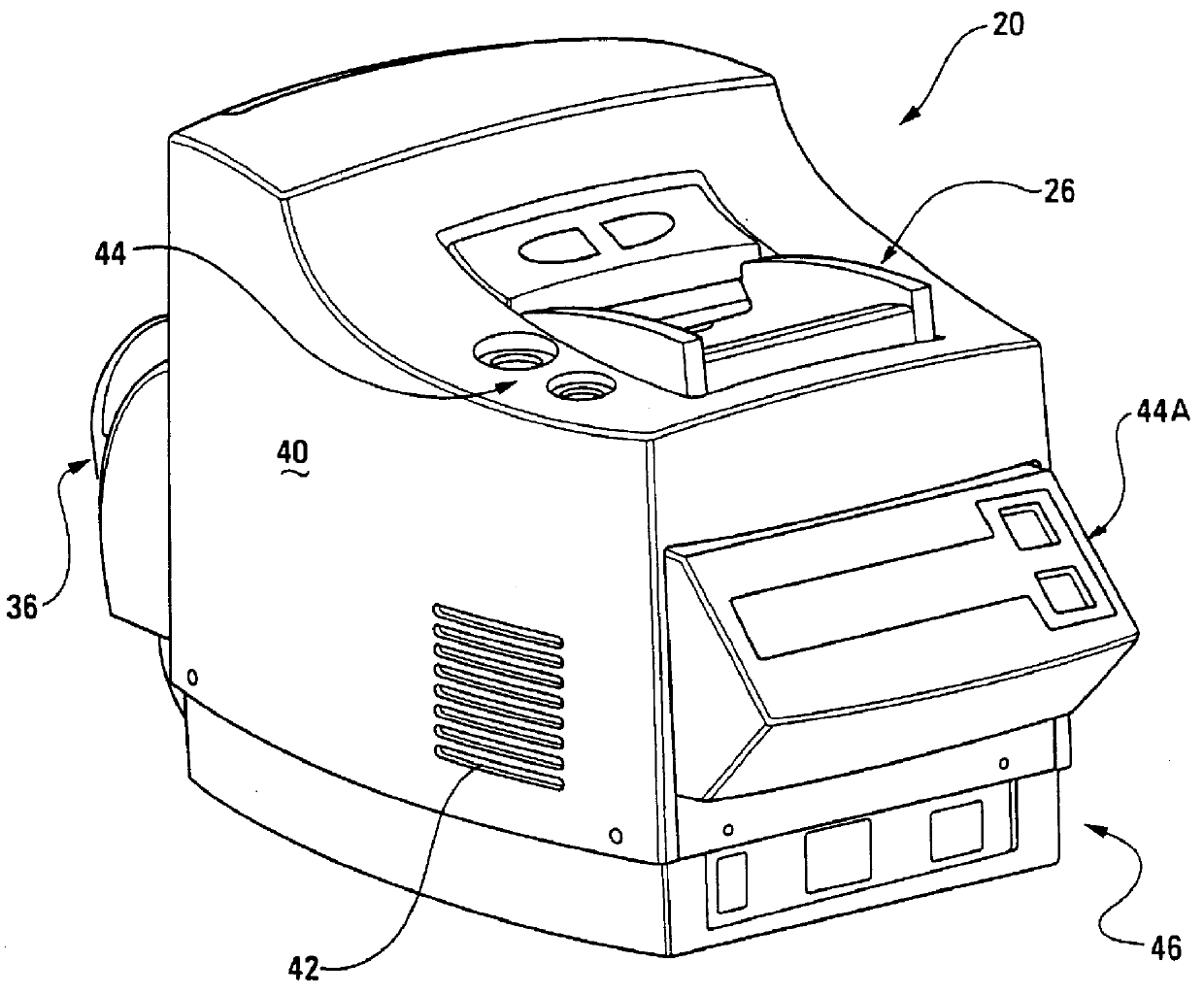

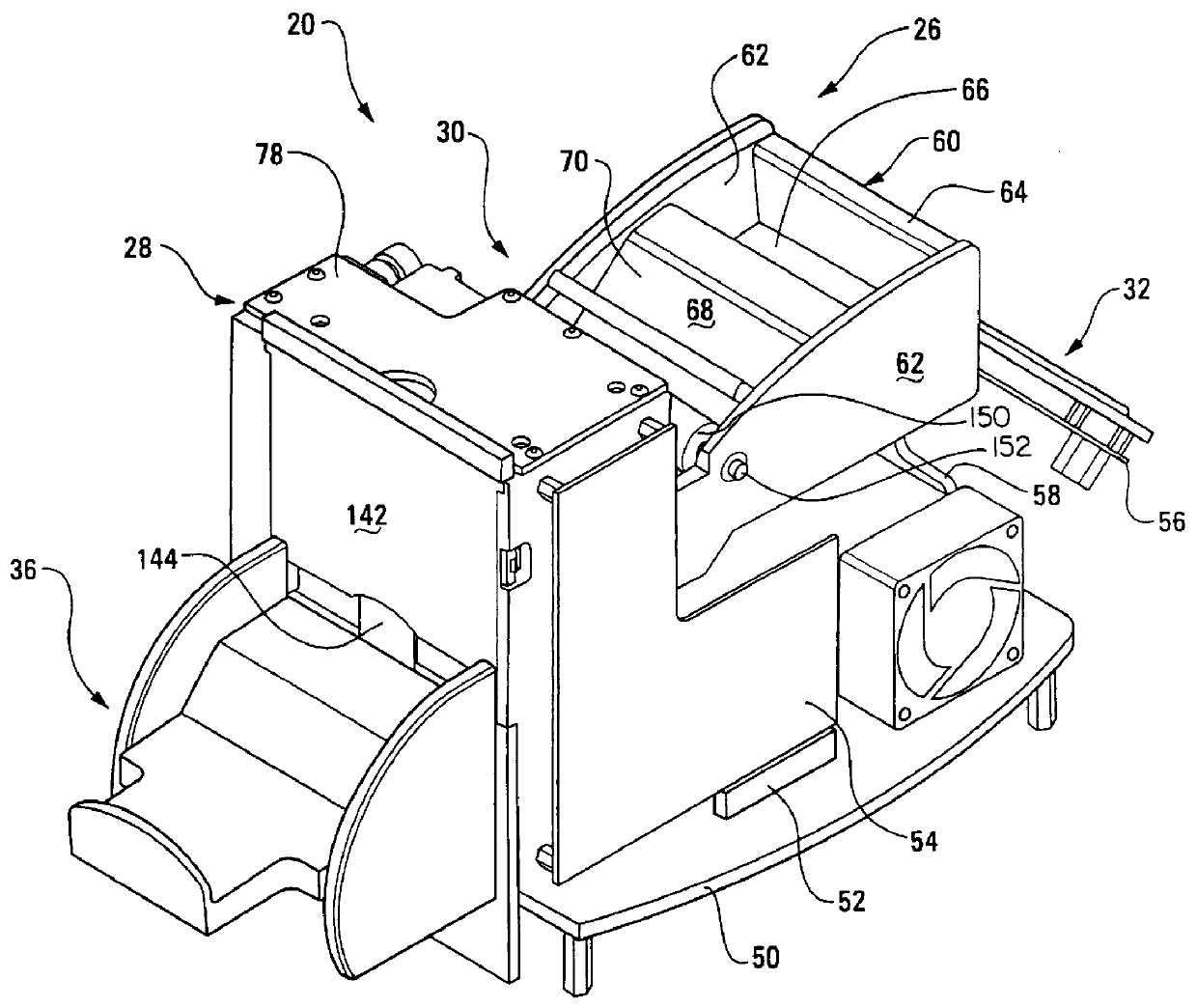

Device and method for forming hands of randomly arranged cards

The present invention provides an apparatus and method for moving playing cards from a first group of cards into plural hands of cards, wherein each of the hands contains a random arrangement of the same quantity of cards. The apparatus comprises a card receiver for receiving the first group of cards, a single stack of card-receiving compartments generally adjacent to the card receiver, the stack generally vertically movable, an elevator for moving the stack, a card-moving mechanism between the card receiver and the stack, and a microprocessor that controls the card-moving mechanism and the elevator so that an individual card is moved into an identified compartment. The number of compartments receiving cards and the number of cards moved to each compartment may be selected.

Owner:BALLY GAMING INC

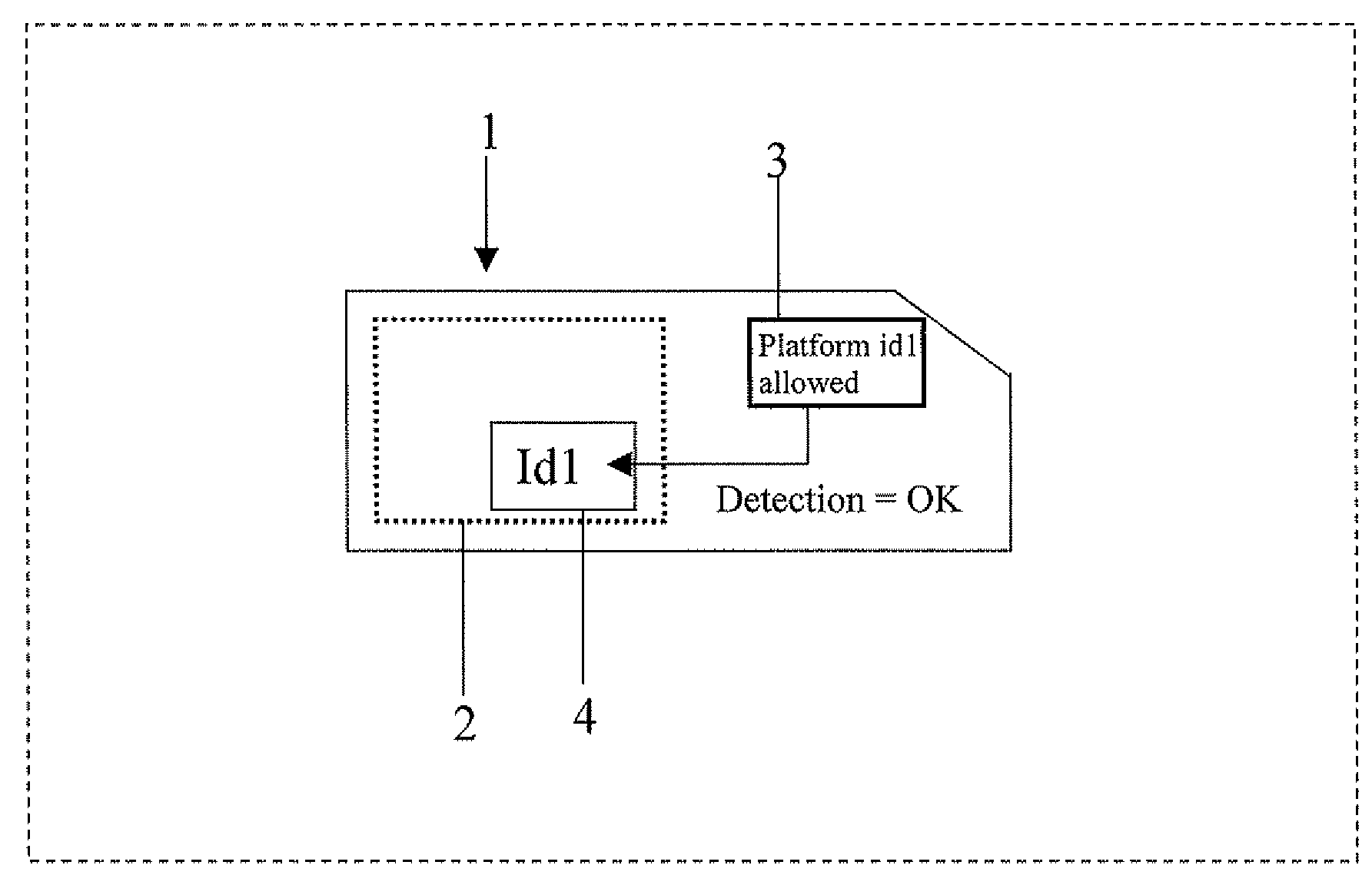

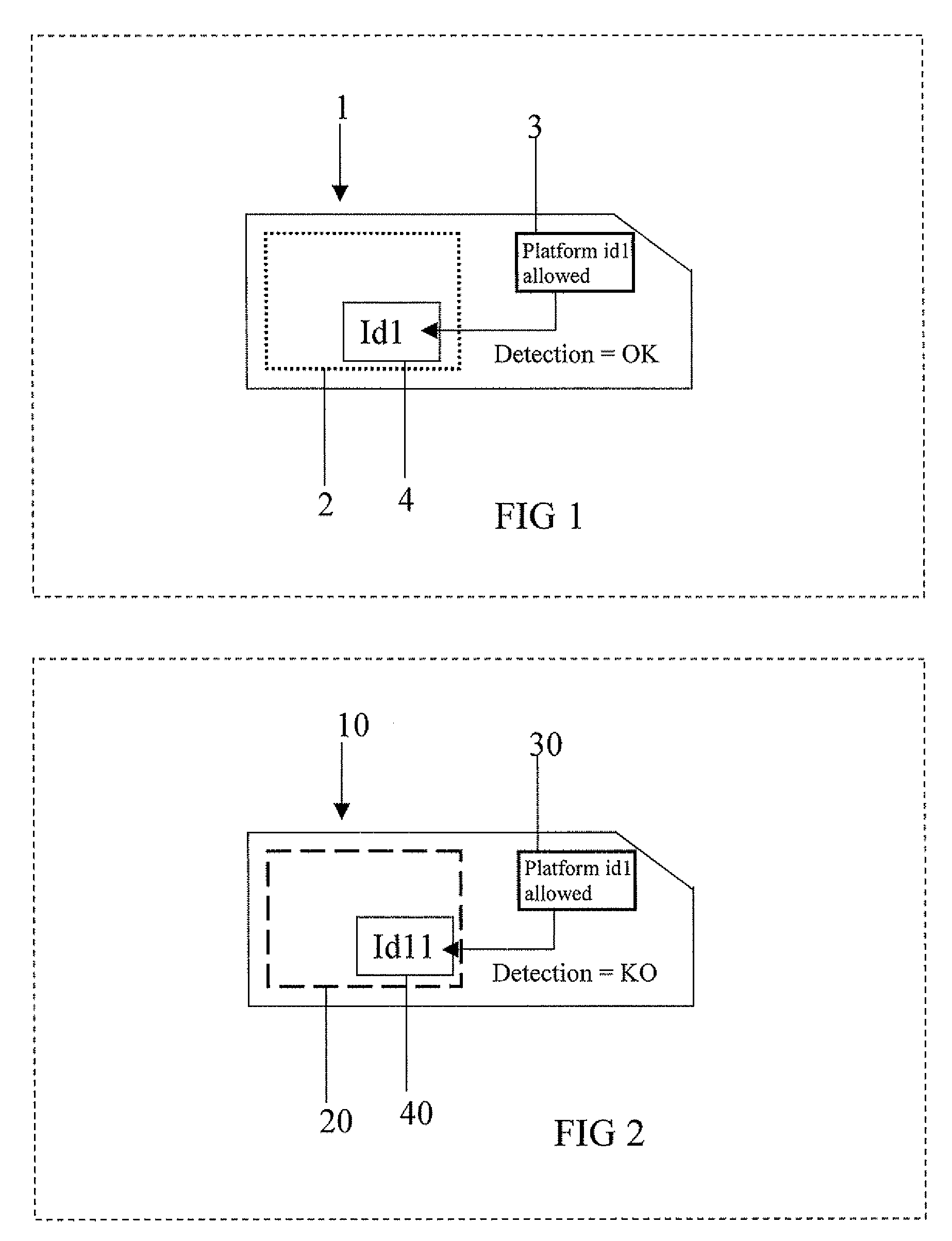

Method for controlling the execution of an applet for an IC card

ActiveUS20080288699A1Preventing executionAvoid business lossInternal/peripheral component protectionComponent plug-in assemblagesOperating systemJava Card

A method for controlling the execution of an applet for an IC Card including a java card platform, includes a phase for downloading the applet inside the IC Card, a phase for executing the applet through the java card platform and a phase for storing an identification platform number inside a memory portion of the IC Card. The phase for executing the applet has a first step for detecting the identification platform number to perform the phase for executing the applet with or without restrictions, respectively if the identification platform number is not or is detected by the step for detecting. The applet is a java card applet or a SIM toolkit applet.

Owner:STMICROELECTRONICS INT NV

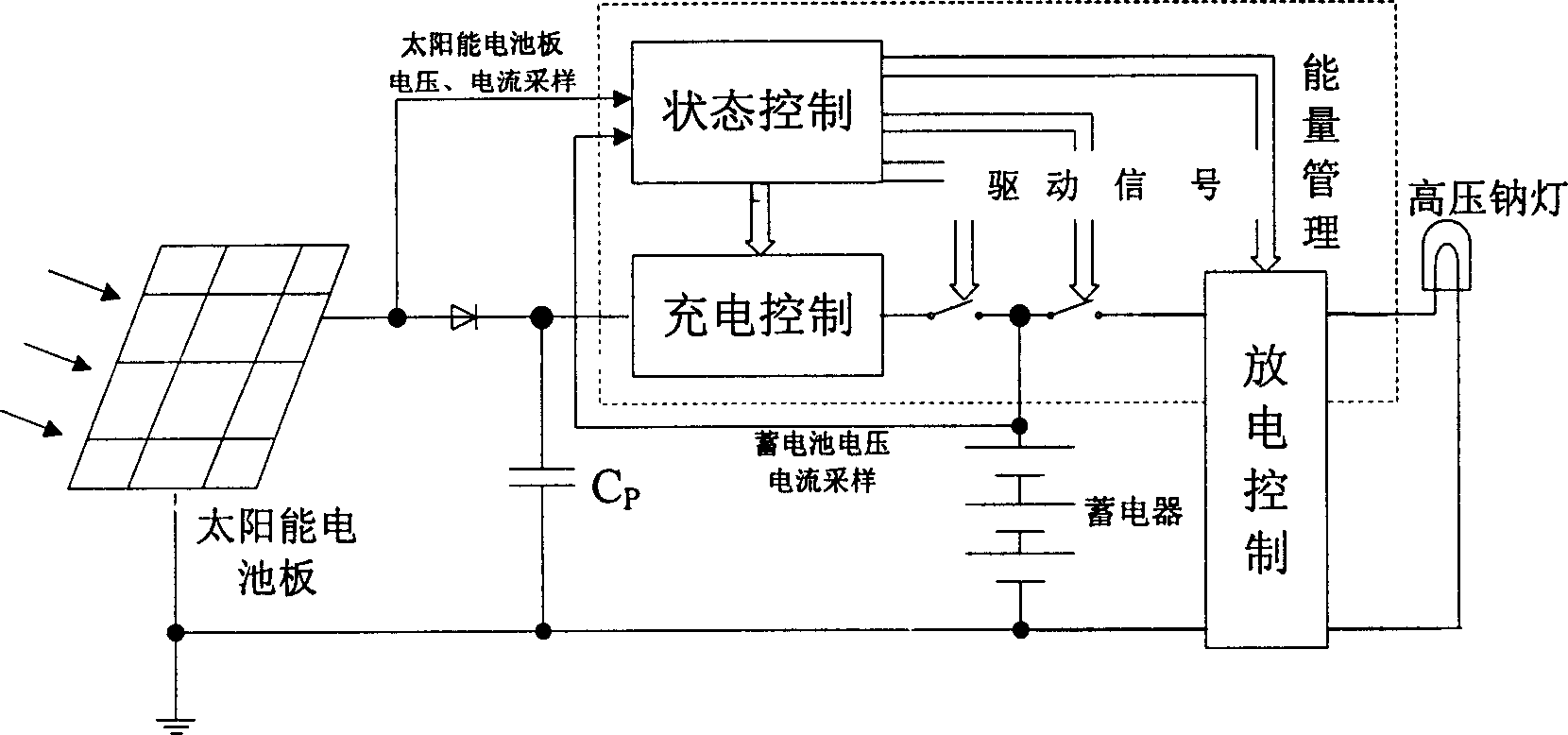

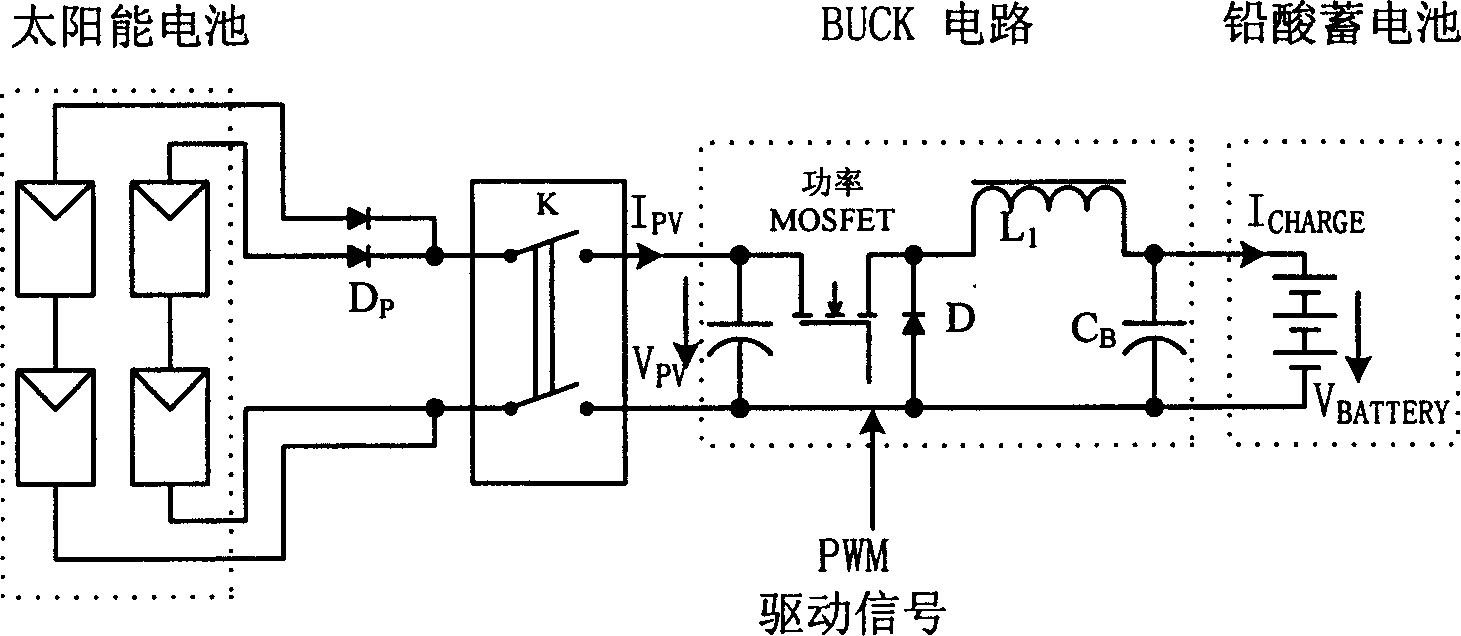

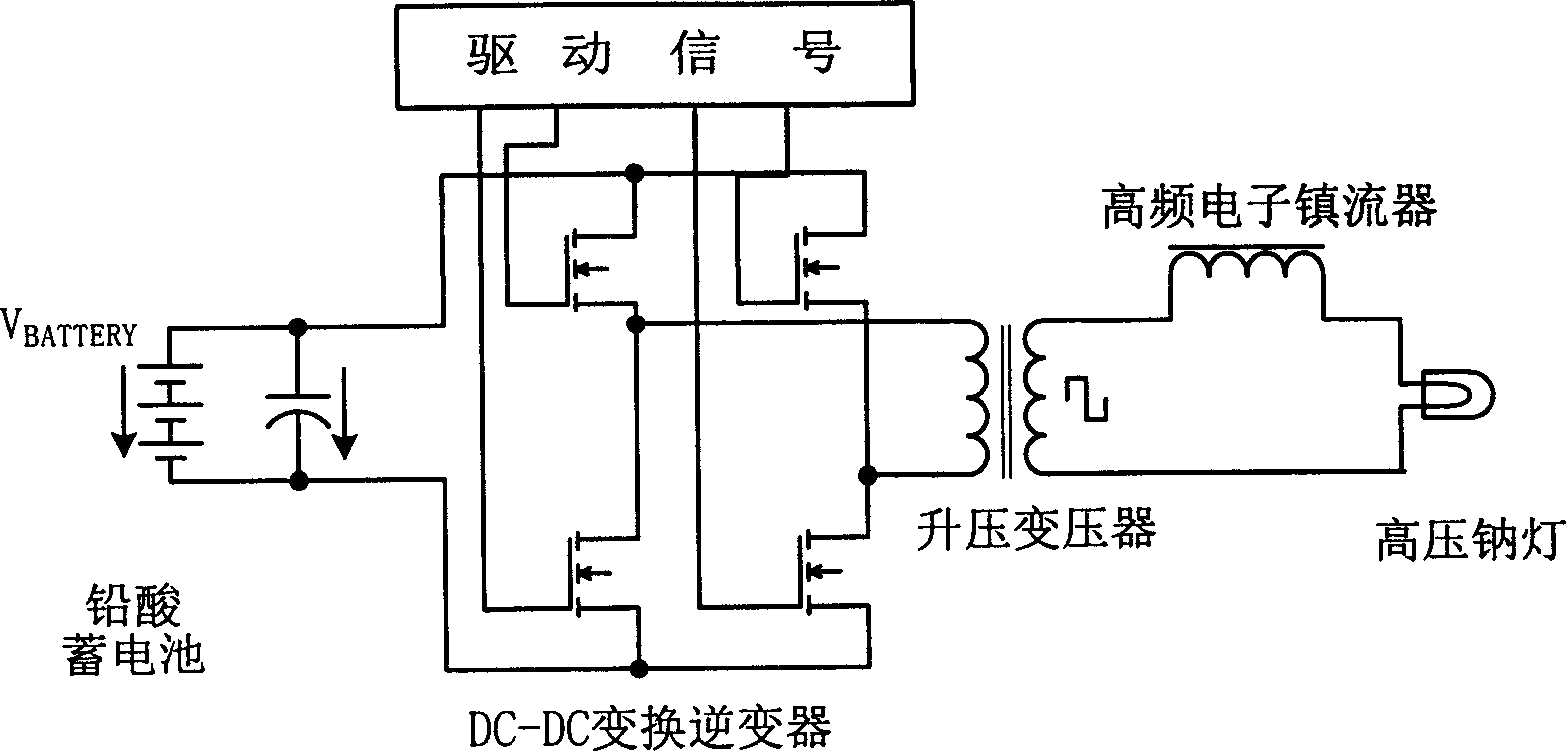

Solar energy high voltage sodium lamp controller based on single stage inverter

InactiveCN1787717ARealize intelligent controlImproved and enhanced charge and discharge capabilitiesBatteries circuit arrangementsElectric lighting sourcesMicrocontrollerEngineering

This invention relates to a solar energy high pressure Na-lamp controller based on a single stage inverter characterizing in applying a sectional charge control and a frequency conversion output control, in which, the hardware includes a singlechip control circuit, a single-stage total bridge inversion circuit, a storage battery charge circuit, a high frequency electronic ballast circuit, a solar energy cell, storage batteries and luminaries, the controller is charged by MPPT to increase the system efficiency and applies frequency conversion output to control the current of the lamp, besides, a design of machine-card separation is applied to the controller on the structure to meet the needs of different luminaries and lamination, the control structure is integrated in a control card suitable for software upgrading.

Owner:TSINGHUA UNIV

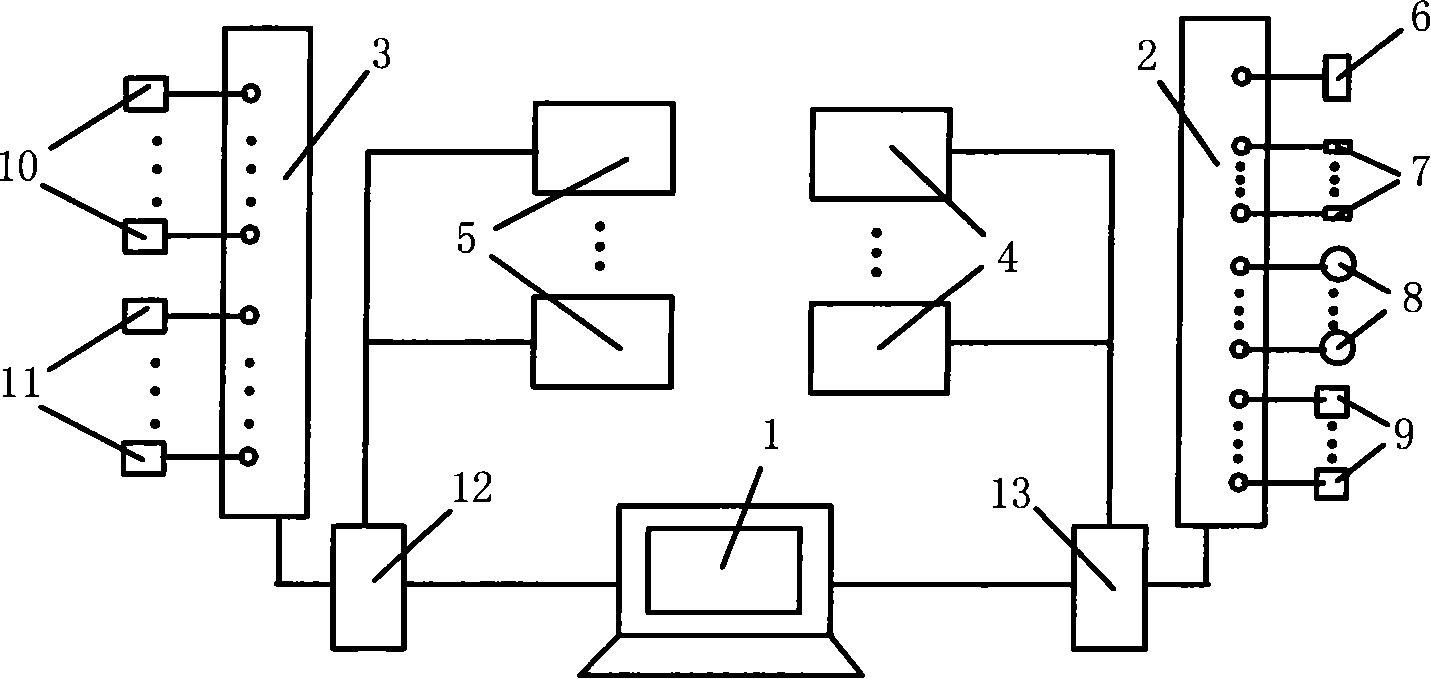

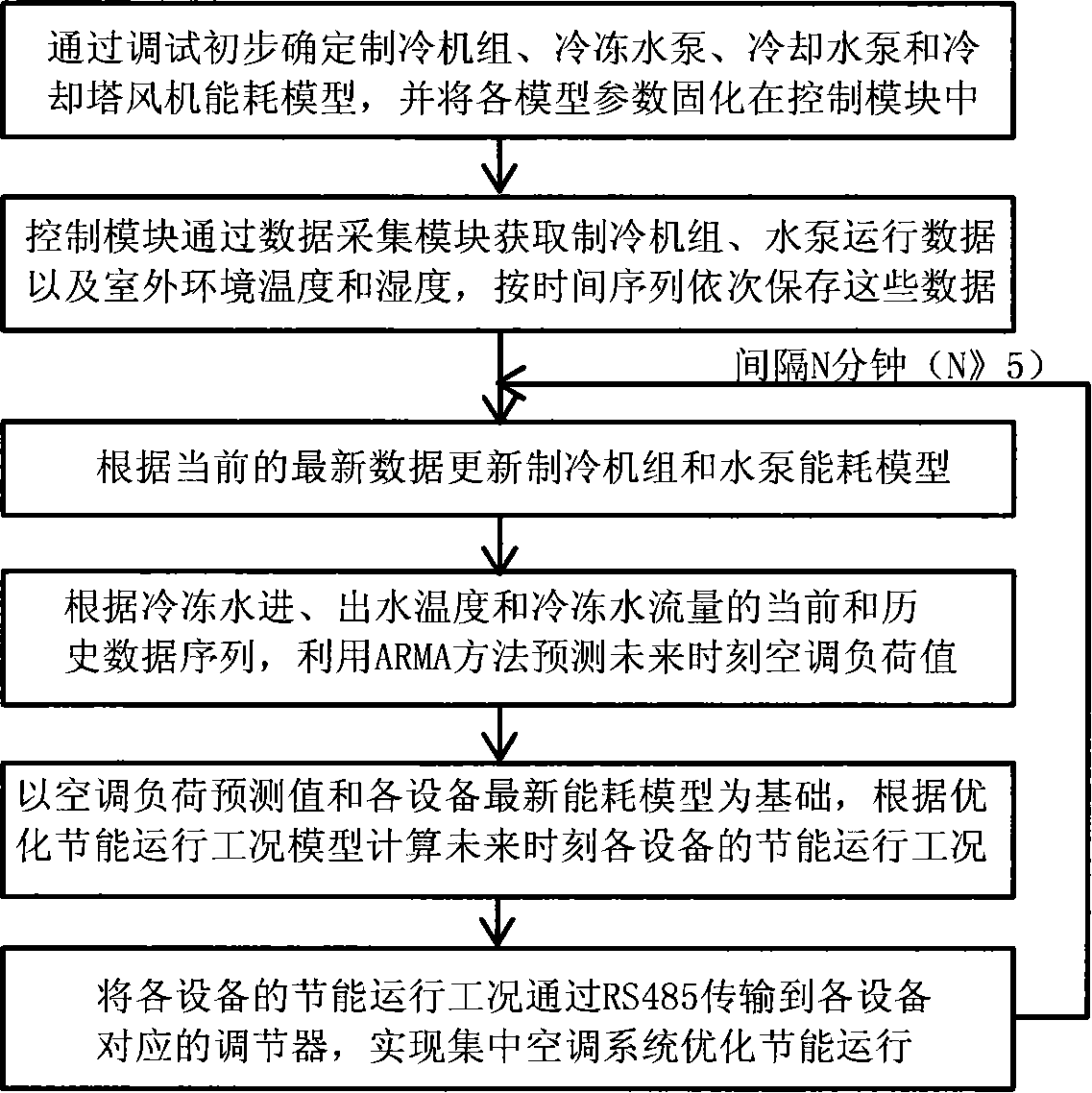

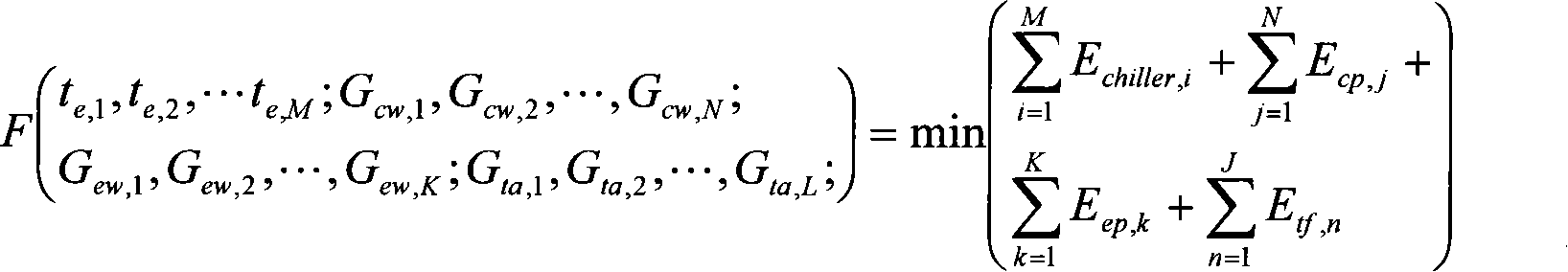

Central air conditioning system global optimization energy-saving control method and device based on model

InactiveCN101251291AImprove controlRealize energy savingSpace heating and ventilation safety systemsLighting and heating apparatusData acquisitionGlobal optimization

The invention provides a method for controlling a global optimization of energy saving for a central air conditioning system based on a model, comprising a control module, a multichannel data acquisition card and control card, a refrigerating unit data collector and a controller, a humidity sensor, a temperature sensor, a flow sensor, a watt transducer, a water pump frequency converter, a fan frequency converter, an RS232 / RS485 conversion module and a RS485 / RS232 conversion module. The whole system can be operated under the condition of most energy saving according to an operating condition of optimized energy saving of each energy consumption device acquired by calculation of a calculation module by taking energy consumption modules of a refrigerating unit, a water pump and a fan and an ARMA air conditioning load forecasting model. The invention thoroughly concerns an influence of the operating condition of each power device in the system to the energy consumption of the whole system, takes a control strategy based on a forecasted air conditioning load, and performs an online update for the energy consumption modules of key energy consumption devices in the system, thereby greatly improving an effect of optimization of energy saving for the central air conditioning system.

Owner:上海真聂思楼宇科技有限公司

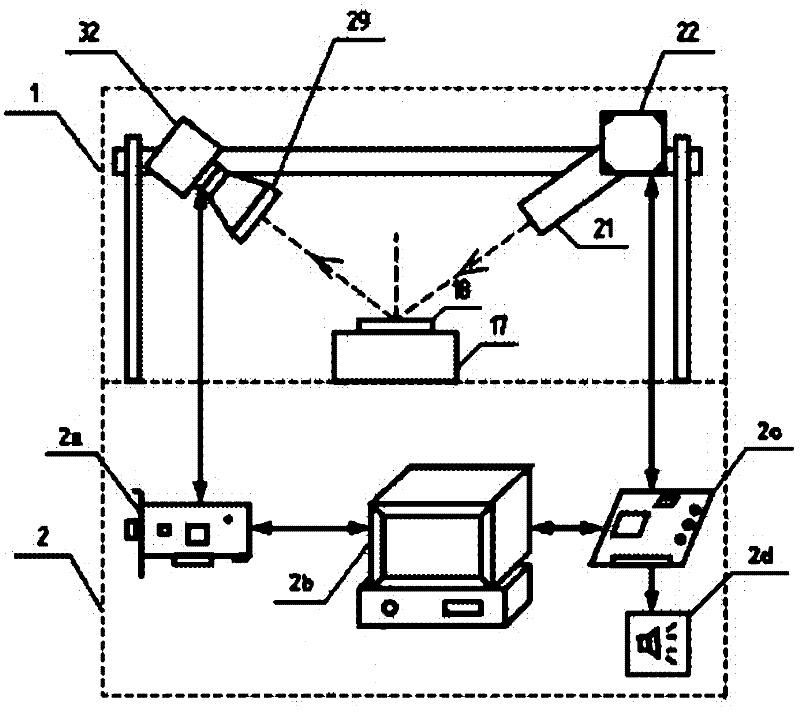

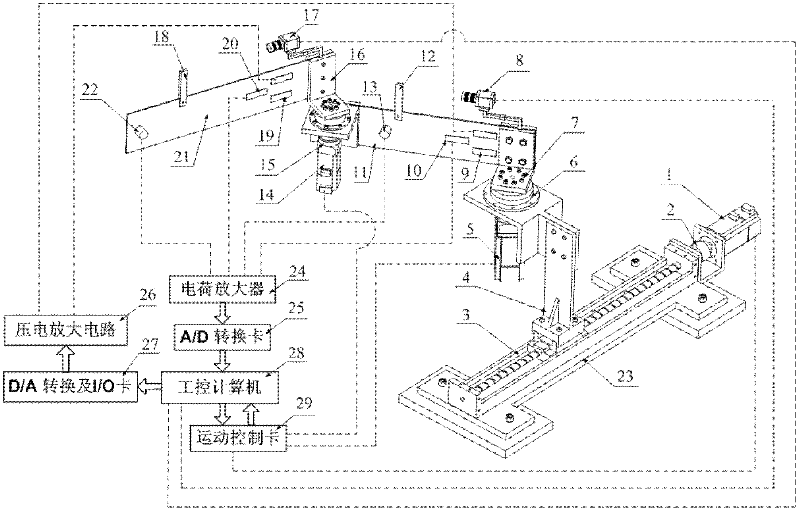

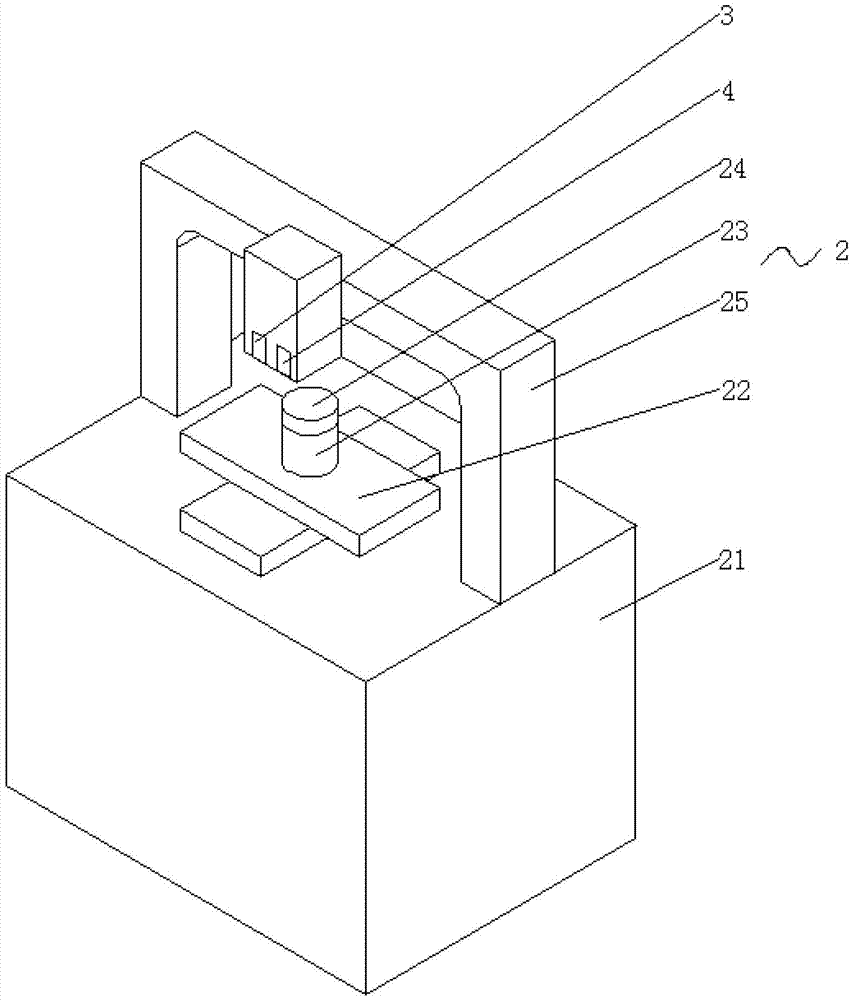

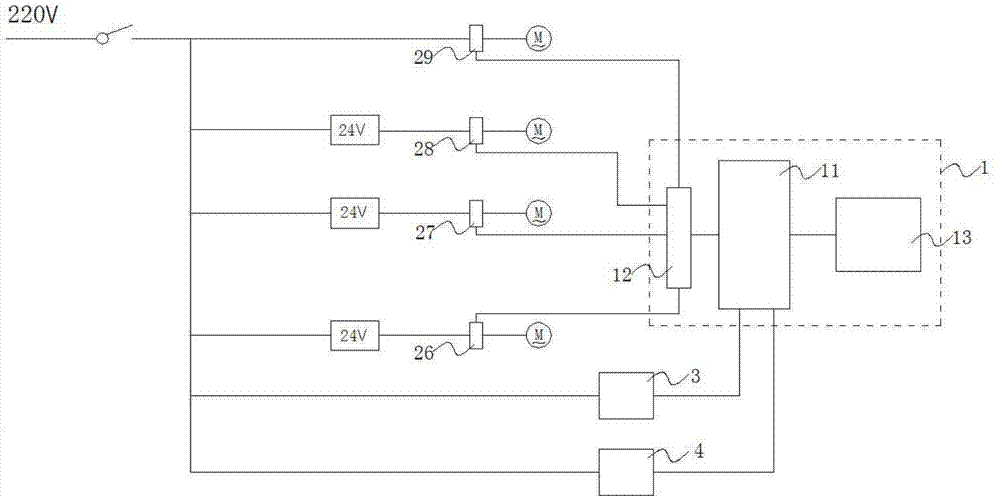

Device and method for detecting micro defects on bright and clean surface of metal part based on machine vision

ActiveCN102590218ARealize installation positioningEasy to operateOptically investigating flaws/contaminationEffect lightCcd camera

The invention relates to a device and method for detecting micro defects on the bright and clean surface of a metal part based on machine vision. The device comprises an imaging, positioning and adjusting mechanism and a processing unit, wherein the imaging, positioning and adjusting mechanism comprises a base plate, a guide rod, a fixed support, a sliding support, a stepping motor, a CCD (Charge Coupled Device) camera, a telecentric lens and parallel light sources, wherein the imaging and coaxial lighting of the CCD camera are primarily adjusted; an image collection card, an industrial personal computer, an equipment control card and an alarm are electrically connected in the processing unit and are used for collecting, transmitting, storing, processing, displaying and alarming image. The method comprises coaxial lighting adjustment and image processing, wherein coaxial lighting adjustment comprises the steps of triggering the equipment control card via software of the industrial personal computer to drive the stepping motor, and adjusting the rotating angles of the parallel light sources until the coaxial lighting condition is satisfied; and image processing comprises the steps of detecting defects on the internal surface of the detected part, respectively detecting large and small defects on the outer edge on the surface of the detected part, displaying the processing images in real time and judging the results.

Owner:安徽中科智能高技术有限责任公司

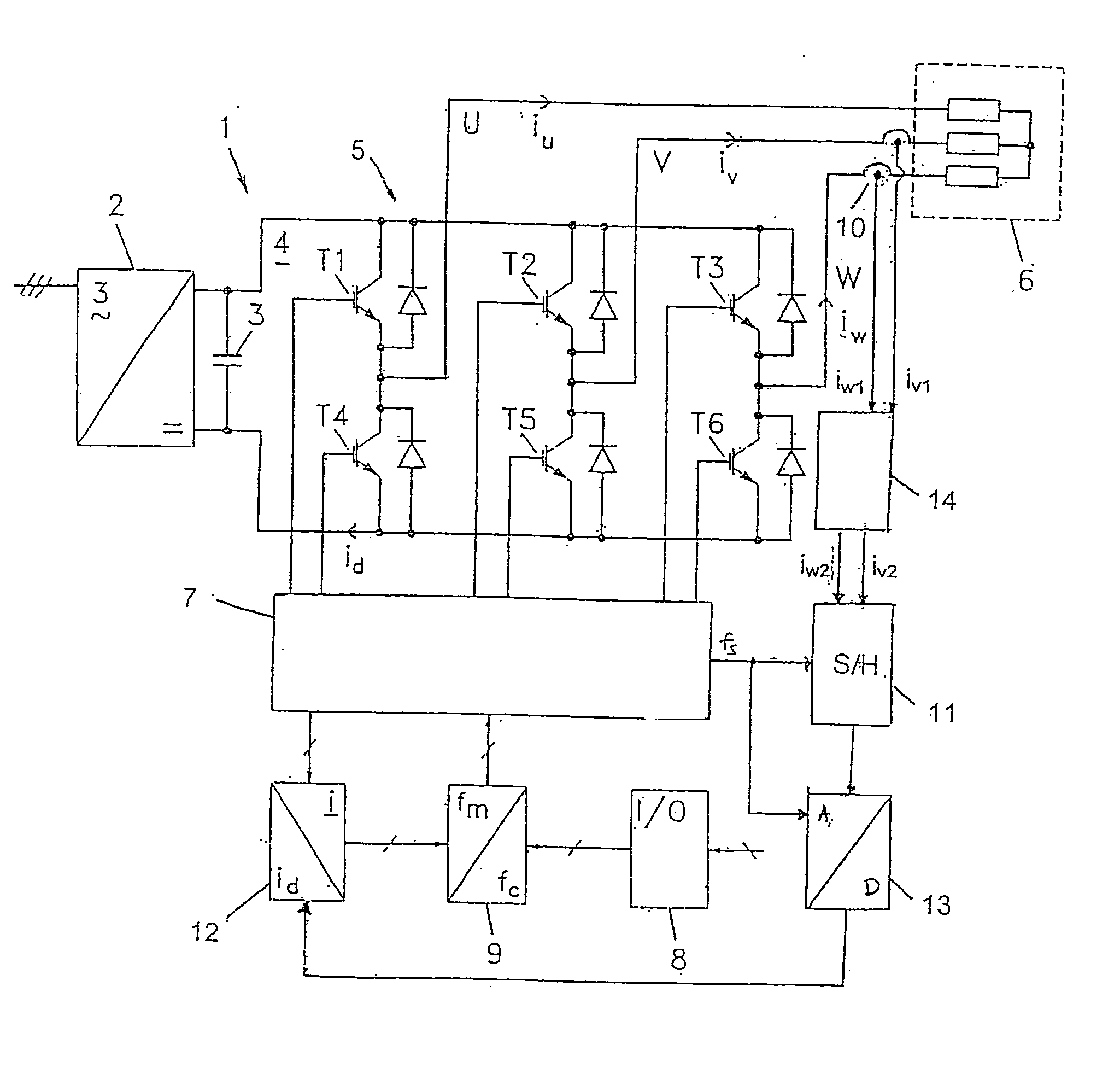

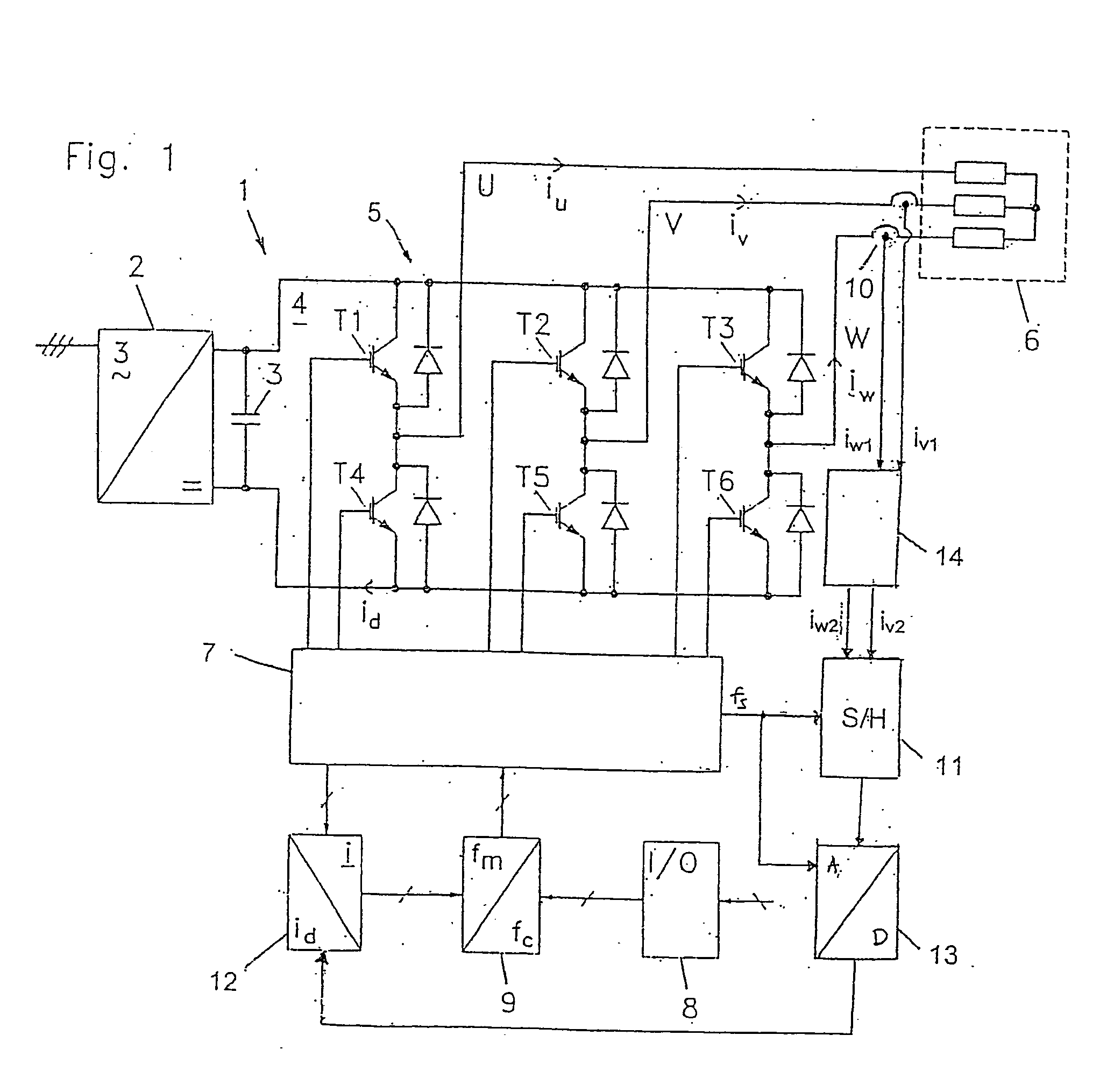

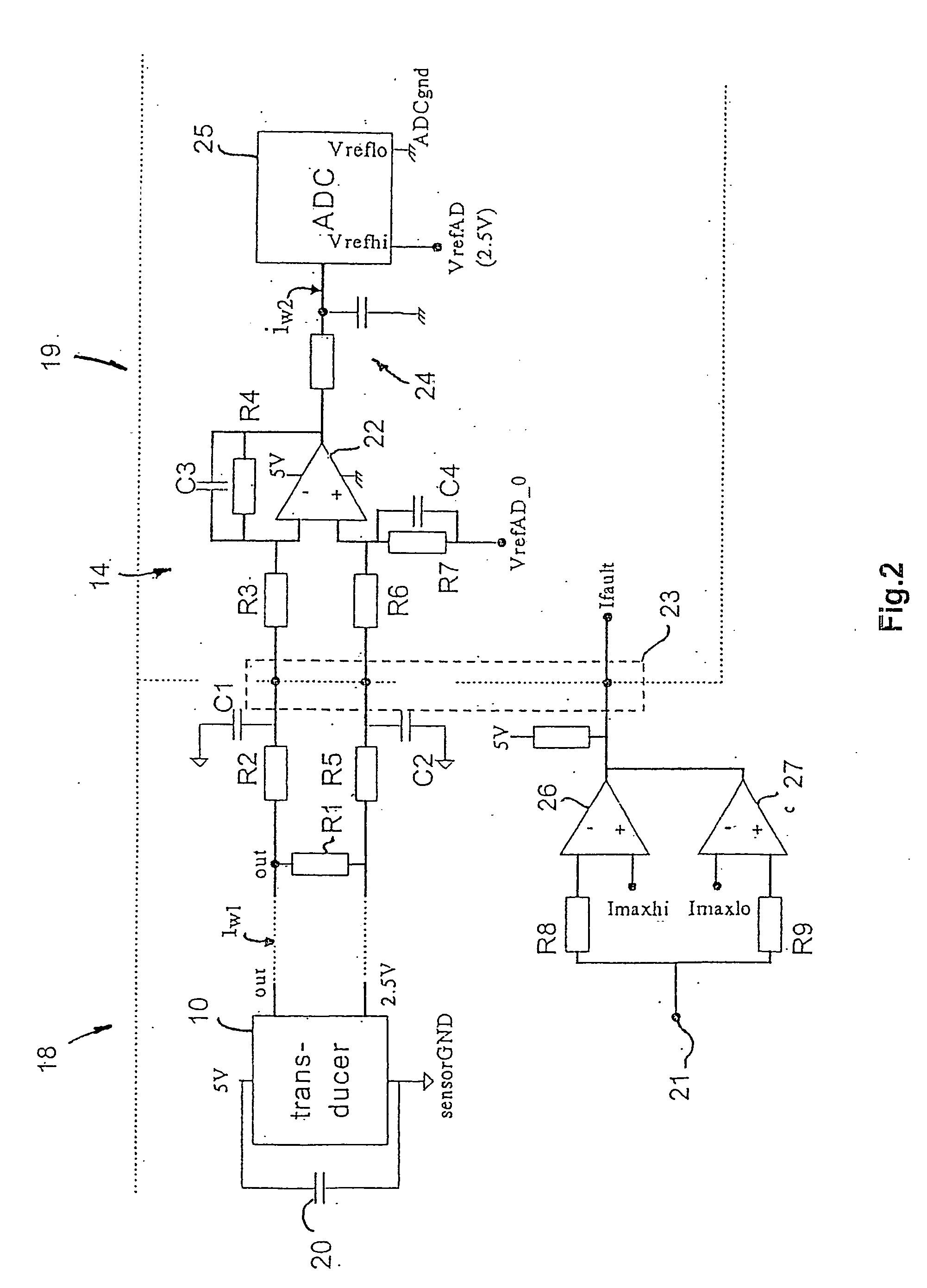

Method for measuring currents in a motor controller and motor controller using such method

InactiveUS20050190094A1Increase heightReduce random noiseElectric signal transmission systemsField or armature current controlSignal-to-noise ratio (imaging)Differential transmission

The invention relates to a method for measuring currents in a motor controller. Some current sensing devices placed on the motor wires or inside the motor controller provide low amplitude output signals thus complicating sampling and data processing. In order to improve the signal / noise ratio, an oversampling technique is disclosed which makes used of a differential transmission of the output signal. Further, by applying intelligent sorting techniques on the sampled data, a substantial improvement in the signal / noise ratio can be obtained. The invention also concerns a motor controller using this method, and discloses the use of a power card and a control card, where the current sensing device is placed on the power card and a differential amplifier is placed on the control card. The gain of the differential amplifier is controlled by components placed on the power card as well as on the control card.

Owner:DANFOSS DRIVES

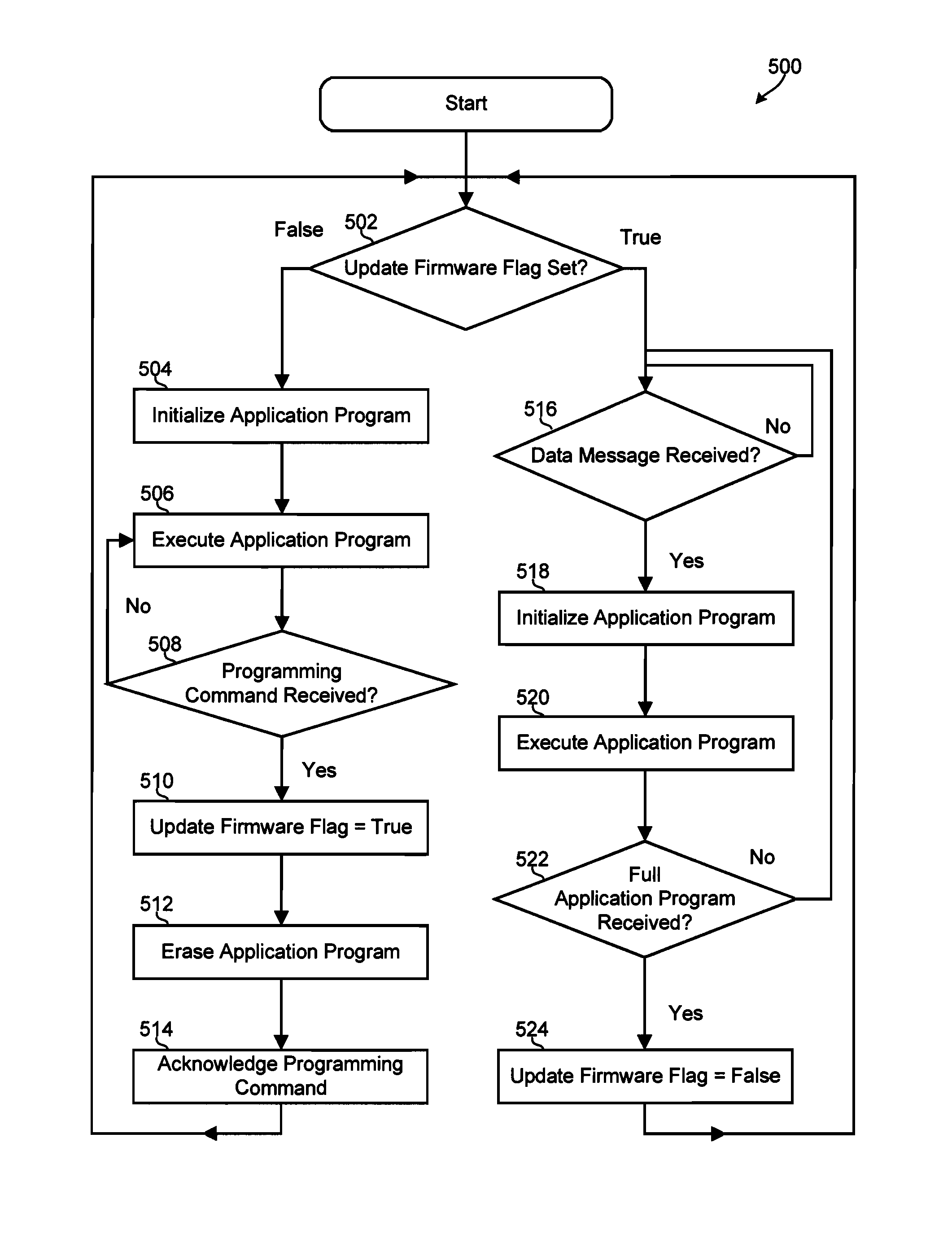

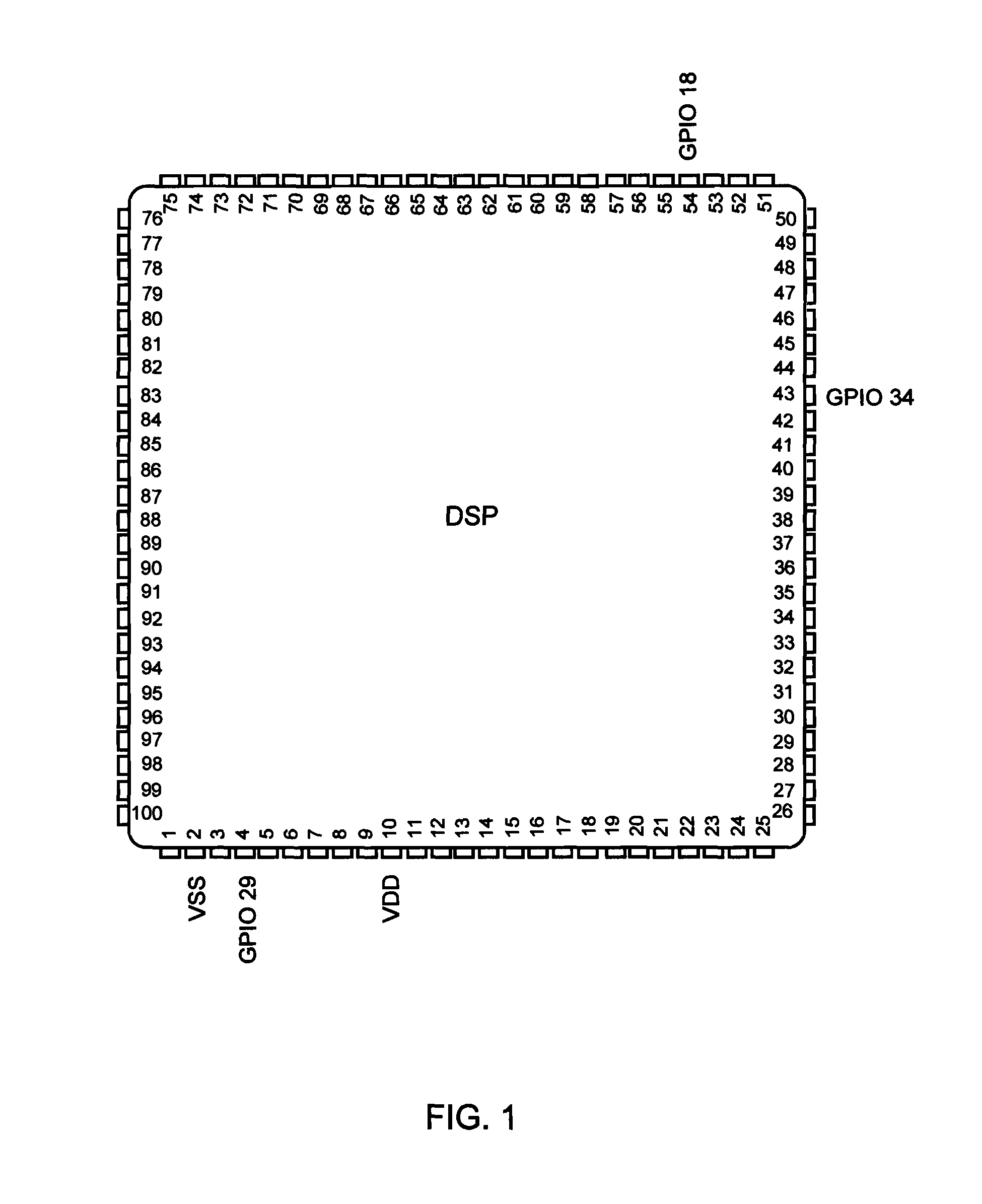

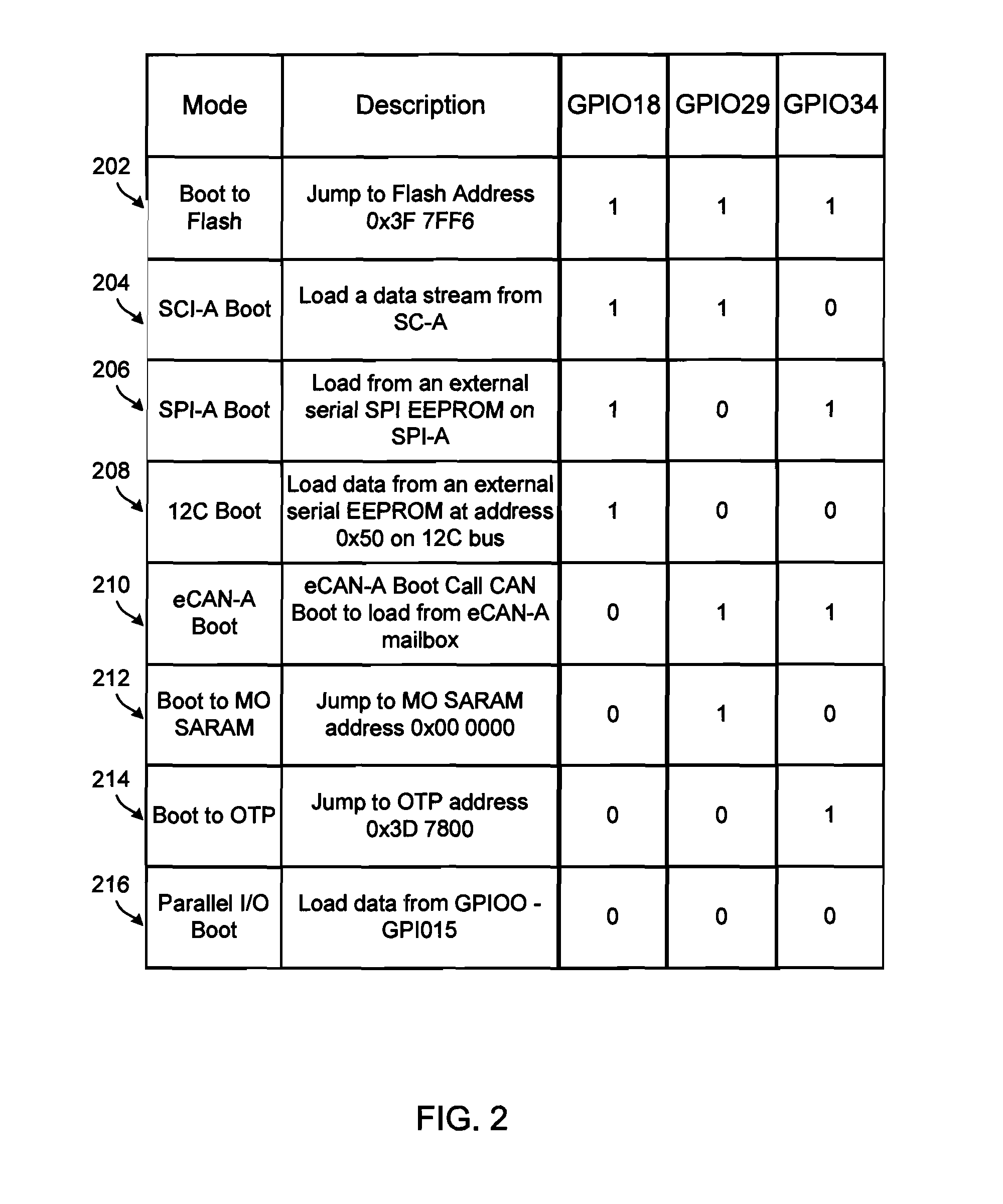

Programming processors through CAN interface without changing the boot mode select pins

Methods, systems and devices for remotely updating software installed on a digital signal processor (DSP) without setting the mode select pins on the DSP control card. Firmware configured to suspend operations upon receiving a programming signal is installed on the processor. A controlling computing device send the programming signal, causing the processor to halt execution, erase portions of the firmware, set an update firmware flag, and send control signals to the controlling computing device. The remote computing device sends updated firmware and an application program cyclic redundancy check to the processor. The processor compares a cyclic redundancy check of an on-chip flash memory with the received application program cyclic redundancy check. If the two match, the processor installs the received firmware, unsets the update firmware flag, and restarts itself.

Owner:BLOOM ENERGY CORP

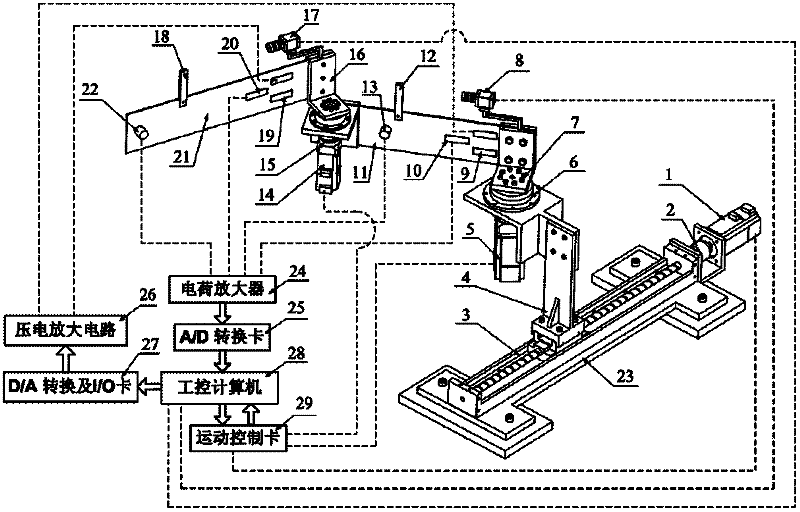

Three-degree-of-freedom flexible manipulator control device and method

InactiveCN102501242AAchieve precise positioning controlProgramme-controlled manipulatorElectric machineryManipulator

The invention discloses a three-degree-of-freedom flexible manipulator control device and method. The device comprises flexible manipulator body parts, a servo motor driving part and a control part. The three-degree-of-freedom distribution is characterized in that two rotating flexible manipulators connected in series are respectively driven by a connected motor and speed reducer and are connected on a moving sliding block driven by a screw; a screw substrate and a fixed base are connected; three alternating servo motors are all provided with photoelectric encoders for detecting a rotation angle. A plurality of piezoelectric ceramic sheets are stuck to the part near a fixing end, on each flexible manipulator to respectively serve as a photoelectric sheet sensor and a photoelectric driver; and acceleration sensors are respectively installed at the parts near a free end, on each flexible manipulator. The photoelectric sheet sensor or the acceleration sensor can respectively detect the vibration of flexible beams. The detected signal is fed back, and three motors are respectively controlled by a motion control card to move after a control algorithm is operated. A control part is used for processing the detected flexible beam rotation and a vibration signal and carries out corresponding processing.

Owner:SOUTH CHINA UNIV OF TECH

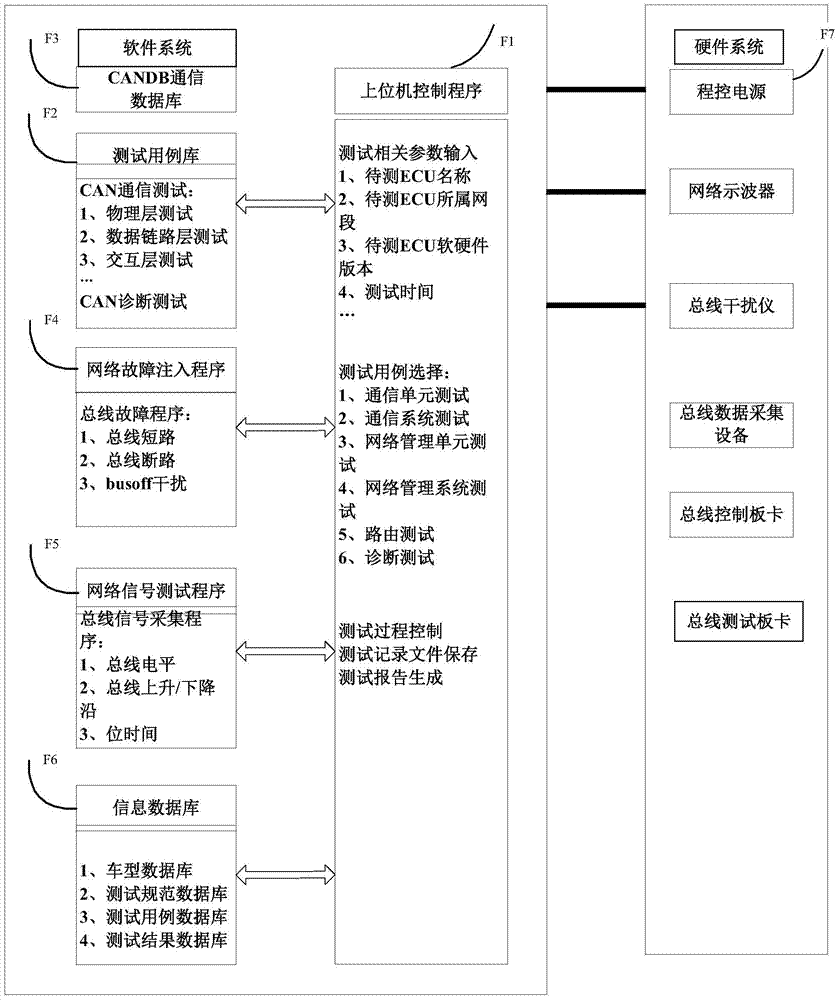

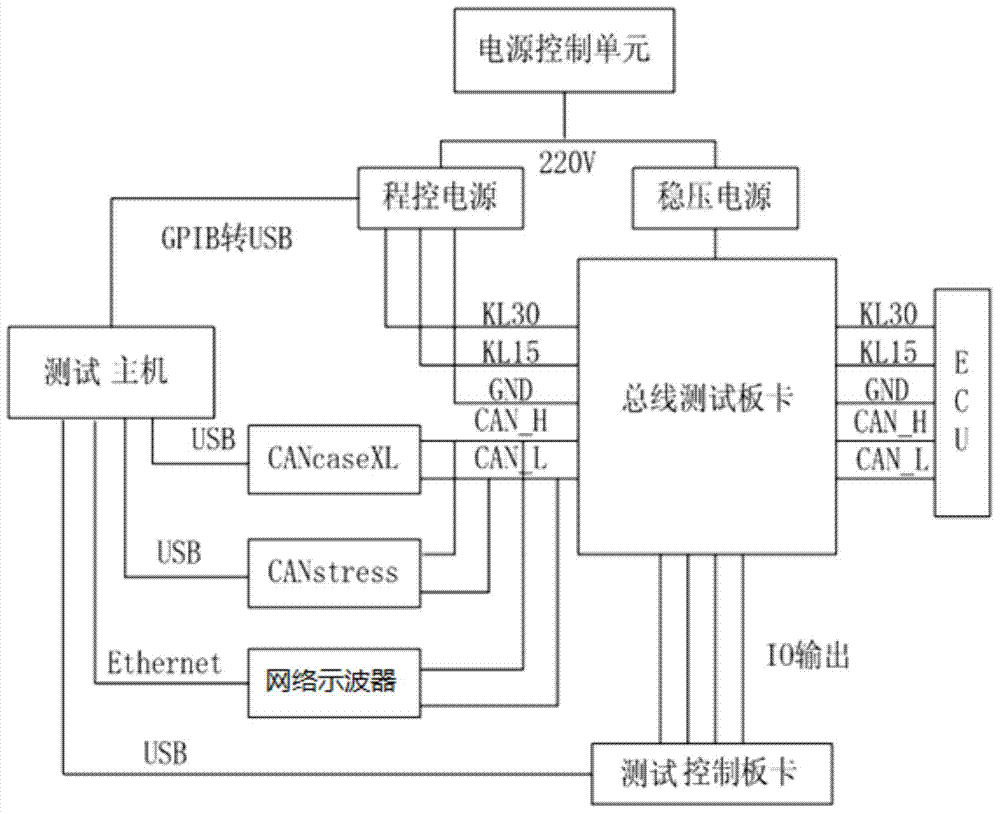

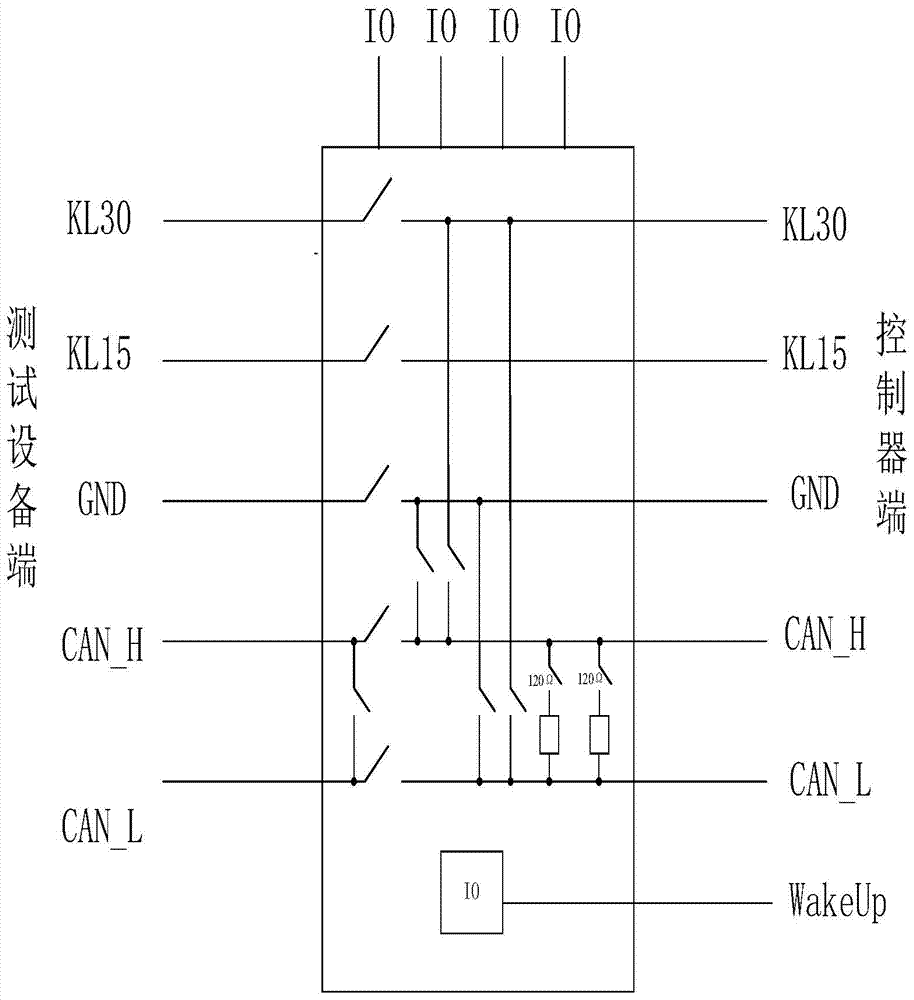

Automatic vehicle-mounted electronic control unit CAN bus communication testing device and system

InactiveCN104298224AReduce duplication of effortAffect accuracyElectric testing/monitoringData acquisitionTest fixture

The invention relates to an automatic vehicle-mounted electronic control unit CAN bus communication testing device. A testing host of the device controls a programmable power supply to output different amplitudes of voltages according to working requirements of an ECU; physical layer testing signals of a CAN bus are output to a network oscilloscope to be displayed, and physical layer testing data are transmitted to the testing host through the network oscilloscope; ECU testing data are transmitted to the testing host through a bus data acquisition device; the testing host records, analyzes and evaluates the testing data of the ECU and the CAN bus to generate a test report. A bus interferometer is used for interfering with bus waveforms of the tested ECU in real time. The testing host controls on-off states of relays of a bus testing board card through a testing control card board to execute the bus fault injection operation. By means of the automatic vehicle-mounted electronic control unit CAN bus communication testing device, various defects of a manual test are overcome, unnecessary repeated labor of a vehicle-mounted network engineer is reduced, and the testing result is accurate.

Owner:CHINA FIRST AUTOMOBILE

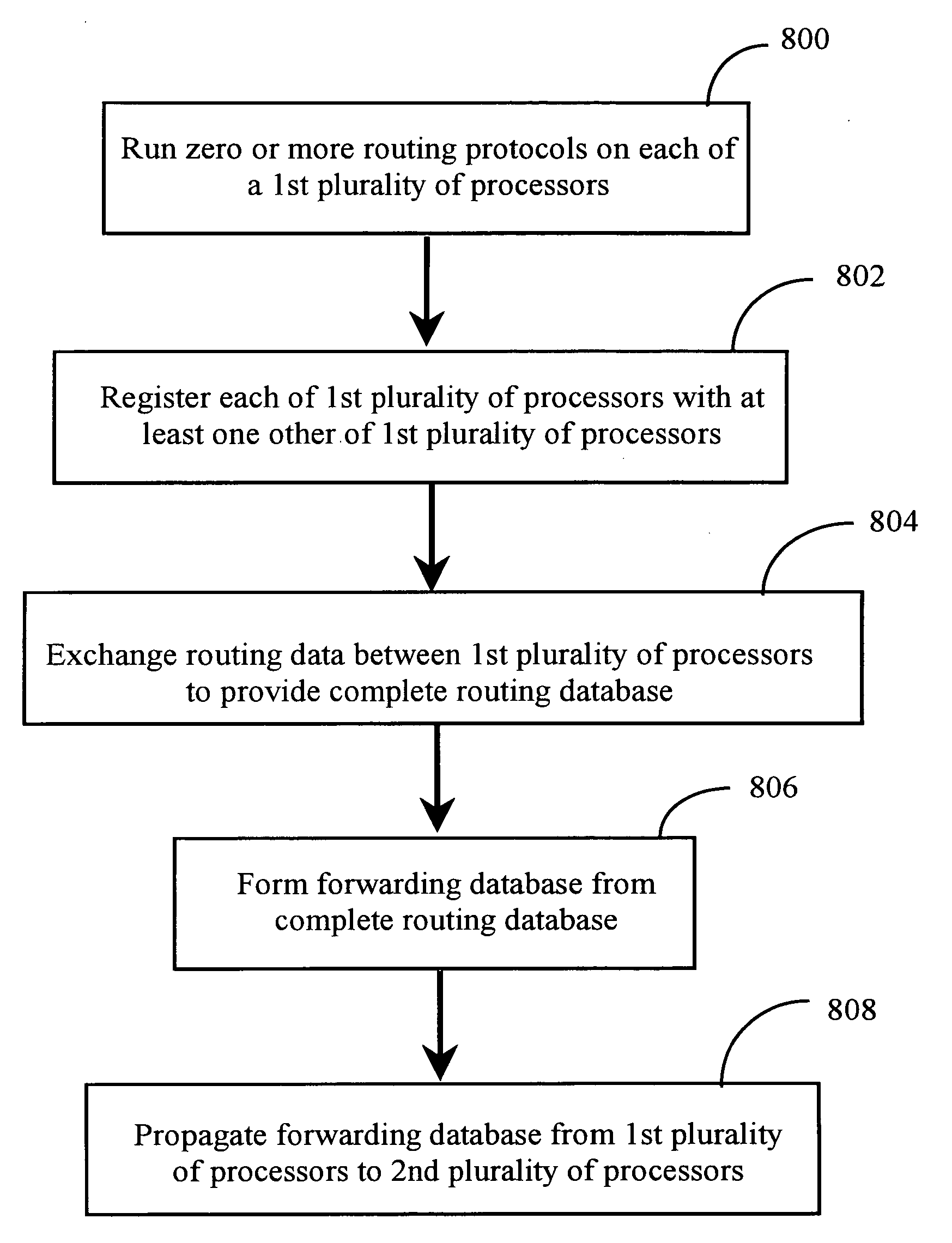

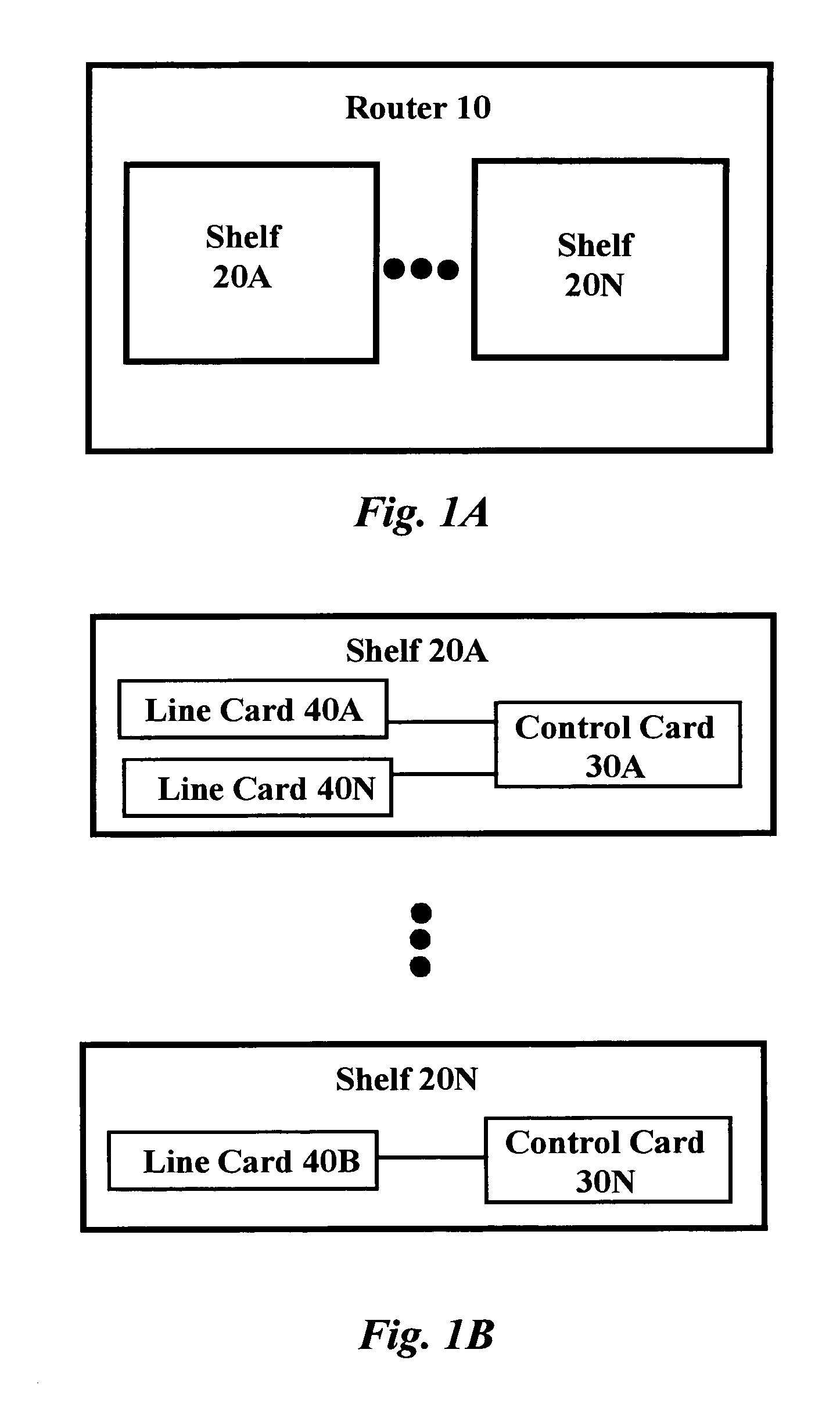

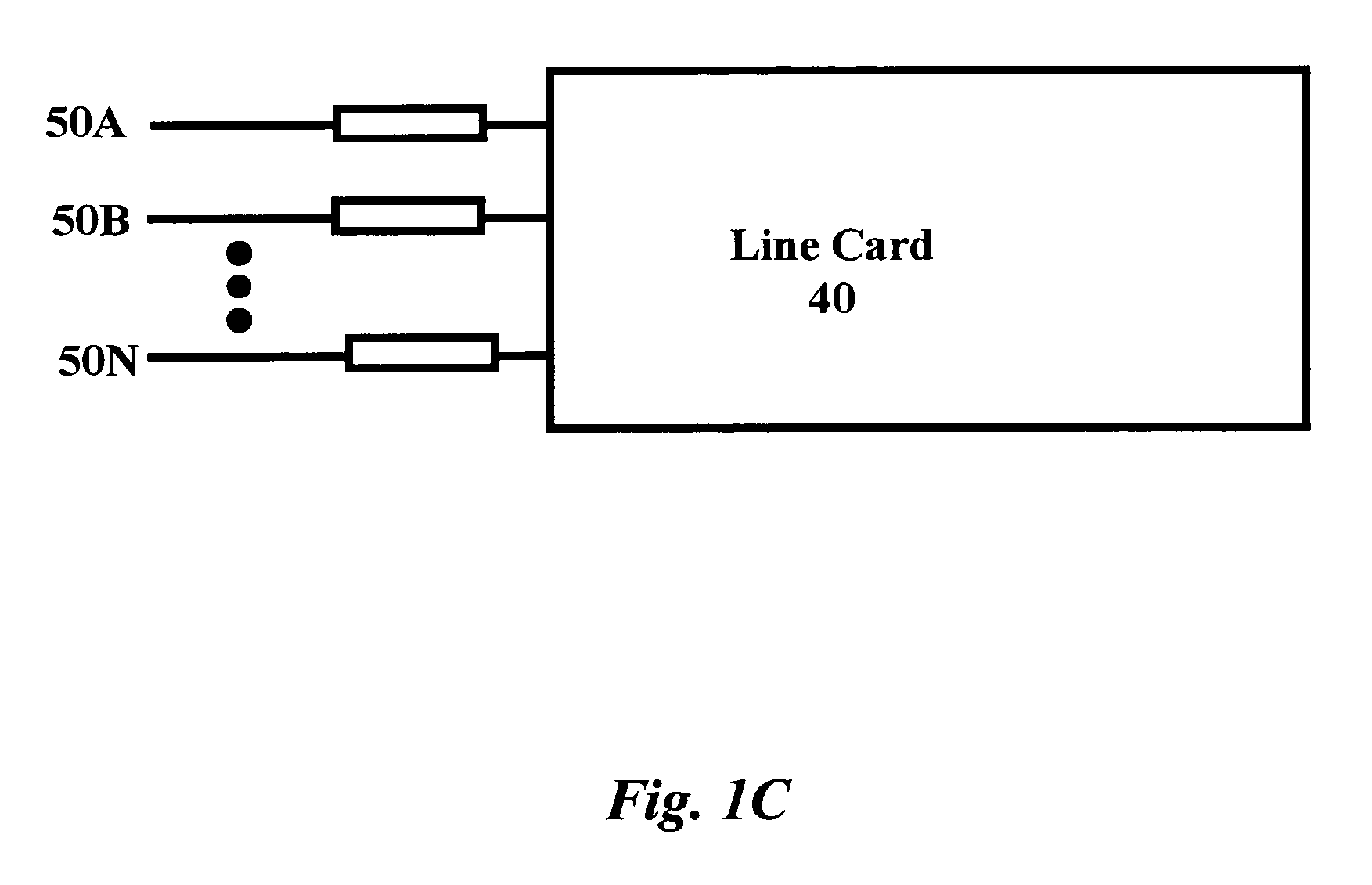

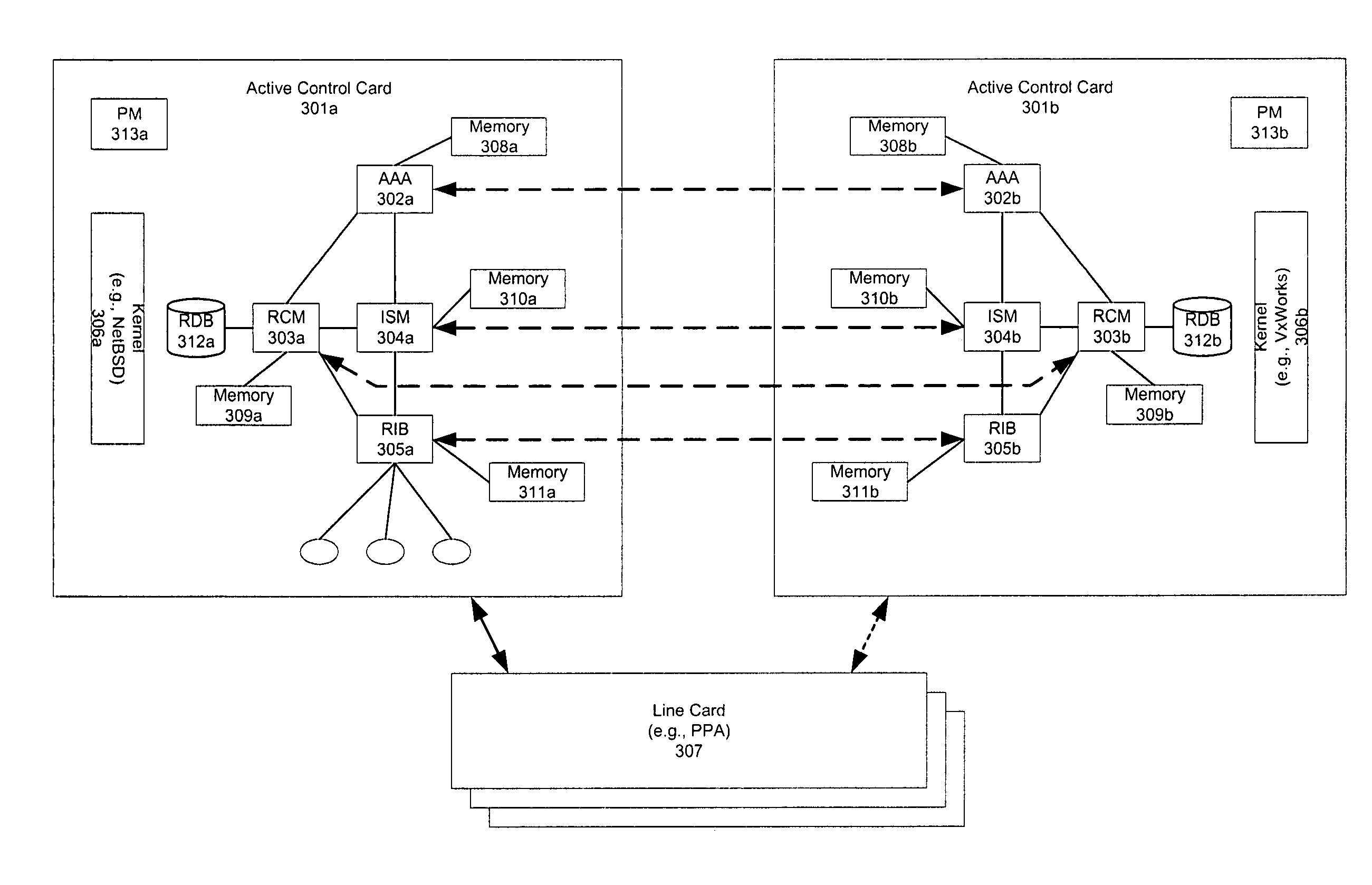

Methods and apparatus for synchronizing and propagating distributed routing databases

InactiveUS6947963B1Special service provision for substationMultiple digital computer combinationsClient-sideDistributed computing

A method of and apparatus for distributing data for a database between a plurality of processors in a distributed processor system involves running a database management system on a first plurality of processors in conjunction with a plurality of protocols that generate or amend data for the database. Data is distributed from servers to clients registered in a server-client relationship. Server-client relationships may also be registered between a second, and a third plurality of processors that do not run protocols generating or amending data for the database. Fault tolerant redundancy is provided by clients registering with two or more servers, one as a primary and another as a secondary, and activating the secondary if the primary fails. The method is particularly applicable to scalable data packet routers having a plurality of processors operating on different line and control cards.

Owner:PLURIS

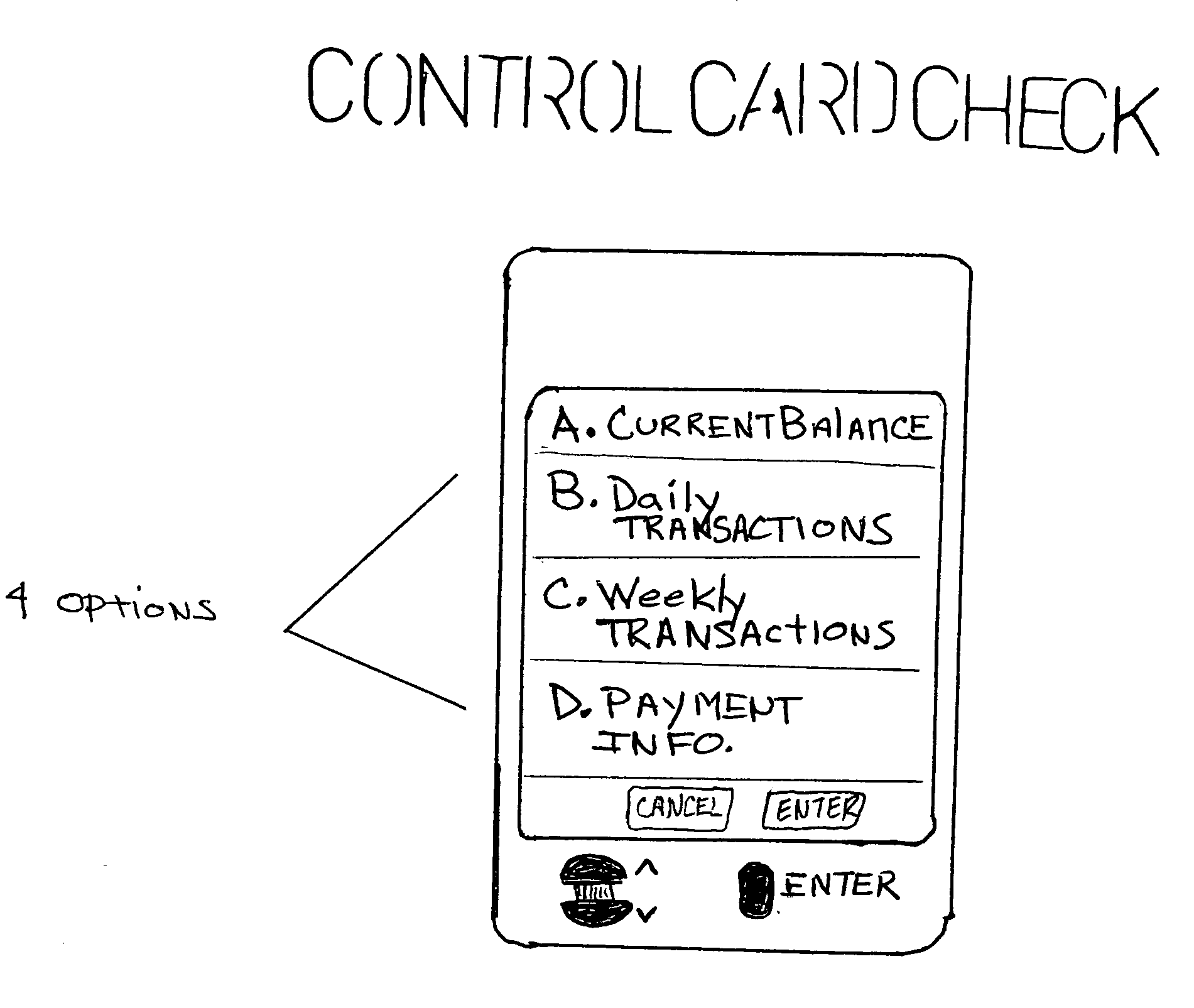

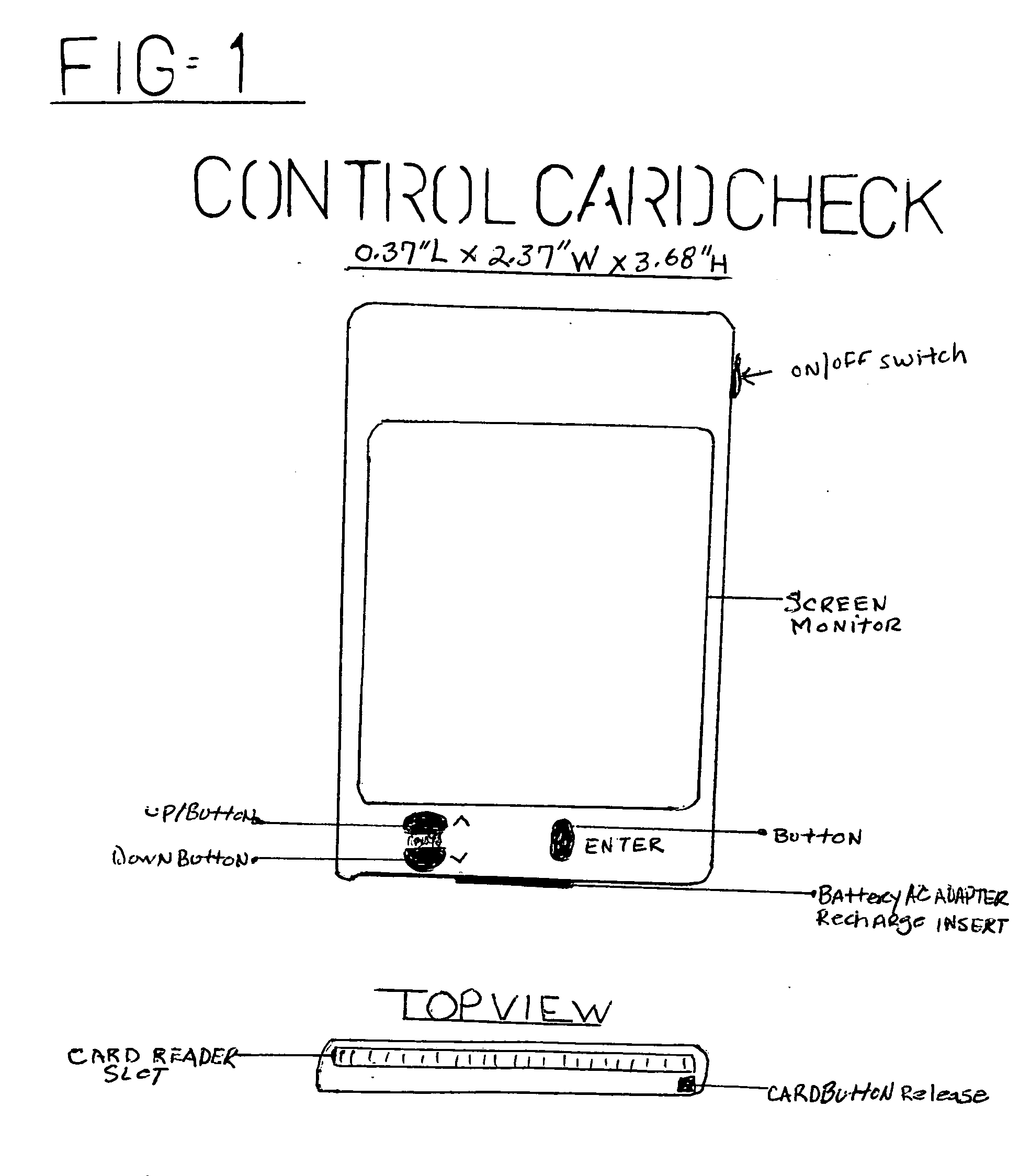

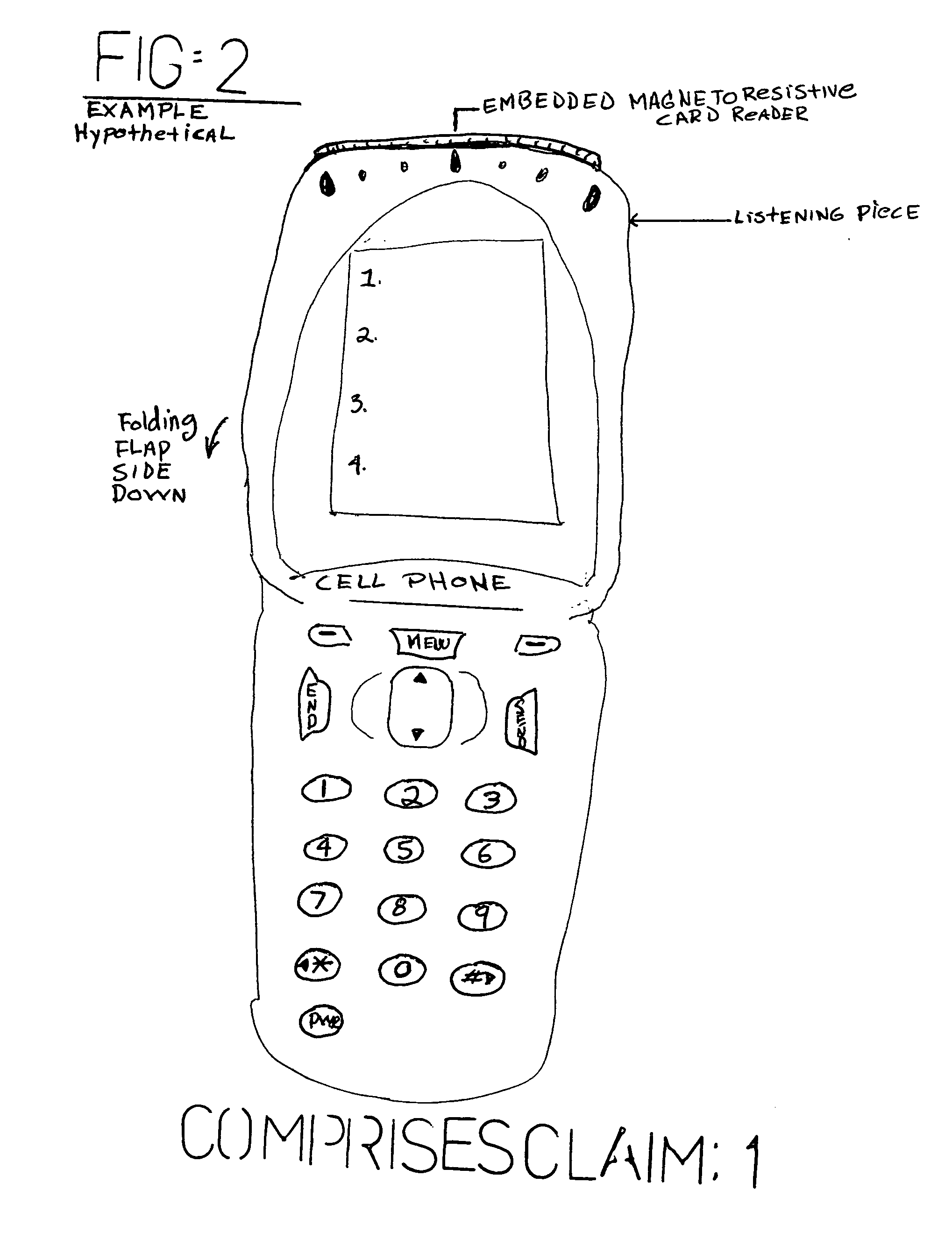

Control card check

CONTROL CARD CHECK is a pocket size system and a method for auditing personal accounts. It is an individual module that operates on a digital level. This invention is for bank account and credit card information inspecting only. This technology system provides access to your bank and credit card information instantaneously, without having to log onto the Internet, drive to your bank (ATM), or call a service bank agent. This system will allow you to check your current balance on any account card you own, excluding gas cards, retail cards, and phone cards, just by inserting the card into the card reader. The design of the pocket electro mechanism is slightly larger than your account card with a magnet strip-card reader embedded to the back of the instrument. In seconds, see your balance by entering your four-digit security pin number on the touch screen. On the menu screen you will have four options to choose from. 1. Current balance. 2. Daily transactions. 3. Weekly transactions. 4. Payment information and Due date. (Bank payment address & phone numbers). Ideal for any situation

Owner:FIGUERAS ILKA H +2

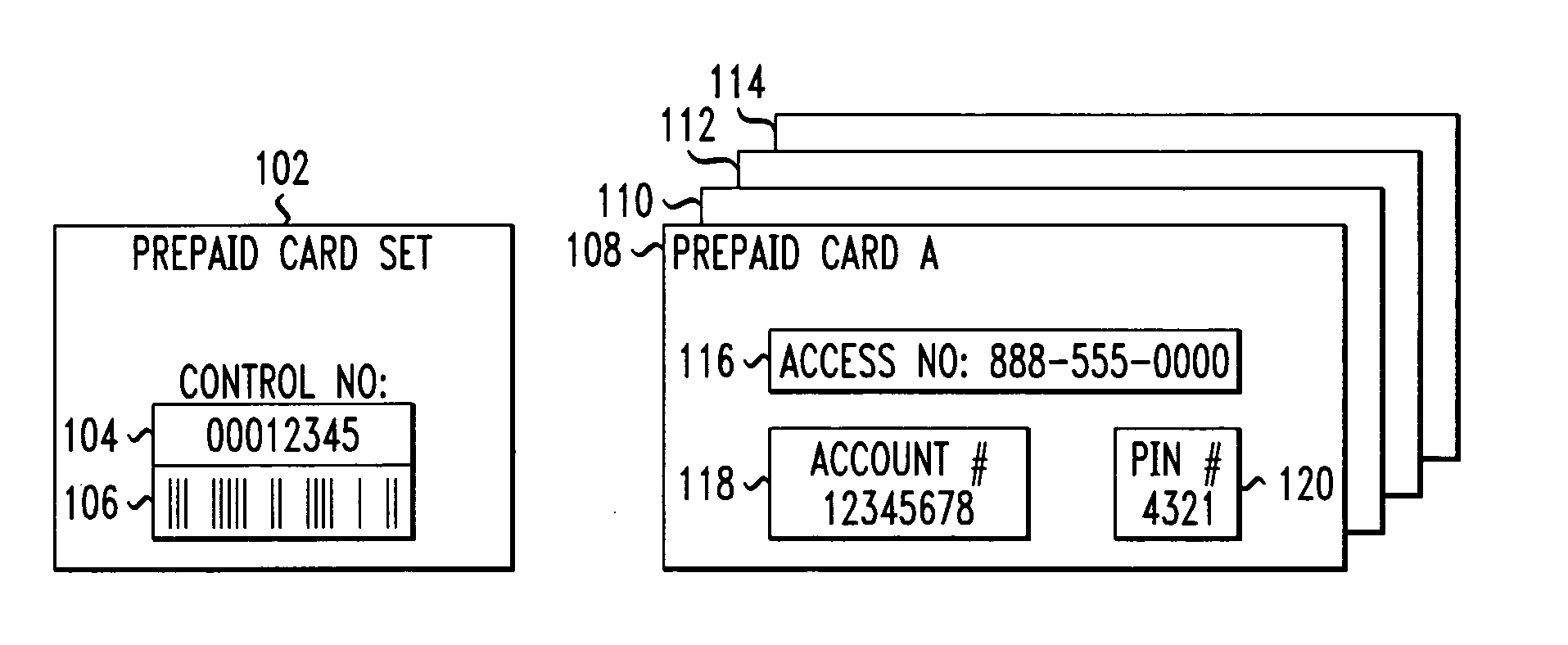

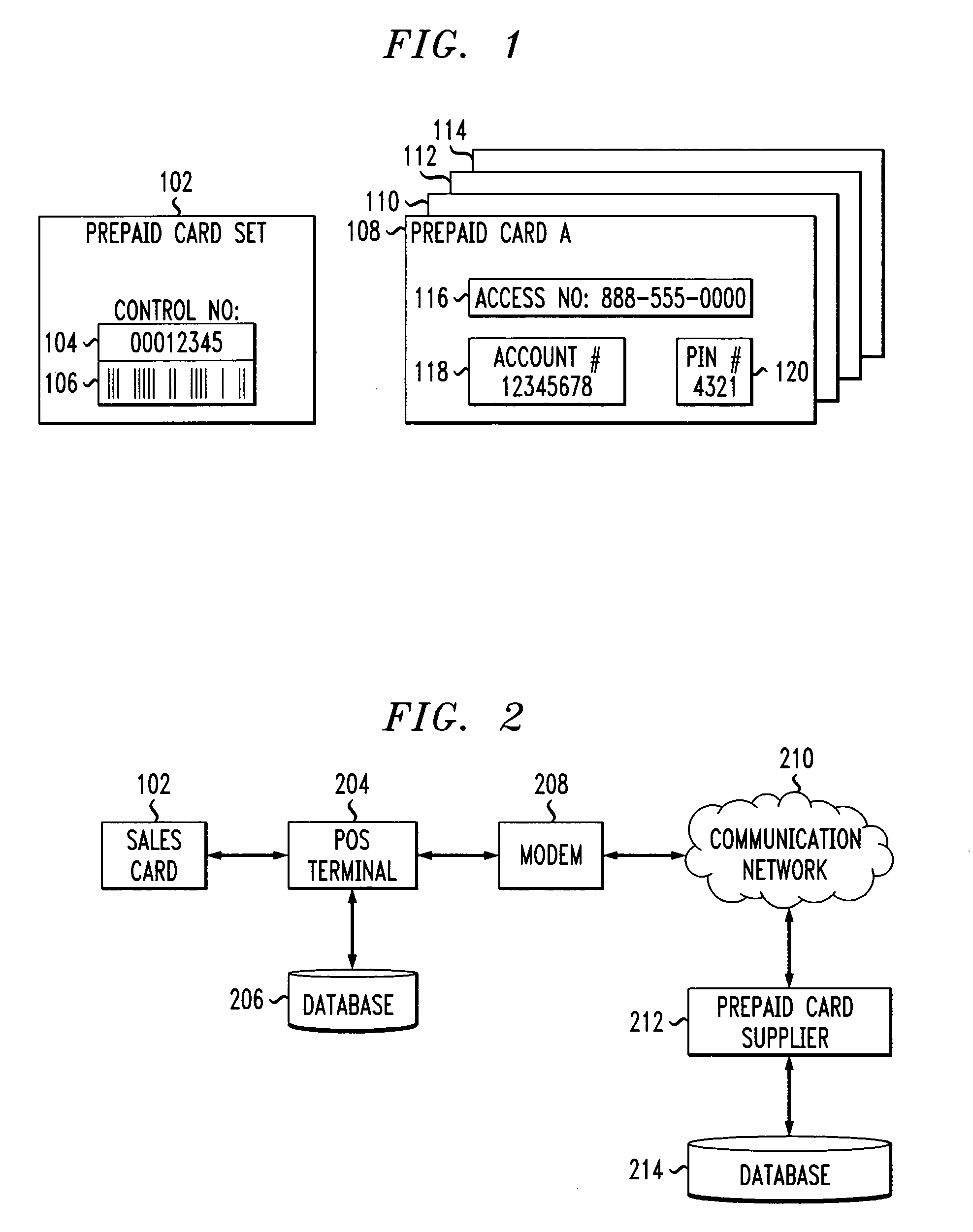

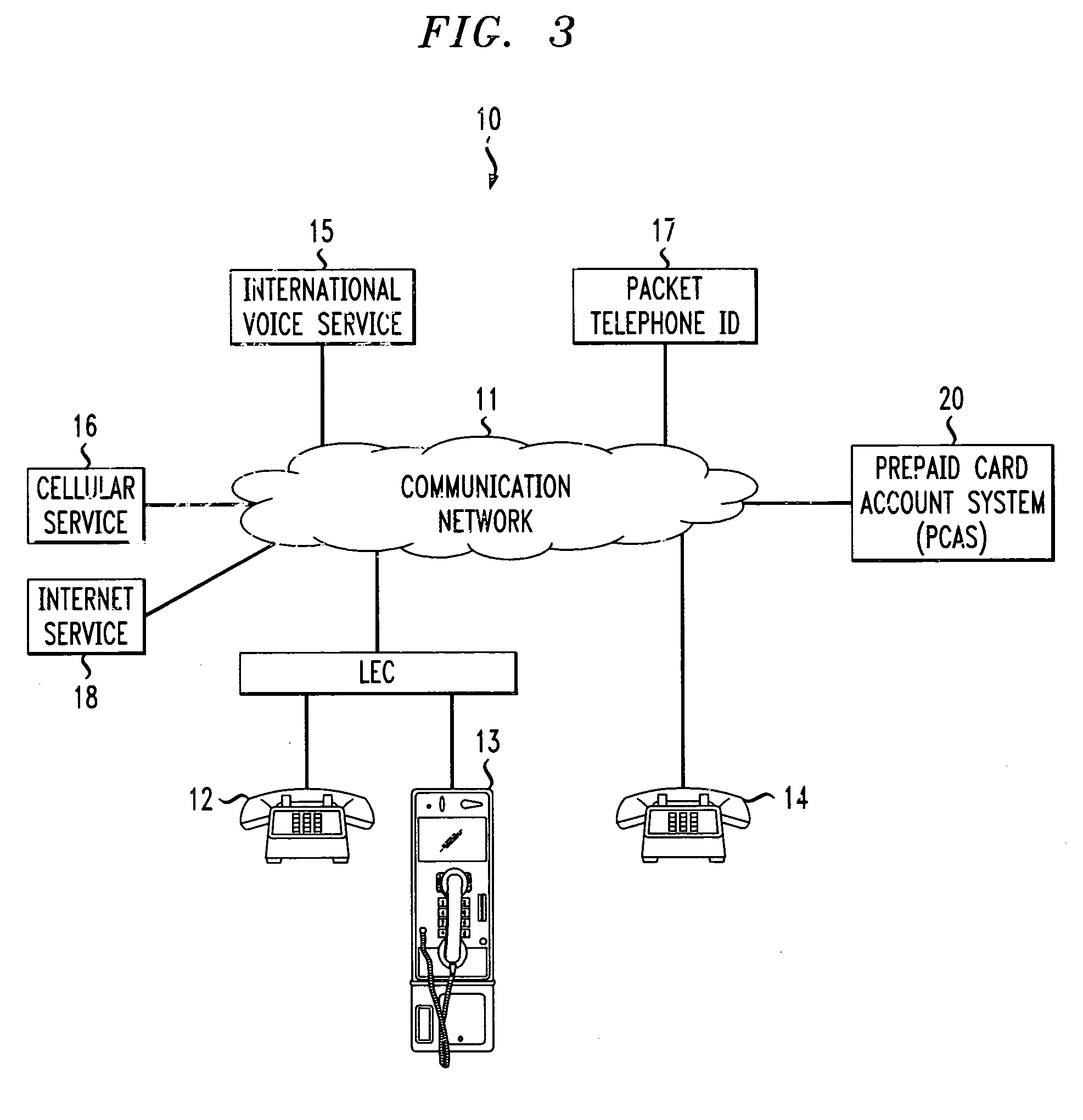

Method of associating multiple prepaid cards with a single account

InactiveUS7280645B1Metering/charging/biilling arrangementsPrepayment with prepaid account/card rechargingPrepaid telephone callPersonal identification number

Owner:AMERICAN TELEPHONE & TELEGRAPH CO +1

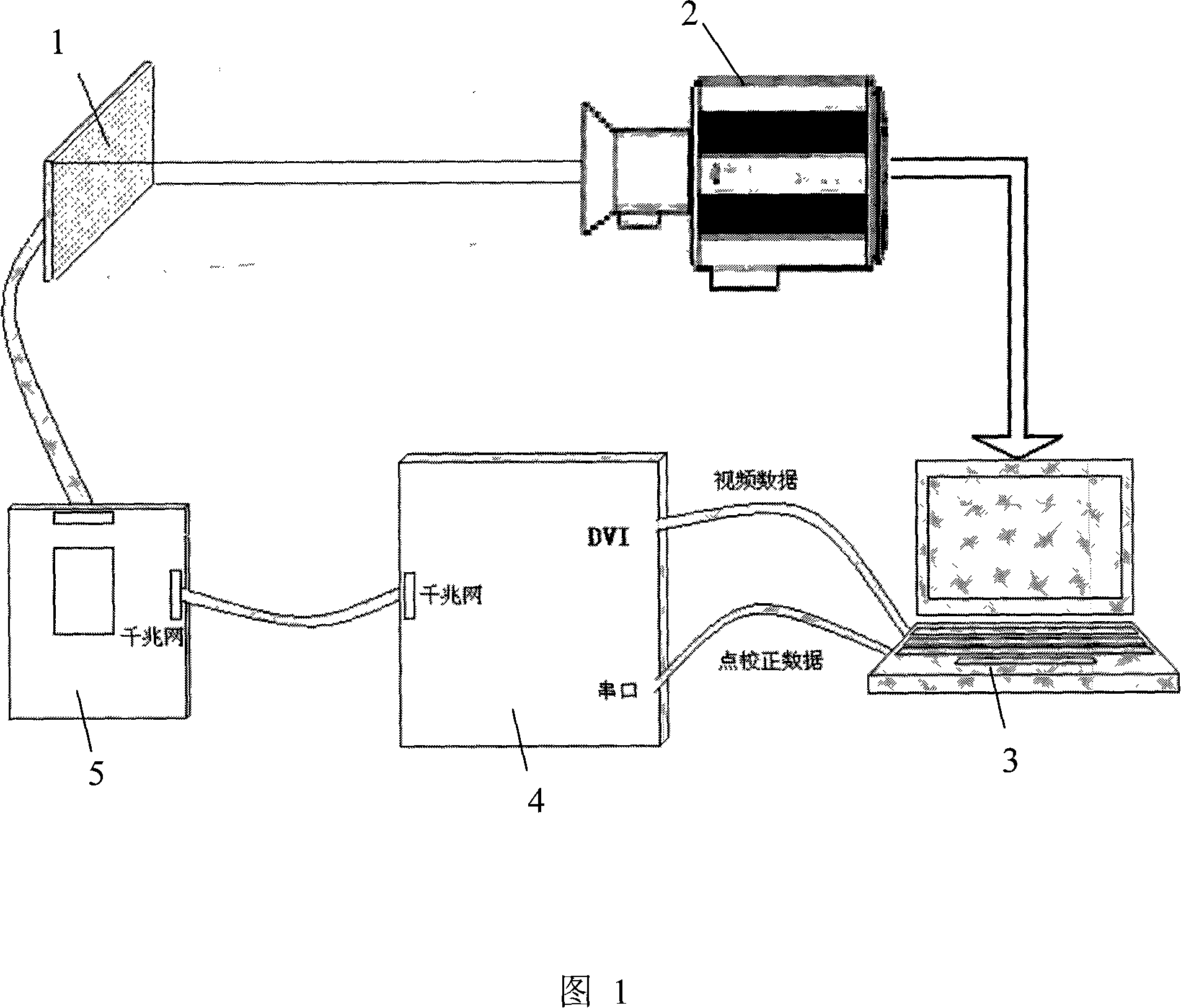

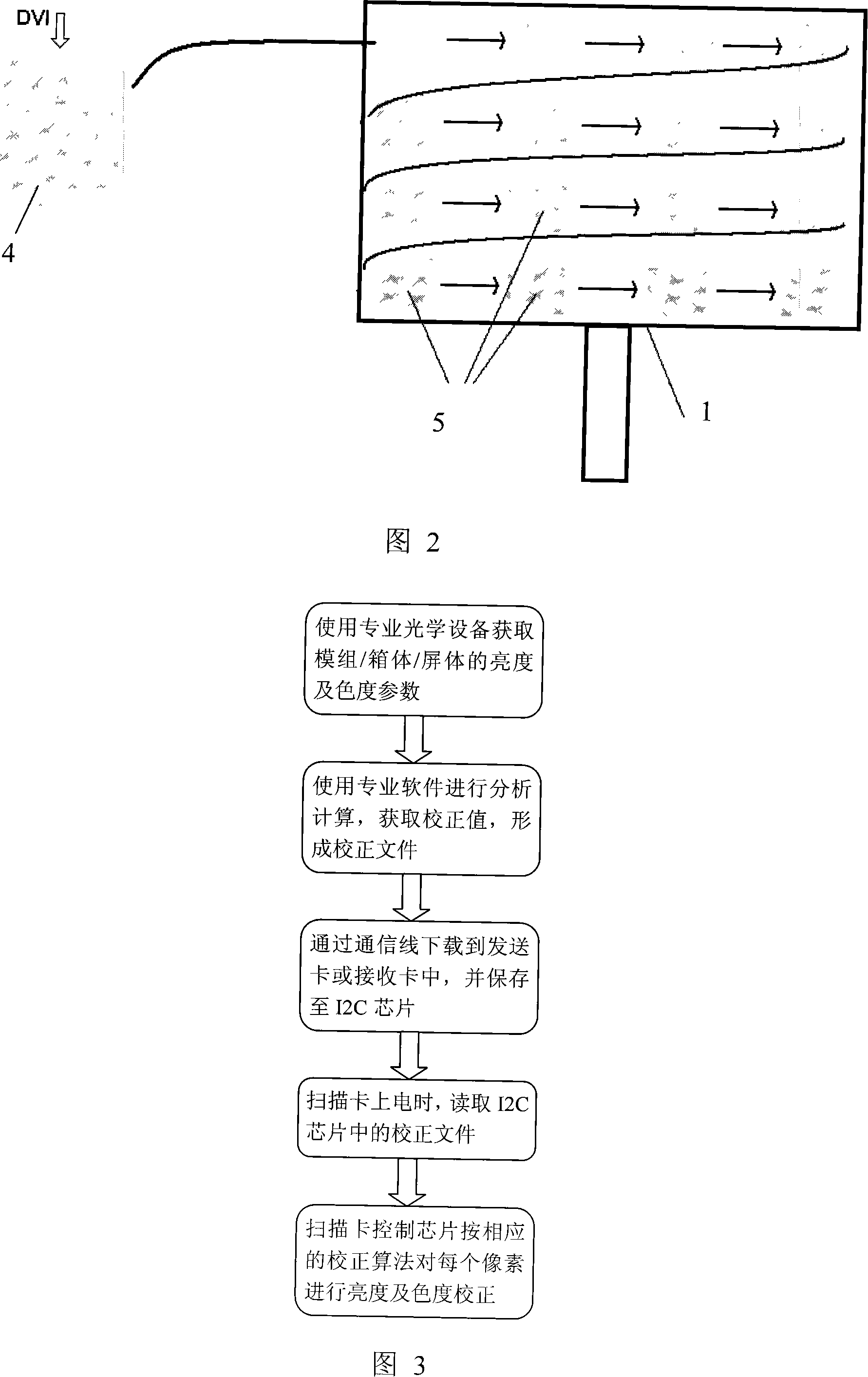

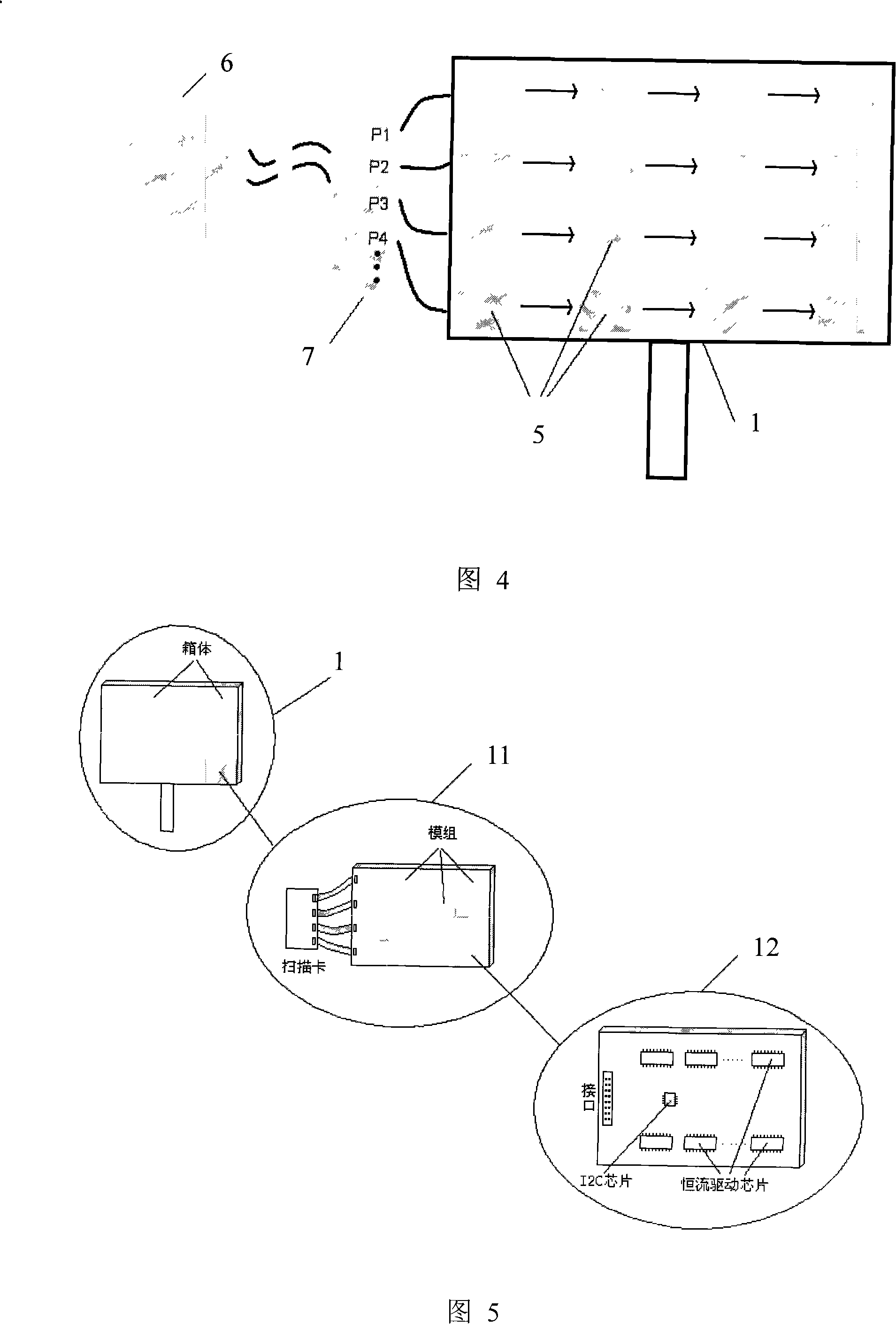

A LED display screen display calibration system and calibration method

ActiveCN101217022AReduce bandwidth requirementsSolve complexityCathode-ray tube indicatorsBandwidth requirementDistributor

The invention relates to a display calibration system of a LED display screen and a calibration method thereof. The system comprises a video capture controller, a data distributor, scanning control cards and LED display modules; the memory chips of the display modules save simple-point calibration data of the display modules, which is uniformly arrayed in a LED display box in the light of a row or column cascade; a plurality of LED display boxes are uniformly arrayed in the light of the row or column cascade to constitute the LED display screen; the head end scanning control cards of each row cascade or each column cascade of the LED display screen are respectively connected with a GigE communication interface circuit of the data distributor, and the data distributor is connected with the GigE communication interface circuit of the video capture controller via the GigE communication interface circuit thereof; based on the systems, the method takes the LED display modules for saving the simple-point calibration data as units, thus realizing the calibration of display screen pixel. The invention reduces the bandwidth requirements on the connection among the scanning control cards, realizes the function of plug and play of the display modules, is convenient for batch production and simple in maintenance operation, and improves the synchronicity of calibration of the display screen.

Owner:SHENZHEN AOTO ELECTRONICS

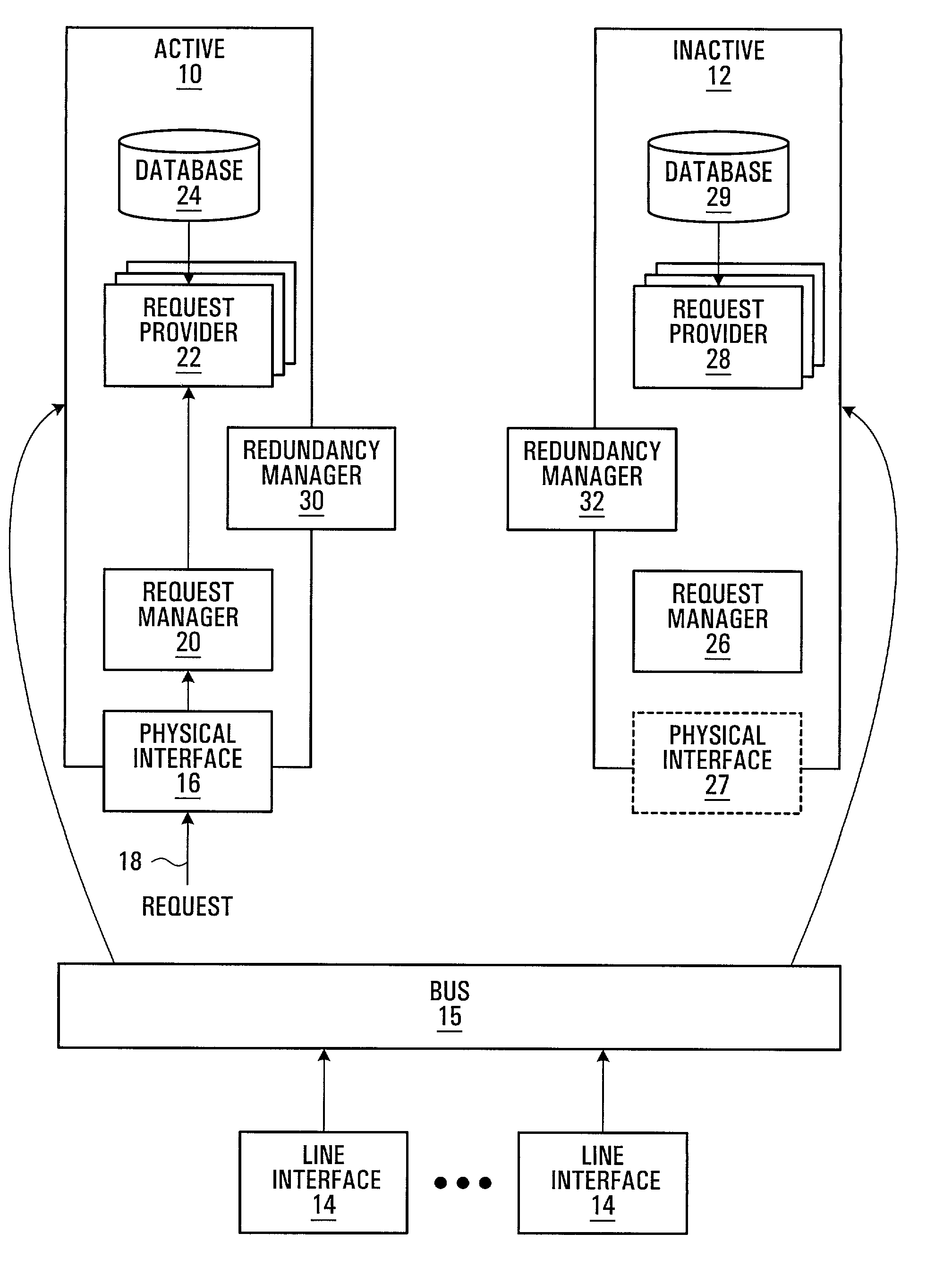

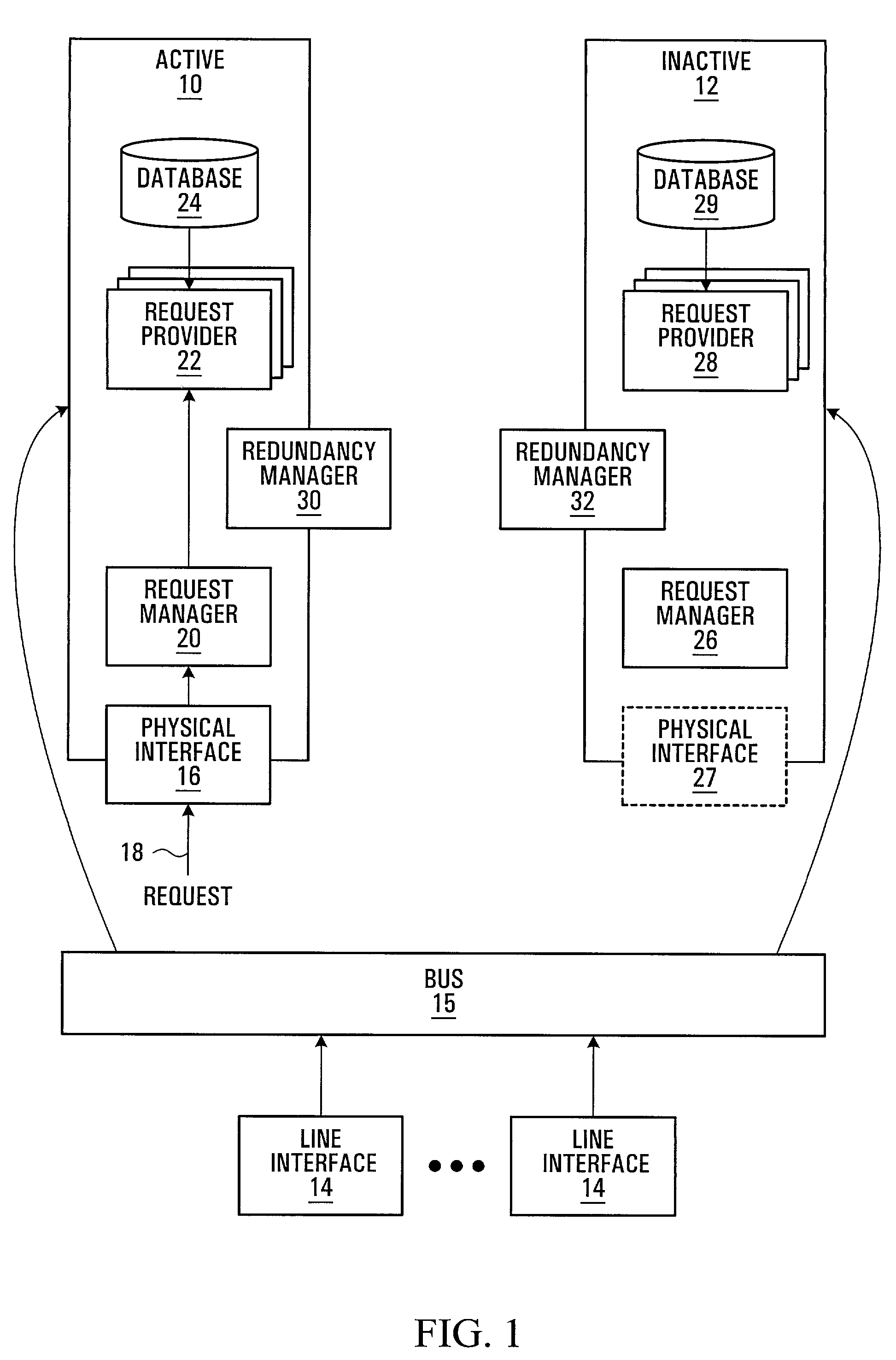

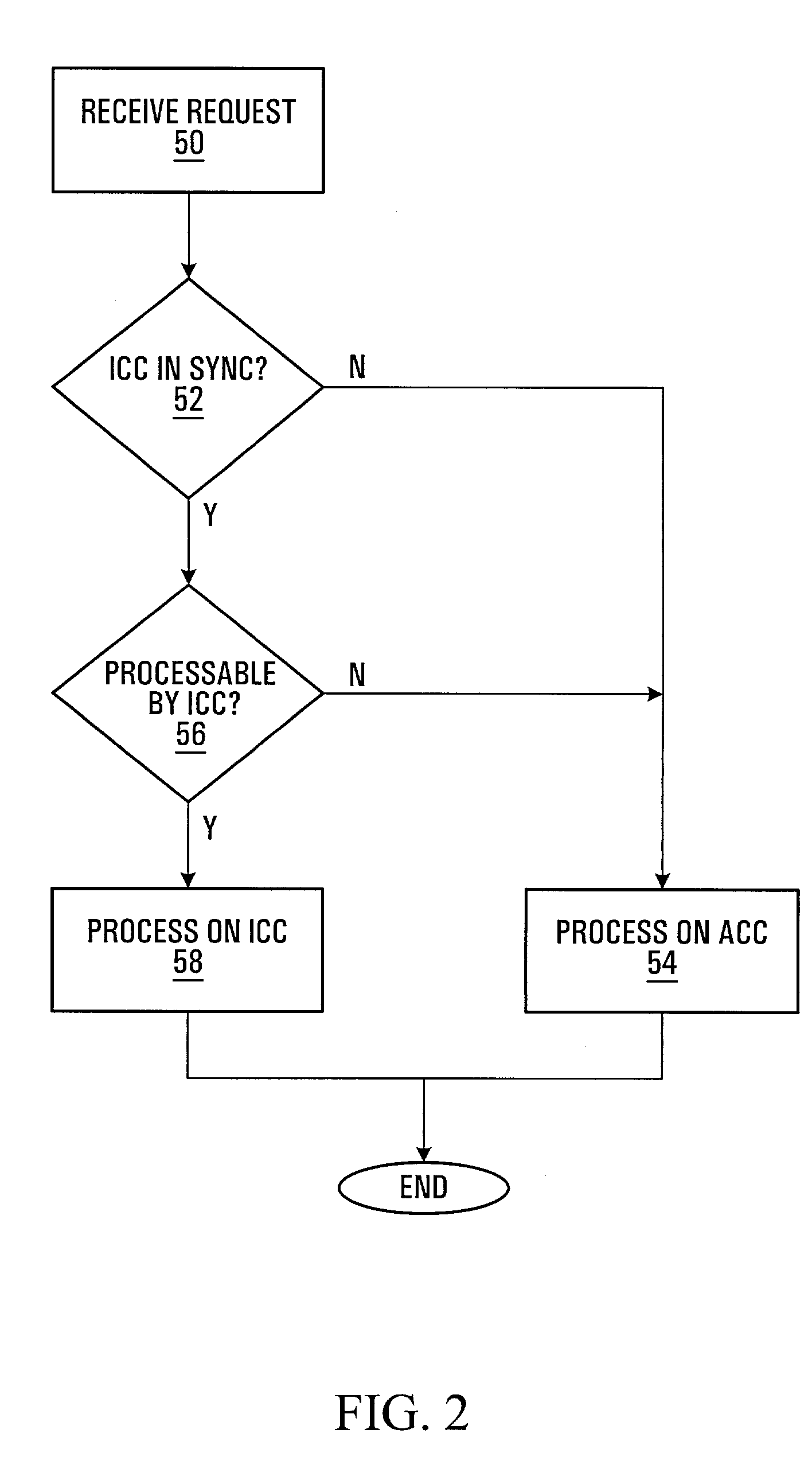

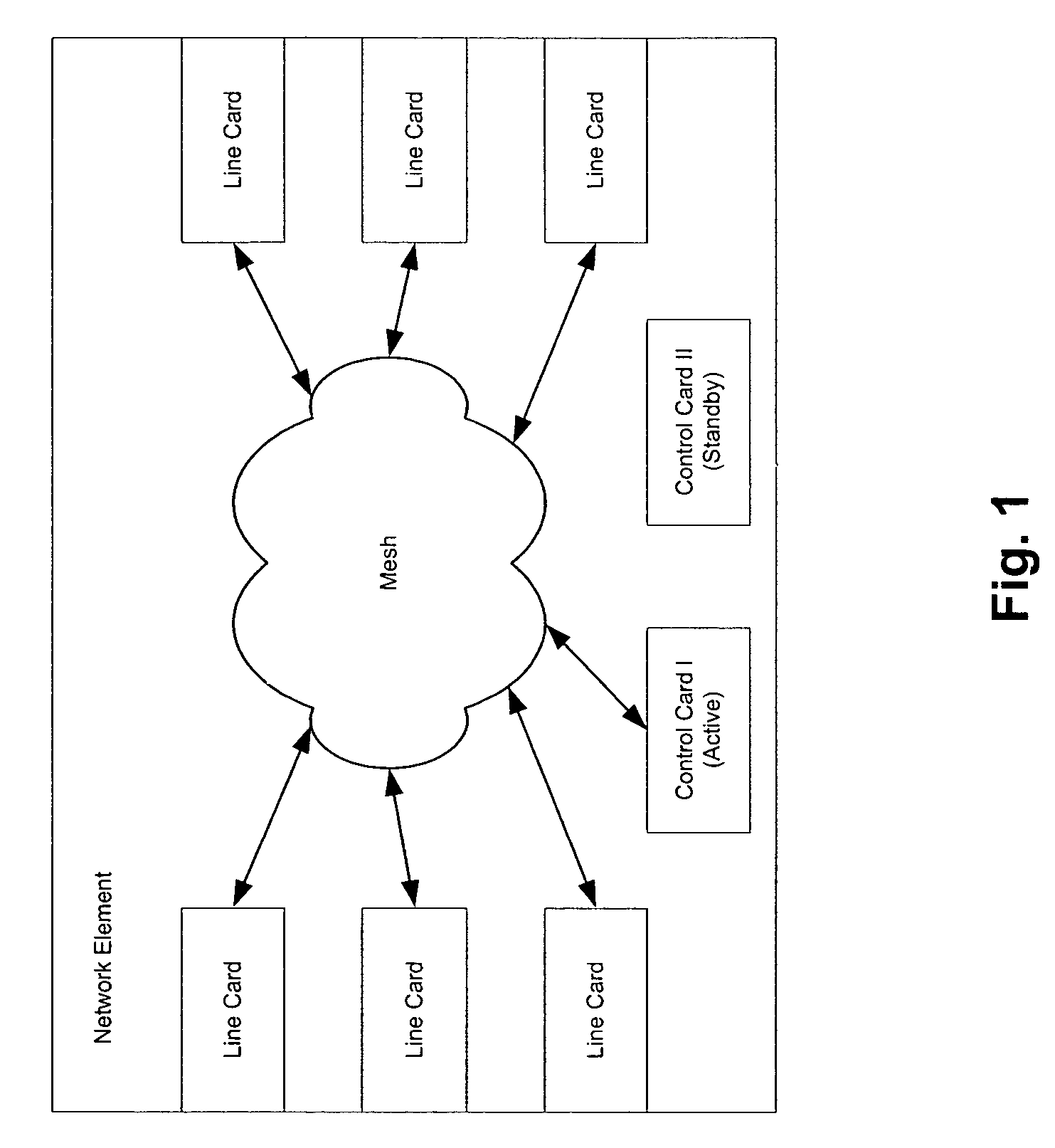

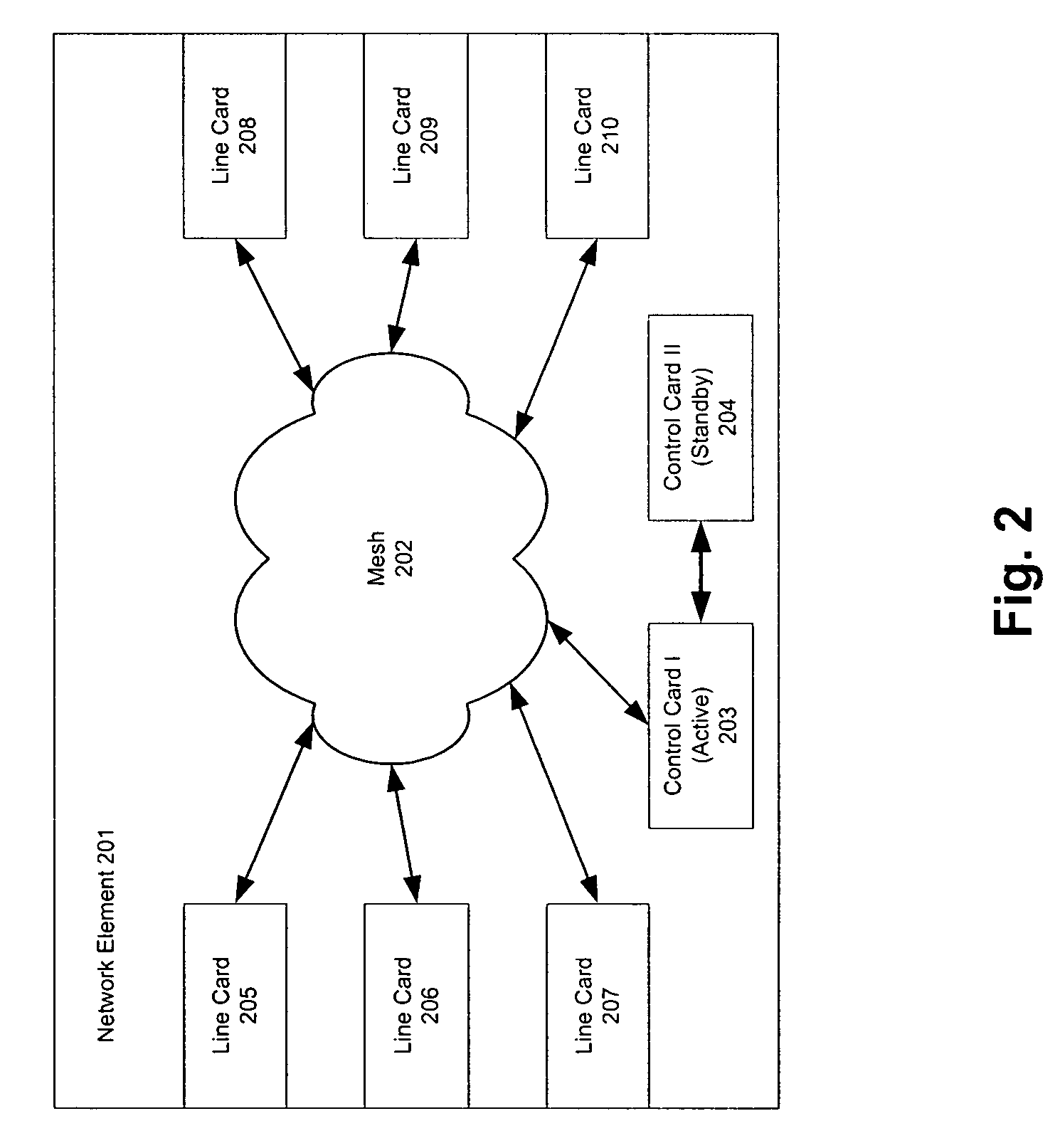

Redundancy systems and methods in communications systems

InactiveUS6983294B2Data processing applicationsData switching networksCommunications systemComputer module

A method and apparatus are provided for improving redundancy and load sharing in control cards in the control plane of a communication node. An active control card which receives a request passes the request to the inactive control card for processing if and only if the inactive control card is synchronized with the active control card and the inactive control card is able to process the request. Redundancy and load sharing are further improved if the active control card separates the processing of managing the request and the determination of a response to the request onto separate processors on the control card. In one embodiment, the control cards are OSPF modules in a router. Redundancy is effected by more accurately synchronizing the link state database of each OSPF module, and by allowing the state of each neighboring router to be determined only by the active OSPF module and not independently by any inactive OSPF module.

Owner:WSOU INVESTMENTS LLC +1

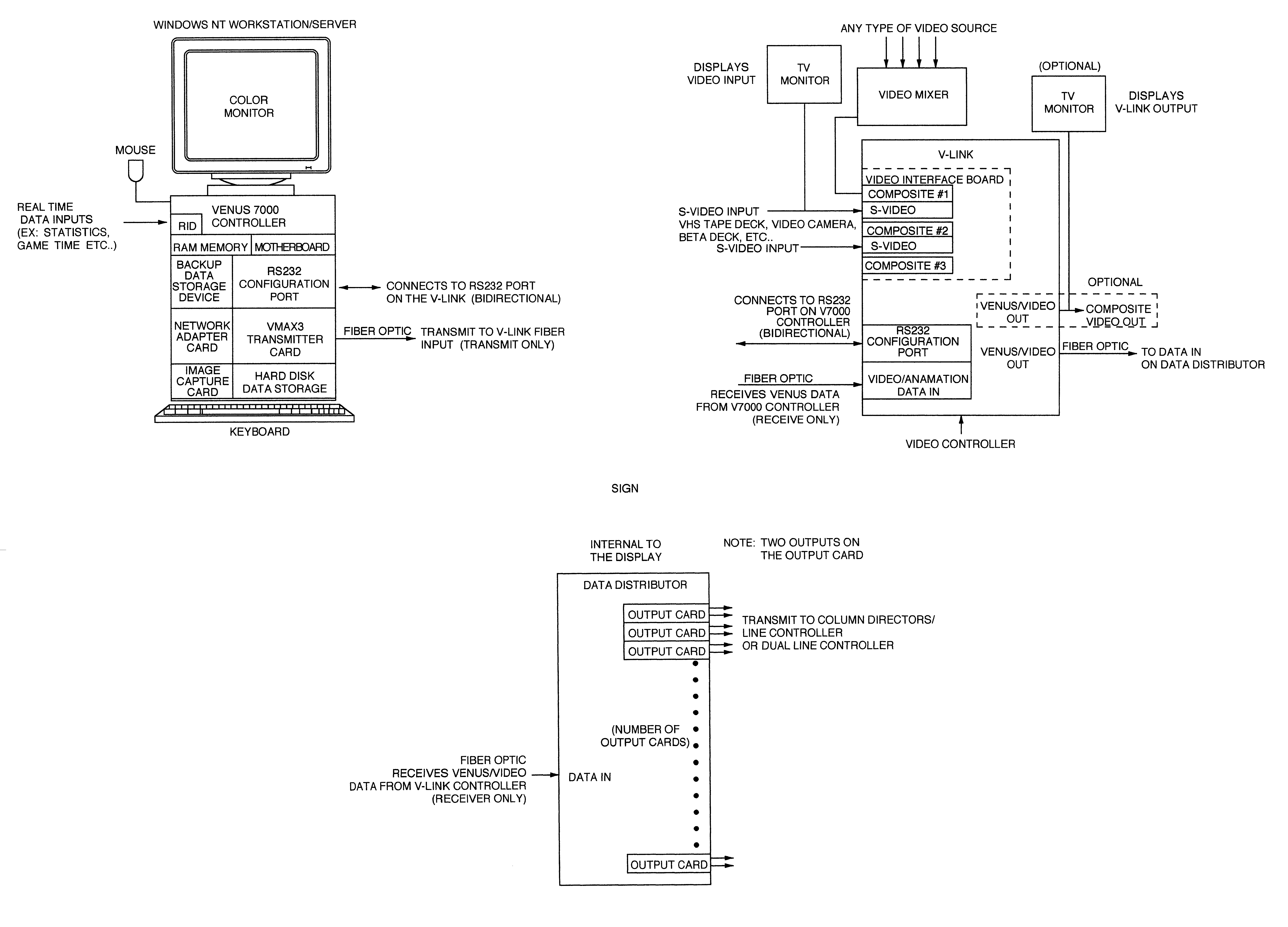

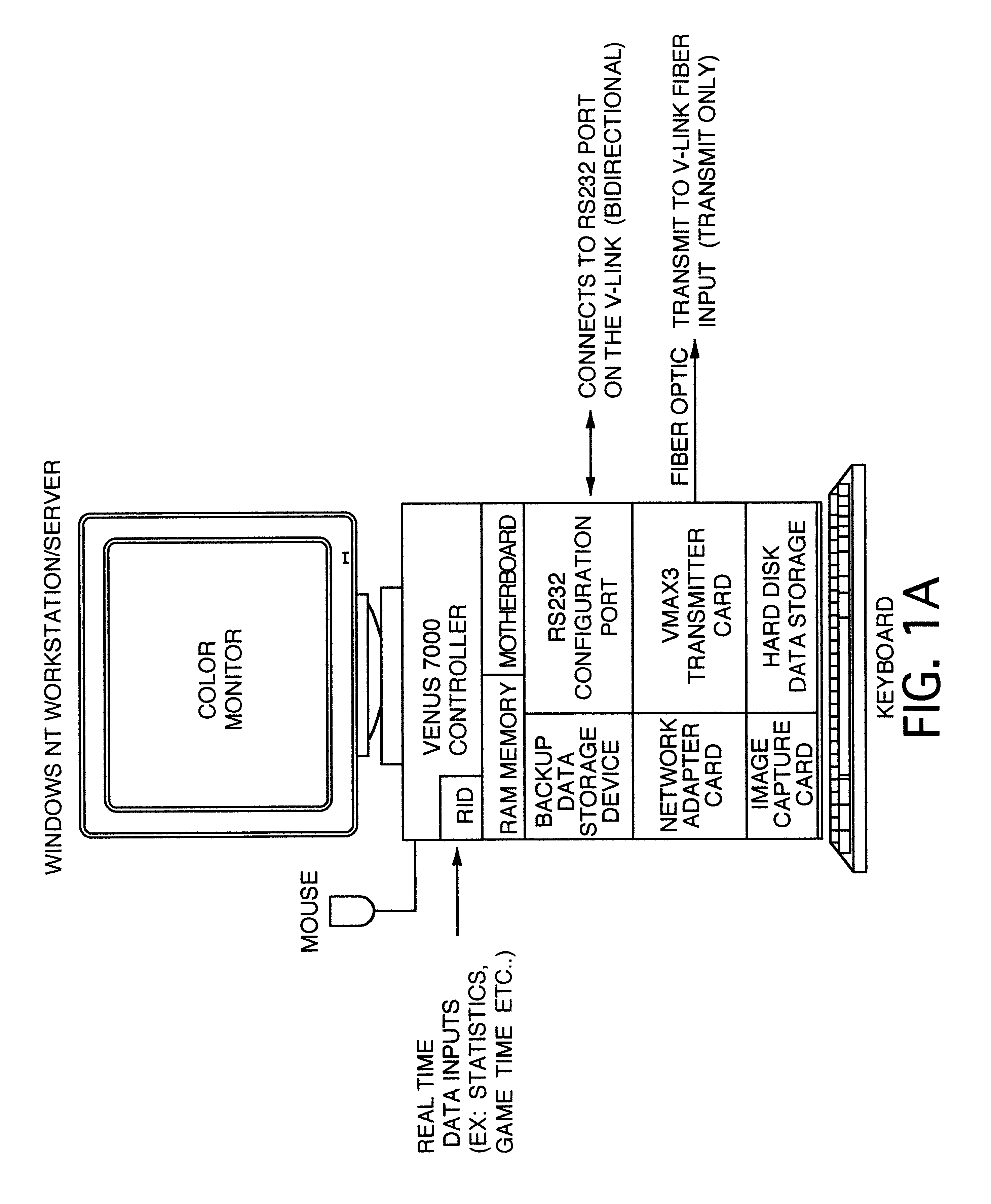

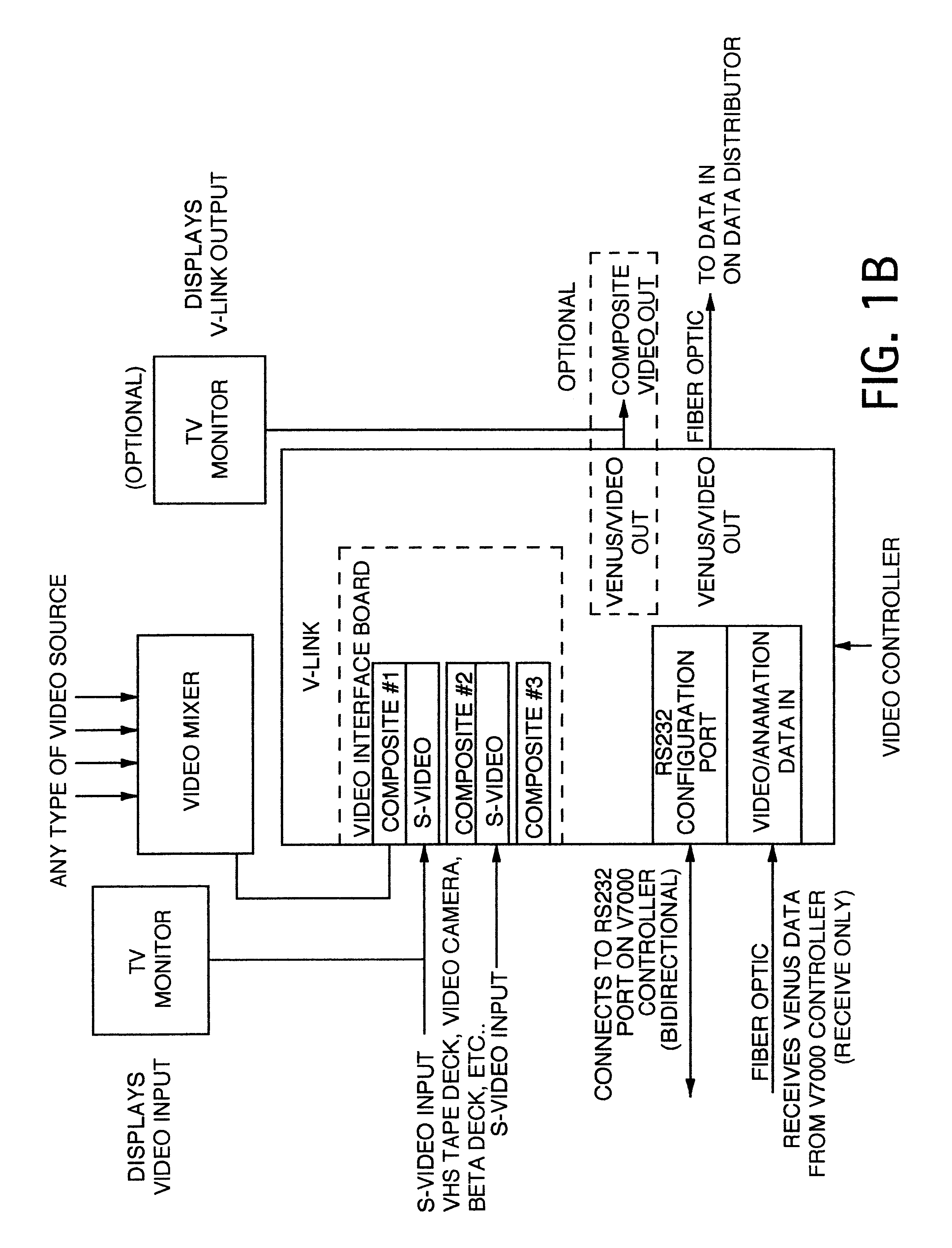

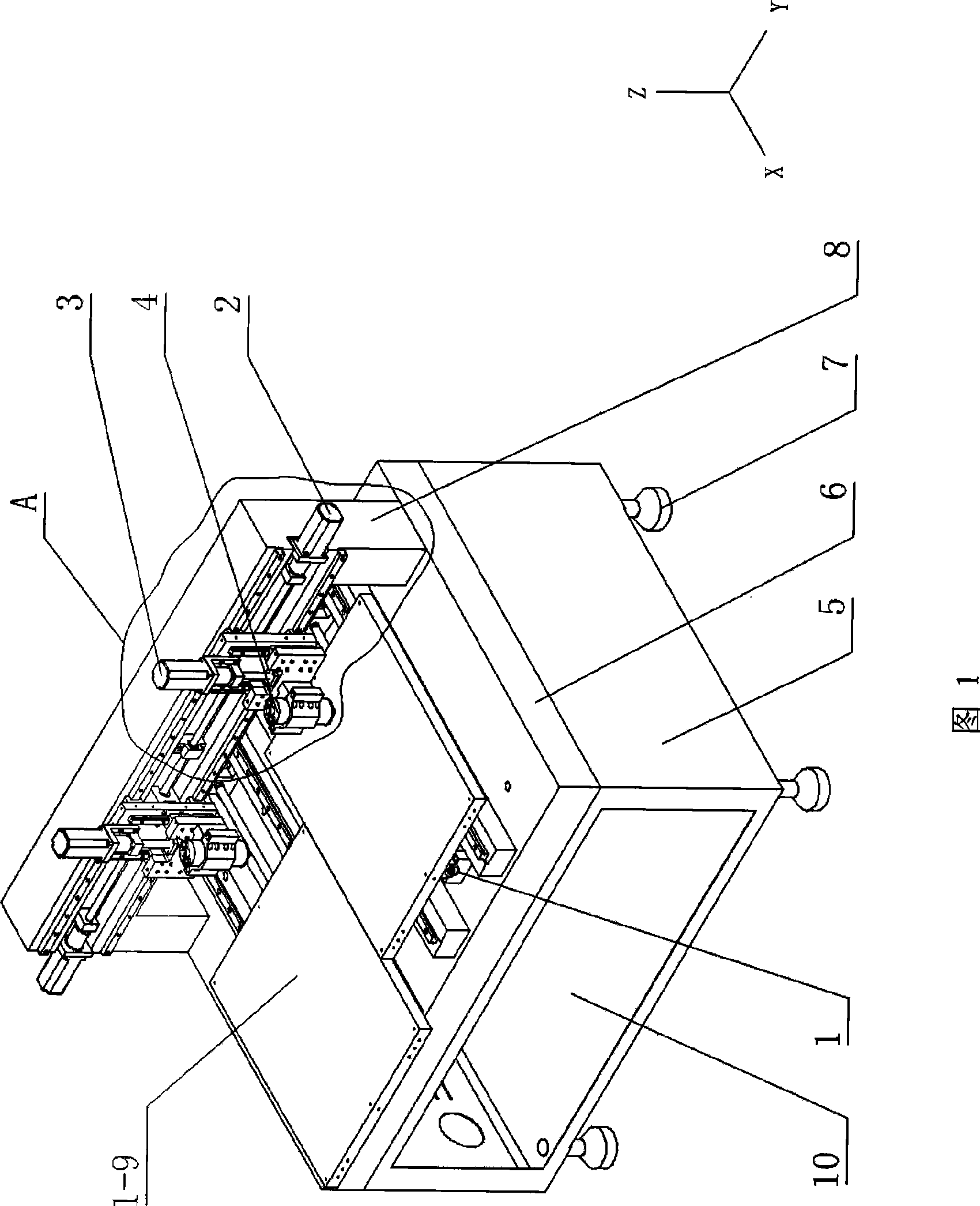

Control system for an electronic sign (video display system)

InactiveUS6819303B1Good flexibilityNice consistent appearanceDigital computer detailsAdvertisingGeneral purposeControl system

A video display system including an electronic sign, a electronic sign control system utilizing a general purpose personal computer, having a video interface card, controlled by clock and command signals from said personal computer, containing a plurality of video and digital input ports and a high speed output port, a transmitter link control card, also under the control of clock and command signals from said personal computer, for transmitting video display, clock, and command signals to a remote data receiver and distributor associated with the electronic sign, which converts said signals into device control signals for controlling individual sign display elements.

Owner:DAKTRONICS

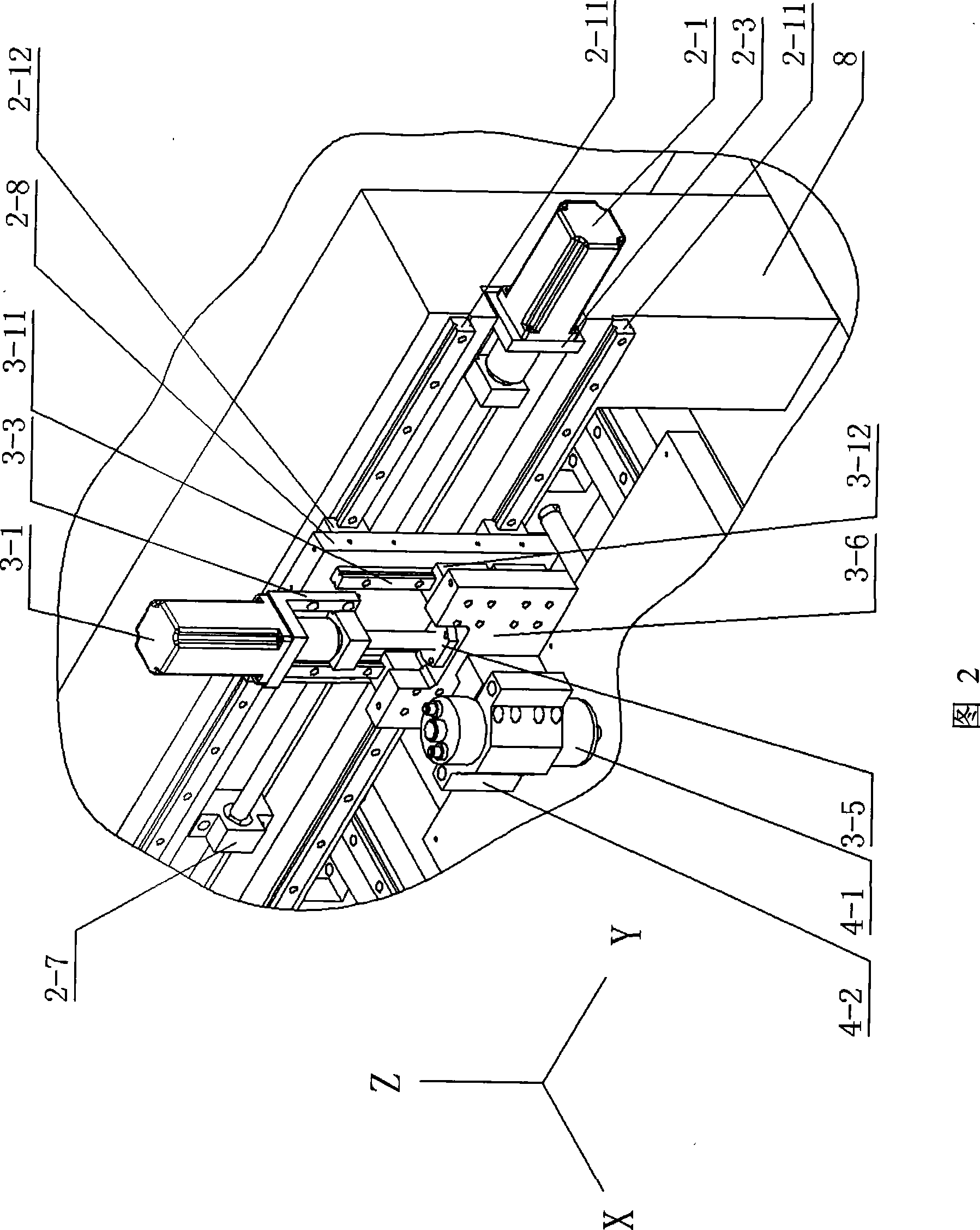

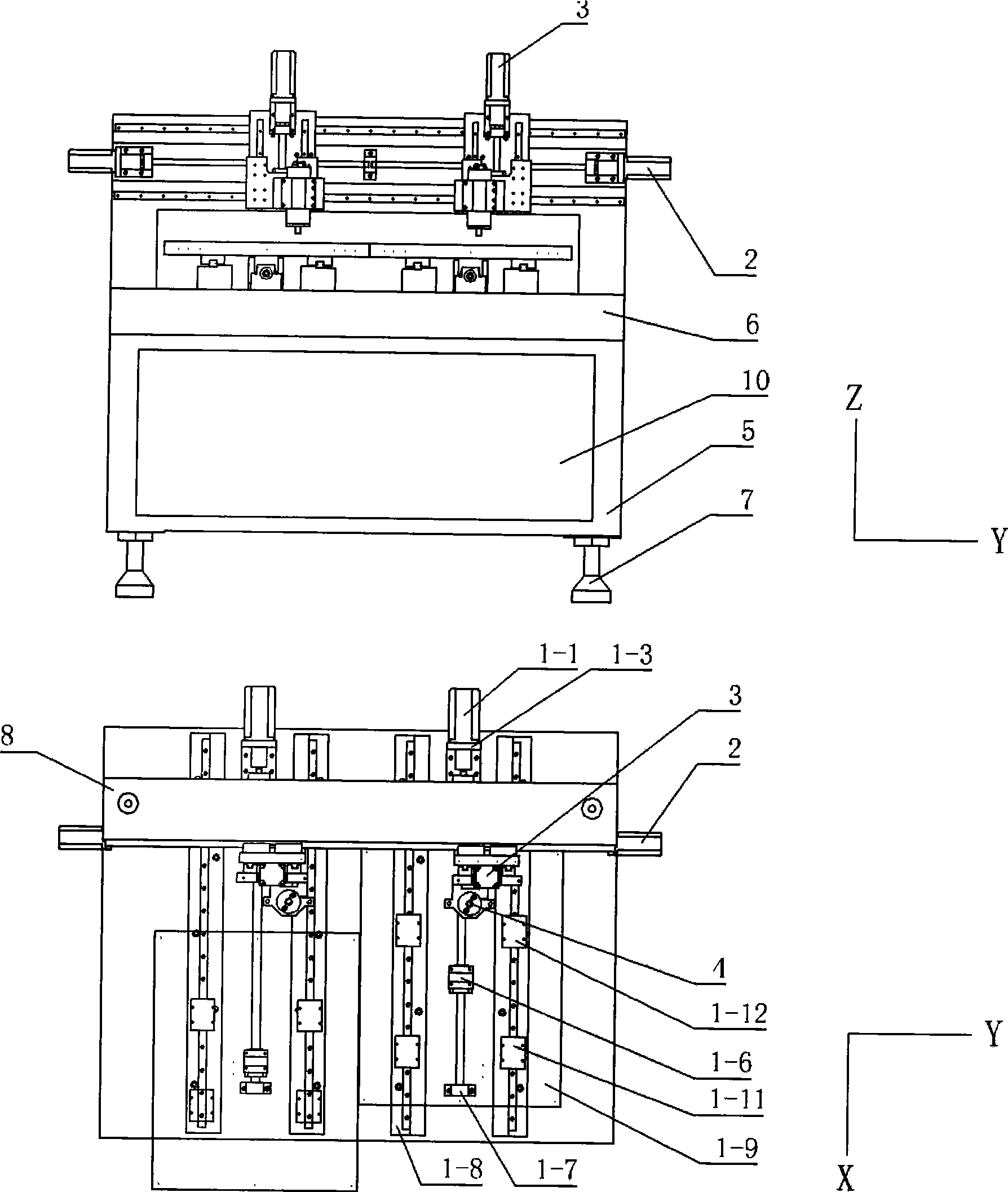

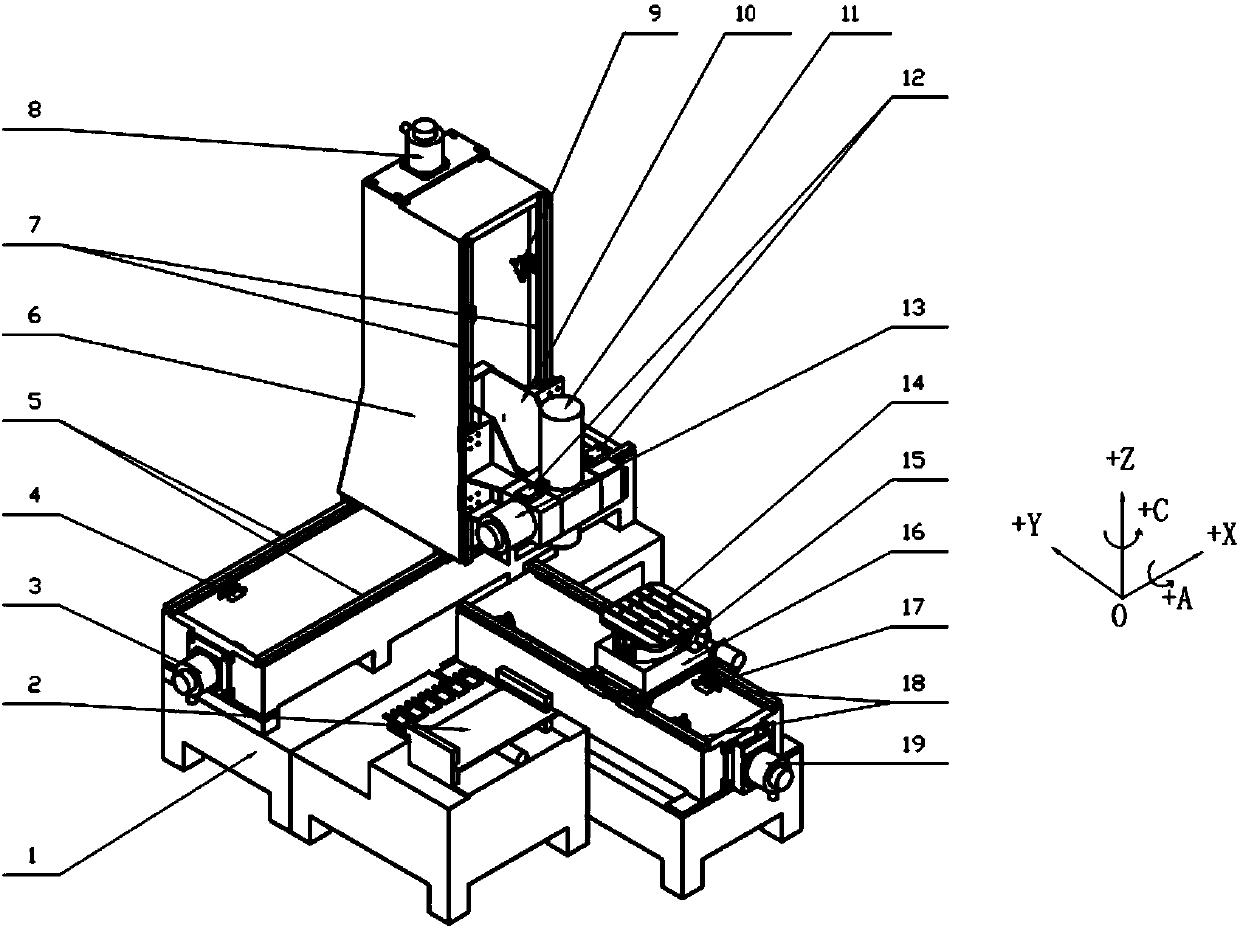

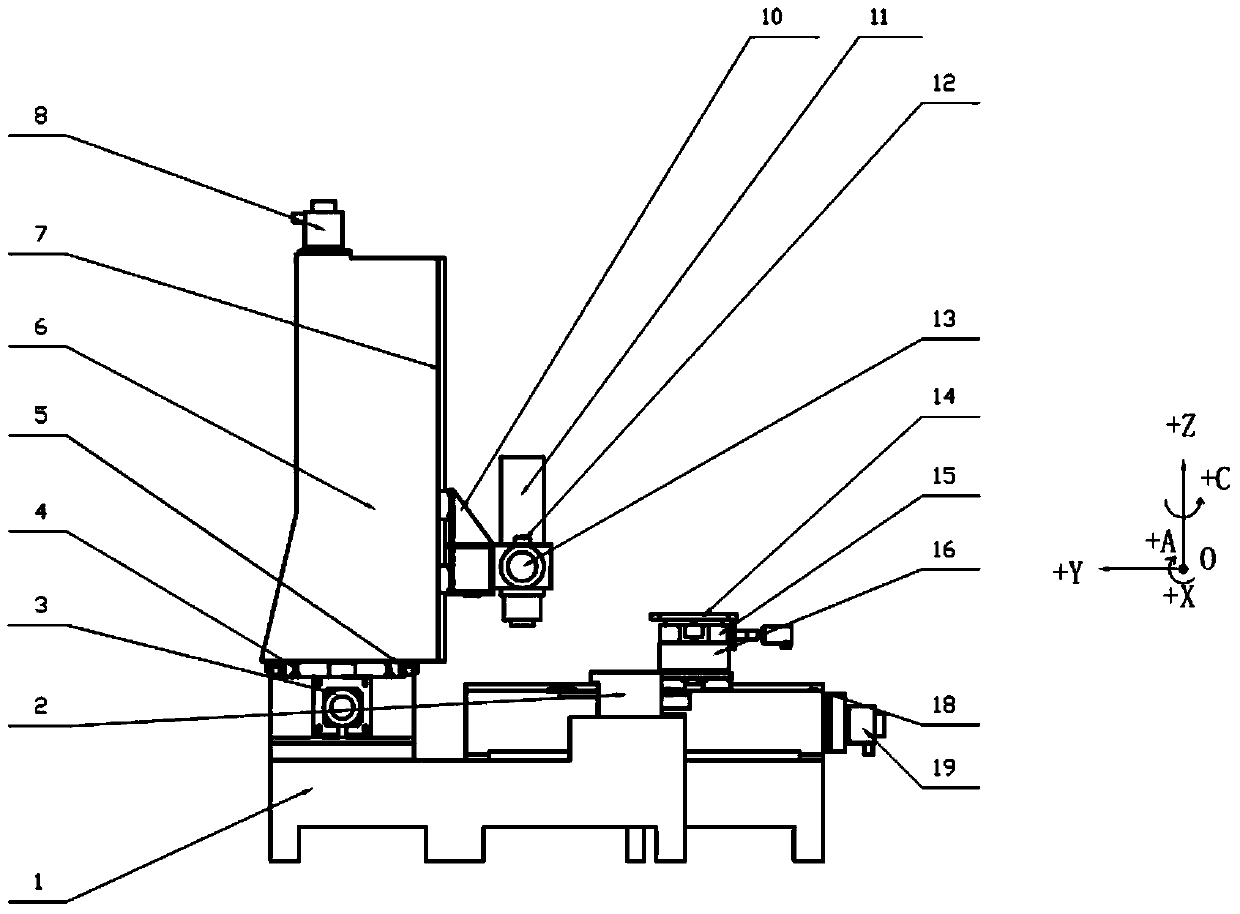

Numerical control drilling-milling apparatus having a plurality of independent process systems

InactiveCN101412185AMany processing modesMeet production requirementsFeeding apparatusOther manufacturing equipments/toolsProcess systemsNumerical control

The invention relates to a numerical control drilling and milling device provided with a plurality of independent processing systems, which comprises a computer for control and a drilling and milling machine. The computer is provided with a numerical control card and connected with the drilling and milling machine through an interface of the numerical control card, and the drilling and milling machine comprises a machine tool frame and a processing unit; and the processing unit is arranged on the machine tool frame which comprises a lathe bed and a gantry, the processing unit comprises a feeding device and a main shaft device, the feeding device comprises an X-axis feeding mechanism, a Y-axis feeding mechanism and a Z-axis feeding mechanism, the main shaft device is arranged on the feeding device, the number of the processing unit is at least two and each processing unit is provided with a corresponding interface of the control card. The drilling and milling device can carry out different processings simultaneously, can carry out two processing modes of drilling and milling simultaneously, has more processing modes and flexible application, can meet production requirement better, has higher production efficiency, and well integrates a plurality of numerical control drilling and milling machines into a numerical control drilling and milling machine provided with the plurality of the independent processing systems.

Owner:鲜于哲善

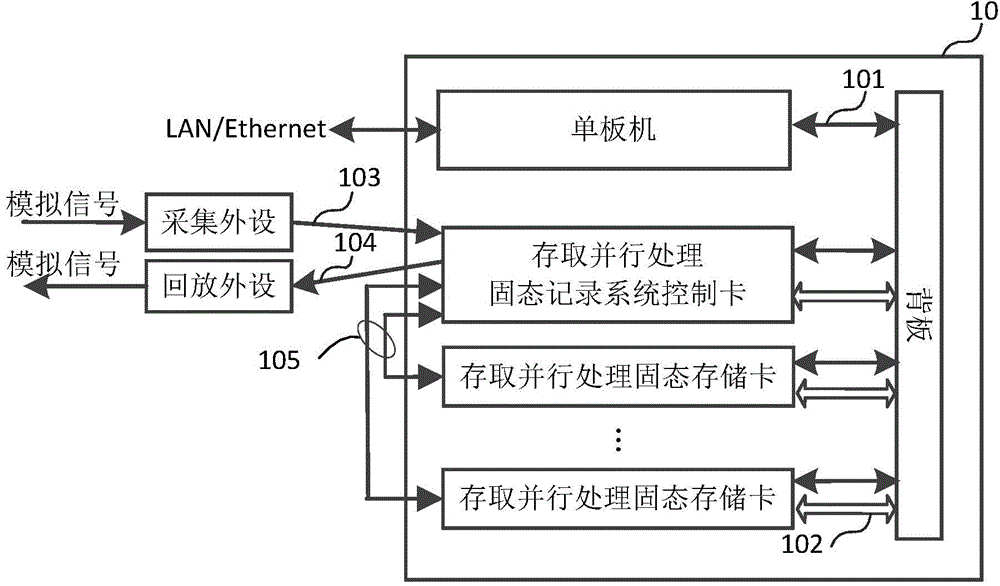

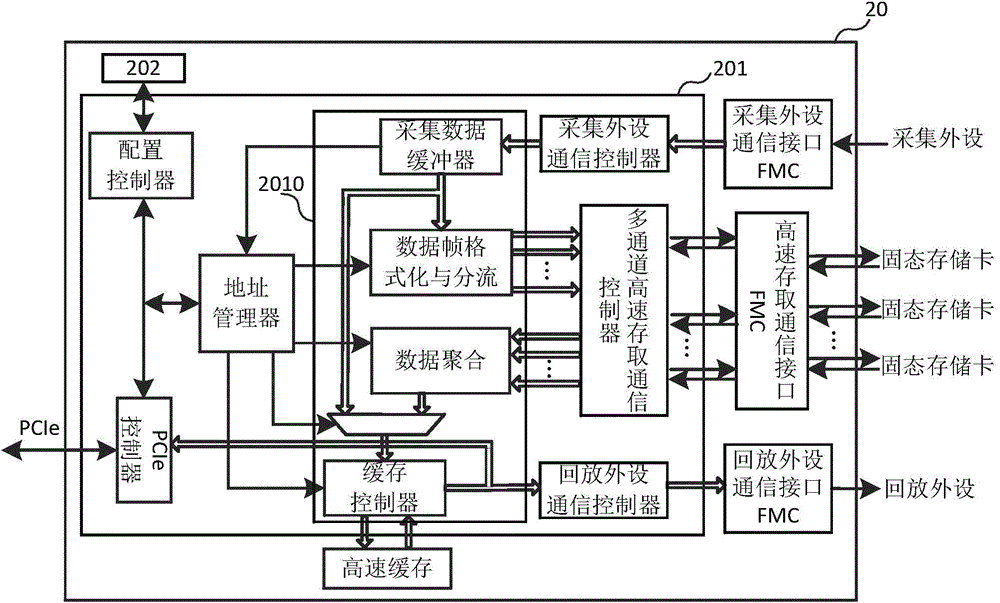

Solid recording device and method for accessing in real time and parallel processing

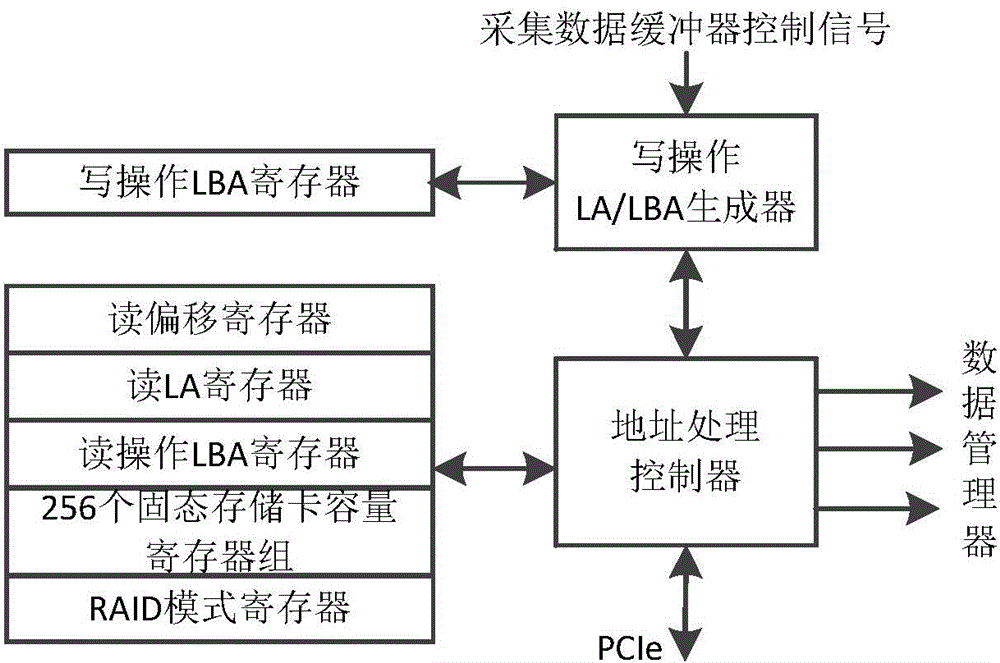

InactiveCN104809075AQuick conversionInput/output to record carriersMemory adressing/allocation/relocationSolid-state storageAssembly line

The invention discloses a solid recording device and a solid recording method for accessing in real time and parallel processing. The solid recording device for accessing in real time and parallel processing comprises a solid recording system control card for accessing and parallel processing, a plurality of solid storage cards for accessing and parallel processing, and a single board computer, wherein the system control card is connected with acquisition and playback peripheral equipment through specific peripheral equipment communication interfaces, and is connected with one or more than one solid storage card which is provided with four groups of independent flash arrays and a controller thereof through multi-channel high-speed access communication interfaces; a reading data link and a writing data link which are independent of each other are established between the acquisition and playback peripheral equipment and any two groups of flash arrays on the solid storage card; the flash array controller performs multistage assembly line read / write operation; the solid recording method for accessing and parallel processing comprises the following steps: performing recording and playback operation on all hard wire parallel processing; accelerating the conversion from LBA (Logic Block Address) to PBA (Physical Block Address) by adopting equalization write and address quadratic mapping strategies; therefore, the aim of performing data recording and playback simultaneously at a high speed is achieved by the solid recording device and the solid recording method for accessing in real time and parallel processing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

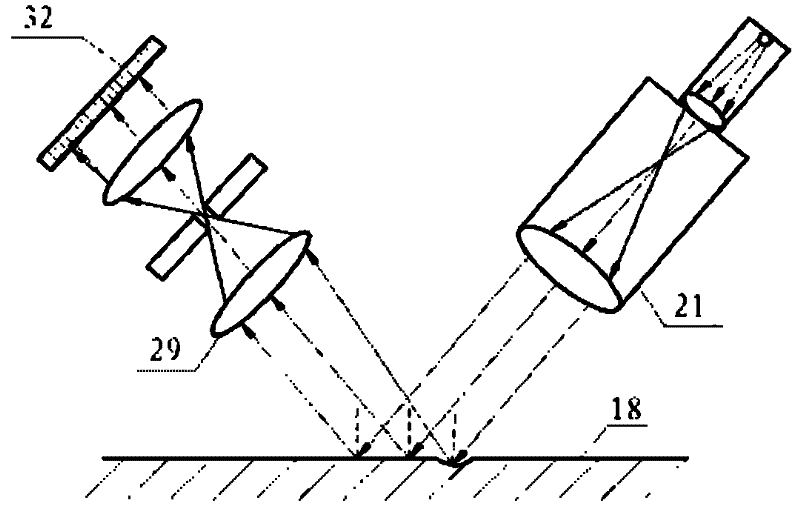

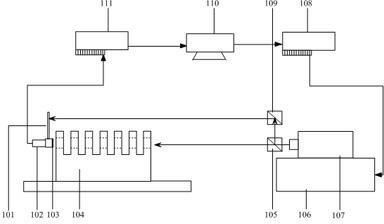

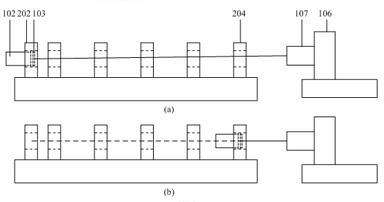

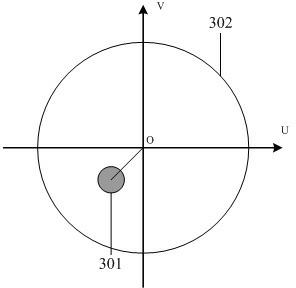

Optical measuring system and method for coaxiality of extra-long-hole part

The invention relates to an optical measuring system and method for coaxiality of an extra-long-hole part, belonging to the technical field of coaxiality measurement. The measuring system comprises an oriented rod (101), a self-centering comprehensive measuring head (102), a position sensitive detector (PSD) (103), the extra-long-hole part (104), a spectroscope (105), a four-dimensional collimation platform (106), a laser transmitter (107), a motion control card (108), a reflecting mirror (109), a computer (110), a data acquisition card (111) and the like. During measurement, a laser collimation centerline is determined firstly according to the centers of a head hole and a tail hole and then the coaxiality value of the holes is obtained through a minimum zone method. The optical measuringsystem and method for the coaxiality of the extra-long-hole part has the advantages of high efficiency and high accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

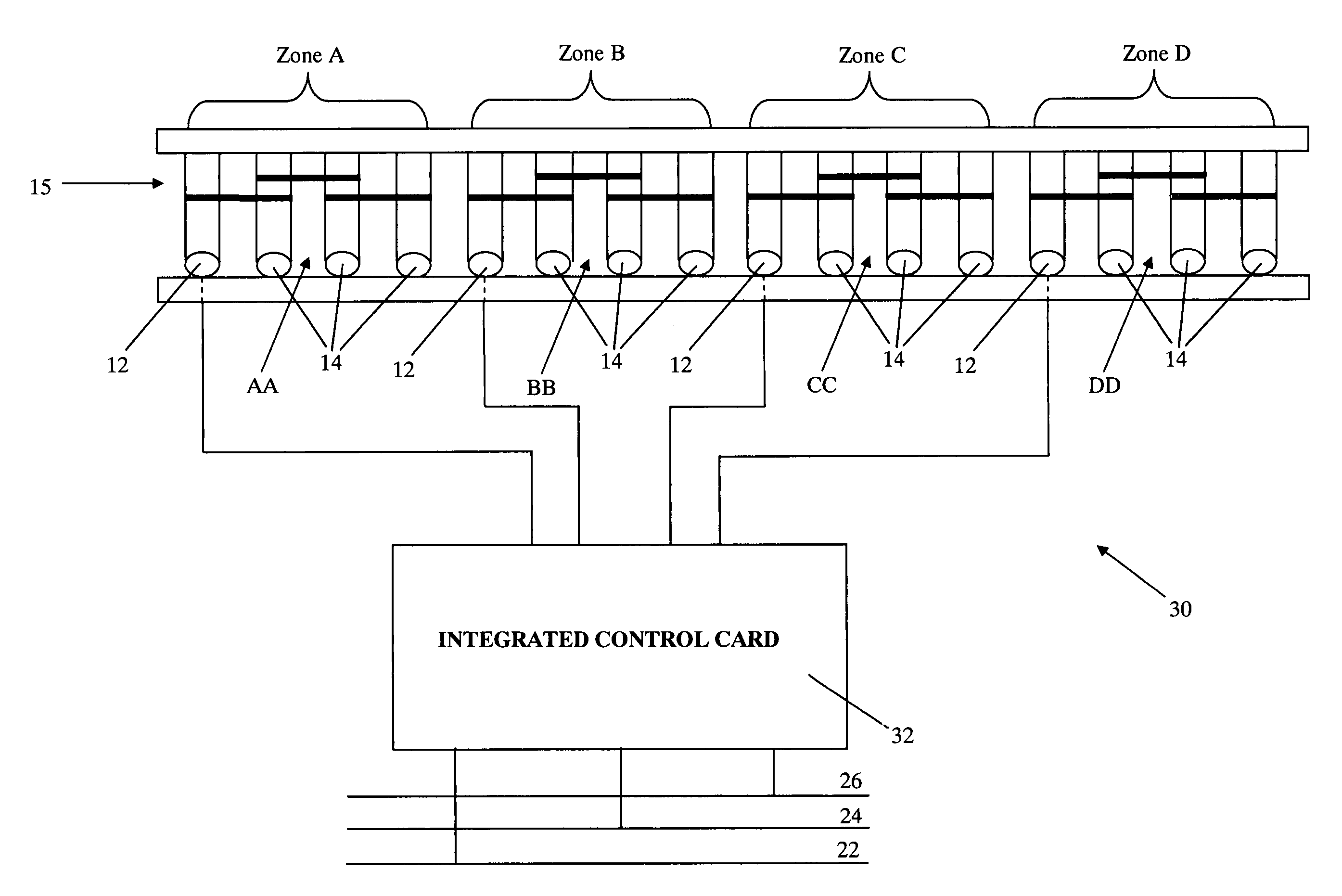

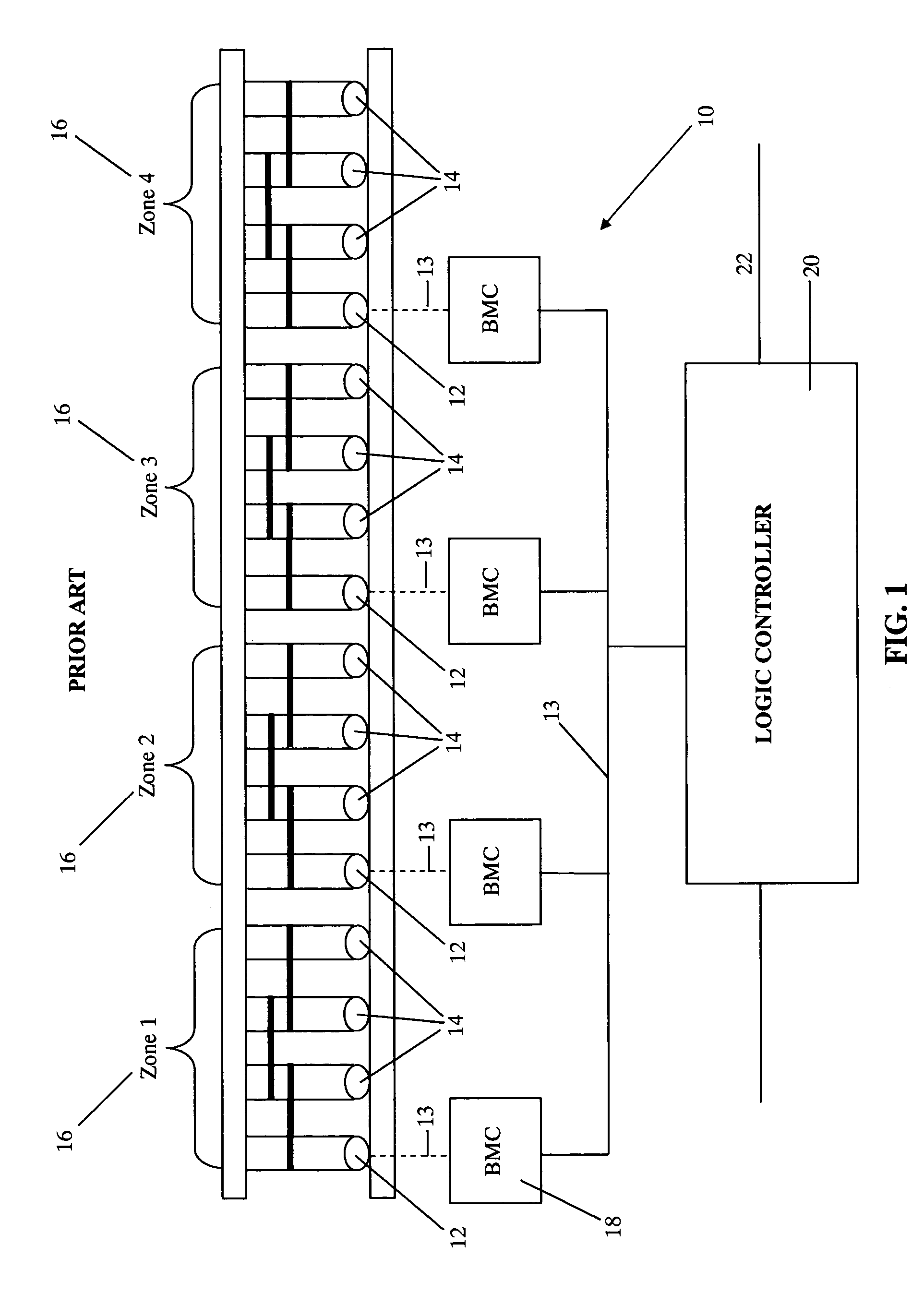

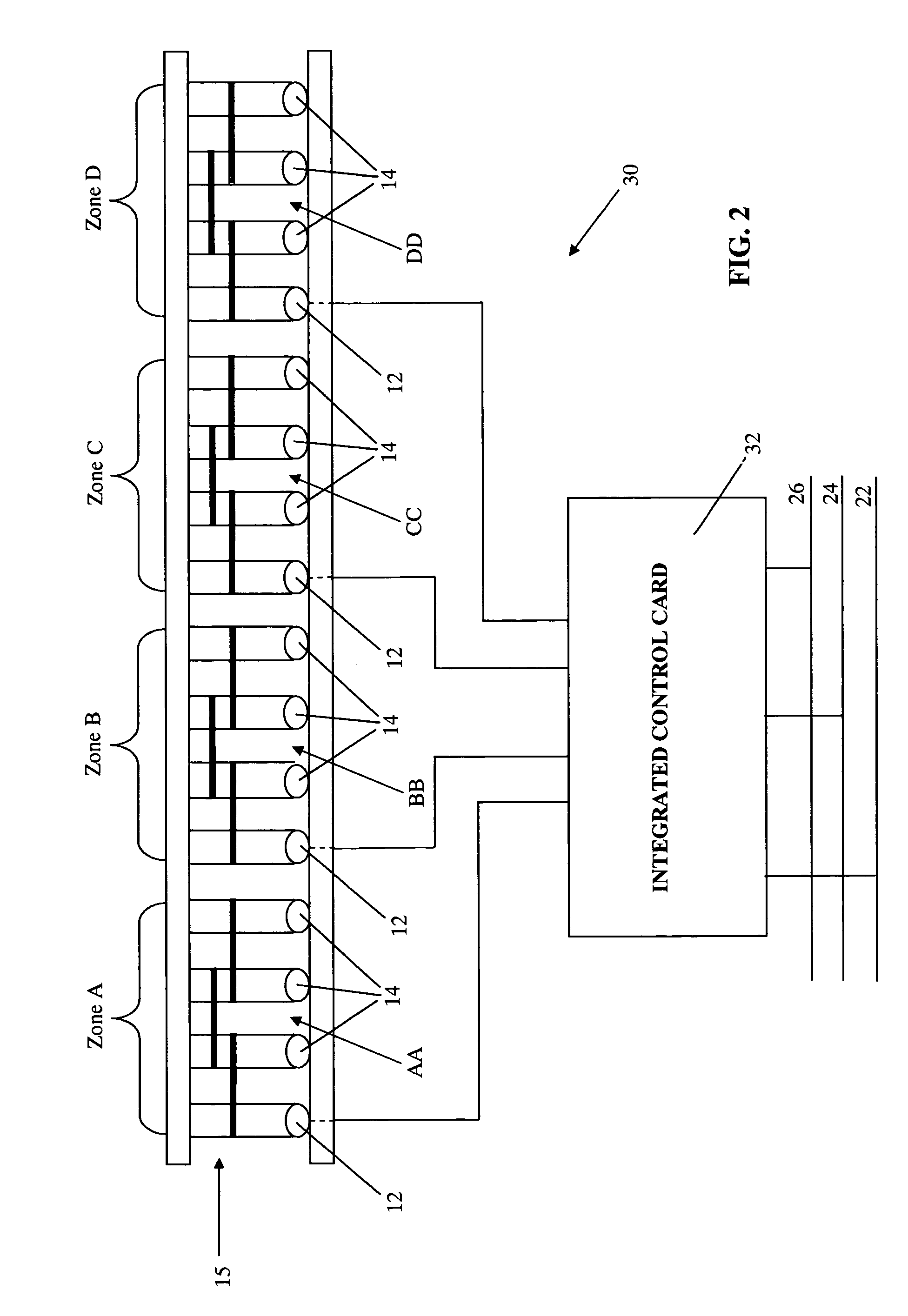

Integrated control card for conveying systems

A material handling system, and method of controlling the material handling system, includes a conveying surface with a plurality of individually controlled zones and a plurality of motors. At least one of the motors propelling the conveying surface at each zone. A plurality of motor controller circuits adapted to control the plurality of motors. An upper-level control circuit in communication with the plurality of motor controller circuits and adapted to send communications to the motor controller circuits for controlling at least one motor. An integrated control card defining the upper-level control circuit and the plurality of motor controller circuits, wherein the upper-level control circuit and the plurality of motor controller circuits are integrated onto the integrated control card.

Owner:KÖRBER SUPPLY CHAIN LLC

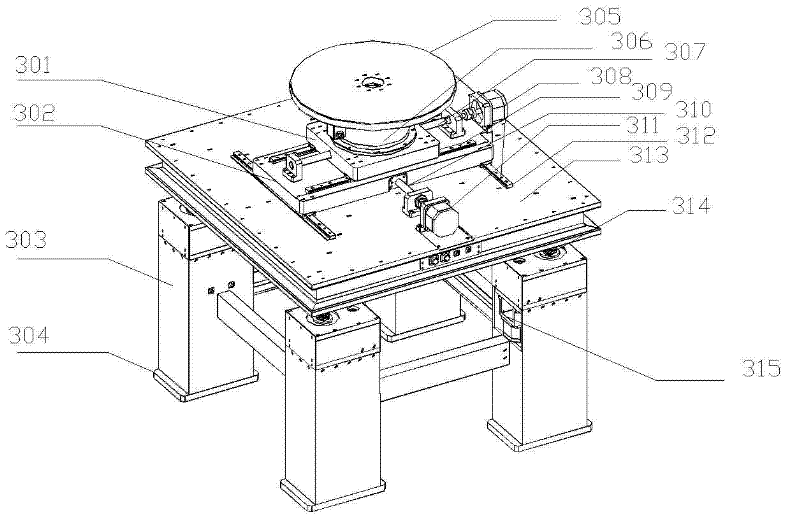

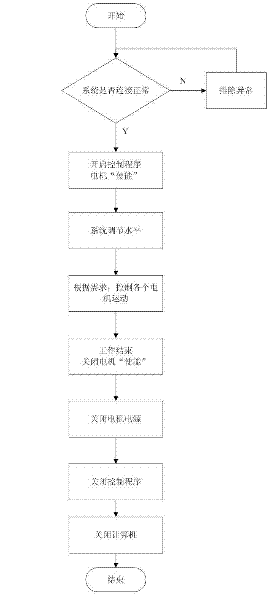

Multi-degree-of-freedom vibration isolation bearing platform

InactiveCN102501230AAchieve level adjustmentIncrease freedomWork benchesElectricityAutomatic control

The invention discloses a multi-degree-of-freedom vibration isolation bearing platform which comprises a computer, a control card and a rotary vibration isolation bearing platform, wherein the bottom of a support leg of an azimuth platform in the rotary vibration isolation bearing platform is fixedly connected with a laminated vibration isolation rubber support. A Z-axis drive motor in the support leg is connected with the azimuth platform. An X-axis guide rail, an X-direction platform, an X-axis screw and an X-axis drive motor arranged on the azimuth platform are sequentially connected; and a Y-axis guide rail, a Y-direction platform, a Y-axis screw and a Y-axis drive motor arranged on the X-direction platform are sequentially connected. The Y-direction platform is provided with a Z-axis rotation drive motor and a stage. The Z-axis drive motor, the X-axis drive motor, the Y-axis drive motor and the Z-axis rotation drive motor are electrically connected with the control card respectively; and the control card is electrically connected with a computer. According to the invention, 4-degree-of-freedom adjustment can be performed on the platform in a vibration isolation condition, the pitching and rolling degree of freedom can be subjected to micro adjustment, and horizontal adjustment of the platform can be realized. The multi-degree-of-freedom vibration isolation bearing platform disclosed by the invention has the advantages of simple structure, heavy load, high position accuracy, automatic control and wide application.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

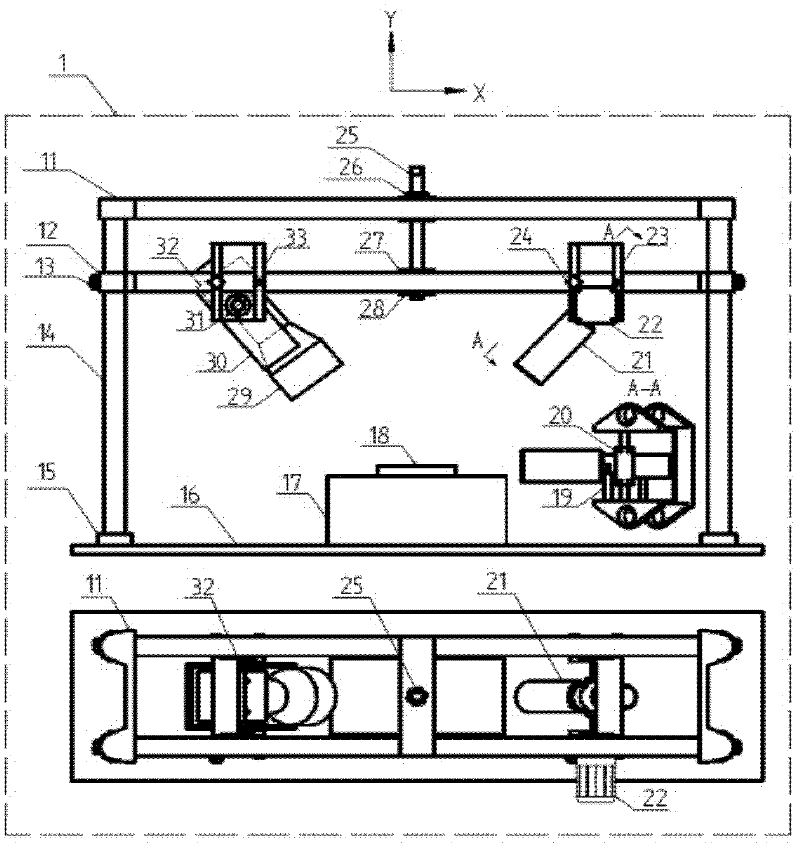

Full-automatic wafer dicing saw control system based on vision

ActiveCN103111753AImprove efficiencyFunction increaseLaser beam welding apparatusAutomatic controlMaser

The invention relates to a full-automatic wafer dicing saw control system based on vision. The full-automatic wafer dicing saw control system based on the vision is matched with a tool device, an optical maser and a micro-camera. Hardware comprises a computer, a motion control card and a displayer, wherein the control card, the displayer, the optical maser and the micro-camera are respectively connected with the computer, motors are respectively connected with the control card through each shaft motion platform and an actuator corresponding to a rotating device, grating sensors are respectively arranged on the motion platform of an axle X and an axle Y and a direct drive motor, and the grating sensors are connected with the computer through an encoder. The computer adopts the Windows system to carry out the modular design based on the VC++. The computer comprises a data processing module, a motion control module, a control system initialization module, a visual inspection locating module, a display interface module and a laser cutting control module. By the technical scheme, the stable operation of the software matching with the hardware of the whole control system is achieved, the control system organically integrates the tool device, the degree of the automatic control is high, and the scribing efficiency is improved by 20% or so compared with the original scribing system.

Owner:福建省威诺数控有限公司

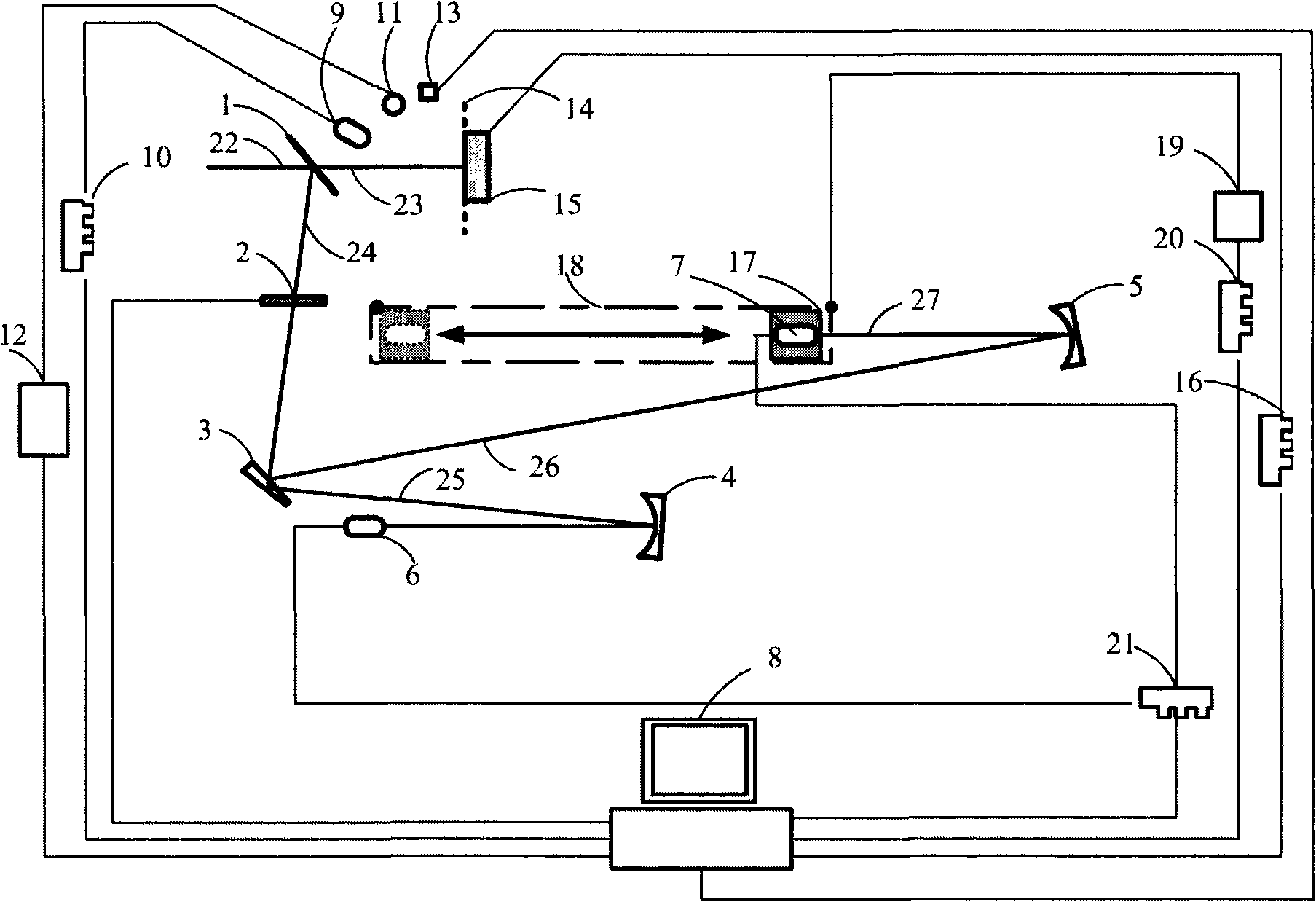

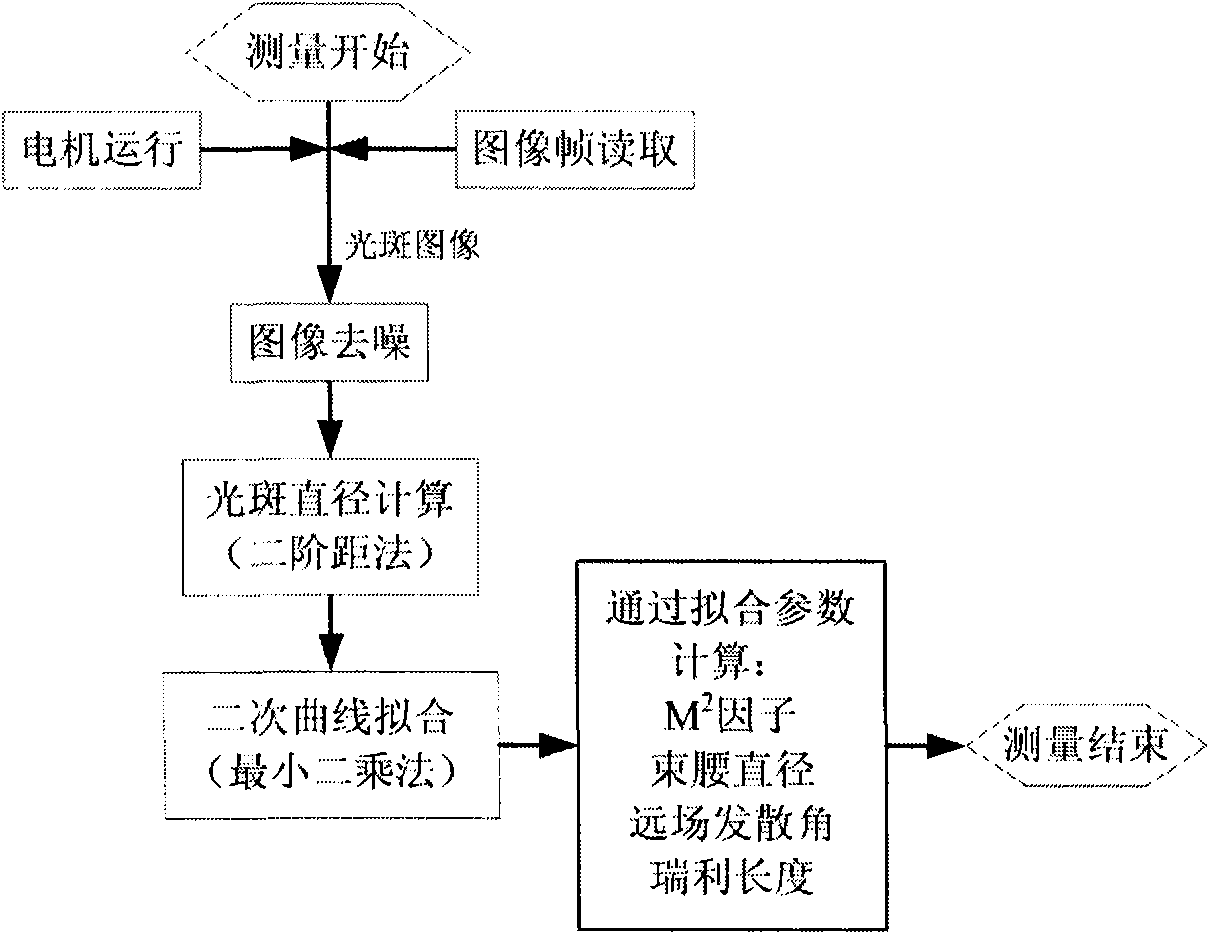

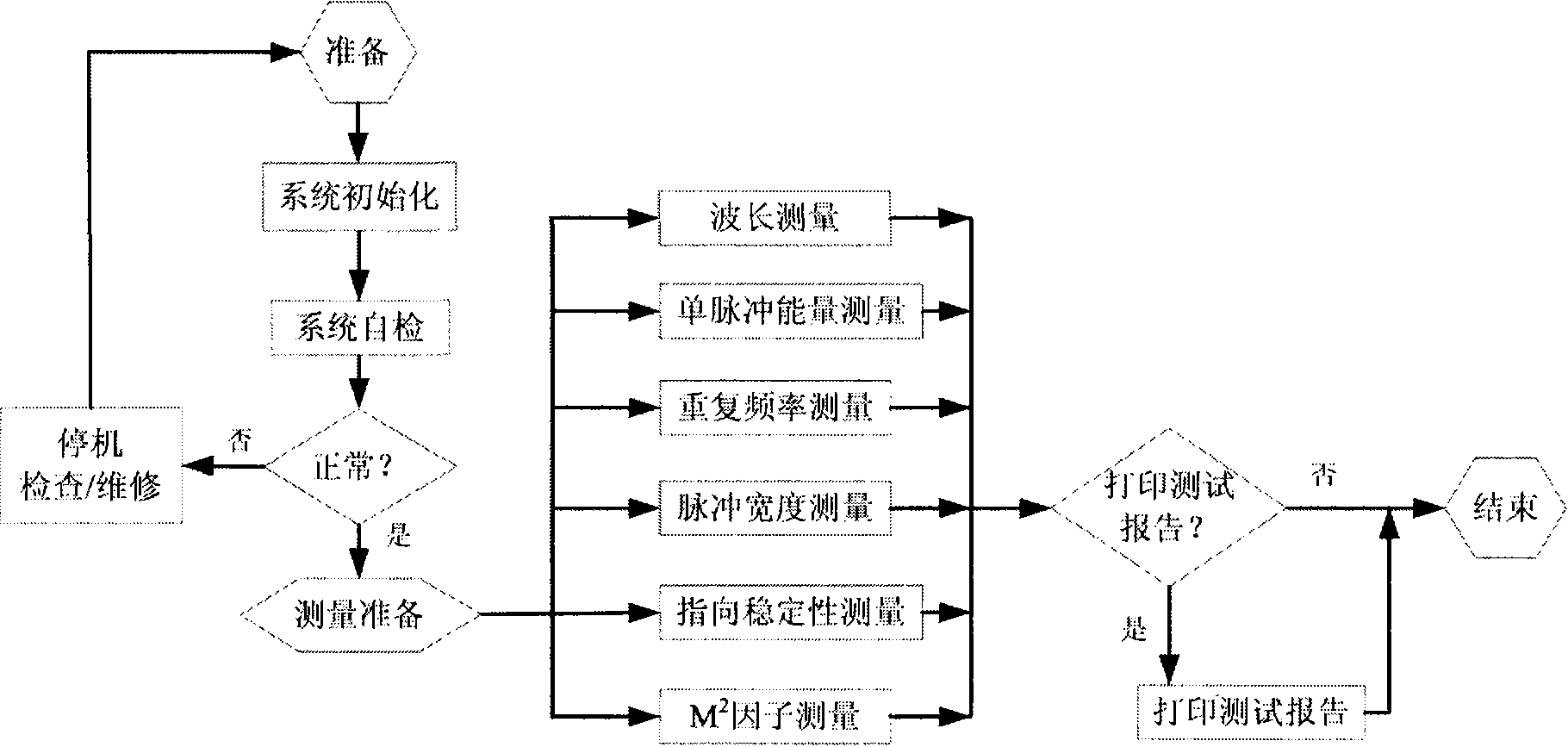

Laser parameter integrated test system

The invention relates to a laser parameter integrated test system, comprising a wedge spectroscope, a concave spherical reflector, a digital plane array charge coupled device (CCD) camera, a silicon photoelectric diode, a photoelectric detector, an energy probe, a spectrometer, an adjustable attenuator, a stepping motor and a computer with an acquisition card and a control card. A laser to be tested is incident upon the plane reflector; the monopulse energy, the pulse width, the repetition frequency and the wavelength of the laser beam are measured by means of the transmission light of the plane reflector; the wedge spectroscope splits the reflection light of the plane reflector into two beams, wherein one beam of laser is used for observing a near field laser spot, and the other beam of laser is used for measuring the M2 factor, the far field divergent angle, the beam waist diameter and the pointing stability of the laser beam. The laser parameter integrated test system can carry out integrating, precise and stable measurements on the monopulse energy, the wavelength, the pulse width, the repetition frequency, the M2 factor and the pointing stability of the laser beam.

Owner:南京帝耐激光科技有限公司

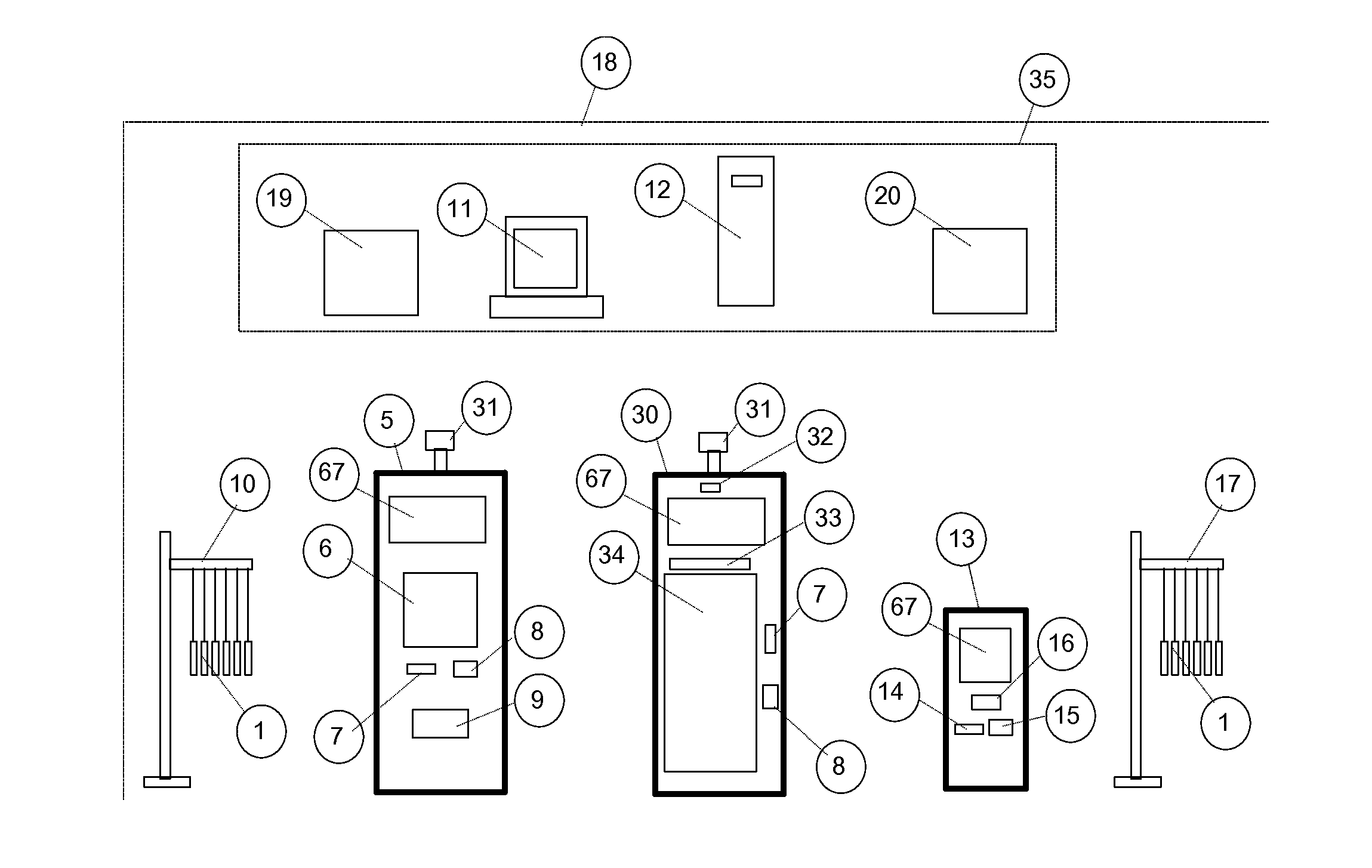

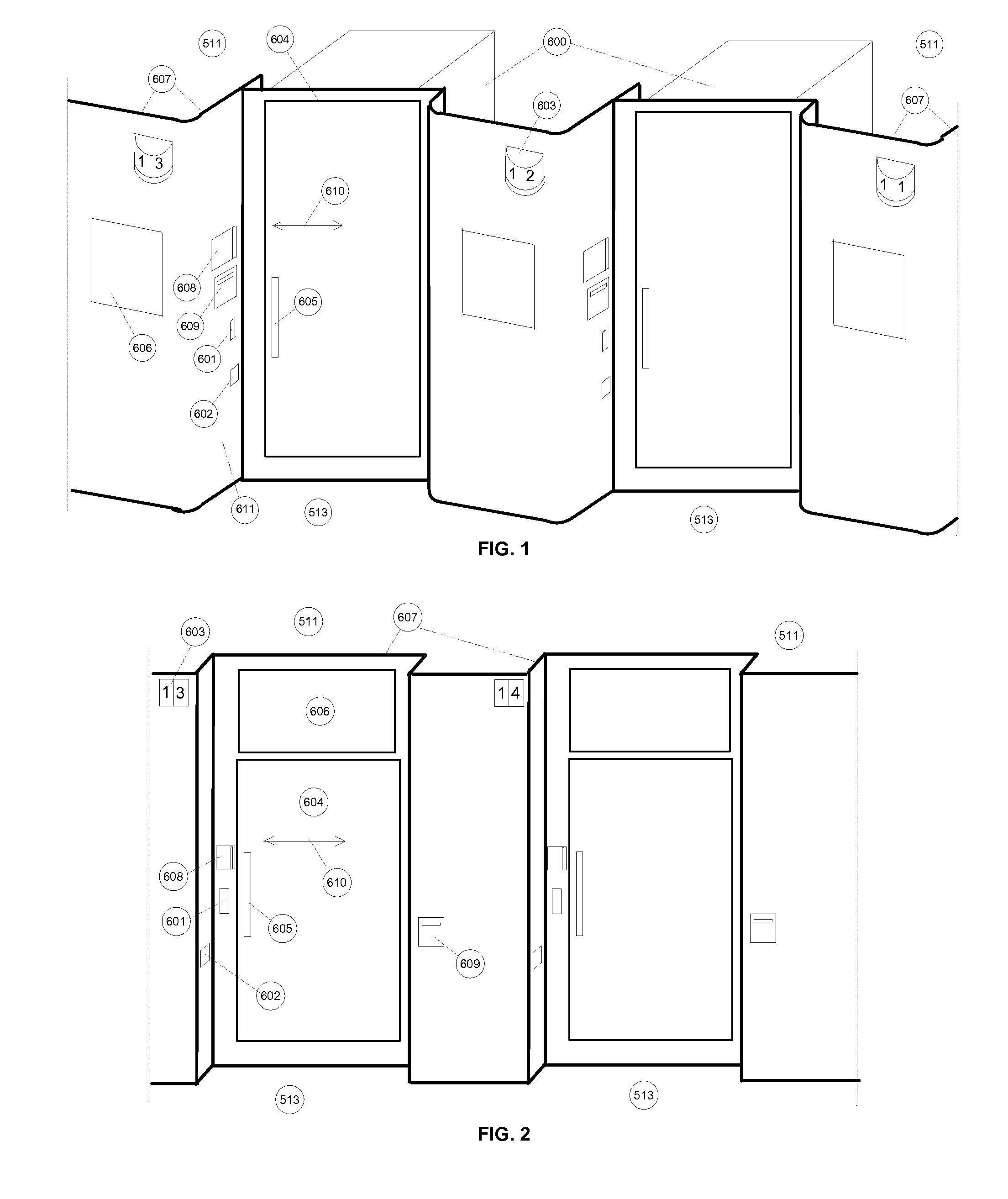

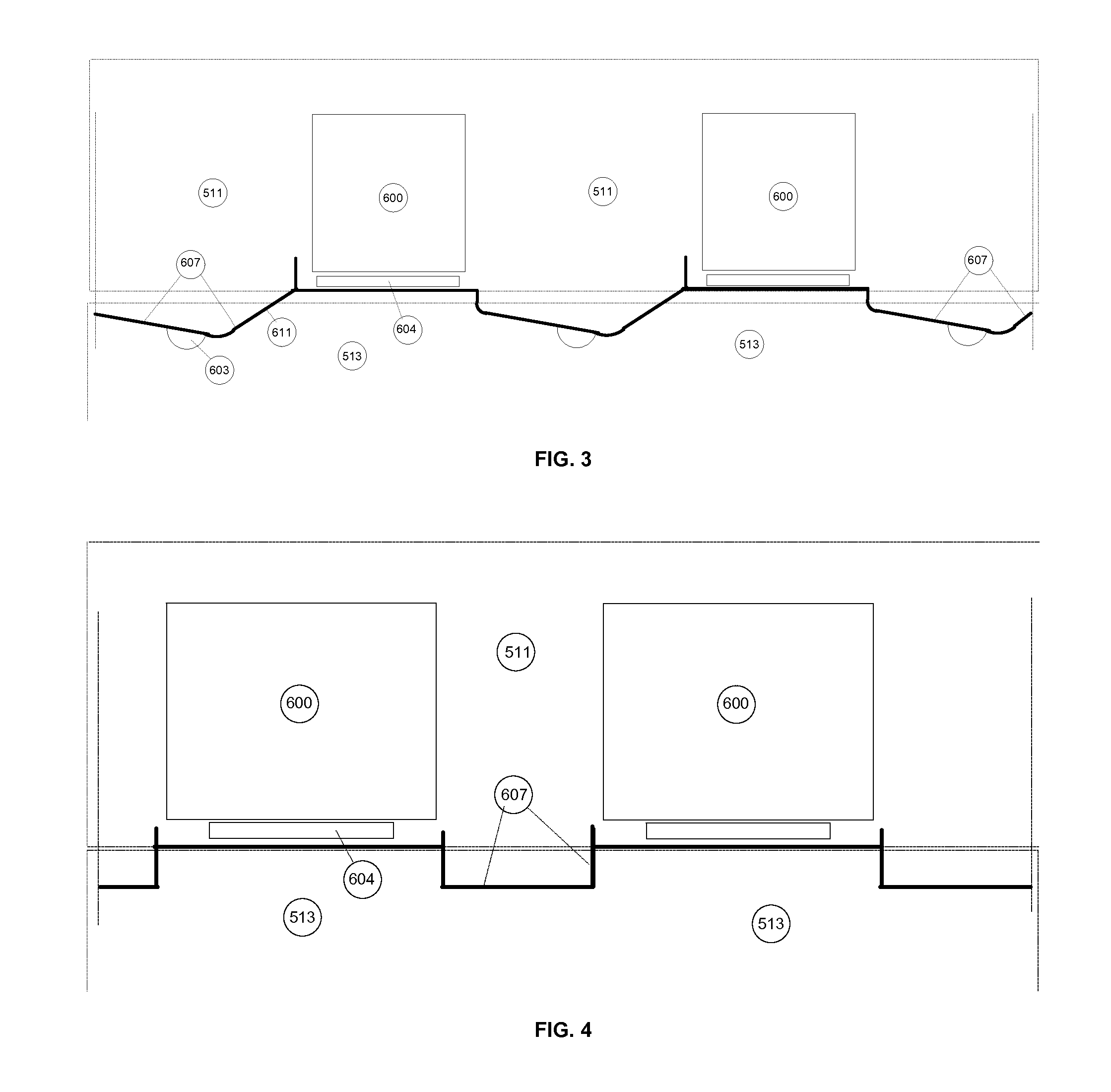

Apparatus improving item transactions with real-time controls and navigation

InactiveUS20120080517A1Reliable matingReliable engagementComplete banking machinesFinanceReal-time Control SystemPayment

Invention describes real-time control system increasing shopping efficiency, maintaining item quality, inventory, and directing customer transactions, requiring handling and processing of items only once. Invention controls access to items inside modules via card with unique embedded identification features. Invention stores customer transactions and entered shopping lists. Invention per customer selected shopping list and items availability, will in real-time navigate customer to complete required transactions within customer selected criteria. Invention controls card identification features and modules containing items. Invention based on card identification and item identification such as barcode information will store customer executed transactions, and will require customer to pay for completed transactions before leaving the store. Invention in real-time maintains inventory of items, controls environment surrounding items, and reports items exceeding shelf life limit preventing their transaction. Invention analyzes transactions executed by the card, correlates transactions to customer at payment module, stores behavior patterns for future optimizations of transactions.

Owner:BRAUNSTEIN ZACHARY L

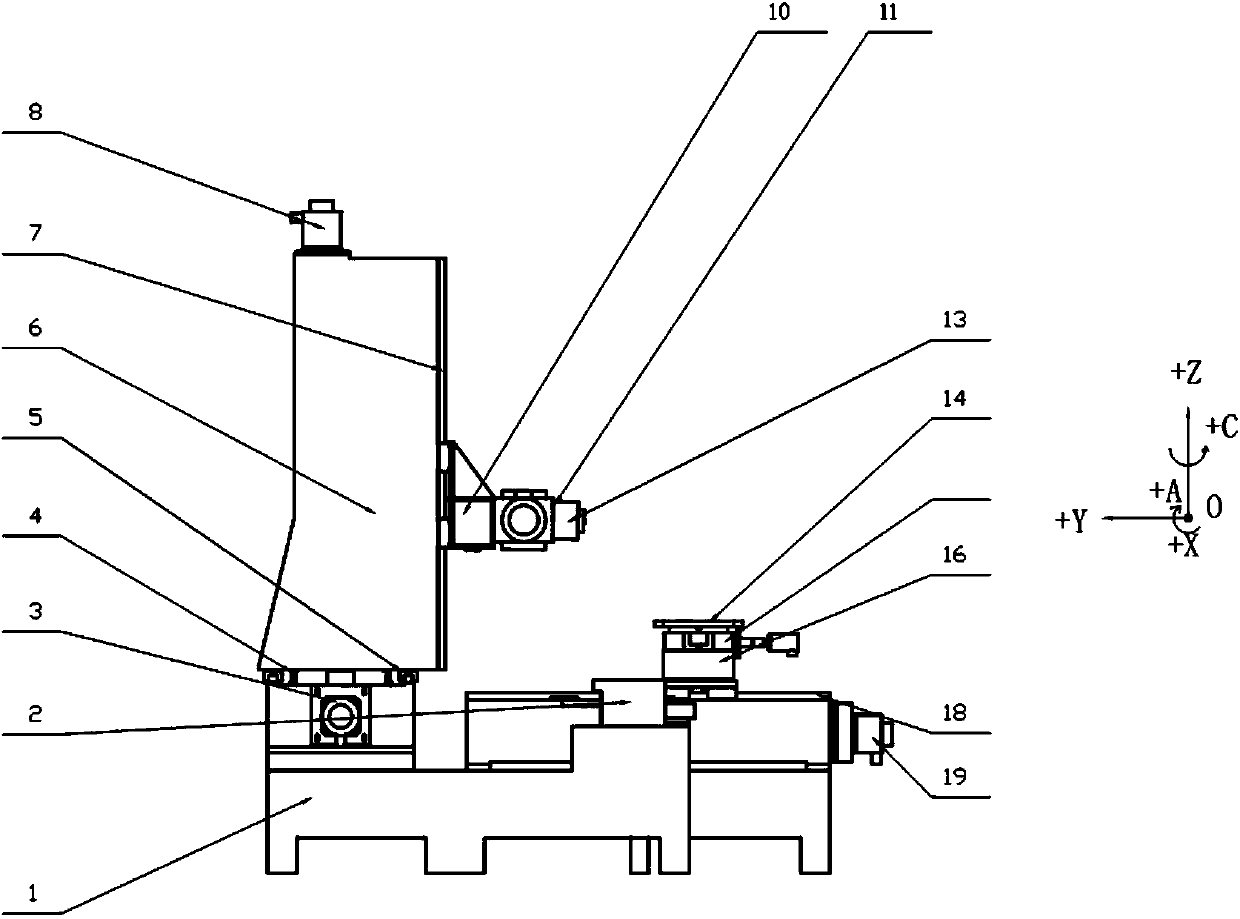

Numerical control five-axis tenon machining machine tool

InactiveCN103802180AImprove machining accuracyPracticalTongue/grooves making apparatusTenon making apparatusNumerical controlMortise and tenon

The invention discloses a numerical control five-axis tenon machining machine tool, and belongs to the technical field of machining machine tools. The numerical control five-axis tenon machining machine tool comprises a machine tool body, upright posts, a rotary positioning turntable, a main shaft component, a tool magazine and a control card used for controlling the machine tool, wherein the upright posts are connected with the machine tool body through X-axial guide rails and move along the X axes under the drive of a drive device; the rotary positioning turntable is connected with the machine tool body through a Y-axial guide rail and moves along the Y axis under the drive of the drive device; the main shaft component is connected with the upright posts through Z-axial guide rails and move along the Z axis under the drive of the drive device; an X-axial guide rail is placed on each of the two cross beams of the machine tool; the upright posts and the cross beams of the machine tool body form guide rail connection; a Y-axial guide rail is placed on each of the two longitudinal beams of the machine tool body; a Y-axial sliding plate and the longitudinal beams of the machine tool body form guide rail connection. The numerical control five-axis tenon machining machine tool can implement the three-dimensional five-axis cutting machining on a complex tenon structure, and the machining level of the machine tool is higher. According to the machine tool, the self gravity of the machine tool is greatly reduced without influencing the use precision of the machine tool.

Owner:刘岩松

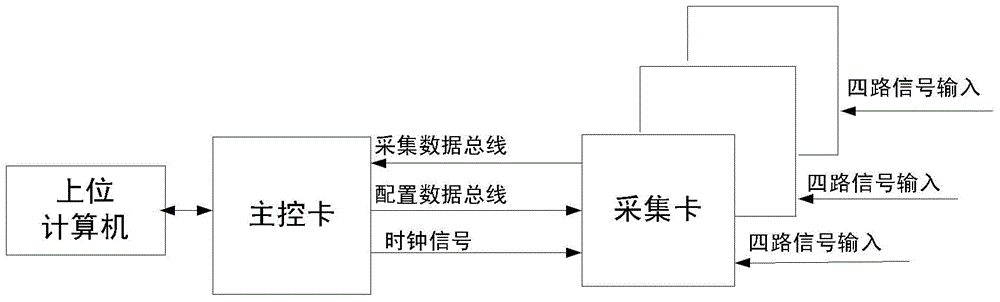

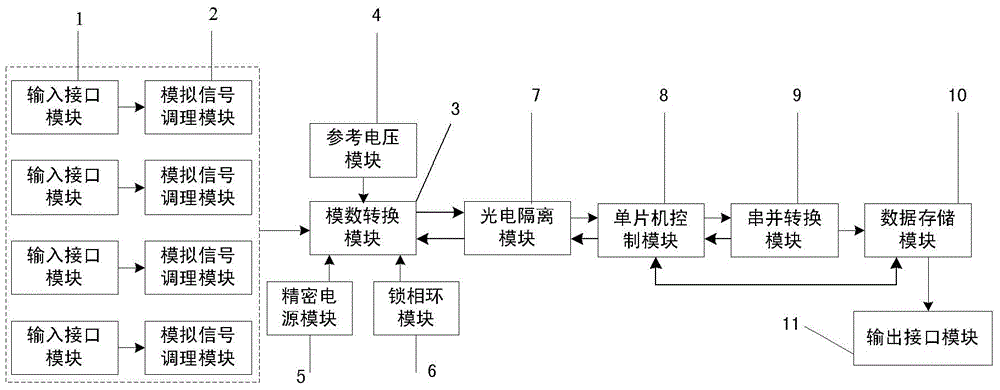

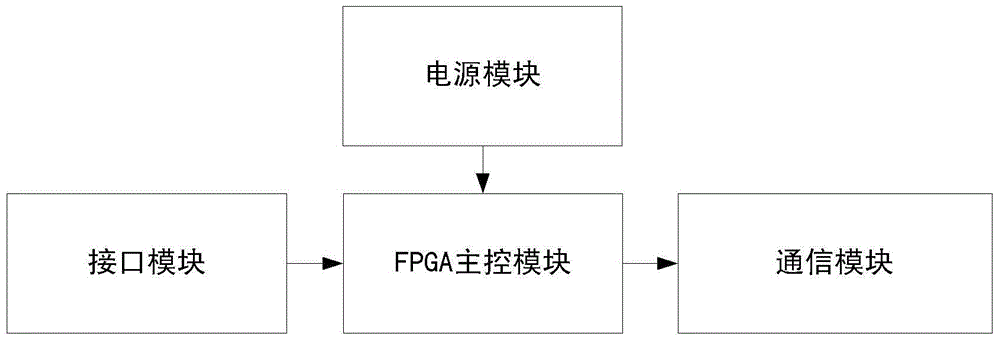

General multi-channel data collection system

ActiveCN103336667AFunction independentStrong targetingEnergy efficient computingInput/output processes for data processingData acquisitionDigital signal

The invention discloses a general multi-channel data collection system. The general multi-channel data collection system comprises a collection card and a master control card. The collection card collects analog signals transmitted from a collection sensor, and the analog signals are collected and converted into digital signals. The master control card carries out denoising and filtering on data in the digital signals, so that real-time correction of the data is achieved, an upper computer is connected with the master control card, and configuration information is written from the master control card, so that control over the work of a whole system is achieved. An analog-digital conversion module of the collection card converts the analog signals into the digital signals, and a photoelectric isolation module of the collection card isolates the analog portion from the digital portion of the whole data collection system completely, so that the transmission of the analog signals is not interfered by noise of a digital circuit. The photoelectric isolation module is used for reducing the influence of the noise of the analog portion on the digital portion, a precision power module of the collection card reduces the influence of power supply noise, and a phase-locked loop of the collection card guarantees phase synchronization of clock signals among the collection cards.

Owner:SHANGHAI ZUOANXINHUI ELECTRONICS TECH

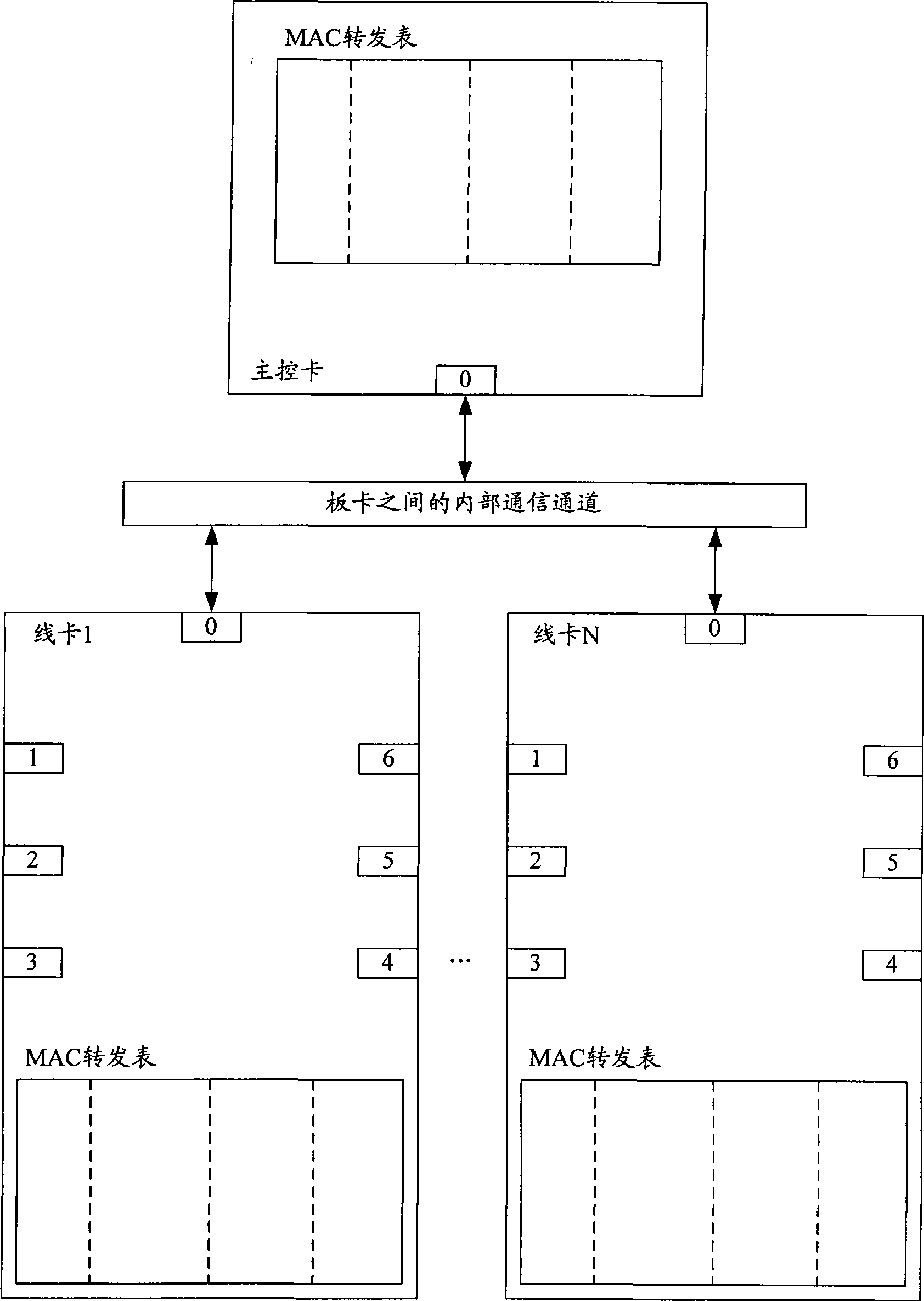

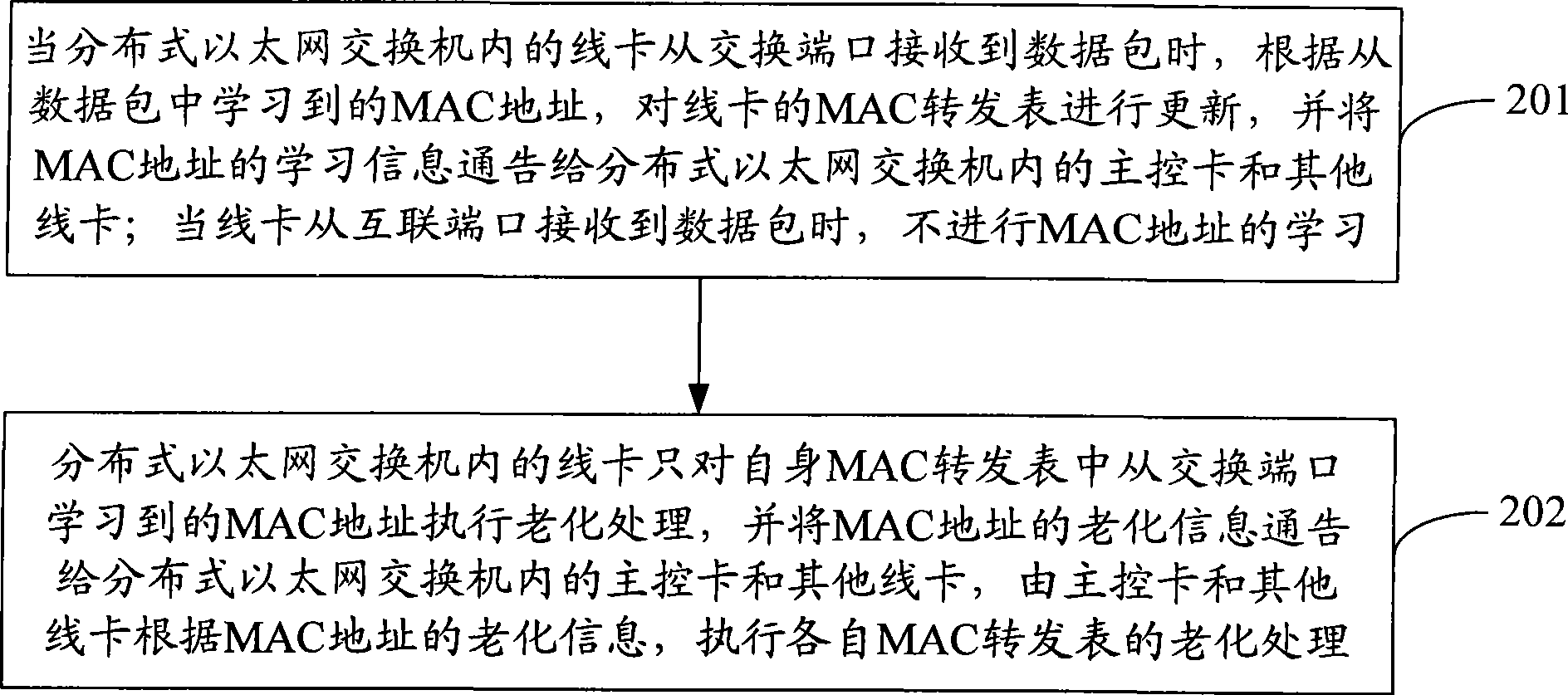

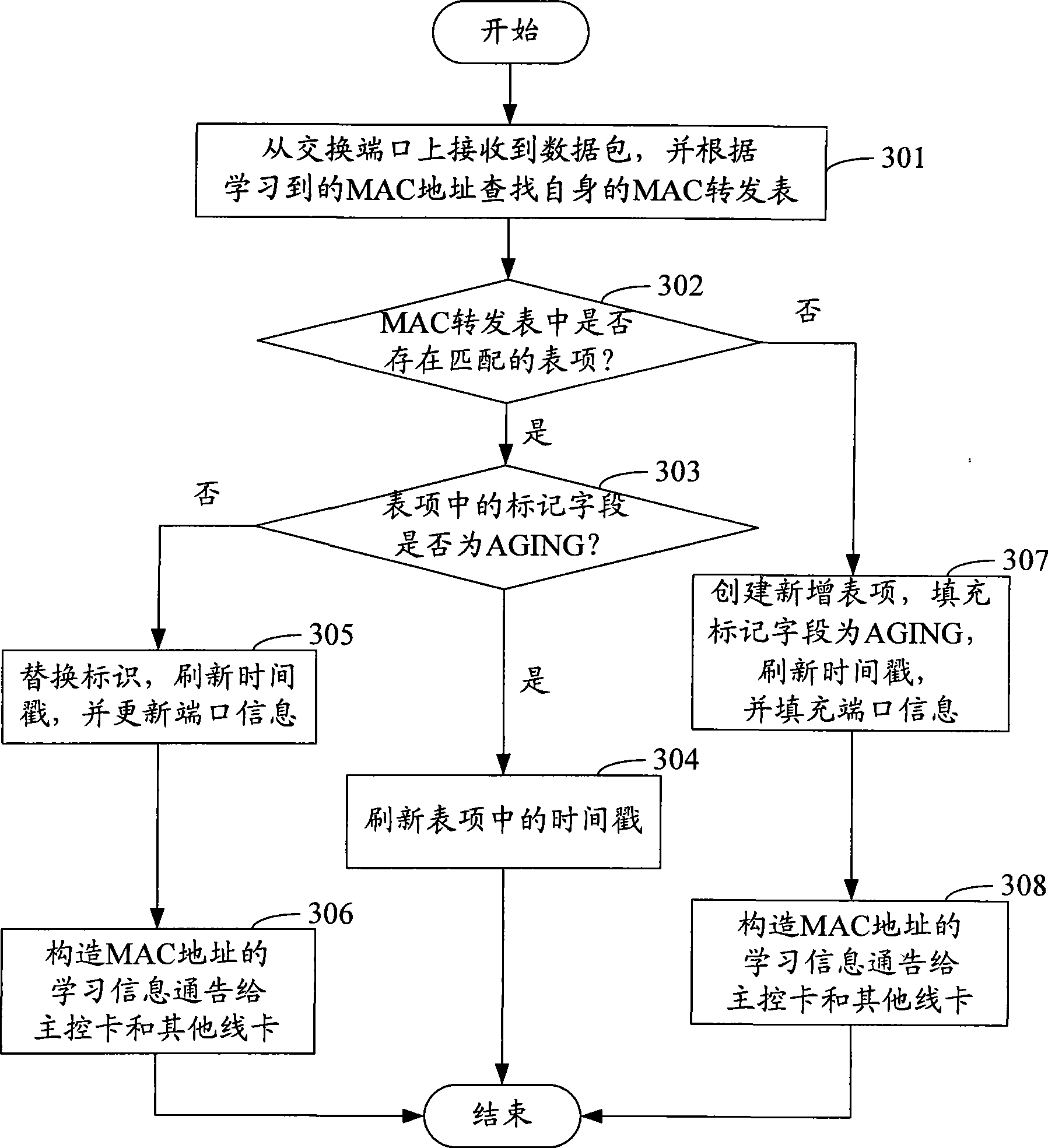

Distributed Ethernet switch and internal MAC address maintaining method thereof

ActiveCN101488862AEasy maintenanceReduce the burden of inter-board communicationData switching detailsNetwork packetLine card

The invention discloses a distributed type medium access control (MAC) address maintenance method inside of Ethernet switch, the method comprises following steps: when a certain line card receives a data packet from an switching port, according to the MAC address learned from the data packet, the MAC forwarding list of the line card is updated according to the MAC address learned from the data packet, and the learning information of the MAC address is notified to the main control card and other line cards; when the line card receives the data packet from the interconnecting port, the learning of the MAC address can not performed; the line card performs aging process for the MAC address learned from the switching port in the oneself MAC forwarding list, and notifies the aging information of the MAC address to the main control card and other line cards, the aging process of each MAC forwarding list can be performed according to the aging information of the MAC address. The invention also discloses a distributed Ethernet switch capable of conveniently implementing the MAC address maintenance inside of the distributed Ethernet switch, the communication between boards can be reduced, and the processing logic can be simplified.

Owner:ZTE CORP

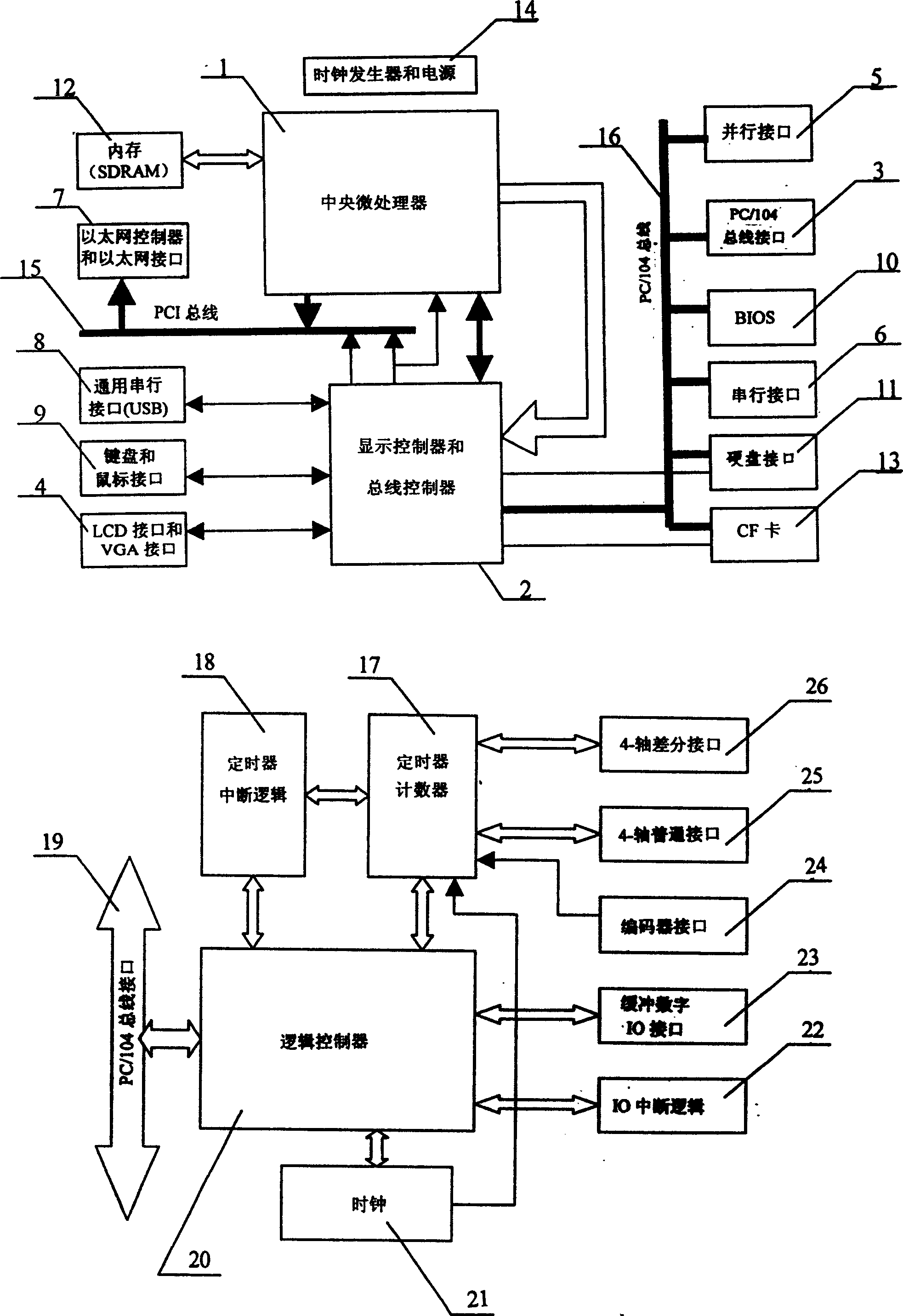

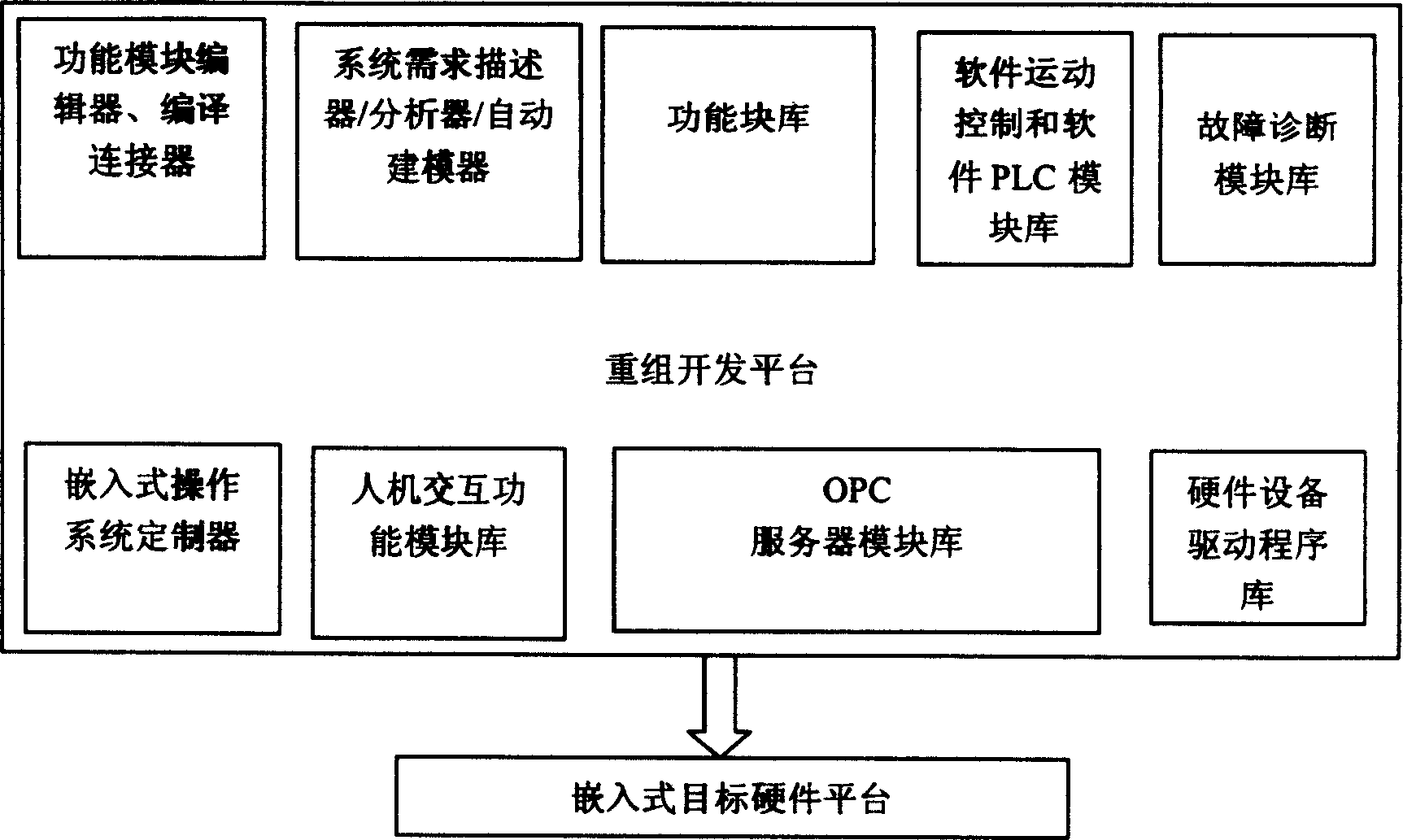

Opening rearrangeable soft digital control system

InactiveCN1601415AIncrease flexibilityQuick responseComputer controlNumerical controlOperational systemDigital control

The invention relates to an open recombinable soft numerical control system. Said system is formed from 32-bit and more than 32-bit embeddent single board computer, digital IO interface card and recombinable development platform consisting of software package. The display controller in the single board computer and bus controller are connected with CF card, and the running software can utilize digital interface board to implement real-time control of machine tool. Said recombinable development platform includes systematic requirement description device / analyzer / automatic modelling device, function block editor, function block connector, function block compilation device, function block library, software movement control and softawre PLC module library, fault diagnosis module library, man-machine interactive function module library, embedded object connection process control server module library, hardware drive program library and embedded operation system custom device.

Owner:SOUTH CHINA UNIV OF TECH

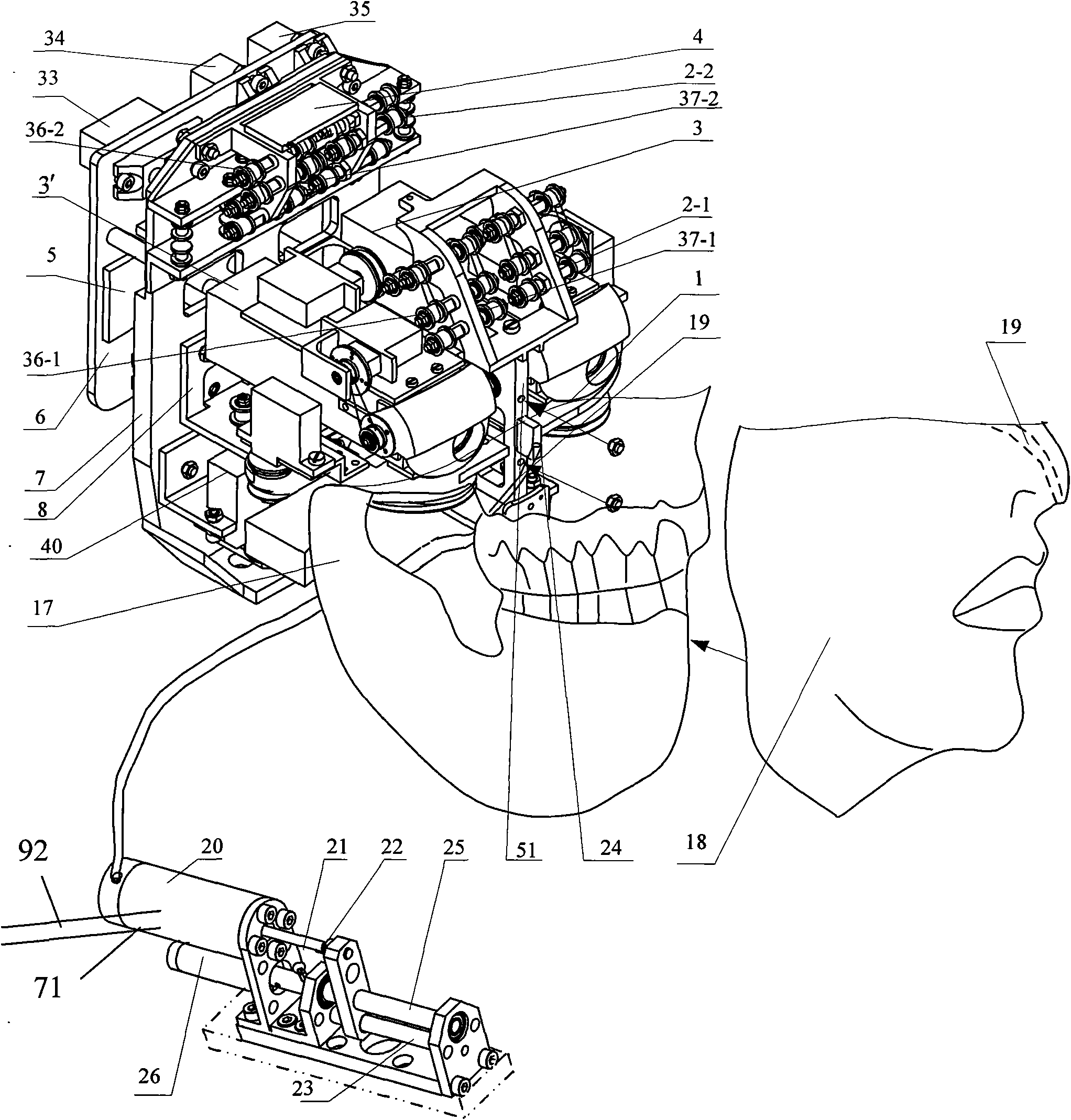

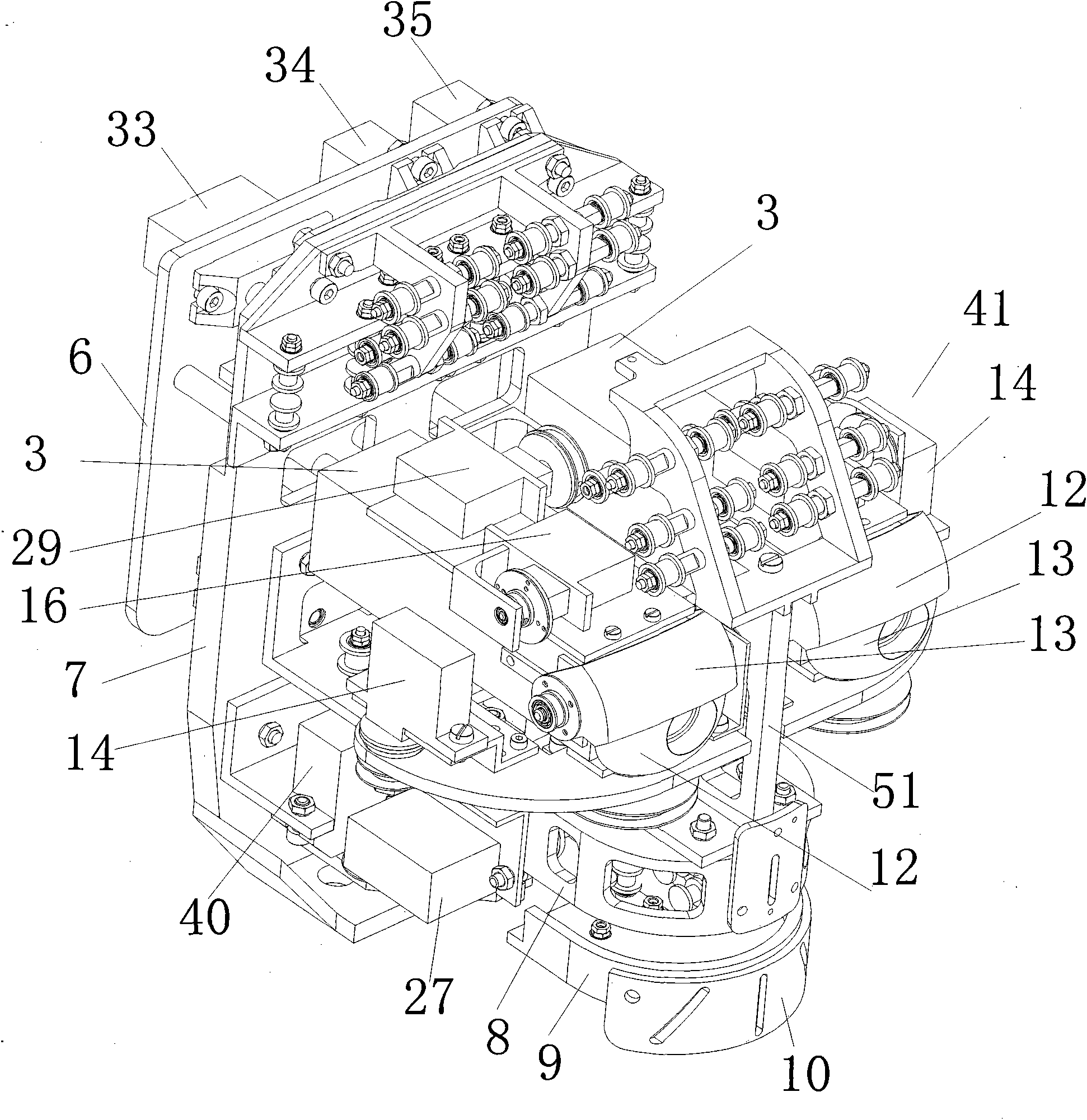

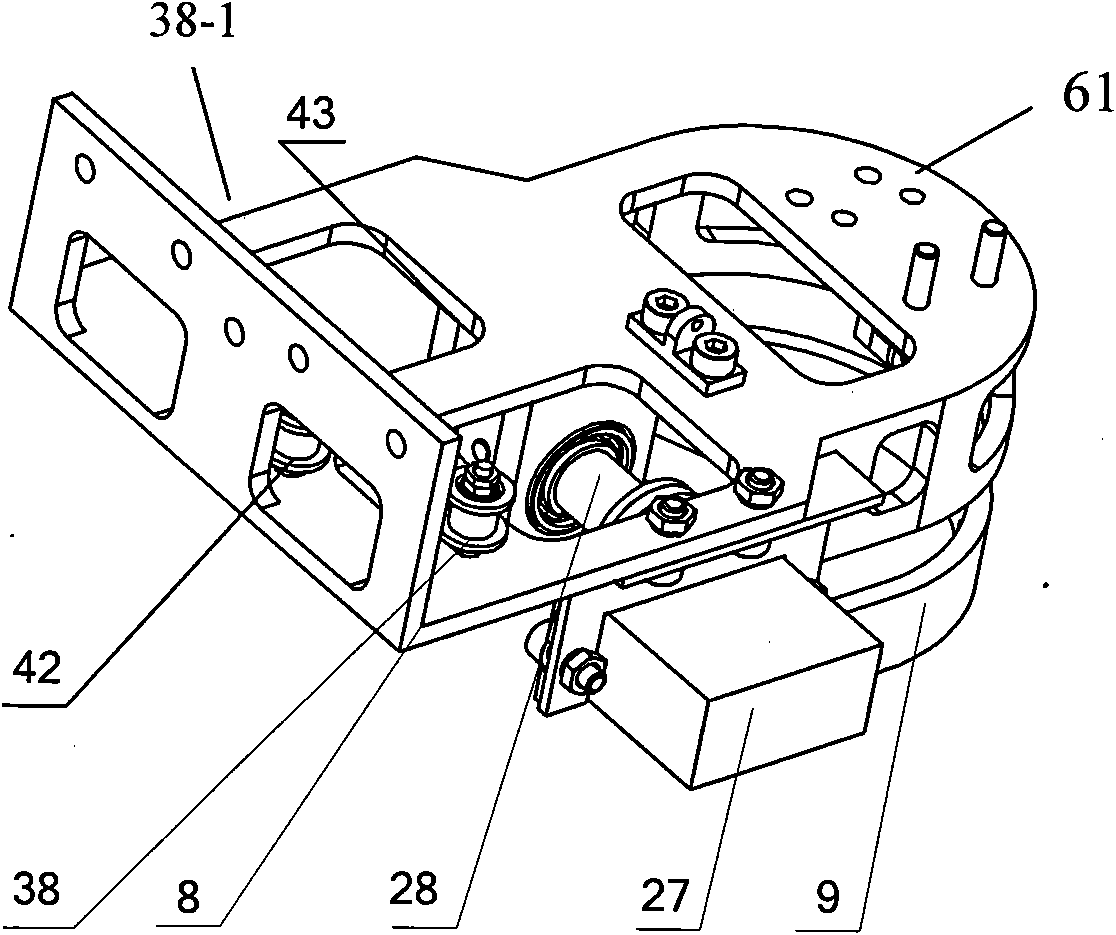

Humanoid-head robot device with human-computer interaction function and behavior control method thereof

ActiveCN101618280AAvoid Definition ConflictsAdd attribute collectionDollsSelf-moving toy figuresBehavior controlEngineering

The invention relates to a humanoid-head robot and a behavior control method thereof, in particular to a humanoid-head robot device with human-computer interaction function and the behavior control method thereof, solving the problems that the prior humanoid-head robot can not completely realize the reproduction of human facial expressions, has limited perceptive function and does not have manual feeling models and the human-computer interaction function. The behavior control method comprises the following steps: a sensor perceptive system outputs perceived information to a main control computer for processing; control system software in a robot behavior control system obtains the relative control quantity of a corresponding motor according to the manual feeling models, executes a motion control instruction to output a PWM pulse by a motion control card to drive the corresponding motor to move to an appointed position and realize the human-computer interaction function and various feeling reactions of a robot; and the sensor perceptive system perceives external feeling signals, recognizes corresponding feeling signals and utilizes the manual feeling models to realize the behavior control of the robot. The invention realizes the reproduction of the human facial expressions and has anthropopathic multi-perception function, such as smell, touch, vision, and the like.

Owner:HARBIN INST OF TECH

Switchover for broadband subscriber sessions

ActiveUS7929424B2Multiplex system selection arrangementsError preventionChannel state informationCross connection

Methods and apparatuses for process a crossconnect switchover in a network element are described. According to one embodiment, an exemplary method includes synchronizing state information regarding broadband subscriber sessions of one or more circuits of a network element between one or more hub devices of an active control card and a standby control card of the network element, and in response to a crossconnect switchover, starting up one or more sessions associated with the one or more hub devices of the standby control card using the synchronized information, such that the one or more sessions are started up as if they are restarted. Other methods and apparatuses are also described.

Owner:TELEFON AB LM ERICSSON (PUBL)

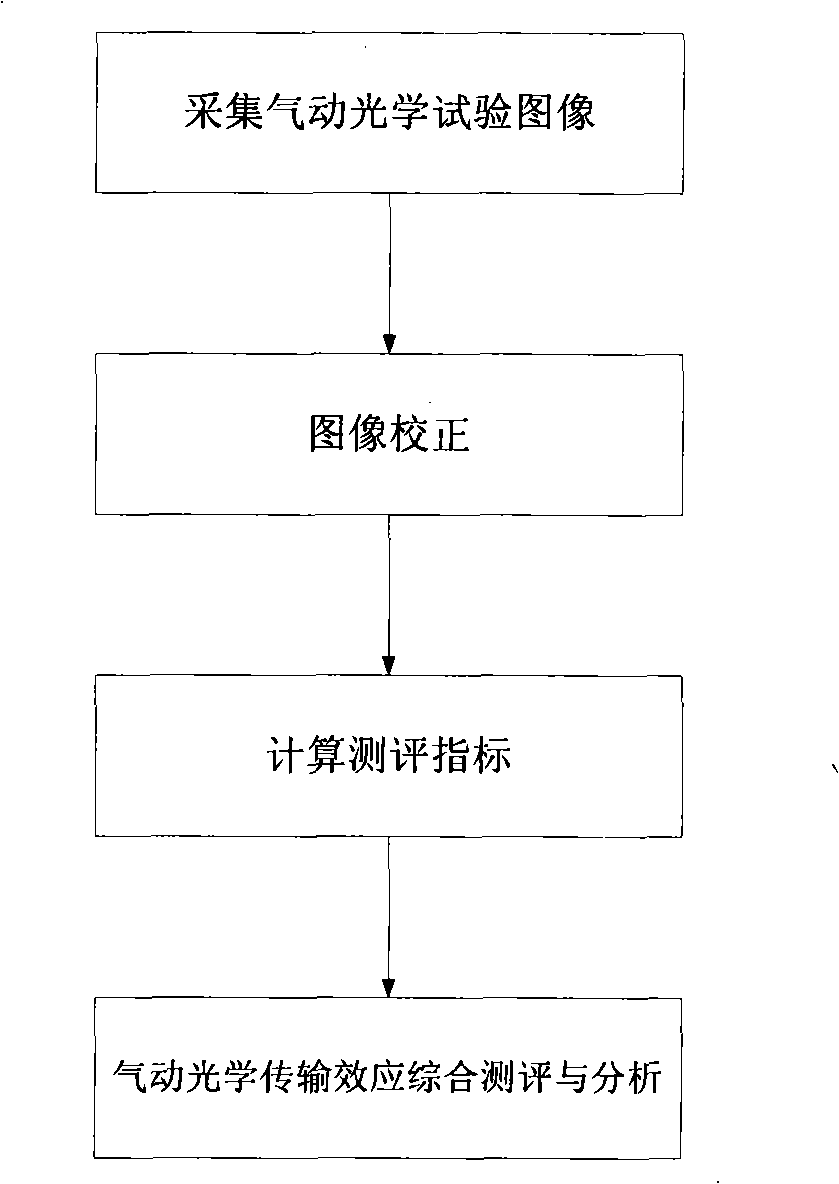

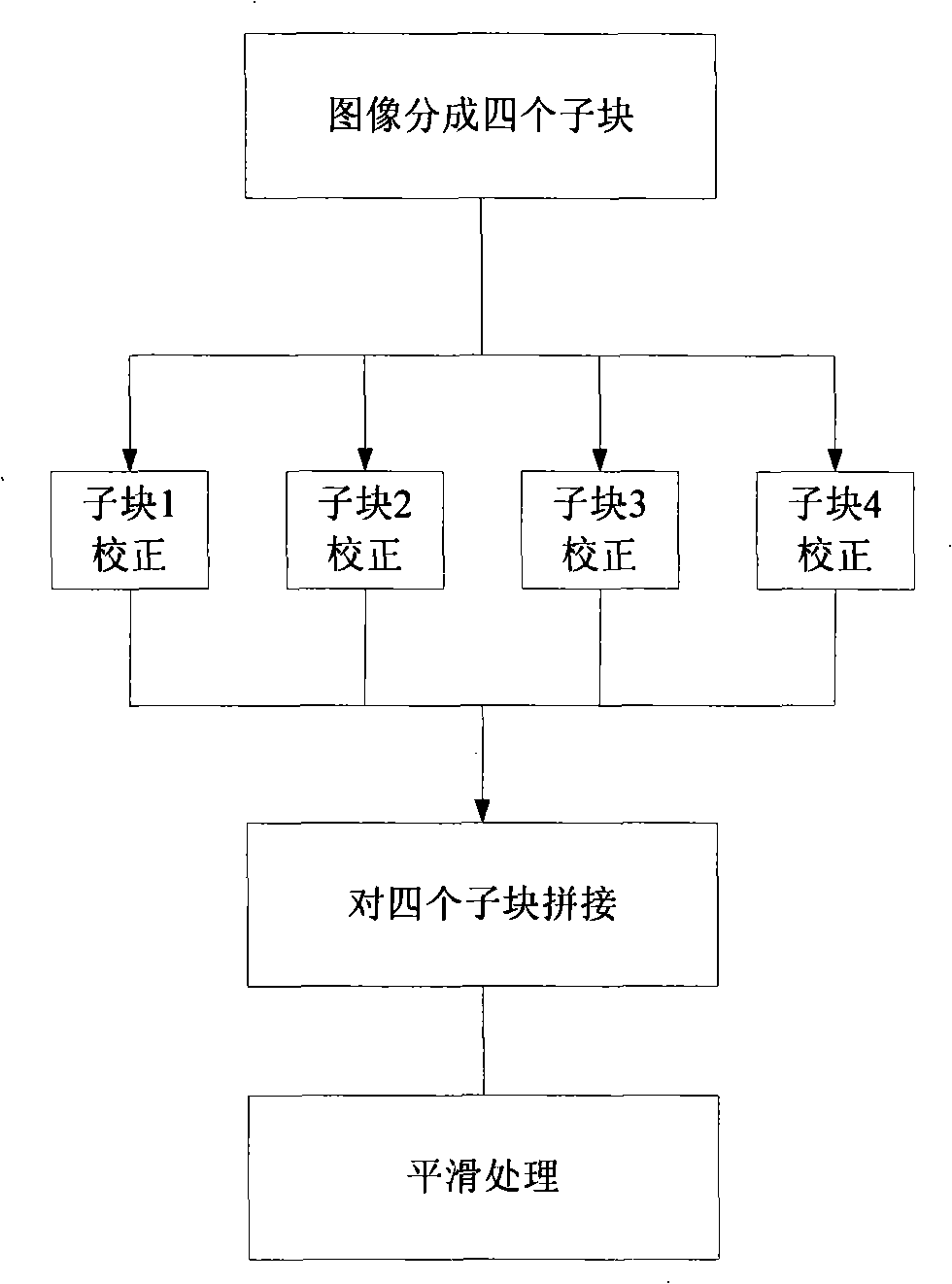

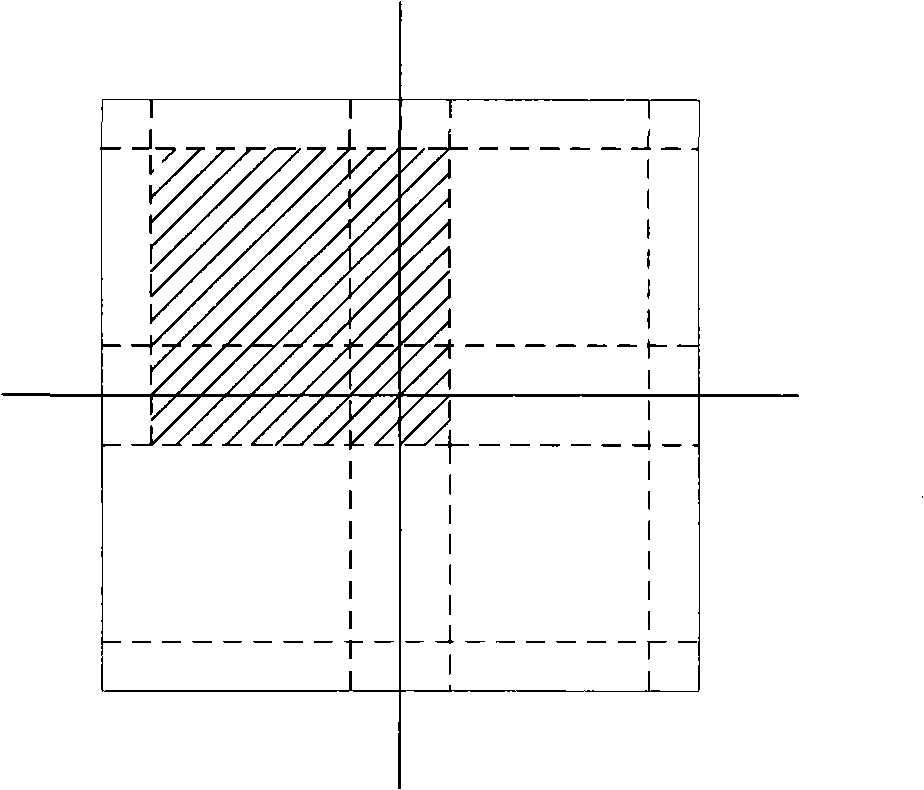

Sequence image correction based pneumatic optical transmission effect evaluation method and apparatus

InactiveCN101261176AImprove scalabilityImprove real-time performanceAerodynamic testingExtensibilityPoint spread function

The invention discloses a pneumatic optical transmission effect evaluation method and a device which are based on sequence image correction. The pneumatic optical transmission effect evaluation method calculates a correction image and a point spread function by three correction methods of space blocking concurrent correction, two-dimensional sampling concurrent correction and concurrent iterative correction, and gains the evaluation indexes by further calculation; the evaluation indexes are used for measuring, analysing and evaluating the pneumatic optical transmission effect. Aiming at the pneumatic optical transmission effect evaluation method, a calculation processing device based on a host computer, a multifunctional image collecting control card and a concurrent digital signal assist processing card is designed. The collecting, processing, memorizing and displaying of different passage image source data can be achieved by the calculation processing device; by virtue of the characteristics of high parallelism of the evaluation device calculation and the extensibility of the processing unit, the quantity of the calculation processing units is smartly adopted so as to achieve the real-time processing; the evaluation device of the invention has the advantages of small volume, light weight, and easy carry.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com