Full-automatic wafer dicing saw control system based on vision

A control system and fully automatic technology, which is applied in the direction of manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problem that the automation degree and function of the dicing machine cannot meet the reliability and technical performance requirements of electronic devices, and cannot meet the high requirements of wafer products. Efficiency, high-precision production requirements, high cost of dicing machine equipment, etc., to achieve the effect of friendly man-machine interface, promote automation intelligence, processing and parameter optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

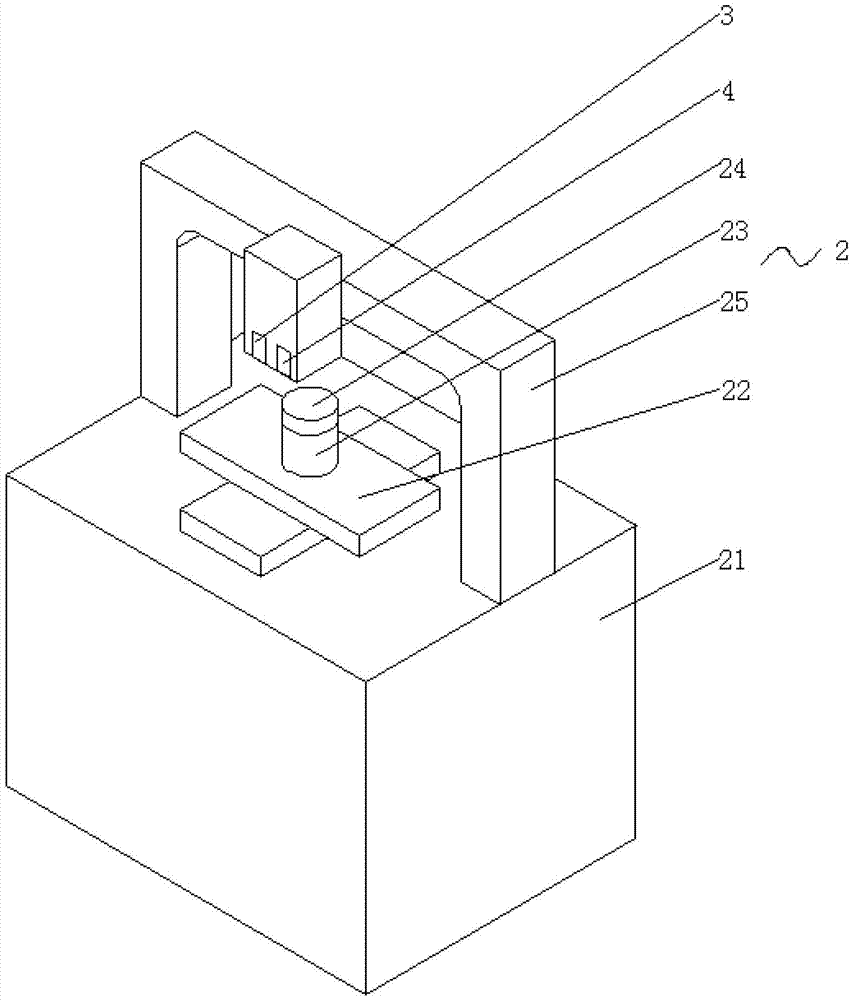

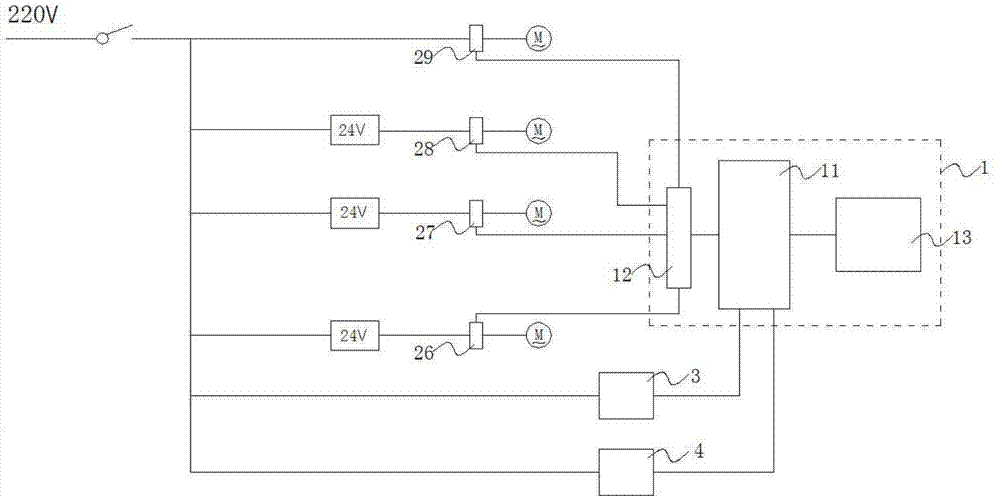

[0017] like figure 1 or figure 2 As shown, the present invention adopts the following technical solutions, and the vision-based fully automatic wafer dicing machine control system 1 is respectively connected with the machine tool equipment platform 2, the laser device 3, and the industrial microscope camera 4. In a specific embodiment of the present invention, due to the The accuracy requirement of the machine tool equipment platform 2 is very high, and the whole equipment must be in a constant temperature room to eliminate the influence of temperature changes on the accuracy of the machine tool equipment platform 2; the machine tool equipment 2 platform includes a machine tool base 21, and a There is an XY axis motion platform 22, a direct drive motor 23 is arranged on the XY axis motion platform 22, an adsorption device 24 is arranged above the direct drive motor 23, and the wafer is fixed on the adsorption device 24; above the XY axis motion platform 22 Also be provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com