Numerical control drilling-milling apparatus having a plurality of independent process systems

An independent processing and system technology, applied in feeding devices, metal processing, metal processing equipment, etc., can solve the problem that the multi-head CNC drilling and milling machine cannot perform processing independently, and achieve the effect of high production efficiency, meeting production requirements and flexible application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

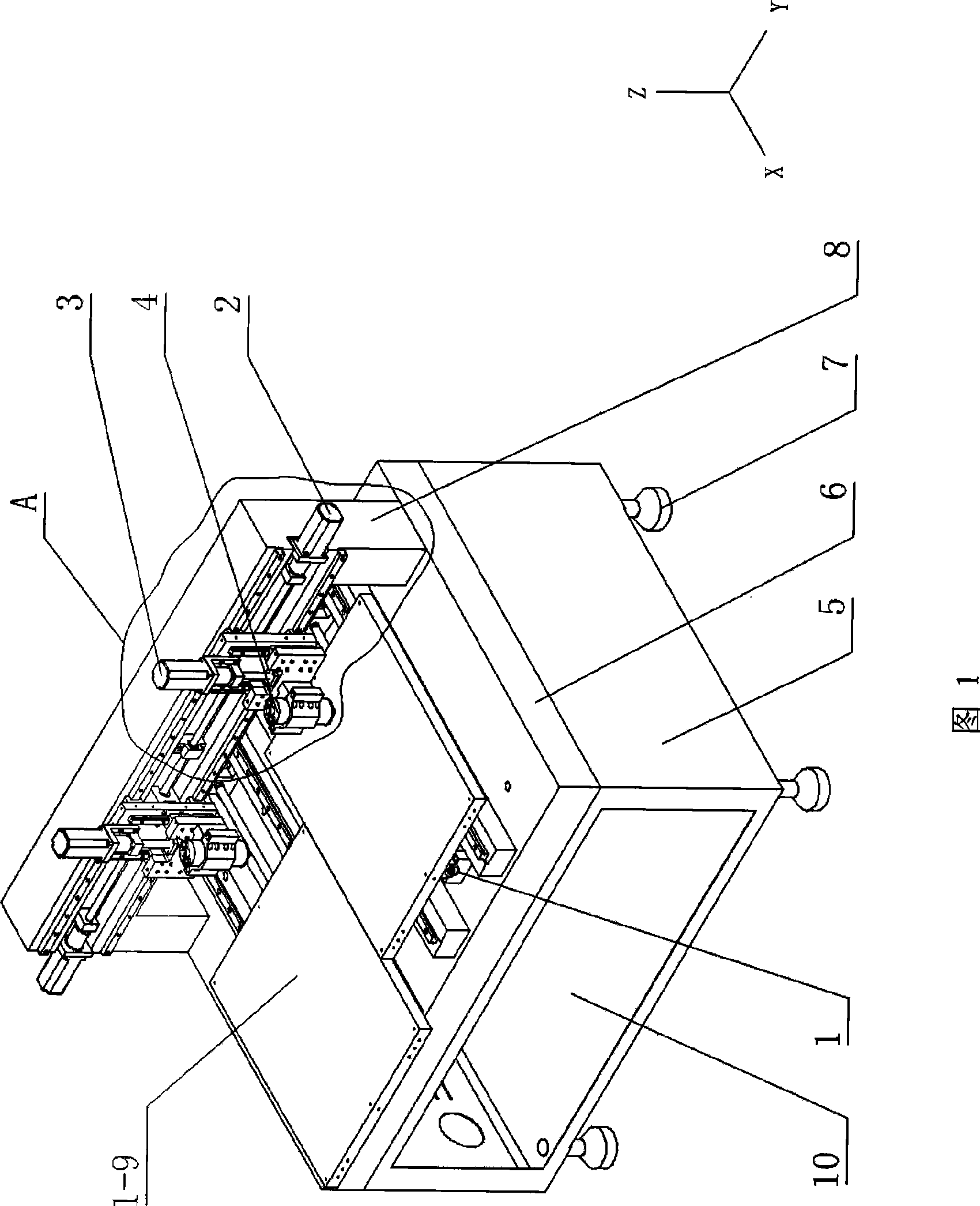

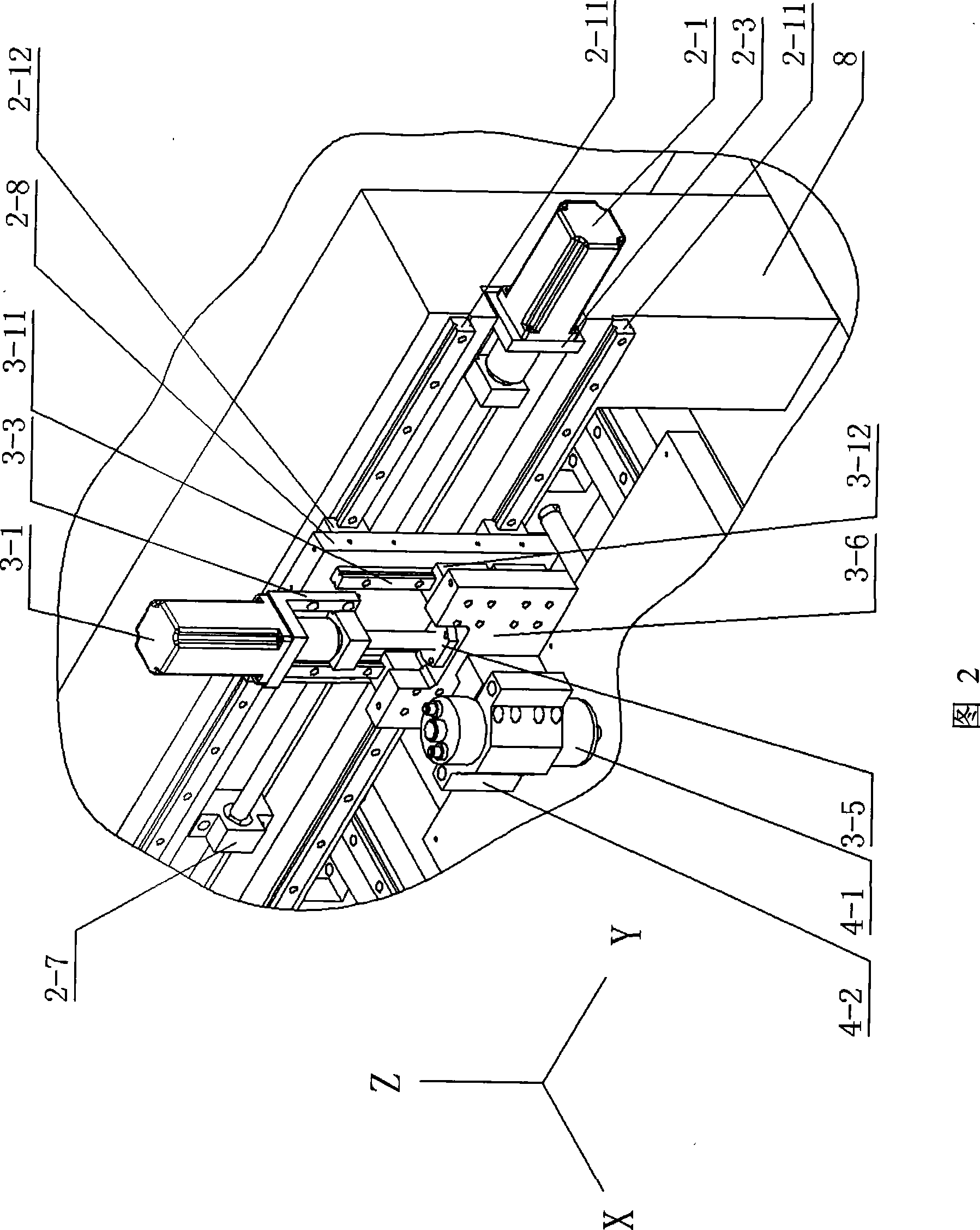

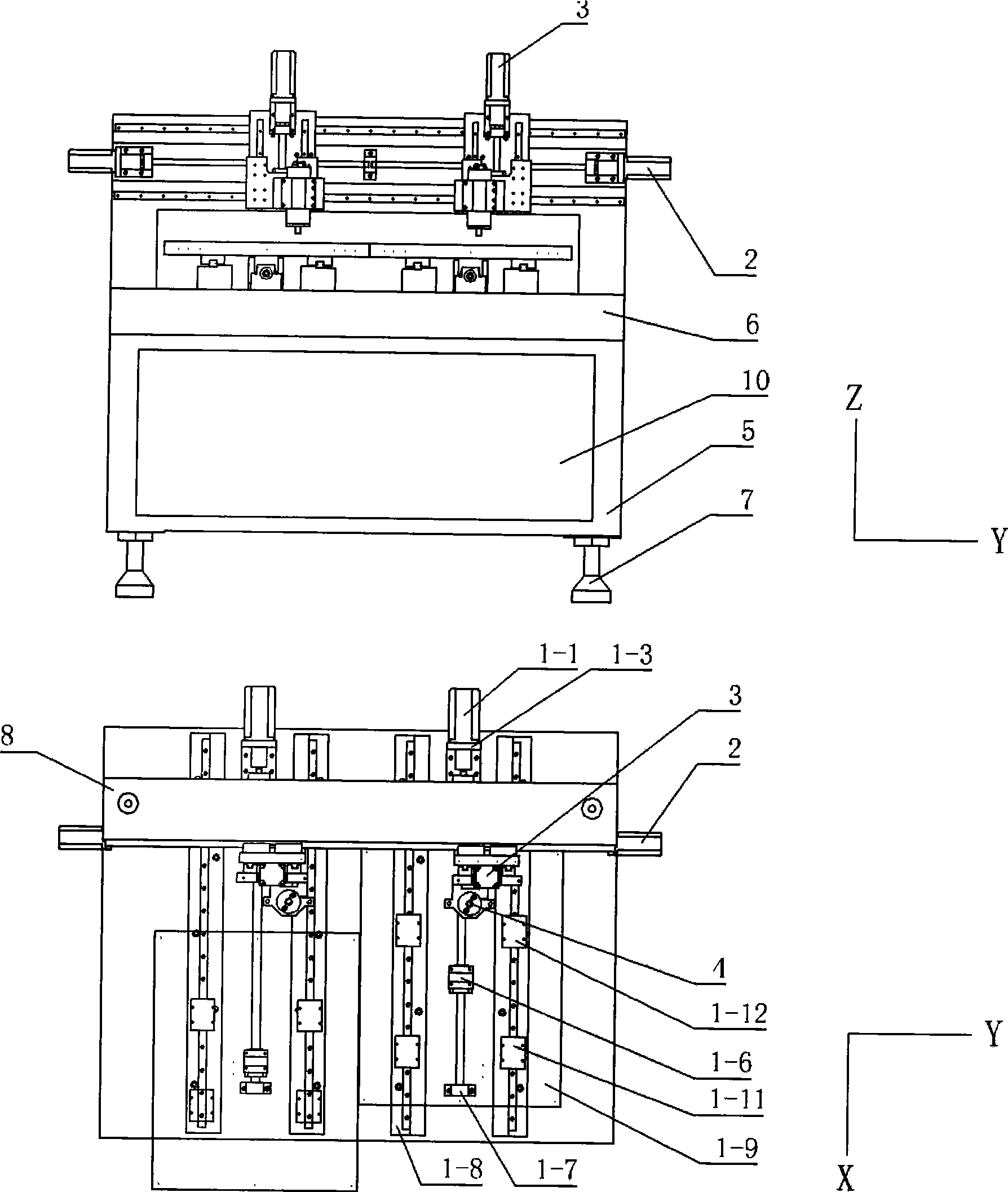

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: as Fig. 1, image 3 As shown, a CNC drilling and milling device with multiple independent processing systems includes a control computer and a drilling and milling machine. The computer is provided with a control card and is connected to the drilling and milling machine through the interface of the control card. The drilling and milling machine includes a machine tool frame and Processing unit, described processing unit is arranged on machine tool frame, and described machine tool frame comprises: machine base 5, lathe bed 6 and gantry 8, and described processing unit comprises: feeding device and spindle device 4, and described machine base 5 is set There is an electric cabinet 10 and a foot 7. The feed device includes an X-axis feed mechanism 1, a Y-axis feed mechanism 2 and a Z-axis feed mechanism 3. The X-axis feed mechanism 1 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com