Equipment and method using fermentation dross to produce high activity high nutrition forage

A high-nutrition, high-activity technology, applied in feed, animal feed, animal feed, etc., can solve the problems of poor applicability, large energy loss, high alcohol concentration, etc. The effect of high rate of increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

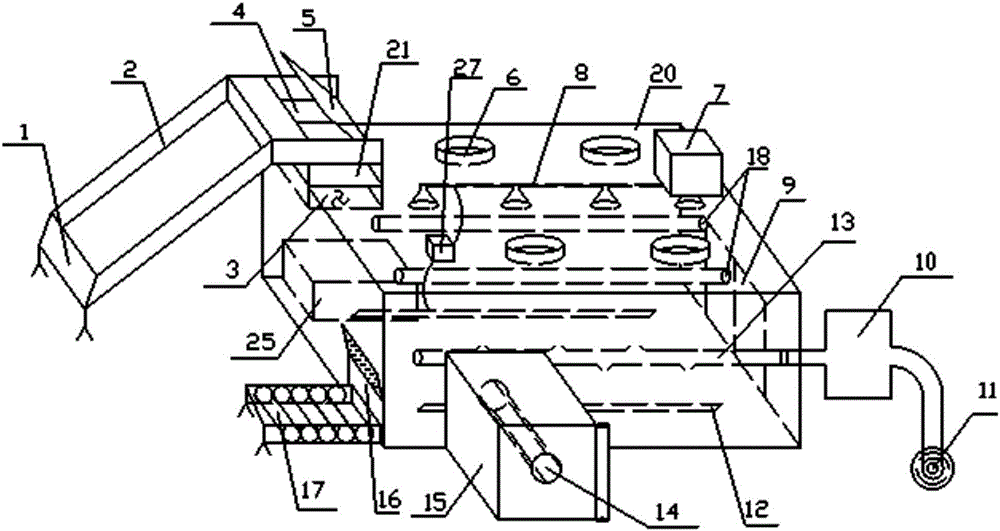

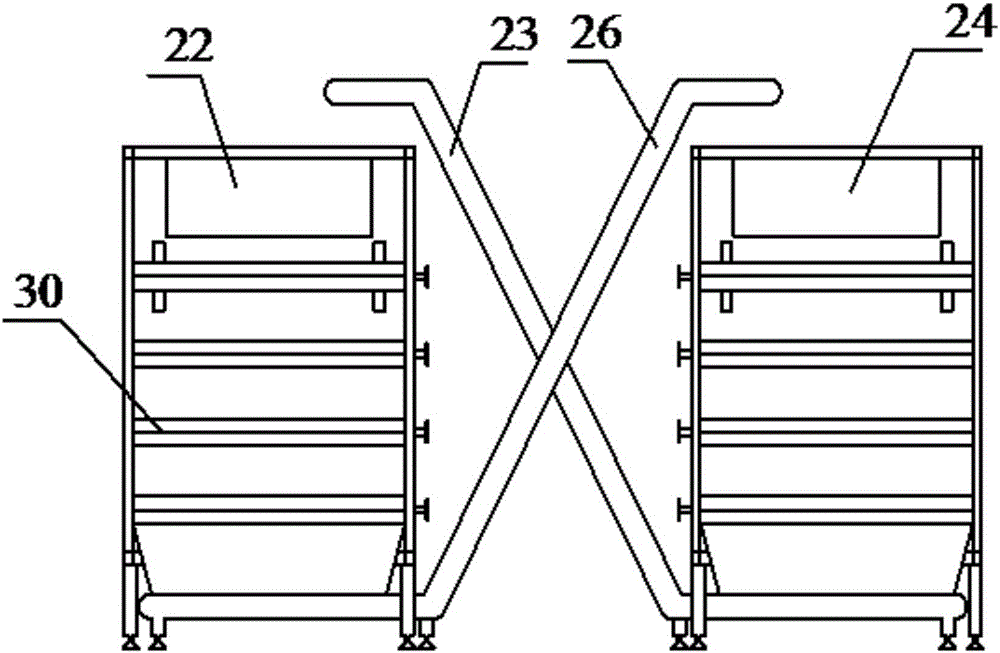

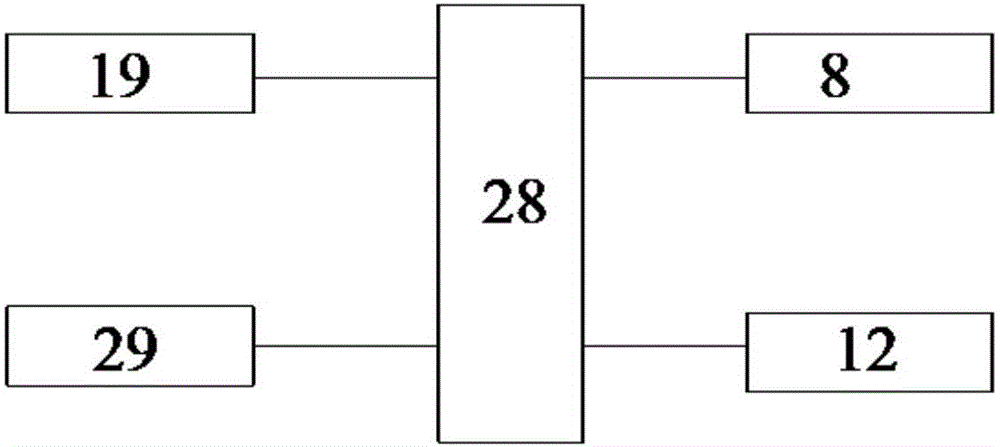

Method used

Image

Examples

preparation example Construction

[0061] (1) Preparation of liquid strains

[0062] A, preparation of edible fungus strains: Inoculate the mycelia of edible fungi through plate activation into comprehensive potato juice culture medium (being the PDA culture medium indicated in the conventional technology), its culture condition is: culture temperature 15 ℃- 28°C, shaker speed 60-180r / min, incubation time 48-96h;

[0063] B, preparation of filamentous fungi (mold) strains: filamentous fungi such as Aspergillus, Rhizopus, Trichoderma, Penicillium are inoculated in Cha's culture medium, and its culture condition is: culture temperature 20 ℃-28 ℃, shaking table speed 100 -180r / min, culture time 24-48h;

[0064] C. Preparation of yeast strains: Inoculate yeasts such as Candida utilis, Saccharomyces cerevisiae, and Geotrichum candida that have been activated on the plate into the wort medium. The culture conditions are: culture temperature 20°C-32°C, shaker speed 120-180r / min, culture time 24-36h;

[0065] D. Pre...

Embodiment 1

[0082] A method for fermenting dross to produce high-activity high-nutrition feed, comprising the following steps:

[0083] Step 1, preparation of strains:

[0084] (1) Preparation of liquid strains: A, preparation of edible fungus strains: inoculate the Pleurotus ostreatus mycelia through plate activation in the comprehensive potato juice medium, and its culture conditions are: culture temperature 22°C-28°C, shaker The rotation speed is 150-180r / min, and the cultivation time is 48h; B. Preparation of mold strains: Inoculate the Aspergillus oryzae activated on the plate into Cha's culture medium, and the cultivation conditions are: cultivation temperature 20°C-28°C, shaker speed 150- 180r / min, culture time 48h; C. Yeast strain preparation: Inoculate the plate-activated Candida into the wort medium, the culture conditions are: culture temperature 25°C-30°C, shaker speed 150-180r / min, culture time 24h; D, preparation of bacillus strains: inoculate the bacillus activated on the...

Embodiment 2

[0090] A method for fermenting dross to produce high-activity high-nutrition feed, comprising the following steps:

[0091] Step 1, preparation of strains:

[0092] (1) Preparation of liquid strains: A, preparation of edible fungus strains: inoculate the mycelium of Bailing mushroom edible fungus through plate activation in the potato juice medium, and its culture condition is: 22 ℃-28 ℃ of culture temperature, The shaker speed is 150-180r / min, and the culture time is 48h; B. Preparation of mold strains: Aspergillus niger activated on the plate is inoculated into Cha's medium, and the culture conditions are: culture temperature 20°C-28°C, shaker speed 150-180r / min, culture time 48h; C. Yeast strain preparation: Inoculate the plate-activated Geotrichum candidum into the wort medium, the culture conditions are: culture temperature 25°C-32°C, shaker speed 150- 180r / min, culture time 24h; D. Preparation of Bacillus strains: Inoculate the Bacillus natto that has been activated on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com