Preparation method for chlorella anti-oxidative peptide

A technology of antioxidant peptides and chlorella, applied in biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., to achieve high efficiency, strong antioxidant activity, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1 Extraction process of chlorella protein

[0041] 1.1 Materials and reagents

[0042] Chlorella dry powder, from Hangzhou Huadan Agricultural Products Co., Ltd., Zhejiang Province; Bio-Rad Protein Assay kit, purchased from Bio-Rad Laboratories Inc; copper sulfate, potassium sulfate, sulfuric acid, boric acid, sodium hydroxide, 95% ethanol, mixed Indicator solution (2 parts of methyl red ethanol solution and 1 part of methylene blue ethanol solution are mixed immediately before use).

[0043] 1.2 Experimental Instruments

[0044] Enzyme-linked immunoassay instrument (Model-550), American Bio-Rad company; High-speed refrigerated centrifuge (5415R), German Eppendorf company; Electronic balance (BS224S); Kjeldahl nitrogen analyzer (KDY-9820) AL04 electronic balance, HH-2 water bath, DHG-9240A blast drying oven, DL-5M centrifuge (with replacement rotor), SANYO ultra-low temperature refrigerator.

[0045] 1.3 Experimental method

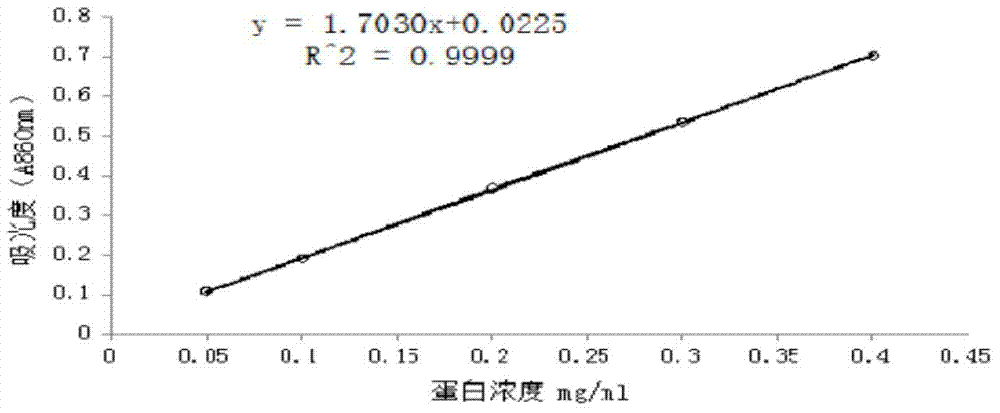

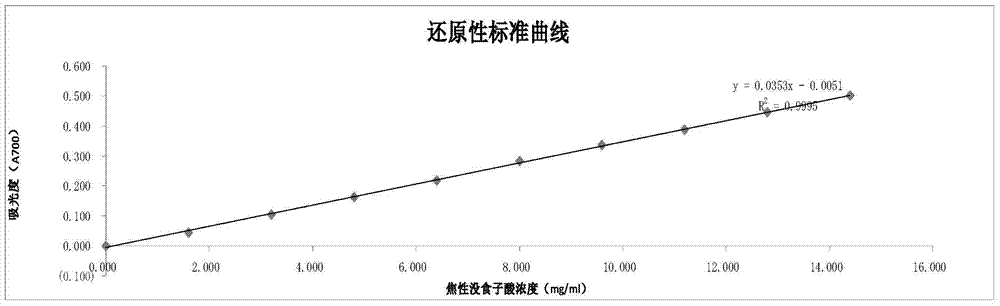

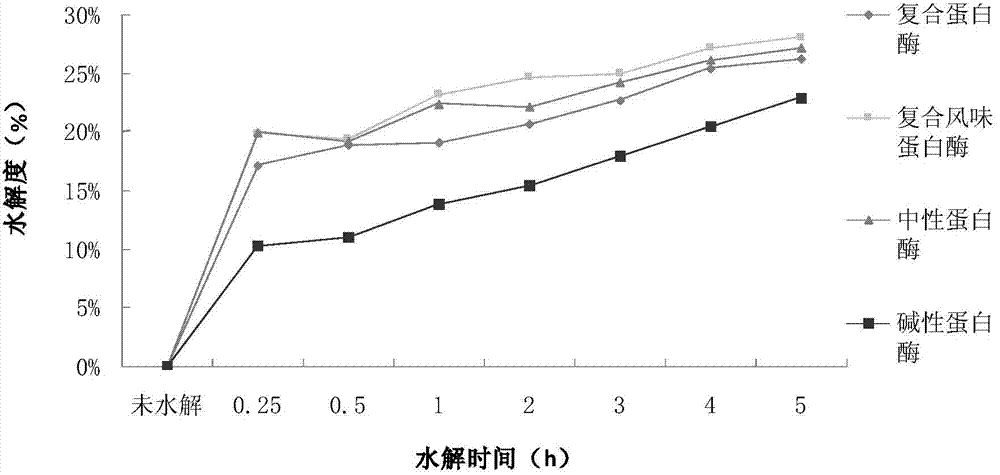

[0046] 1.3.1 Determination of protein co...

Embodiment 2

[0114] Take 20g of chlorella powder, add 400ml of distilled water at a material-to-liquid ratio of 1:20 (m / v), and stir for 1 hour at 4°C; slowly put the chlorella suspension into an ultra-low temperature refrigerator, and freeze at -70°C 12h; then thaw at 30°C to 4°C, slowly add NaOH to the thawed chlorella mixture to a final concentration of 1%, and keep stirring to obtain an alkaline mixture; at 4°C, the alkali The mixed solution was ultrasonically broken for 60 minutes, and the ultrasonic condition was 30KHz, and then the pH was adjusted to 7.0 with 0.5M hydrochloric acid; centrifuged at 4000rpm for 20 minutes, and the supernatant was taken; 95% ethanol solution with a volume fraction of 4 times the volume of the supernatant was added , continuously stirred for 1 min, and stood still for 5 h; centrifuged at 2000 rpm for 10 min, discarded the supernatant, dissolved the precipitate in 50 mL of distilled water, concentrated it to about 30 mL, and obtained 2.26 g of chlorella p...

Embodiment 3

[0121] Take 20g of chlorella powder, add 400ml of distilled water at a material-to-liquid ratio of 1:20 (m / v), and stir for 1 hour at 4°C; slowly pour the chlorella suspension into a high-pressure homogenizer, and adjust the pressure to 100MPa , repeated 20 times, and then in 4°C environment, slowly add NaOH to the chlorella mixed solution after high-pressure homogenization treatment to a final concentration of 1%, and keep stirring to obtain an alkaline mixed solution; Under normal circumstances, the alkaline mixed solution was treated with ultrasonic wall breaking for 60min, and the ultrasonic condition was 30KHz, and then the pH was adjusted to 7.0 with 0.5M hydrochloric acid; centrifuged at 4000rpm for 20min, and the supernatant was taken; a volume fraction of 4 times the volume of the supernatant was added to 95 % ethanol solution, continuously stirred for 1 min, and stood still for 5 h; centrifuged at 2000 rpm for 10 min, discarded the supernatant, dissolved the precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com