Method for preparing palladium-based composite membranes

A composite membrane and hydrogen permeable technology, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as damage, tedious and time-consuming activation and sensitization steps, and increase stability and benefit integrity , the effect of increasing flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of sheet-type supported palladium membrane

[0026] ZrO with a geometric size of 29mm in diameter, 3mm in thickness and an average pore diameter of 0.2μm is used 2 Chip support.

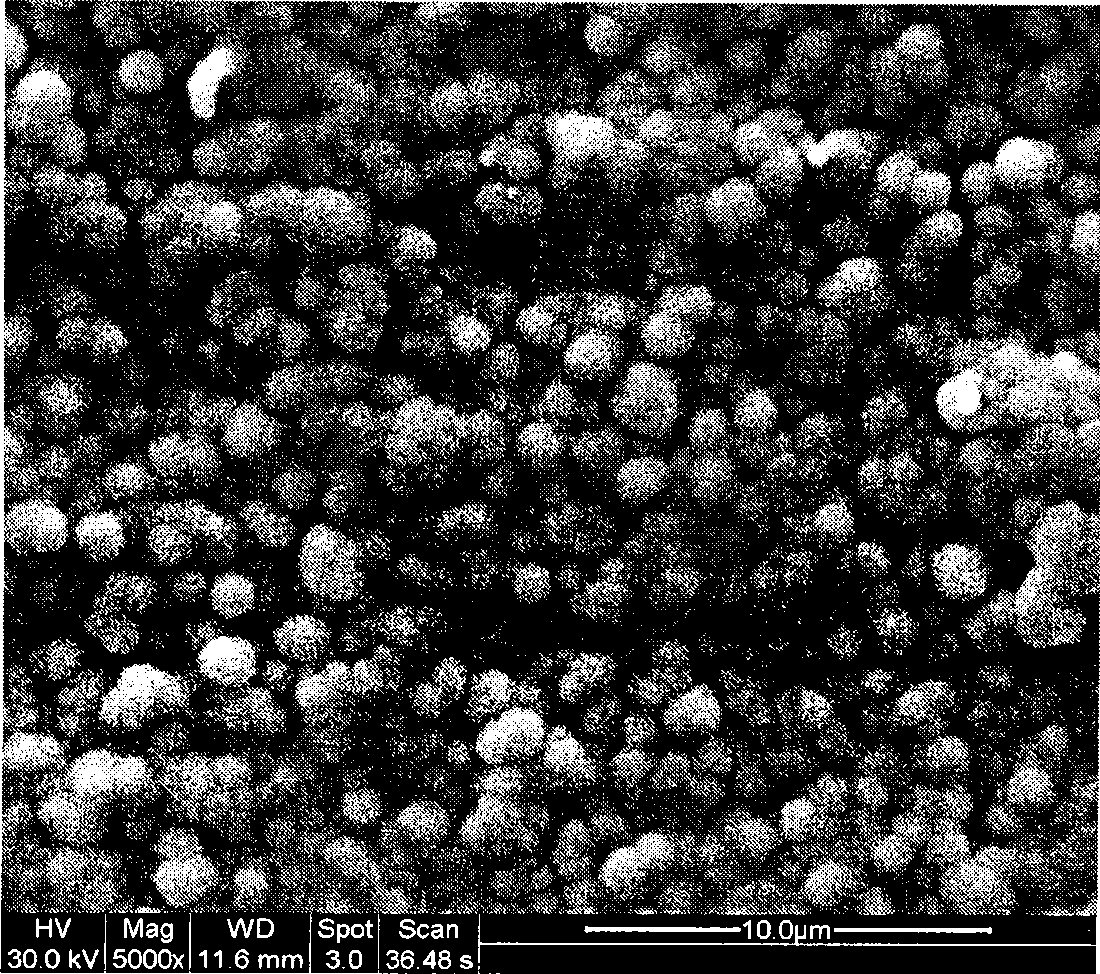

[0027] 1) Preparation of nano-palladium and ceramic mixed slurry: 0.5g nano-palladium powder and 75g TiO with an average particle size of 200nm 2 The powder is added to 500 g of water, and then 5 g of dispersant polyethyleneimine and 10 g of thickener methyl cellulose are added to prepare a uniformly dispersed and stable mixed slurry of nano-palladium and ceramics.

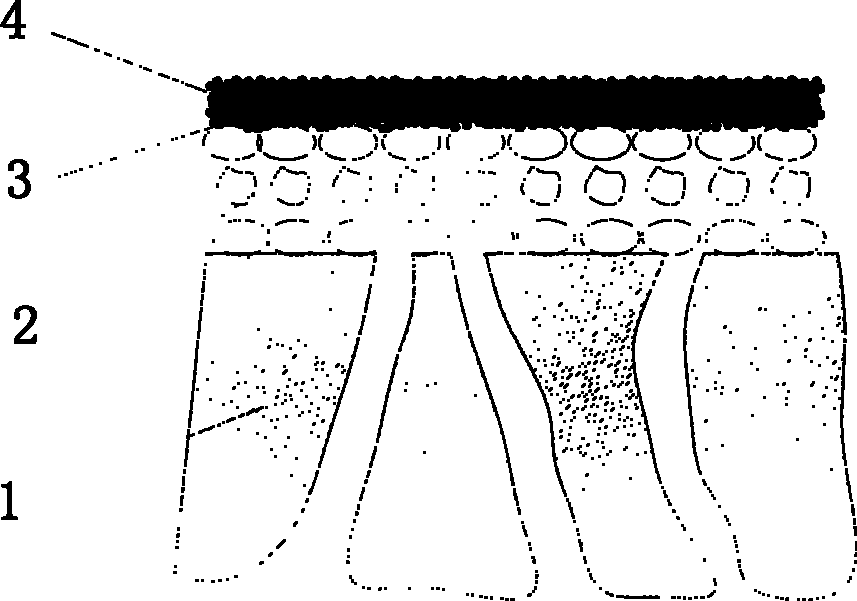

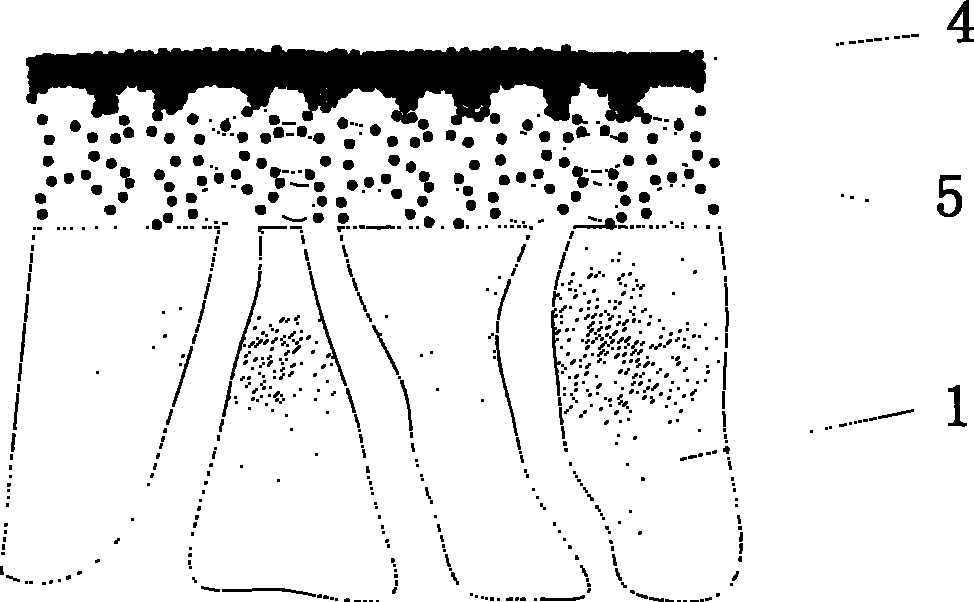

[0028] 2) Preparation of small pore diameter nano-palladium and ceramic composite transition membrane layer: the flake ceramic ZrO 2 The support was slurried in the slurry prepared in step 1) for 10 seconds, dried at 30°C, and then placed in an atmosphere furnace to be calcined at 700°C for 2 hours. The surface of the macroporous support formed with a pore size of 70nm and a thickness of 5μm. Nano-palladium and ...

Embodiment 2

[0030] Example 2: Preparation of Tubular Supported Palladium Membrane

[0031] One end of the tubular support used is glaze-sealed, with a geometric outer diameter of 12mm and a total length of 33cm. The support is α-Al 2 O 3 , The thickness is 2mm, the average pore diameter is 0.2μm, the coatable film length is 5cm, and the area is 18.84cm 2 , The remaining part is coated with glaze and sealed.

[0032] 1) Preparation of nano-palladium and ceramic mixed slurry: 10g nano-palladium powder and 100g ZrO with an average particle size of 300nm 2 The powder is added to 500 g of water, and then 10 g of dispersant polymethacrylic acid and 15 g of thickener methyl cellulose are added to prepare a uniformly dispersed and stable mixed slurry of nano-palladium and ceramics.

[0033] 2) Preparation of small pore diameter nano-palladium and ceramic composite transition membrane layer: the tubular ceramic α-Al 2 O 3 The support was slurried in the slurry prepared in step 1) for 20 seconds, dried...

Embodiment 3

[0035] Example 3: Preparation of Tubular Supported Palladium Membrane

[0036] One end of the tubular support used is sealed with glaze, with a geometric outer diameter of 12mm and a total length of 50cm. The support is α-Al 2 O 3, Thickness 2mm, average pore diameter 0.5μm, coating film length is 33cm, area is 124.34cm 2 , And the remaining part is glaze sealed.

[0037] 1) Preparation of nano-palladium and ceramic mixed slurry: 40g nano-palladium powder and 50g Al with an average particle size of 400nm 2 O 3 Powder and 75g ZrO with an average particle size of 300nm 2 The powder is added to 500 g of water, and 15 g of dispersant sodium dodecylbenzene sulfonate and 20 g of thickener sodium carboxymethyl cellulose are added to prepare a uniformly dispersed and stable mixed slurry of nano-palladium and ceramics.

[0038] 2) Preparation of small pore diameter nano-palladium and ceramic composite transition membrane layer: the tubular ceramic α-Al 2 O 3 The support was slurried in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com