Device and method for researching hydrogen permeation behavior of metal subjected to dead-load pulling stress in gaseous medium

A gaseous medium and tensile stress technology, applied in the direction of material electrochemical variables, can solve the problems of lack of reasonable evaluation devices and methods, difficulty in measuring hydrogen permeation current, etc., and achieve the effect of high precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

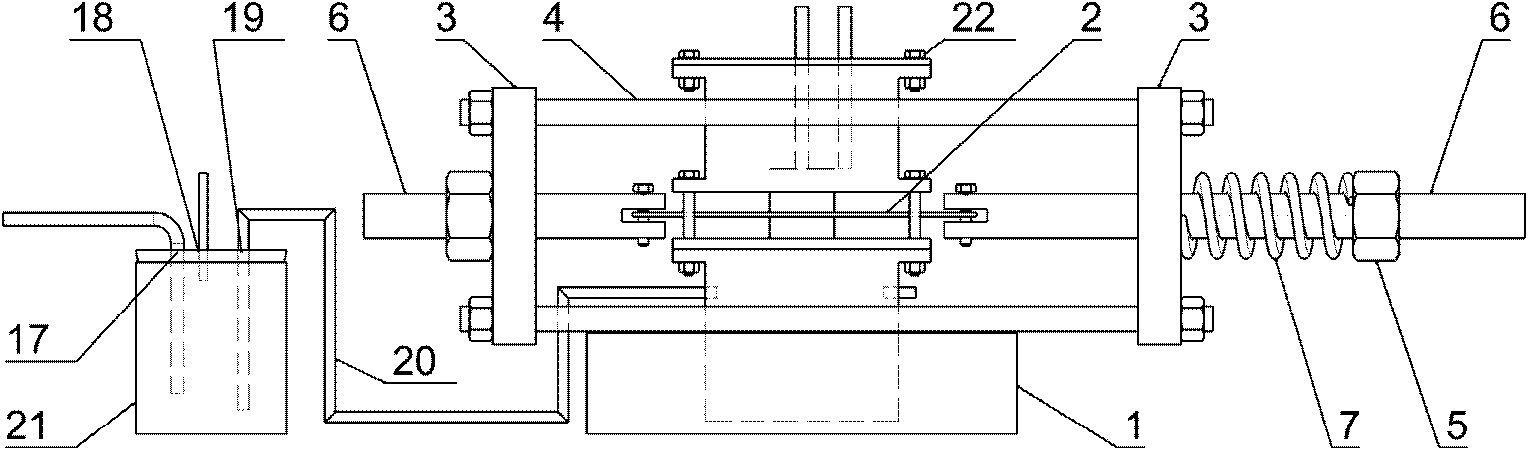

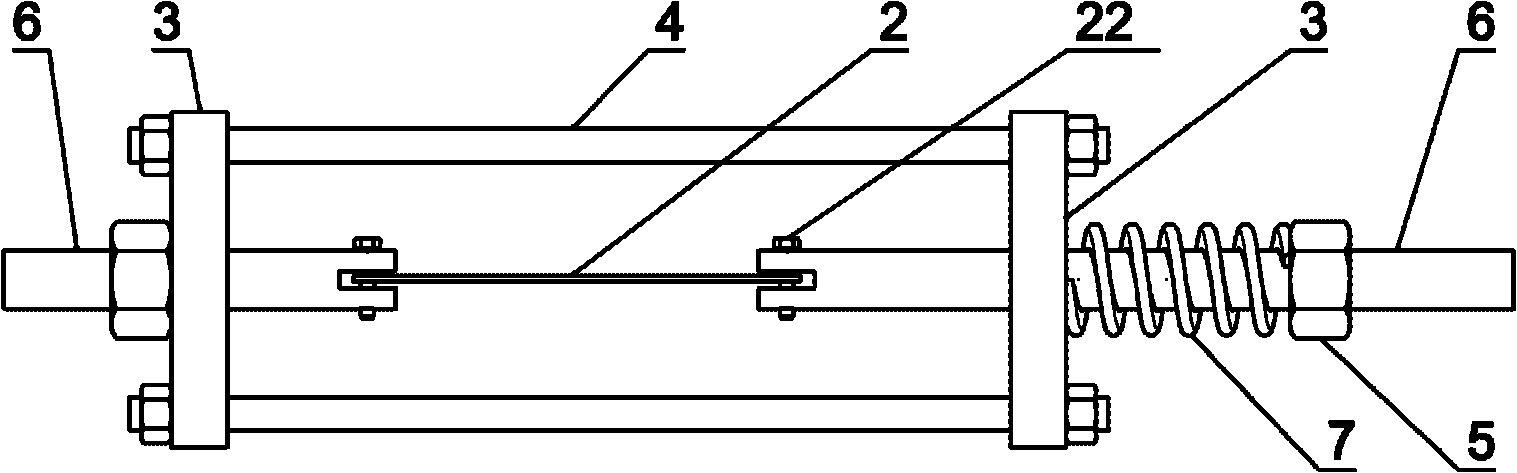

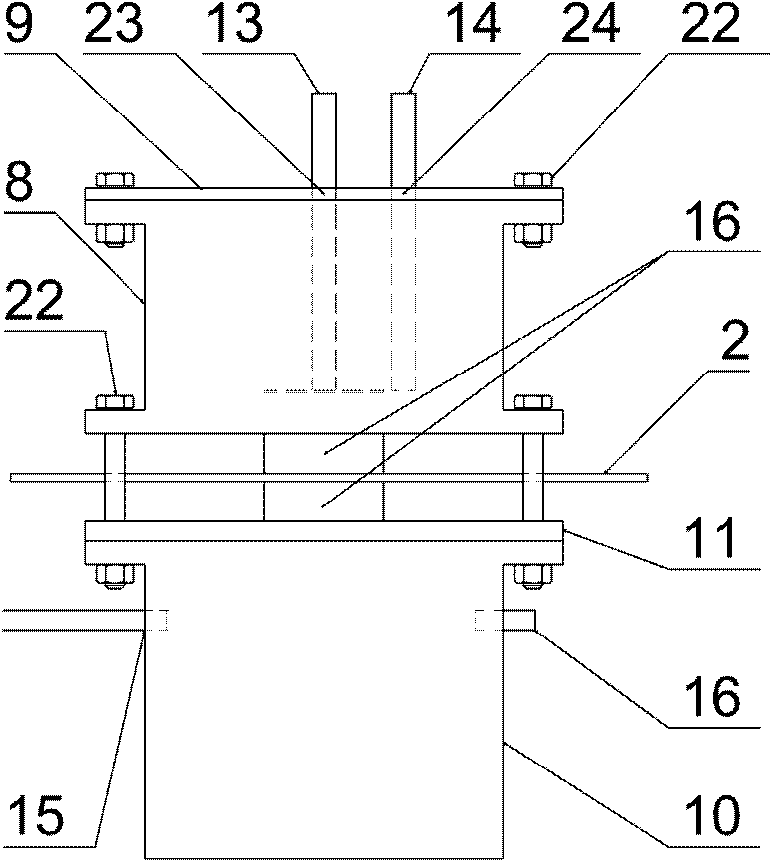

[0022] The invention includes a heating device, a stretching device, an electrolytic cell and a liquid / gas bottle (21). figure 1 It is a schematic diagram of the structure of the present invention. figure 2 The support plate (3) and the support column (4) of the stretching device in the above are selected from high-strength steel, and the stretching rod (6) is selected from a titanium alloy resistant to acid and alkali corrosion. image 3 The anode pool (8) and the anode pool upper cover (9), the environmental pool (10) and the environmental pool upper cover (11) are all made of acid and alkali resistant and high temperature resistant organic glass.

[0023] figure 2 The support plate (3) and the support column (4) in the middle stretching device are connected by 4 bolts (21), and the 2 titanium alloy tensile rods (6) are inserted into the holes of the support plate (3) and extend outside The two ends of the screw are threaded, and the front and back movement is prevented by a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com