Patents

Literature

143 results about "Metallic hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallic hydrogen is a phase of hydrogen in which it behaves like an electrical conductor. This phase was predicted in 1935 on theoretical grounds by Eugene Wigner and Hillard Bell Huntington. At high pressure and temperatures, metallic hydrogen can exist as a liquid rather than a solid, and researchers think it might be present in large quantities in the hot and gravitationally compressed interiors of Jupiter, Saturn, and in some exoplanets.

Low oxygen refractory metal powder for powder metallurgy

InactiveUS6261337B1Electrolytic capacitorsTransportation and packagingMetallic hydrogenOxygen content

One step process for producing formed Ta / Nb powder metallurgy products using Ta and / or Nb hydride powders with an oxygen content greater than a target level, e.g., 300 ppm, heating the metal hydride in the presence of another metal having a higher affinity for oxygen, removing the other metal and any reaction byproducts, to form a metal powder with an oxygen content less than the target level and forming a metallurgical product from said oxygen reduced Ta / Nb powder with an oxygen content less than the target level.

Owner:H C STARCK INC

Method of fabricating thinned free-standing metallic hydrogen-selective palladium-bearing membranes and novel pin-hole-free membranes formed thereby

A new method of creating thin free-standing pin hole-free hydrogen-selective palladium-bearing membranes that comprises thinning cold-rolled membranes by chemical etching or electrochemically electrolyzing of at least one membrane surface, and novel membranes produced thereby and including membranes with selected portions only thereof so thinned.

Owner:HYDRIP LLC

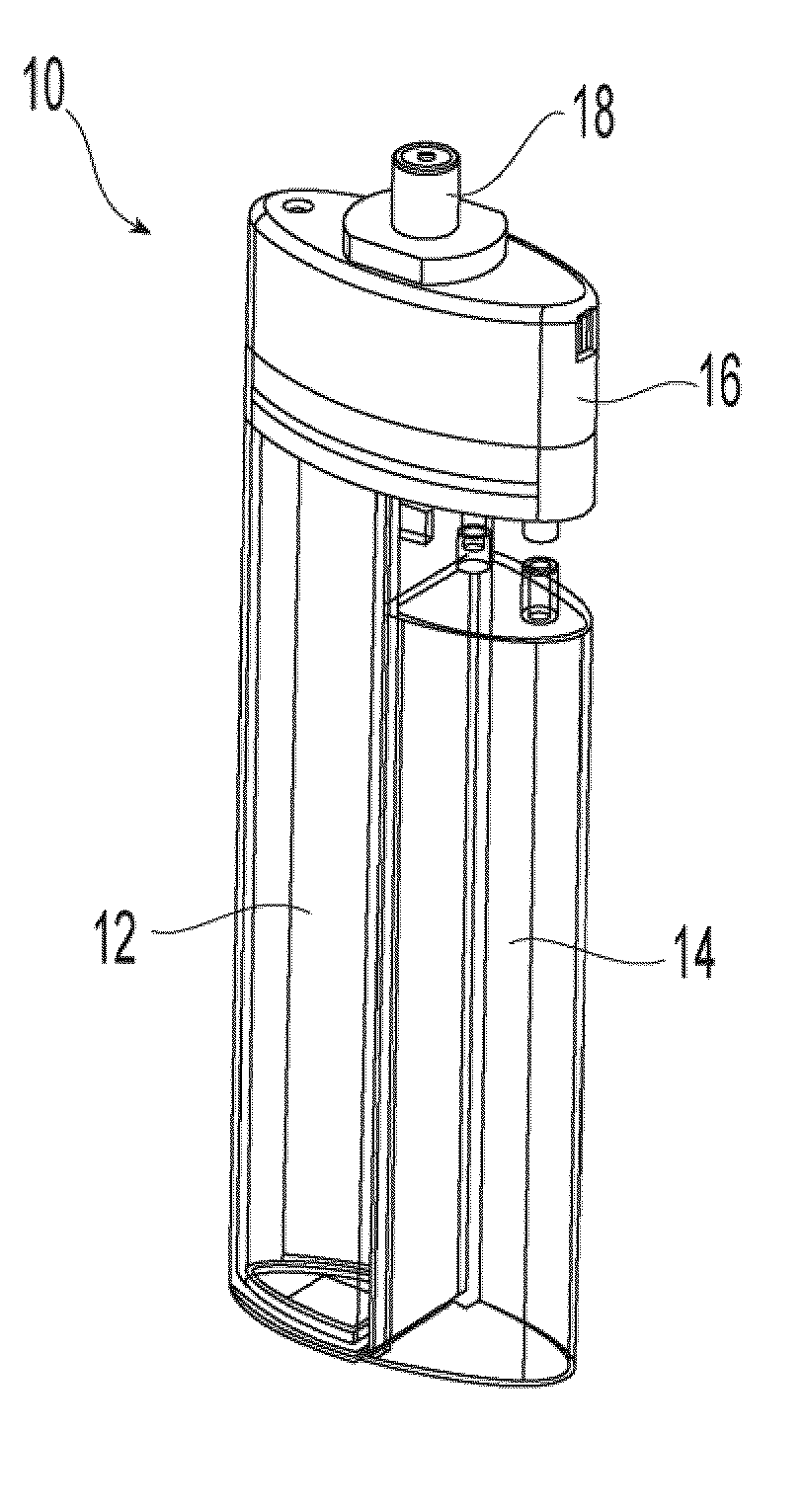

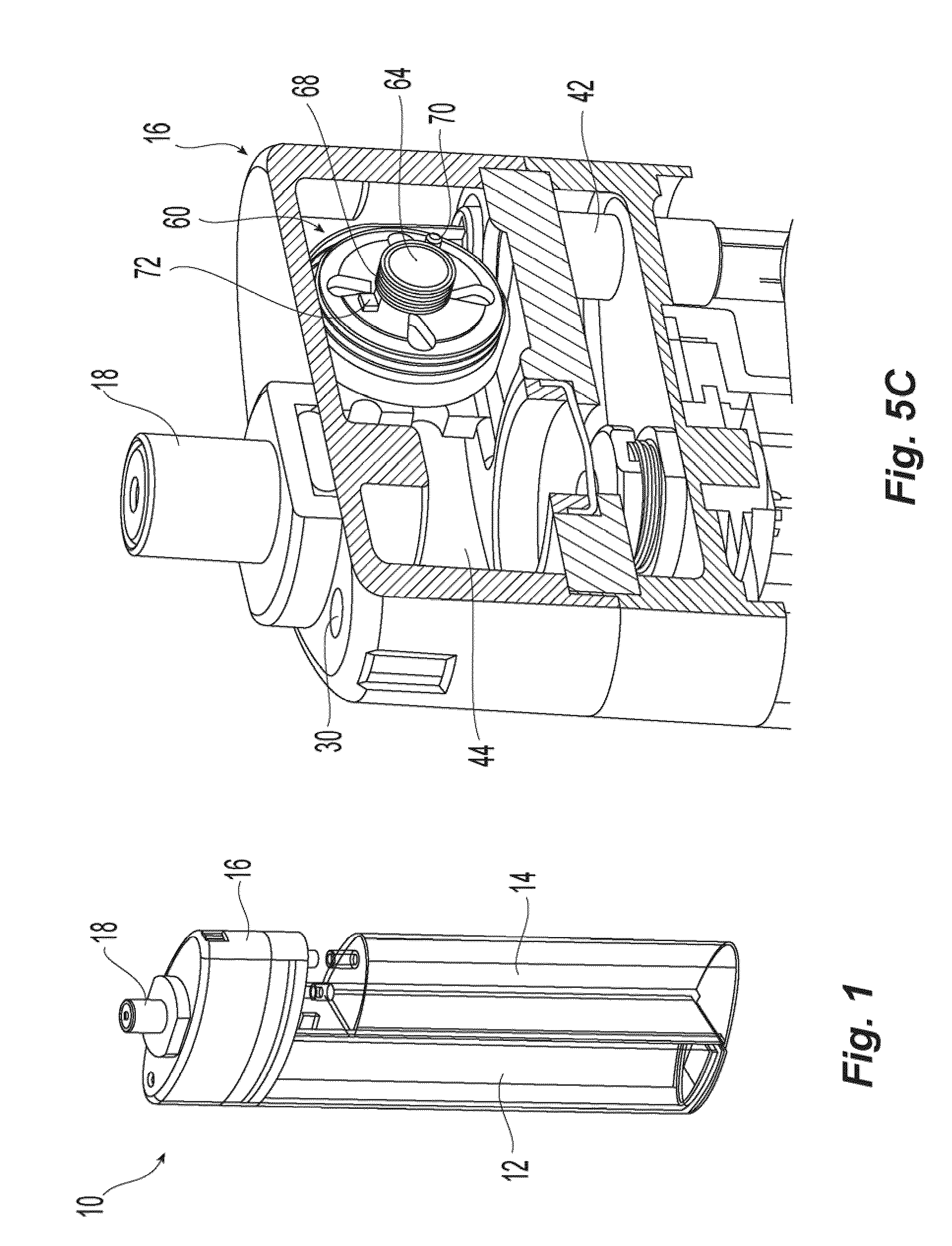

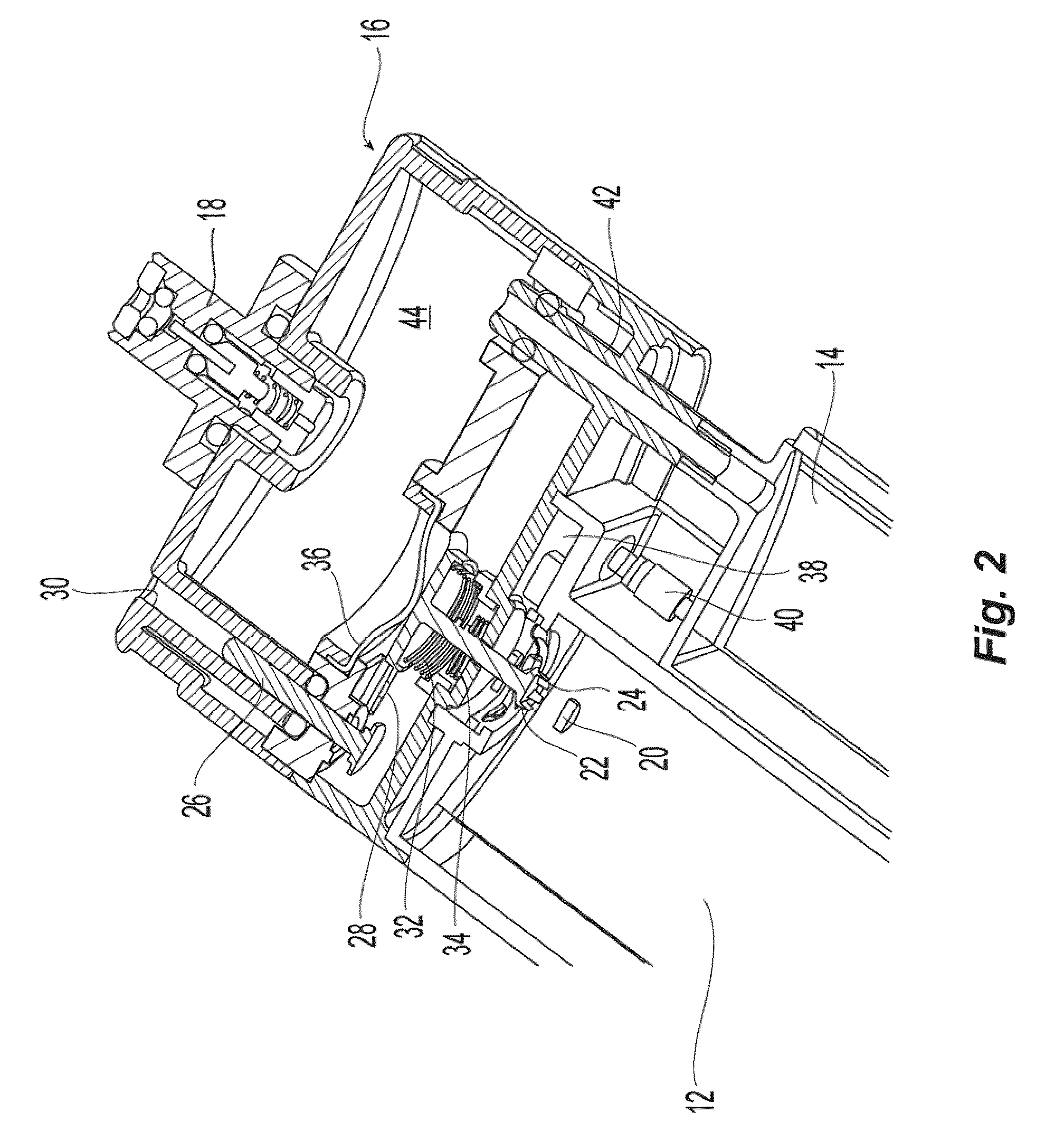

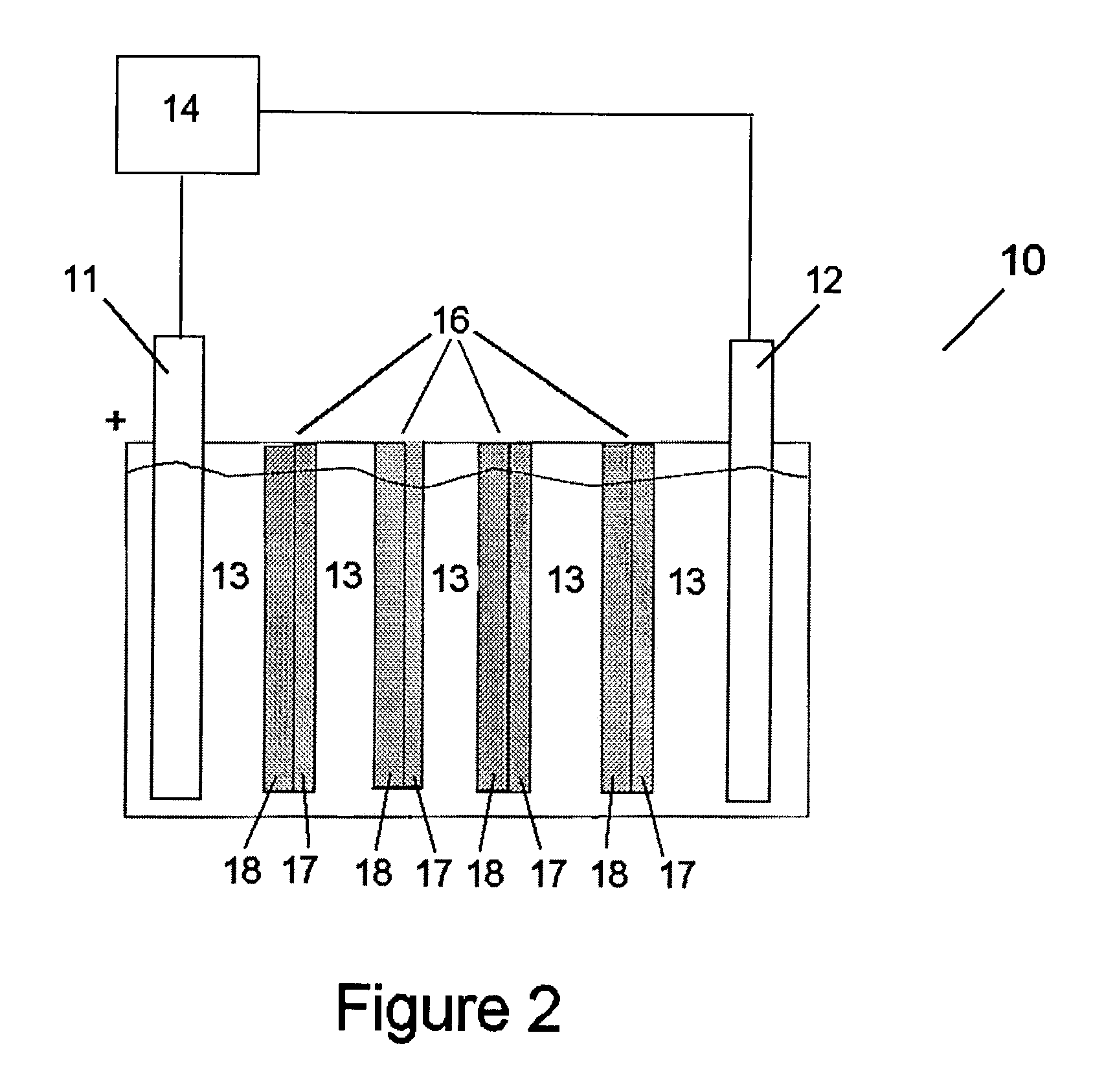

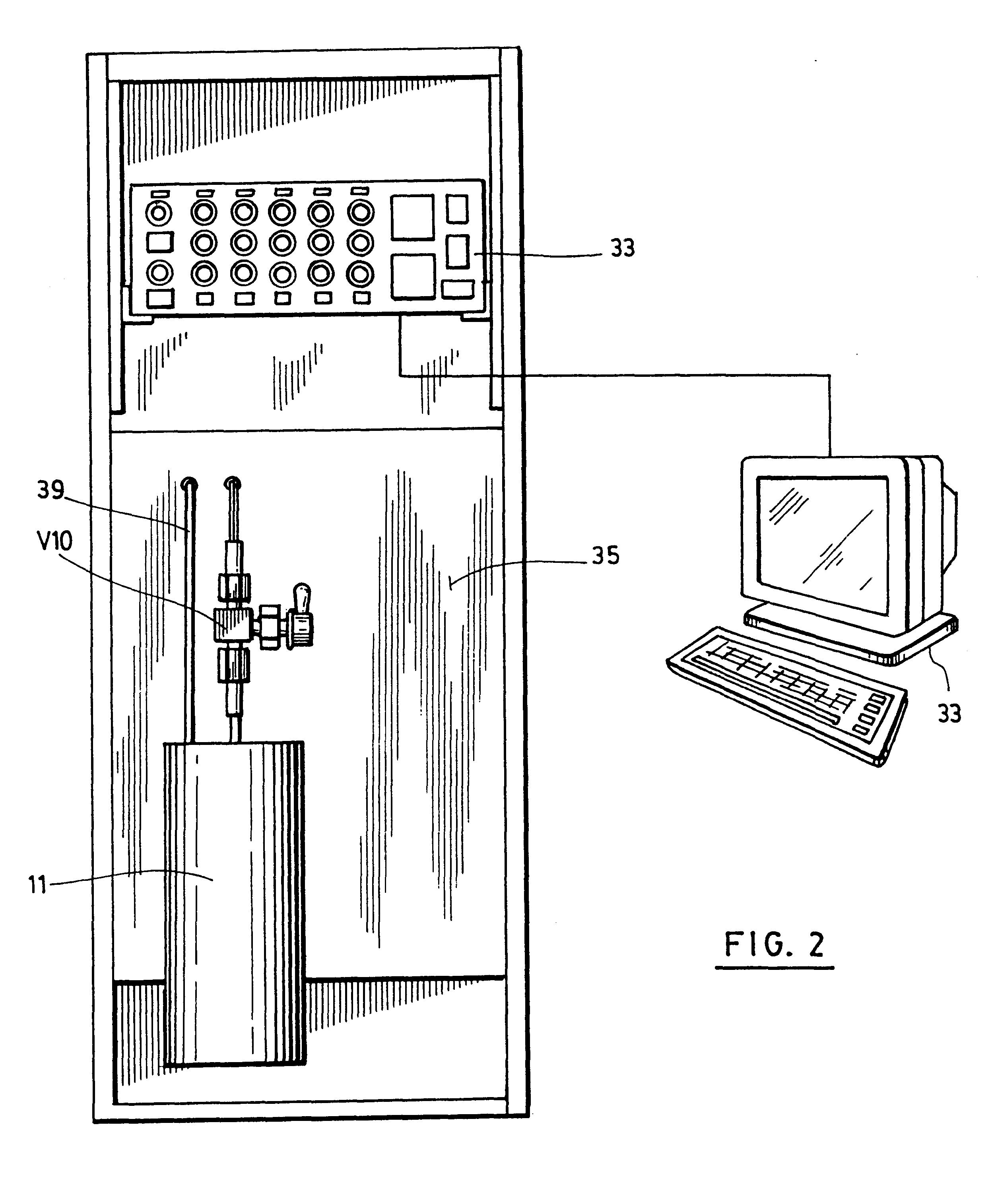

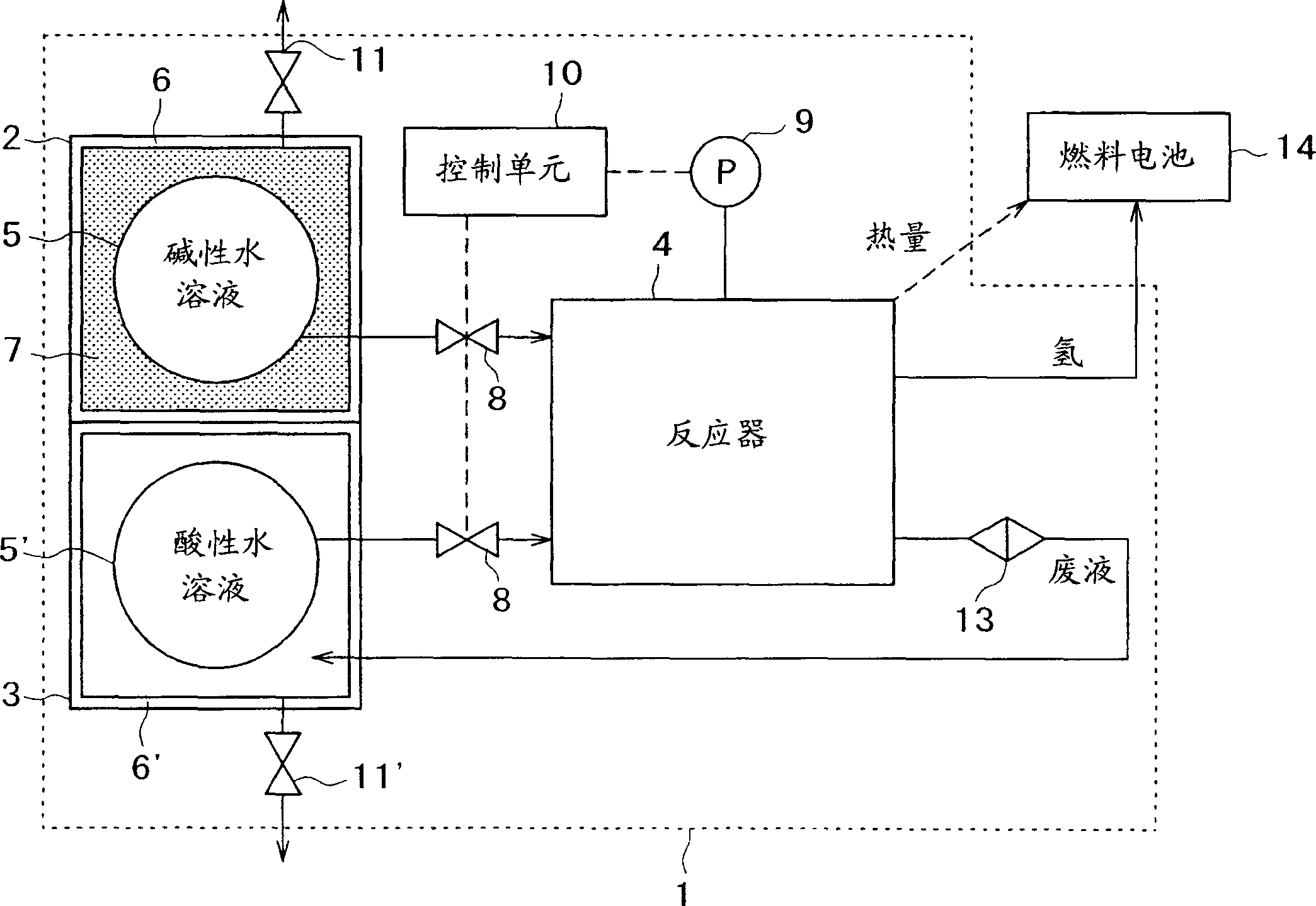

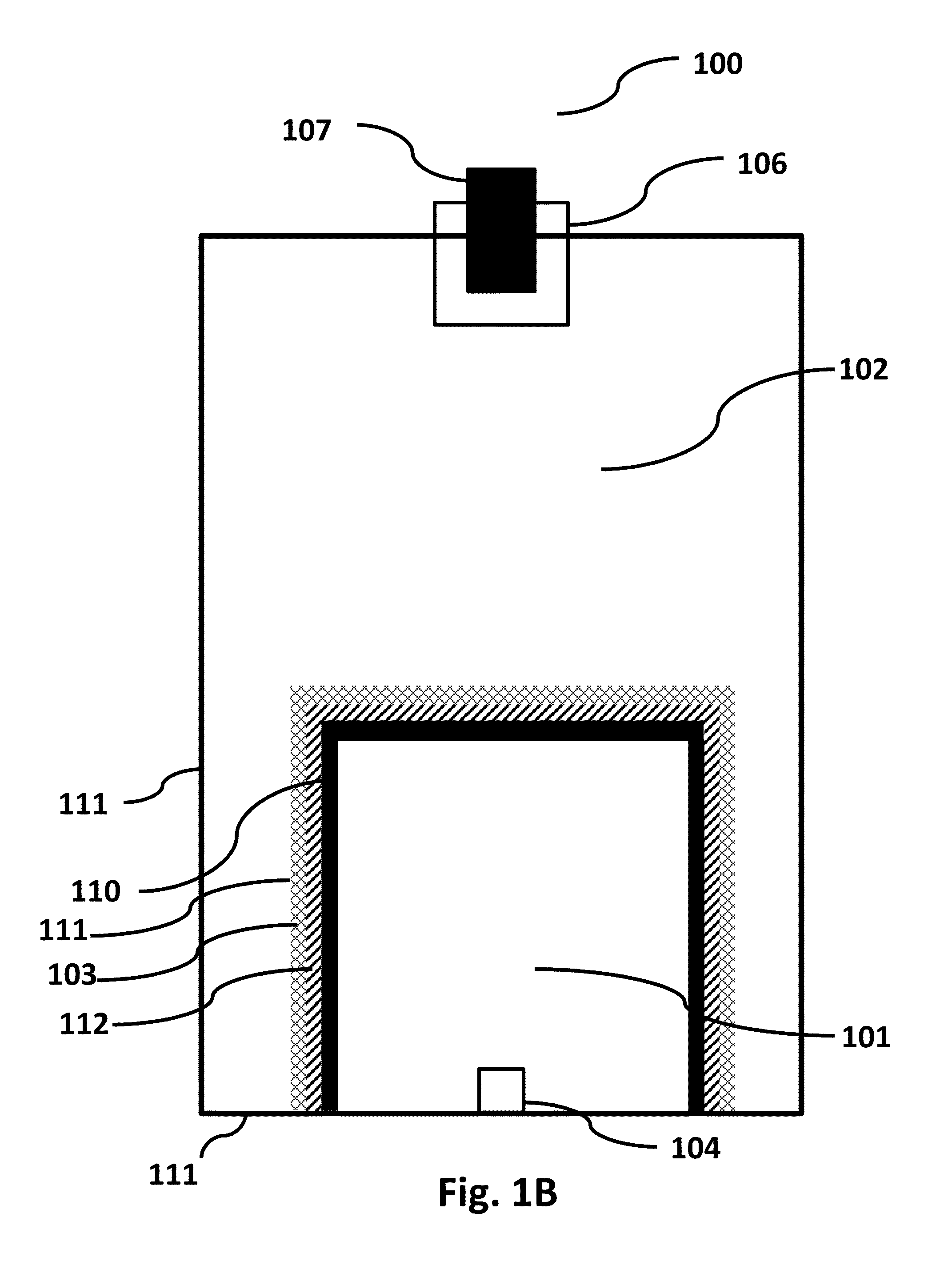

Hydrogen Gas Generators

InactiveUS20100104481A1Reactant parameters controlHydrogen productionNuclear engineeringGas generator

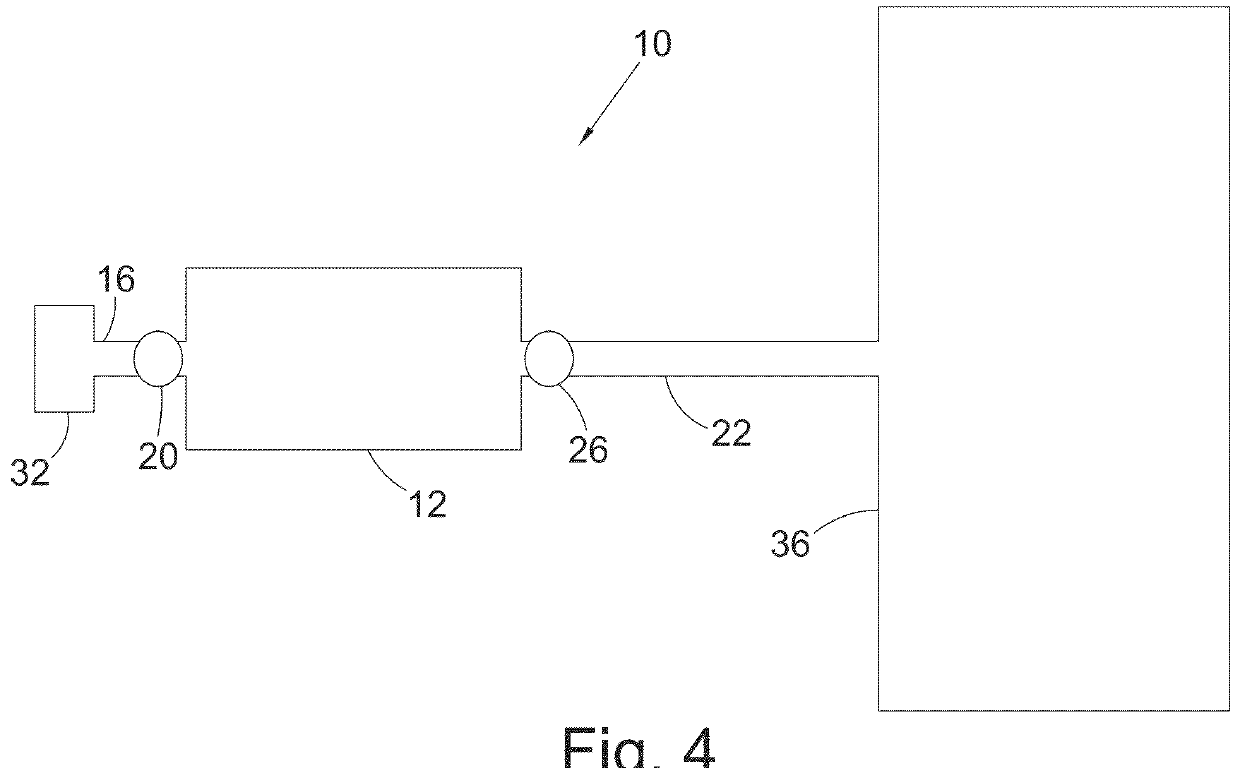

Disclosed herein are multiple embodiments of a hydrogen generator (10) that measures, transports or stores a single dose of a viscous fuel component from first fuel chamber (12) in storage area (38) when the internal hydrogen pressure (44, 44′) of the hydrogen generator is high, and transports this single dose to a metal hydride fuel component in second fuel chamber (14) when the internal pressure is low, so that the viscous liquid and metal hydride fuel components react together to generate more hydrogen and to restart the cycle. The viscous fuel component can be water or alcohol, such as methanol, in liquid or gel form, and the metal hydride fuel component can be sodium borohydride or other metal hydride that chemically reacts with the viscous fuel to produce hydrogen. The metal hydride fuel component can be in solid or viscous form, e.g., aqueous form.

Owner:INTELLIGENT ENERGY LTD

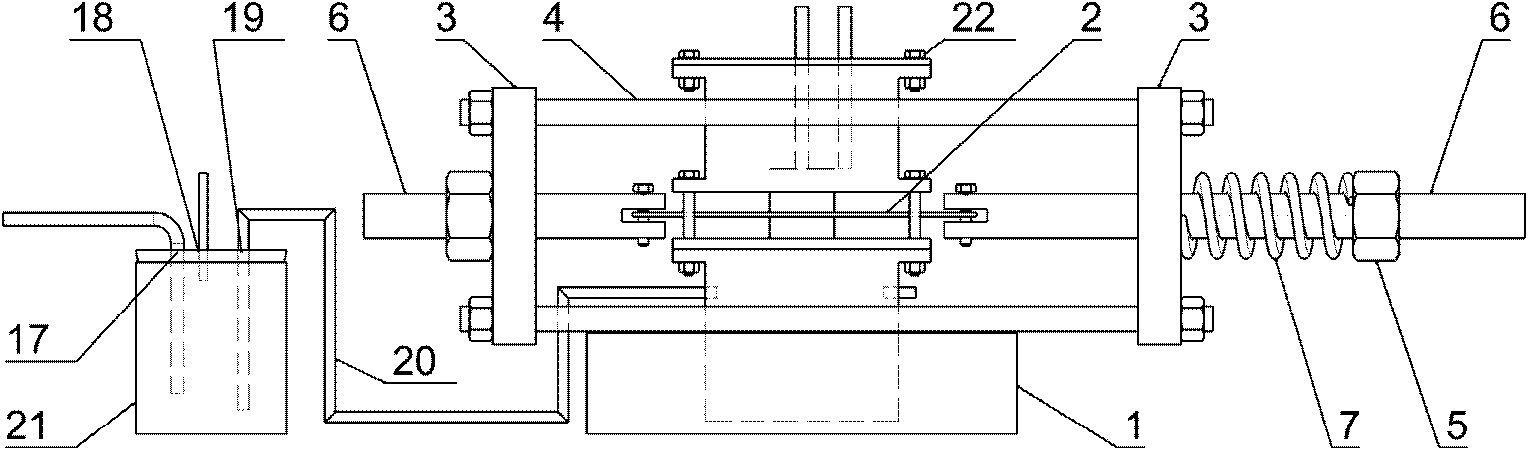

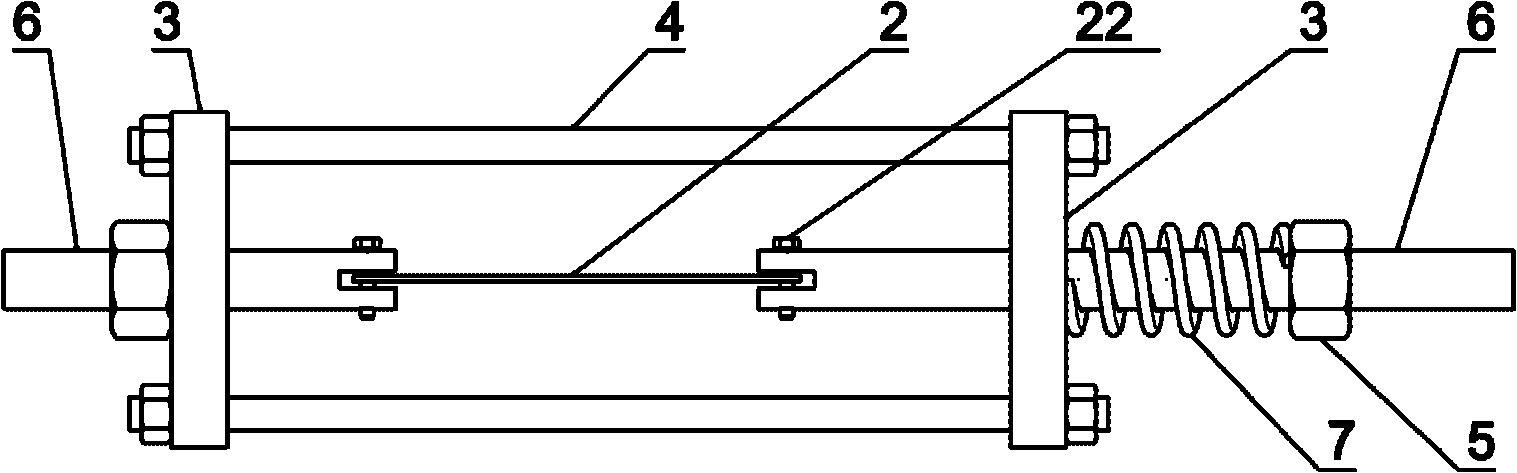

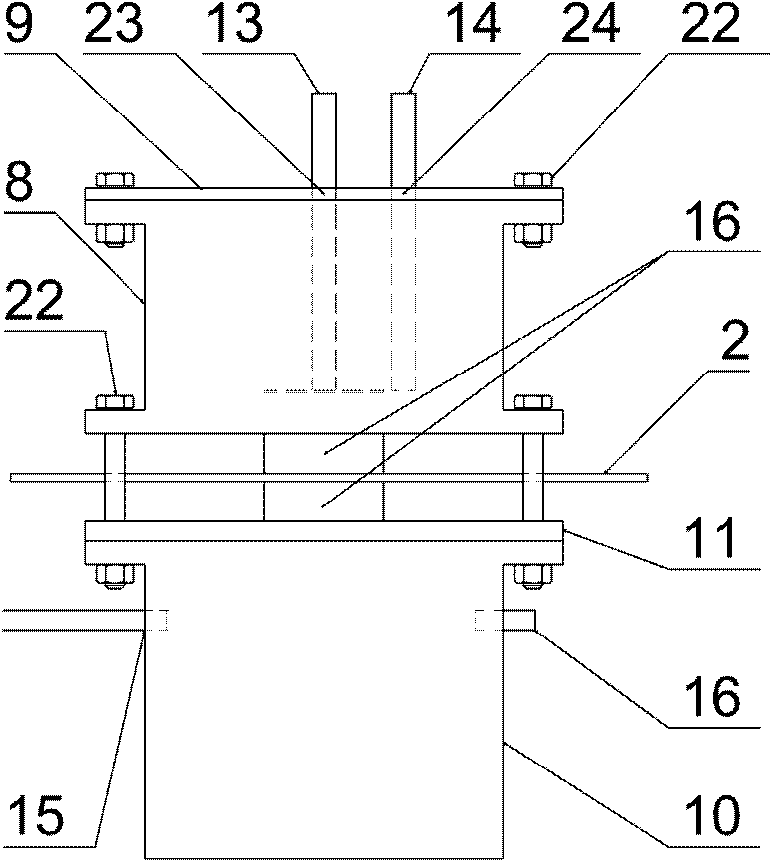

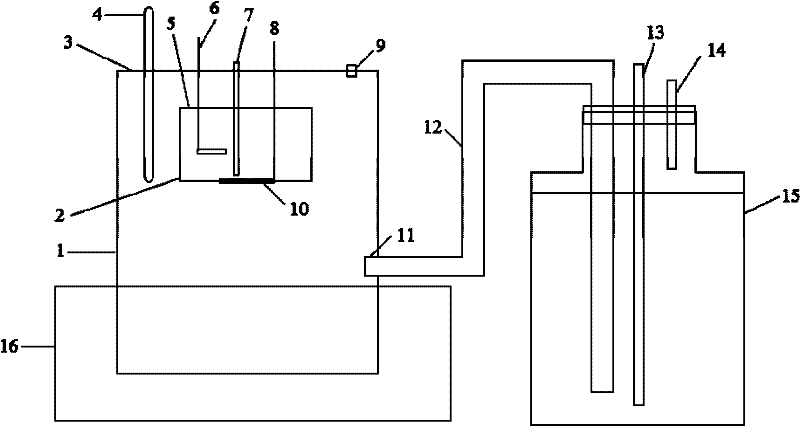

Device and method for researching hydrogen permeation behavior of metal subjected to dead-load pulling stress in gaseous medium

ActiveCN102323308ARealize continuous recordingEasy to operateMaterial electrochemical variablesWater bathsGas cylinder

The invention relates to a device and method for researching the metallic hydrogen permeation behavior, in particular to a device and method for researching the hydrogen permeation behavior of metal subjected to dead-load pulling stress in a gaseous medium, and the device and method are used for researching the interactive influence of pulling stress and a gaseous environment on the metallic hydrogen permeation behavior. The device comprises a heating device, a stretching device, an electrolytic bath and a liquid / gas storage bottle. The method comprises the steps of: nickel-plating a single side of a test piece to be tested, and fixing the test piece between a lower opening of an anode pool and an upper opening of an environmental pool, wherein the nickel-plated layer of the test piece faces the environmental pool; and providing dead-load pulling stress for the test piece by the stretching device. An experimental medium in the anode pool is a NaOH solution. An experimental solution inthe environmental pool forms a gaseous medium environment under the action of water bath. The device and method provided by the invention can be used for researching the hydrogen permeation behavior of a metallic material subjected to dead-load pulling stress in the gaseous medium, the control of the magnitude of the pulling stress and the environment and atmosphere can be realized, and the deficiency that the influence of a stressed state and the gaseous environment on the metallic hydrogen permeation behavior cannot be measured through the traditional electrolytic bath is made up.

Owner:UNIV OF SCI & TECH BEIJING

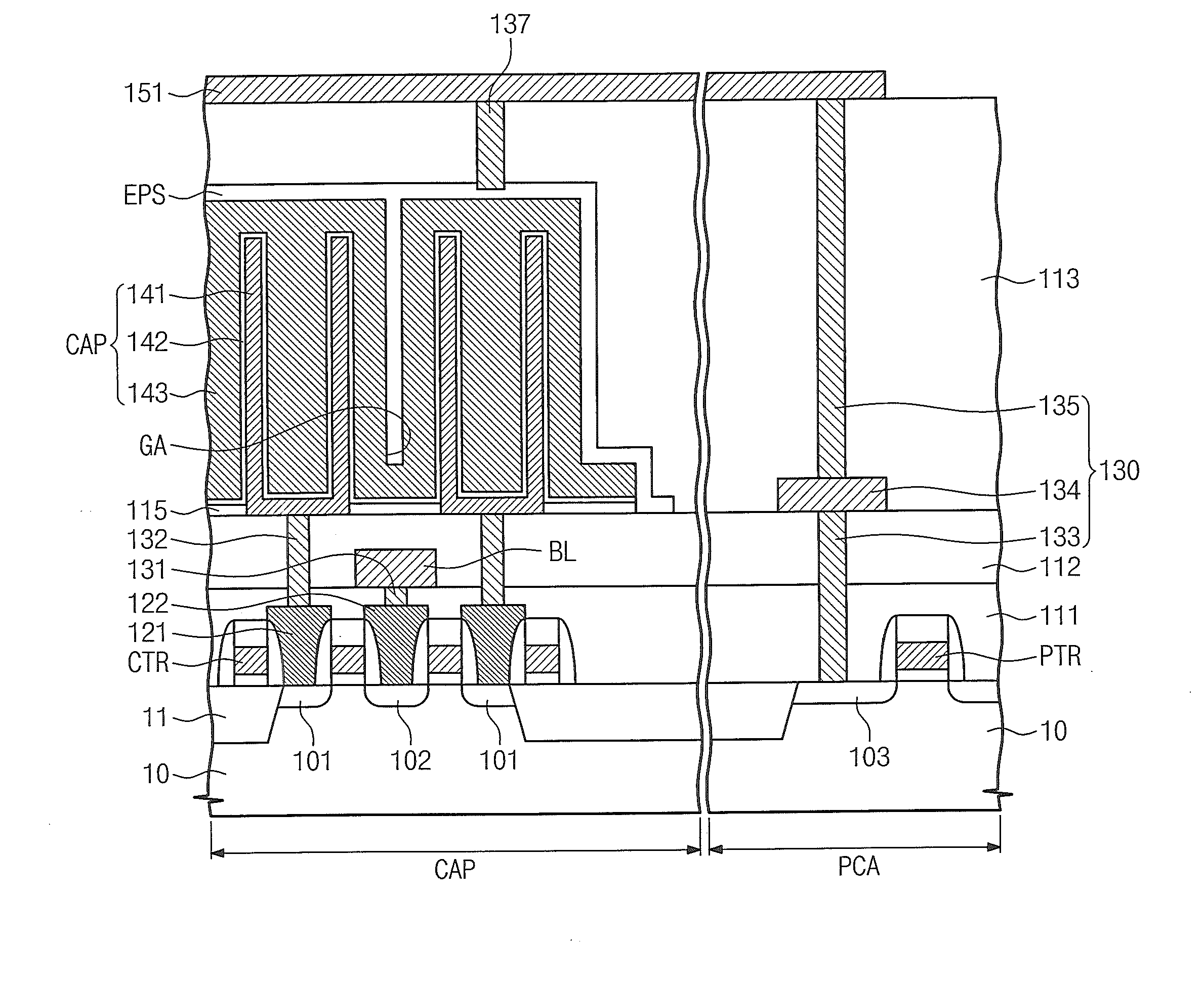

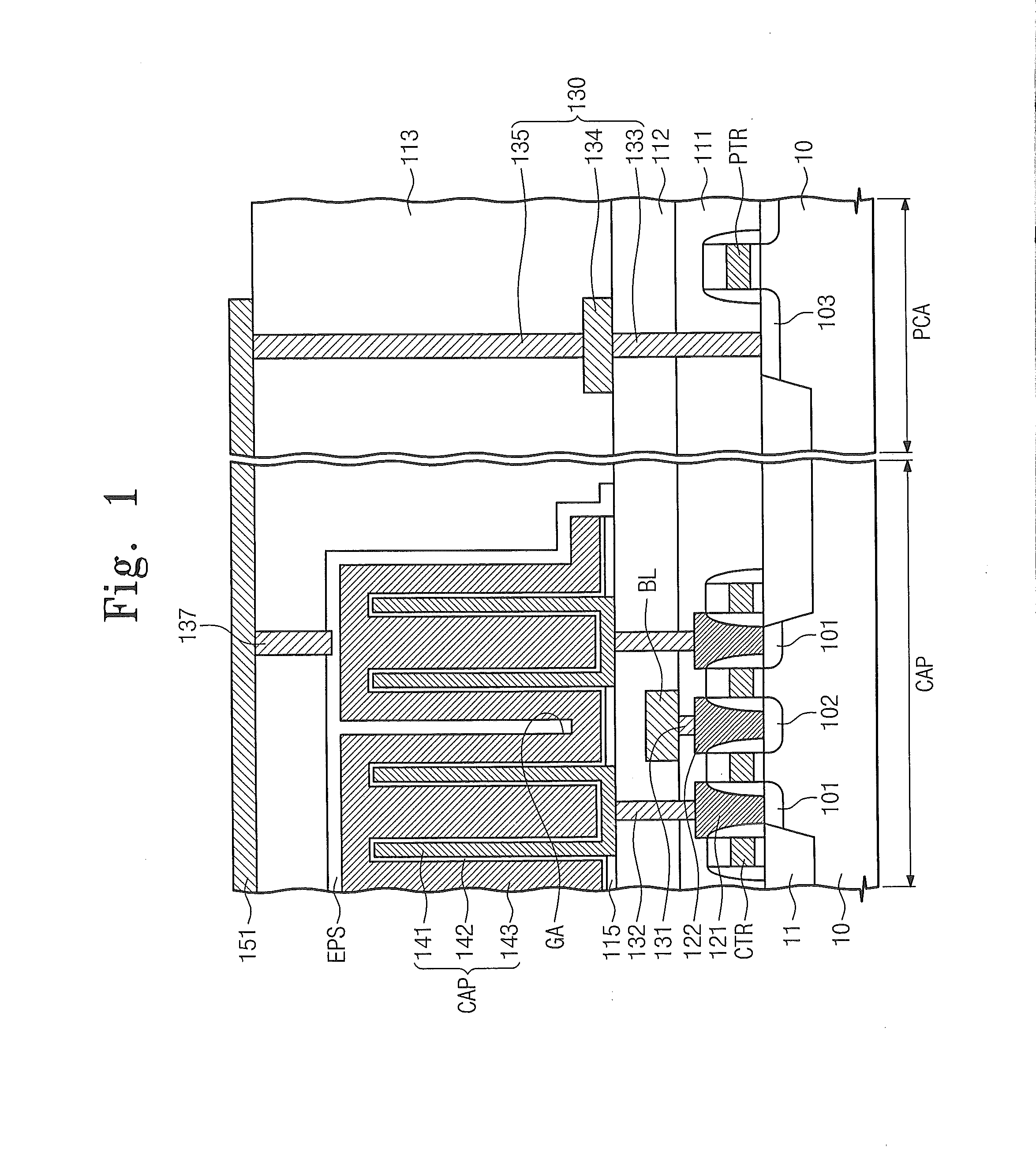

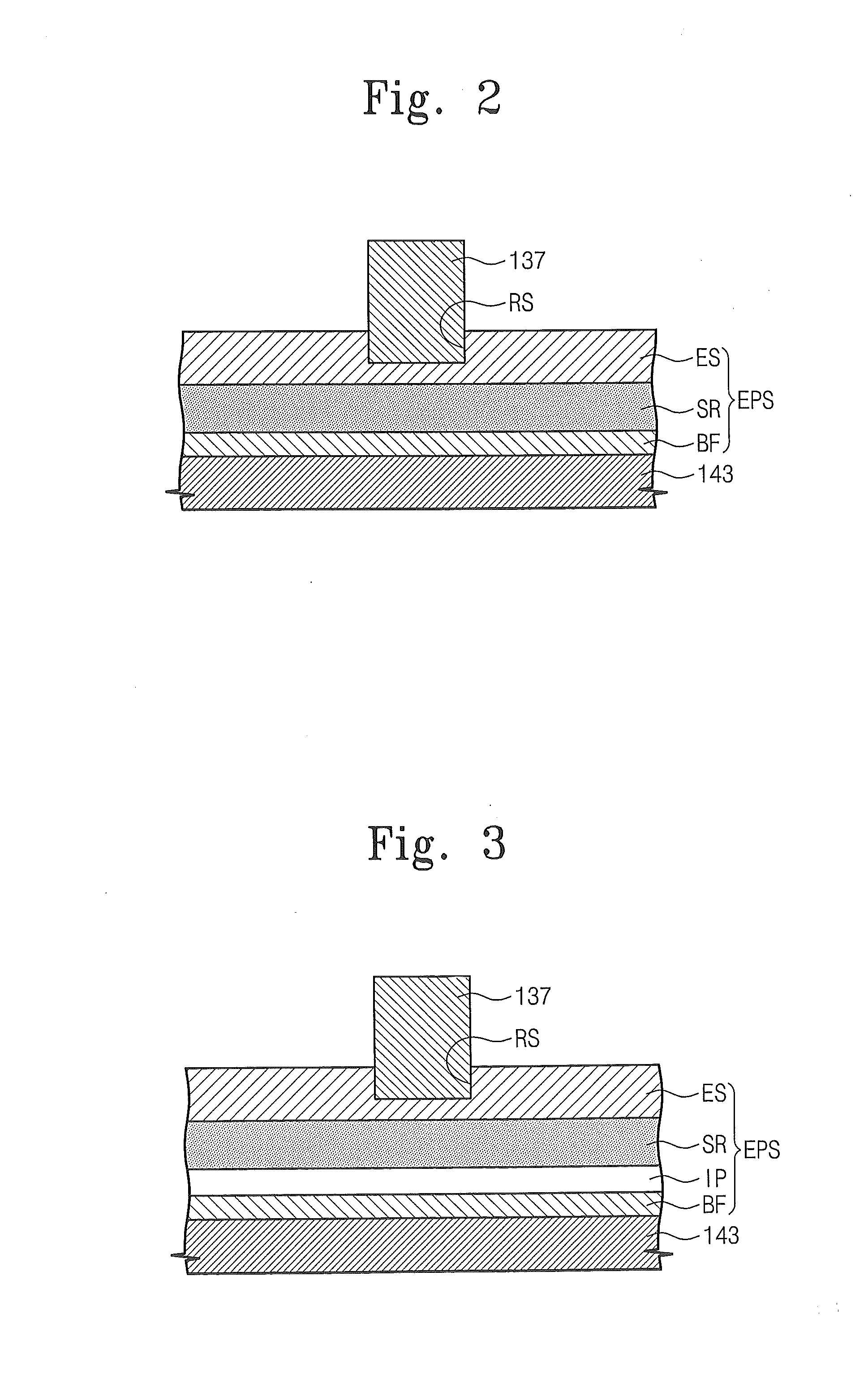

Semiconductor devices

ActiveUS20140103491A1Avoid conductionSolid-state devicesSemiconductor/solid-state device manufacturingReaction layerEngineering

The present inventive concept provides semiconductor devices that may include a capacitor including a lower electrode, a dielectric layer, and an upper electrode which are sequentially stacked. An electrode-protecting layer may be provided on the capacitor. The upper electrode may include a conductive metal oxide and the electrode-protecting layer may include a sacrificial reaction layer including a metal-hydrogen compound.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for producing and transporting hydrogen

A method for the production and storage of hydrogen. The hydrogen is produced via electrolysis and as the hydrogen is formed it is absorbed into a hydrogen storing cathode. Once the hydrogen storing cathode has become completely hydrided, it is shipped to end users as a metal hydride supply of hydrogen.

Owner:TACTICAL FUEL CELLS

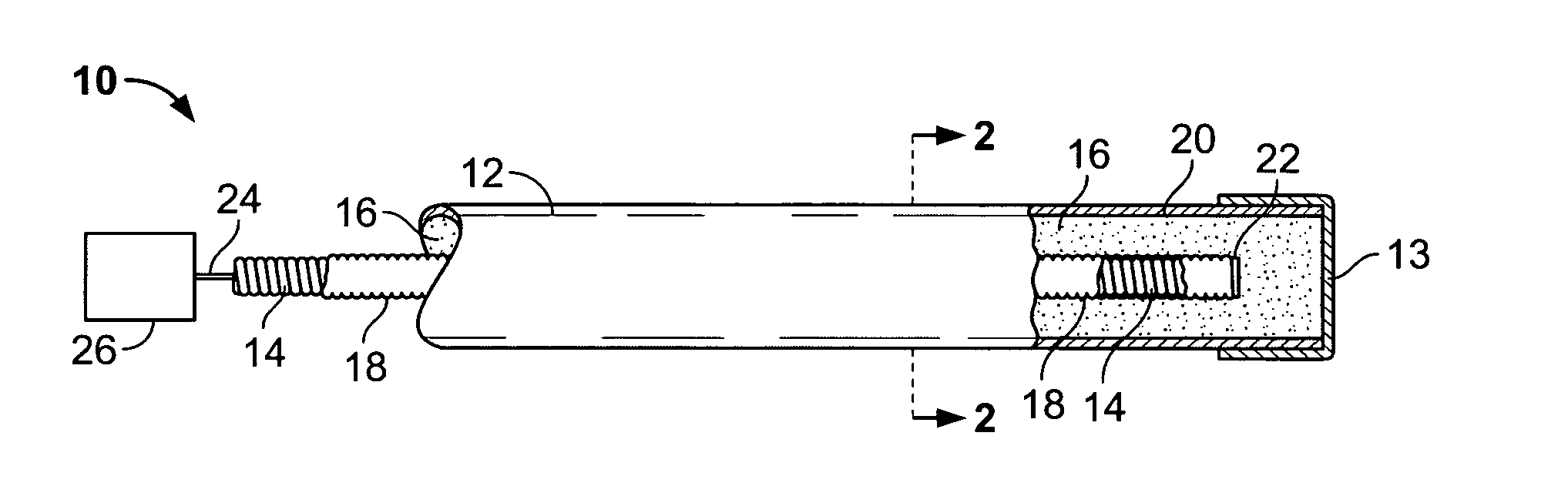

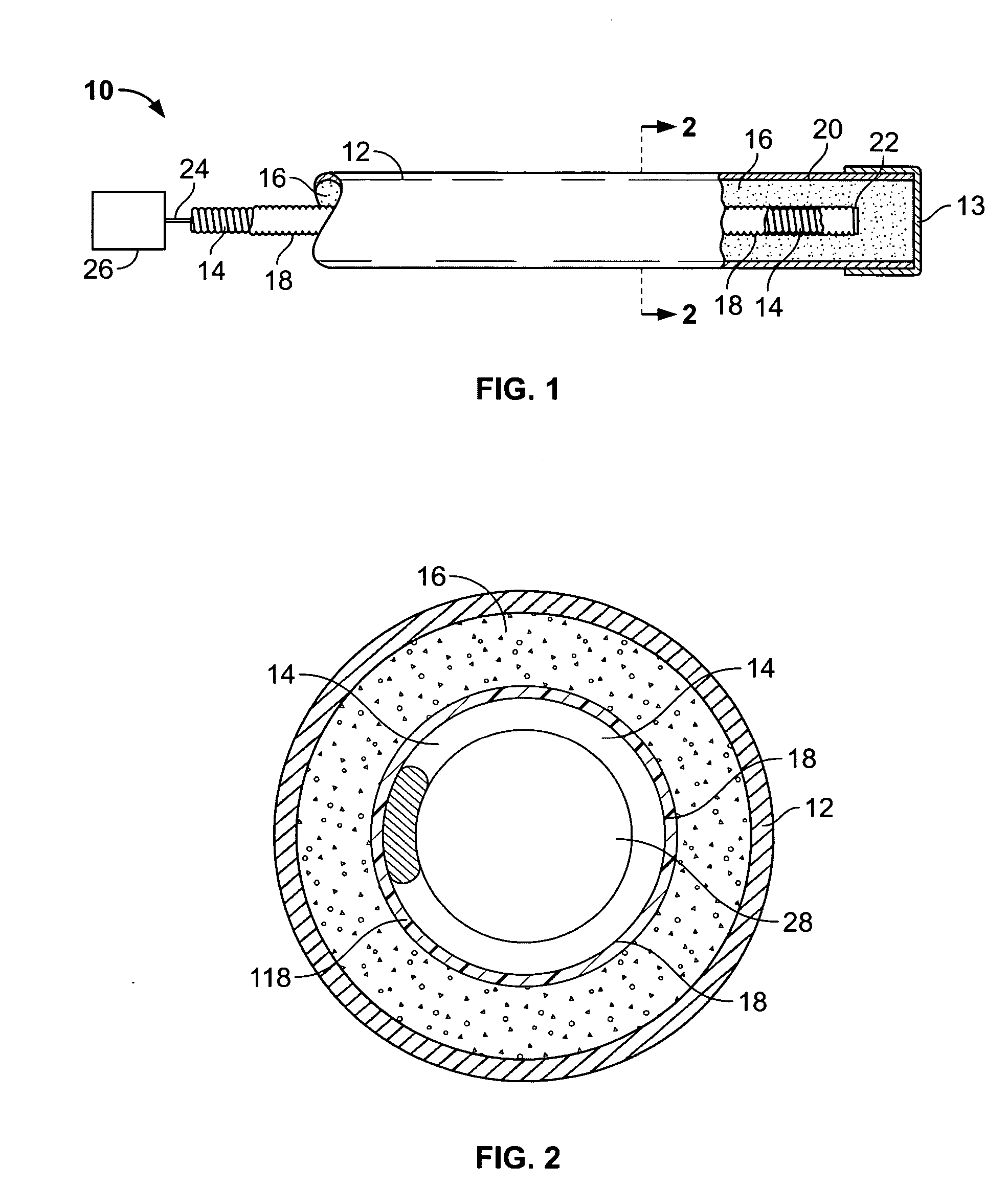

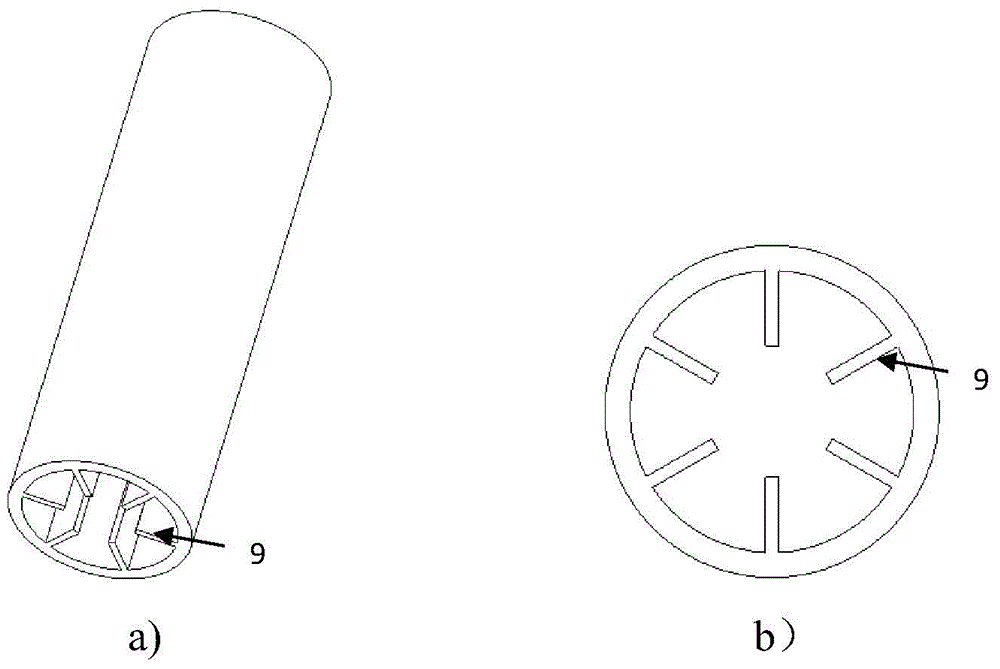

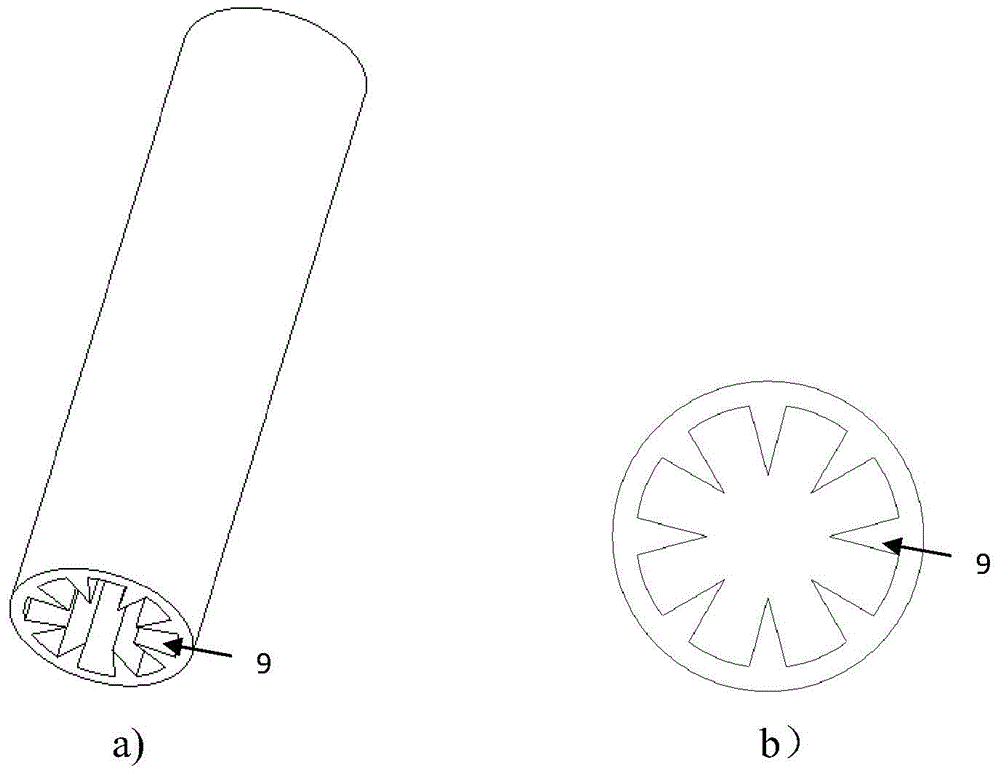

Flexible and semi-permeable means of hydrogen delivery in storage and recovery systems

InactiveUS20060065552A1Equally distributedProvide protectionReactant parameters controlDrying solid materials without heatMechanical engineeringMaterial Perforation

A container for use in hydrogen transfer includes structural tubular members and perforations for fluid communication with a central passage covered with a film that is selectively permeable to hydrogen, but not to other gases. The tubular member walls comprise a sturdy material to fix the hydride powder, preventing it from shifting within the container. The hydrogen flow, when being absorbed or desorbed by the metal hydride, will pass through the film both as it is absorbed in the hydride material and also after it is desorbed to pass into the central passage. Simultaneously, the tubular member material, acting as a flexible cover or support for the film, retains contaminant gases within the conduit passage, but permits hydrogen to flow therethrough. Alternatively, a flexible conduit may be interspersed within selected ones of the longitudinal structural members, and hydride material may be packed within the springs, which provide for expansion protection.

Owner:MPD TECH

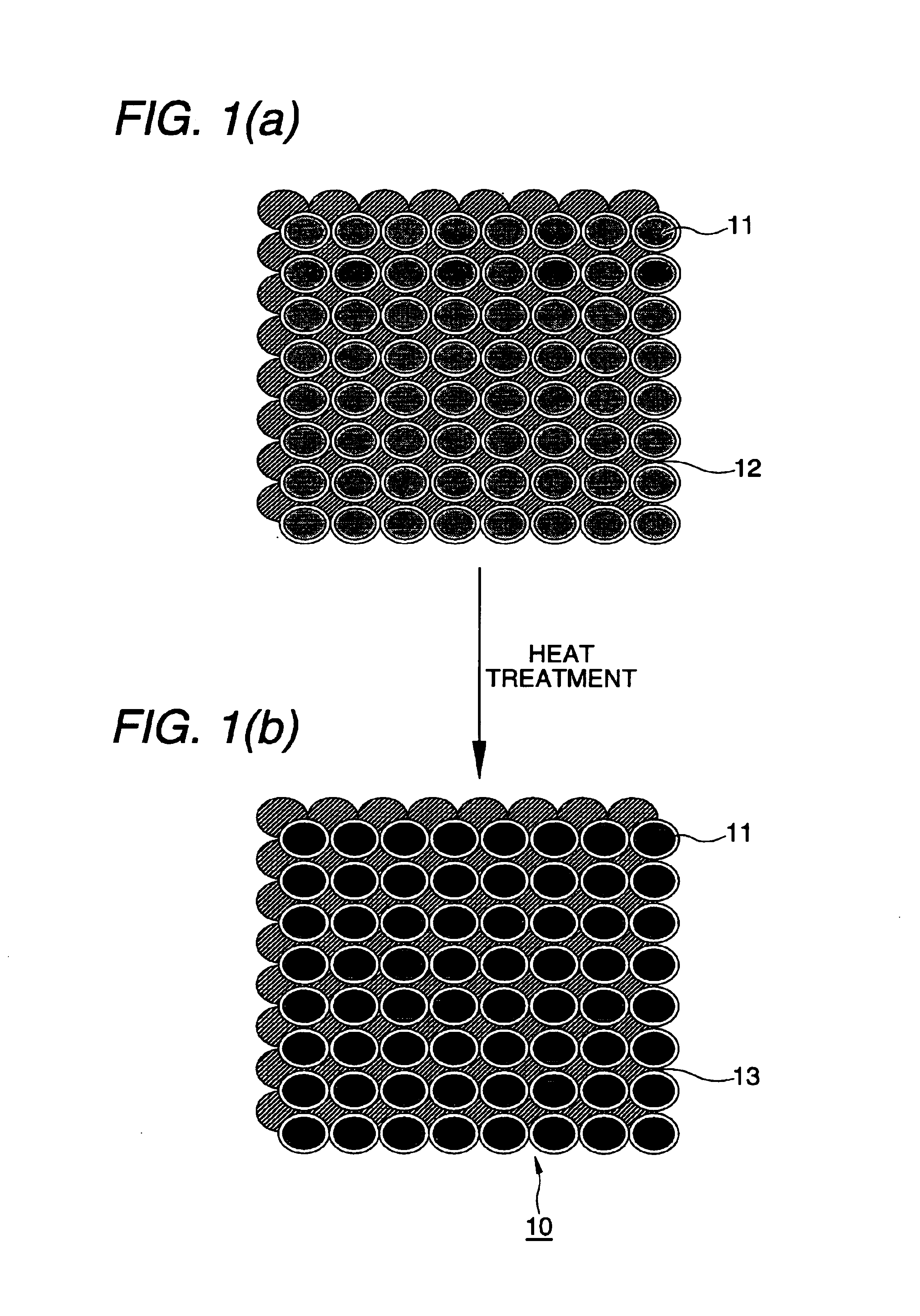

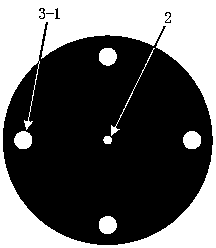

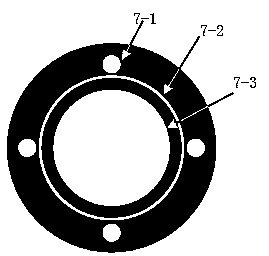

Discharge surface treating electrode and production method thereof

InactiveUS6935917B1Reduce manufacturing costImprove processing efficiencySpark gapsCathode ray tubes/electron beam tubesCompression moldingCarbide

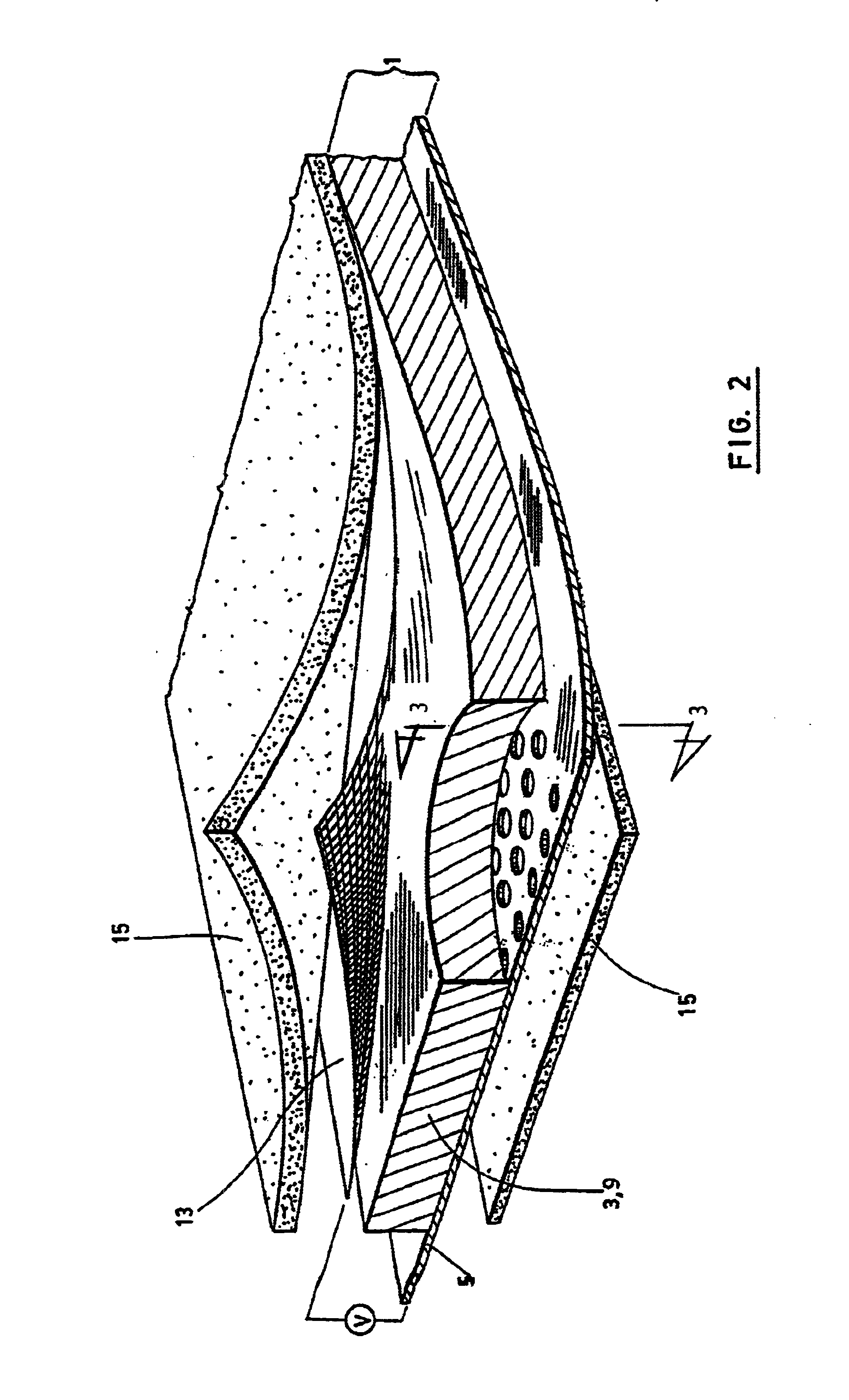

In an electrode for electric discharge surface treatment used in electric discharge surface treatment for forming a hard coating on the surface of a treated material through the energy by generating electric discharge between the electrode and the treated material, a TiC powder (11) which is metal carbide and a TiH2 powder (12) which is metal hydride are mixed and heating treatment is performed after compression molding and hydrogen in the TiH2 powder (12) is desorbed to make a Ti powder (13) and a practical electrode (10) for electric discharge surface treatment having moderate strength and crumbliness as well as safety is formed.

Owner:MITSUBISHI ELECTRIC CORP

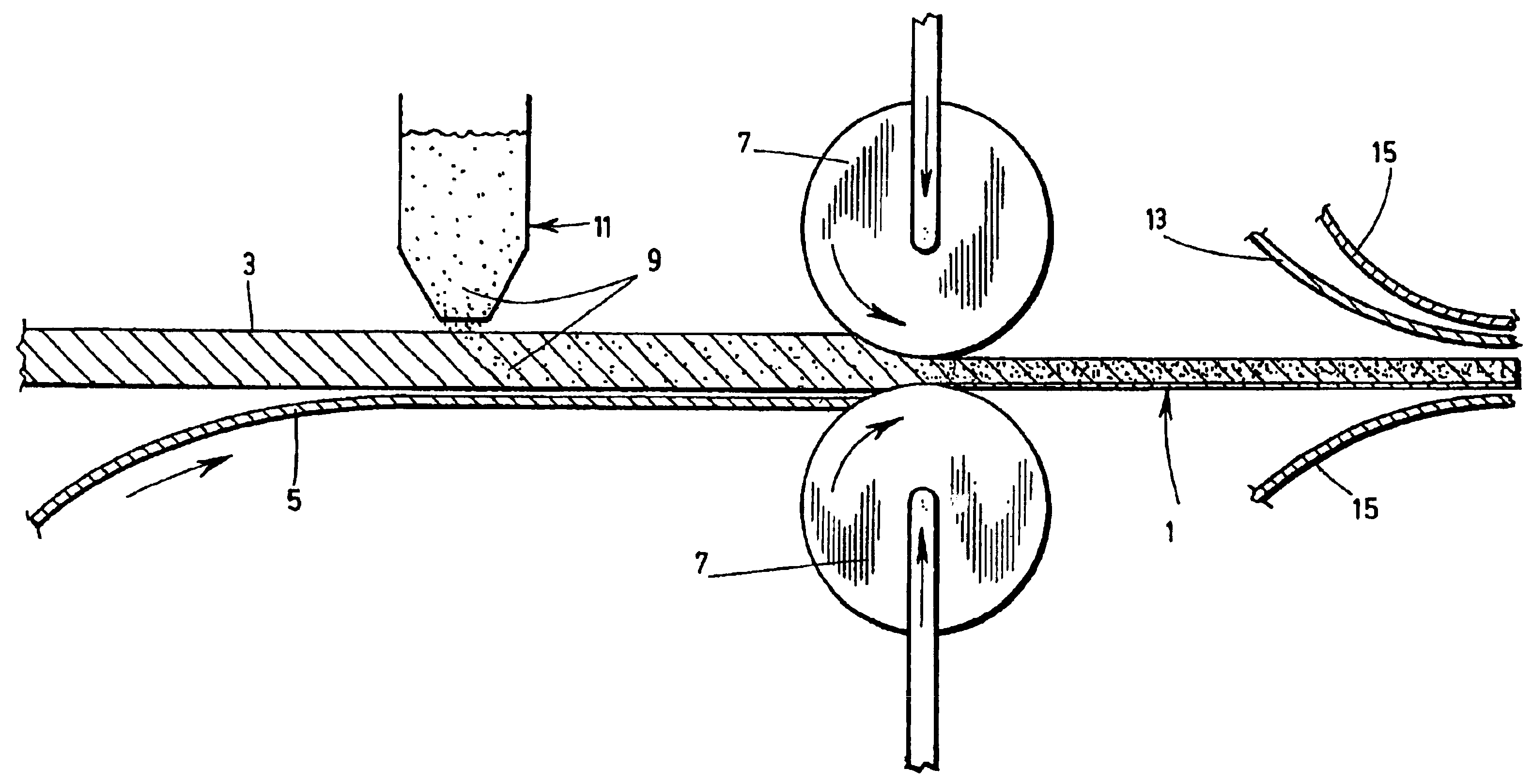

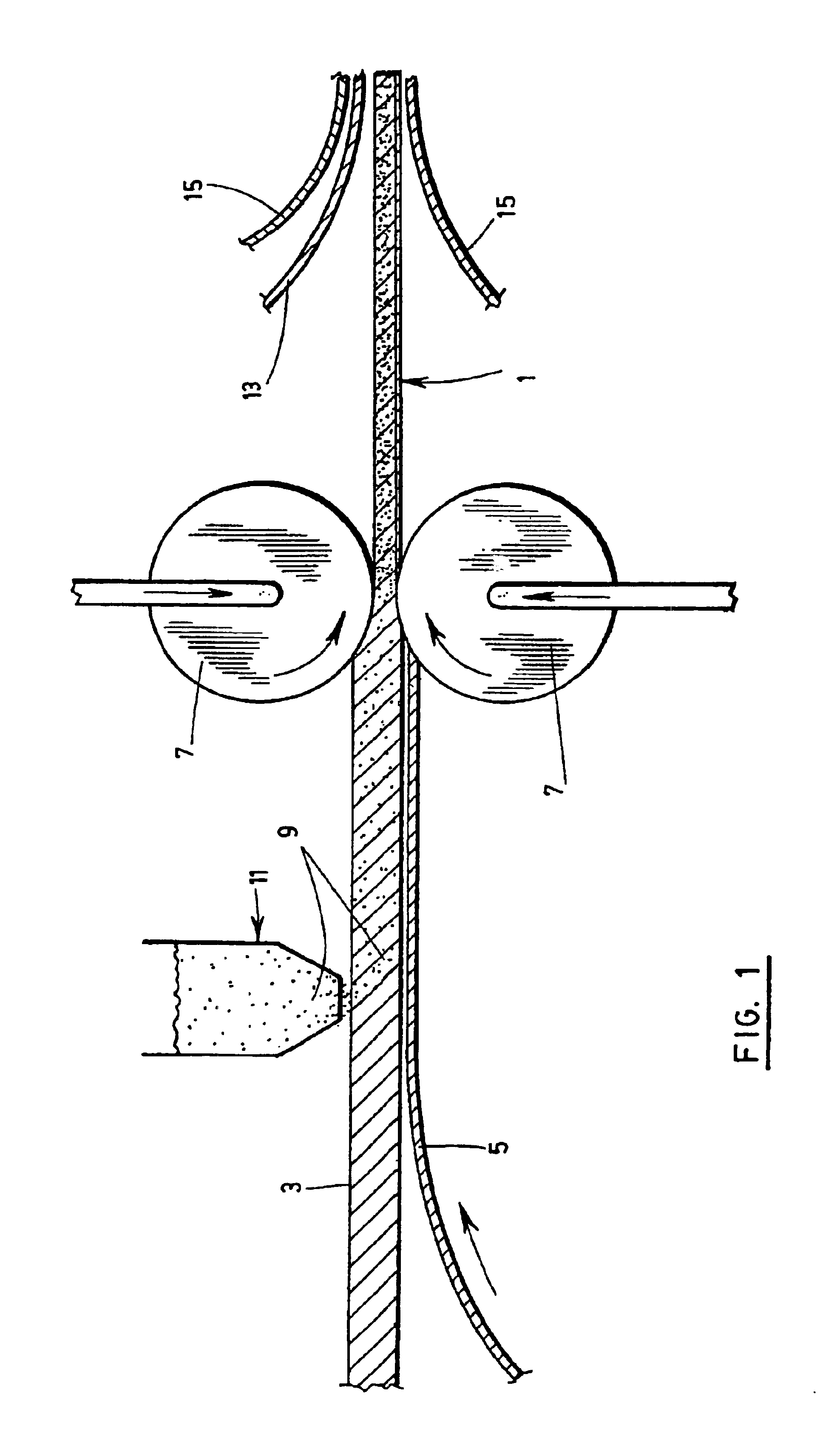

Metal hydride bands and use thereof for storing hydrogen

InactiveUS6936185B1Efficient solutionEasy to carryReversible hydrogen uptakeTransportation and packagingPorosityEngineering

The invention concerns a piece based on one or several metal hydrides capable of reversibly absorbing hydrogen. Said piece is in the form of a thin and dense band, having a thickness preferably not more than 1 mm and porosity preferably less than 20%. The piece is obtained by rolling a powder of selected hydride(s), with or without additional component(s), such as binders or heat-transfer elements. Said piece can easily be produced on an industrial scale. By its very nature, it is particularly adapted for use as a base element in a tank for storing and transporting hydrogen. It can also be used in a Ni-MH typre battery for storing and transporting energy.

Owner:HYDRO QUEBEC CORP

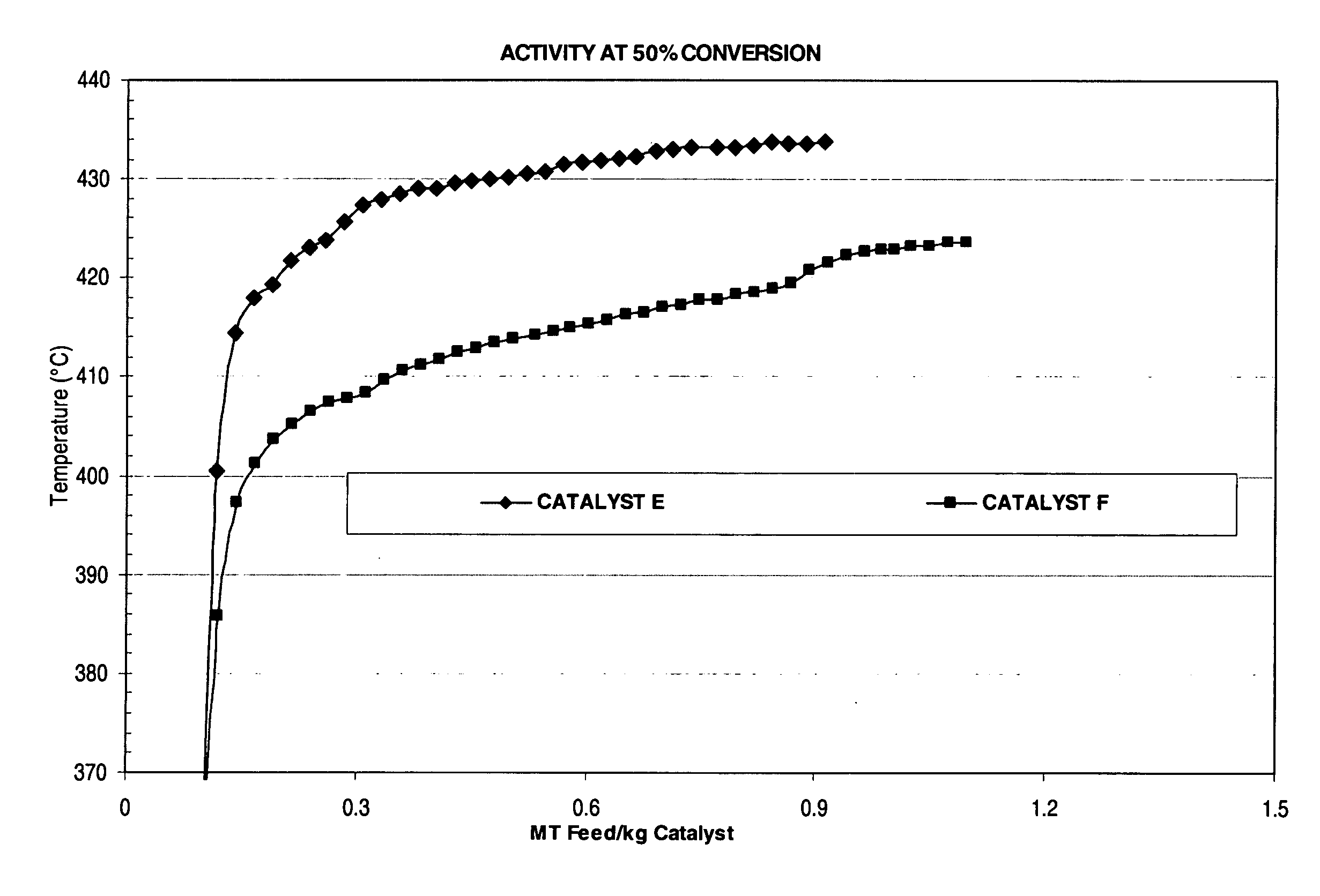

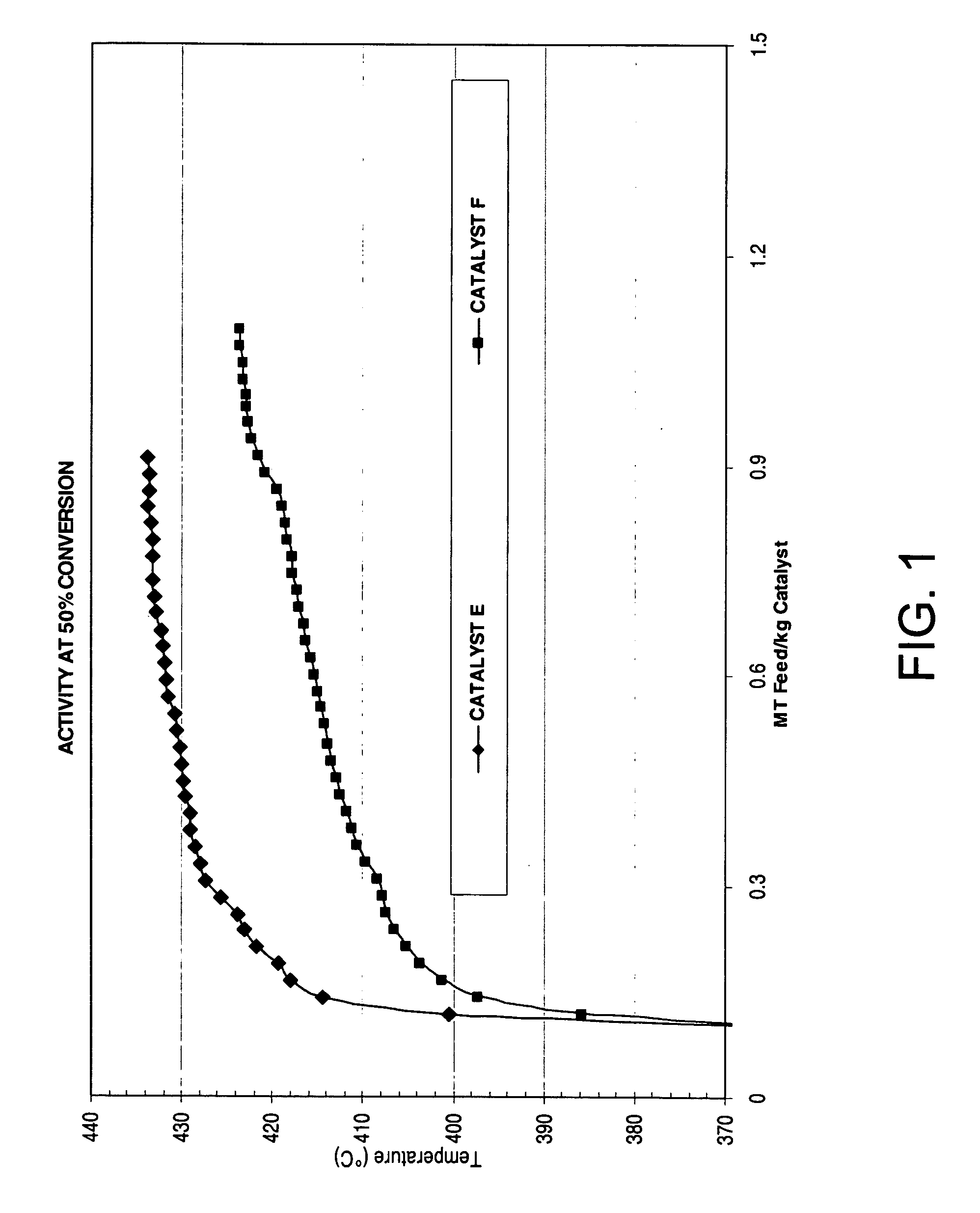

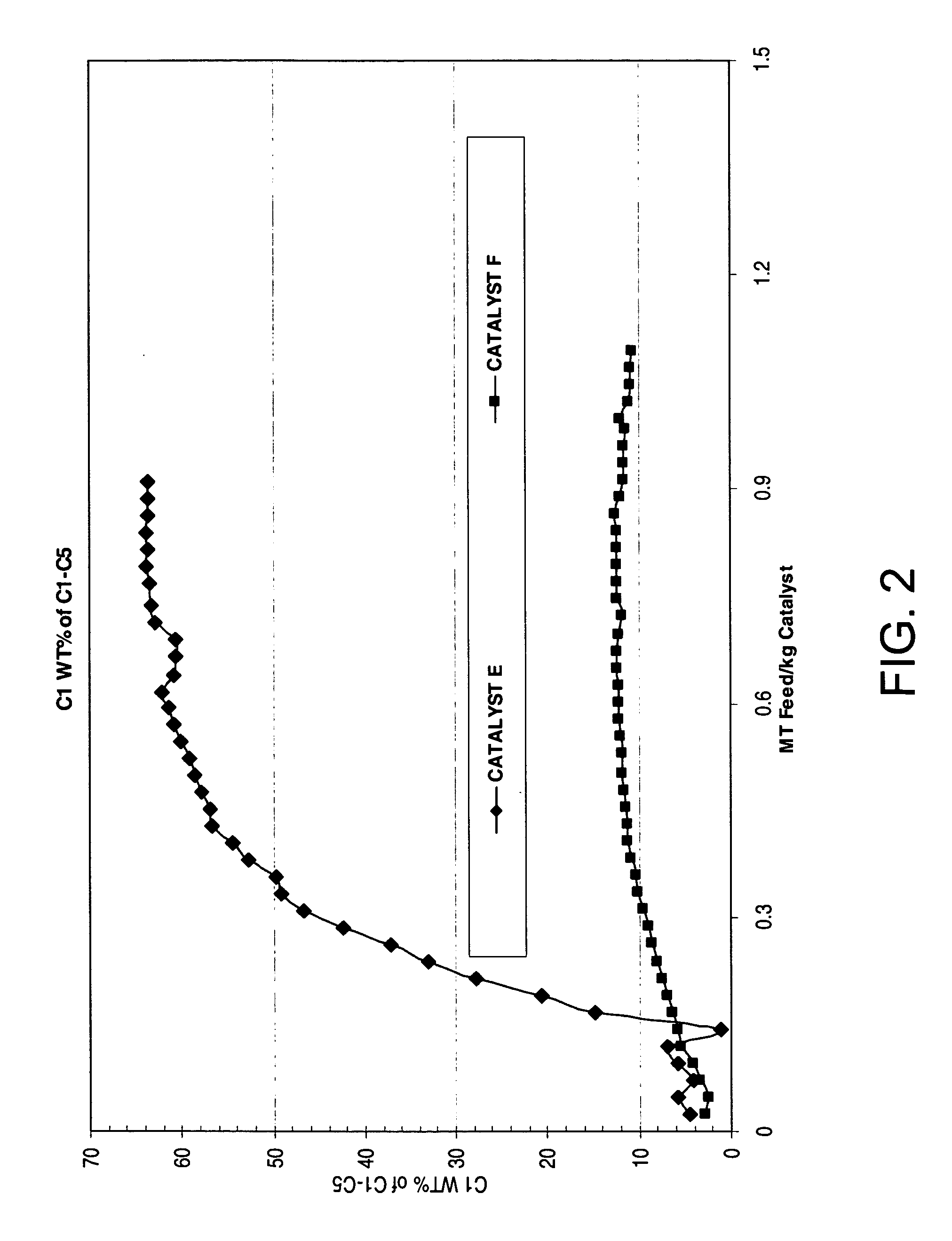

Catalyst treatment useful for aromatics conversion process

A process for preparing a transalkylation catalyst, the catalyst itself, and a transalkylation process for using the catalyst are herein disclosed. The catalyst comprises rhenium metal on a solid-acid support such as mordenite, which has been treated with a sulfur-based agent. Such treatment reduces the amount of methane produced by metal hydrogenolysis in a transalkylation process wherein heavy aromatics like A9+ are reacted with toluene to produce xylenes. Reduced methane production relative to total light ends gas production results in lower hydrogen consumption and lower reactor exotherms.

Owner:UOP LLC

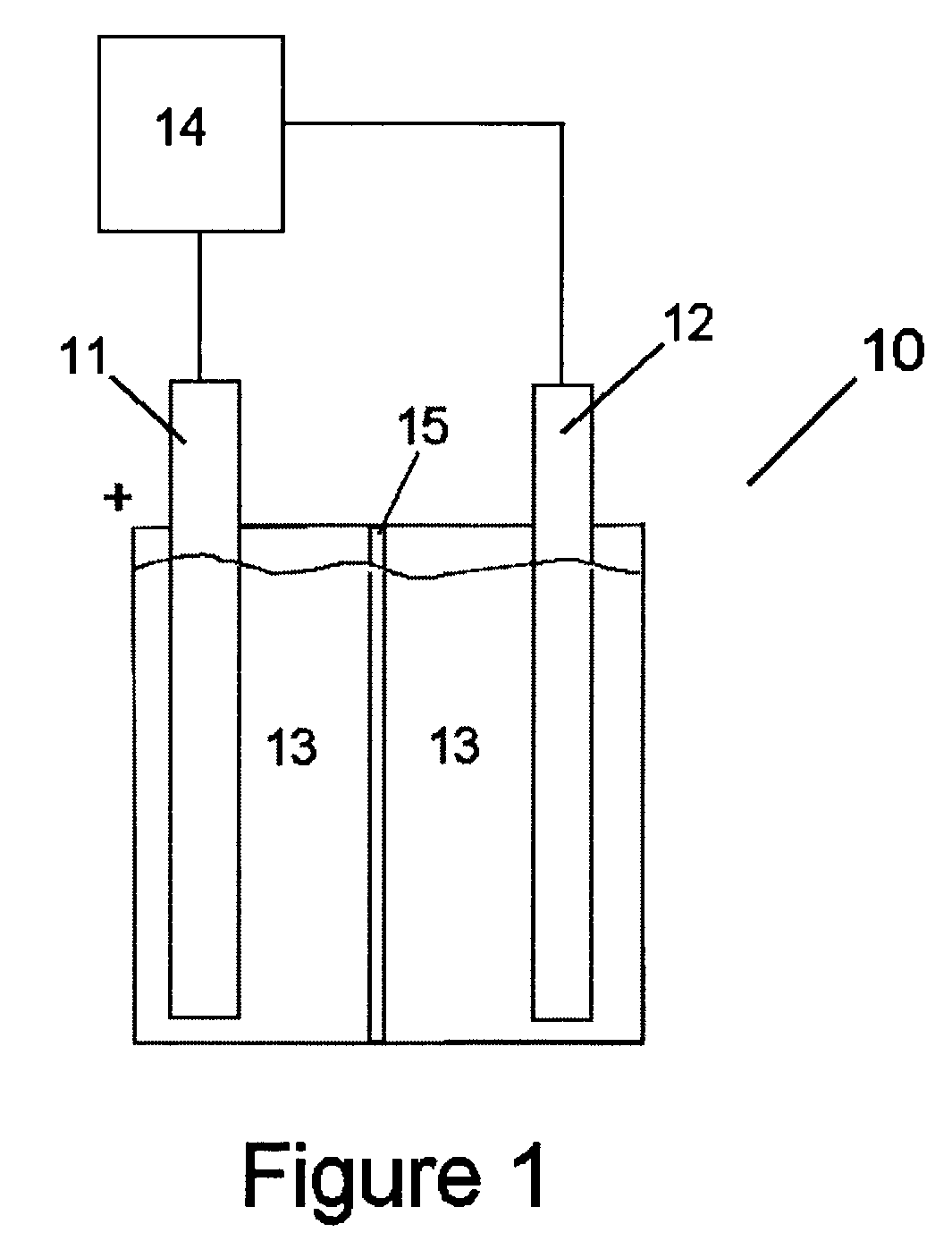

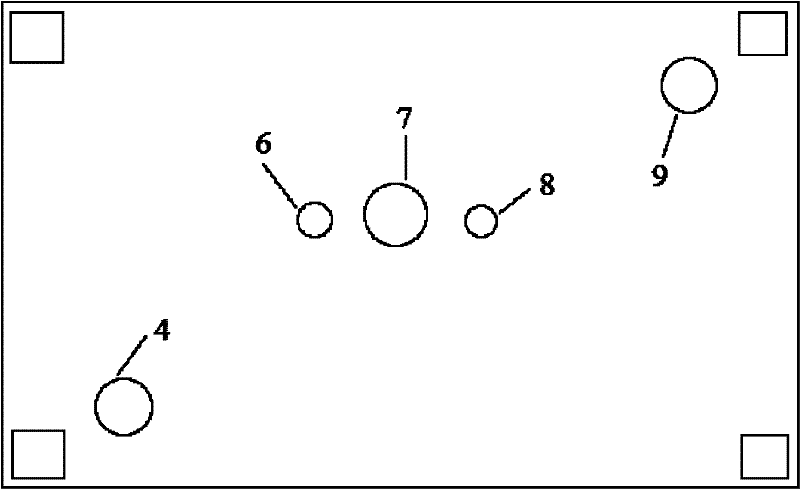

A device and method for studying hydrogen permeation behavior of metals in acidic atmospheric medium

ActiveCN102288654AEasy to measureHigh simulationPreparing sample for investigationMaterial electrochemical variablesElectrolytic agentGas phase

The invention relates to a device and a method for research on hydrogen permeation of metal, in particular to a device and a method for research on hydrogen permeation of metal in acidic atmospheric medium with an adjustable pH value. The device comprises an environmental tank, an anode tank and a liquid storage bottle. A specimen to be tested is fixed at an opening at the bottom of the anode tank, and electrolyte in the anode tank adopts NaOH solution. Acidic solution in the environmental tank can form an acidic atmospheric medium environment under a water bath. Three electrodes are connected with corresponding ports of an electrochemical working system through wires. By adopting the device and the method, the hydrogen permeation current of metal materials in the acidic atmospheric medium can be measured, gas-phase components can be controlled, and the relevant defects of the conventional double electrolytic tanks for electrochemical hydrogen permeation can be overcome.

Owner:河北维立方科技有限公司

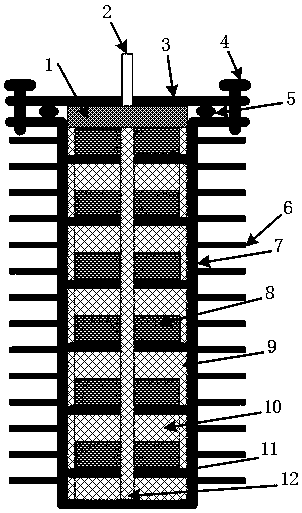

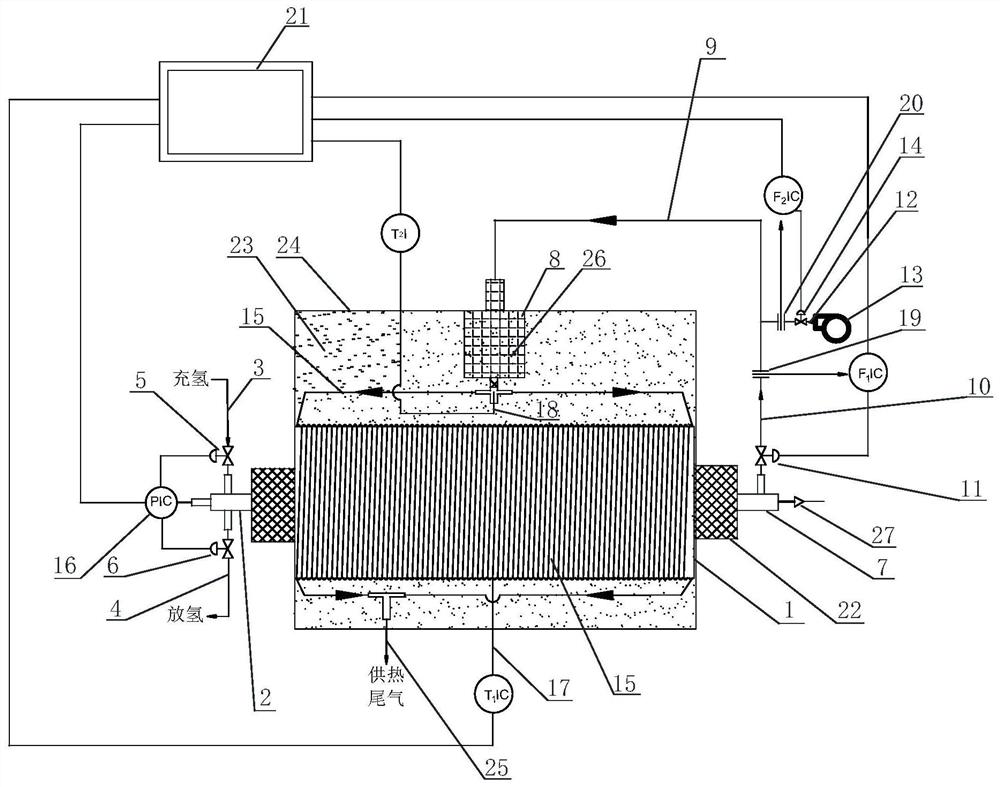

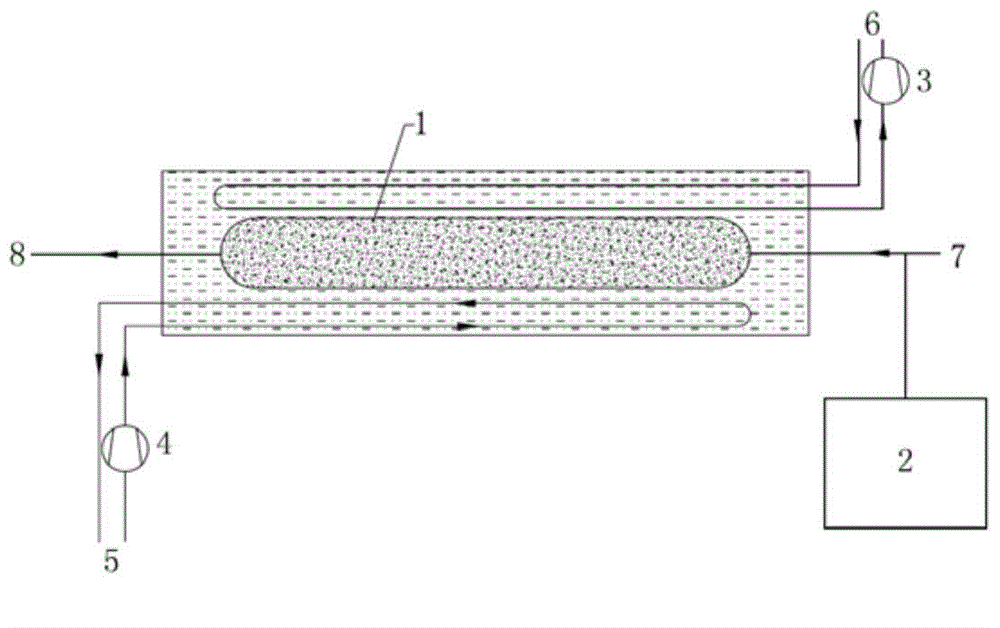

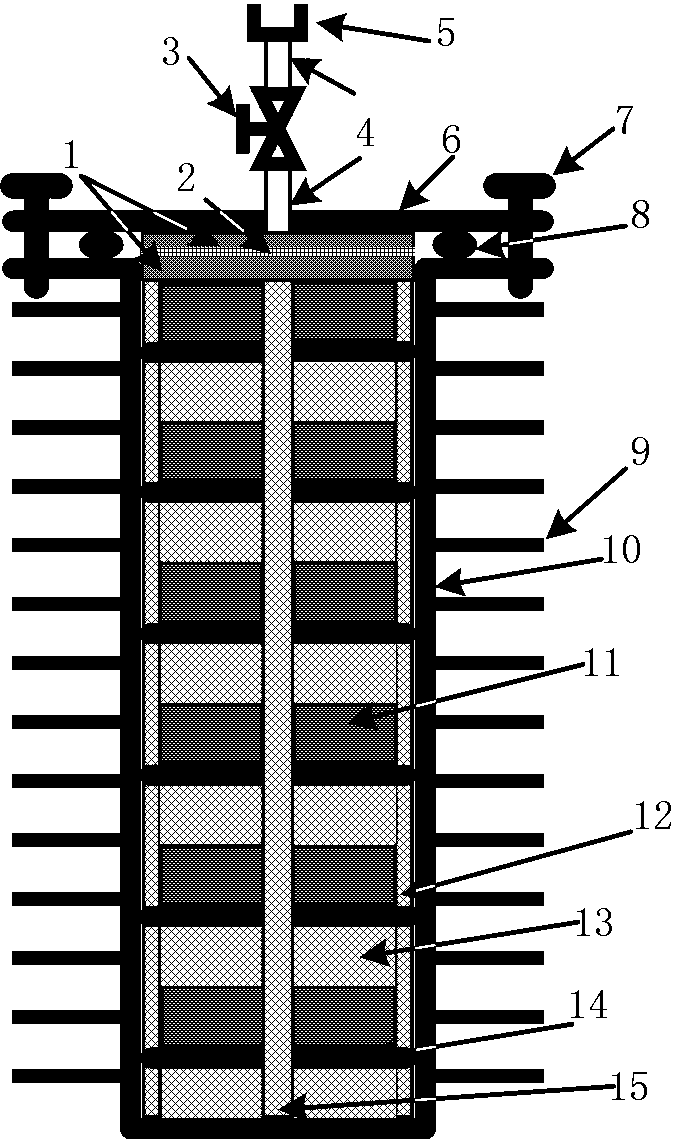

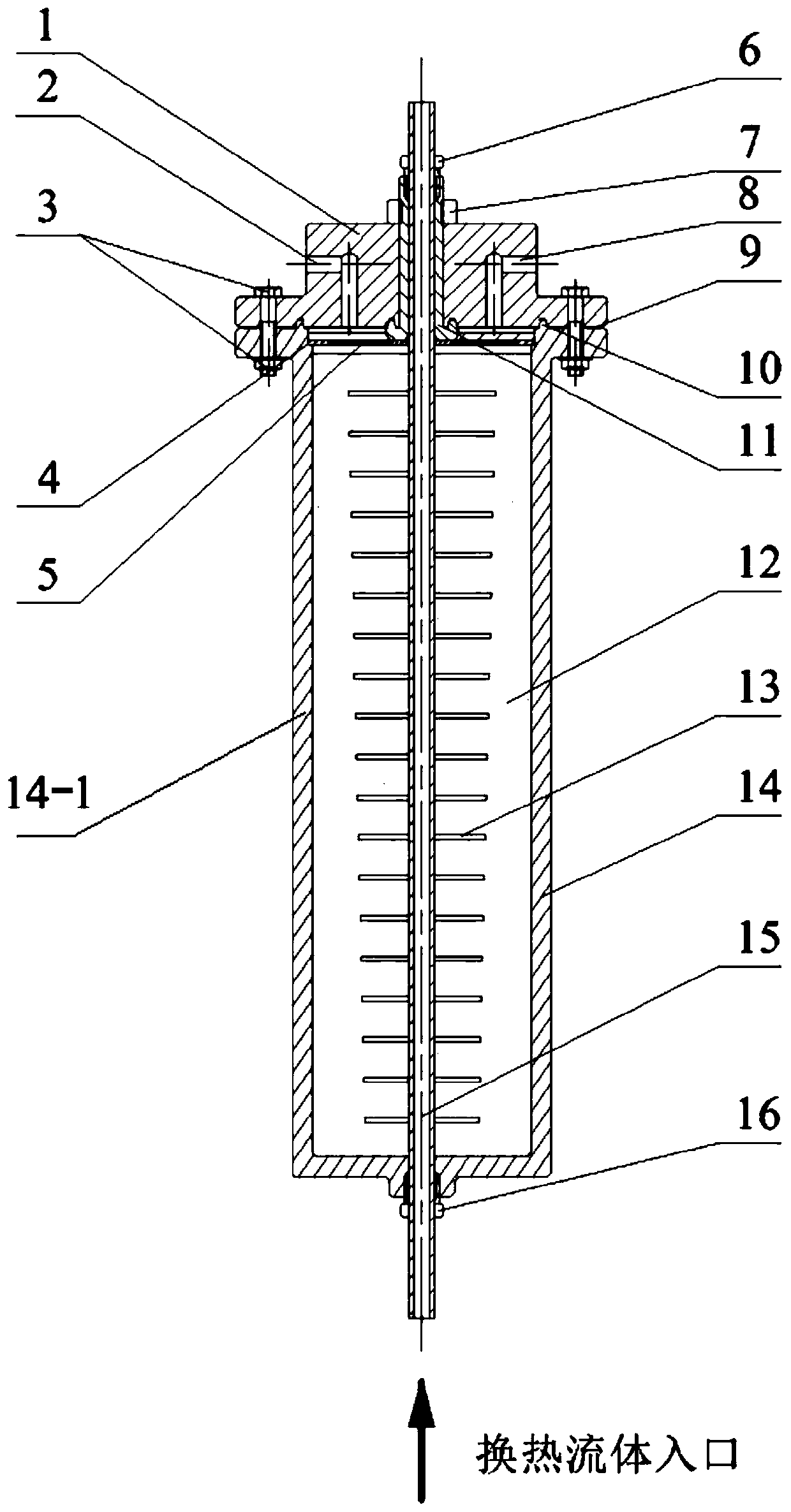

Low-cost, high-hydrogen-absorption-and-desorption-speed and high-safety metal hydride hydrogen storage tank

PendingCN111022912AFast hydrogen absorption and desorptionIncrease productivityVessel geometry/arrangement/sizeVessel wallsMetallurgyMetallic hydrogen

The invention relates to a hydrogen storage technology, in particular to a low-cost, high-hydrogen-absorption-and-desorption-speed and high-safety metal hydride hydrogen storage tank. The hydrogen storage tank mainly comprises a round foam metal cover, a gas pipe, a flange cover, bolts, an O-shaped sealing ring, cooling fins, a tank body, hydrogen storage material powder, a round foam metal barrel, a foam metal disc, a heat pipe and a foam metal cylinder. The metal hydride hydrogen storage tank is simple in structure and easy to realize, the condition that metal hydride powder flows out of thegas pipe with the gas flow to damage downstream components can be prevented, the hydrogen storage tank has the excellent heat and mass transfer performance, and thus the hydrogen storage tank has thehigh hydrogen absorption and desorption speeds. Besides, according to the hydrogen storage tank, damage to the tank body of the hydrogen storage tank due to self-compaction and hydrogen absorption expansion of the metal hydride powder can be avoided, so that the hydrogen storage tank is high in safety and can be used repeatedly.

Owner:YANGZHOU UNIV

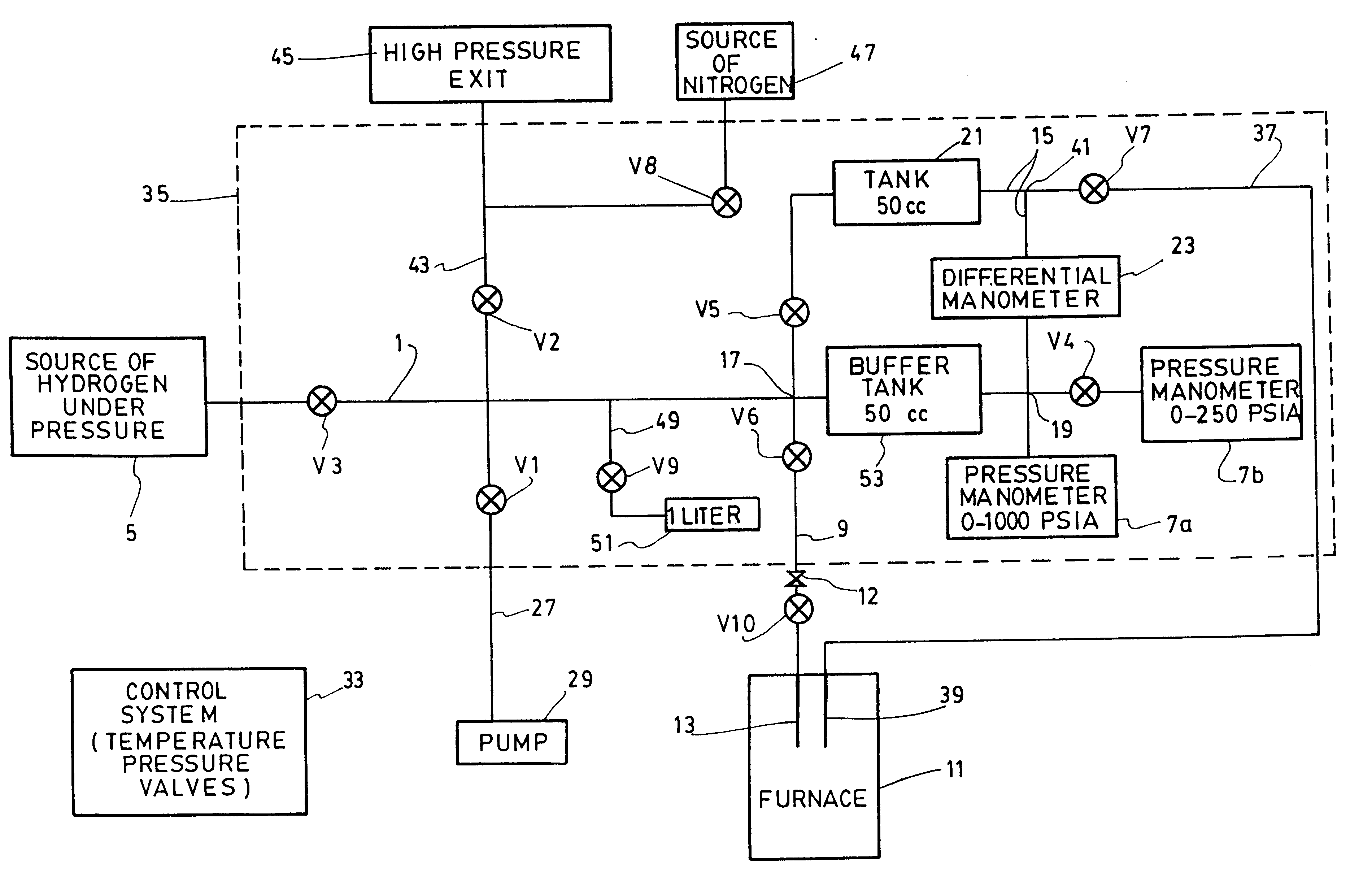

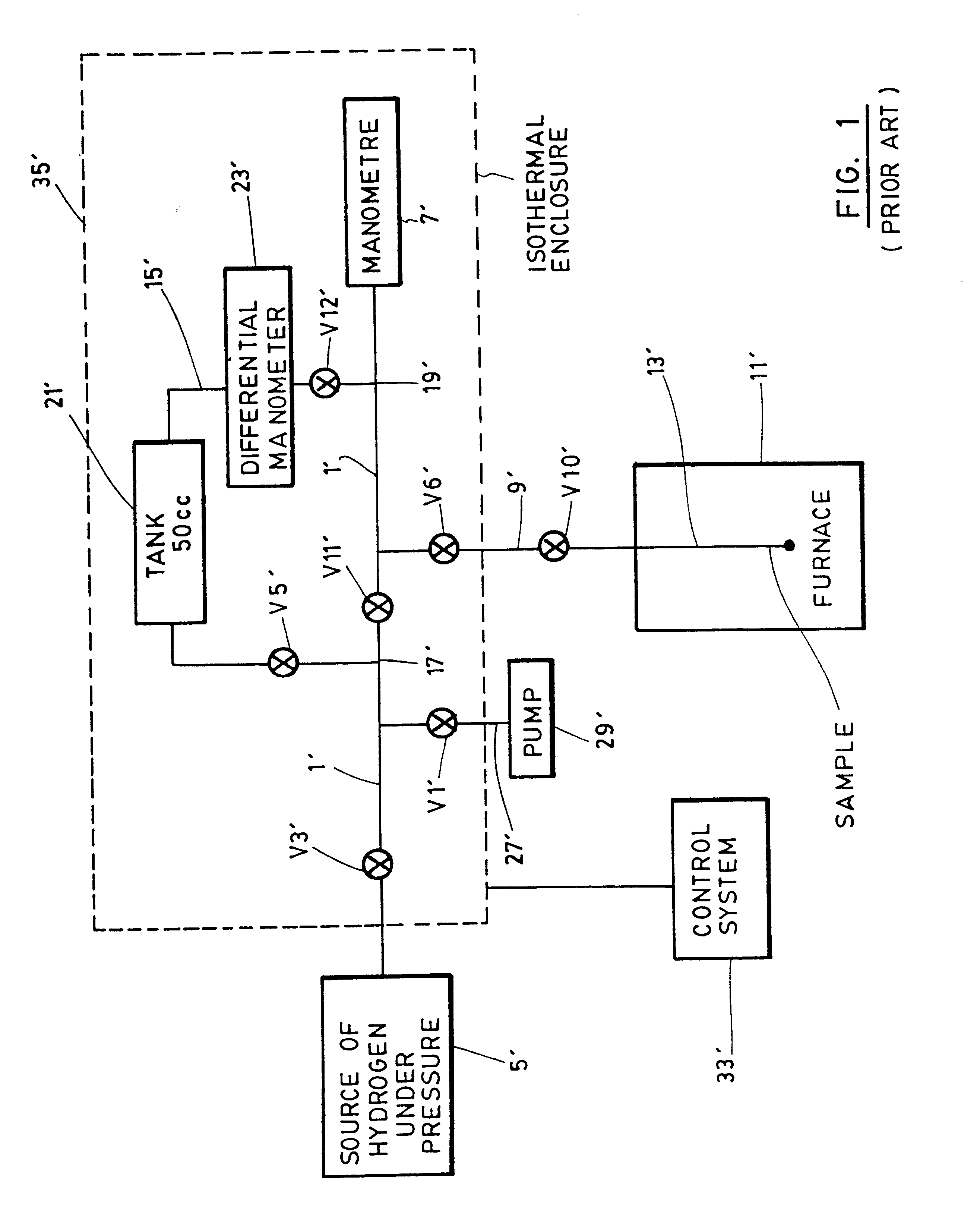

Apparatus for titration and circulation of gases and circulation of an absorbent or adsorbent substance

InactiveUS6582663B1Improve performanceHigh sensitivityComponent separationLaboratory glasswaresDifferential pressureSorbent

The invention concerns an apparatus for the titration and circulation of gases to determine metal hydride storing properties, with improved response time, greater dynamic range in terms of the usable amount of powder and the maximum pressure accessible and increased sensitivity. The invention also concerns a circulating apparatus considerably reducing the time for analysing and determining the properties of absorbent and adsorbent materials during a large number of adsorption-desorption cycles. Both sets of apparatus are provided with a reference tube inside their oven, near the sample-holder. Said sample-holder tube and reference tube are connected on either side of the differential pressure sensor, thereby considerably enhancing the overall performance of the titration system.

Owner:HYDRO QUEBEC CORP

Self-heating metal hydride hydrogen storage system and hydrogen charging and discharging method

ActiveCN112303490ARealize autonomous temperature controlVessel geometry/arrangement/sizeVessel wallsPtru catalystMetallic hydrogen

The invention discloses a self-heating metal hydride hydrogen storage system which comprises a hydrogen storage system and a hydrogen catalytic combustion heating system used for heating the hydrogenstorage system. The hydrogen storage system comprises a hydrogen storage tank, a metal hydride hydrogen storage material is contained in the hydrogen storage tank, a hydrogen charging and dischargingport is formed in one end of the hydrogen storage tank, and a hydrogen outlet port used for supplying hydrogen to the hydrogen catalytic combustion heating system is formed in the other end of the hydrogen storage tank. The hydrogen catalytic combustion heating system comprises a hydrogen catalytic combustor, a catalyst is contained in the hydrogen catalytic combustor, the gas inlet end of the hydrogen catalytic combustor is connected with a mixed gas conveying main pipeline, the gas outlet end of the hydrogen catalytic combustor is connected with a heat conduction pipe, and the heat conduction pipe is wound on the hydrogen storage tank. According to the self-heating metal hydride hydrogen storage system, part of hydrogen in the hydrogen storage tank is separated out to be subjected to catalytic combustion on the catalyst in the combustor, and the hydrogen storage tank is heated through high-temperature gas generated after combustion, so that autonomous temperature control and autonomous heat supply can be achieved, and a heating system does not need to be additionally arranged.

Owner:SHANDONG UNIV OF SCI & TECH

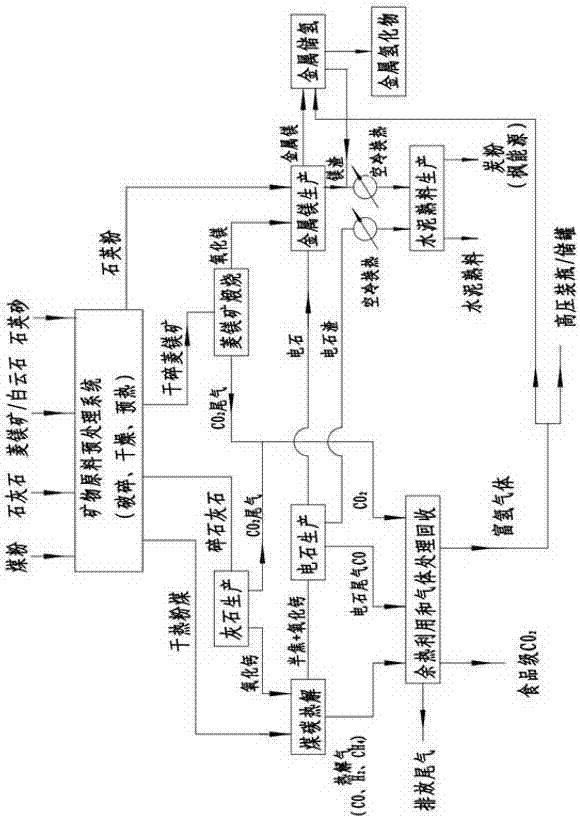

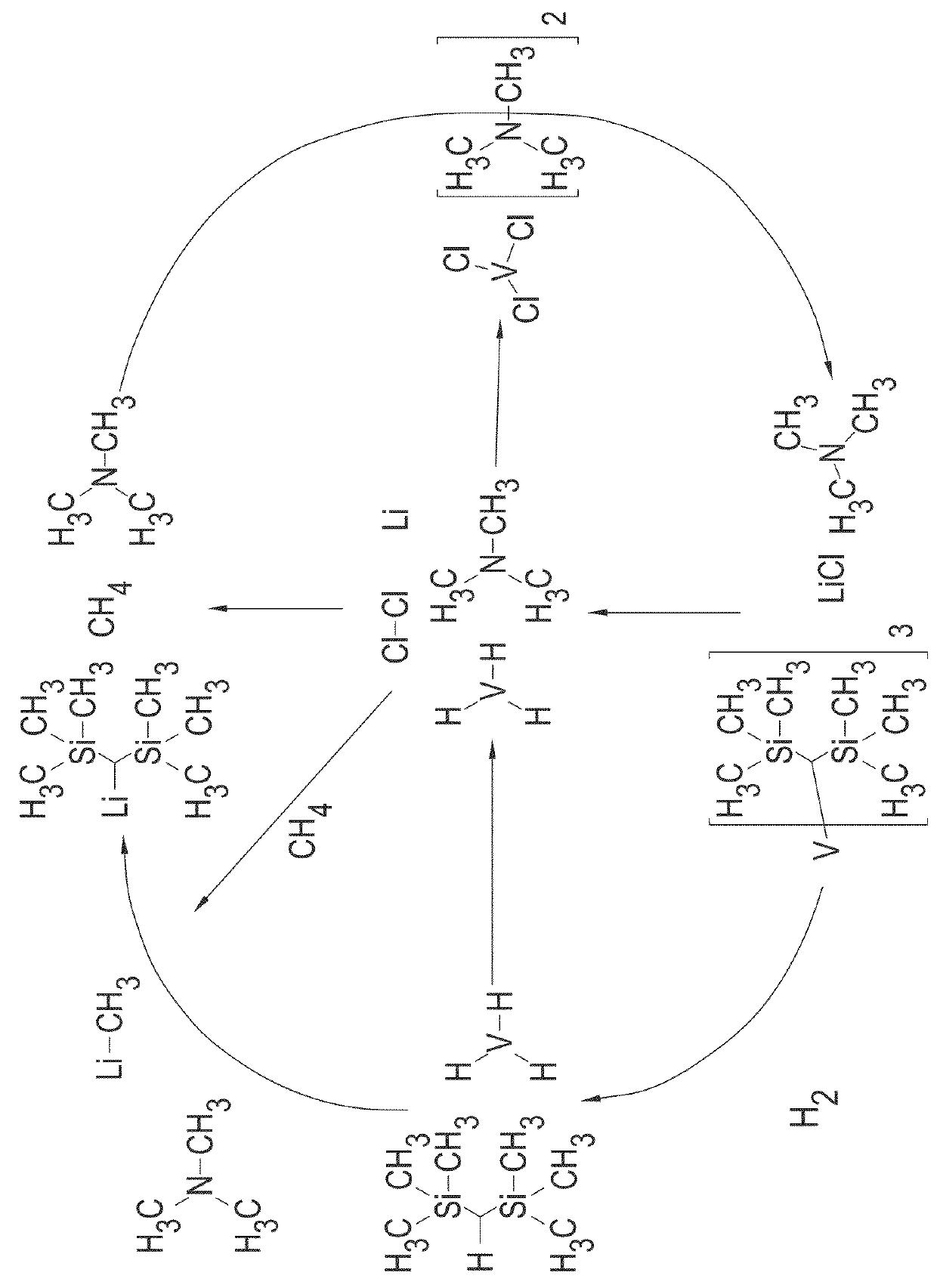

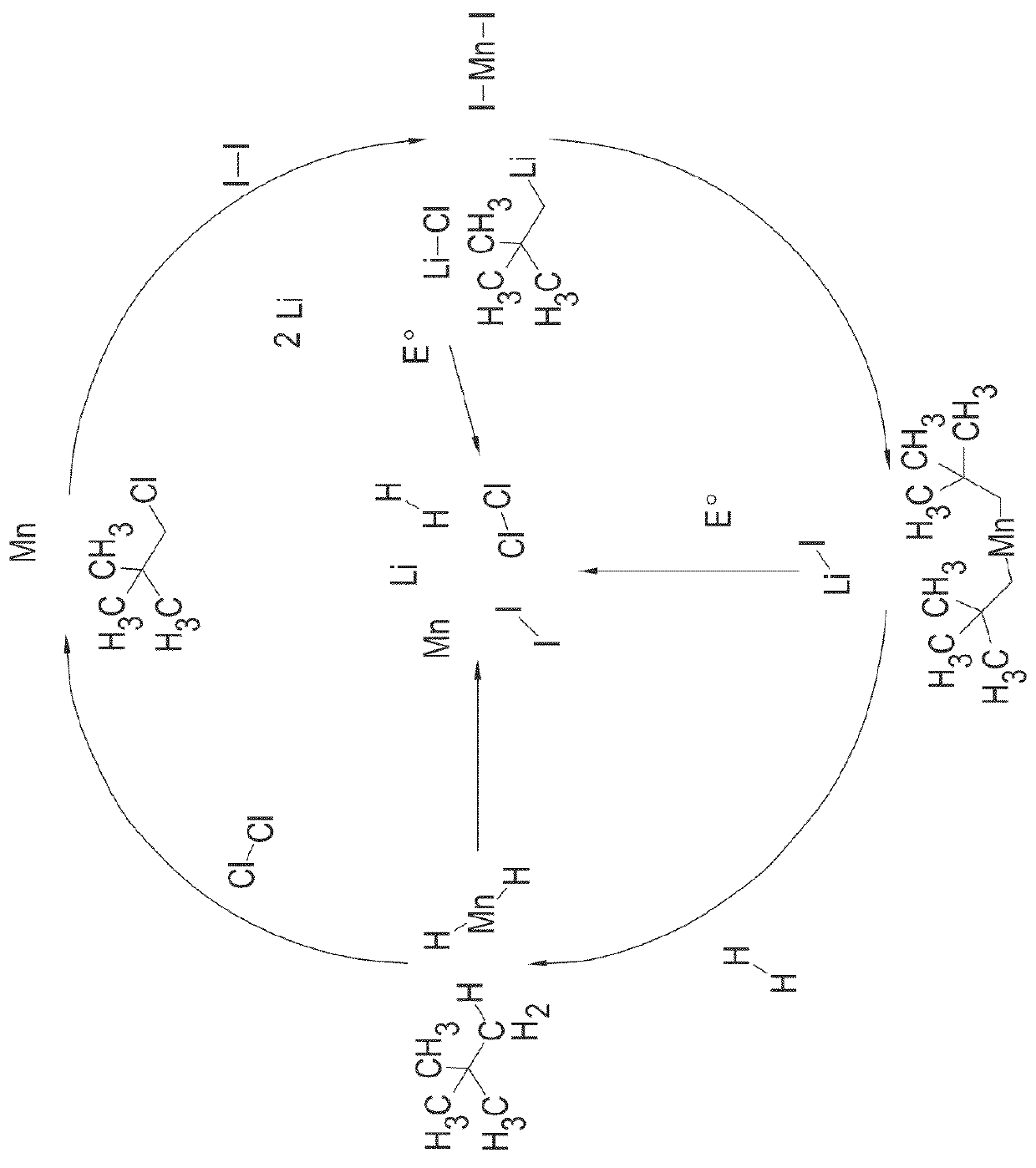

Rotary kiln and poly-generation system utilizing rotary kiln for producing metal hydride

InactiveCN107091569ARealize continuous productionNo emissionsFurnace componentsAlkali/alkaline-earth/beryllium/magnesium hydridesHigh concentrationBrick

The invention discloses a rotary kiln and a poly-generation system utilizing the rotary kiln for producing metal hydride. The poly-generation system comprises a lime production sub-system, a pulverized coal production sub-system, a calcium carbide production sub-system, a magnesium metal production sub-system, a waste heat utilizing and gas recycling sub-system, a metal hydrogen storage sub-system and a cement clinker production subsystem. Limestone, magnesite / dolomite, quartz sand and coal serve as raw materials, and the limestone is roasted into lime; in a lime kiln built through zirconia bricks, the lime and the coke powder are subjected to the high-temperature reaction so that liquid calcium carbide can be obtained; the magnesite / dolomite is roasted into magnesium oxide, and the calcium carbide, the magnesium oxide and the quartz sand are mixed to generate magnesium; high-concentration carbon dioxide, coal pyrolysis gas and calcium carbide tail gas obtained through decomposing of the limestone and the magnesite are recycled and processed, and hydrogen and food-level carbon dioxide are obtained; magnesium hydride is generated through union of hydrogen and magnesium; and carbide slag and magnesium slag are processed, and cement clinker and carbon powder are obtained. According to the poly-generation system, emission of solid waste is avoided, and carbon emission is greatly reduced.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

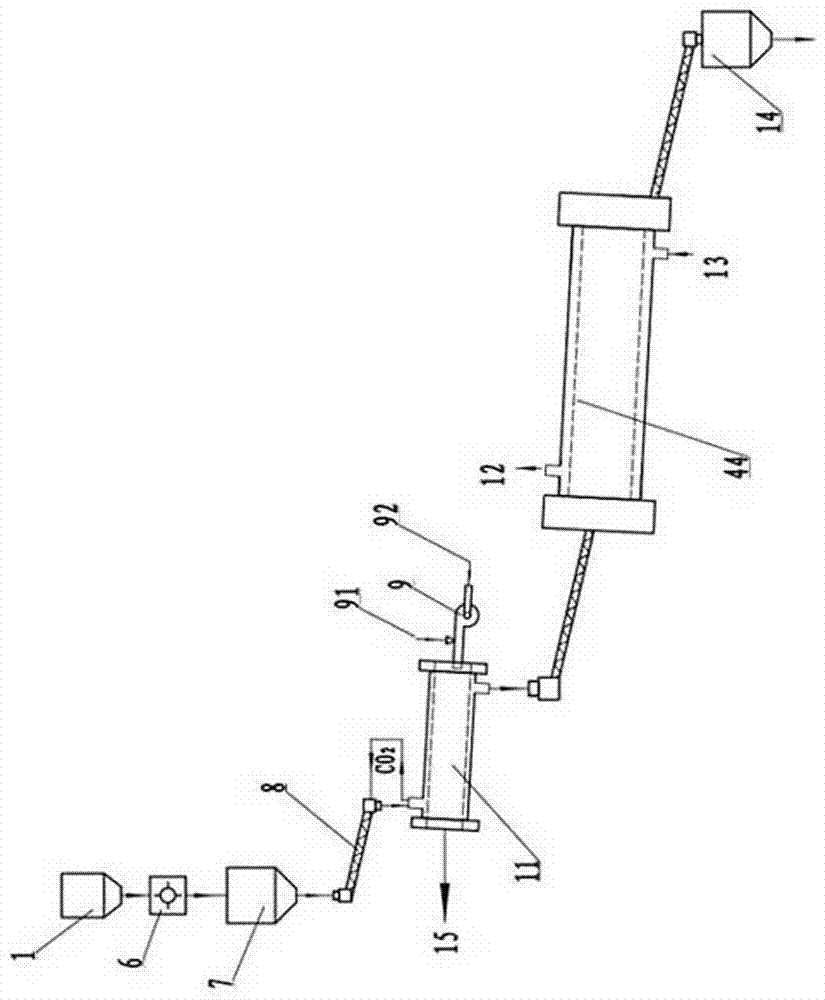

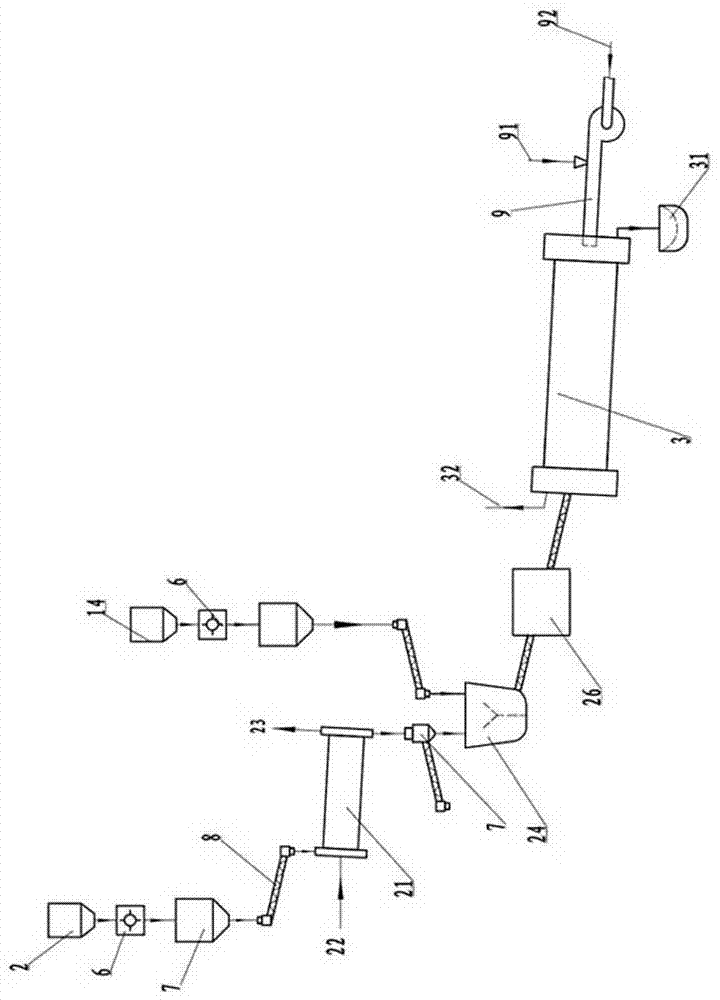

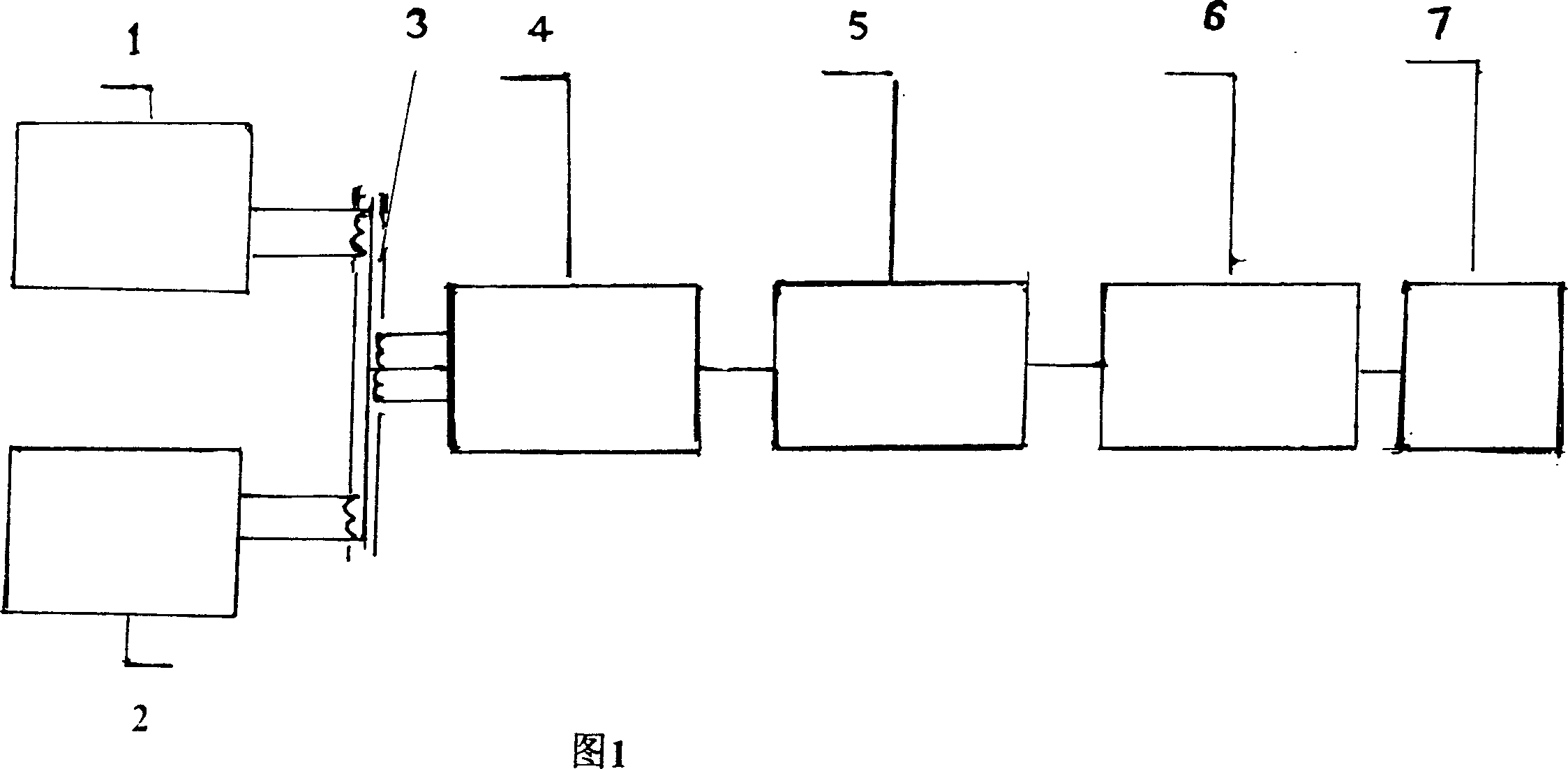

Method and apparatus for wind-light hydroyen-making and extracting heavy water

InactiveCN101024883AImprove efficiencyQuality improvementCellsFinal product manufactureHeavy waterElectric generator

The invention relates to a method and device for preparing hydrogen with wind and light and refining heavy water. And it comprises the five parts of: 1. solar power generating part; 2. wind power generating part; 3. hydrogen and oxygen producing part by electrolysis; 4. common hydrogen storage part; and 5. high pressure ultrapure making part, where the first part comprises: heat collector set composed of solar heat collecting plates, heat collecting loop, circulating pump, heat exchanger, steam loop, turbine engine, power generator, and cooler; the second part comprises vertical shaft, speed change gear, arm of force, active throttle, ground gear, railway, electrobath, steam-water separator, cooling drying gas, circulating pump, motor, water supply tank, heavy water collecting tank, heavy water outlet pipe, hydrogen gas outlet, and oxygen gas outlet; the fourth part comprises steel case, oxygen gas outlet, hydrogen gas outlet, active pressure plate, rubber hydrogen storage soft gallbladder, rubber hydrogen storage soft gallbladder, valve, hydrogen gas inlet and oxygen gas inlet; and the fifth part comprises catalytic deoxidation drying purifiers, metal oxide terminal purifying compressors, product storage steel cylinders and the connecting pipeline, and valves. By a 140KW standard, the invention can per hour produce high pressure ultrapure hydrogen 101.2kg; oxygen gas 896kg; refines heavy water 0.15kg; consumes water 2000kg; has efficiency 90%; pressure 13-15MPa; and purity able to be up to 99.9999%.

Owner:刘书亭 +1

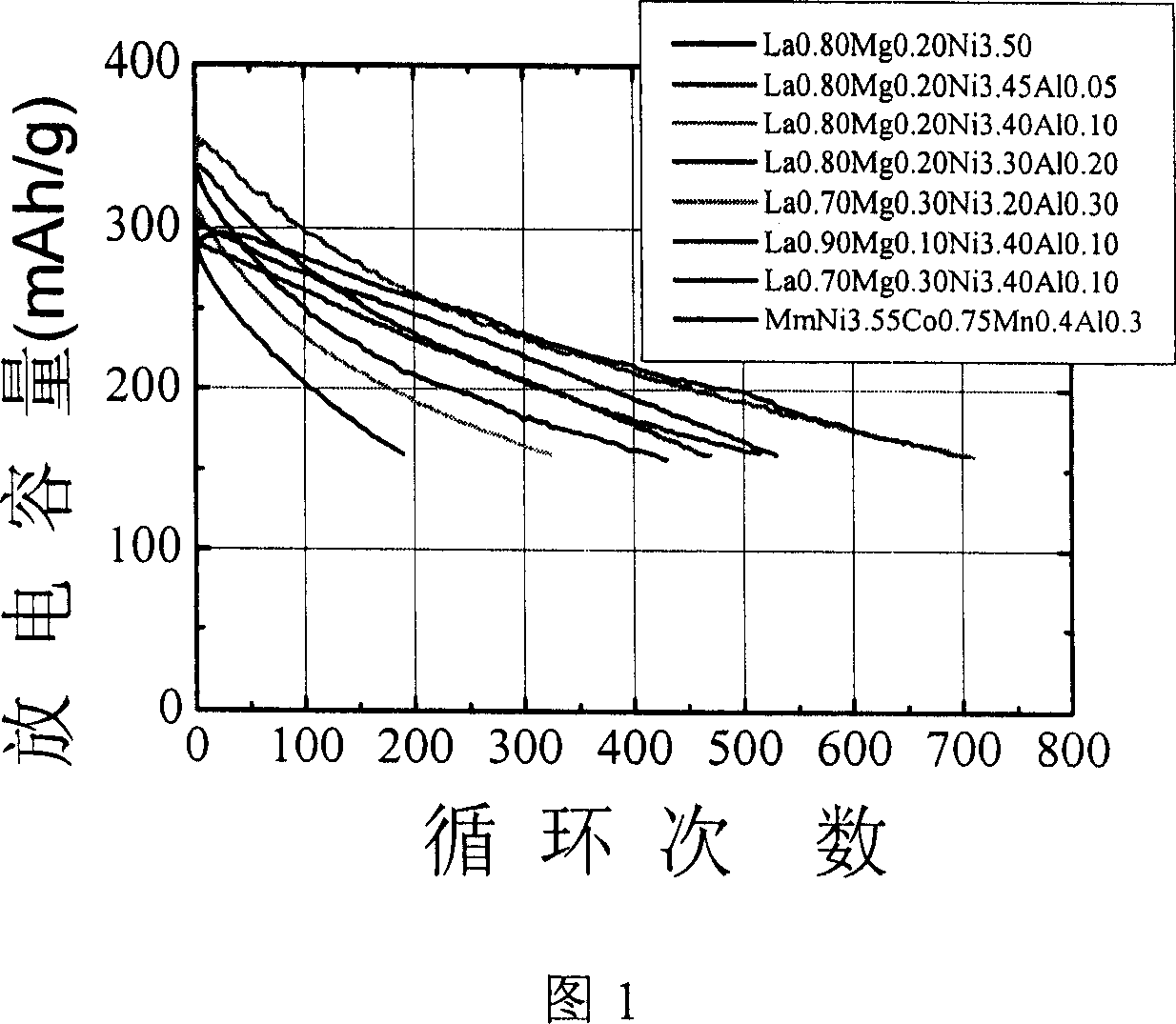

AB3.5 type hydrogen-storing negative pole material and its prepn process and use

InactiveCN1974812AHigh electrochemical discharge capacityHigh charge and discharge capacityOther chemical processesMultiple metal hydridesVacuum pumpInduction furnace

The process of preparing AB3.5 type hydrogen-storing negative pole material includes: setting the material inside crucible in a vacuum inducing furnace, vacuuming before introducing Ar in the pressure of 0.2-3 atm, smelting and casting. There is one pipe with one end stretched over the crucible inside the furnace and the other end connected to the vacuum pump outside the furnace, and one valve connected to the pipe outside the furnace to control vacuuming rate, so that the Mg vapor may be pumped out from the furnace. The cast ingot is homogenizing treated in a vacuum heat treating furnace at 850-1020 deg.c for 6-15 hr before being cooled inside the furnace to room temperature. The AB3.5 type hydrogen-storing negative pole material is used in metal hydride-nickel cell.

Owner:北京宏福源科技有限公司

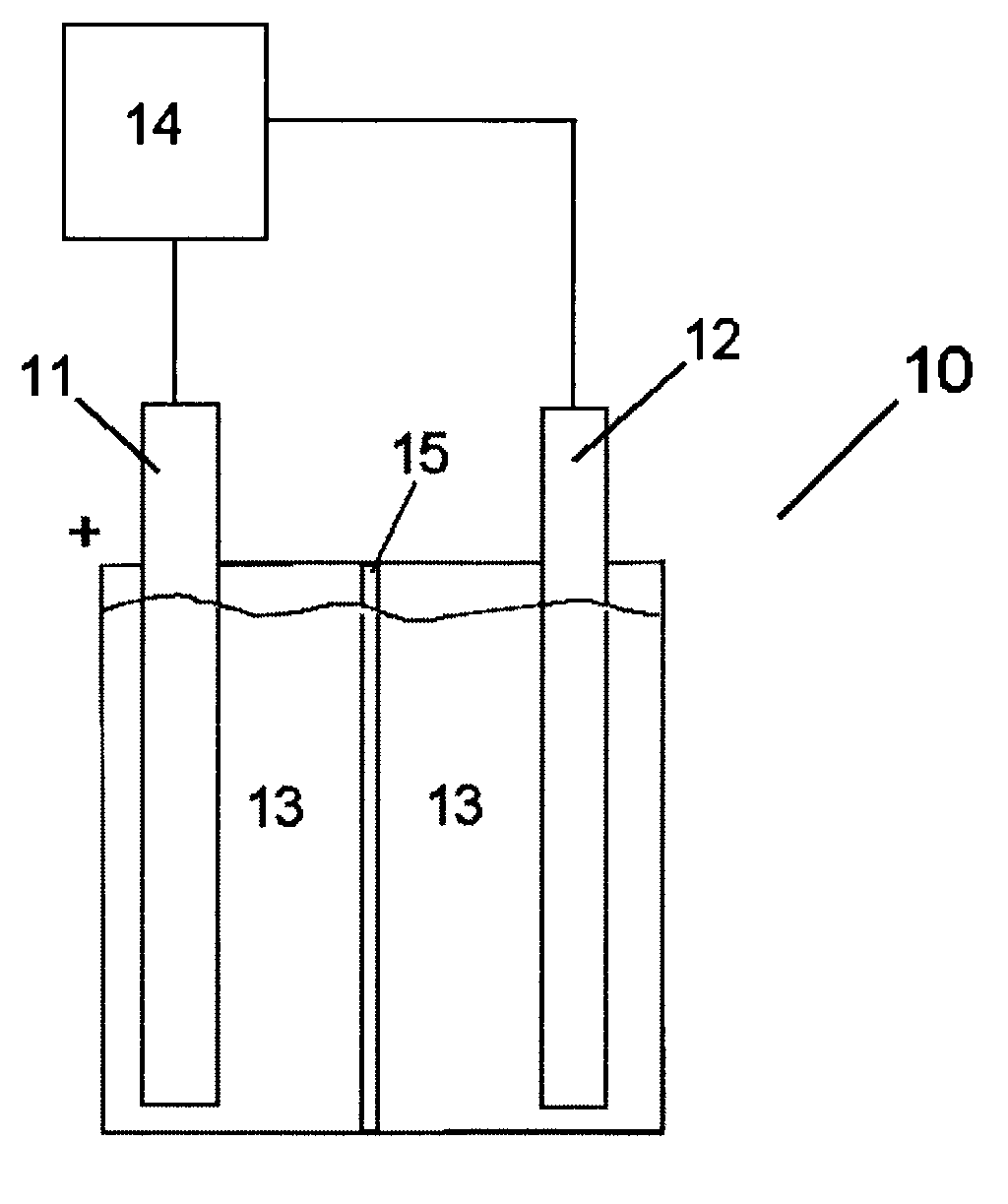

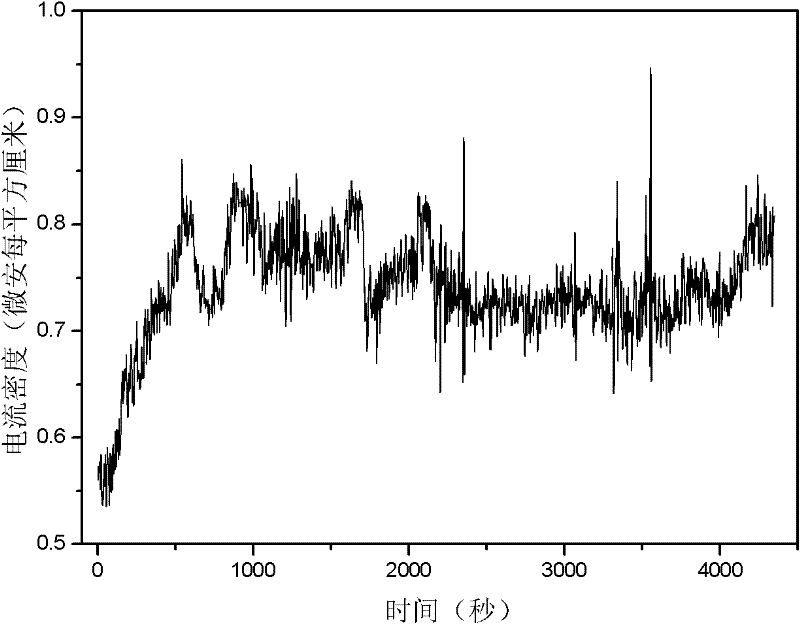

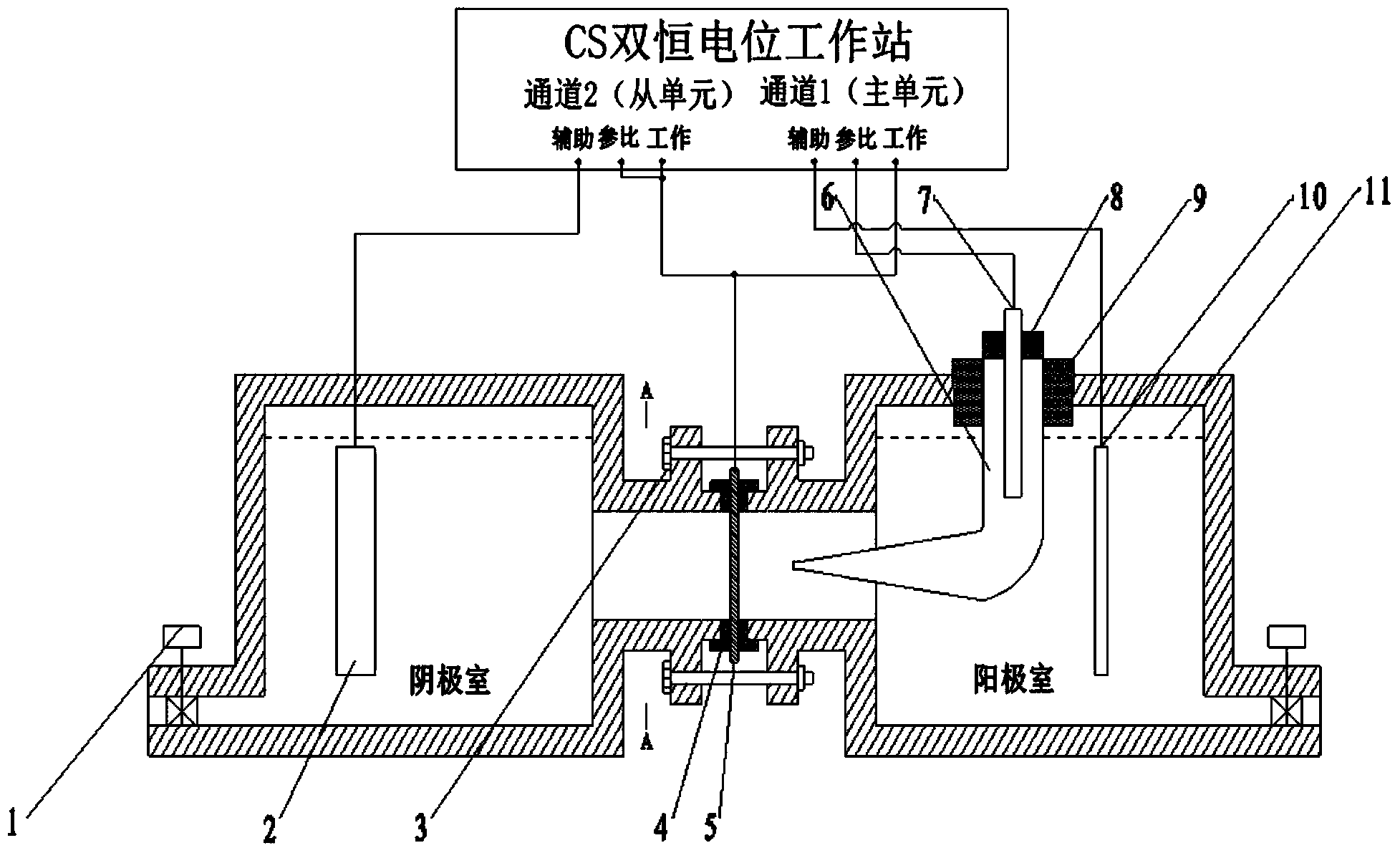

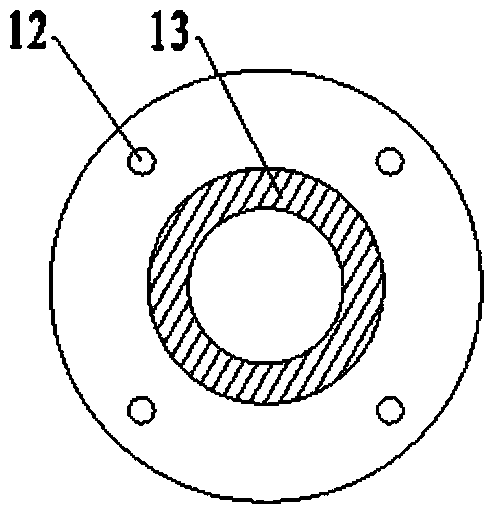

Determination device for metallic hydrogen diffusion current

The invention discloses a determination device for metallic hydrogen diffusion current. The determination device comprises a cathode chamber, an anode chamber and a CS double constant potential workstation, wherein the cathode chamber and the anode chamber are communicated with each other; a hole provided with a drain valve is formed in the lower part of one side of each of the cathode chamber and the anode chamber; a beak bent-tube stretching from the anode chamber to a communicating channel is mounted at the top opening of the anode chamber through a tightened rubber plug, a saturated calomel reference electrode is mounted in the beak bent-tube through a rubber plug, and an auxiliary electrode II connected with a conducting wire is also arranged in the anode chamber and positioned near to one side of the beak bent-tube; an auxiliary electrode I connected with the conducting wire is also arranged in the cathode chamber; a sample connected with the conducting wire is clamped between the connecting end faces of the communicating channel through sealed rubber rings; the auxiliary electrode I, the sample, the saturated calomel reference electrode and the auxiliary electrode II are connected to related interfaces in the CS double constant potential workstation through the conducting wires. The determination device has the advantages that the good accuracy is realized, the operation is convenient, the measuring results are stable and reliable and the usage and maintenance cost is low.

Owner:JIANGSU UNIV OF SCI & TECH

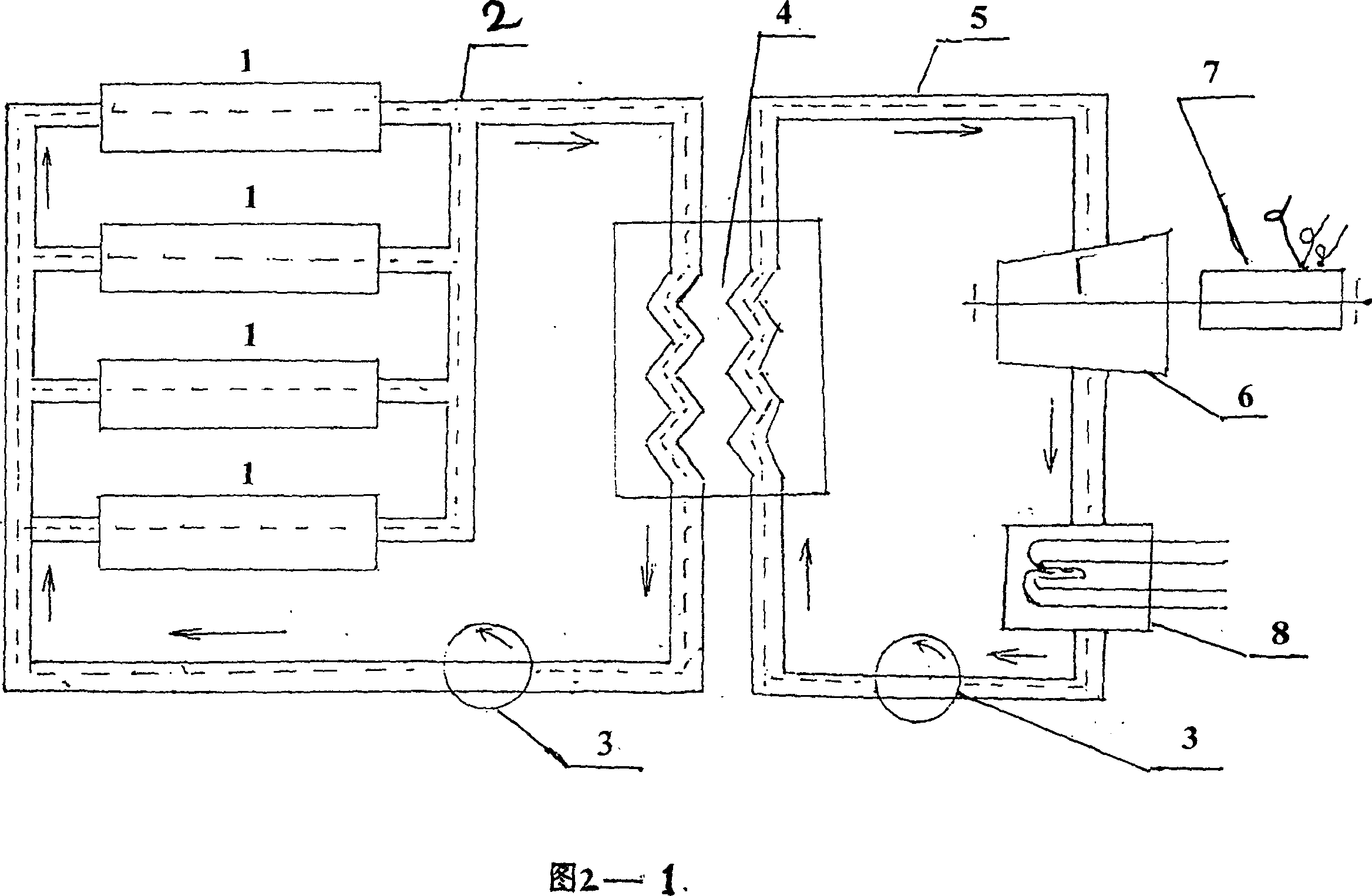

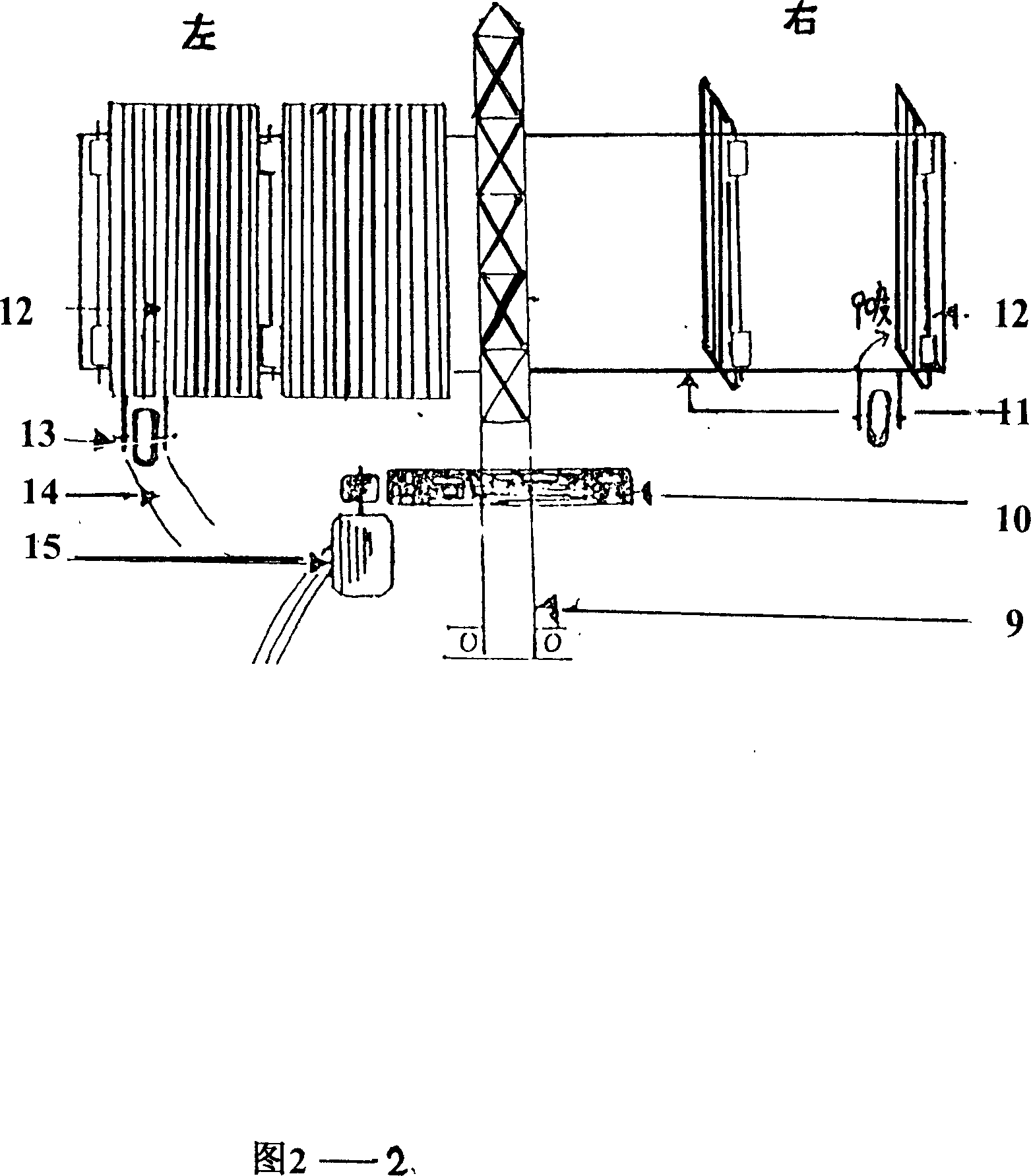

Device for preparing high-pressure hydrogen by using metal hydrides

ActiveCN104671199AEnsure safetyGuaranteed to work under safe temperature/pressure rangeEnergy inputHydrogen productionStatic compressionControl manner

The invention discloses a device for preparing high-pressure hydrogen by using metal hydrides and belongs to the technical field of static compression of hydrogen. The device comprises a control part, a heating loop, a cooling loop, a reaction bed, a circulation water pump and a gas pipeline, wherein the heating loop and the cooling loop are wound around the outer wall of the reaction bed at intervals and are connected to the circulation water pump respectively; the gas pipeline is arranged in a reaction bed body; the control part is connected to the gas pipeline of the device. By virtue of the device, the hydrogen is pressurized from 0.2MPa to 20MPa due to the adoption of AB2 type metal hydride such as Ti-Mn base and Ti-Cr base; the pressurization ratio reaches 100; the purity of the output gas reaches 99.999%; the accurate and continuous regulation of the hydrogen output pressure can be implemented by temperature / pressure double alarm control manners of the system, thereby ensuring that the device works under the safe temperature / pressure range and ensuring the safety of the system. The device also has the advantages that the structure is simple, the noise is avoided, the vibration is also avoided, and low-quality waste heat can be utilized.

Owner:GRIMAT ENG INST CO LTD

Metal hydrides and their use in hydrogen storage applications

ActiveUS9376316B2Reduce pressureReversible hydrogen uptakeCell electrodesPhysical chemistryMetallic hydrogen

Owner:HYDRO QUEBEC CORP

Hydrogen purification device

InactiveCN105060248AEasy to operateGuaranteed uptimeHydrogen separation using solid contactPhysical chemistryMetallic hydrogen

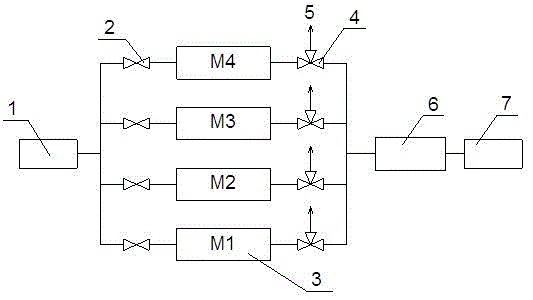

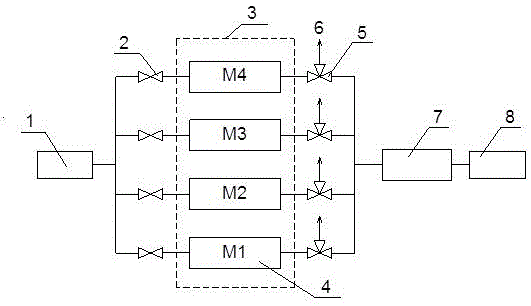

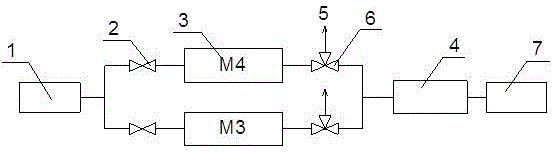

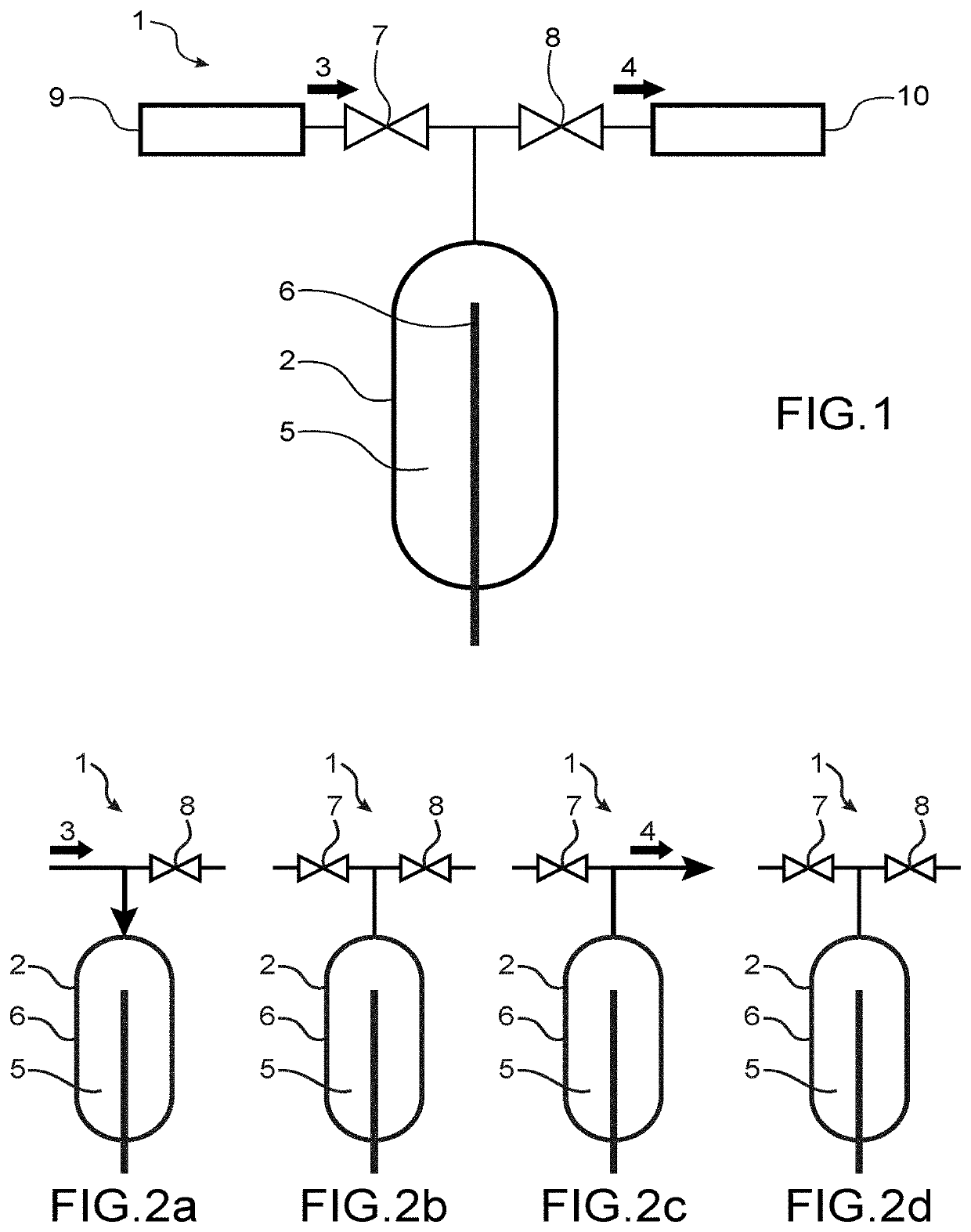

The invention provides a hydrogen purification device. The hydrogen purification device comprises at least two metal hydride reactors and a flow and pressure control system, wherein the at least two metal hydride reactors are filled with hydrogen storage alloys, inlets and outlets are controlled through valves, the inlet ends are connected with a hydrogen source with lower purity, purified hydrogen with higher purity is released from the outlet ends, and the outlet ends are connected to hydrogen utilization equipment through the flow and pressure control system. By means of the hydrogen purification device, hydrogen can be continuously purified, hydrogen with higher purity is output ceaselessly, the output flow and pressure are controlled, and the device is convenient to operate and runs stably.

Owner:WHOLE WIN BEIJING MATERIALS SCI & TECH

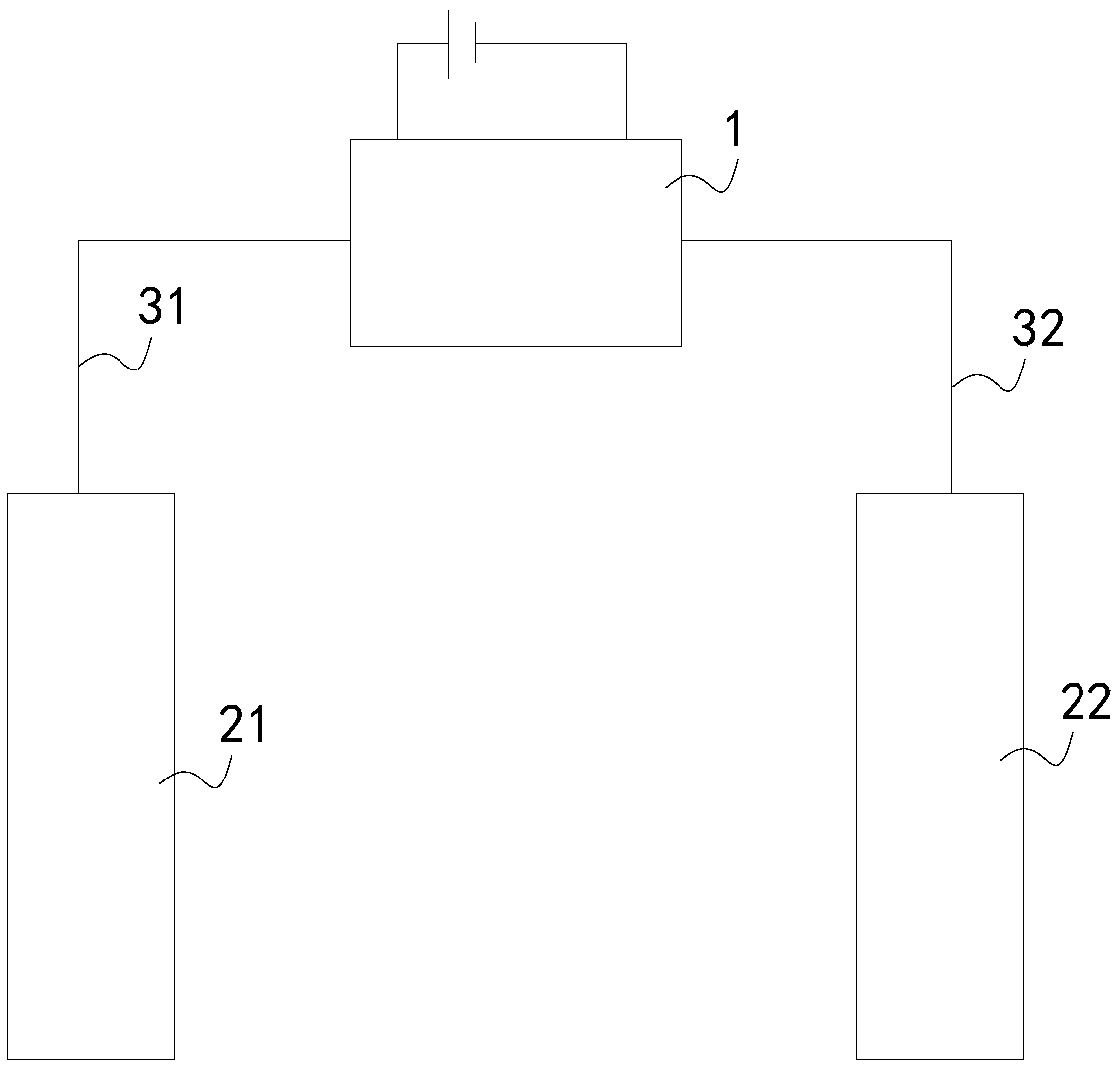

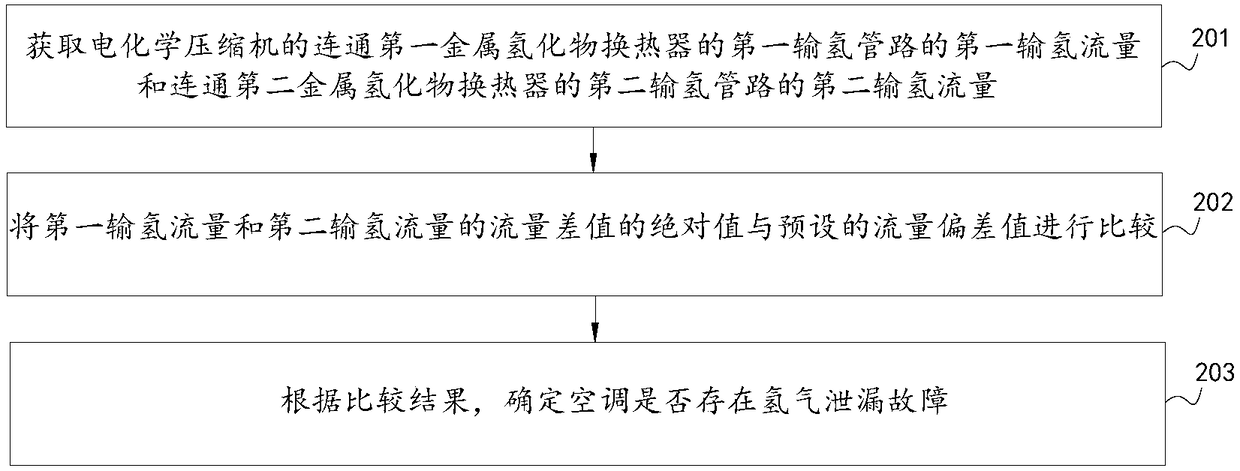

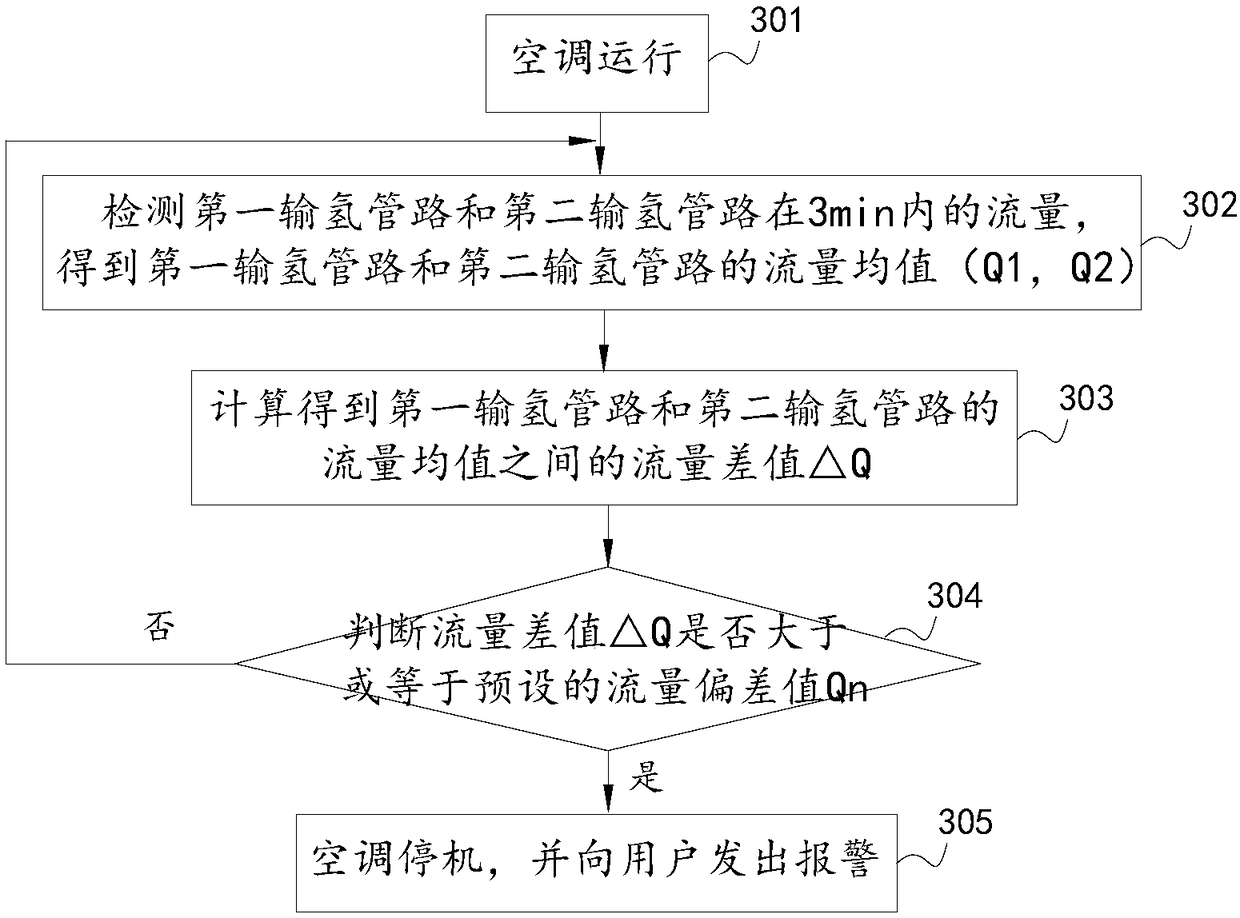

Air conditioner capable of applying electrochemical compressor and detection method and device for hydrogen leakage

The invention discloses an air conditioner capable of applying an electrochemical compressor and a detection method and device for hydrogen leakage, and belongs to the technical field of air conditioners. The detection method comprises the steps that a first hydrogen conveying flow rate in a first hydrogen conveying pipeline which communicates with a first metal hydride heat exchanger and a secondhydrogen conveying flow rate in a second hydrogen conveying pipeline which communicates with a second metal hydride heat exchanger in the electrochemical compressor are obtained; the absolute value of a flow rate difference value of the first hydrogen conveying flow rate and the second hydrogen conveying flow rate and a pre-set flow rate deviation value are compared; and whether the air conditioner has a hydrogen leakage fault or not is determined according to the comparison result. According to the detection method for the hydrogen leakage, whether the air conditioner has the hydrogen leakage fault or not is simply, directly and effectively determined according to the comparison result between the flow rate difference value of hydrogen conveying flow rates of the two hydrogen conveying pipelines and the pre-set deviation value, great help to the performance and service life of the air conditioner capable of applying the electrochemical compressor is achieved, and the safety of a useris guaranteed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Hydrogen storage material and related system

Owner:GENERAL ELECTRIC CO

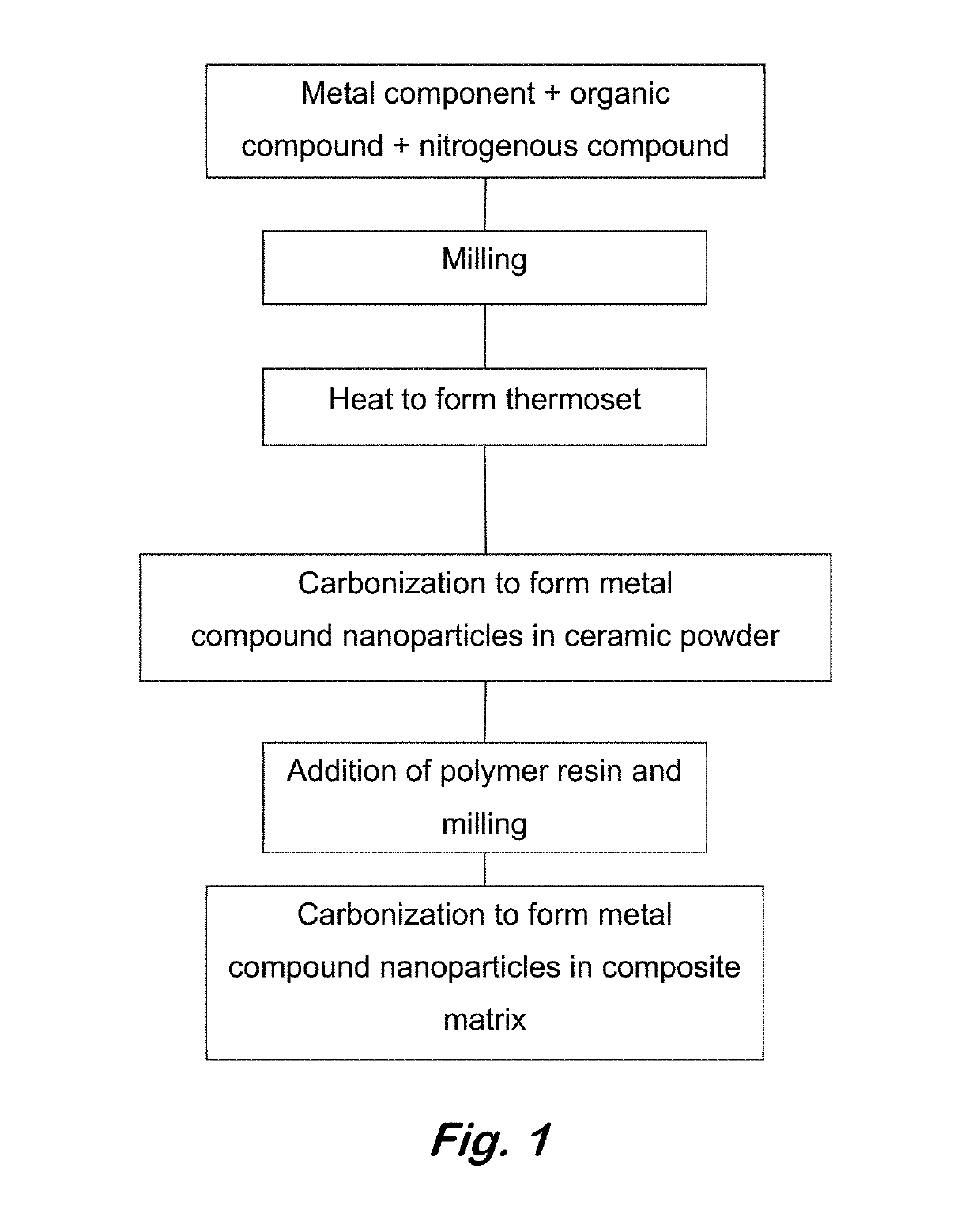

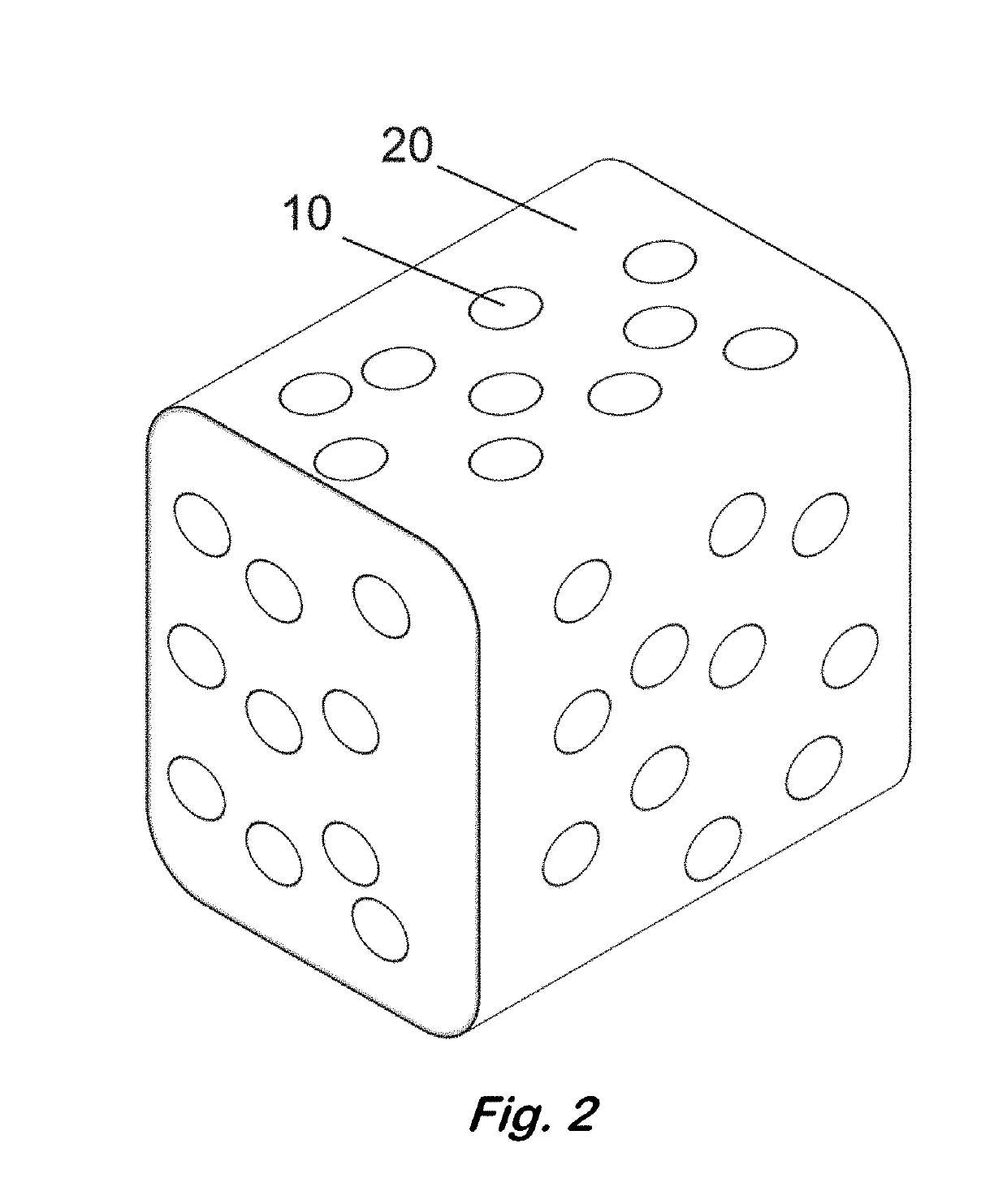

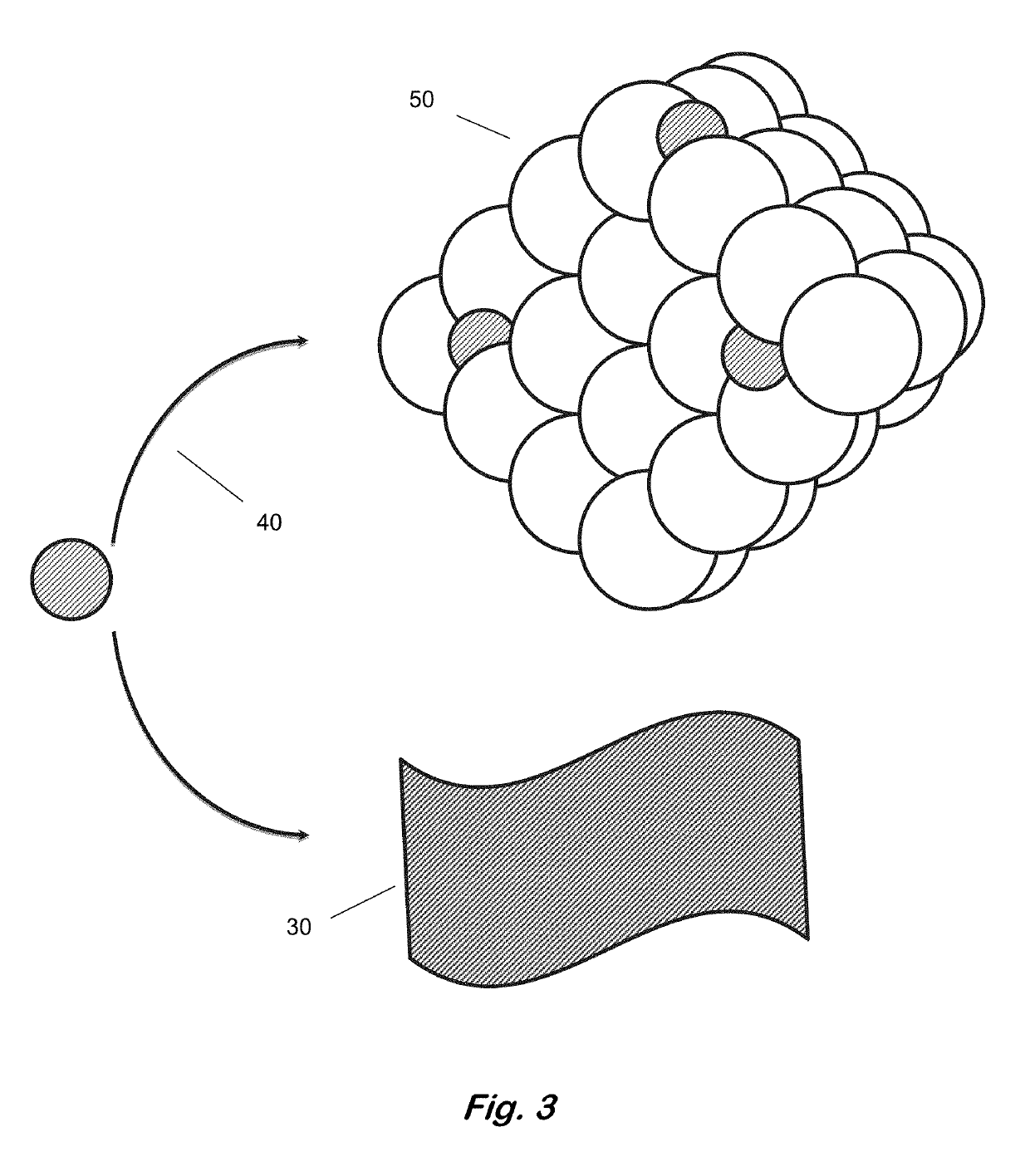

Metal nitrides and/or metal carbides with nanocrystalline grain structure

Disclosed is a composition having nanoparticles or particles of a refractory metal, a refractory metal hydride, a refractory metal carbide, a refractory metal nitride, or a refractory metal boride, an organic compound consisting of carbon and hydrogen, and a nitrogenous compound consisting of carbon, nitrogen, and hydrogen. The composition, optionally containing the nitrogenous compound, is milled, cured to form a thermoset, compacted into a geometric shape, and heated in a nitrogen atmosphere at a temperature that forms a nanoparticle composition comprising nanoparticles of metal nitride and optionally metal carbide. The nanoparticles have a uniform distribution of the nitride or carbide.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

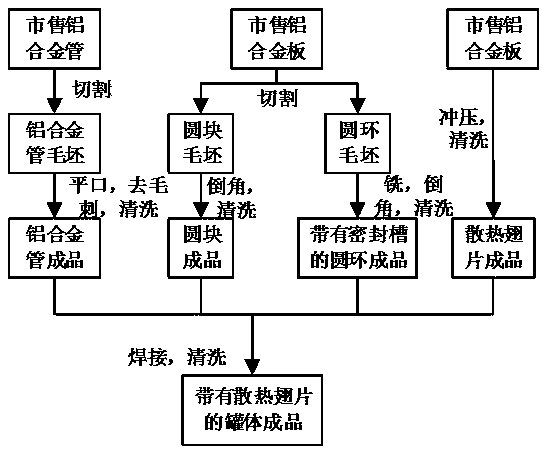

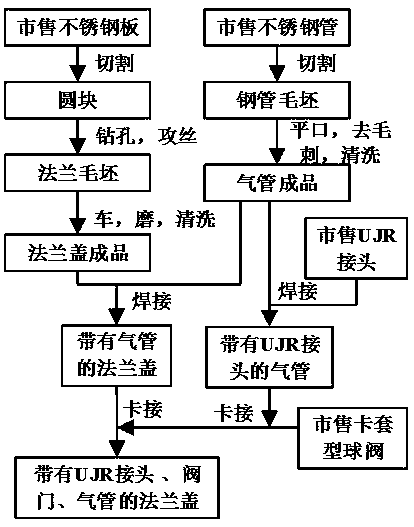

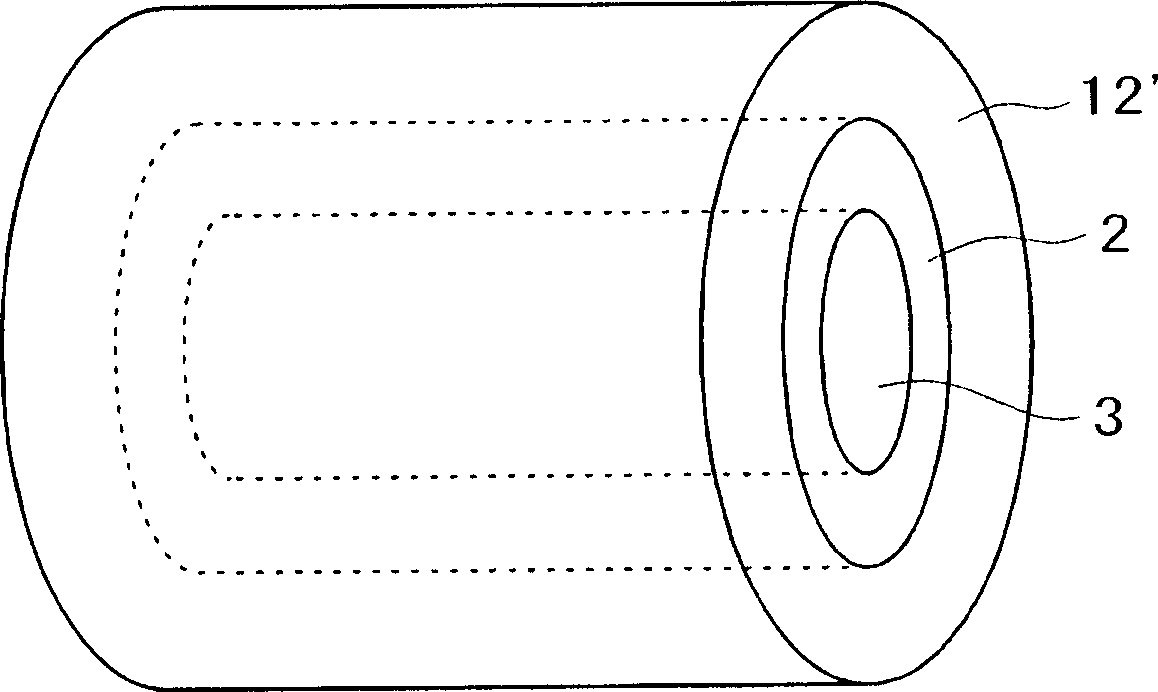

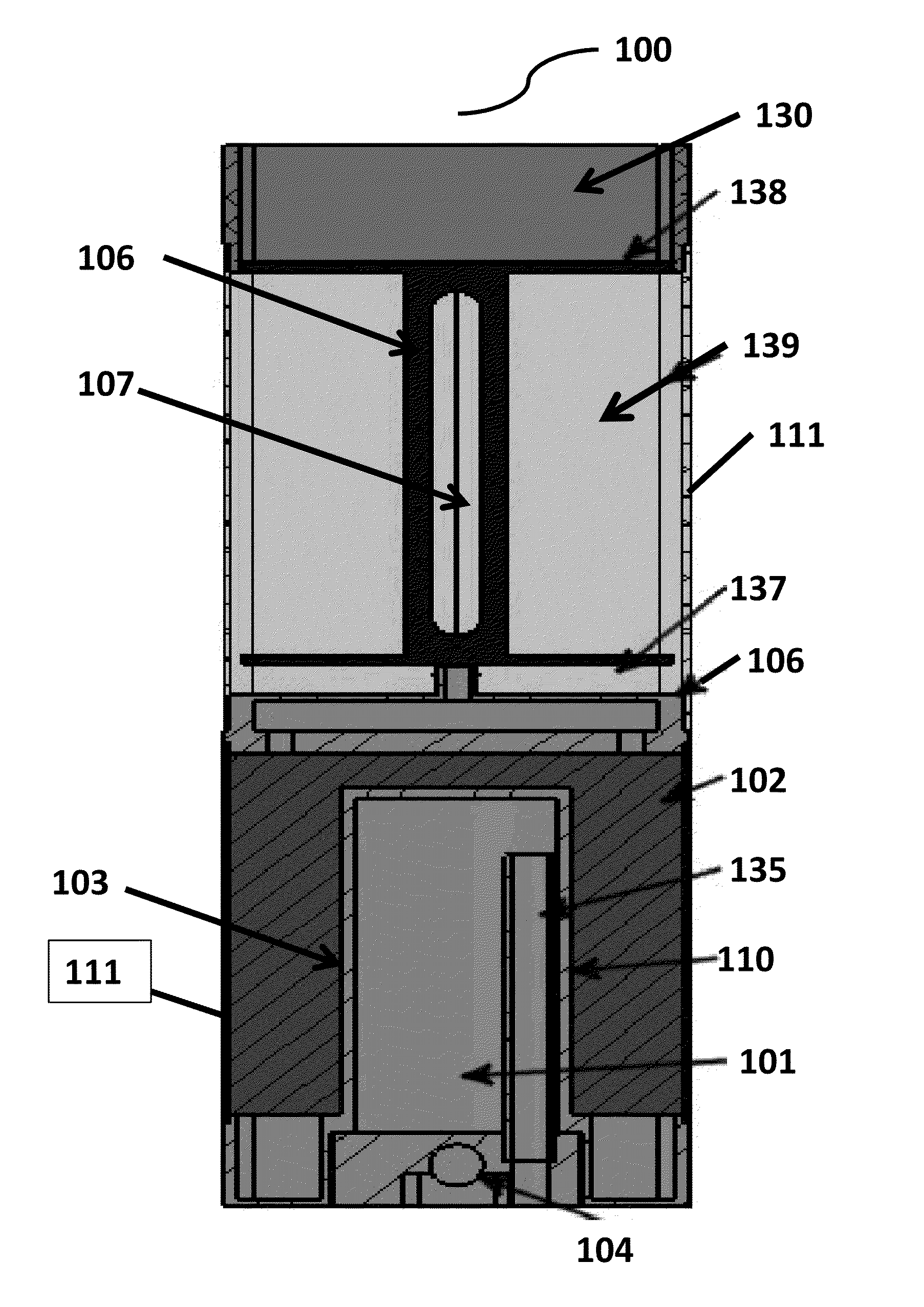

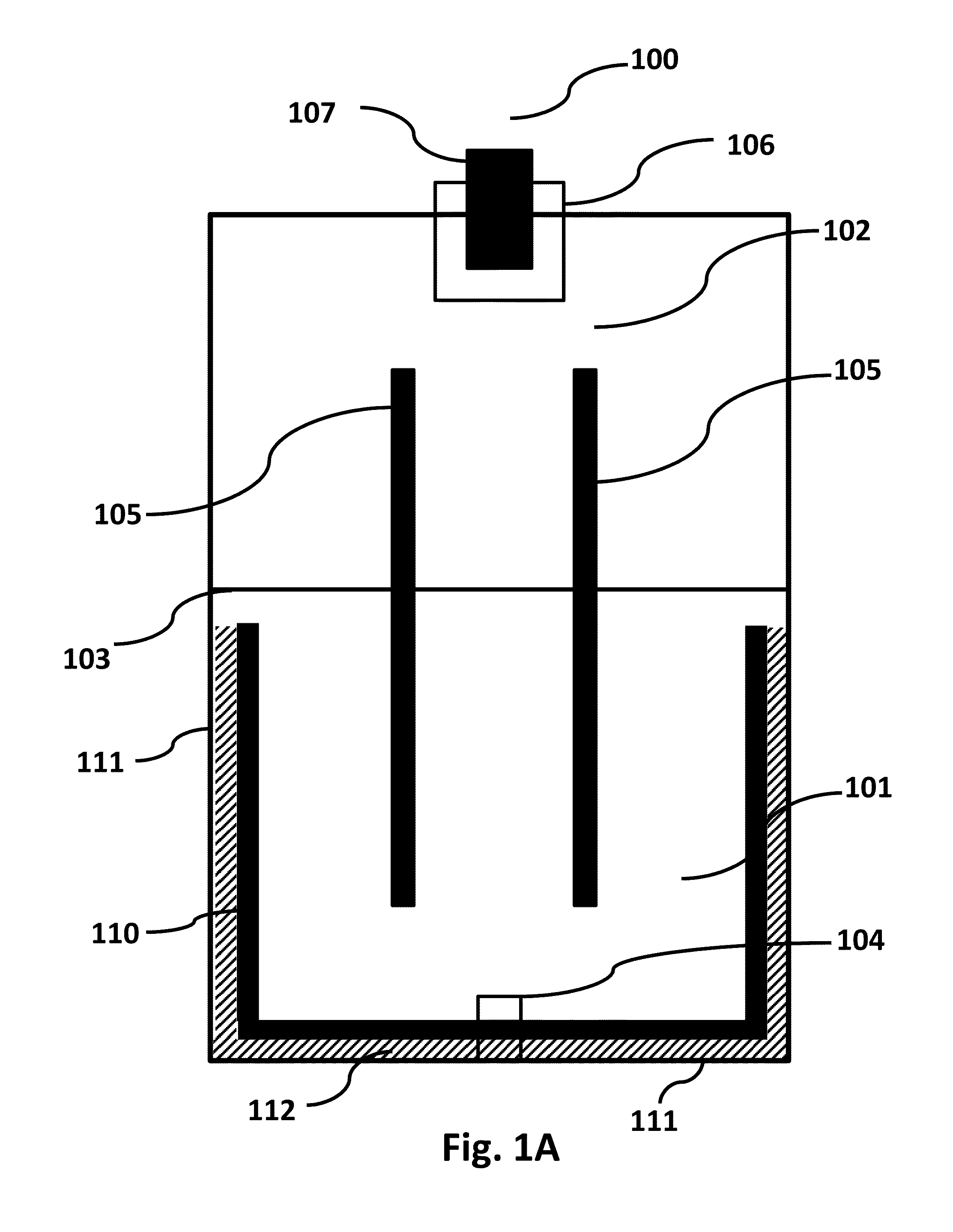

Manufacturing method of metal-hydride hydrogen storage tank

ActiveCN111195808ASimple structureImprove space utilizationVessel manufacturingVessel wallsCircular discMetallic hydrogen

The invention relates to a manufacturing method of a metal-hydride hydrogen storage tank. The method includes the steps of machining of a tank body, machining of a flange cover, machining of foam copper elements, preparation of hydrogen storage alloy powder and assembly line assembling and production of the hydrogen storage tank. The hydrogen storage tank comprises parts including a round foam copper cover, a mat type copper net, a clamping sleeve type ball valve, an air pipe, a UJR joint, the flange cover, bolts, an O-shaped sealing ring, cooling fins, the tank body, the hydrogen storage alloy powder, a foam copper drum, a foam copper disk, a copper-water heating pipe, a foam copper cylinder and the like. The manufacturing method is high in production efficiency, high in yield and low inmanufacturing cost, the metal-hydride hydrogen storage tank manufactured with the method is simple in structure, high in space utilization rate, large in hydrogen storage amount, good in sealing performance, excellent in heat and mass transfer performance, high in hydrogen absorption and release speed and good in long-time use safety, breakage of the tank body due to hydrogen absorption expansionof a hydrogen storage material can be avoided, no cooling media are required to be introduced, repeated recycling can be realized, and the use cost is low.

Owner:YANGZHOU UNIV

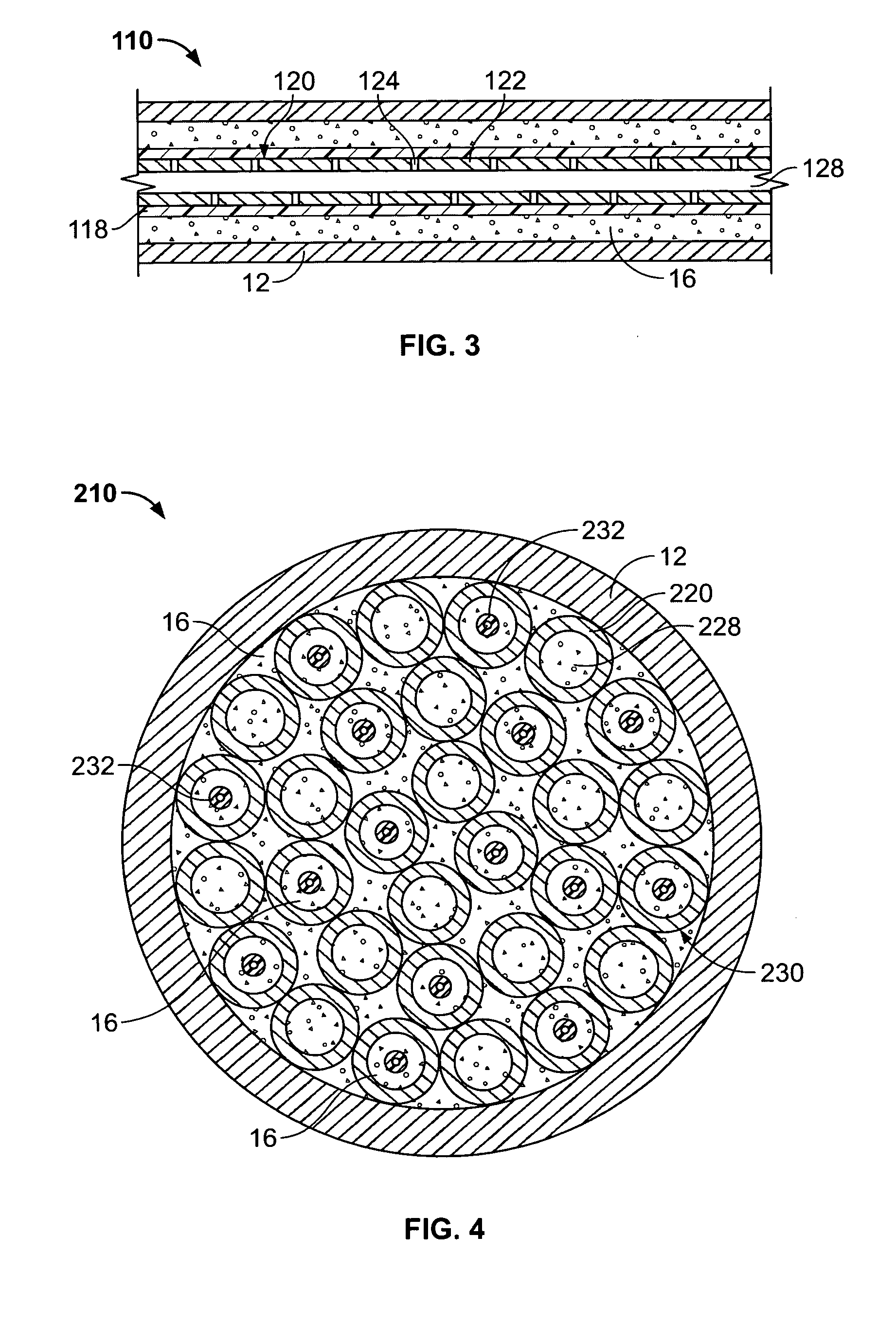

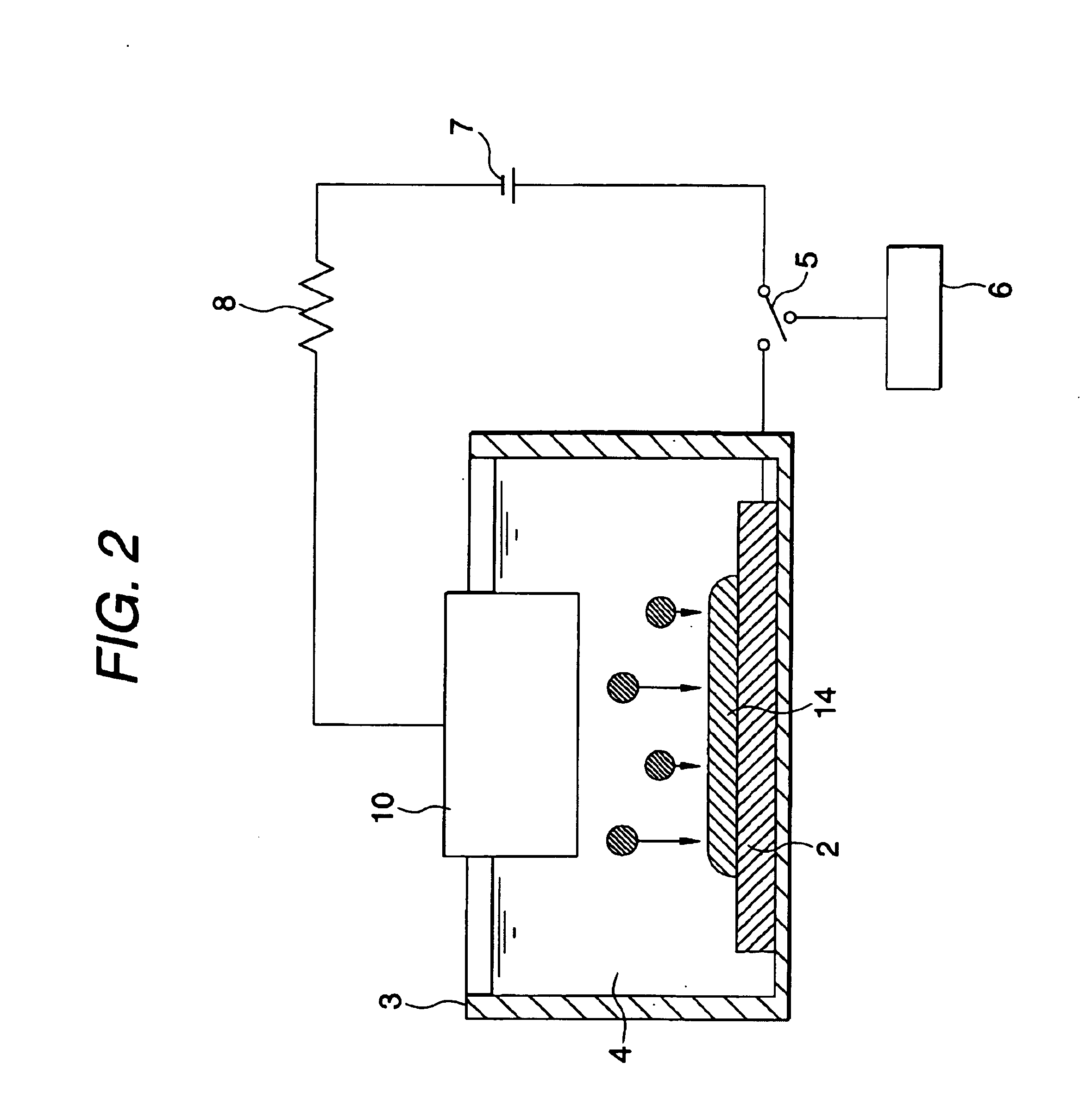

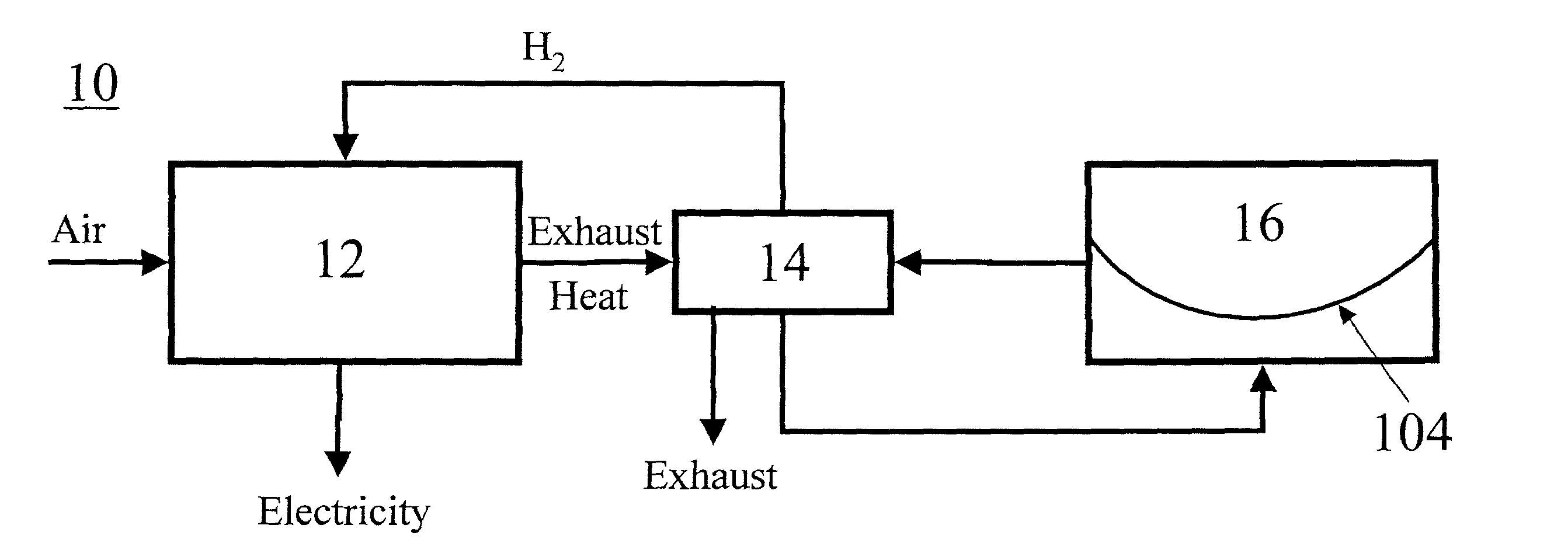

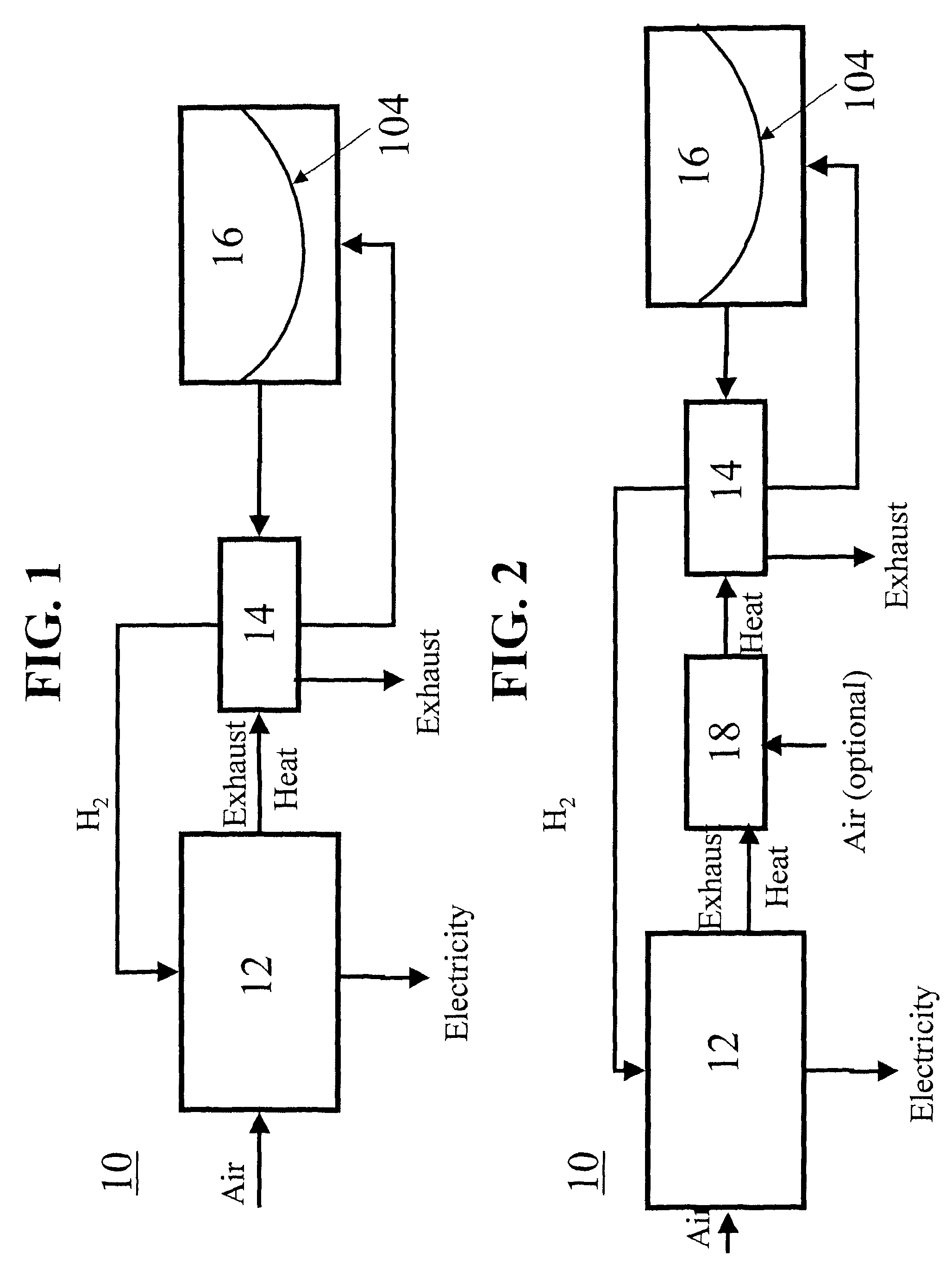

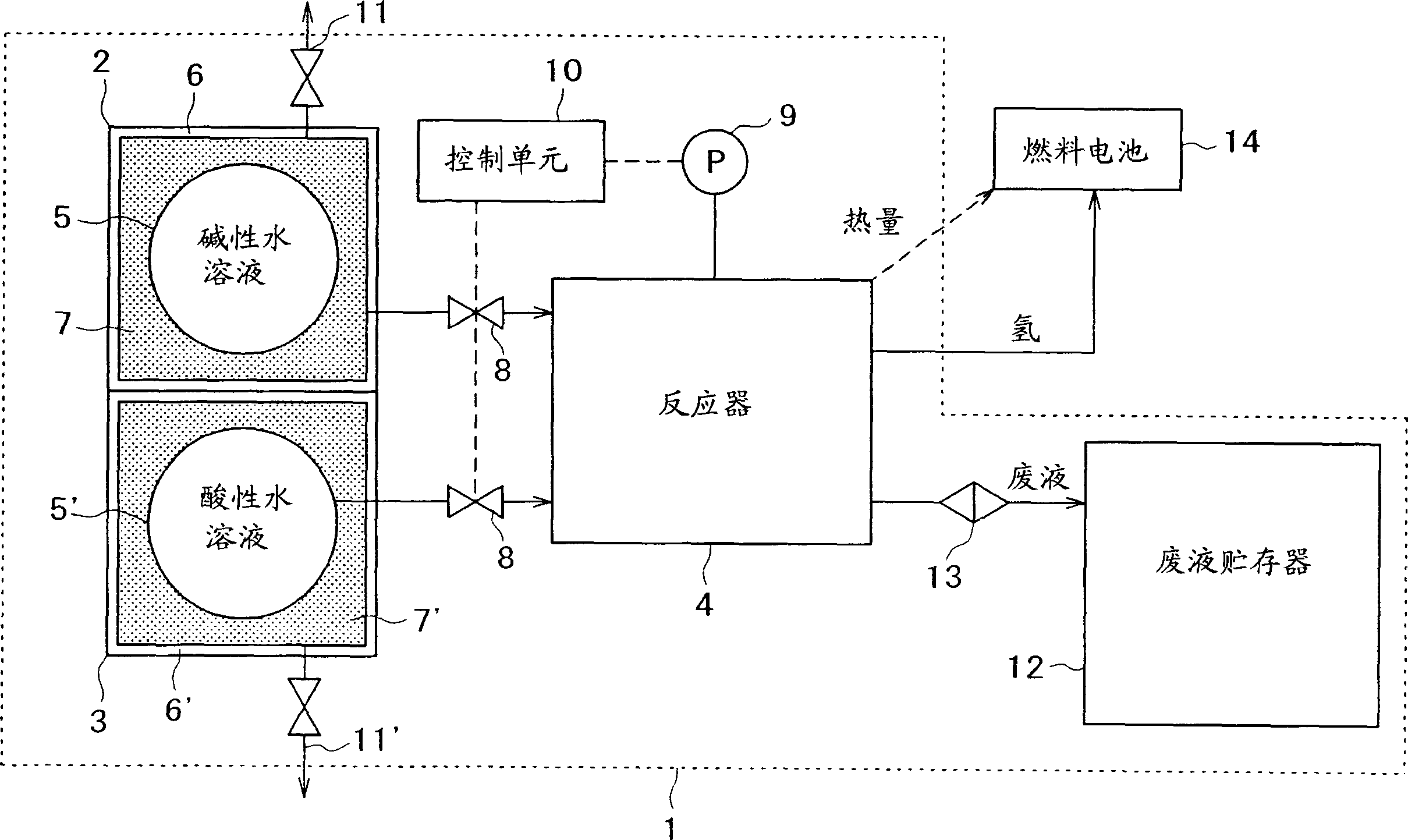

Method of generating hydrogen gas, hydrogen gas production apparatus and energy conversion system

InactiveCN1678518AEffective generationImprove reliabilityHydrogen productionFuel cellsPtru catalystMetallic hydrogen

A method of generating hydrogen gas, which can enhance the efficiency of hydrogen generation even in the absence of catalysts and can enhance reliability in repeated and long-term uses; a hydrogen gas production apparatus therefor; and an energy conversion system. A mixture system comprised of a metal hydride of the general formula: alphaz(1-x)betazx[BHy] (wherein each of alpha and beta represents an atom selected from among those of Groups 1A, 2A and 2B of the periodic table; 3 < y < 6; 0 <= x <= 1; and 0 < z < 3), water and another liquid whose pH value is lower than that of the metal hydride in the form of an aqueous solution is provided, and the metal hydride is decomposed. The apparatus comprises first storage section (2) for storing an aqueous solution of metal hydride, second storage section (3) for storing another liquid whose pH value is lower than that of the above aqueous solution, and reaction section (4) for mixing the aqueous solution with the other liquid to thereby generate hydrogen gas. The thus obtained hydrogen gas is converted to electrochemical energy by means of an energy converter.

Owner:SONY CORP

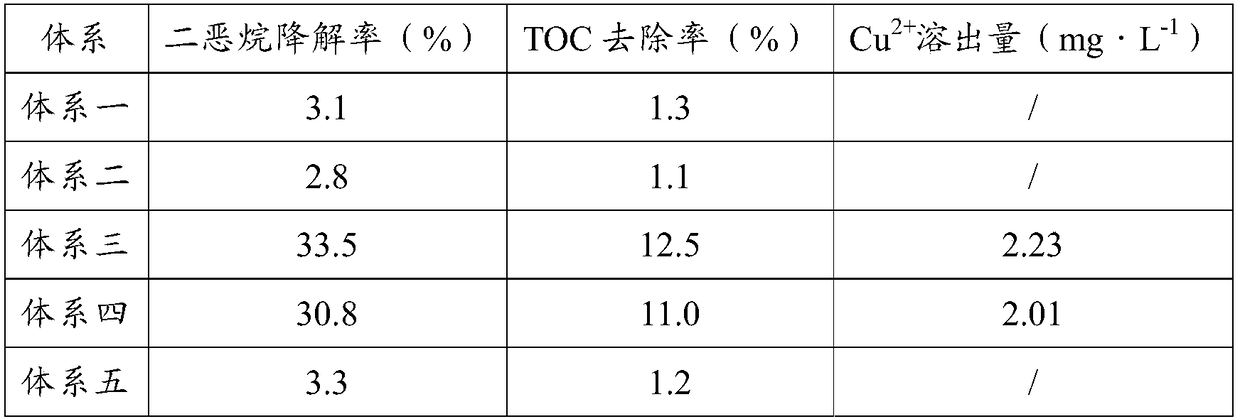

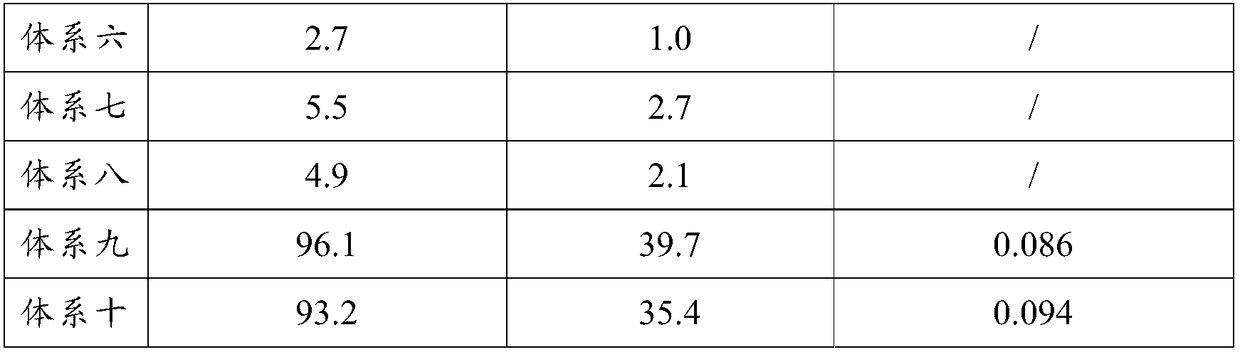

Method of degrading organic pollutants

InactiveCN109081419ALarge specific surface areaImprove performanceWater treatment compoundsWater contaminantsMetallic hydrogenCopper

A method of degrading organic pollutants includes adding peroxides into water containing organic pollutants, wherein the molar ratio of the peroxides to the organic pollutants is 10:1 to 100:1; addinga catalyst while stirring, wherein the catalyst is a copper-bearing layered metallic hydrogen oxide, and the addition of the catalyst is 0.02-0.5 g L<-1>. The method allows peroxides to be effectively catalyzed, can degrade organic pollutants efficiently and enables little Cu2+ to be dissolved out during reaction.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

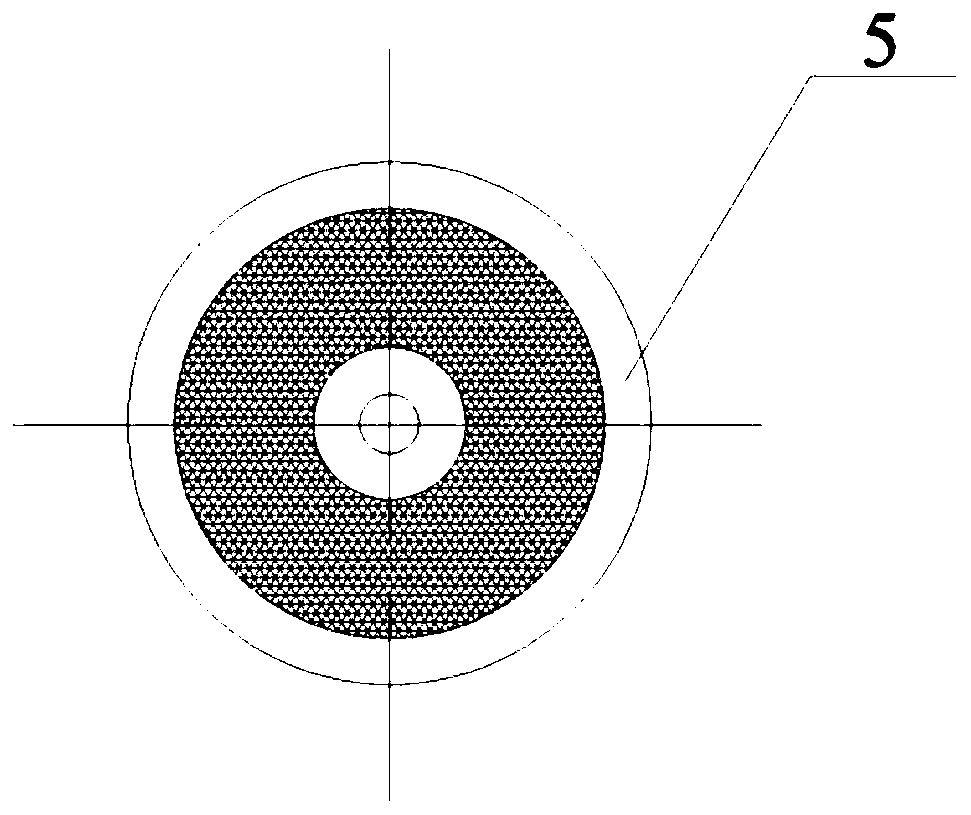

Hydrogen compressor with metal hydride

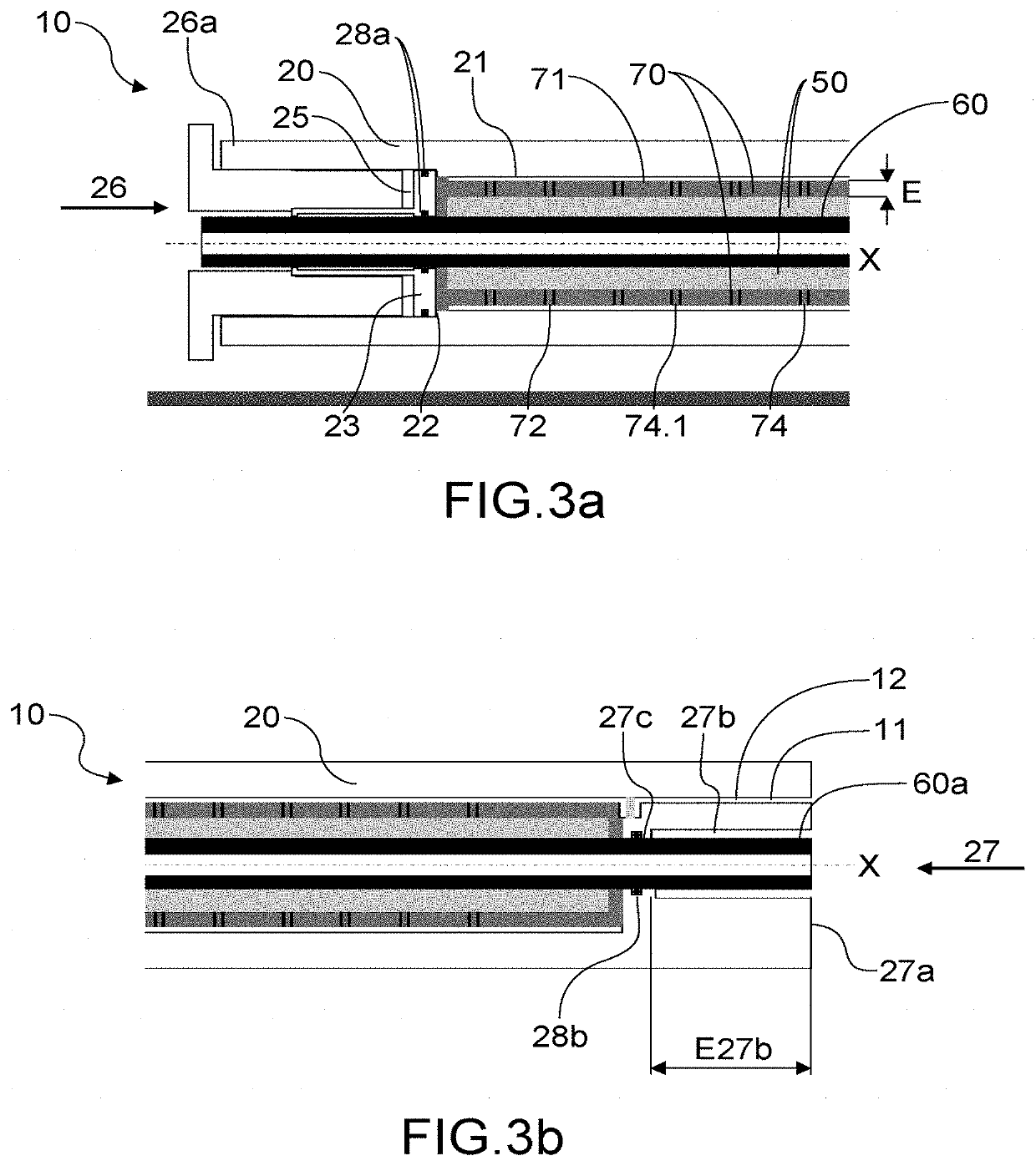

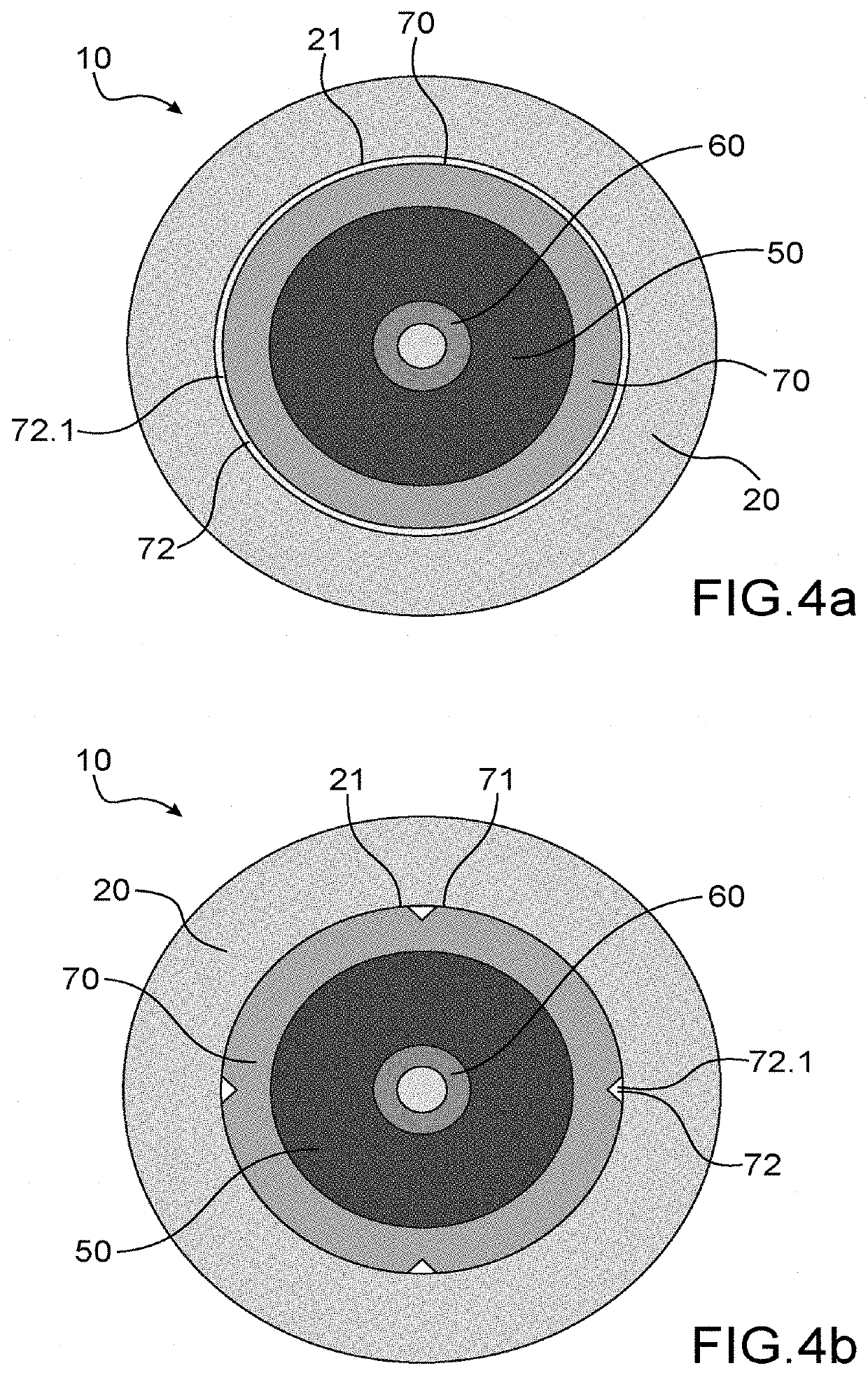

ActiveUS20200332783A1Heat exchange is limitedLimit lossHydrogenFluid transferredPhysical chemistryMetallic hydrogen

The invention relates to a hydrogen compressor (10) with metal hydride comprising: a pressure chamber (20), comprising an inner space, defined by a first inner surface (21); a shell (70) with a thickness E, the shell (70) comprising a first outer surface (71) facing the first inner surface (21), the shell (70) comprising an insulating material with first thermal conductivity; and a hydrogen storage element (50), contained in the shell (70), comprising a storage material suitable for storing or releasing hydrogen as a function of a temperature that is imposed on same, and having a second thermal conductivity higher than the first thermal conductivity.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

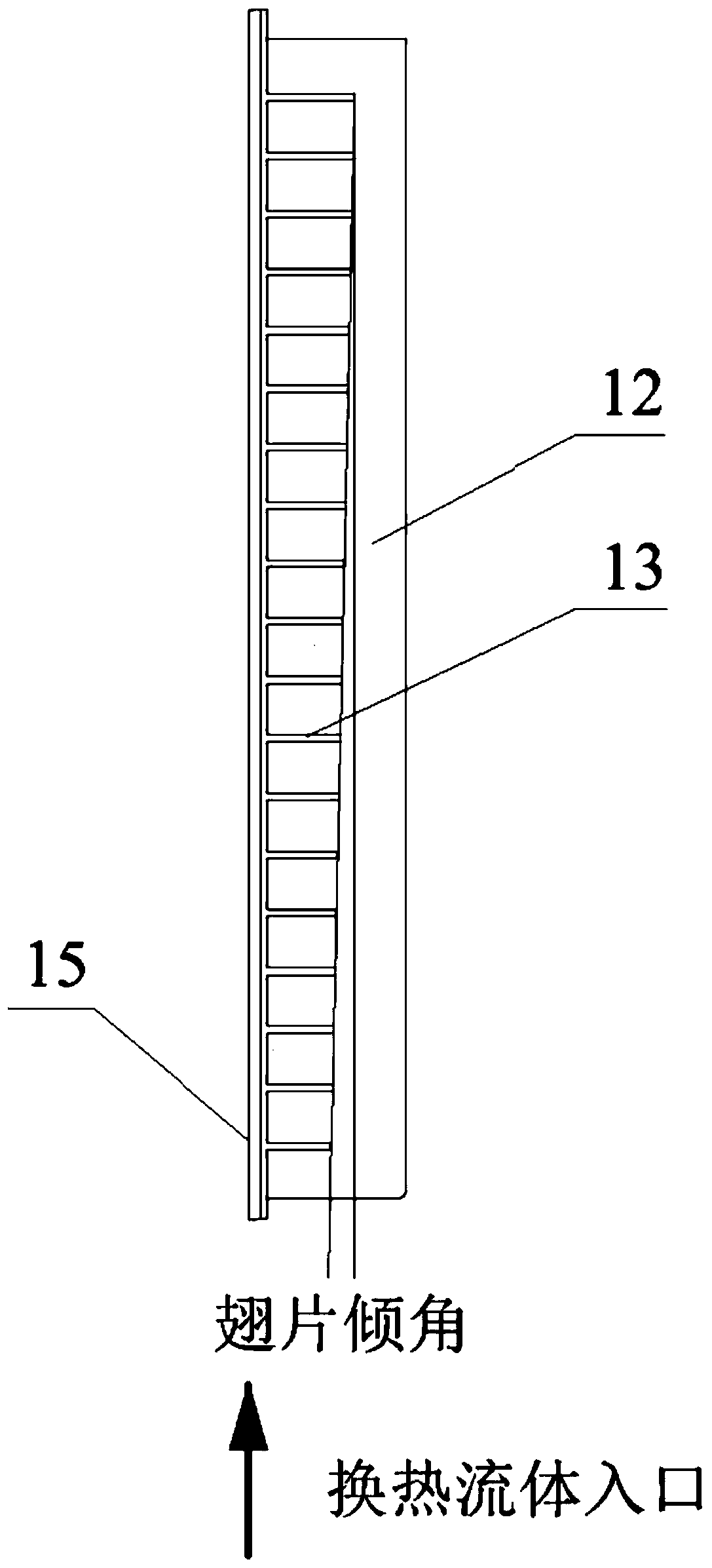

Metal hydride based annular fin type efficient heat storage reactor

PendingCN111076593AIncreased effective heat outputImprove heat transfer performanceHeat storage plantsEnergy storageMetallic hydrogenEngineering

The invention discloses a metal hydride based annular fin type efficient heat storage reactor which comprises a reactor shell and a heat exchanging fluid pipe, wherein a gas hole allowing hydrogen toenter and exit and a safety valve port are formed in the upper end of the reactor shell; the heat exchanging fluid pipe penetrates to the upper end of the reactor shell from the lower end of the reactor shell; the upper end lower ends of the heat exchanging fluid pipe extend into the external part of the reactor shell; a plurality of annular fin structures are mounted on the part, in the reactor shell, of the heat exchanging fluid pipe at intervals in the axial direction; the diameters of the annular fins are sequentially reduced from top to bottom; a metal hydride powder bed is filled in thereactor shell; and the heat exchanging fluid pipe is connected with the reactor shell in a sealing manner. The metal hydride based annular fin type efficient heat storage reactor solves the problems that during the heat releasing process, the traditional shell-and-tube metal hydride heat storage reactor is lower in output temperature and poorer in heat exchanging performance.

Owner:XI AN JIAOTONG UNIV

Thermal hydrogen generator using a metal hydride and thermite

ActiveUS20140076043A1Fit in very small volumeHighly beneficialHydrogen productionExplosivesThermiteHydride

Owner:ANASPHERE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com