Metal hydride based annular fin type efficient heat storage reactor

A hydride and fin-type technology, applied in heat storage equipment, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as non-uniform reaction and poor heat transfer performance, and achieve effective heat output power increase and slow down Effect of non-uniform reaction and elimination of non-uniform reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

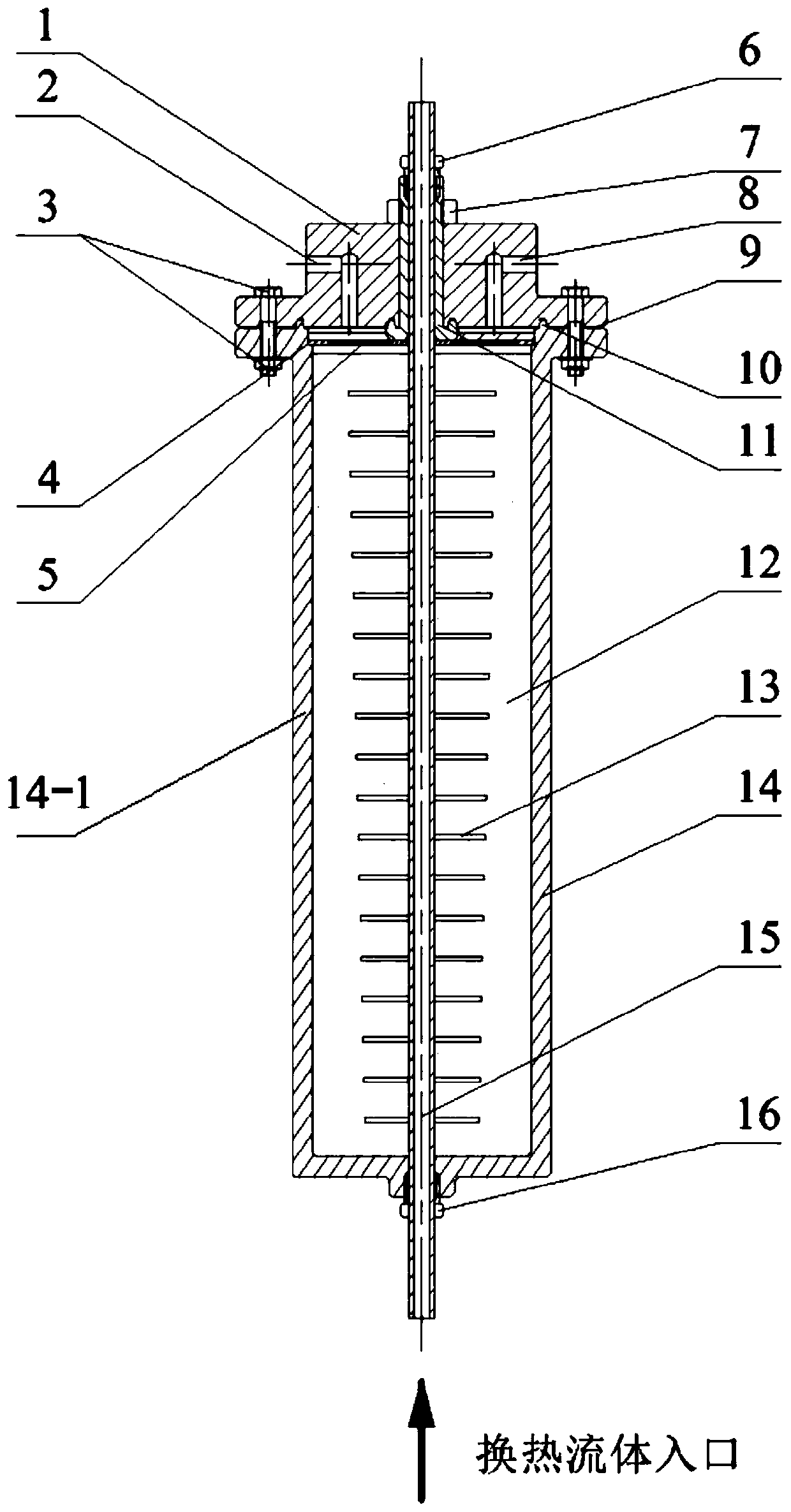

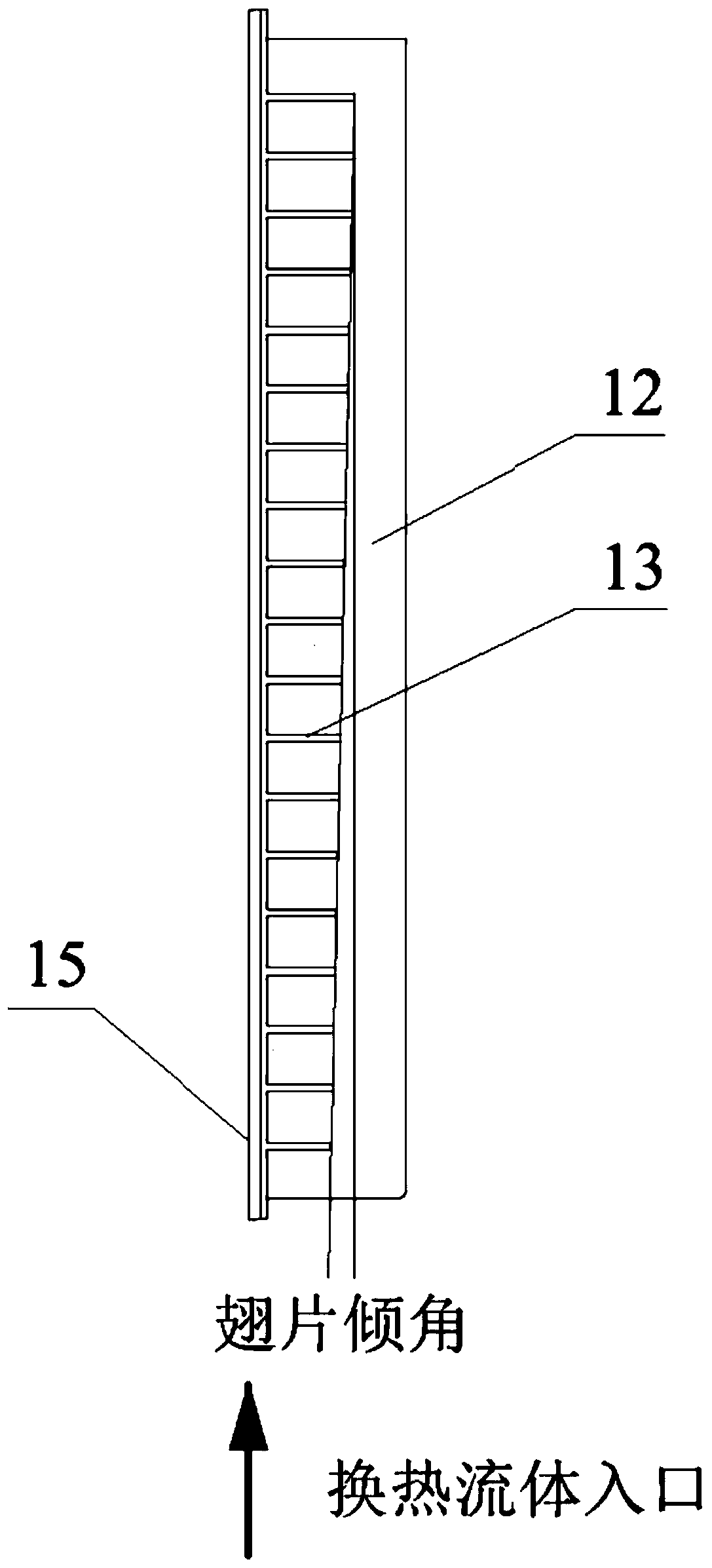

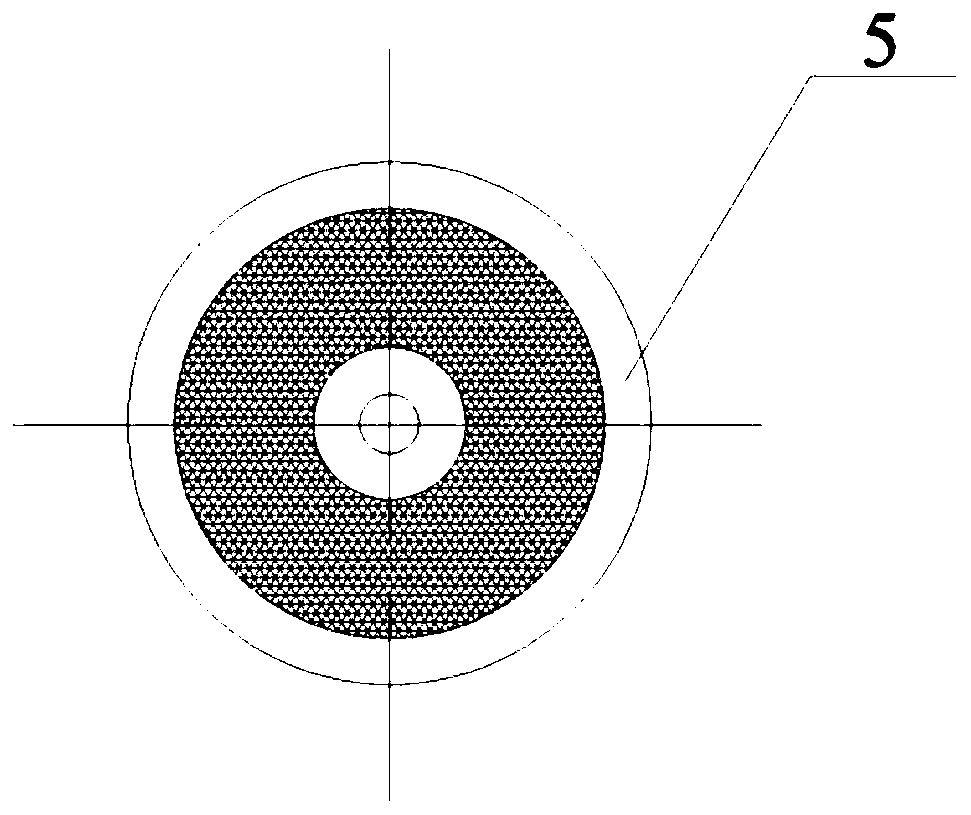

[0050] The metal hydride-based annular fin-type high-efficiency heat storage reactor in this embodiment is placed vertically, and mainly includes a fin structure 13, a heat exchange pipe 15, a metal hydride powder bed 12, a reactor shell 14, Sealing device and other auxiliary devices, the reactor shell 14 includes a cylinder 14 - 1 and a flange 1 . It is mainly aimed at the process of absorbing and releasing heat in the metal hydride heat storage reactor, along the flow direction of the heat exchange fluid, the heat exchange temperature difference of the heat exchange fluid is different, resulting in uneven heat and mass transfer in the bed, and there is a serious non-uniform reaction. The problem of the reduction of effective heat output power.

[0051] see figure 1 As shown, the metal hydride-based annular fin-type high-efficiency heat storage reactor in this embodiment includes a flange 1 , a metal hydride powder bed 12 , a cylinder 14 - 1 and a heat exchange fluid pipe 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com