Method of generating hydrogen gas, hydrogen gas production apparatus and energy conversion system

An energy conversion system, hydrogen technology, applied in chemical instruments and methods, hydrogen, electrical components, etc., can solve problems such as hindering continuous use, restriction, hydrogen pollution, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

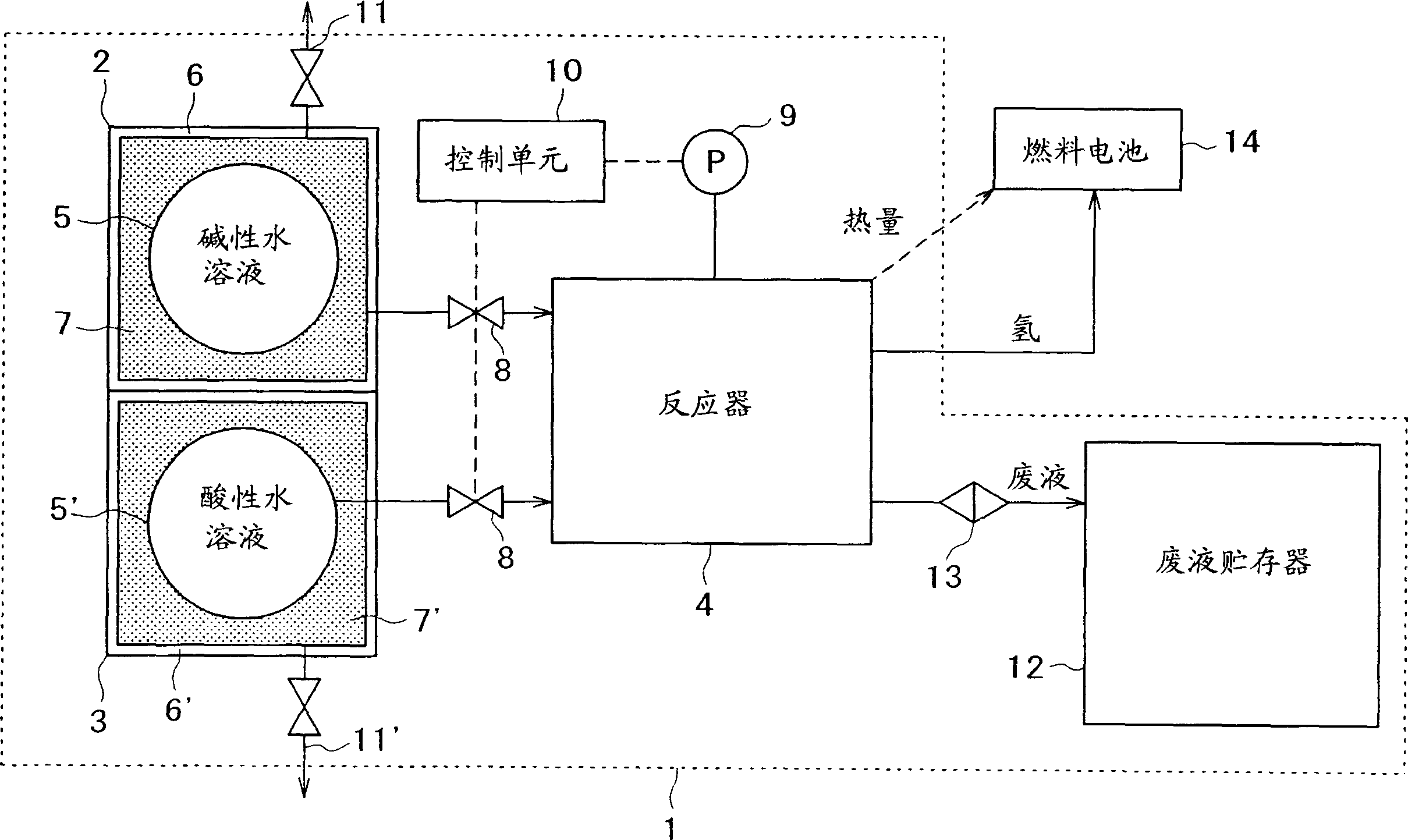

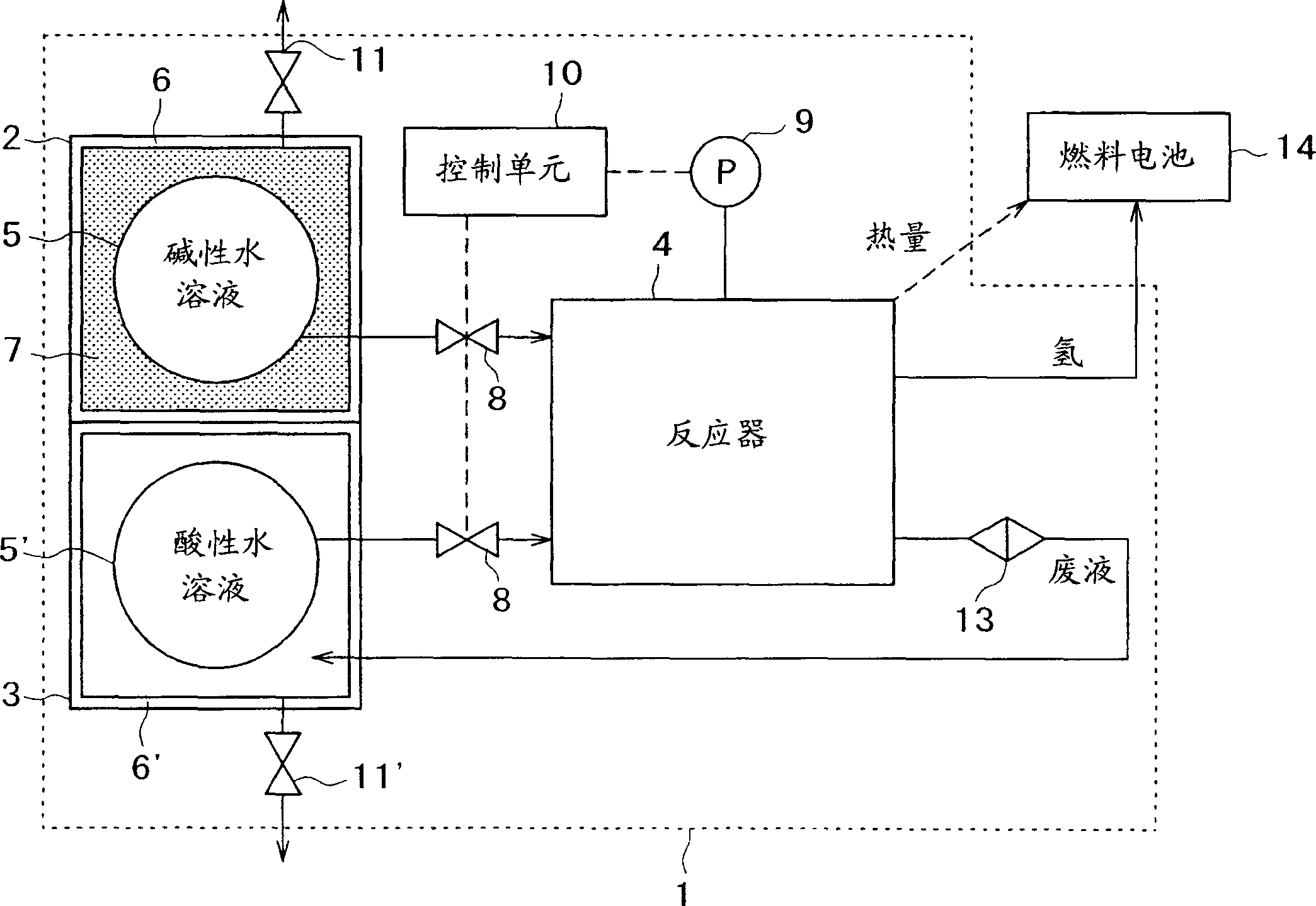

[0053] figure 1 is a schematic diagram showing the apparatus of the present invention for generating hydrogen.

[0054] Such as figure 1 As shown, the device 1 for generating hydrogen of the present invention is composed of a first storage tank 2 for storing an alkaline aqueous solution of a metal hydride, a second storage tank 3 for storing an acidic aqueous solution as a second solution, and a reactor 4. In the reactor A basic aqueous solution and an acidic aqueous solution are mixed together for a reaction in which hydrogen gas is released. The first reservoir 2 and the second reservoir 3 are connected to the reactor 4 .

[0055] Between the first and second reservoirs 2 and 3 and the reactor 4 there is a flow regulator 8 . The reactor 4 is equipped with a pressure sensor 9 that detects the flow rate and a control unit 10 that controls the flow rate regulator 8 in response to the pressure detected by the pressure sensor 9 .

[0056] The device 1 for generating hydrogen ...

Embodiment approach 2

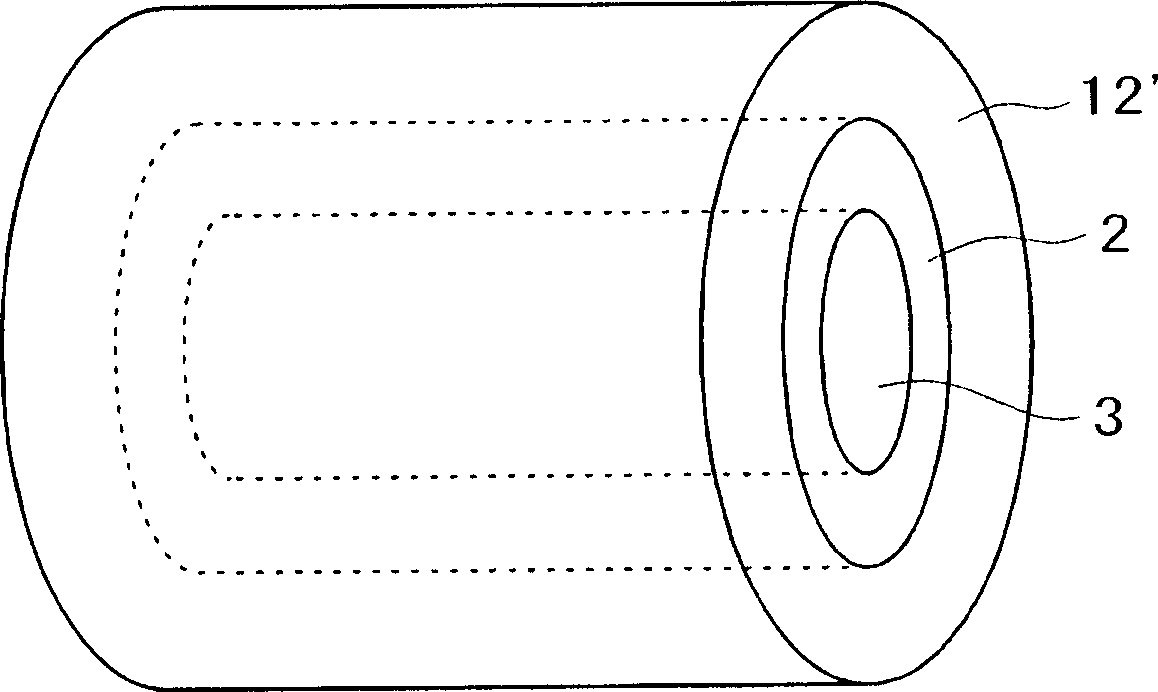

[0072] The device for generating hydrogen according to Embodiment 2 of the present invention such as image 3 and 4 shown. It has a first reservoir 2 for storing an alkaline aqueous solution of a metal hydride and a second reservoir 3 for storing an acidic aqueous solution as a second solution, which are concentric double (or multi) tube structures. Reservoirs 2 and 3 can be connected to reactor 4 . In this case, as image 3 and 4 As shown, the waste liquid reservoir 12' is installed coaxially on the outside of the second reservoir 2, although it can be as figure 1 shown installed separately.

[0073] A syringe-type structure is applicable to the first reservoir 2, the second reservoir 3, and the waste liquid reservoir 12'. In this case, the first and second reservoirs 2 and 3 are equipped with movable walls 15 to push out the alkaline and acidic aqueous solutions. The movable wall 15 is urged in one direction by elastic means 16 (eg a spring). In other words, it acts ...

Embodiment approach 3

[0080] The method of generating hydrogen of the present invention is based on a liquid phase reaction. The hydrogen gas thus produced can entrain droplets (or moisture) of the aqueous solution. Such entrainment not only limits the choice of device materials, but also degrades the properties.

[0081] Therefore, it is required to modify the hydrogen generating apparatus 1 of the present invention so that the reactor 4 is equipped with a mechanism for separating only hydrogen.

[0082] That is to say, the reactor 4 is required to be connected with the perforated pipe 17 that can permeate hydrogen but not permeate liquid, such as Figure 5A and 5B shown. In this case, the reaction to release the hydrogen takes place in the reactor 4 and / or the porous pipe 17, so that the released hydrogen 21 and the mixture 22 (consisting of waste liquor and unreacted alkaline and acidic aqueous solutions) pass through the porous When the tube 17 is connected, only the hydrogen gas 21 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com