Determination device for metallic hydrogen diffusion current

A diffusion current and measurement device technology, applied in the detection field, can solve problems such as uneven nickel plating layer, reduced contact area, cumbersome steps, etc., and achieve the effects of avoiding solution leakage, improving measurement accuracy, and avoiding aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A metal hydrogen diffusion current measuring device of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

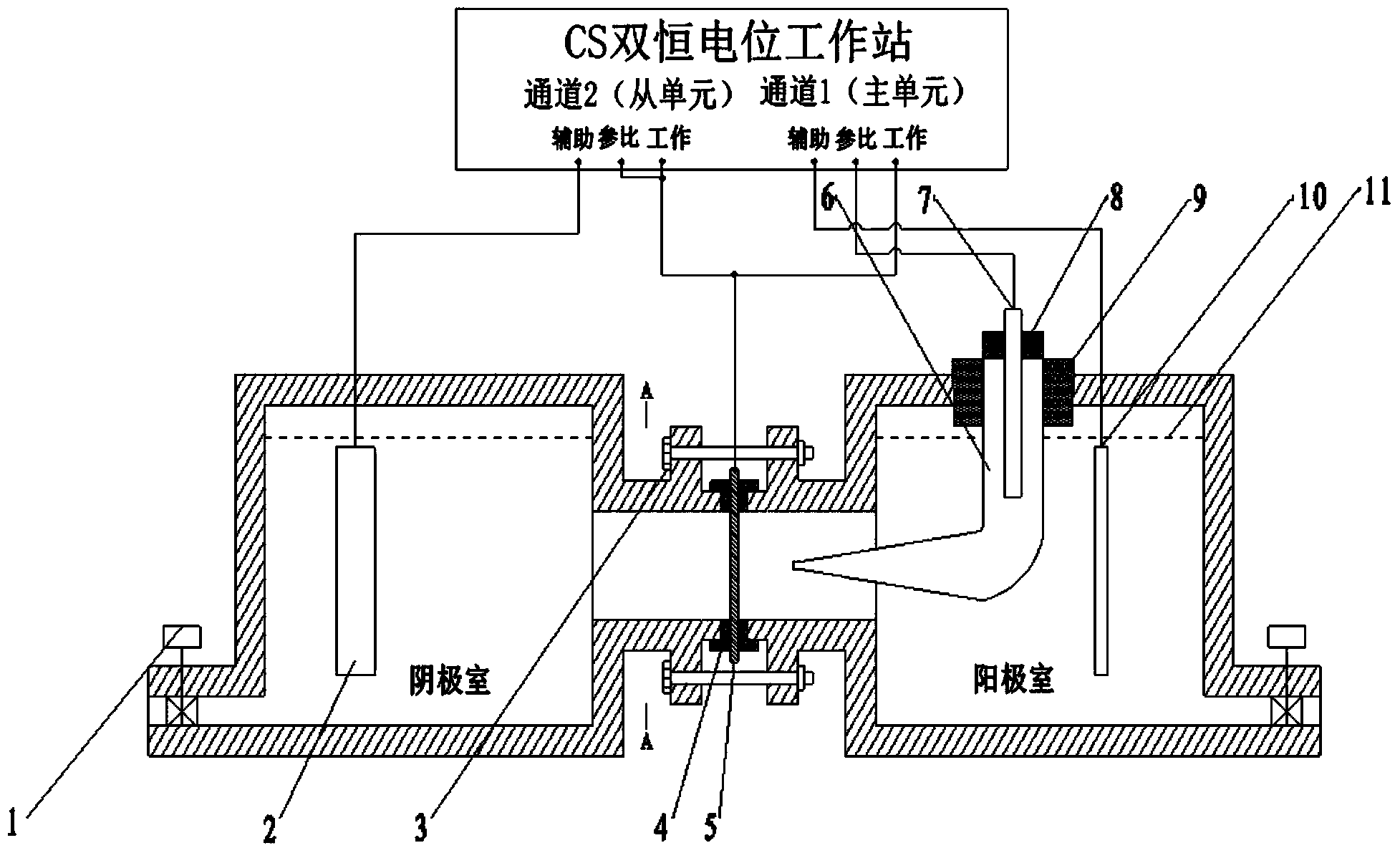

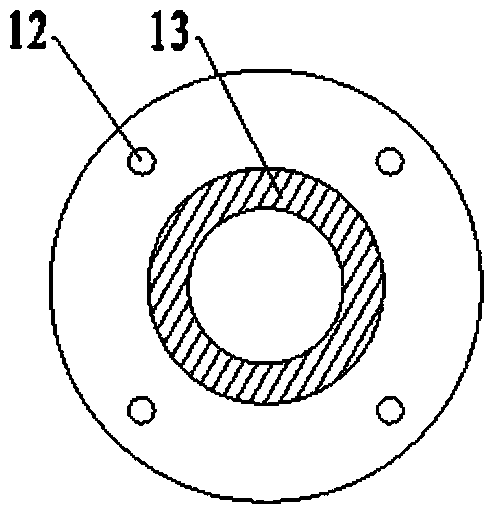

[0017] Such as figure 1 with figure 2 As shown, a measuring device for the diffusion current of metal hydrogen includes a cathode chamber and an anode chamber that have the same shape and size, and are mirror-imaged and horizontally connected with a communication channel, as well as a CS double constant potential workstation containing a master unit and a slave unit. One side of the lower part of the cathode chamber and the anode chamber are provided with holes for installing the drain valve 1, wherein the top opening of the anode chamber adopts a fastening rubber plug 9 and is equipped with a pointed mouth extending into the anode chamber to the communication channel. Elbow 6, saturated calomel reference electrode 7 is installed by rubber stopper 8 in described sharp-nose elbow 6, is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com