Low-cost, high-hydrogen-absorption-and-desorption-speed and high-safety metal hydride hydrogen storage tank

A high-speed hydrogen absorption and desorption technology, which is applied to fixed-capacity gas storage tanks, container discharge methods, and outer walls of container structures. Large and other problems, to achieve the effect of excellent heat and mass transfer performance, fast hydrogen absorption and desorption speed, low manufacturing cost and use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

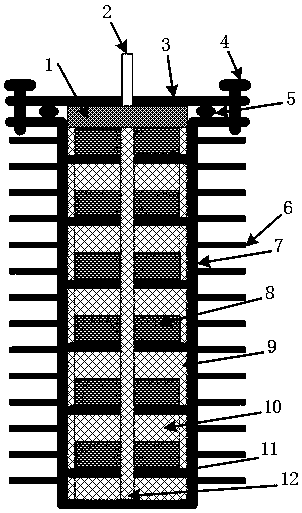

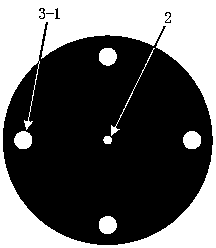

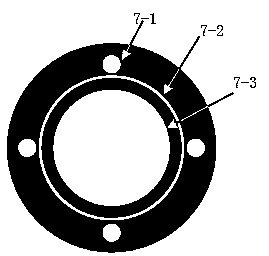

[0037] Such as Figure 1-9 As shown, a metal hydride hydrogen storage tank with low cost, fast hydrogen absorption and desorption, and high safety, including: foam metal round cover 1, gas pipe 2, flange cover 3, bolts 4, O-ring 5 , radiating fins 6, tank body 7, hydrogen storage material powder 8, metal foam cylinder 9, metal foam disc 10, heat pipe 11, metal foam cylinder 12. Circular cooling fins 6 are welded around the outer wall of the tank body 7 . The bottom of the chamber 7-3 in the tank body 7 is equipped with a metal foam disc 10, the metal foam cylinder 9 is arranged around the inwall of the tank body 7, and the metal foam cylinder 12 is housed in the middle of the cavity, and the metal foam cylinder 9 and the There is a clearance fit between the metal foam discs 10, a clearance fit between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com