Magnesium base hydrogen storage material and its mechanical-alloying preparation method

A technology of mechanical alloying and hydrogen storage materials, applied in electrical components, circuits, battery electrodes, etc., can solve the problems of poor cycle stability, high working temperature, difficult activation, etc., achieve stable performance, fast hydrogen absorption and desorption, and storage The effect of a large amount of hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Firstly, La and Ni are melted according to RE by traditional smelting method. 2-x m x (x=0.5) ratio, in an argon protective atmosphere, use an electric arc furnace to melt repeatedly 6 times to ensure that the alloy composition of the material is uniform. The alloy is crushed and passed through a 400-mesh sieve under the protection of argon, and packed in a vacuum seal.

[0029] La 1.5 Ni 0.5 and Mg metal powders according to La 1.5 Ni 0.5 Mg 17 Mix evenly, place in a sealed stainless steel ball mill tank, the ball-to-material ratio is 15:1, the ball quality is stainless steel, first vacuumize to 10 -3 Pa, and then filled with 5MPa hydrogen as a protective atmosphere. The Spex-8000 ball mill is used for ball milling, the speed of the ball mill is 1750 rpm, the ball milling time is 20-80 hours, and air cooling is carried out at the same time. The finally obtained magnesium-based hydrogen storage materials were measured by XRD, SEM, TEM, hydrogen storage capacity ...

Embodiment 2

[0032] La and Ni are made into LaNi alloy by smelting method, except La and Ni according to RE 2-x m x Except that the proportioning of (x=1) is different from embodiment 1, all the other smelting processes are all the same as embodiment 1.

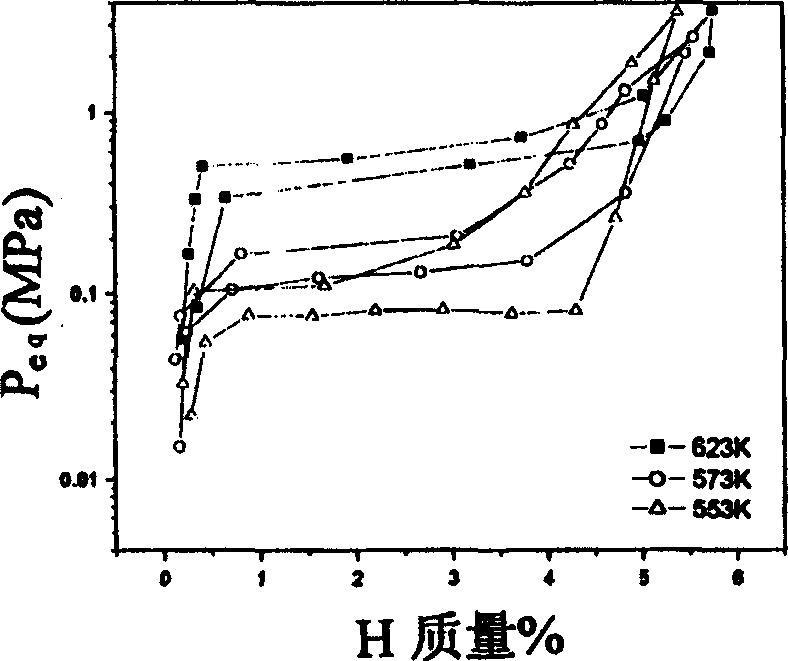

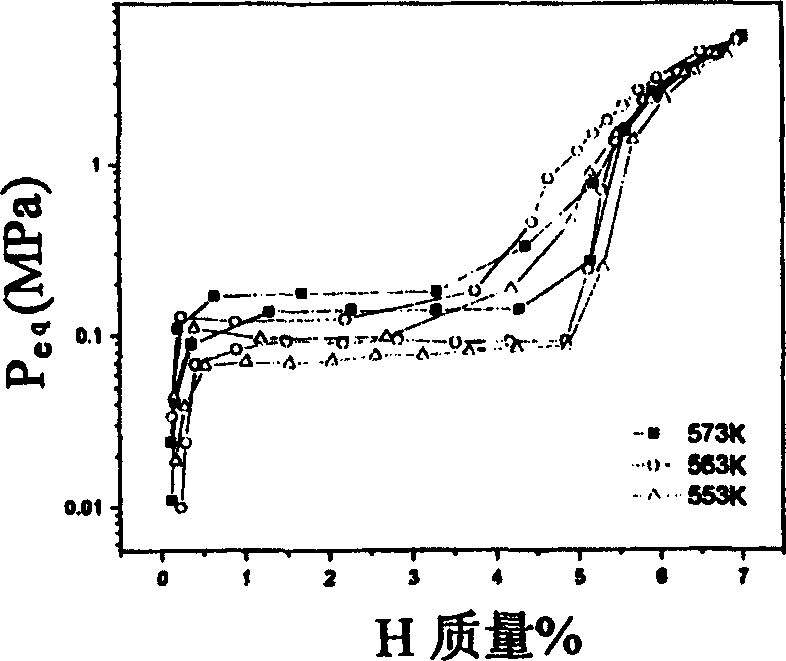

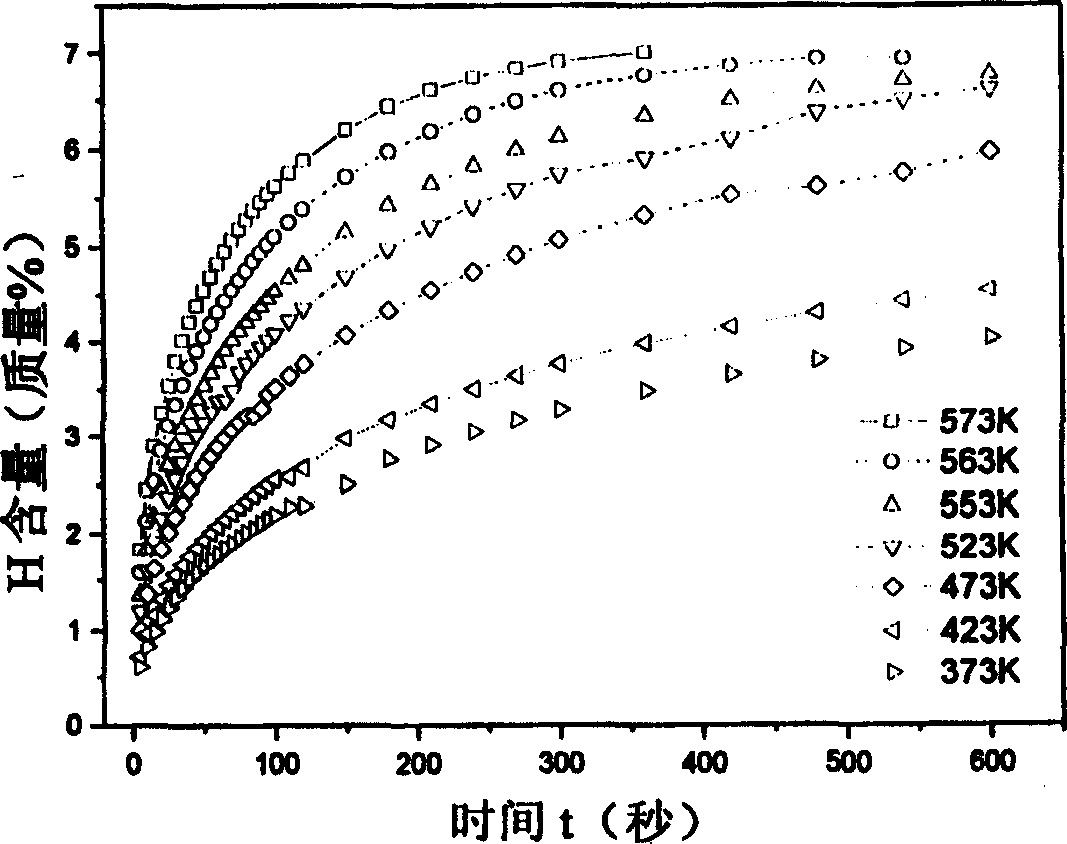

[0033] Then LaNi and Mg metal powders were mixed according to LaNiMg 17Mix evenly, place in Spex-8000 type ball mill for ball milling, the ball mill speed is 1750 rpm, the ball to material ratio is 15:1, the ball milling time is 80 hours, the ball milling process is carried out under the protection of hydrogen at 5MPa, and the material The preparation and hydrogenation processes are combined and completed at one time. PCT, XRD and hydrogen absorption and desorption rate were measured for the material. PCT curve such as Figure 1-a As shown, the material can absorb 5.23wt% hydrogen at 280°C under 1MPa hydrogen gas. It can also absorb hydrogen up to 2.31wt% at 100°C.

[0034] When the temperature is between 150 and 300°C, the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com