Patents

Literature

34results about How to "Fast hydrogen absorption and desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

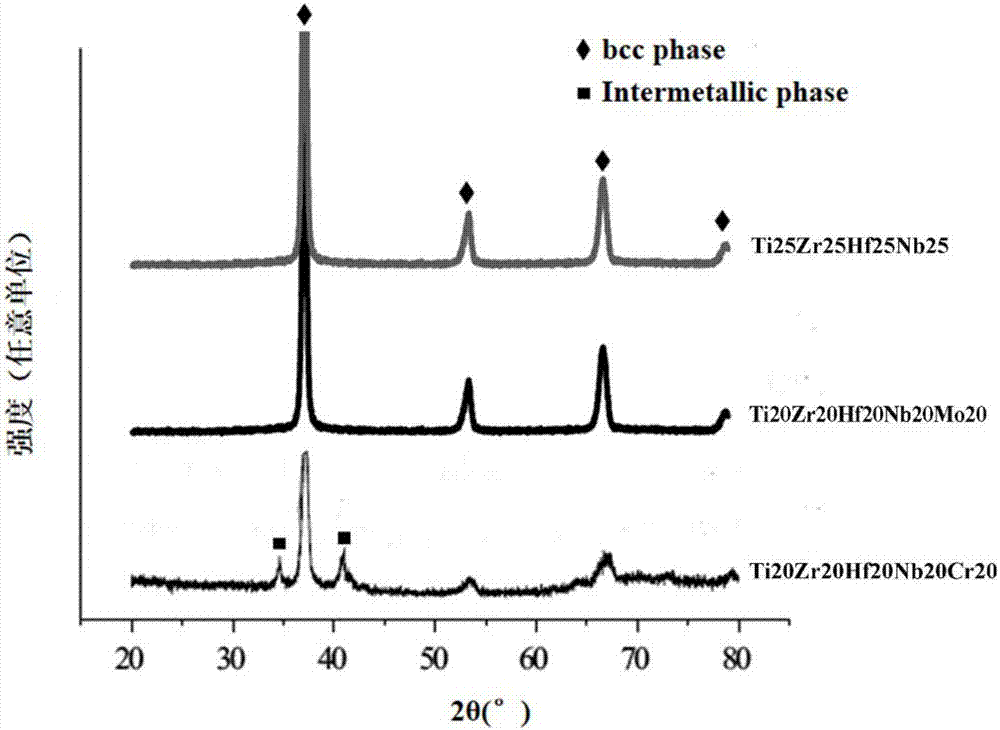

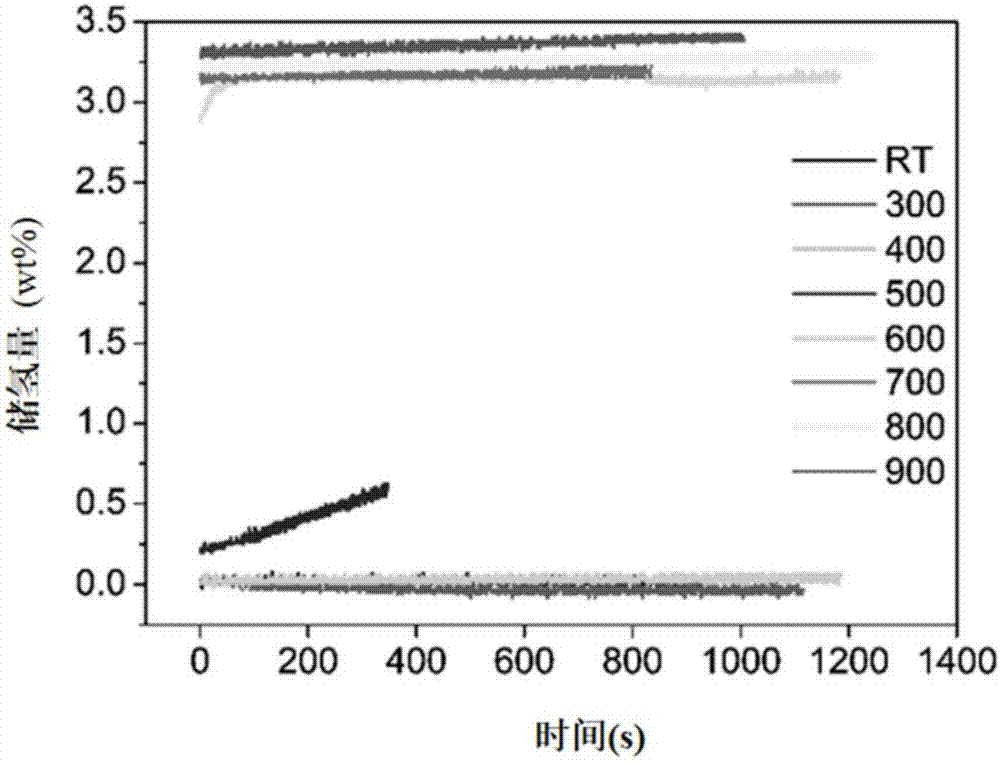

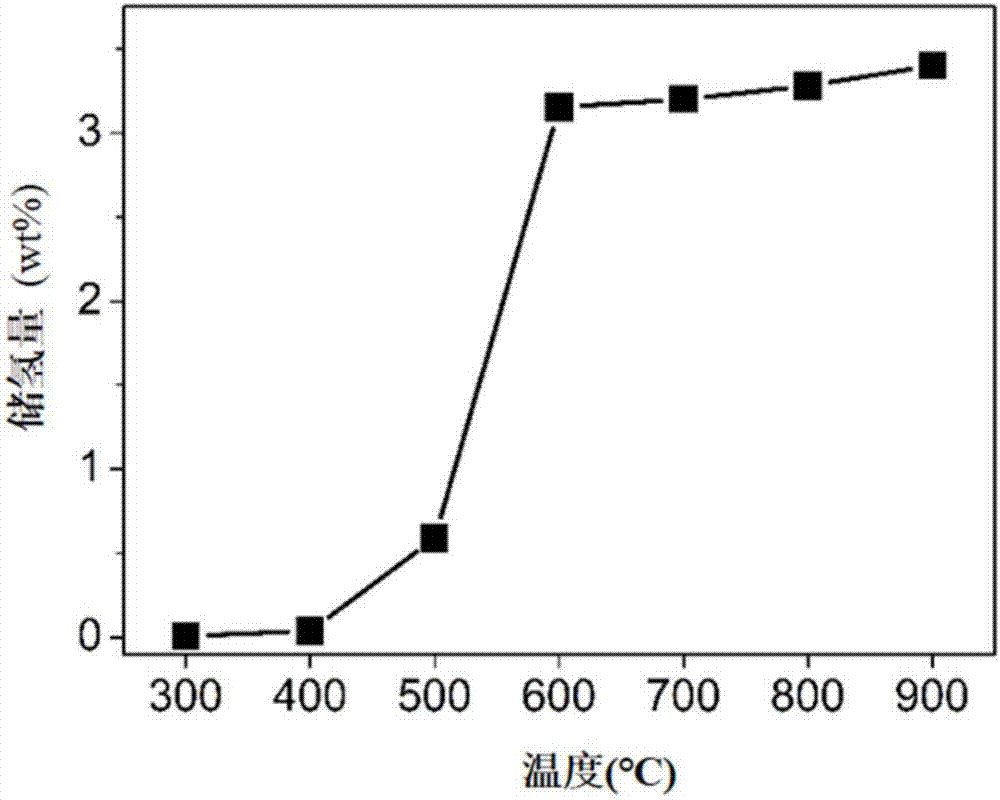

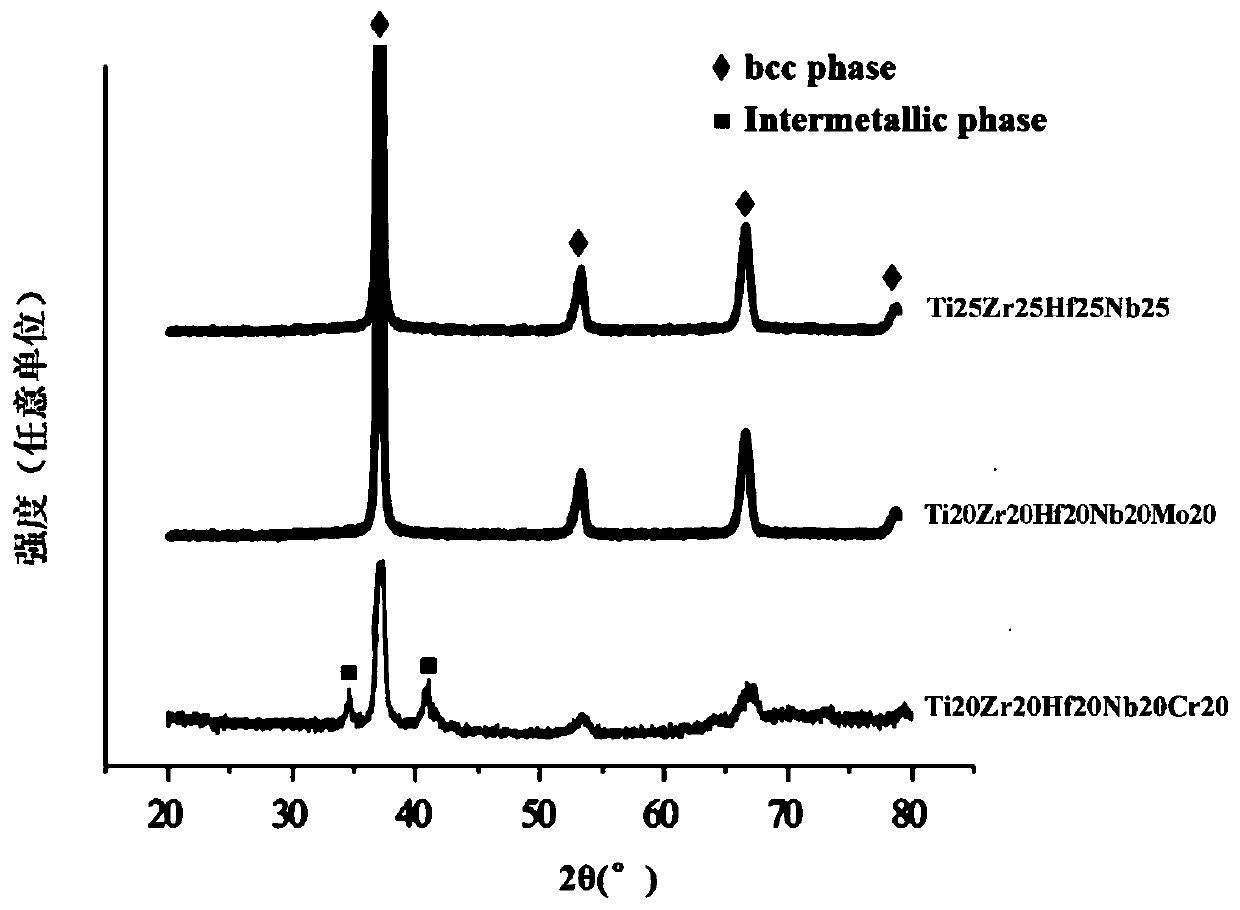

Hydrogen storage high-entropy alloy taking body-centered cubic structure as principal thing and preparation method for hydrogen storage high-entropy alloy

ActiveCN107338385AHigh hydrogen storage capacityFast hydrogen absorption and desorptionElectric arc furnaceHigh entropy alloys

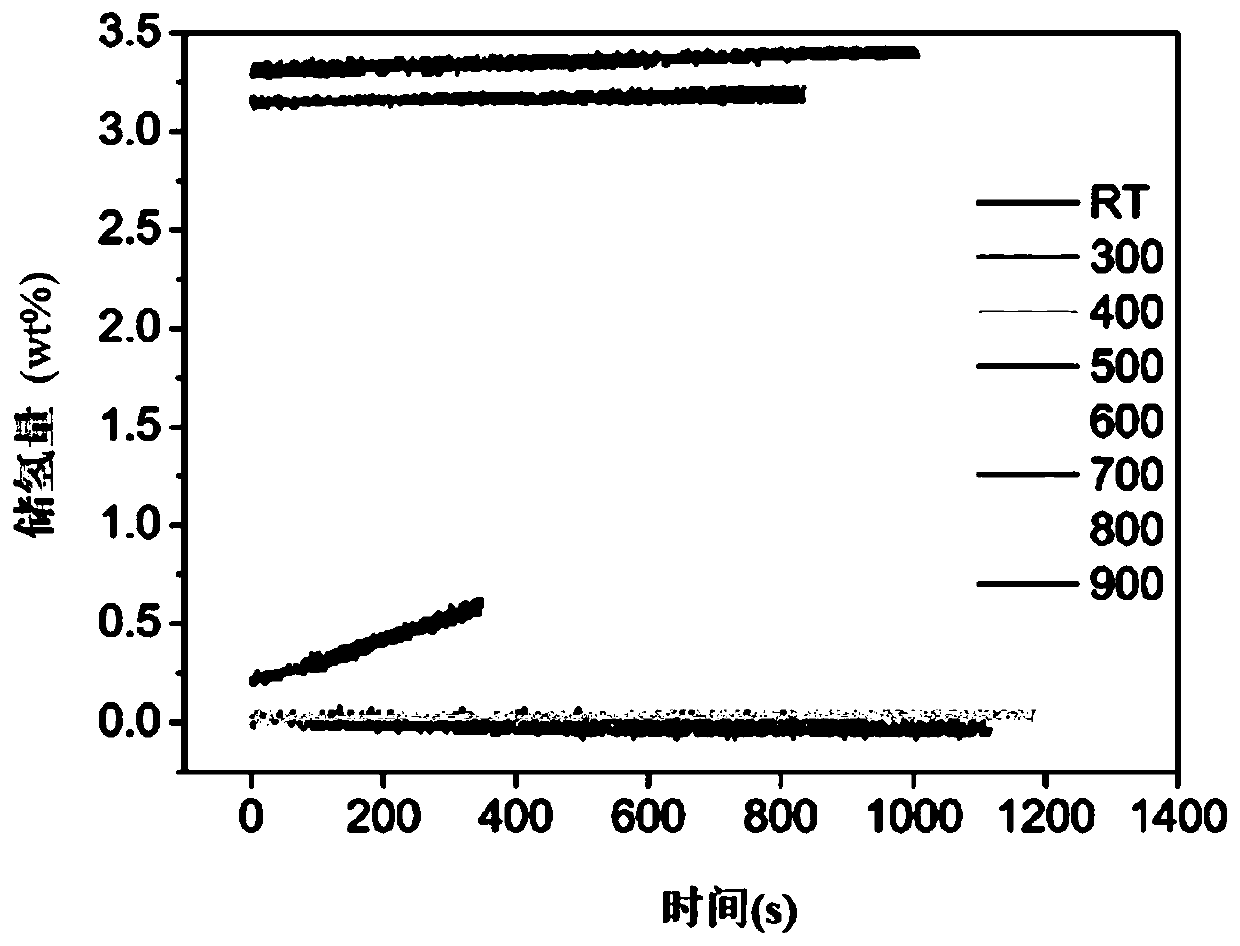

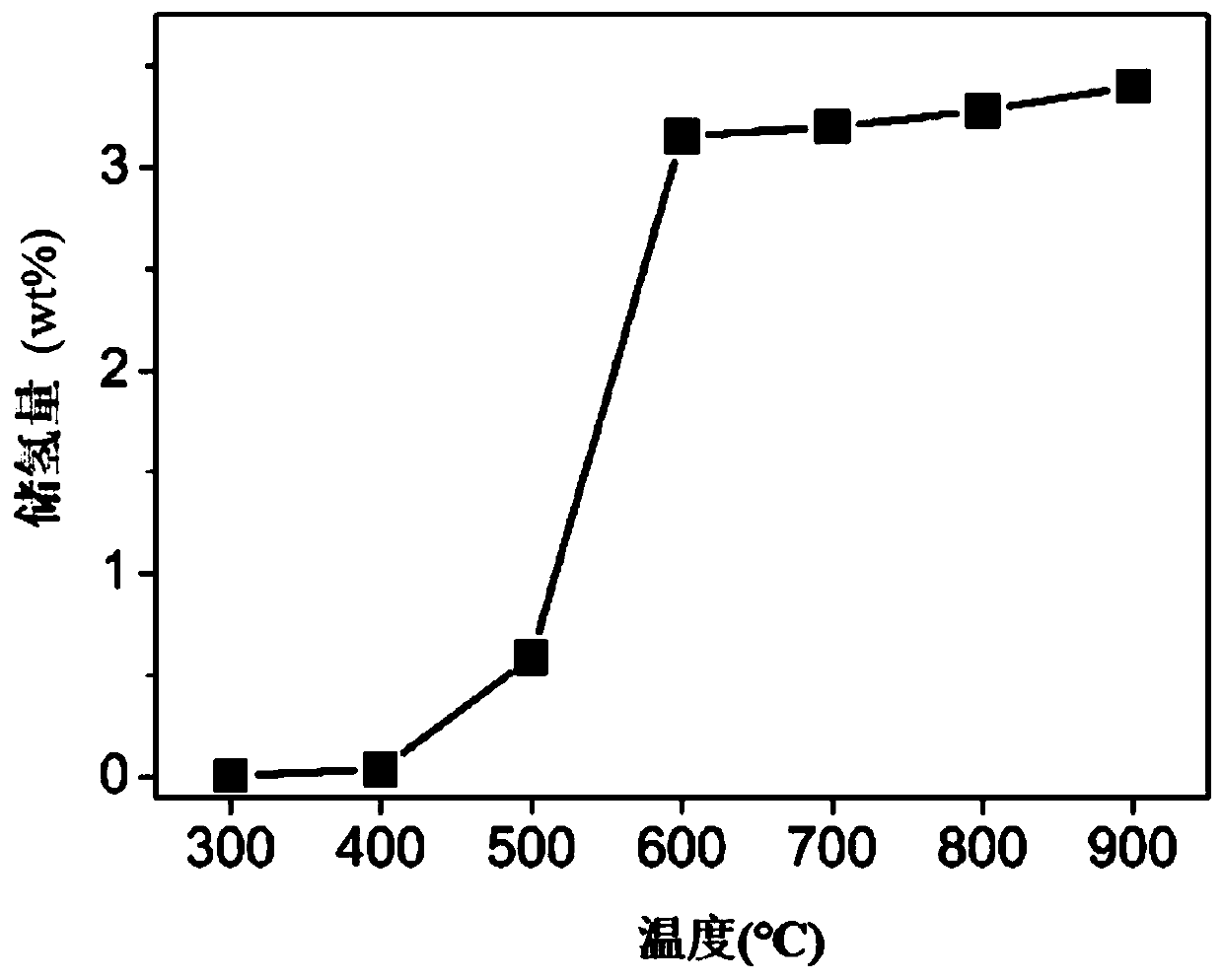

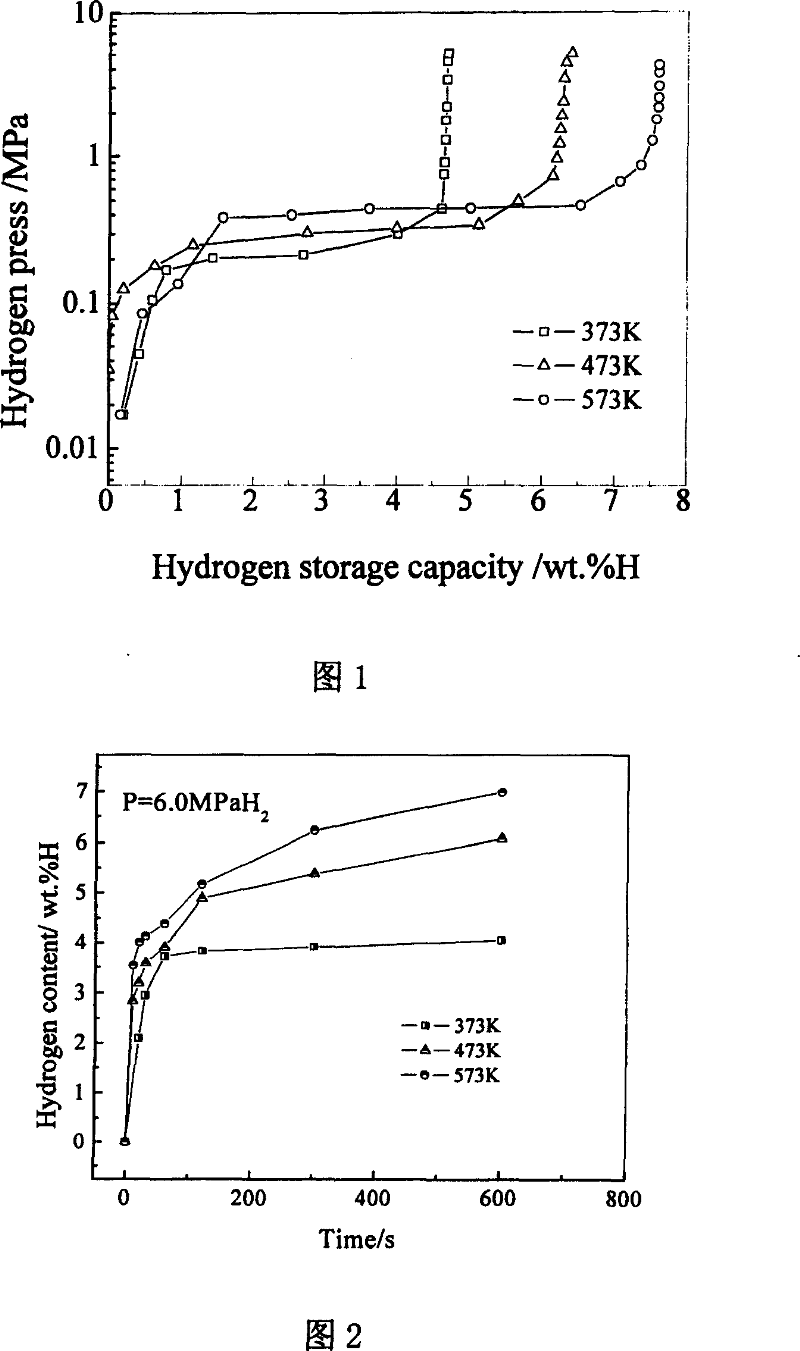

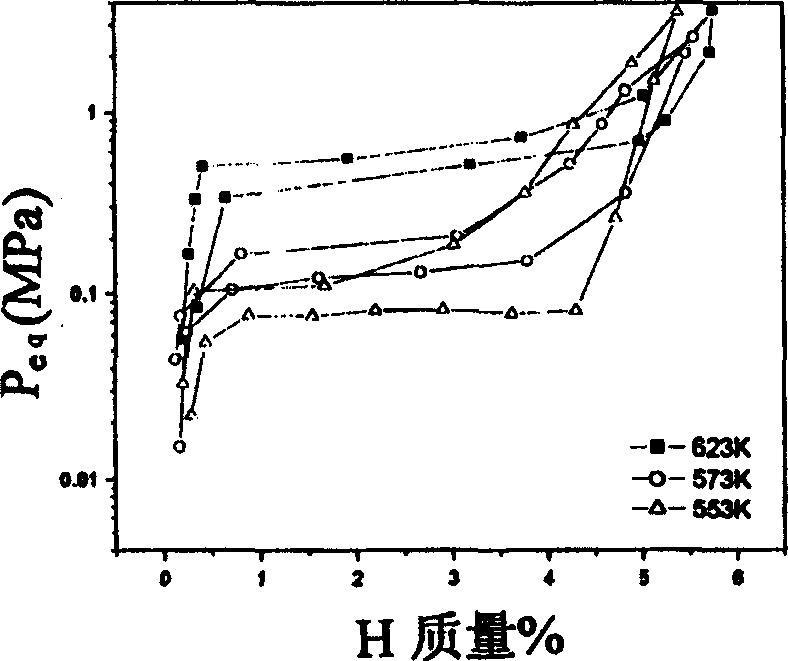

The invention belongs to the field of hydrogen storage materials, and relates to a hydrogen storage high-entropy alloy taking a body-centered cubic structure as the principal thing and a preparation method for the hydrogen storage high-entropy alloy. A component expression formula of high-entropy alloy is as follows: (TiaZrbNbc)xMy, wherein a is greater than or equal to 5at% and smaller than or equal to 35at%, b is greater than or equal to at5% and smaller than or equal to 35at%, c is greater than or equal to 5at% and smaller than or equal to 35at%, a+b+c is equal to x, x is greater than or equal to 15at% and smaller than or equal to 100at%, M is any one or more of Hf, Fe, Co, Cr, Mn, Ni, Mo and W; and atomic percent of each M is 0-35%, and x+y is equal to 100. The preparation method for the hydrogen storage high-entropy alloy comprises the following steps of: adopting a non-consumable vacuum electric-arc furnace to smelt to prepare alloy; and adopting suction casting to sucking alloy into a water-cooling cooper mould, thereby obtaining a high-entropy alloy rod. The high-entropy alloy has high hydrogen storage capacity (3 mass% or more) and excellent hydrogen absorption and desorption dynamic performances; when hydrogen absorption and desorption amount is great, the high-entropy alloy, in comparison with a pure element, does not need to completely purify, so that cost can be saved to a great extent. The hydrogen storage high-entropy alloy taking the body-centered cubic structure as the principal thing has the characteristics of the high-entropy alloy, and has a wide application prospect in the fields of new energy resources and transportation.

Owner:UNIV OF SCI & TECH BEIJING

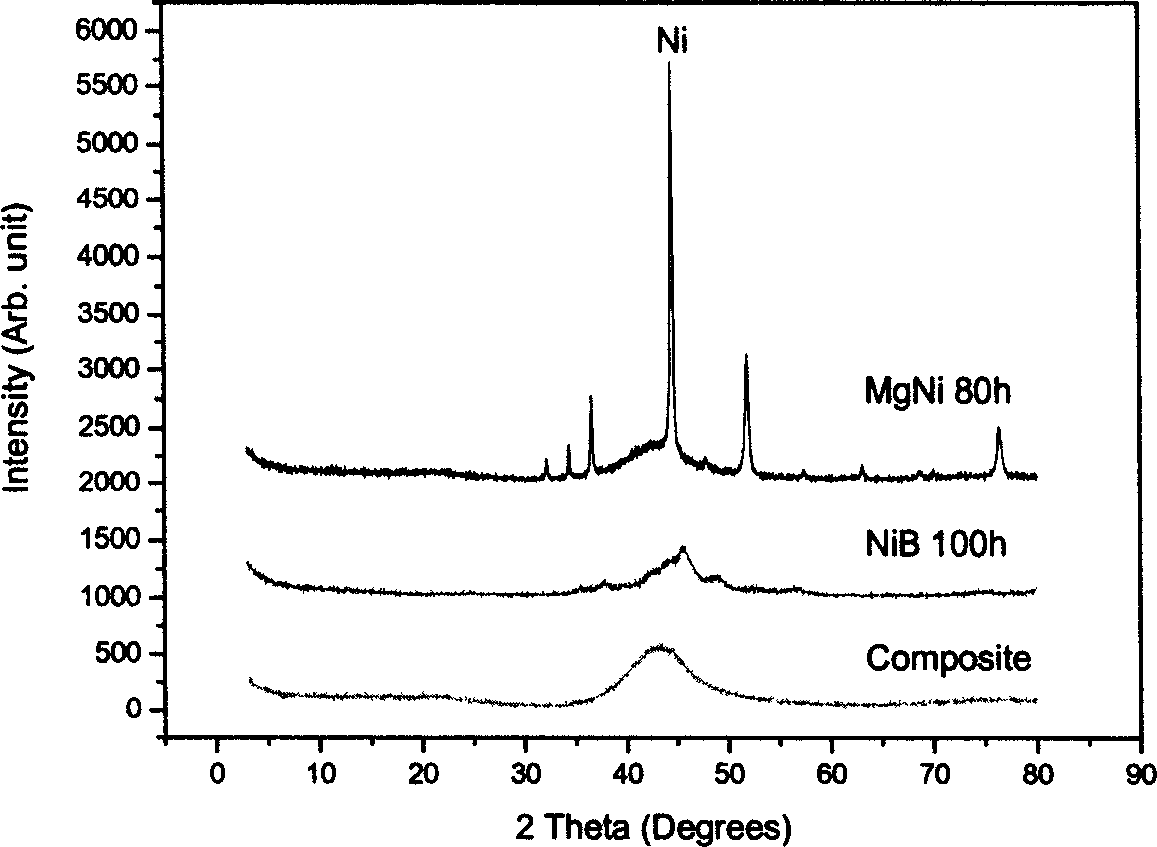

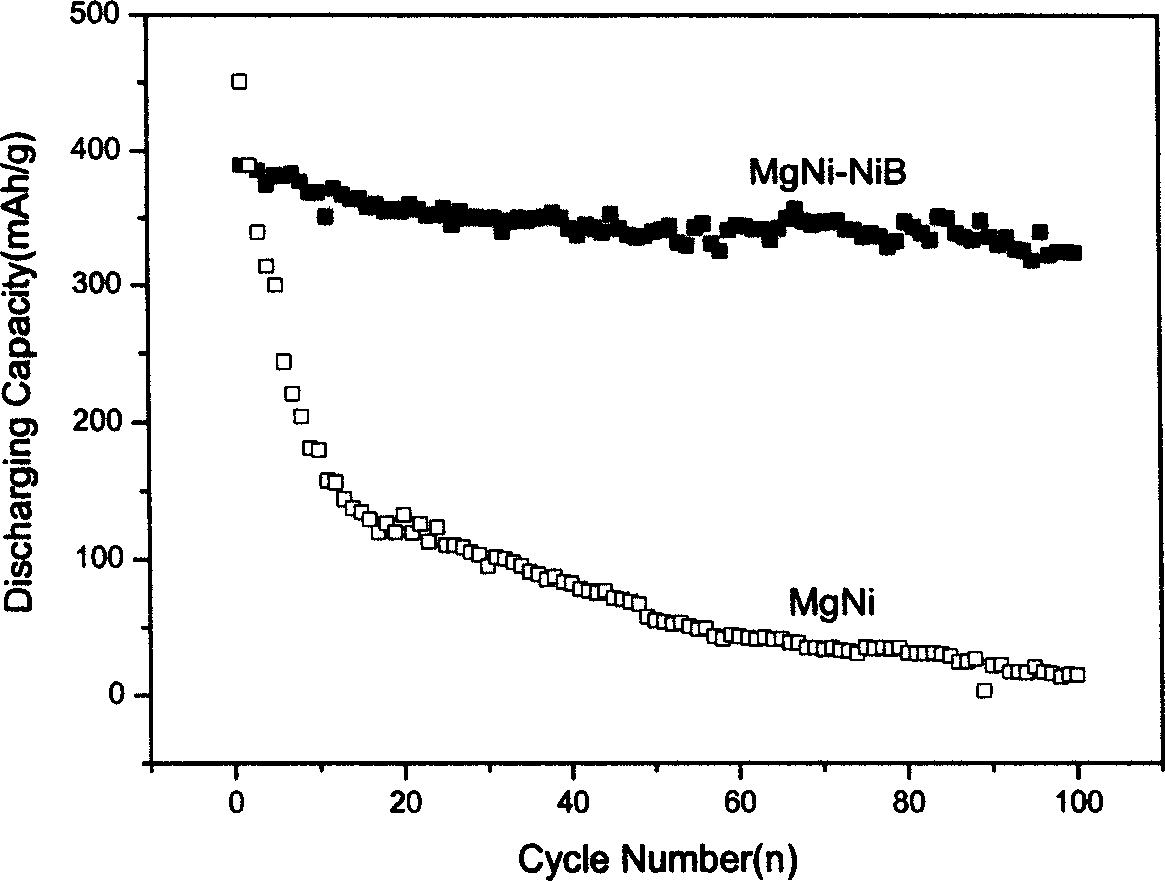

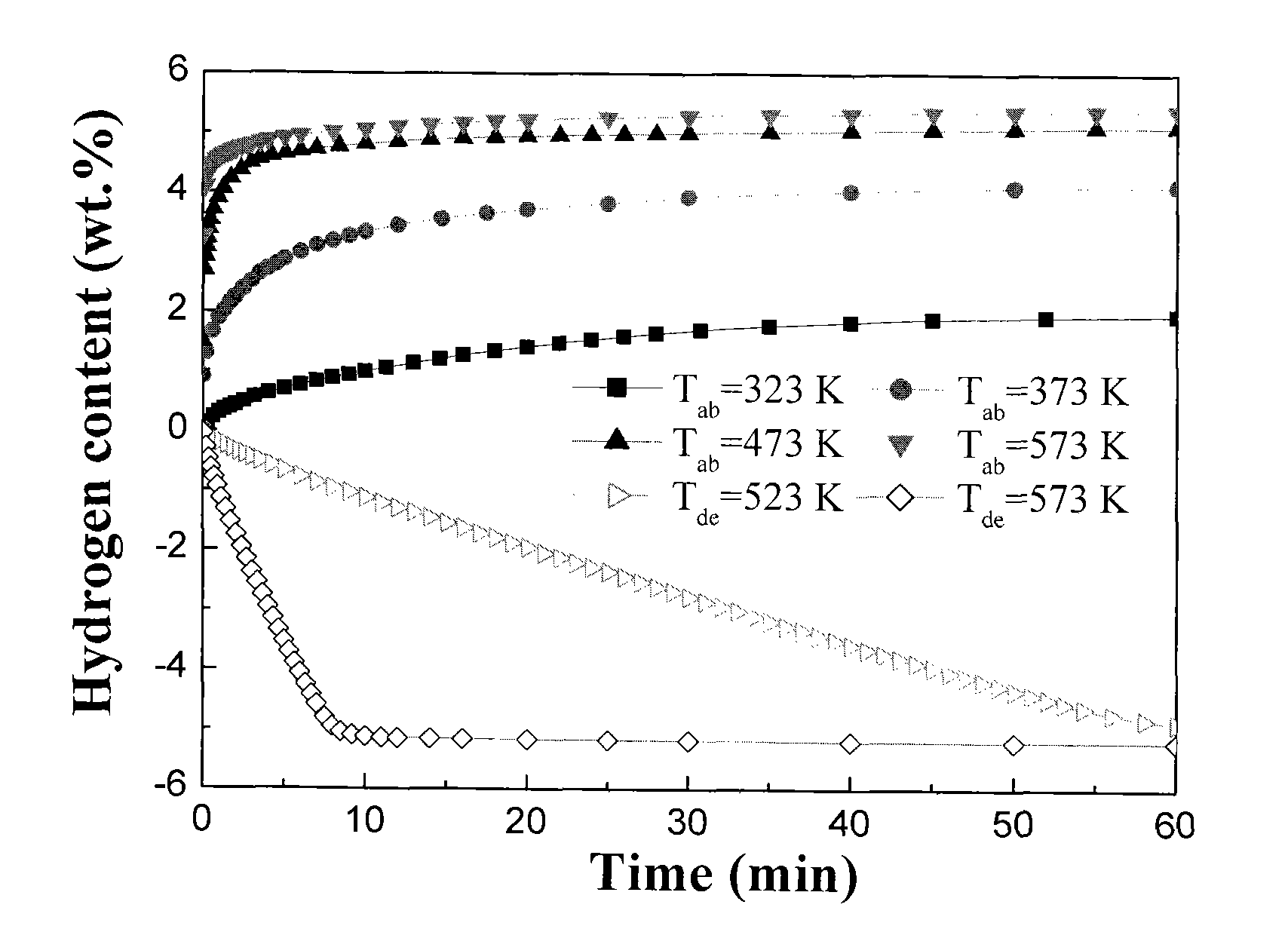

Magnesium based hydrogen storing alloy composite material and production thereof

The invention is about Mg-base hydrogen storage material and the method of the procedure. It has the chemical composition of Mgp-xMxNi-yNy-NieBf, M has the alternative of Al, Mn, Sn, Ca, Li, B, Na, B, Na, K, La, Ce, Nd, Pr, Y and misch metal. N has the alternative of V, Cu, Ti, Co, Fe, Ag, Cr, Zr, Se, Nb, Mo, W, Nb, C, Si and Sn, 1.0 <=p<=2.5, 0<=x<=1.0, 0<=y<=0.8, 1<=e<=3, 1<=f<=3. It has a good property under normal temperature and pressure, the electric pole that made by it has a high galvano-chemistry capability and cycle life. Its advantages include stable property; low price; extensive use of Ni-H battery, H accumulator, H power auto and fuel battery.

Owner:NANKAI UNIV

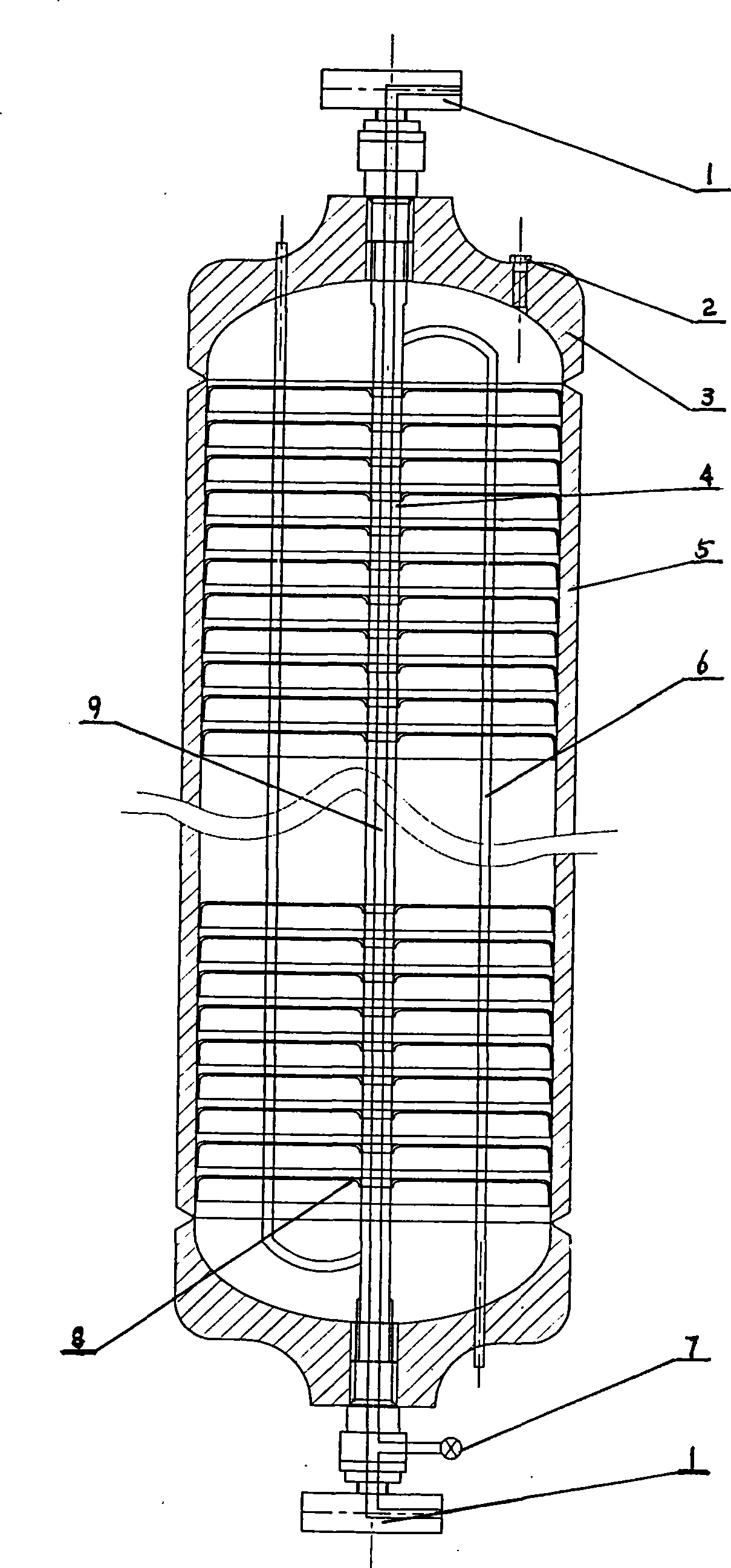

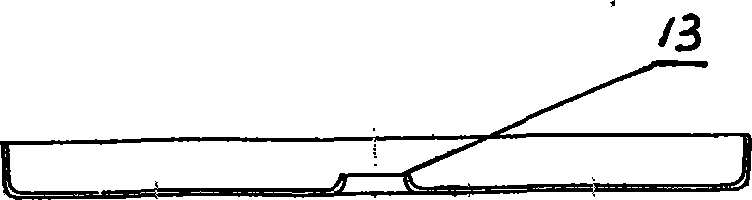

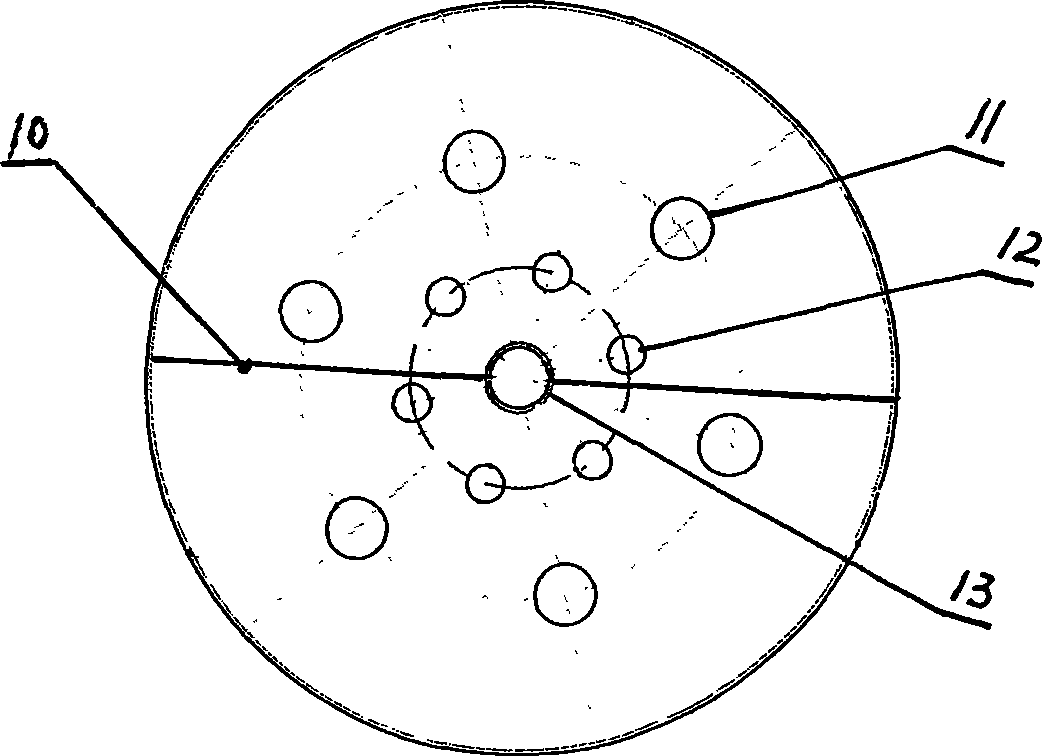

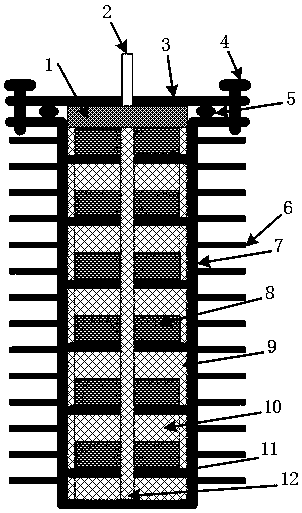

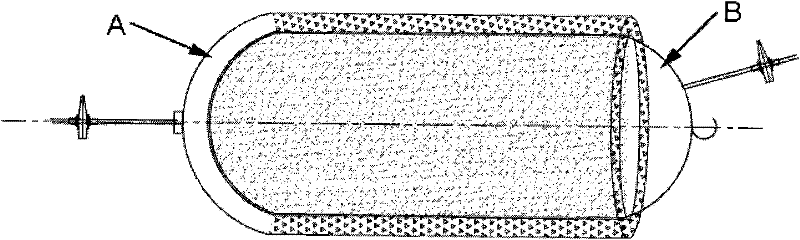

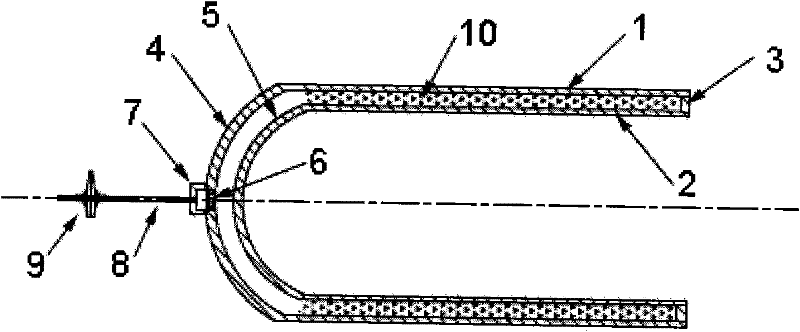

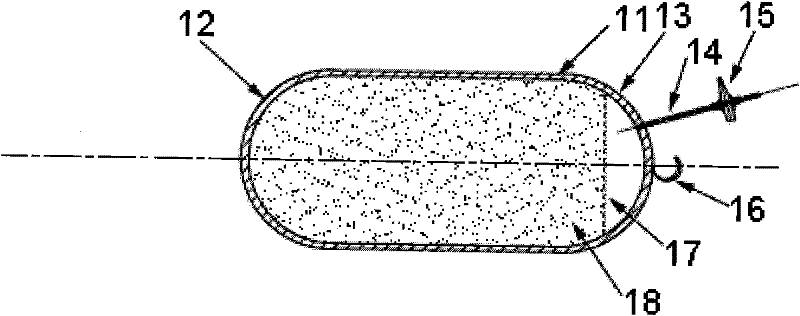

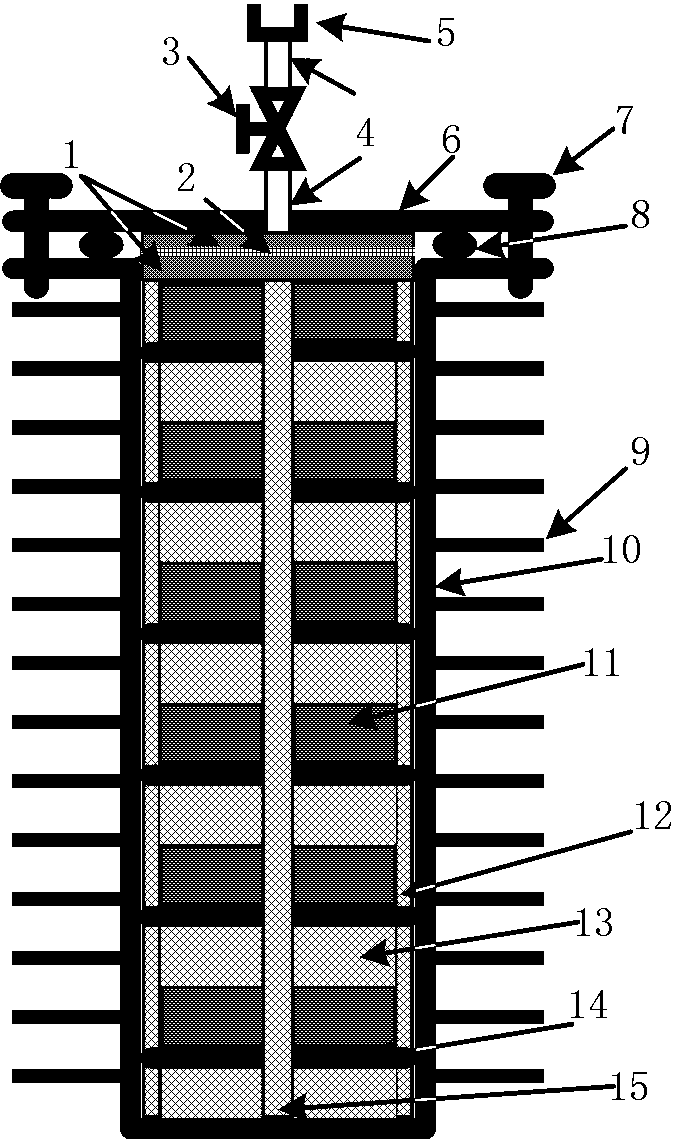

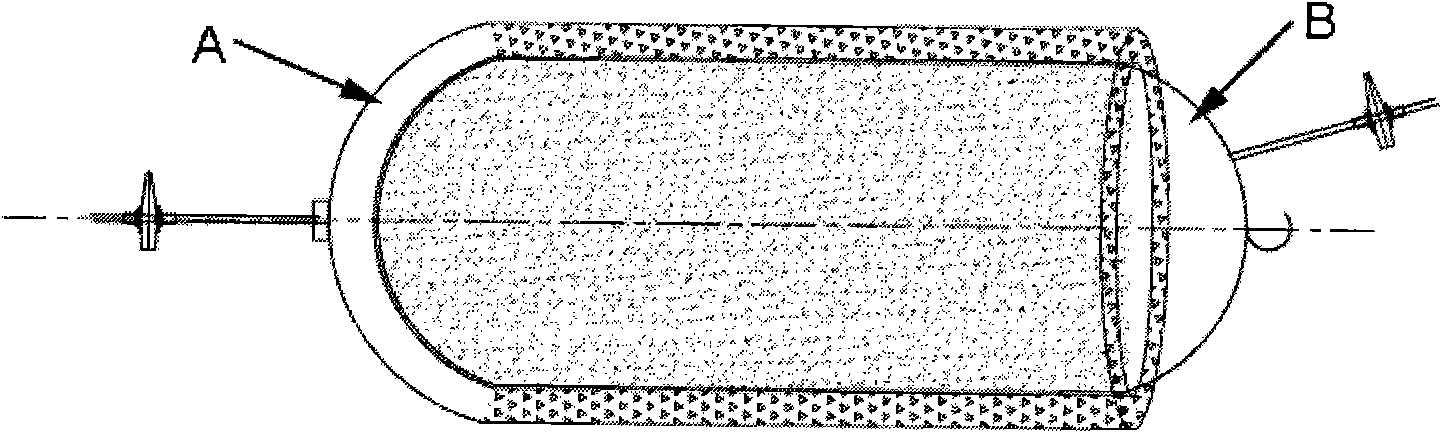

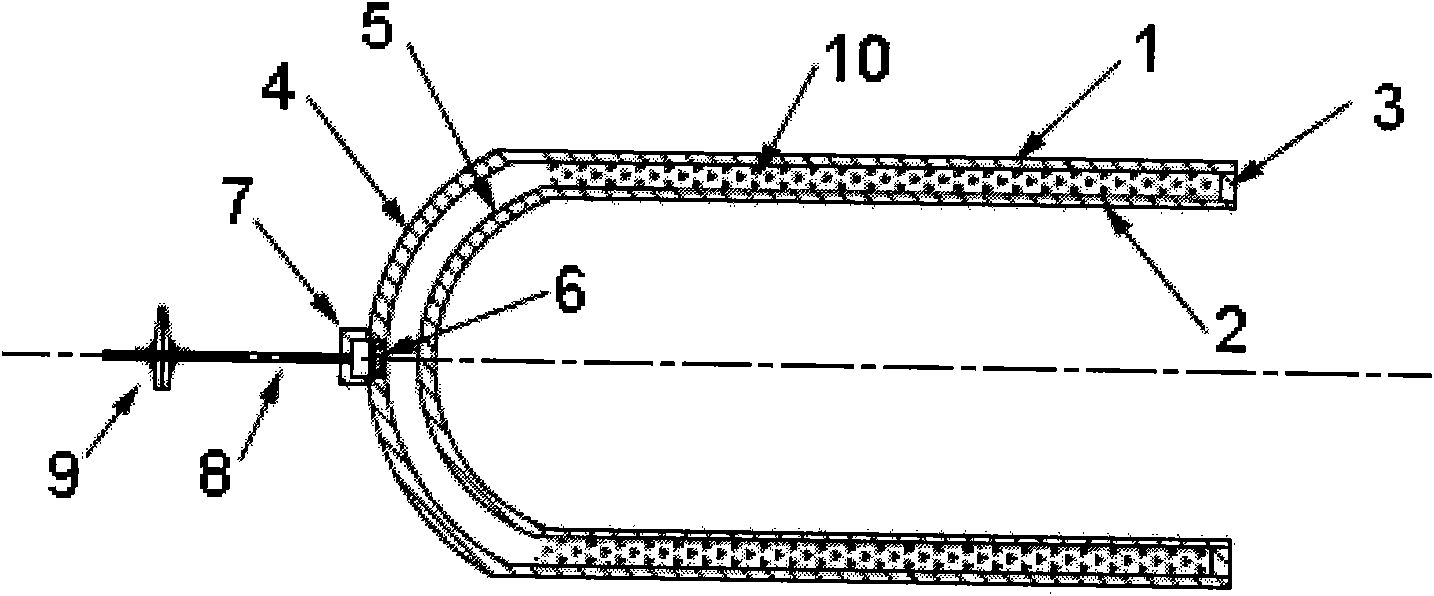

Solid hydrogen storing device

InactiveCN101245895ADoes not affect settingsDoes not affect installationContainer filling methodsFixed capacity gas holdersInlet valveEngineering

The invention provides a solid hydrogen storage device. A cylinder is internally connected with a heat conductive sheet; a hydrogen inlet valve and a hydrogen outlet valve are respectively connected with the exteriors of the two ends of the cylinder; a filter passes through the central hole of the heat conductive sheet; two ends of the filter are respectively connected with the hydrogen inlet valve and the hydrogen outlet valve; the cylinder is internally provided with a snake-shaped water circulation pipe which is arranged longitudinally along the cylinder and is connected with the heat conductive sheet; the heat conductive sheet is connected with a sheet-shaped crossing. Large holes are uniformly distributed along 2 / 3 of the radius of the heat conductive sheet; small holes are uniformly distributed along 1 / 3 of the radius of the heat conductive sheet; the sheet-shaped crossing is horizontally arranged between the large holes and the small holes of the heat conductive sheet; the snake-shaped water circulation pipeline passes through the heat conductive sheet and deviously passes through the large holes in 120 DEG on the heat conductive sheet with an arc ranging from 30-90 DEG; the water outlet and the water inlet of the snake-shaped water circulation pipe are respectively arranged at the end plates of the two ends of the cylinder.

Owner:石锋

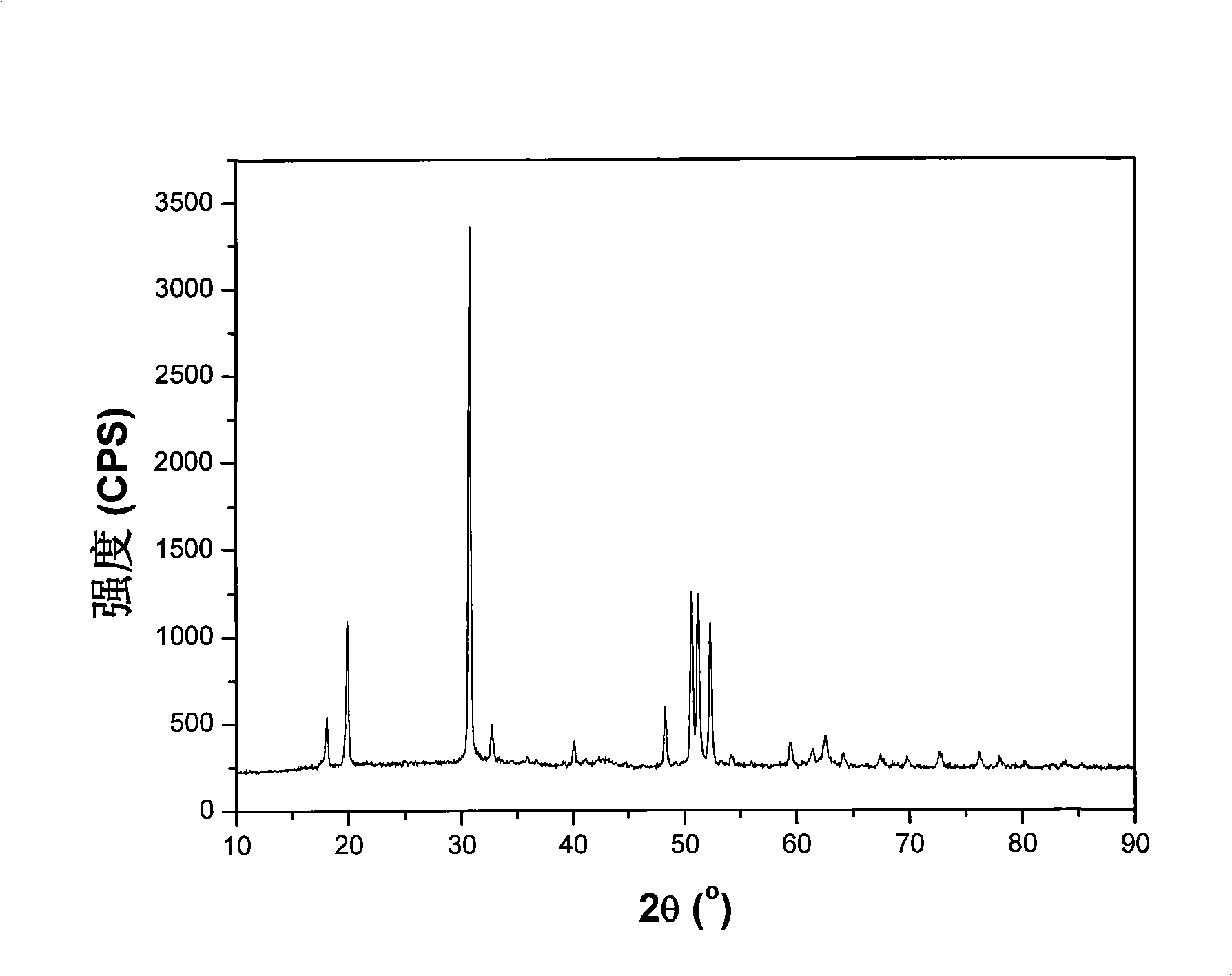

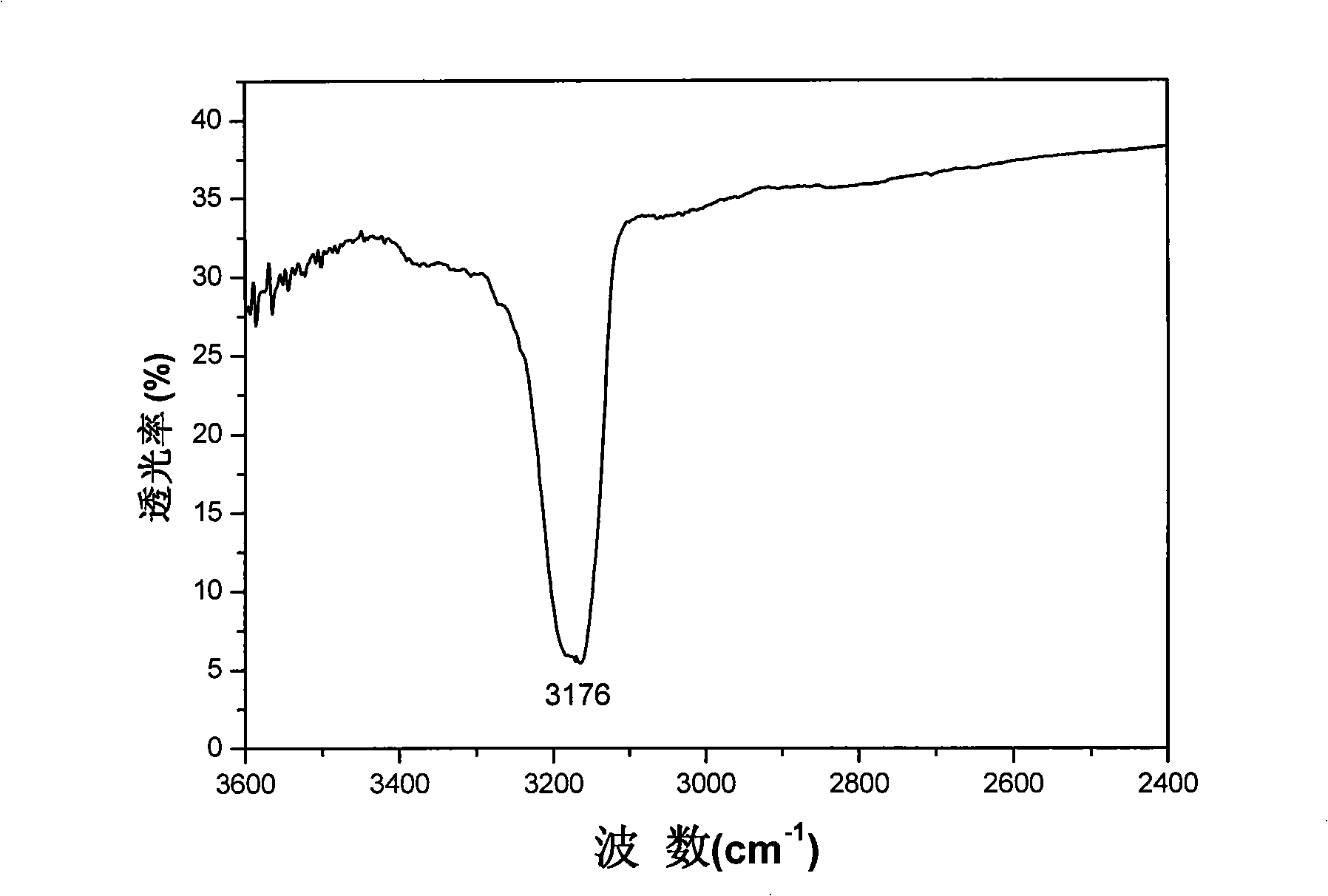

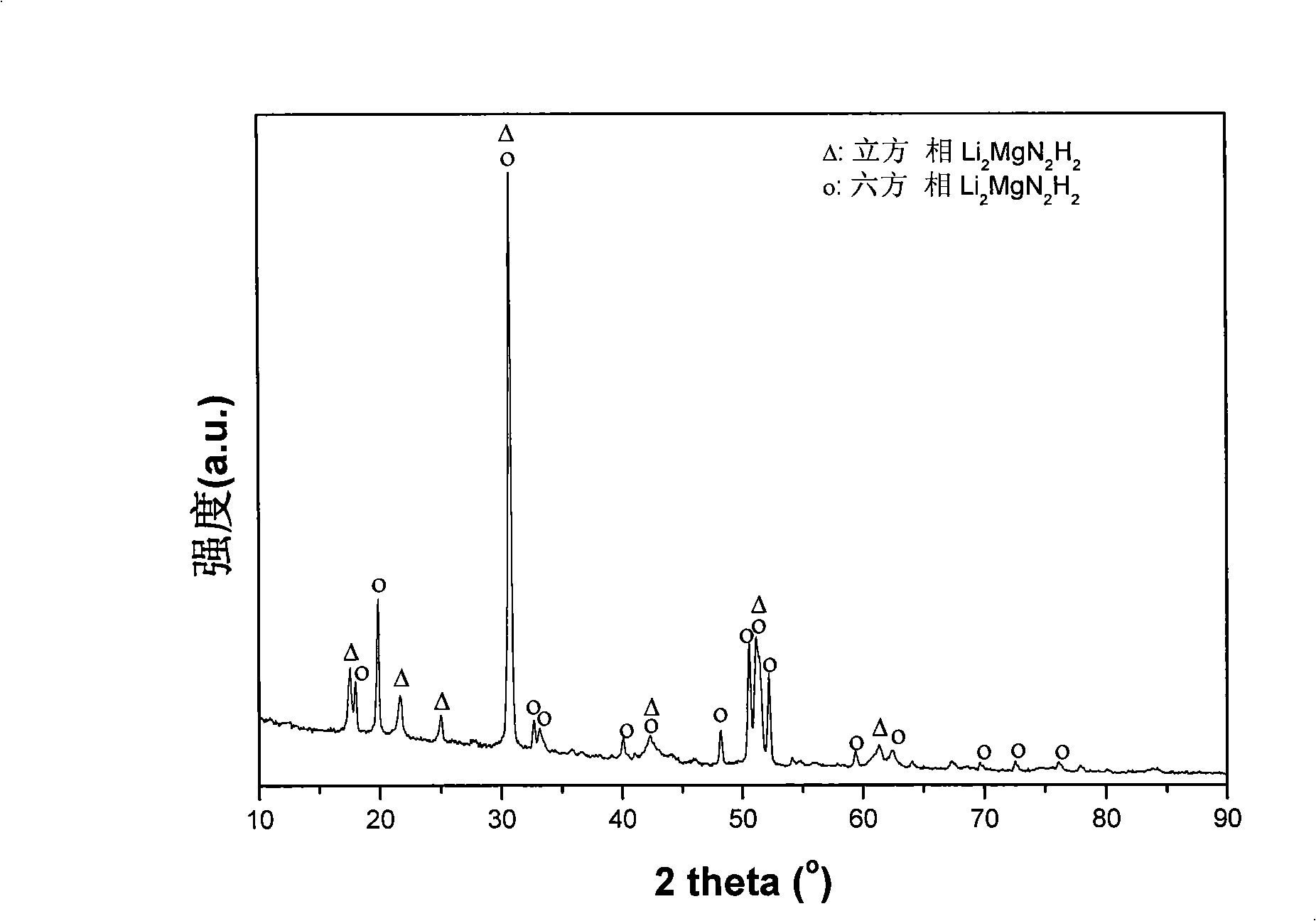

Method for preparing Li-Mg-N-H hydrogen-storing material

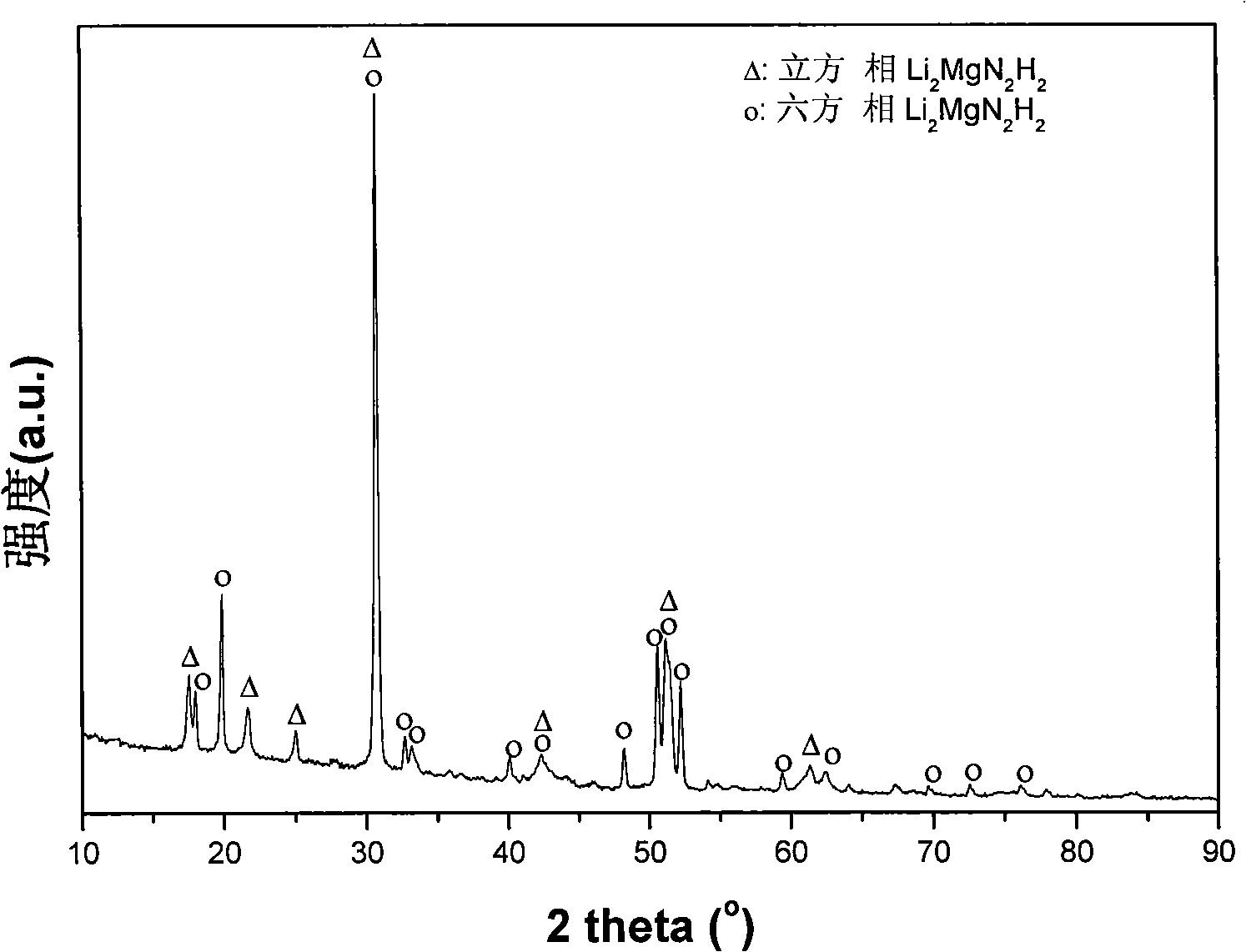

InactiveCN101332976ALower working temperatureFast hydrogen absorption and desorptionMultiple metal hydridesHydrogen productionBall millWorking temperature

The invention discloses a method for preparing Li-Mg-N-H hydrogen storage material. The mixture of the nitride or amino-compound of Li and Mg, the nitride or amino-compound of Mg is loaded in a stainless steel tank and evenly blended by a mechanical mixing or mechanical ball milling way; the evenly blended mixture is loaded in a sintering furnace, the sintering furnace is vacuumized or charged with inert gases and is heated to the temperature range from 250 to 350 DEG C for heat preservation and then the Li-Mg-N-H hydrogen storage material is obtained; the Li-Mg-N-H hydrogen storage material is loaded into a ball milling tank and undergoes ball milling process on a ball mill, and the grain diameter of the sample powder processed with ball milling is smaller than 100nm. The preparation method has simple operation, easy control and low cost. The Li-Mg-N-H prepared and processed by the invention has high hydrogen storage capacity, low working temperature and high speed of hydrogen absorbing and discharging and good reversibility, thus being the hydrogen storage material with excellent performance and being suitable for the storage and transportation of hydrogen.

Owner:ZHEJIANG UNIV

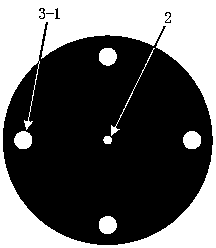

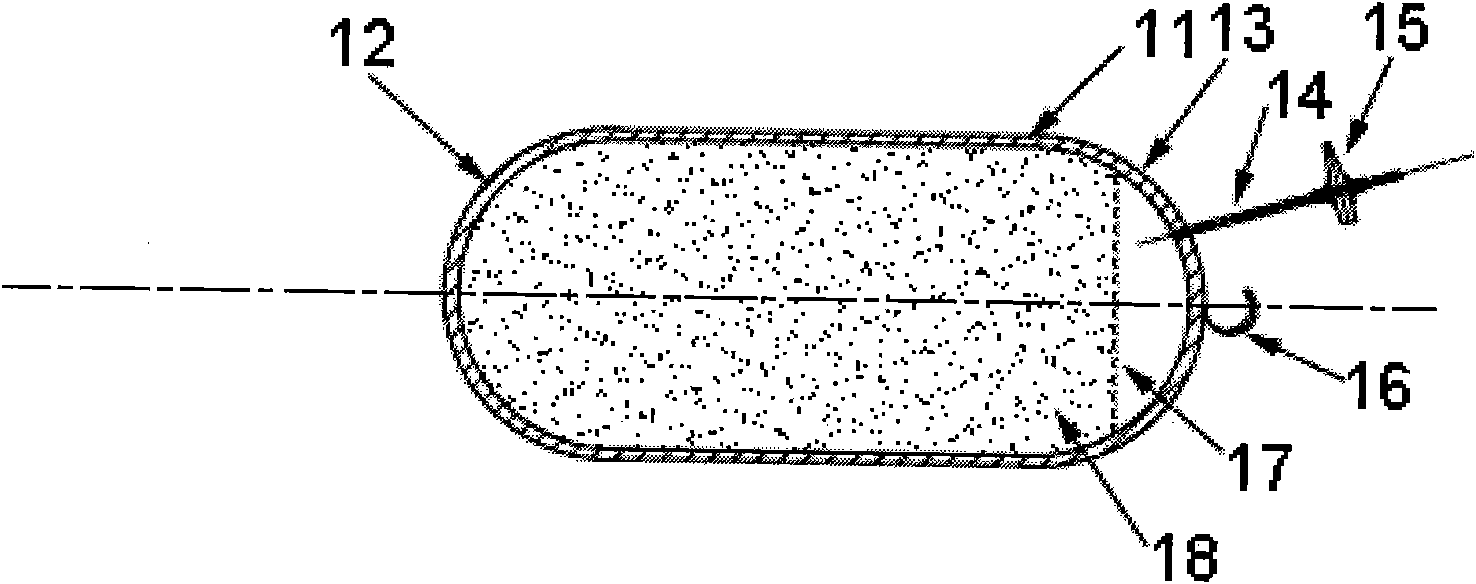

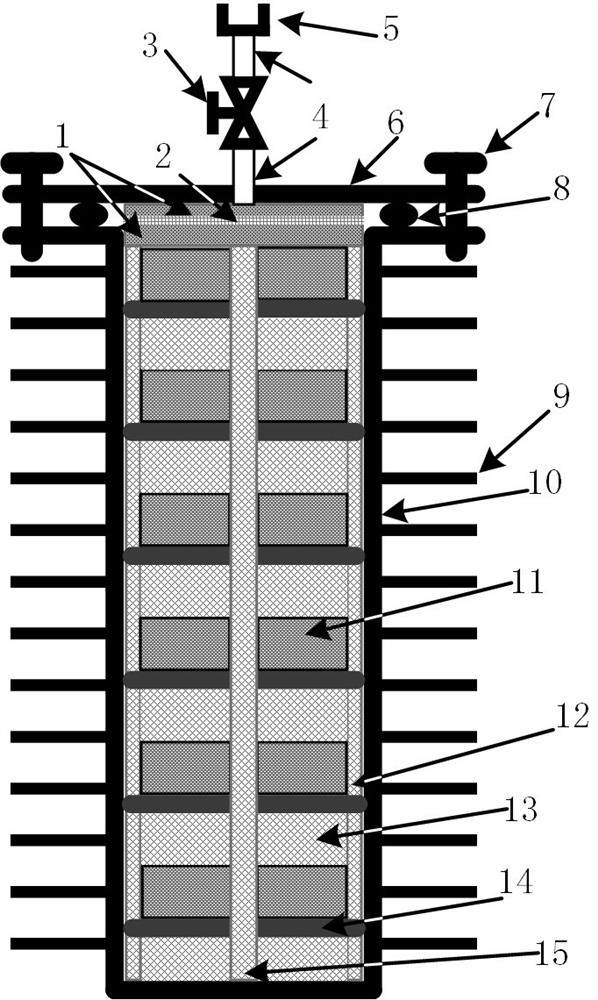

Low-cost, high-hydrogen-absorption-and-desorption-speed and high-safety metal hydride hydrogen storage tank

PendingCN111022912AFast hydrogen absorption and desorptionIncrease productivityVessel geometry/arrangement/sizeVessel wallsMetallurgyMetallic hydrogen

The invention relates to a hydrogen storage technology, in particular to a low-cost, high-hydrogen-absorption-and-desorption-speed and high-safety metal hydride hydrogen storage tank. The hydrogen storage tank mainly comprises a round foam metal cover, a gas pipe, a flange cover, bolts, an O-shaped sealing ring, cooling fins, a tank body, hydrogen storage material powder, a round foam metal barrel, a foam metal disc, a heat pipe and a foam metal cylinder. The metal hydride hydrogen storage tank is simple in structure and easy to realize, the condition that metal hydride powder flows out of thegas pipe with the gas flow to damage downstream components can be prevented, the hydrogen storage tank has the excellent heat and mass transfer performance, and thus the hydrogen storage tank has thehigh hydrogen absorption and desorption speeds. Besides, according to the hydrogen storage tank, damage to the tank body of the hydrogen storage tank due to self-compaction and hydrogen absorption expansion of the metal hydride powder can be avoided, so that the hydrogen storage tank is high in safety and can be used repeatedly.

Owner:YANGZHOU UNIV

Metal hydride hydrogen compression device with heat source and manufacture method thereof

ActiveCN102530860AAchieve superchargingSimple structureHydrogen productionHydrogen compressionRoom temperature

The invention relates to a metal hydride hydrogen compression device with a heat source and a manufacture method thereof. The manufacture method is characterized in that the metal hydride hydrogen compression device is heated by self under the condition of no additional heat sources, and then the metal hydride hydrogen compression device adsorbs hydrogen at the room temperature and discharges high-voltage hydrogen at high temperature. The device comprises a hydrogen compression part with metal hydride and a heat source part, wherein a phase change energy storage material in the heat source part is subjected to temperature raising and phase change and stores heat under the heating condition, and heat is provided for the metal hydride in the hydrogen compression part; then, the metal hydride releases hydrogen at a certain temperature range of 50-300DEG C in more than two hours; and the hydrogen release pressure is between 10MPa and 100MPa.

Owner:GRIMAT ENG INST CO LTD

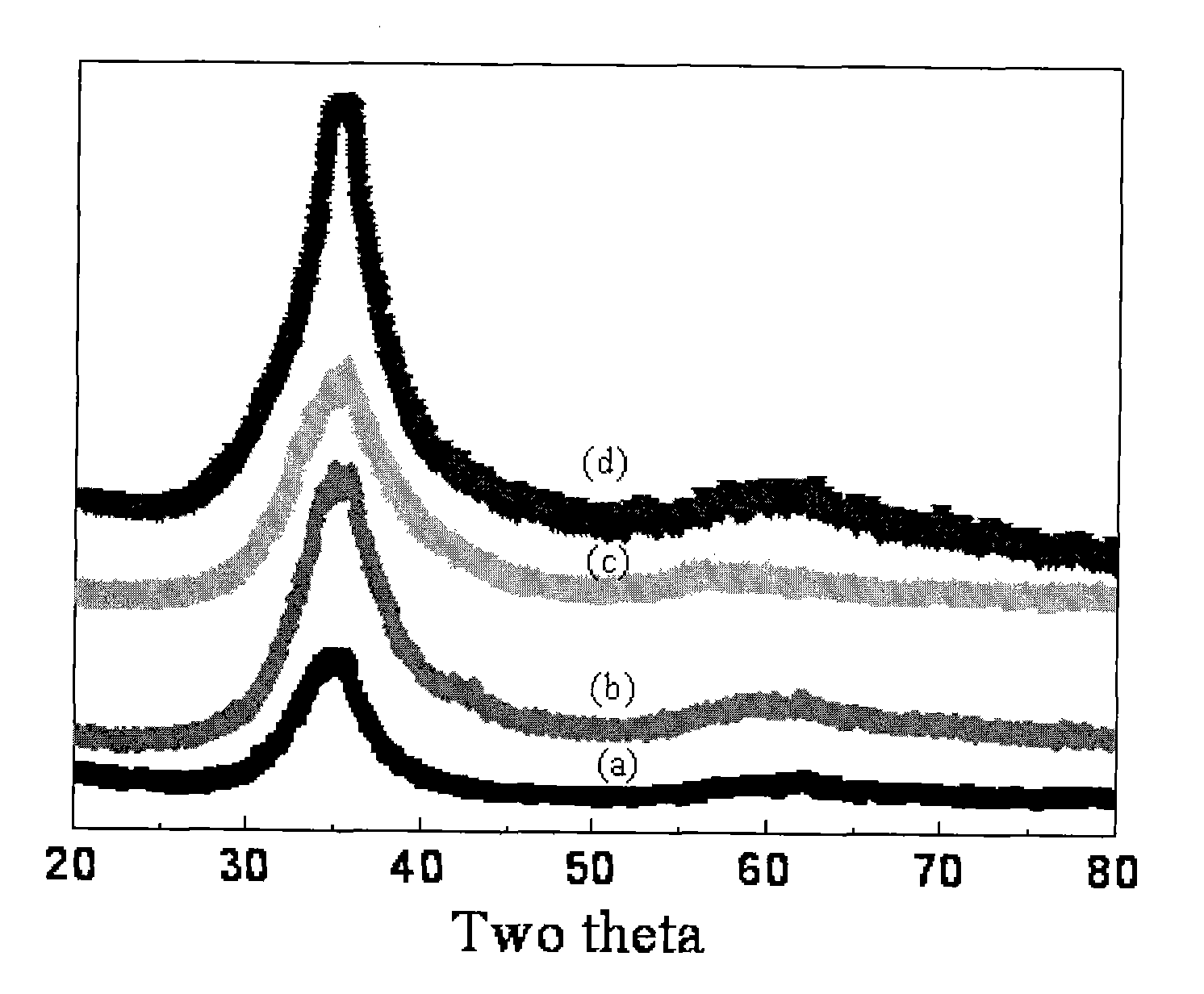

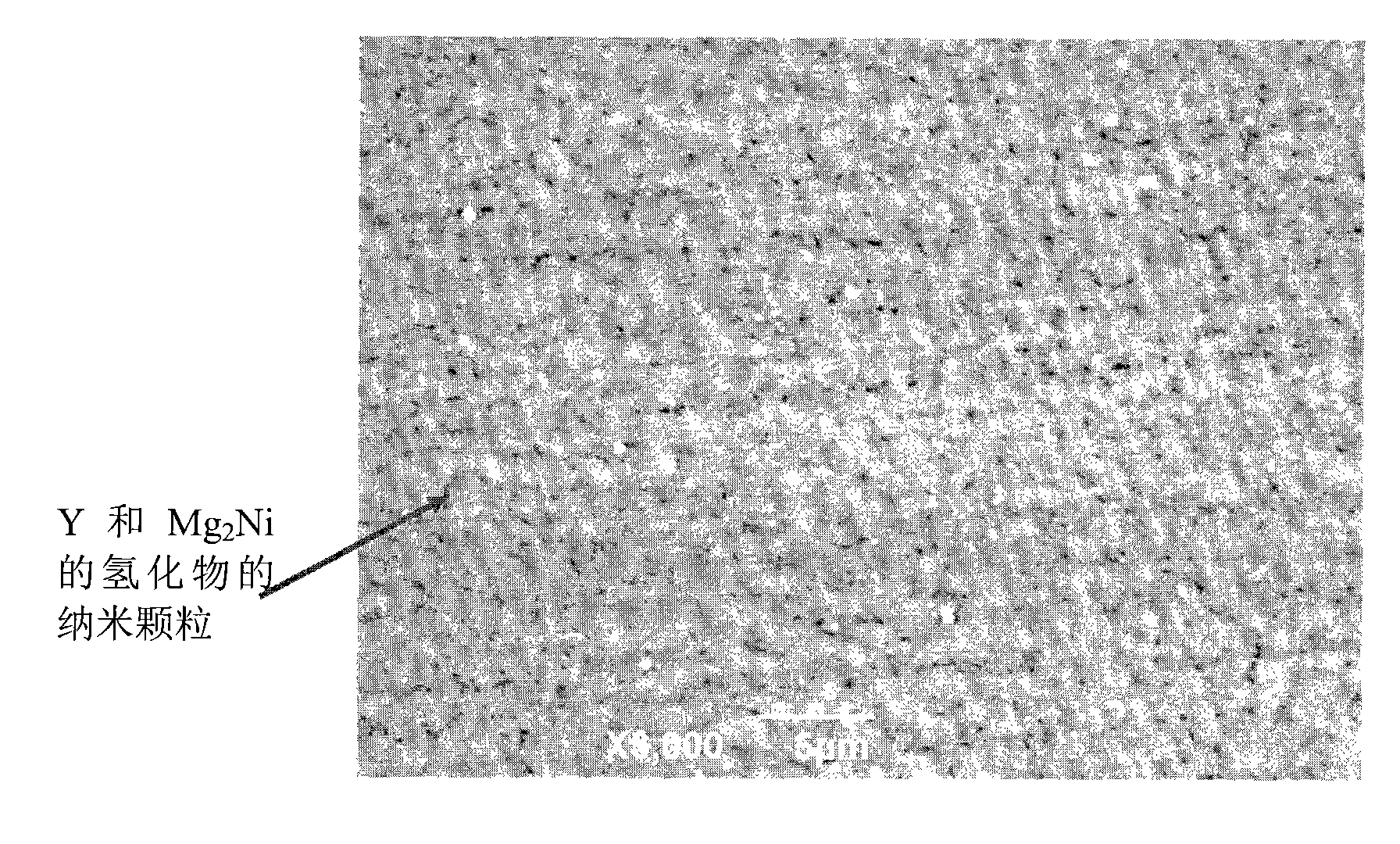

Amorphous magnesium-yttrium-transition metal hydrogen storage material and preparation method thereof

The invention provides an amorphous magnesium-yttrium-transition metal hydrogen storage material and a preparation method thereof, belonging to the technical field of hydrogen storage materials. The content of Mg in the hydrogen storage material is 70-90at.%, the transition metal is Co, Ni and Cu, and the yttrium and the transition metal are added in a combined addition manner based on the mol ratio of 1 to 1. The preparation method comprises the steps of: firstly, melting and preparing intermediate alloy of the yttrium and the transition metal by using an induction melting furnace; secondly, remelting and rapidly quenching the metal Mg and the intermediate alloy of the yttrium and the transition metal in a vacuum single-roller liquor rapid quenching furnace, wherein the prepared material is an amorphous ribbon with the width of 3mm and the thickness of 30-50 microns; and grinding the prepared amorphous ribbon into powder with different granularities in a glove box, wherein the amorphous ribbon or powder is the finished products of hydrogen storage materials. In the invention, the provided hydrogen storage material overcomes the disadvantage of low hydrogen storage amount; the combined addition of the Y and the transition metal facilitates the formation of the amorphous body and improves the hydrogen storage performance of the material. In addition, the invention has the characteristics of simple preparation method and low cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of zeolite composite magnesium base hydrogen storage material

InactiveCN105478798ASimple preparation stepsLow costCell electrodesPhysical chemistryBiological activation

The invention relates to a preparation method of a zeolite composite magnesium base hydrogen storage material, and belongs to the field of preparation of hydrogen storage materials. Firstly, FeCl2 is dehydrated, grinded and sieved; then, dried dimethylformamide is mixed, and is added with magnesium powder for heating, stirring and extracting; filter cakes are collected, and are washed by using the dried dimethylformamide and acetone; then, the washed filter cakes are dried, activated, pressurized, insulated and cooled to room temperautre, and perform ball milling with zeolite molecules in a ball milling machine to prepare zeolite composite Mg2FeH6 powder; and the zeolite composite Mg2FeH6 powder is put in a hydrogen activation reaction kettle for hydrogen treatment. The preparation method has the following beneficial effects: the prepared zeolite composite magnesium base hydrogen storage material quickens the hydrogen sucking and releasing speed, and is prominent in dynamics performance when keeping higher hydrogen storage quantity; the hydrogen releasing quantity is 2.3-4.8 wt.%; and the practical development of the magnesium base hydrogen storage material is promoted.

Owner:雷春生

Chemical improvement method of performances of La-Mg-Ni serial hydrogen storage alloy

InactiveCN104726747ANot easy to pulverizeImprove corrosion resistanceCell electrodesSurface layerBiological activation

Hot alkali treatment affects the electrochemical performances of La-Mg-Ni serial A2B7 type hydrogen storage alloy electrodes. The hot alkali treatment is carried out after alloy melting annealing, so the content of nickel in the surfaces of alloy particles increases with the dissolving of La, Mg, Al and other elements in a surface layer to realize strong activation performances.

Owner:HEILONGJIANG FULONG BUILDING DECORATION ENG

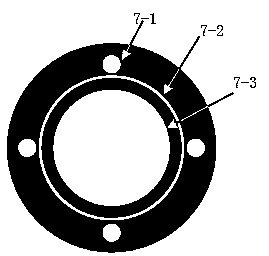

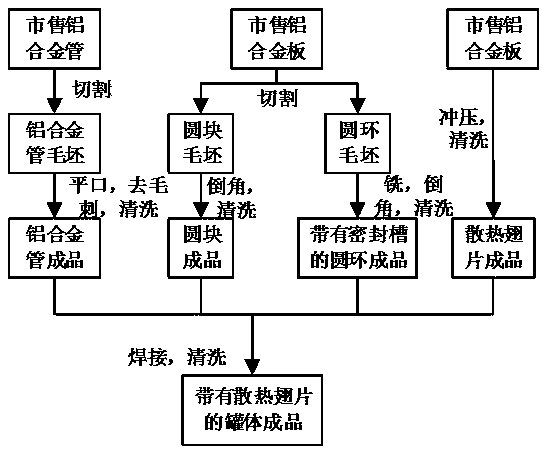

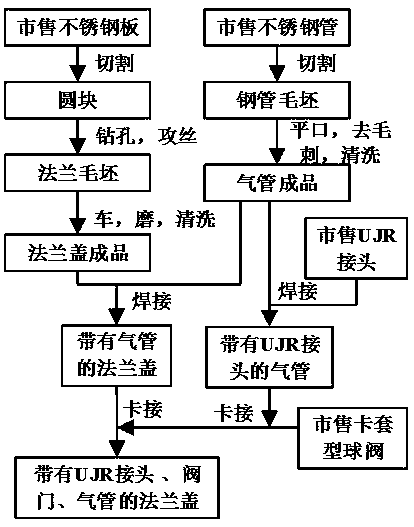

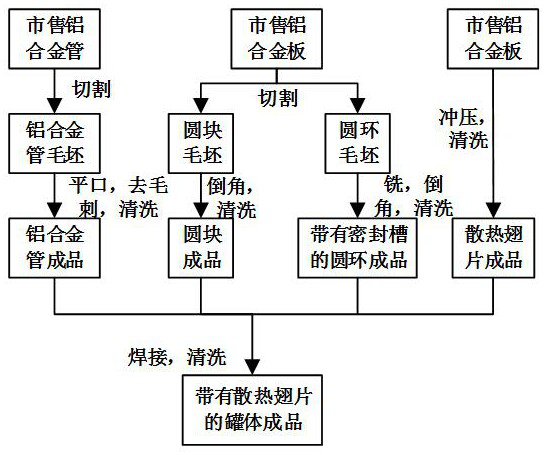

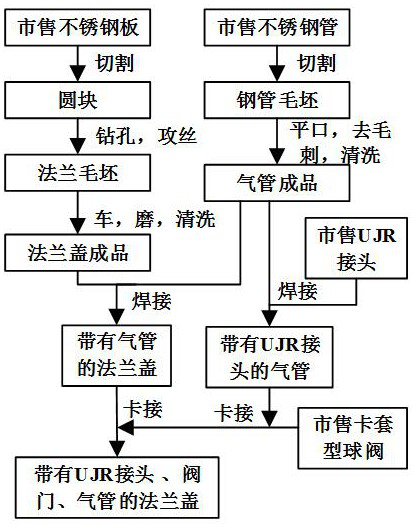

Manufacturing method of metal-hydride hydrogen storage tank

ActiveCN111195808ASimple structureImprove space utilizationVessel manufacturingVessel wallsCircular discMetallic hydrogen

The invention relates to a manufacturing method of a metal-hydride hydrogen storage tank. The method includes the steps of machining of a tank body, machining of a flange cover, machining of foam copper elements, preparation of hydrogen storage alloy powder and assembly line assembling and production of the hydrogen storage tank. The hydrogen storage tank comprises parts including a round foam copper cover, a mat type copper net, a clamping sleeve type ball valve, an air pipe, a UJR joint, the flange cover, bolts, an O-shaped sealing ring, cooling fins, the tank body, the hydrogen storage alloy powder, a foam copper drum, a foam copper disk, a copper-water heating pipe, a foam copper cylinder and the like. The manufacturing method is high in production efficiency, high in yield and low inmanufacturing cost, the metal-hydride hydrogen storage tank manufactured with the method is simple in structure, high in space utilization rate, large in hydrogen storage amount, good in sealing performance, excellent in heat and mass transfer performance, high in hydrogen absorption and release speed and good in long-time use safety, breakage of the tank body due to hydrogen absorption expansionof a hydrogen storage material can be avoided, no cooling media are required to be introduced, repeated recycling can be realized, and the use cost is low.

Owner:YANGZHOU UNIV

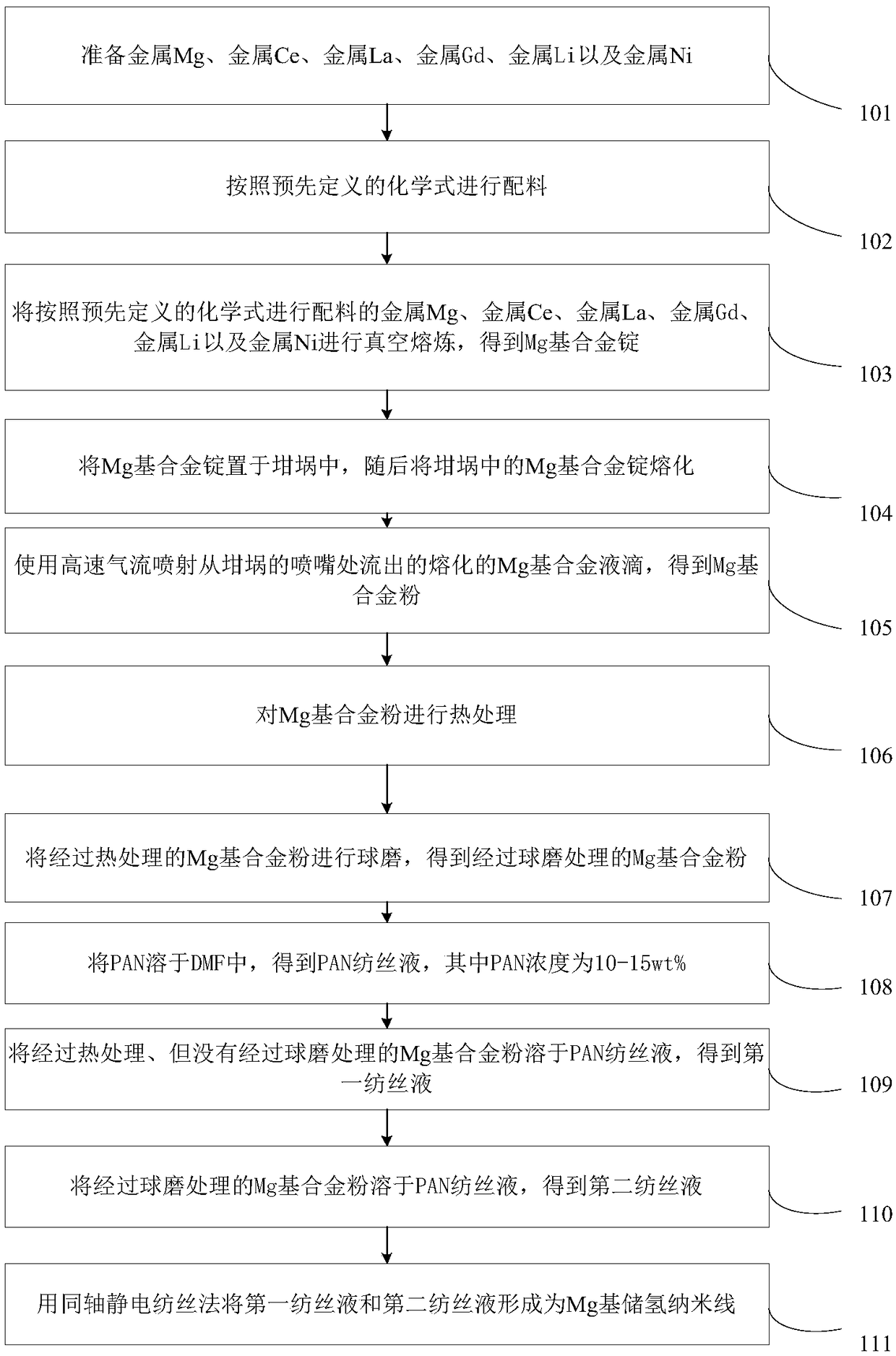

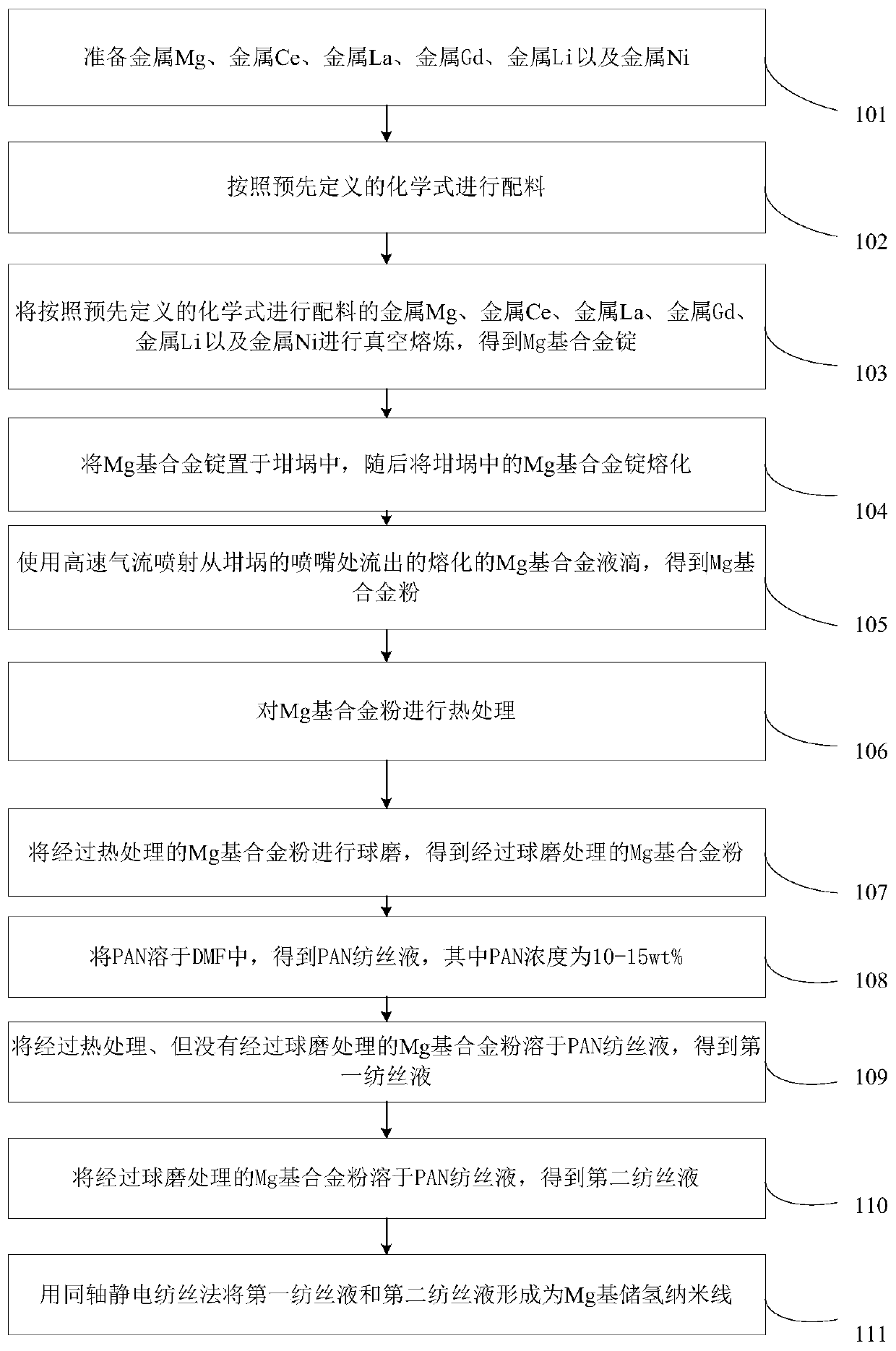

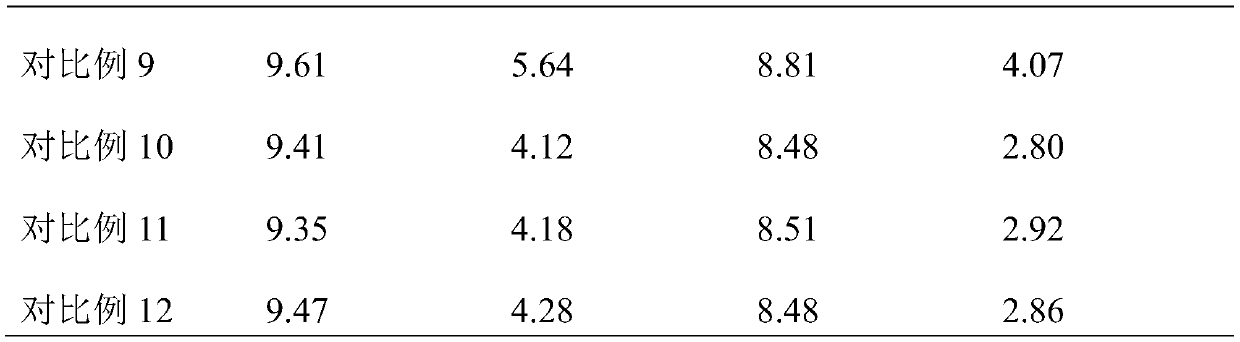

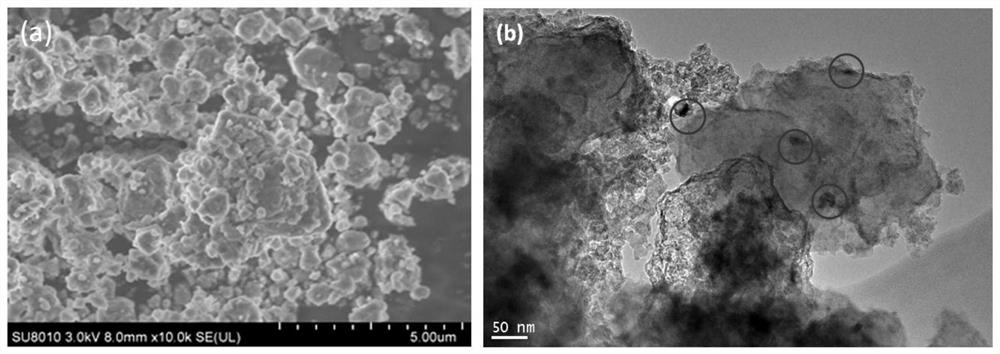

Preparation method for Mg-based hydrogen storage nanowire

ActiveCN108950260AImprove hydrogen storage performanceLarge total hydrogen storageTransportation and packagingMetal-working apparatusNanowireElectrospinning

The invention provides a preparation method for a Mg-based hydrogen storage nanowire. The preparation method comprises the following steps that metal Mg, metal Ce, metal La, metal Gd, metal Li and metal Ni are prepared, batching and vacuum melting are carried out, and a Mg-based alloy ingot is obtained; the Mg-based alloy ingot is atomized, and Mg-based alloy powder is obtained; heat treatment iscarried out on the Mg-based alloy powder; ball milling is carried out on the heat-treated Mg-based alloy powder, and the ball-milled Mg-based alloy powder is obtained; PAN is dissolved in DMF, and a PAN spinning solution is obtained, wherein the PAN concentration ranges from 10 wt% to 15 wt%; the Mg-based alloy powder subjected to heat treatment but not ball milling treatment is dissolved in the PAN spinning solution, and a first spinning solution is obtained; the Mg-based alloy powder subjected to ball milling treatment is dissolved in the PAN spinning solution, and a second spinning solutionis obtained; and the first spinning solution and the second spinning solution are formed into the Mg-based hydrogen storage nanowire by a coaxial electrostatic spinning method. By the adoption of thepreparation method for the new hydrogen storage material. The alloy prepared by the preparation method has larger hydrogen storage amount and higher hydrogen absorption and release speed.

Owner:中盛鑫控股有限公司

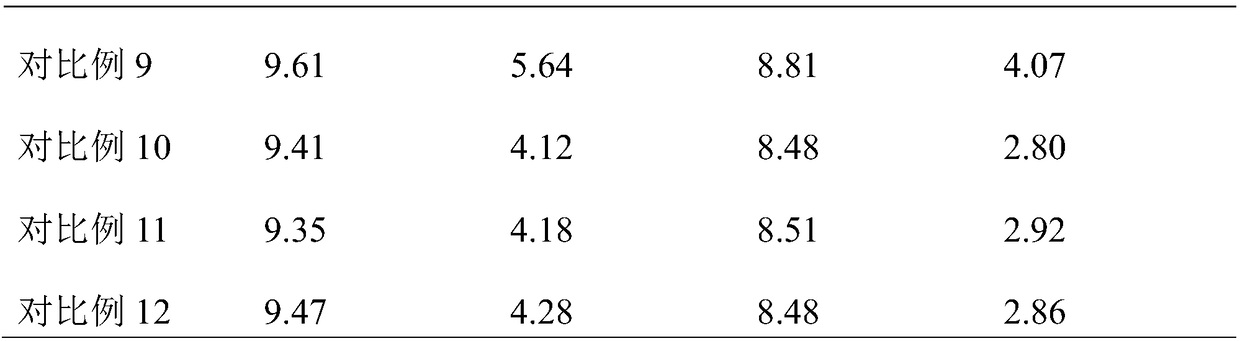

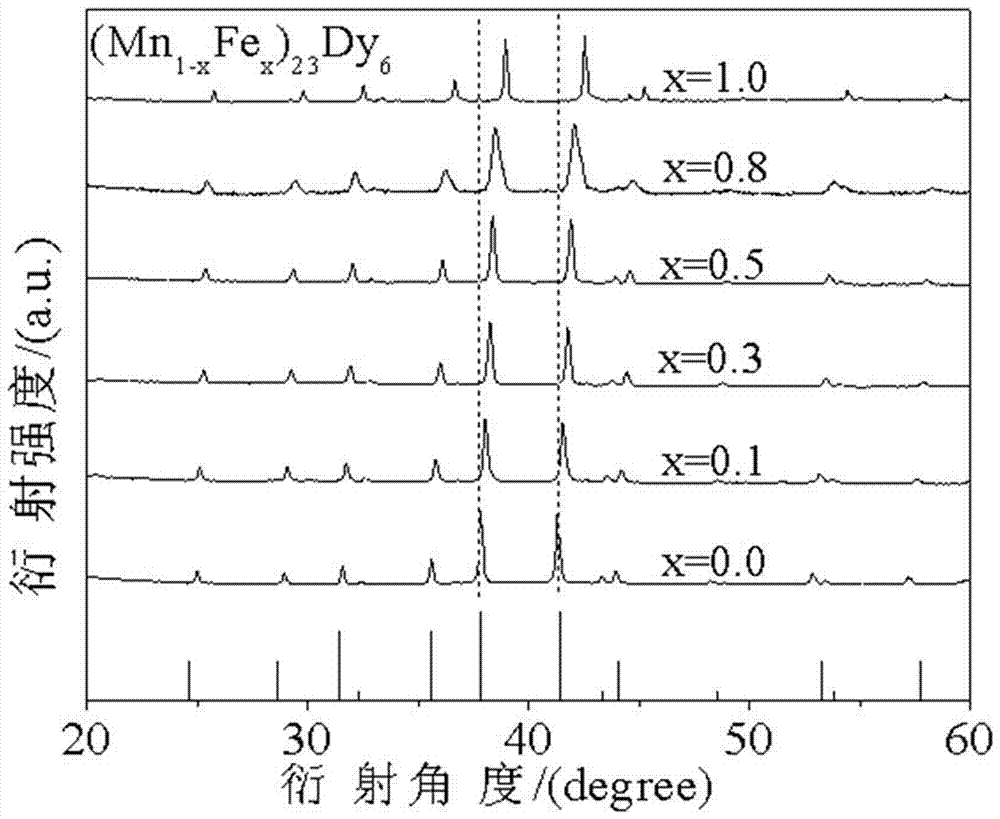

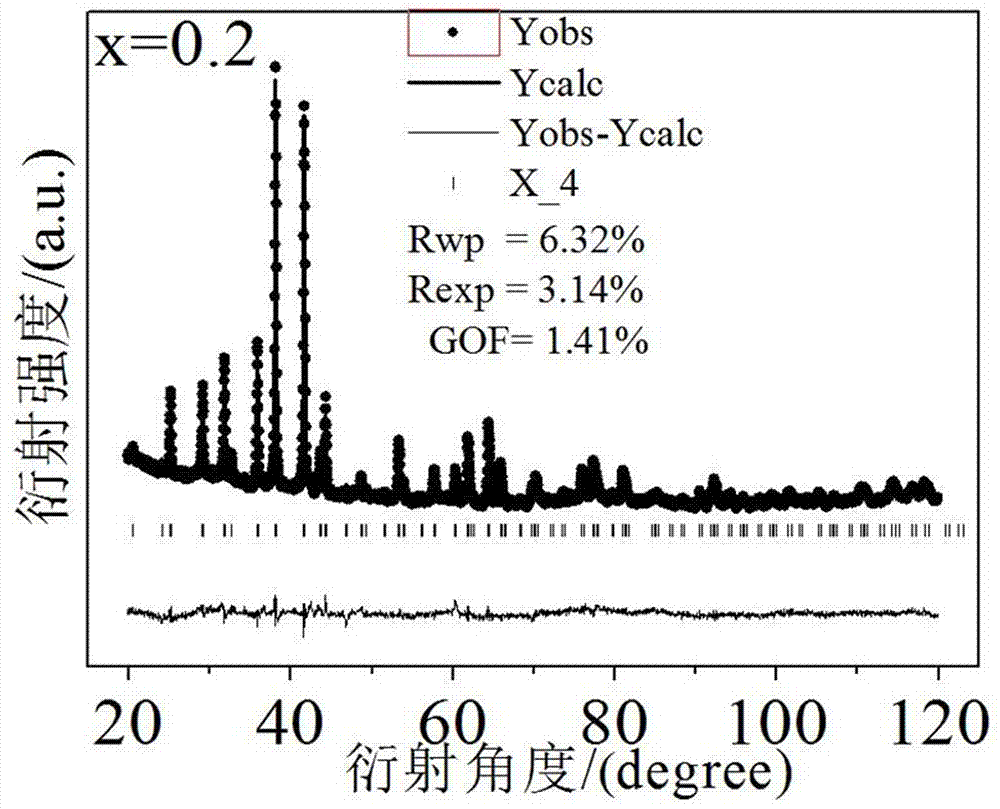

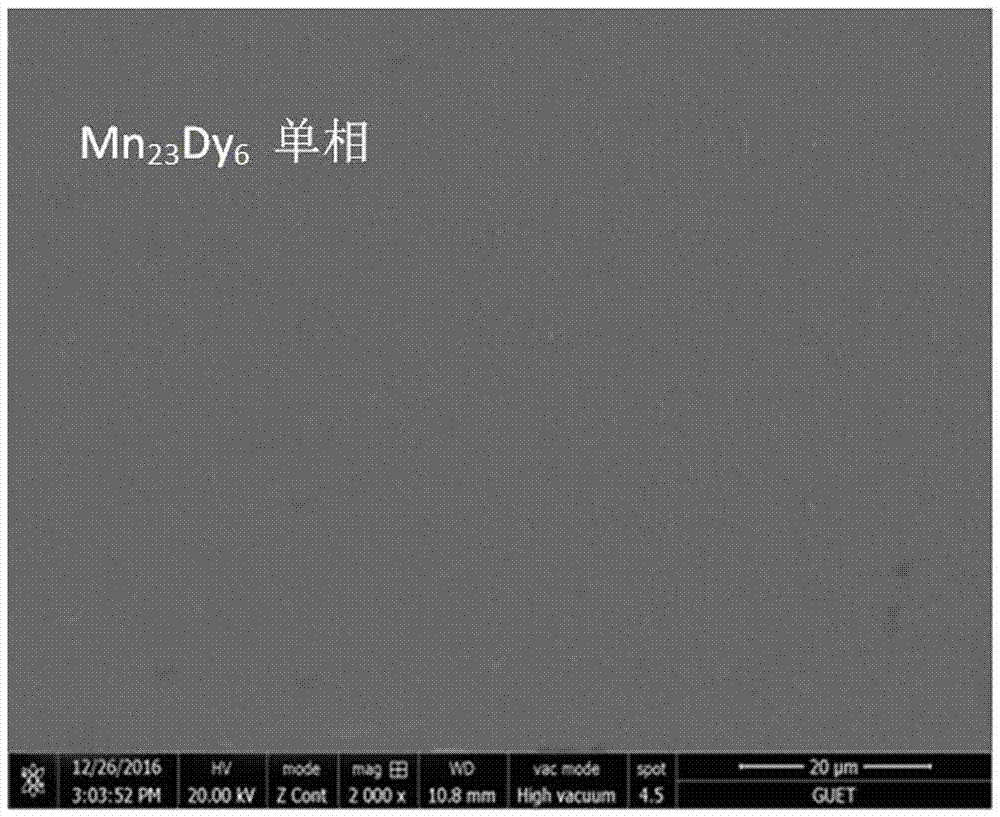

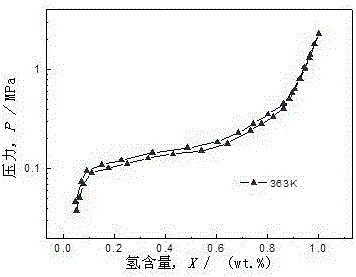

Mn-Fe-Dy hydrogen storing material and preparing method thereof

The invention discloses a novel material with the high hydrogen storing property. A preparing method of the novel material with the high hydrogen storing property comprises the following steps of sample proportioning, preparing, heat treating, hydrogen absorbing testing and magnetic performance testing. The proportioned sample is an alloy formed by proportioning cheap main raw materials of Fe, Mn and rear earth Dy according to the chemical formula of (Mn<1-x>Fe<x>) 23Dy6. The preparing method is a vacuum argon arc smelting method. Heat treating is that the prepared sample is placed in an annealing furnace and is subjected to heat treatment for 100 hours at 800 DEG C; hydrogen absorbing testing is that a hydrogen absorbing capacity test is conducted by adopting a gas absorbing analyzer (PCT); and magnetic performance testing is that a magnetic performance test is conducted by adopting a vibrating sample magnetometer (VSM). The disclosed novel material with the high hydrogen storing property has the characteristics that components are simple, the raw materials are easy to obtain, the formula is reasonable and the preparing technology is simple, and meanwhile, the novel material has good hydrogen storing property and magnetic property and has potential application value in the field of hydrogen absorbing materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Synthetic method of Mg-based hydrogen storage alloy

InactiveCN102424917AHigh charge and discharge capacityImprove corrosion resistanceMass ratioHigh energy

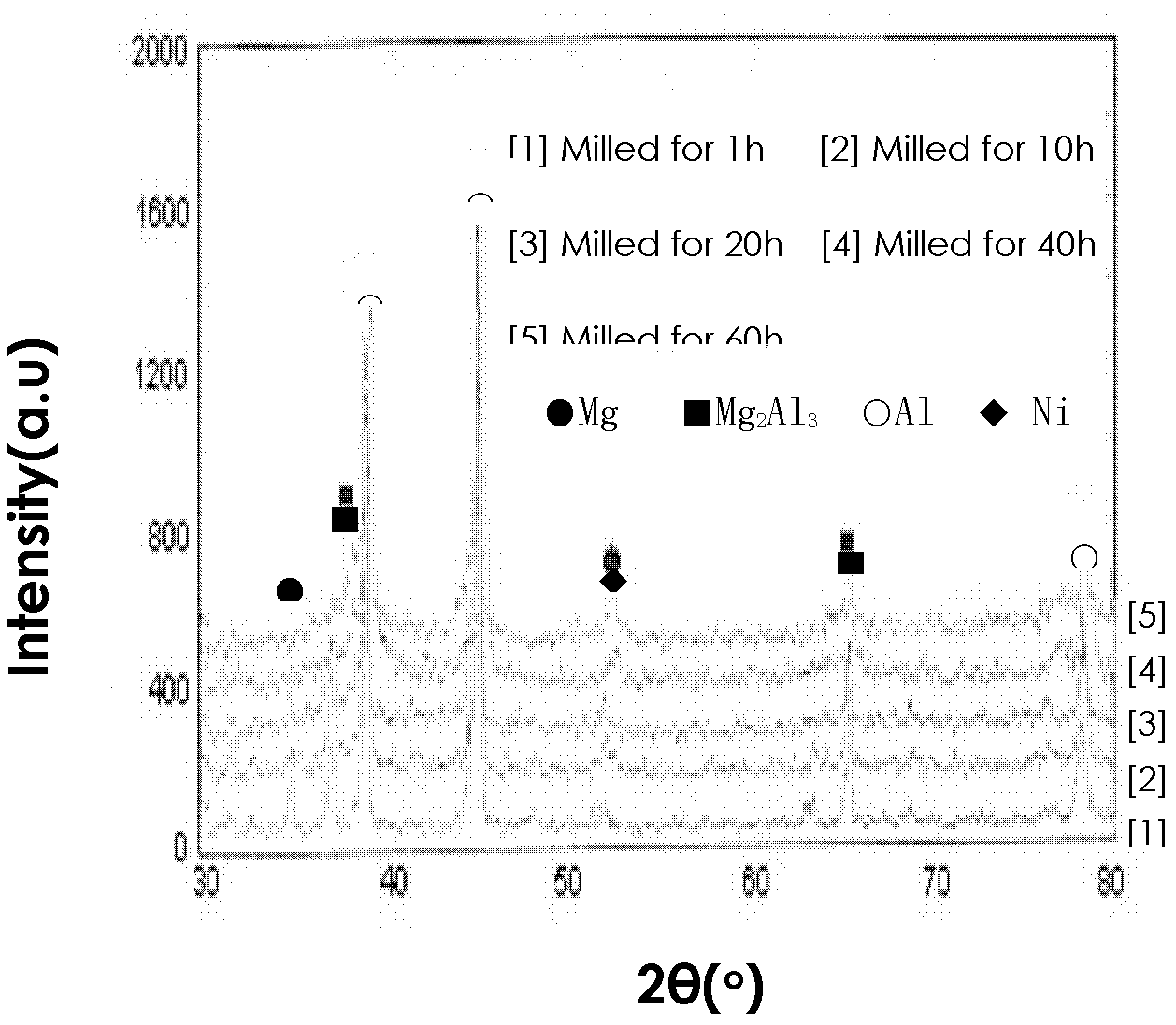

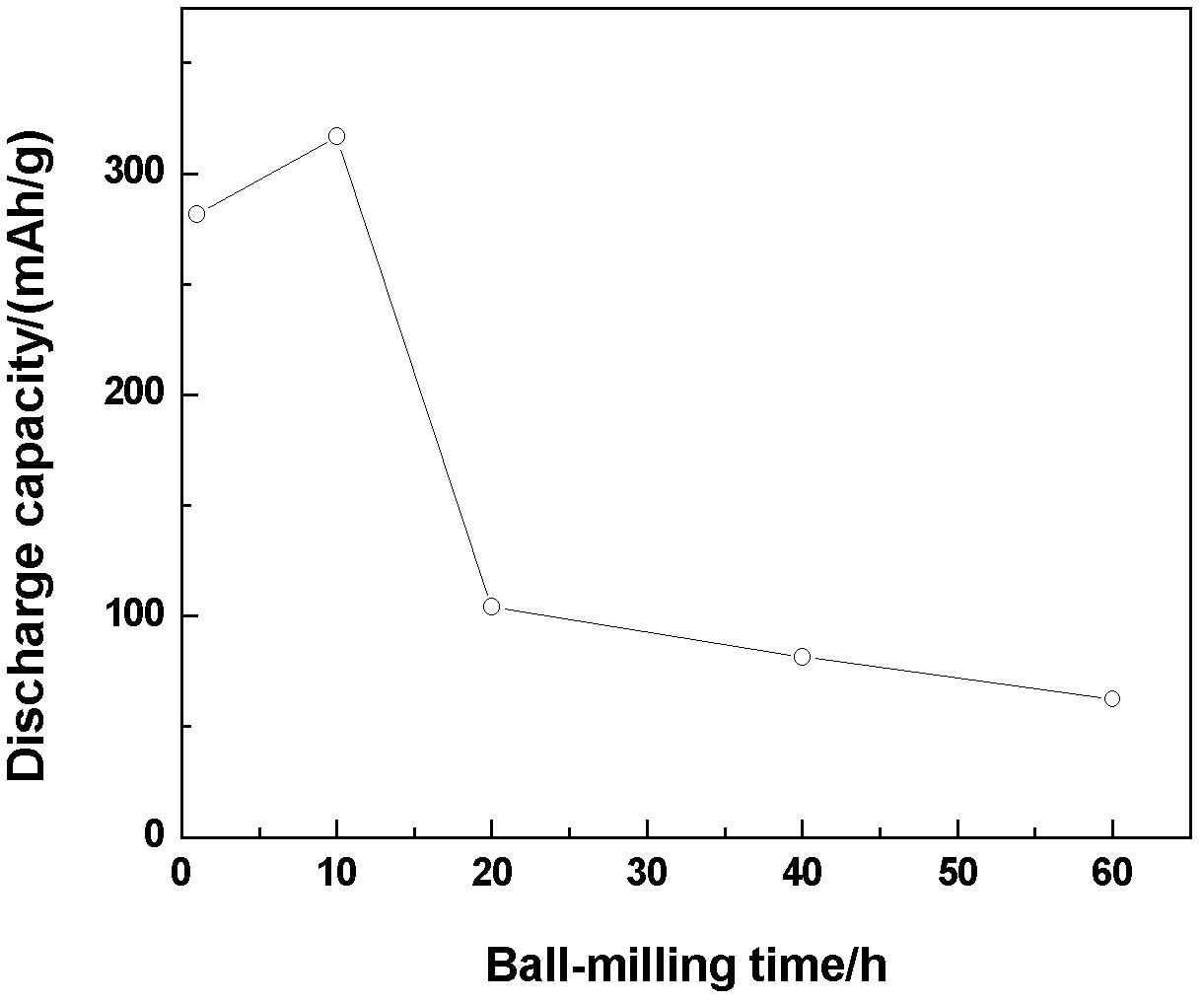

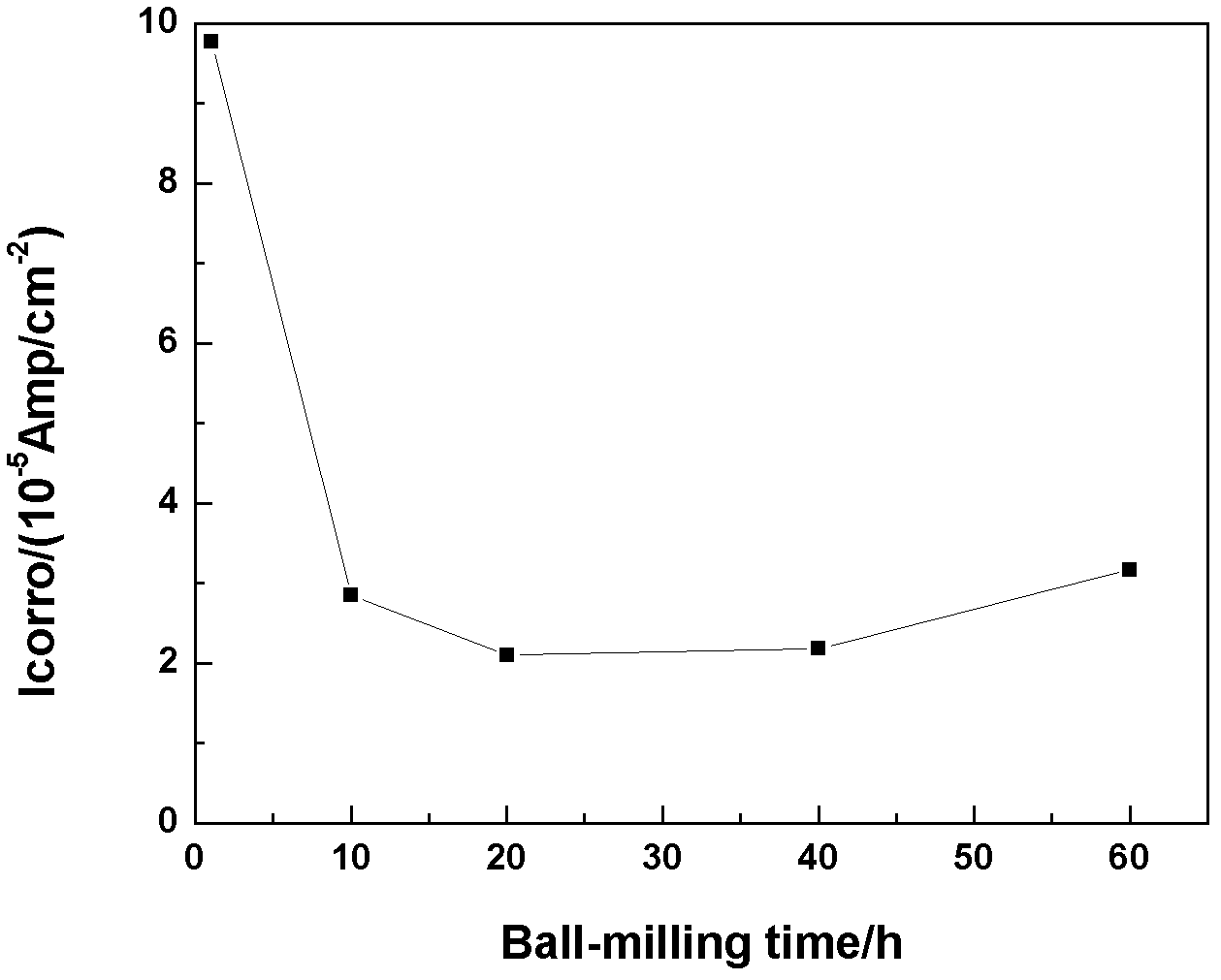

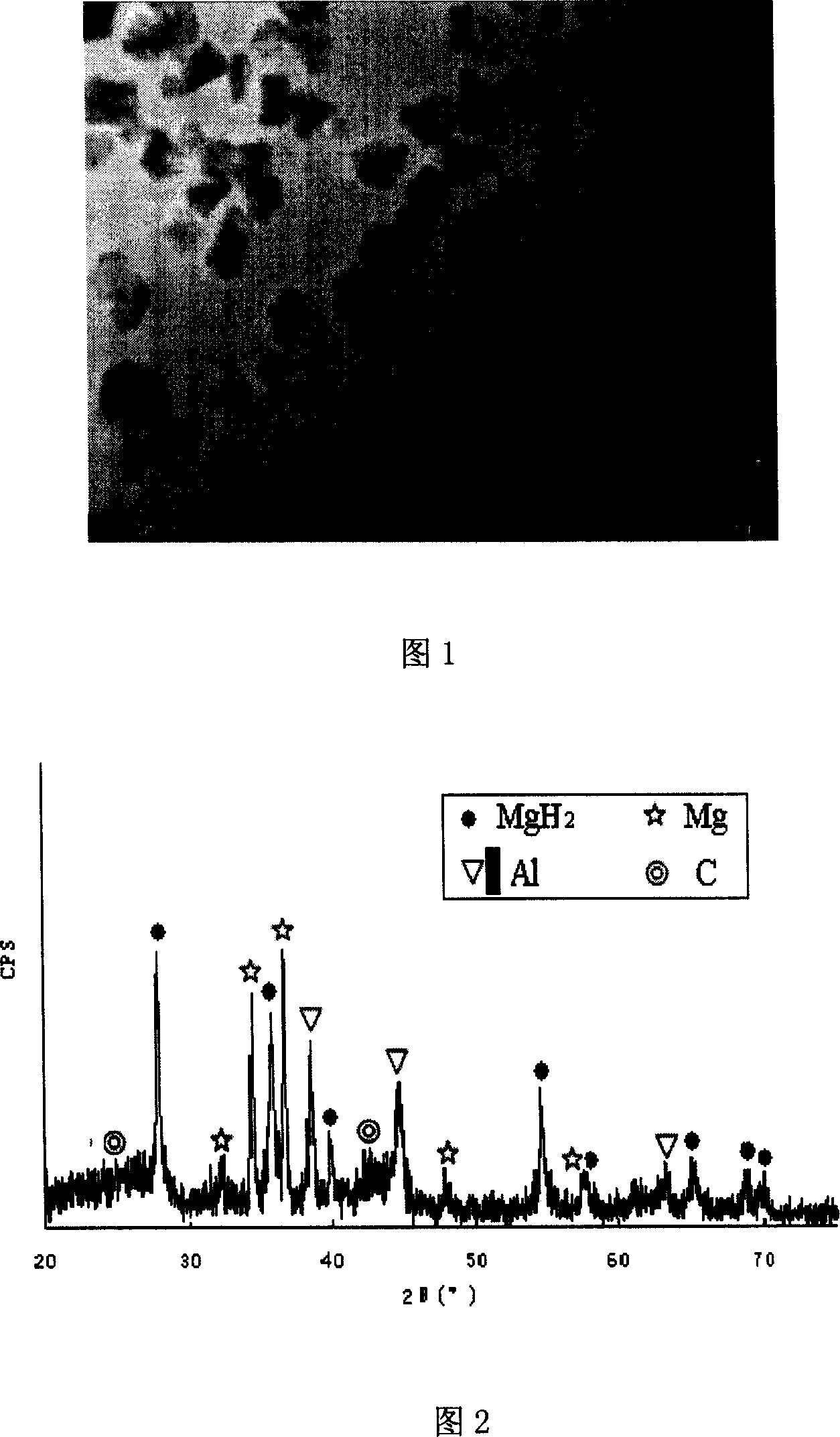

A synthetic method of Mg-based hydrogen storage alloy is designed to solve technical problems of high hydrogen absorption and desorption temperature, low hydrogen absorption and desorption speed, less charge and discharge capacity, and poor corrosion resistance of currently synthesized Mg-based alloy. The method prepares (M40Al60)90Ni10 hydrogen storage alloy by controlling alloy components and ball milling time, and the method is realized by the following steps: proportionally mixing pure Mg, pure Al and pure Ni with a particle size of more than 100 microns and a mass ratio of not less than 99.99%, performing ball milling in a ball milling tank of a high-energy ball mill with a mass ratio of balls and the materials of 10:1; vacuumizing the ball milling tank firstly, then introducing argon; shutting down for 30 min after ball milling for every 1 hour, wherein the total time for ball milling is 10 hours, so as to obtain the (M40Al60)90Ni10 hydrogen storage alloy which is provided with a Ml2Al3 new phase. The beneficial effect is that: the synthetic method has low requirements for the hydrogen absorption and desorption temperature, increases the hydrogen absorption and desorption speed, and enhances the reaction dynamic and thermodynamic performance; the discharge capacity determined in a 6 mol / L KOH solution is 316.7 mAh / g, and the corrosion current density is 2.84*10<-5> Amp / cm2; and the charge and discharge capacity and the corrosion resistance of the Mg-based hydrogen storage alloy are obviously increased.

Owner:SHENYANG NORMAL UNIV

Magnesium/petroleum coke nano hydrogen-storing material

It relates to a magnesium or oil coke nanometer composite hydrogen storing material. The material is made oil coke with 30wt%-60wt% grain size 10-100nm, 2wt%-15wt% catalyst Cu,Al,Fe,Co, Ni,Pd,Mn, either one of them or several with the combination of magnesium. It bakes oil coke and catalysts in 660-1600DEG C temperature for one hour, ball grinding with magnesium powder in 0.5-3MPa hydrogen for 0.5-5 hours. It features in the high density of hydrogen of the material, with moderate hydrogen drawing and releasing, low cost in material and simple making process.

Owner:SHANDONG UNIV OF SCI & TECH

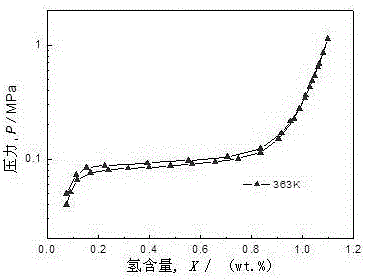

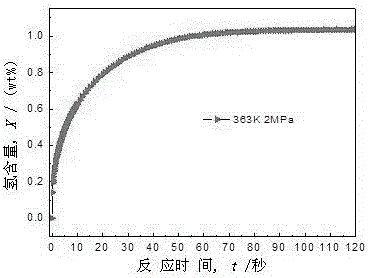

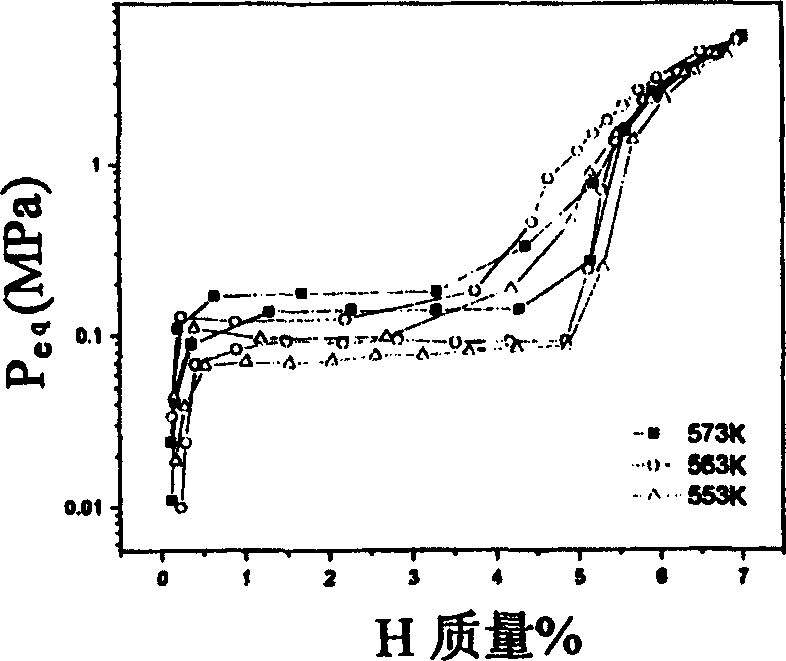

AB5 type rare earth hydrogen storage alloy for tritium storage and preparation method of AB5 type rare earth hydrogen storage alloy

The invention discloses an AB5 type rare earth hydrogen storage alloy for tritium storage in the field of hydrogen storage alloys and a preparation method of the AB5 type rare earth hydrogen storage alloy. The general formula of the composition of the alloy is La[1-x]MgxNi[5-y]My, wherein M refers to Mn or Al, x is more than 0 and less than or equal to 0.2, and y is more than 0 and less than or equal to 1.2. The hydrogen storage alloy is prepared by the following steps: smelting in three steps adopting a vacuum levitation induction melting furnace and adopting a method of coating Mg blocks with Ni foil according to space placement sequence of raw material metals in a water cooled copper crucible; and finally, encapsulating the metals in a quartz tube, performing heat treatment at a high temperature of 900-1100 DEG C for 4-10 hours, and performing furnace cooling, thereby obtaining the product. The alloy production method is simple, small in Mg volatilization amount, stable in components, easy to activate, low in platform pressure and slight in hydrogen absorption and desorption lag, has good hydrogen absorption and desorption dynamic performances and is suitable for tritium storage.

Owner:YANGZHOU UNIV

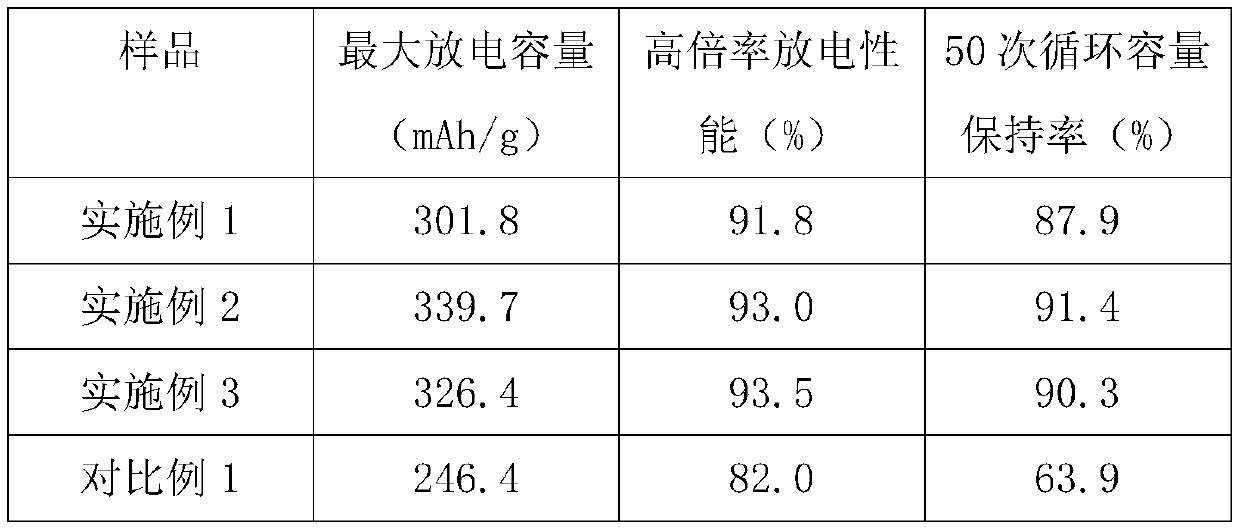

Alloy powder surface processing method for power battery

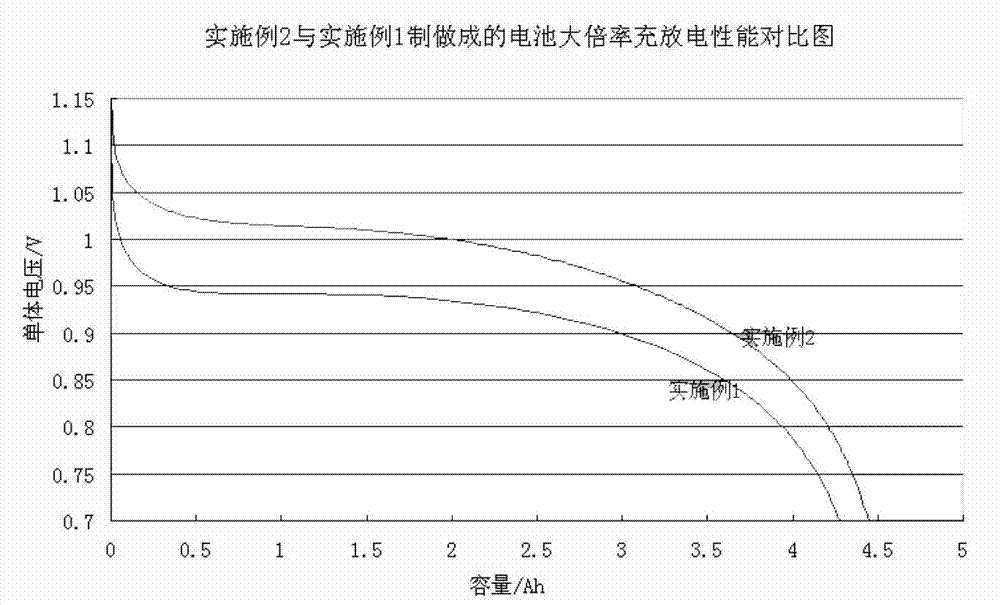

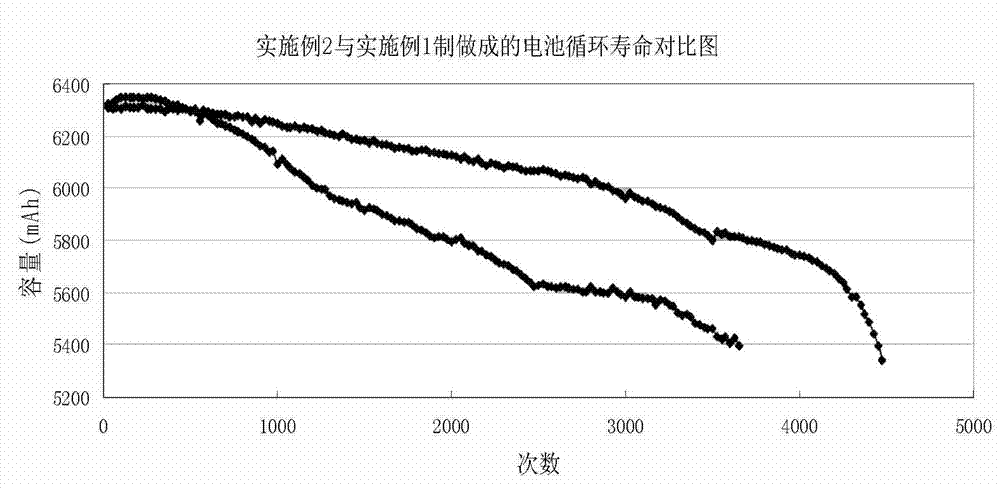

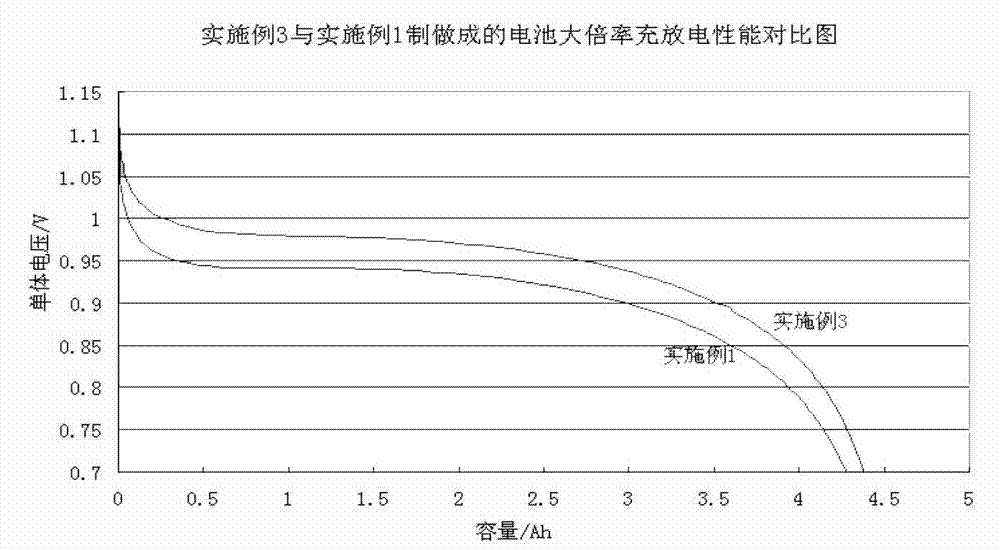

InactiveCN104852018AEasy to reach full capacityExtend your lifeAlkaline accumulator electrodesPower batteryHigh rate

The invention discloses an alloyed powder surface processing method for a power battery. The method comprises the steps as follows: a first step of processing large granular alloy blocks into alloy powder with a needed grain diameter for surface processing; a second step of contacting the alloy powder for surface processing, which is obtained in the first step, with an alkali treatment solution mixed with a reducing agent, performing high-temperature treatment on the obtained mixture, and washing the heated product until the pH value of washing liquor is about 7. The alloy powder surface processing method for the power battery of the invention overcomes the defects in high-rate discharge performance and cycle life of NI-MH power batteries in the prior art. The alloy powder surface processing method for the power battery of the invention is simple, comprehensive and effective in treatment process, and improves high-rate discharge performance and cycle life performance of the NI-MH power batteries.

Owner:FUJIAN WEIDONG NEW ENERGY

A hydrogen storage high-entropy alloy based on a body-centered cubic structure and its preparation method

ActiveCN107338385BHigh hydrogen storage capacityFast hydrogen absorption and desorptionElectric arc furnaceHigh entropy alloys

The invention belongs to the field of hydrogen storage materials, and relates to a hydrogen storage high-entropy alloy taking a body-centered cubic structure as the principal thing and a preparation method for the hydrogen storage high-entropy alloy. A component expression formula of high-entropy alloy is as follows: (TiaZrbNbc)xMy, wherein a is greater than or equal to 5at% and smaller than or equal to 35at%, b is greater than or equal to at5% and smaller than or equal to 35at%, c is greater than or equal to 5at% and smaller than or equal to 35at%, a+b+c is equal to x, x is greater than or equal to 15at% and smaller than or equal to 100at%, M is any one or more of Hf, Fe, Co, Cr, Mn, Ni, Mo and W; and atomic percent of each M is 0-35%, and x+y is equal to 100. The preparation method for the hydrogen storage high-entropy alloy comprises the following steps of: adopting a non-consumable vacuum electric-arc furnace to smelt to prepare alloy; and adopting suction casting to sucking alloy into a water-cooling cooper mould, thereby obtaining a high-entropy alloy rod. The high-entropy alloy has high hydrogen storage capacity (3 mass% or more) and excellent hydrogen absorption and desorption dynamic performances; when hydrogen absorption and desorption amount is great, the high-entropy alloy, in comparison with a pure element, does not need to completely purify, so that cost can be saved to a great extent. The hydrogen storage high-entropy alloy taking the body-centered cubic structure as the principal thing has the characteristics of the high-entropy alloy, and has a wide application prospect in the fields of new energy resources and transportation.

Owner:UNIV OF SCI & TECH BEIJING

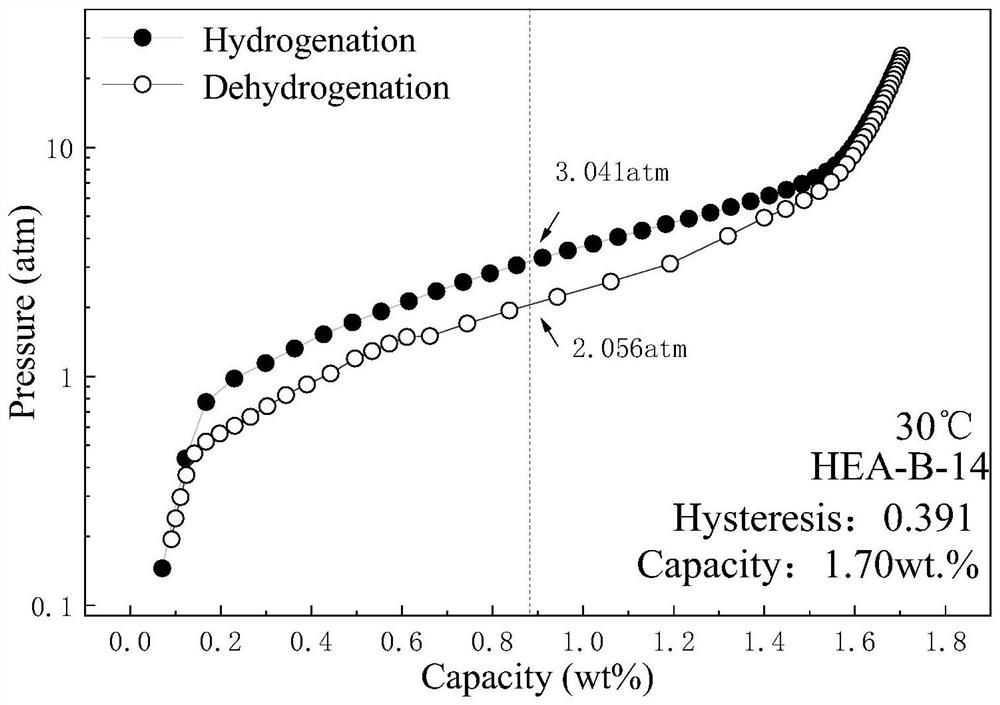

High-entropy hydrogen storage alloy and preparation method thereof

ActiveCN114672714AGood hydrogen absorption and desorption platformSmall lagHydrogenRare-earth elementNew energy

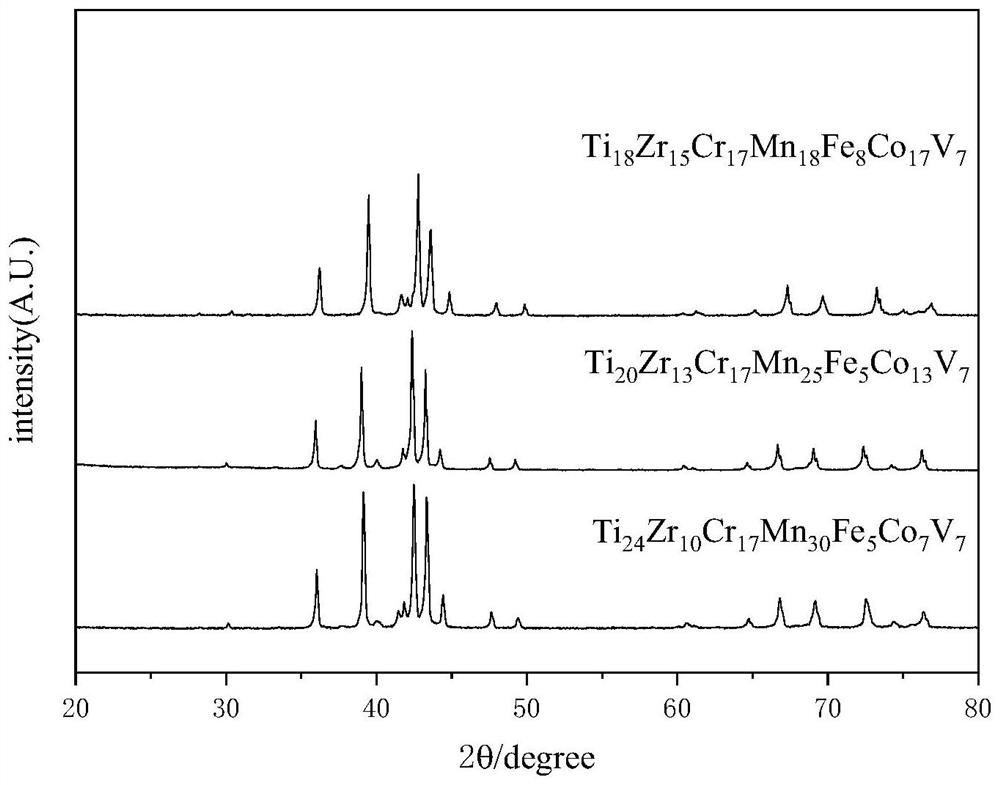

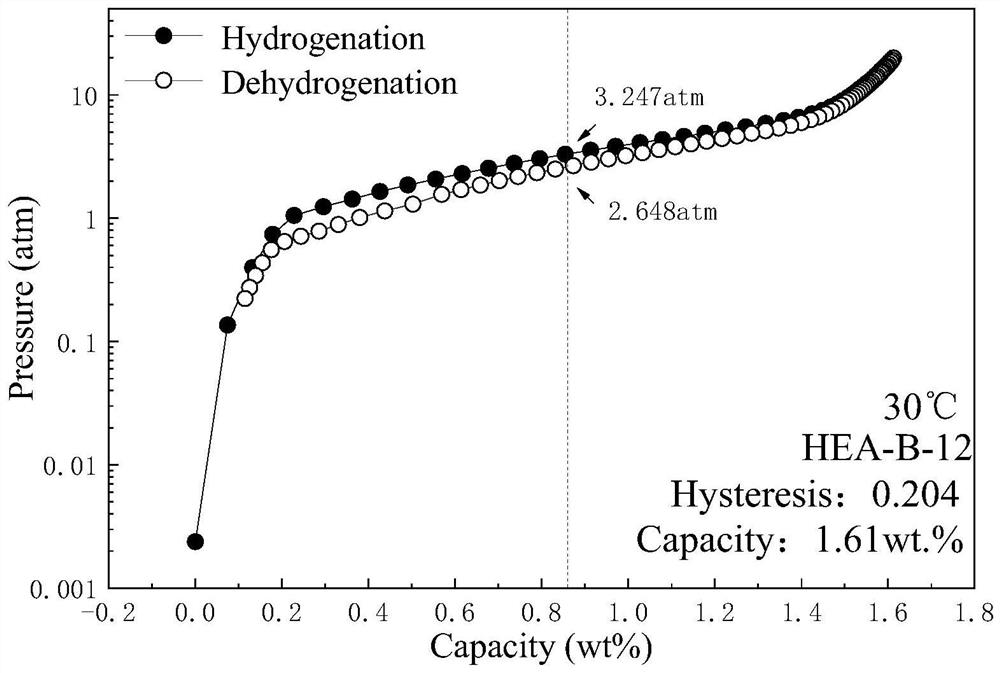

The invention discloses a high-entropy hydrogen storage alloy. The molecular general formula of the high-entropy hydrogen storage alloy is Ti Zr Cr < c > Mn < d > Fe < x > Co < y > V < z >, wherein 16 < = a < = 28 at%, 5 < = b < = 16 at%, 5 < = c < = 23 at%, 16 < = d < = 30 at%, 5 < = x < = 12 at%, 5 < = y < = 16 at%, 5 < = z < = 8 at%, and a + b + c + d + x + y + z = 100. The invention further discloses a preparation method of the high-entropy hydrogen storage alloy. The high-entropy hydrogen storage alloy disclosed by the invention has high hydrogen storage capacity, and is relatively small in hysteresis while reversibly absorbing and desorbing hydrogen at room temperature; meanwhile, rare earth elements are not contained, the cost is low, activation is not needed before use, and wide application prospects are achieved in the fields of new energy and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of surface microporous nickel-plating hydrogen-storage alloy

ActiveCN109913700AImprove cycle stabilityHigh bonding strengthLiquid/solution decomposition chemical coatingHigh rateElectrochemistry

The invention discloses a preparation method of a surface microporous nickel-plating hydrogen-storage alloy. The preparation method of the surface microporous nickel-plating hydrogen-storage alloy comprises the following steps of (1) smelting; (2) preparing a hydrogen-storage alloy thin strip; (3) carrying out surface microporous treatment; (4) fluorinating; and (5) plating nickel. According to the preparation method provided by the invention, the binding force of a surface coating of the hydrogen-storage alloy and the surface of the alloy can be effectively improved, so that the coating is tightly combined to the surface of the hydrogen-storage alloy, and the cycling stability, the discharge capacity, the high-rate discharge performance and other electrochemical performances of the hydrogen-storage alloy are comprehensively improved.

Owner:三桥惠(佛山)新材料有限公司

A kind of ab for tritium storage 5 Type rare earth hydrogen storage alloy and preparation method thereof

The invention discloses an AB5 type rare earth hydrogen storage alloy for tritium storage in the field of hydrogen storage alloys and a preparation method thereof. The composition formula of the alloy is La1-xMgxNi5-yMy, wherein M is Mn or Al, and 0<x ≤0.2, 0<y≤1.2. The hydrogen storage alloy of the present invention is smelted in three steps by using a vacuum magnetic levitation induction smelting furnace, through the spatial placement sequence of the raw material metal in the water-cooled copper crucible, and the method of wrapping the Mg block with Ni foil, and finally packaging it in a quartz In the tube, it is obtained by heat treatment at 900-1100°C for 4-10 hours and then cooling with the furnace. The alloy has a simple production method, less Mg volatilization, stable composition, easy activation, low platform pressure, small hydrogen absorption and desorption hysteresis, and good hydrogen absorption and desorption kinetic properties, and is suitable for tritium storage.

Owner:YANGZHOU UNIV

Preparation method of mg-based hydrogen storage nanowires

ActiveCN108950260BImprove hydrogen storage performanceLarge total hydrogen storageTransportation and packagingMetal-working apparatusNanowireSpinning

The invention provides a method for preparing Mg-based hydrogen storage nanowires, comprising the following steps: preparing metal Mg, metal Ce, metal La, metal Gd, metal Li and metal Ni, and performing batching and vacuum melting to obtain a Mg-based alloy ingot ; Atomize the Mg-based alloy ingot to obtain Mg-based alloy powder; heat-treat the Mg-based alloy powder; ball mill the heat-treated Mg-based alloy powder to obtain the ball-milled Mg-based alloy powder; dissolve PAN in DMF In the process, the PAN spinning solution is obtained, wherein the PAN concentration is 10-15wt%; the Mg-based alloy powder that has been heat-treated but not ball-milled is dissolved in the PAN spinning solution to obtain the first spinning solution; the ball-milled The Mg-based alloy powder is dissolved in the PAN spinning solution to obtain a second spinning solution; and the first spinning solution and the second spinning solution are formed into Mg-based hydrogen storage nanowires by coaxial electrospinning. The invention proposes a new method for preparing a hydrogen storage material. The alloy prepared by the method of the invention has a larger total amount of hydrogen storage and a faster rate of hydrogen absorption and desorption.

Owner:中盛鑫控股有限公司

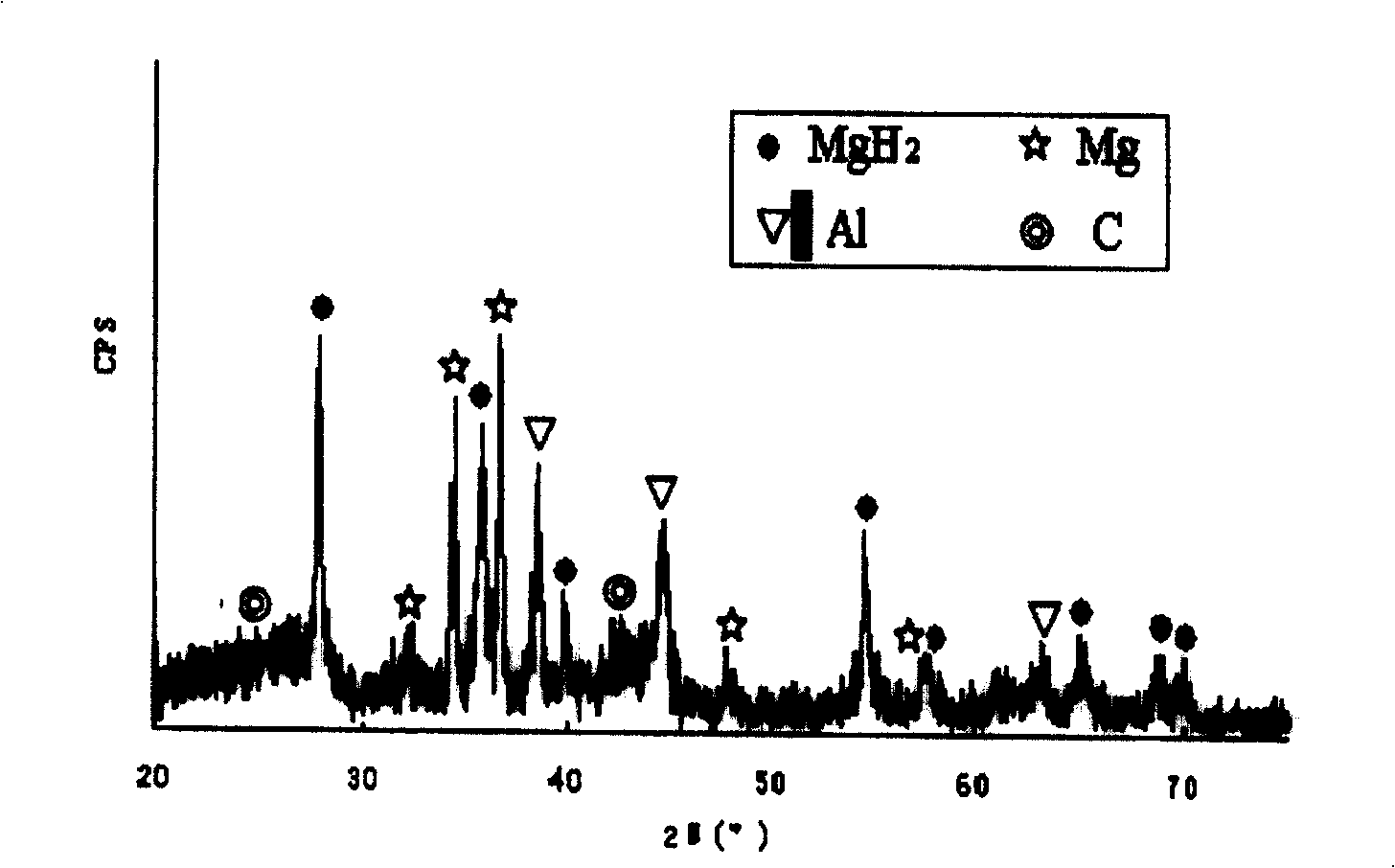

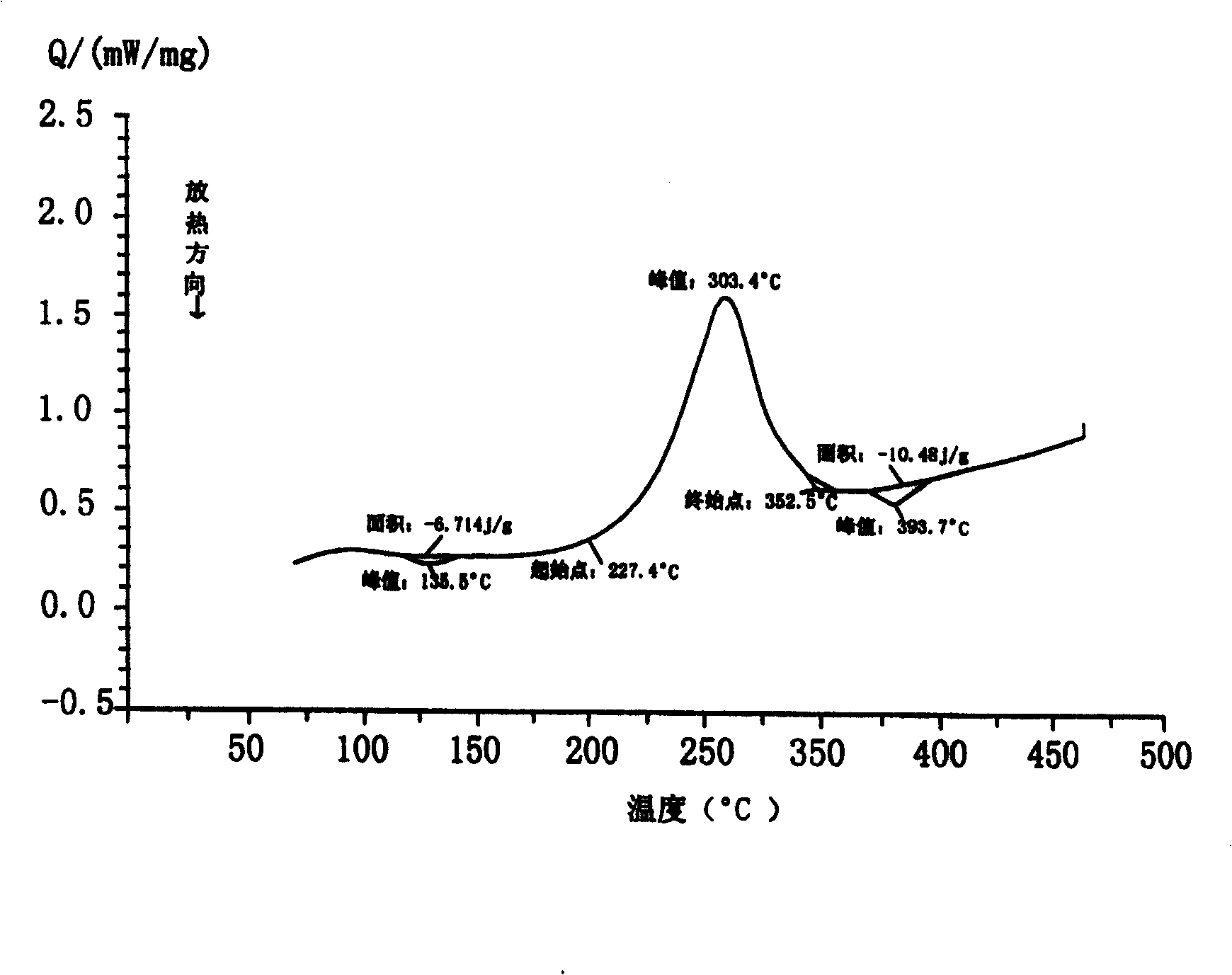

Magnesium-based hydrogen storage material capable of absorbing hydrogen at room temperature and preparation method thereof

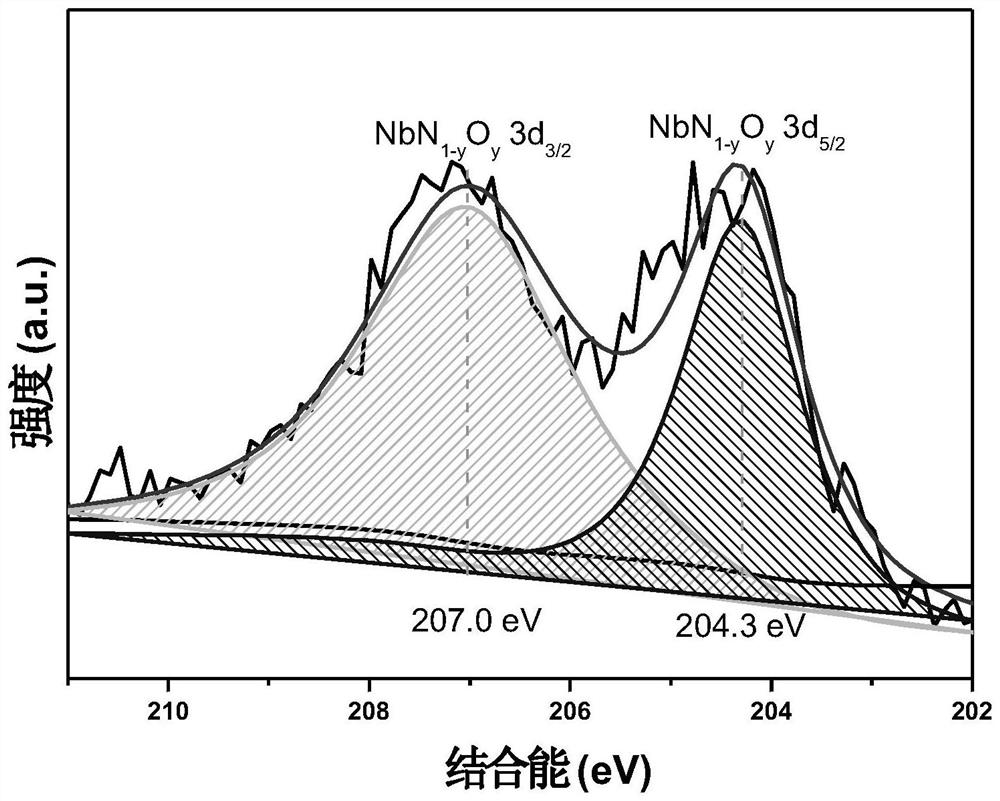

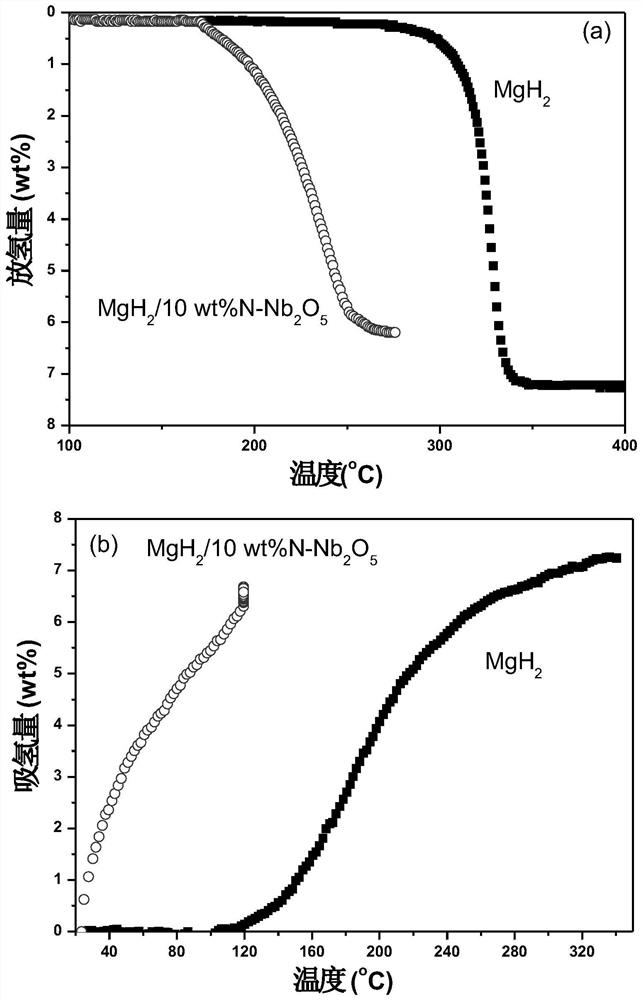

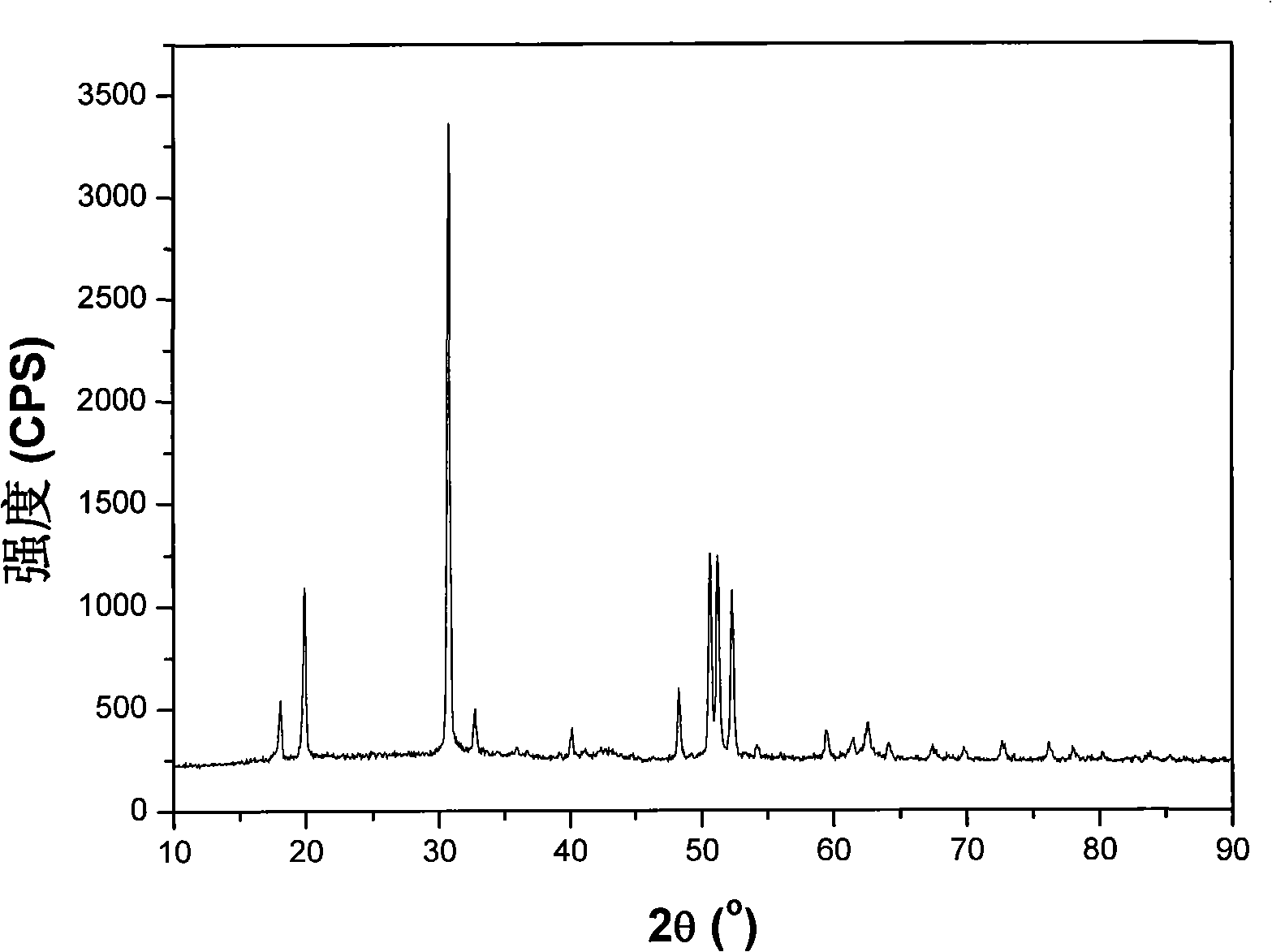

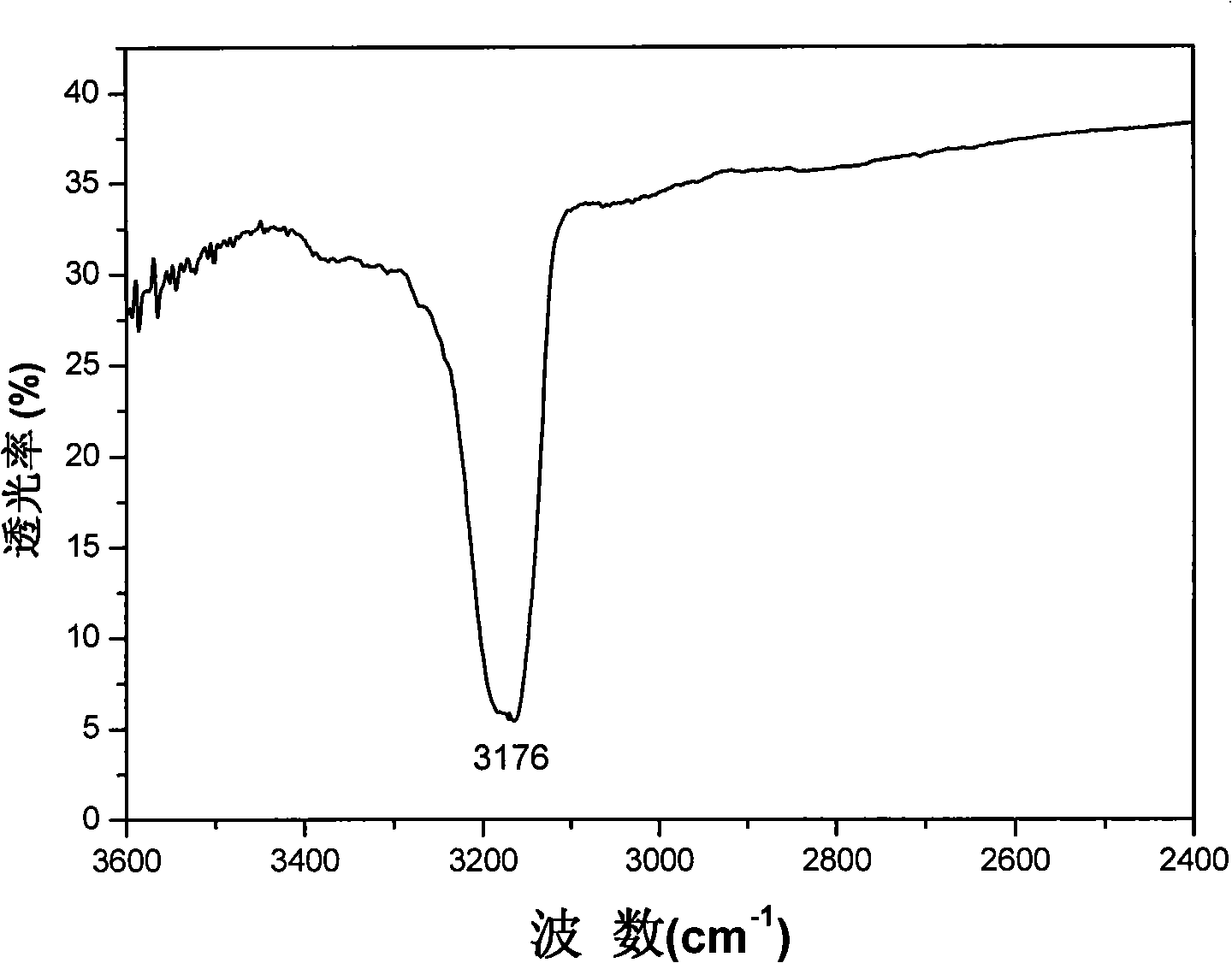

ActiveCN110155940BImprove hydrogen absorption and desorption performanceHigh catalytic activityHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHydrogen atmosphere

The invention discloses a magnesium-based hydrogen storage material with room-temperature hydrogen absorption and a preparation method of the magnesium-based hydrogen storage material. The preparationmethod comprises the following step: in the presence of an inert gas or a hydrogen atmosphere, carrying out ball milling on MgH2 with an N-doped niobium oxide-based catalyst, thereby obtaining the magnesium-based hydrogen storage material with room-temperature hydrogen absorption, wherein the mass ratio of the MgH2 to the N-doped niobium oxide-based catalyst is (10-150):1, and the mole ratio of an N element to an Nb element is (0.005-0.15):1. Compared with a niobium oxide-based catalyst which is free of N doping, the magnesium-based hydrogen storage material which is prepared by introducing the N element into the niobium oxide-based catalyst and by carrying out ball milling with MgH2 is excellent in catalytic activity, is capable of further improving the hydrogen absorption and release performance of a magnesium-based hydrogen storage material and remarkably reducing hydrogen absorption and release temperatures, and can be completely hydrogenated at the room temperature; and in addition, a rapid hydrogen absorption and release speed and high circulation stability of the magnesium-based hydrogen storage material are kept, and the hydrogen storage capacity is kept at 6.0wt% or above.

Owner:ZHEJIANG UNIV

Method for preparing Li-Mg-N-H hydrogen-storing material

InactiveCN101332976BLower working temperature for hydrogen absorption and desorptionLower working temperatureMultiple metal hydridesHydrogen productionWorking temperatureNitride

The invention discloses a method for preparing Li-Mg-N-H hydrogen storage material. The mixture of the nitride or amino-compound of Li and Mg, the nitride or amino-compound of Mg is loaded in a stainless steel tank and evenly blended by a mechanical mixing or mechanical ball milling way; the evenly blended mixture is loaded in a sintering furnace, the sintering furnace is vacuumized or charged with inert gases and is heated to the temperature range from 250 to 350 DEG C for heat preservation and then the Li-Mg-N-H hydrogen storage material is obtained; the Li-Mg-N-H hydrogen storage material is loaded into a ball milling tank and undergoes ball milling process on a ball mill, and the grain diameter of the sample powder processed with ball milling is smaller than 100nm. The preparation method has simple operation, easy control and low cost. The Li-Mg-N-H prepared and processed by the invention has high hydrogen storage capacity, low working temperature and high speed of hydrogen absorbing and discharging and good reversibility, thus being the hydrogen storage material with excellent performance and being suitable for the storage and transportation of hydrogen.

Owner:ZHEJIANG UNIV

Metal hydride hydrogen compression device with heat source and manufacture method thereof

ActiveCN102530860BAchieve superchargingSimple structureHydrogen productionHydrogen compressionRoom temperature

The invention relates to a metal hydride hydrogen compression device with a heat source and a manufacture method thereof. The manufacture method is characterized in that the metal hydride hydrogen compression device is heated by self under the condition of no additional heat sources, and then the metal hydride hydrogen compression device adsorbs hydrogen at the room temperature and discharges high-voltage hydrogen at high temperature. The device comprises a hydrogen compression part with metal hydride and a heat source part, wherein a phase change energy storage material in the heat source part is subjected to temperature raising and phase change and stores heat under the heating condition, and heat is provided for the metal hydride in the hydrogen compression part; then, the metal hydride releases hydrogen at a certain temperature range of 50-300DEG C in more than two hours; and the hydrogen release pressure is between 10MPa and 100MPa.

Owner:GRIMAT ENG INST CO LTD

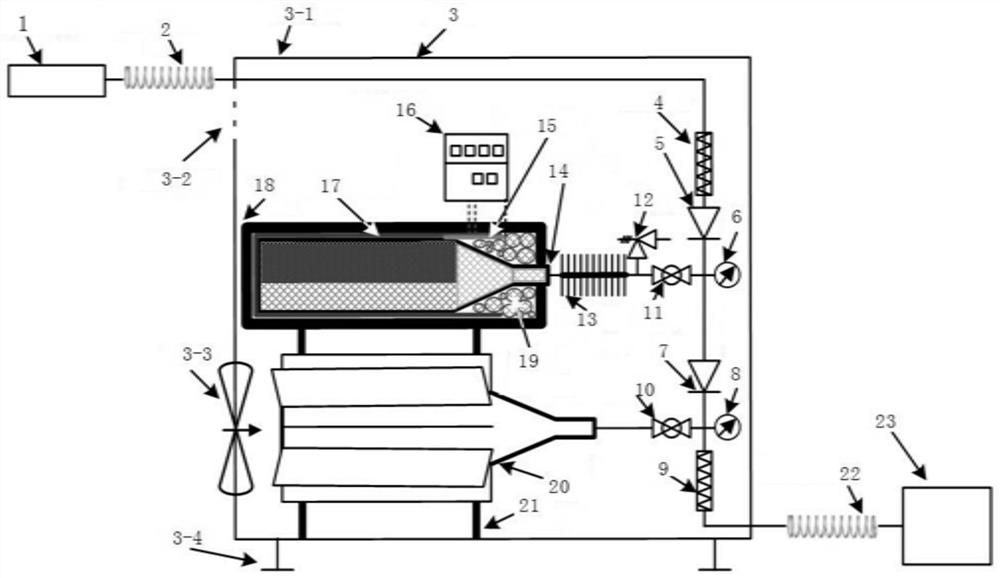

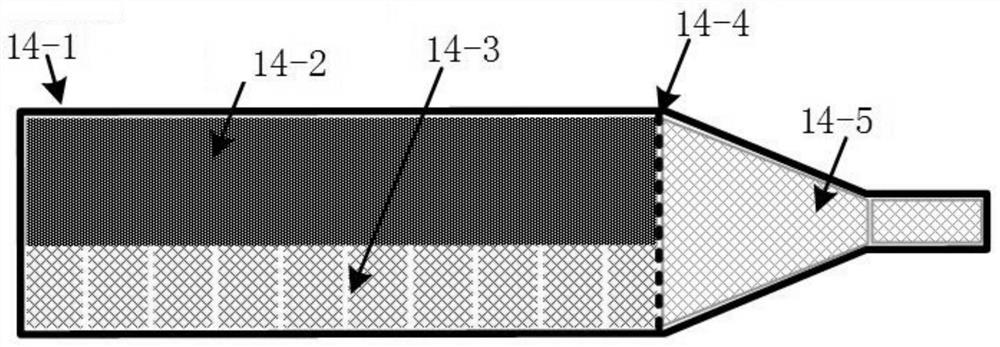

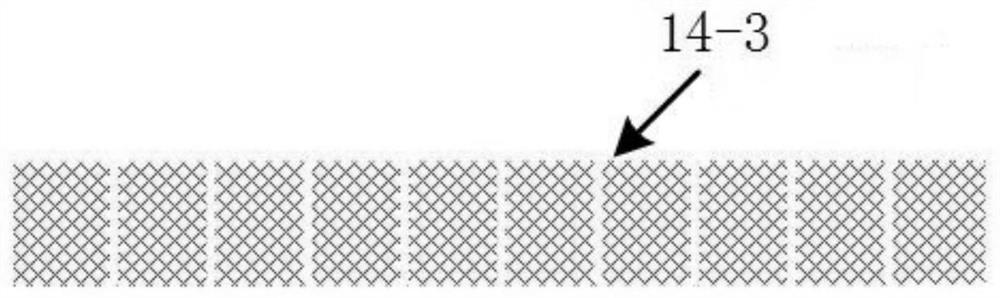

A method for manufacturing hydrogen supply device

ActiveCN112158804AAchieve coolingImprove securityHydrogen separation by selective and reversible uptakeHydrogen/synthetic gas productionFiberProcess engineering

The invention discloses a method for manufacturing a hydrogen supply device and belongs to the field of hydrogen supply. The device comprises an air inlet coil pipe, a cabinet, two 0.5 mu m filters, two check valves, two pressure gauges, two ball valves, a fin heat dissipation pipe, a safety valve, a hydrogen pressurization tank, a thermocouple, a temperature controller, a silica gel heating sleeve, a heat preservation sleeve, a magnesium silicate fiber ball, a hydrogen storage tank, a support and an air outlet coil pipe. The manufacturing process of the hydrogen supply device mainly starts from commercially available parts and raw materials and comprises the steps of machining of an air inlet / outlet coil pipe, machining of a cabinet, machining of a hydrogen pressurizing tank, machining ofa hydrogen storage tank, machining of a support and assembling production of the hydrogen supply device. The invention is high in production efficiency, high in safety, low in cost, capable of purifying hydrogen and providing hydrogen of 1-20 MPa, free of vibration noise, small, exquisite, light and particularly suitable for hydrogen supply of laboratory instruments.

Owner:YANGZHOU UNIV

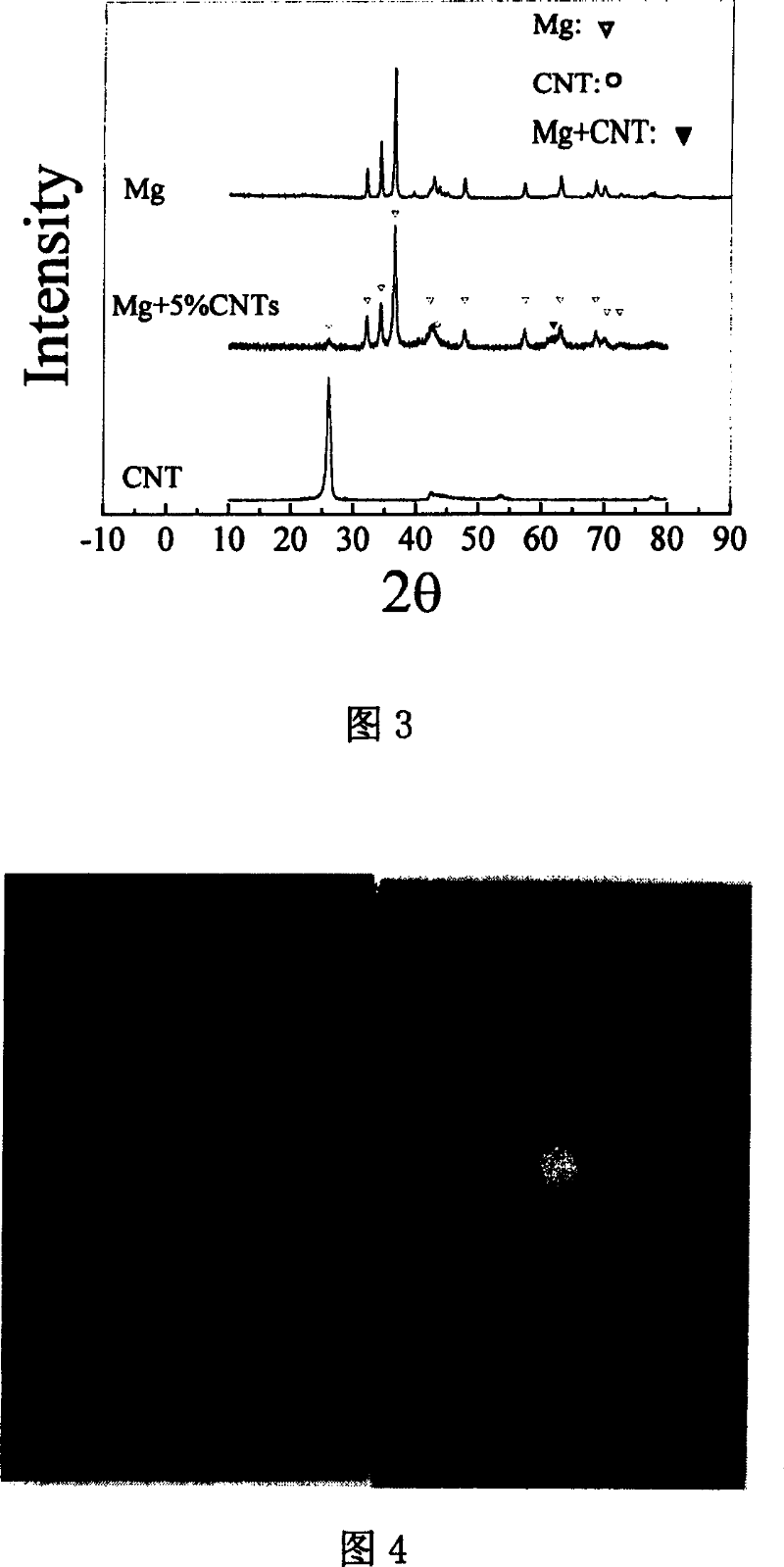

Method for preparing magnesium composite carbon nanometer tube hydrogen-storage material

InactiveCN100357019CEasy to oxidizeAvoid problems such as difficult performance controlOther chemical processesAnthraceneReaction temperature

A process for preparing the Mg compounded carbon nano-tube material as hydrogen-bearing material includes such steps as loading Mg powder, carbon nano-tube and anthracene into reactor under protection of inertial gas, adding tetrahydrofuran, reaction while electromagnetic stirring, ordinary-pressure distilling and thermal decomposing. It has high activity and high hydrogen absorbing and releasing performance.

Owner:SHANGHAI UNIV

Magnesium/petroleum coke nano hydrogen-storing material

InactiveCN100413577CLow costHigh hydrogen storage densityOther chemical processesHigh densityPetroleum coke

It relates to a magnesium or oil coke nanometer composite hydrogen storing material. The material is made oil coke with 30wt%-60wt% grain size 10-100nm, 2wt%-15wt% catalyst Cu,Al,Fe,Co, Ni,Pd,Mn, either one of them or several with the combination of magnesium. It bakes oil coke and catalysts in 660-1600DEG C temperature for one hour, ball grinding with magnesium powder in 0.5-3MPa hydrogen for 0.5-5 hours. It features in the high density of hydrogen of the material, with moderate hydrogen drawing and releasing, low cost in material and simple making process.

Owner:SHANDONG UNIV OF SCI & TECH

Magnesium base hydrogen storage material and its mechanical-alloying preparation method

ActiveCN1281775CLarge hydrogen storage capacityFast hydrogen absorption and desorptionCell electrodesMagnesiumBall mill

The chemical components of the magnesium-base hydrogen storage material is La2-xMxMg17, in which M is selected from Cu, al, Ni, Fe, Co, Mn, V, Cr, Zn, Ca and Sn etc..., and 0<x<2. its production steps are: 1) preparing alloy La2-xMx by using traditional smelting method; 2) La2-xMx alloy and Mg powder are ball-milled under the atmosphere of hydrogen and argon gas. Said ball-mill procedure is conducted under the protection by hydrogen at 0.3-20.0. MPa to make the material preparation and hydrgenation procedure completed in one time.

Owner:GRIMAT ENG INST CO LTD

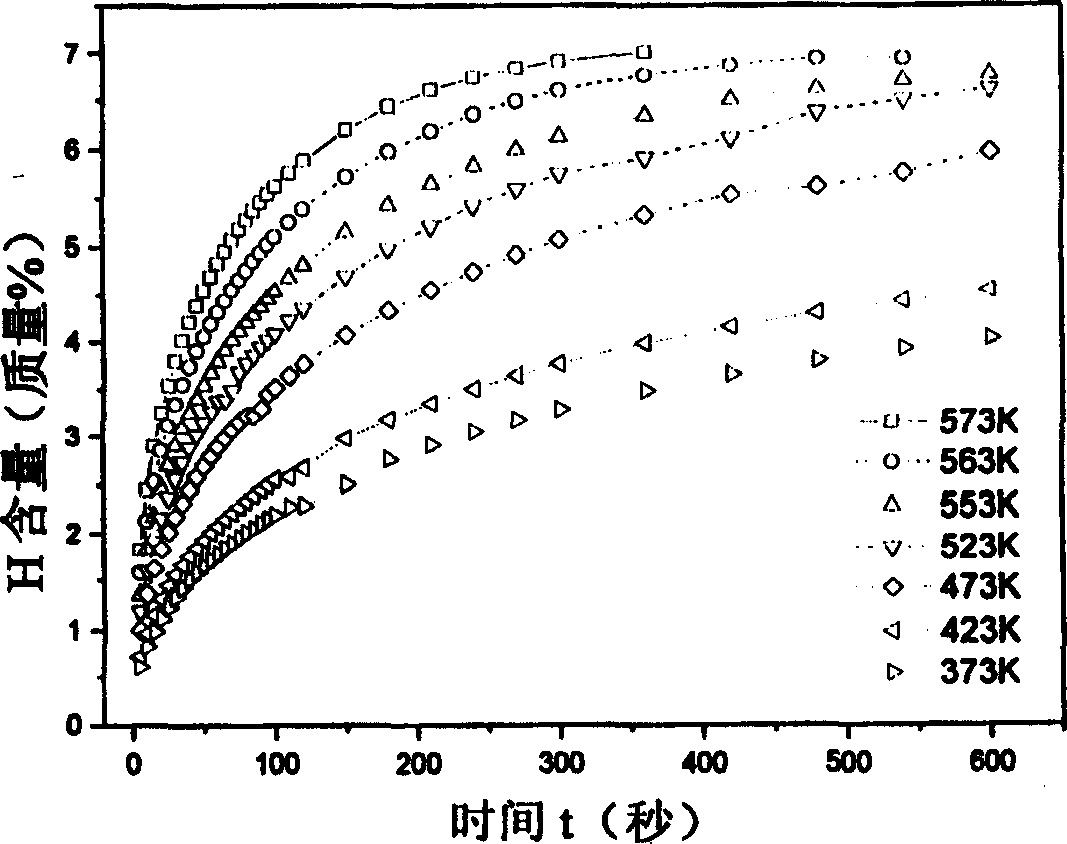

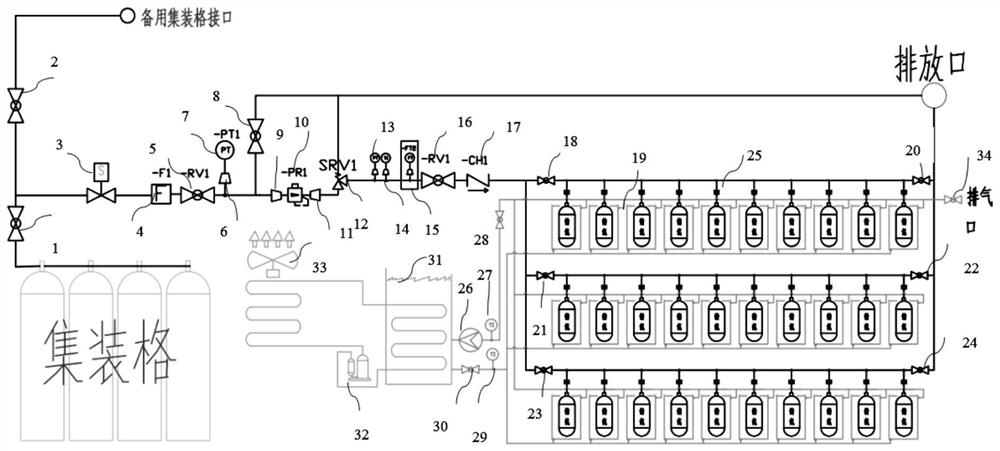

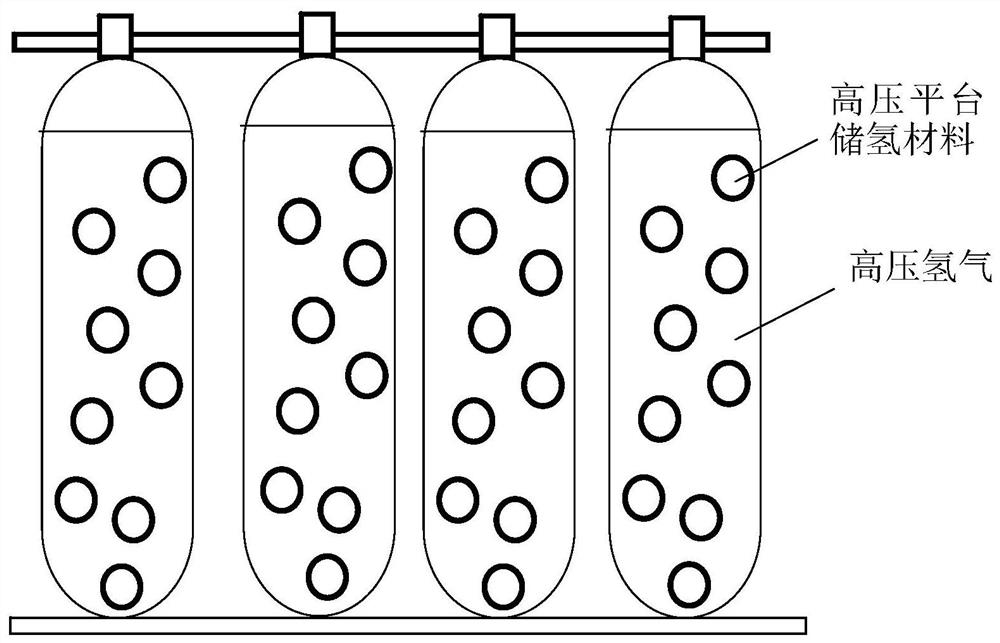

A hydrogen refueling station with an industrialized high-pressure composite metal hydride hydrogen storage system as a hydrogen source

ActiveCN111006127BHigh hydrogen storage capacityImprove dynamic performanceVessel mounting detailsVessel geometry/arrangement/sizeSolenoid valveMetallic hydrogen

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com