Magnesium/petroleum coke nano hydrogen-storing material

A technology for hydrogen storage material and petroleum coke, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of high cost of additives, no hydrogen storage capacity, and reduced hydrogen storage density of materials, so as to achieve low cost of raw materials and hydrogen storage. The effect of high density and rich resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

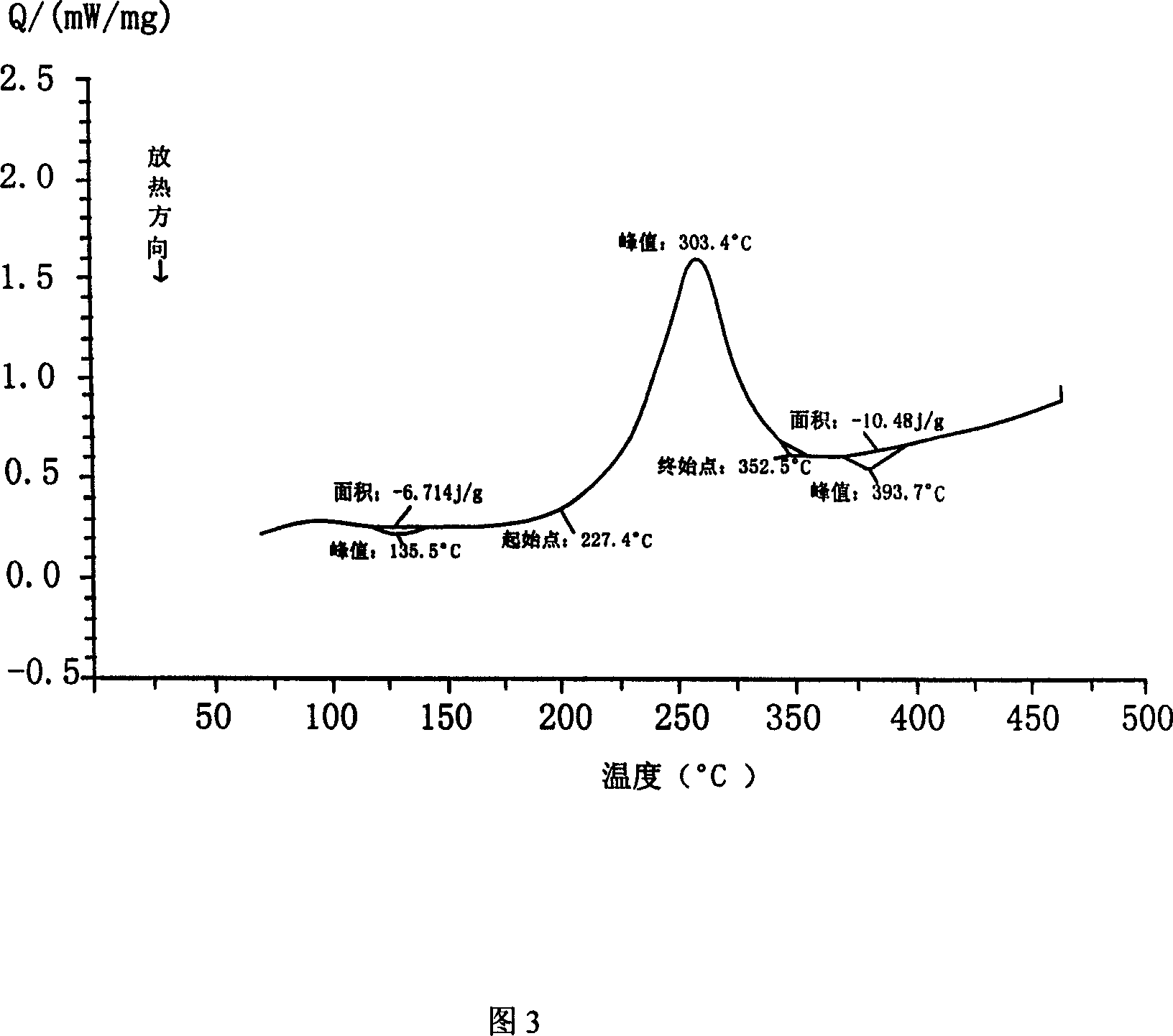

[0020] The particle size is 74μm, the content of 47wt% petroleum coke and 6wt% aluminum powder catalyst are mixed uniformly, and roasted in a high-temperature box-type electric furnace at 660 ℃ for 1 hour, and then mixed with magnesium powder with a particle size of 74μm and a content of 47wt% Put it into a 250mL vacuum ball milling tank, the mass ratio of grinding balls to material is 60:1, replace the air in the ball mill tank with hydrogen and fill it with hydrogen to 2MPa, and then place it in a planetary ball mill for 1.5 hours to obtain magnesium / petroleum coke nanometers. hydrogen storage material. The transmission electron microscope photo of this hydrogen storage material is shown in Figure 1, which shows that its particle size is 10-100 nm; its X-ray diffraction analysis is shown in Figure 2, indicating that there are MH 2 Its differential scanning calorimetry analysis curve is shown in Figure 3, indicating that its hydrogen desorption temperature is 227 °C, and its ...

Embodiment 2

[0022] The difference from Example 1 is that the raw materials are 25wt% magnesium, 60wt% petroleum coke, 15wt% aluminum, and the hydrogen desorption amount of the obtained hydrogen storage material is 4.32wt%.

Embodiment 3

[0024] The difference from Example 1 is that the raw materials are 68wt% magnesium, 30wt% petroleum coke, 2wt% aluminum, and the hydrogen desorption amount of the obtained hydrogen storage material is 6.68wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com