Alloy powder surface processing method for power battery

A surface treatment, alloy powder technology, applied in the direction of alkaline battery electrodes, etc., to achieve the effect of improving the life of the alloy, improving the activation performance, and increasing the effective surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take the above alloy powder without surface treatment, and directly use it in the production of 6Ah nickel-hydrogen power battery, and then measure its performance.

Embodiment 2

[0037] Accurately weigh 1000g of the above alloy powder for use.

[0038] Add 1L of 7mol / L of sodium hydroxide: lithium hydroxide: potassium hydroxide = 0.70:0.25:0.05 into the vacuum stirred steel drum, and then add 2.65g of mixed lye treatment solution. Agent (one of sodium borohydride, potassium borohydride or sodium hypophosphite), and finally add 1000g of alloy powder for use. The alloy powder surface treatment is carried out in the above manner.

[0039] The alloy powder after the above treatment was used to make a nickel-hydrogen power battery with a capacity of 6Ah, and its performance was measured.

Embodiment 3

[0041] Accurately weigh 800g of the above alloy powder for use.

[0042] Add 0.8L of 10mol / L of sodium hydroxide: lithium hydroxide: potassium hydroxide = 0.70:0.25:0.05 into the vacuum stirred steel drum, and then add 2.12g of mixed lye treatment solution. Reducing agent (one of sodium borohydride, potassium borohydride, or sodium hypophosphite), and finally add 800g of alloy powder for use. The alloy powder surface treatment is carried out in the above manner.

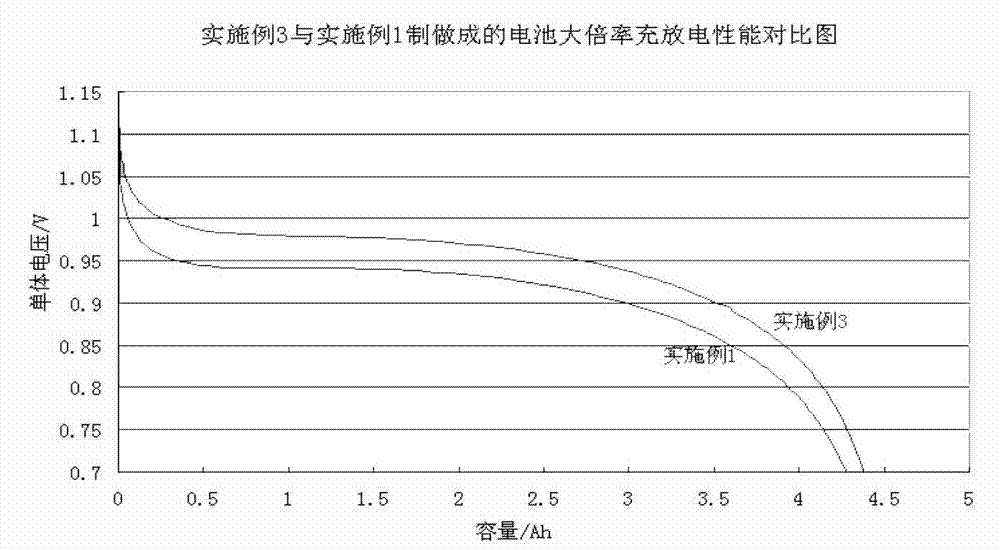

[0043] According to the alloy powder after the above treatment, a nickel-hydrogen power battery with a capacity of 6Ah is made, and its performance is measured, such as Figure 1 to Figure 5 .

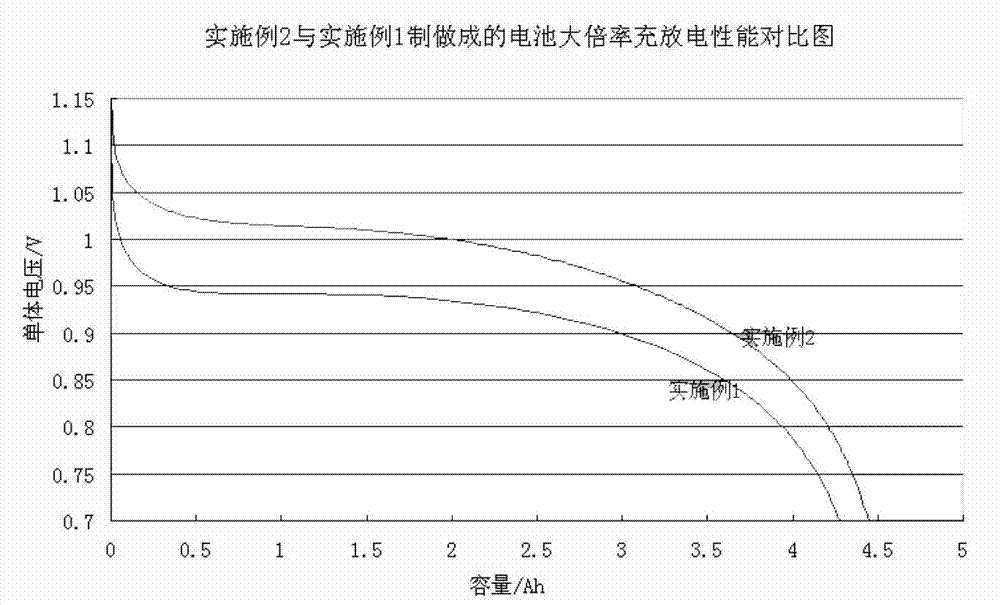

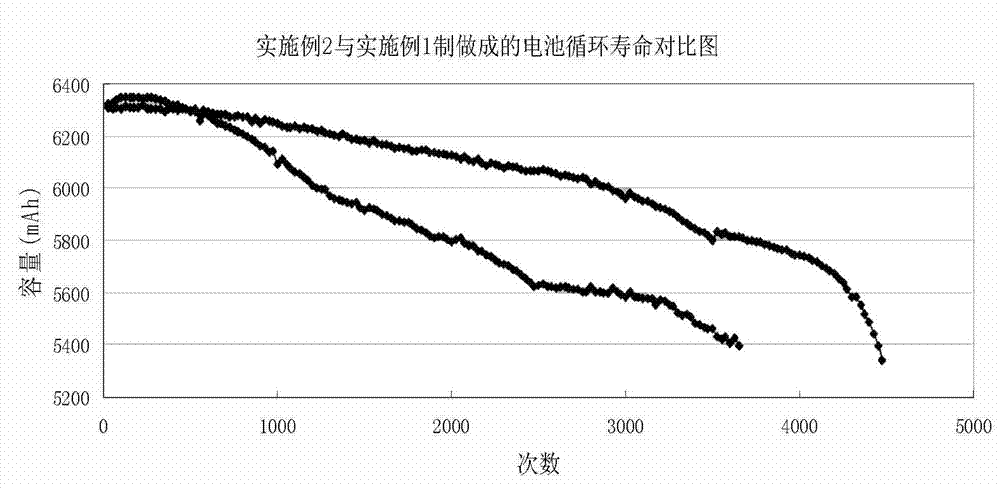

[0044] by Figure 1-4 It can be seen that the battery made of the alloy powder treated by the method of the present invention and the battery made of the untreated alloy powder fully show their superiority in both high-rate charge-discharge performance and lifespan comparison.

[0045] Figure 5 It can be seen that the comparison c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com