Mn-Fe-Dy hydrogen storing material and preparing method thereof

A hydrogen storage material, mn-fe-dy technology, applied in the direction of material magnetic variables, etc., can solve the problems of poor composition and microstructure uniformity, intragranular segregation and lattice defects, high heat treatment temperature, and achieve the slope of the hydrogen absorption and desorption platform. The effect of low, fast hydrogen absorption and desorption, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A preparation method of Mn-Fe-Dy hydrogen storage material comprises the following steps:

[0039] Step 1) According to the chemical formula (Mn 0.7 Fe 0.3 ) 23 Dy 6 , weighing Fe is 0.3433g, Mn is 0.7880g, and Dy is 0.8686g. Since Mn is relatively volatile during the smelting process, the quality of the above-mentioned Mn is increased by 3% to compensate for the loss. Therefore, the actual quality of Mn is 0.7880×1.03 =0.8117g, the prepared elemental substance is prepared by vacuum argon arc melting method (Mn 0.7 Fe 0.3 ) 23 Dy 6 alloy;

[0040] Step 2) the (Mn 0.7 Fe 0.3 ) 23 Dy 6 After the alloy was placed in a quartz tube for vacuum sealing, it was placed in an annealing furnace for heat treatment at 800°C for 100 hours, and after heat treatment, it was placed in an ice-water mixture for rapid cooling to obtain a Mn-Fe-Dy hydrogen storage material.

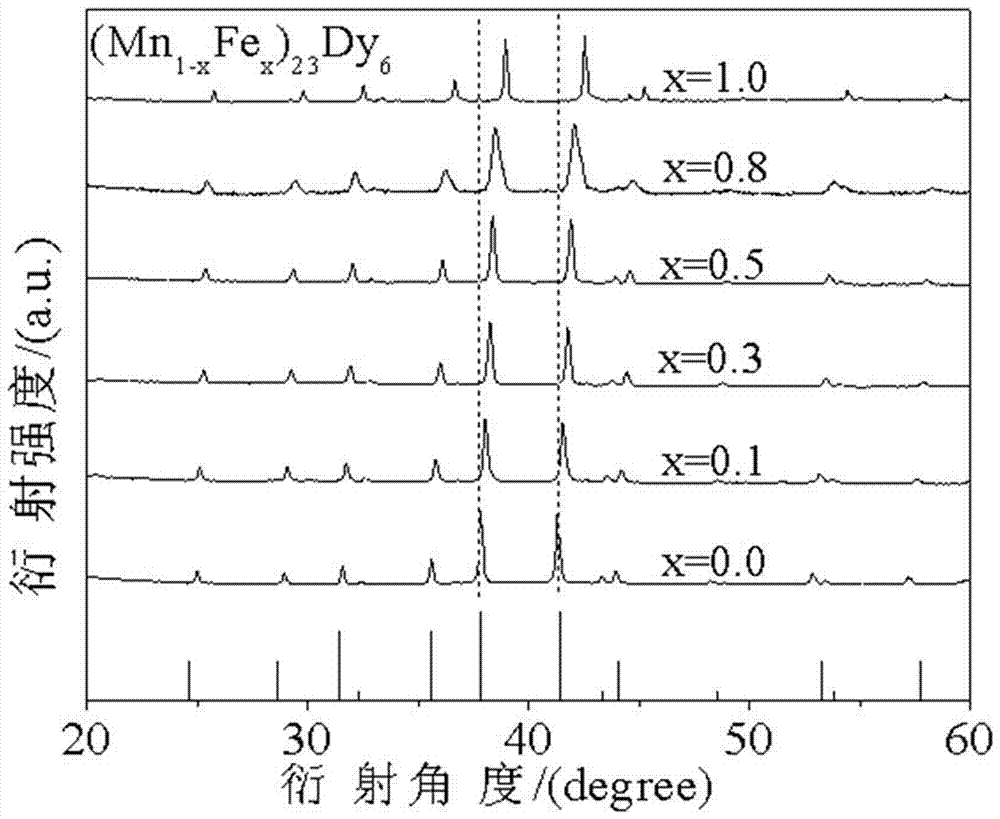

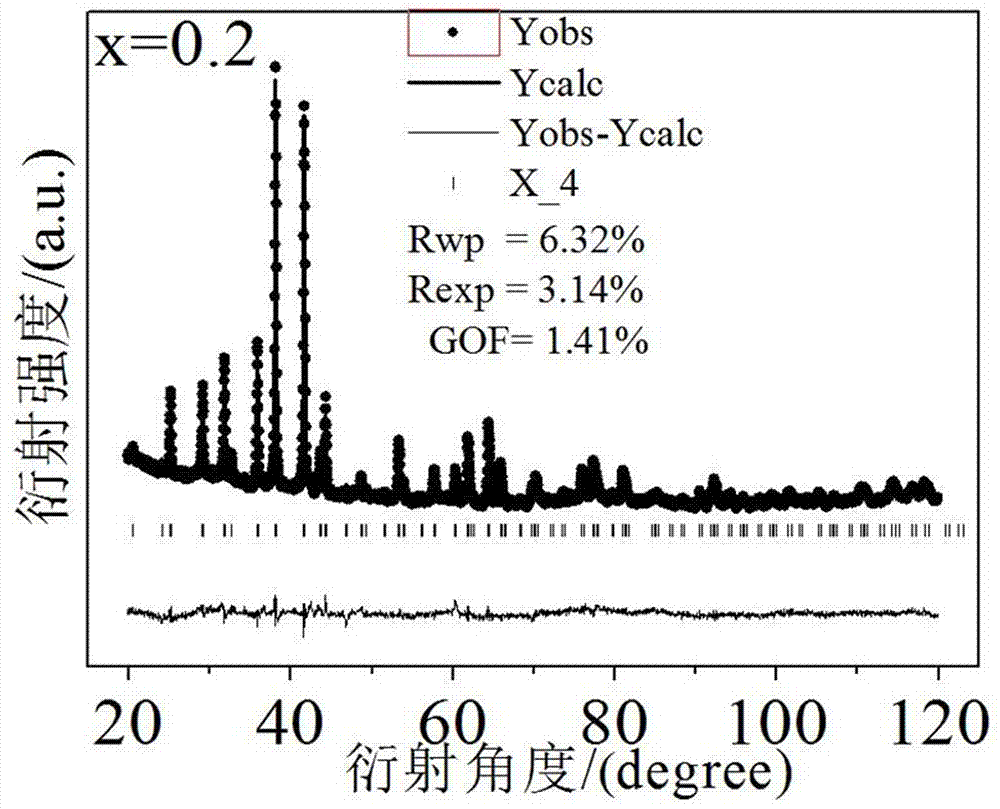

[0041] In order to study the effect of different Fe contents on the performance of Mn-Fe-Dy hydrogen sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com